Patents

Literature

129results about How to "Uniform stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

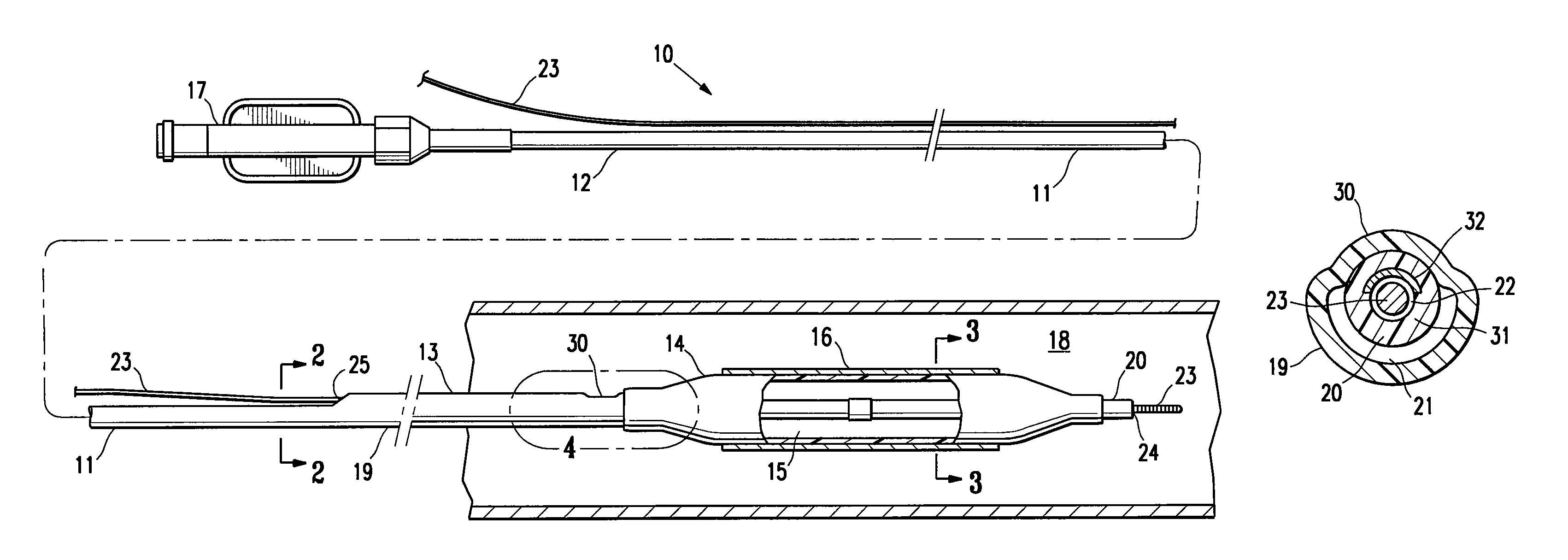

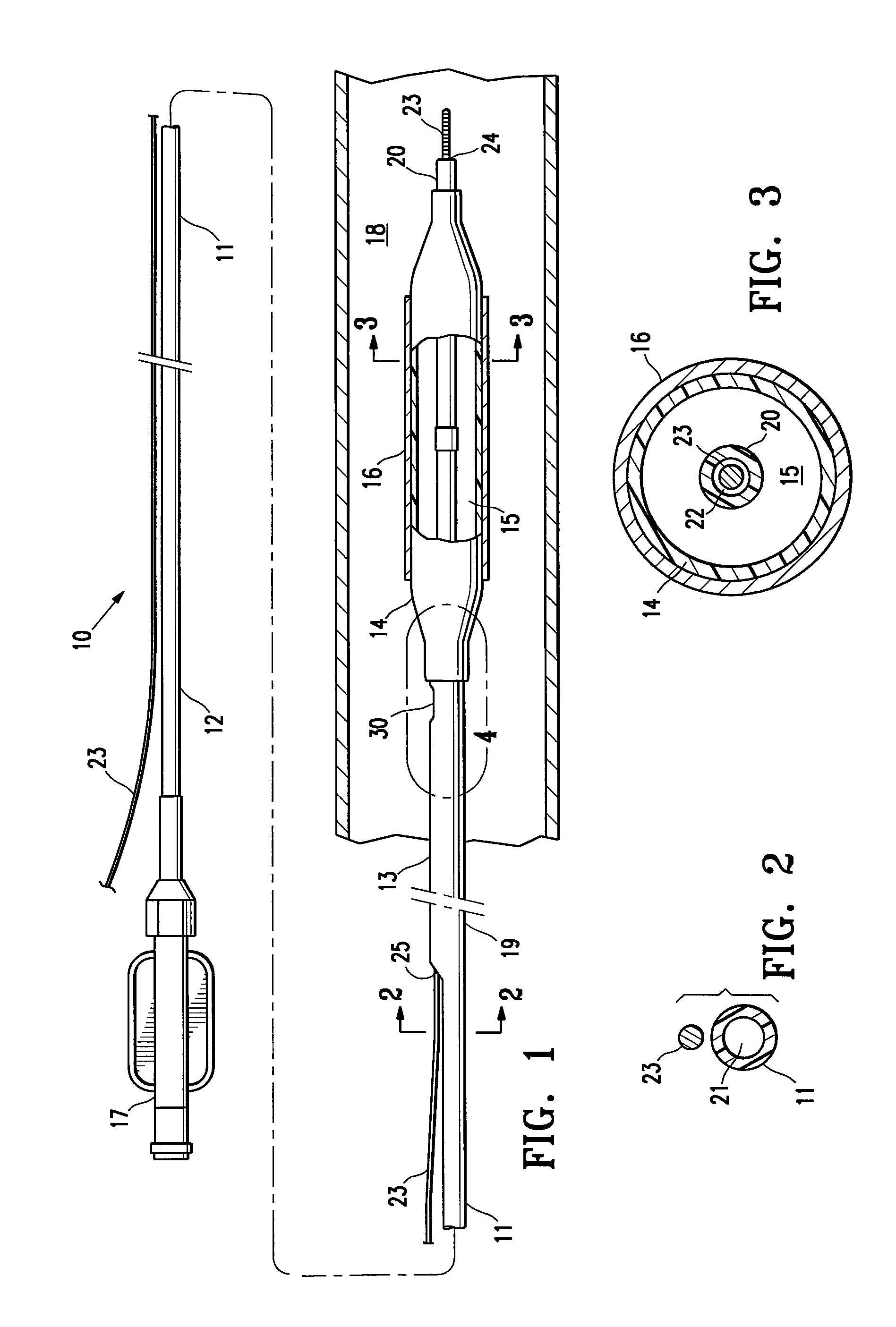

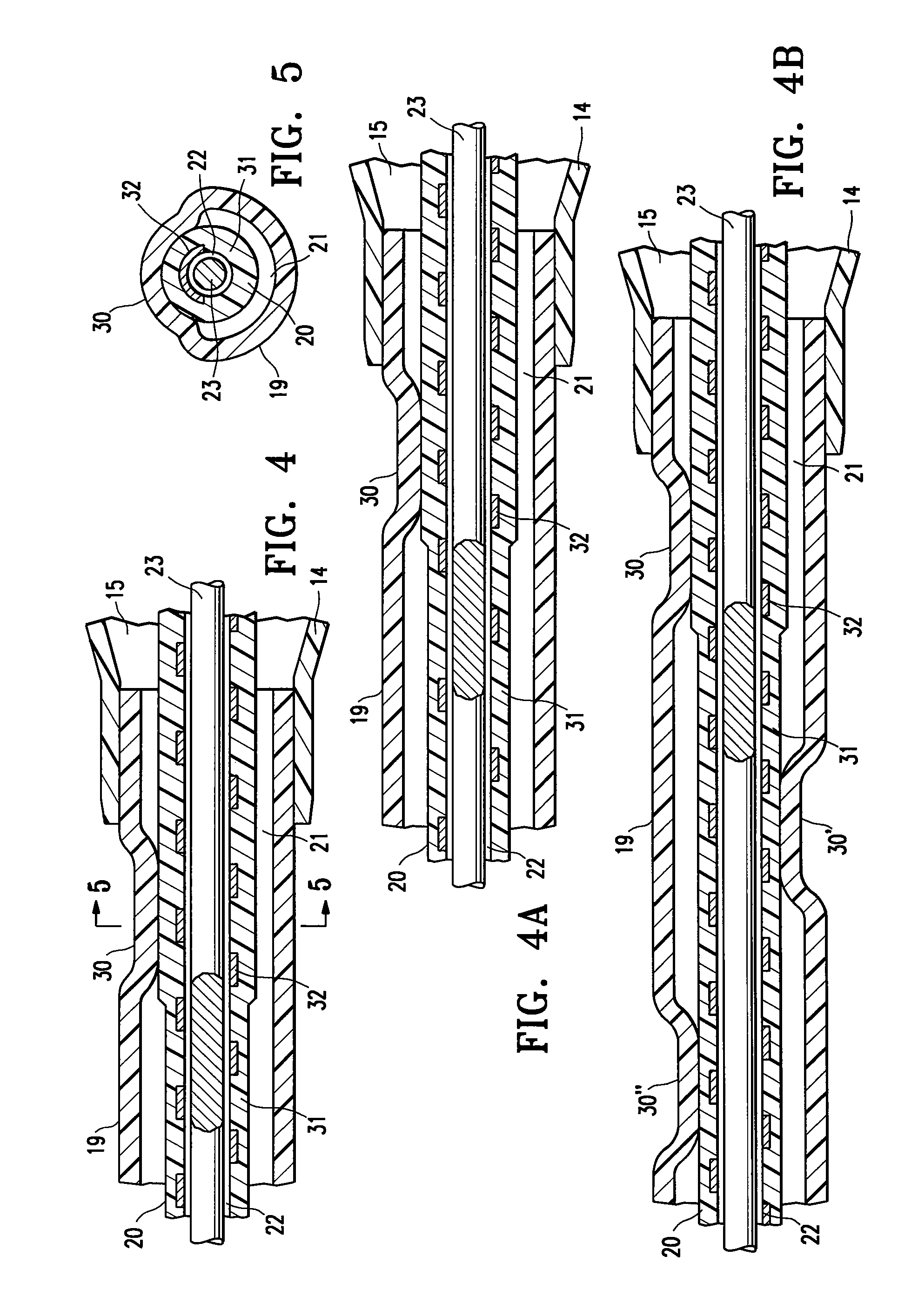

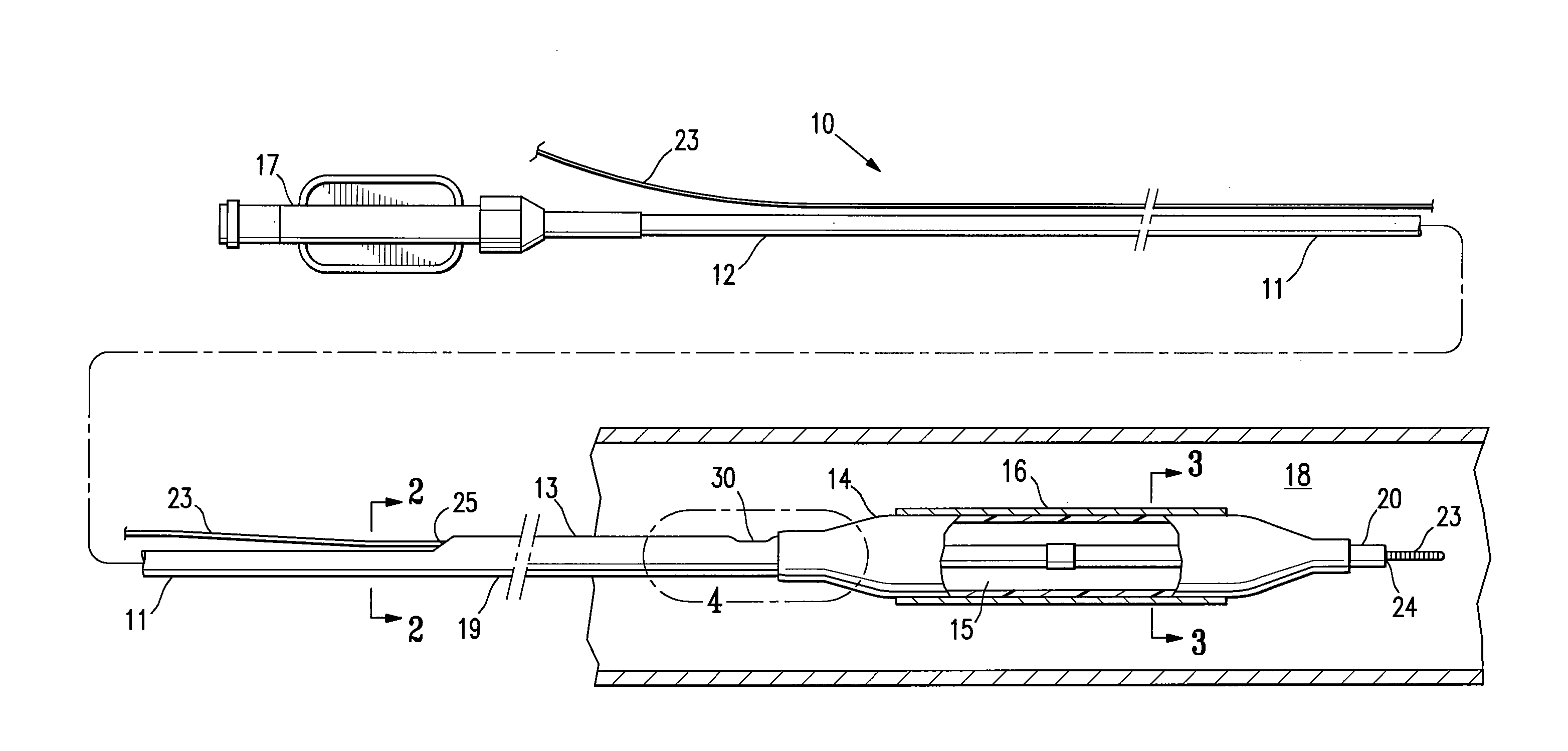

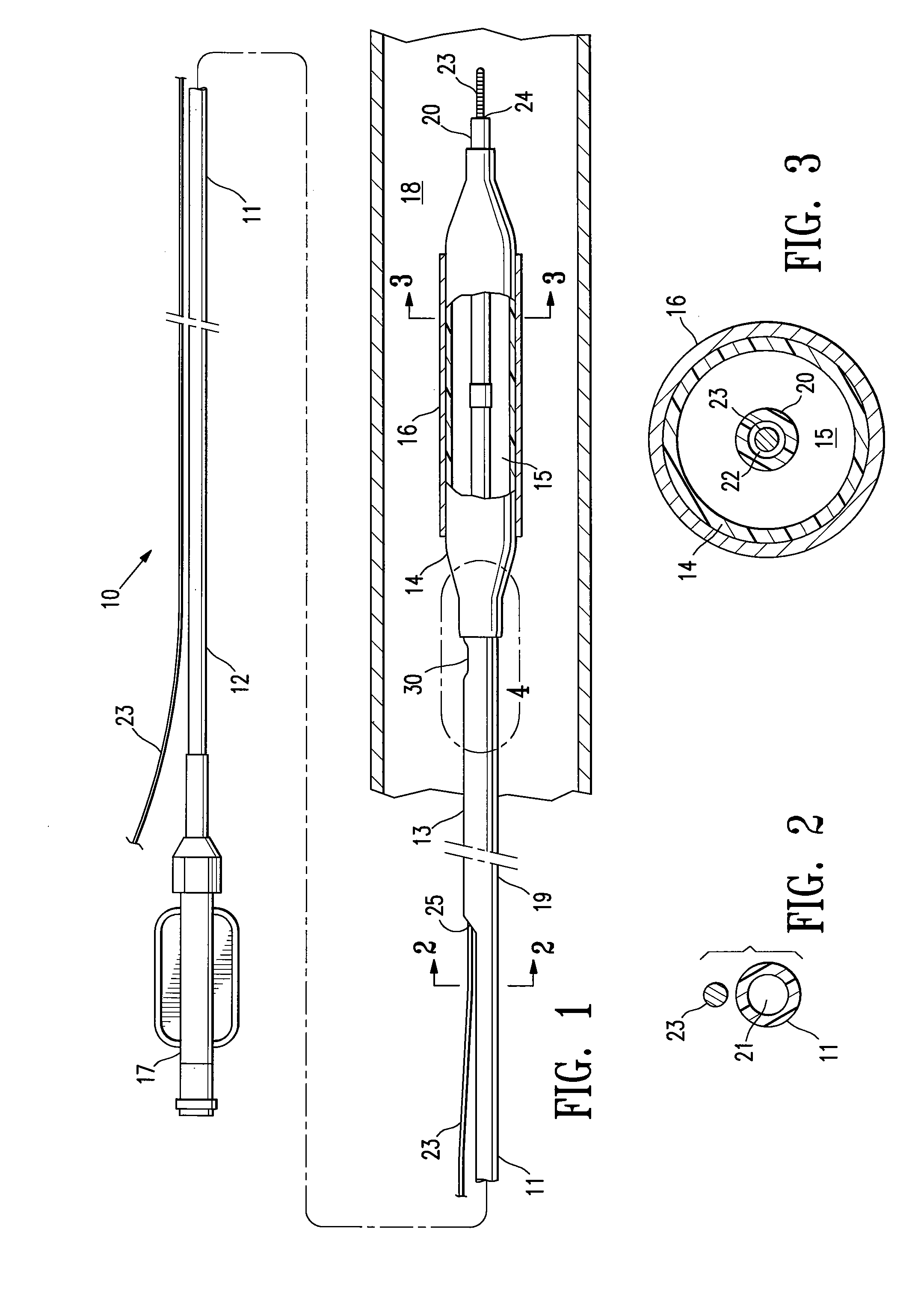

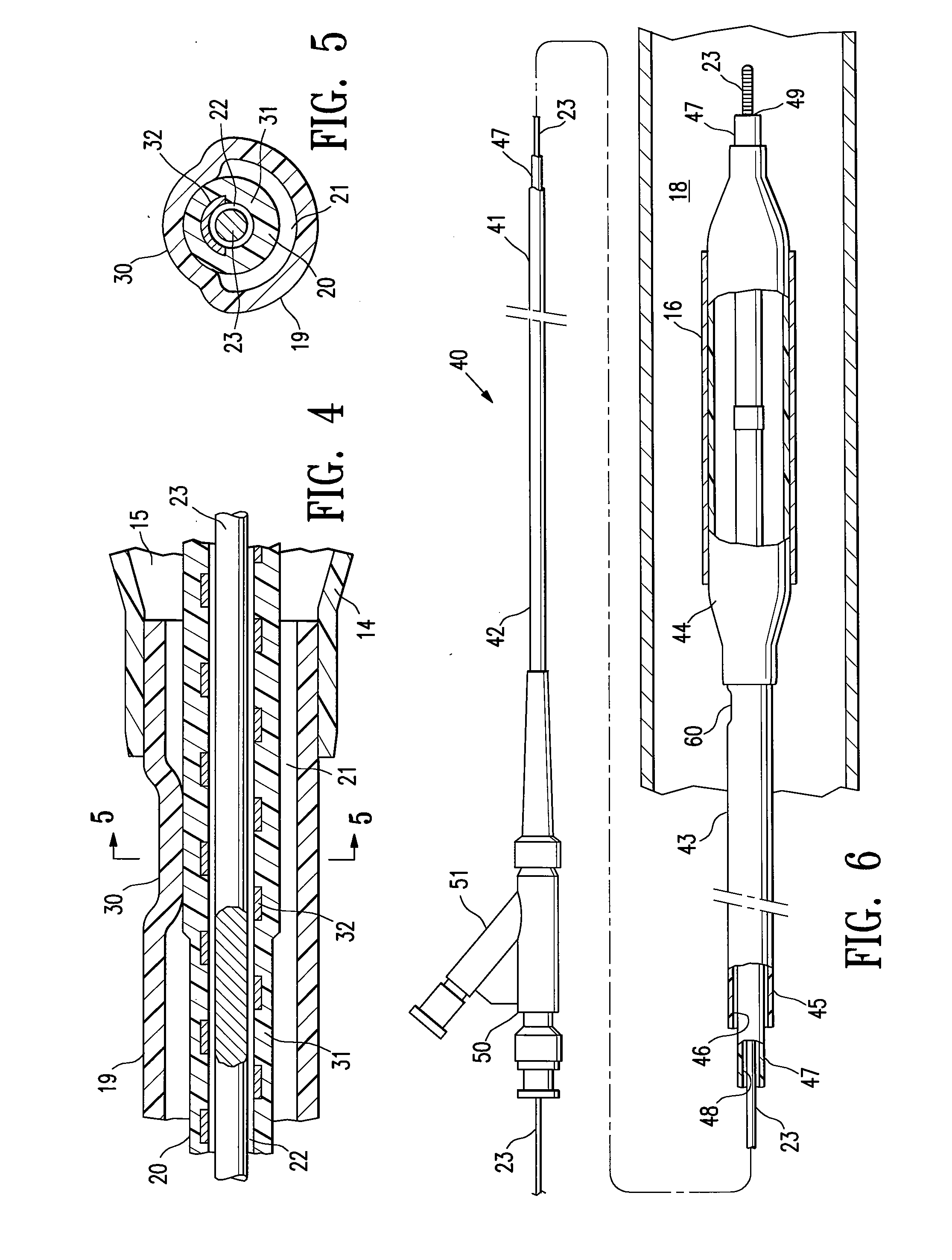

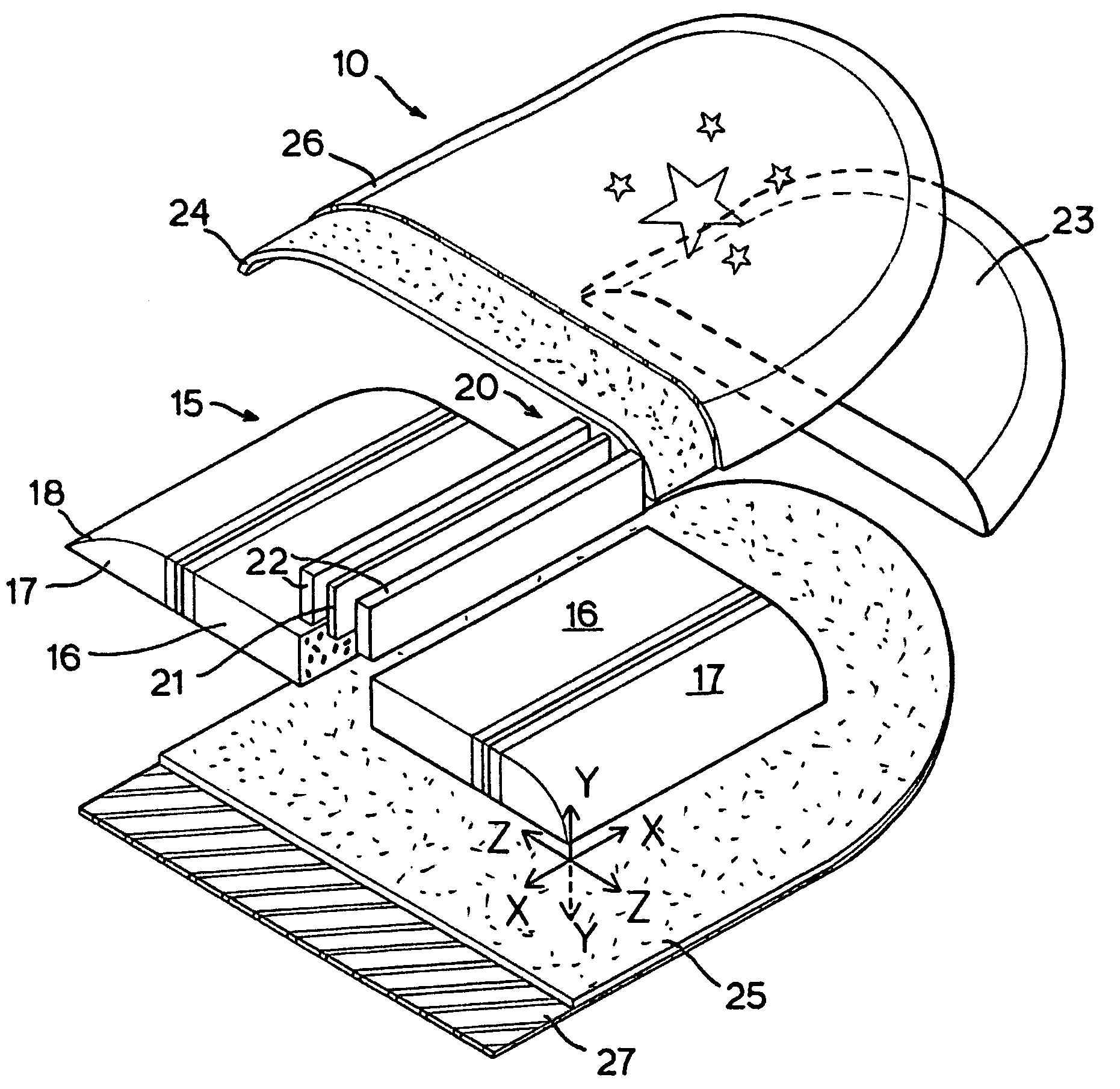

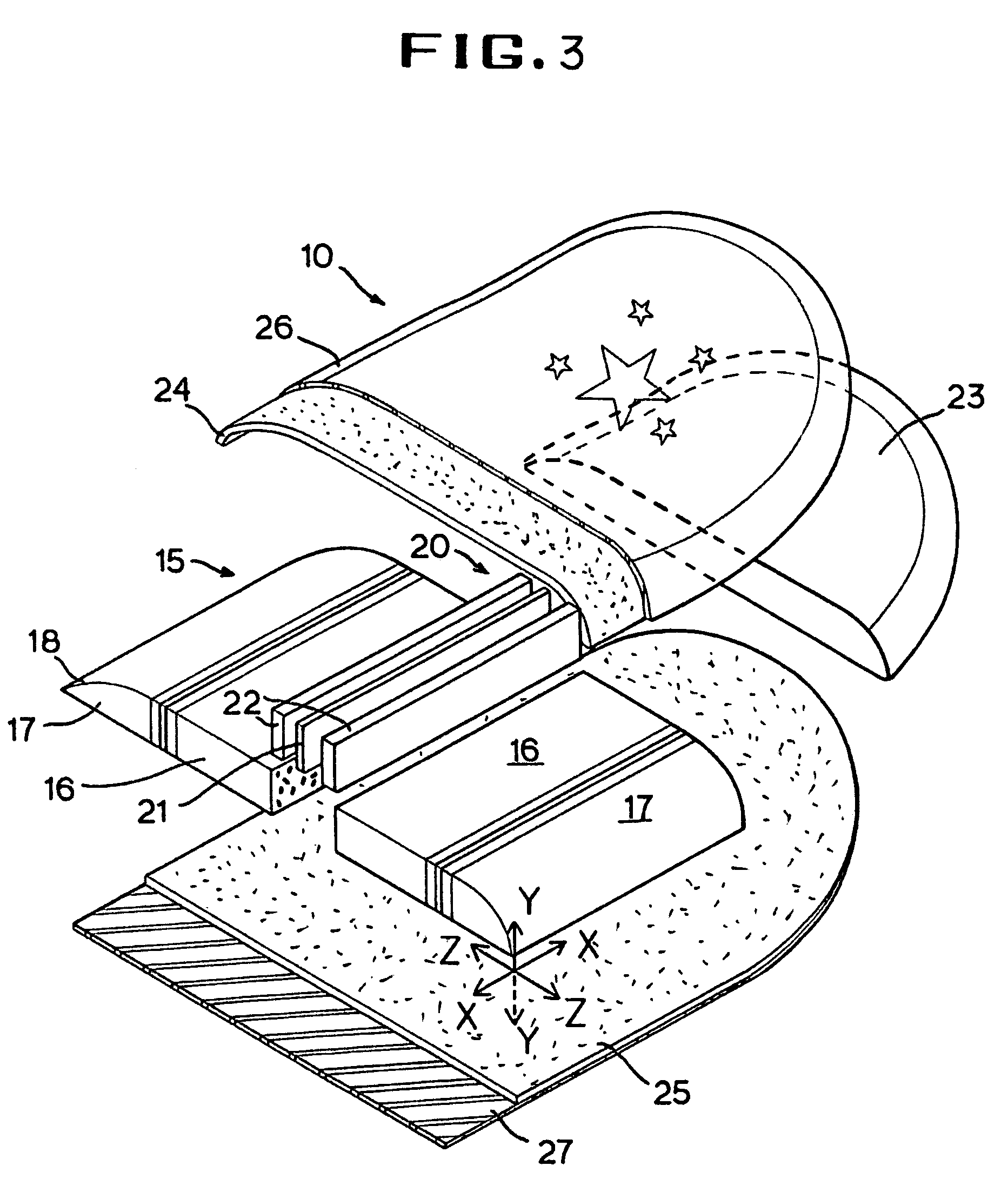

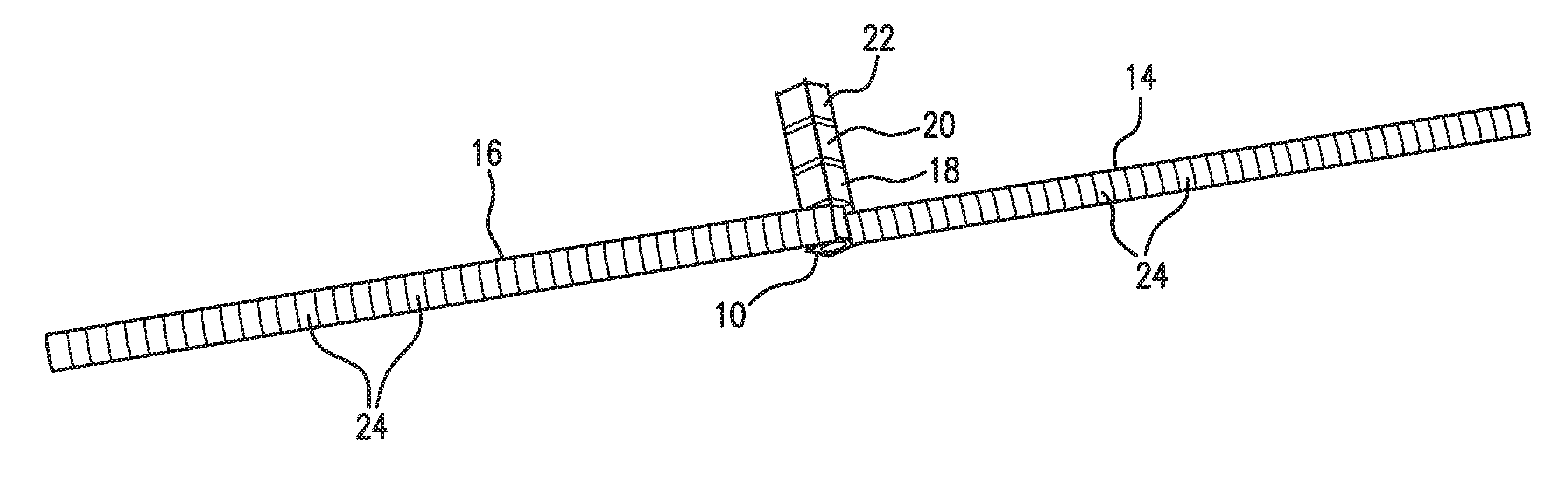

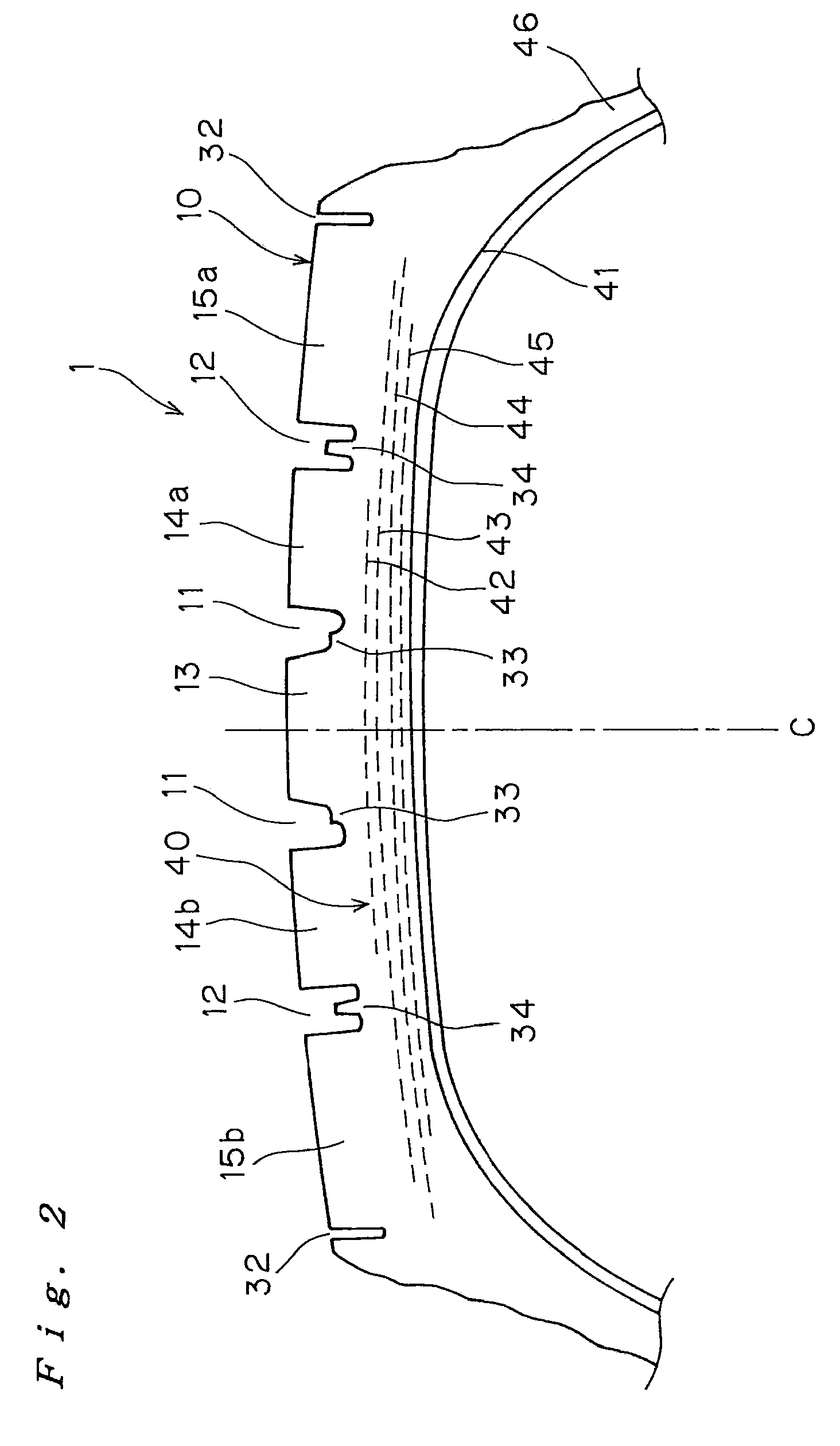

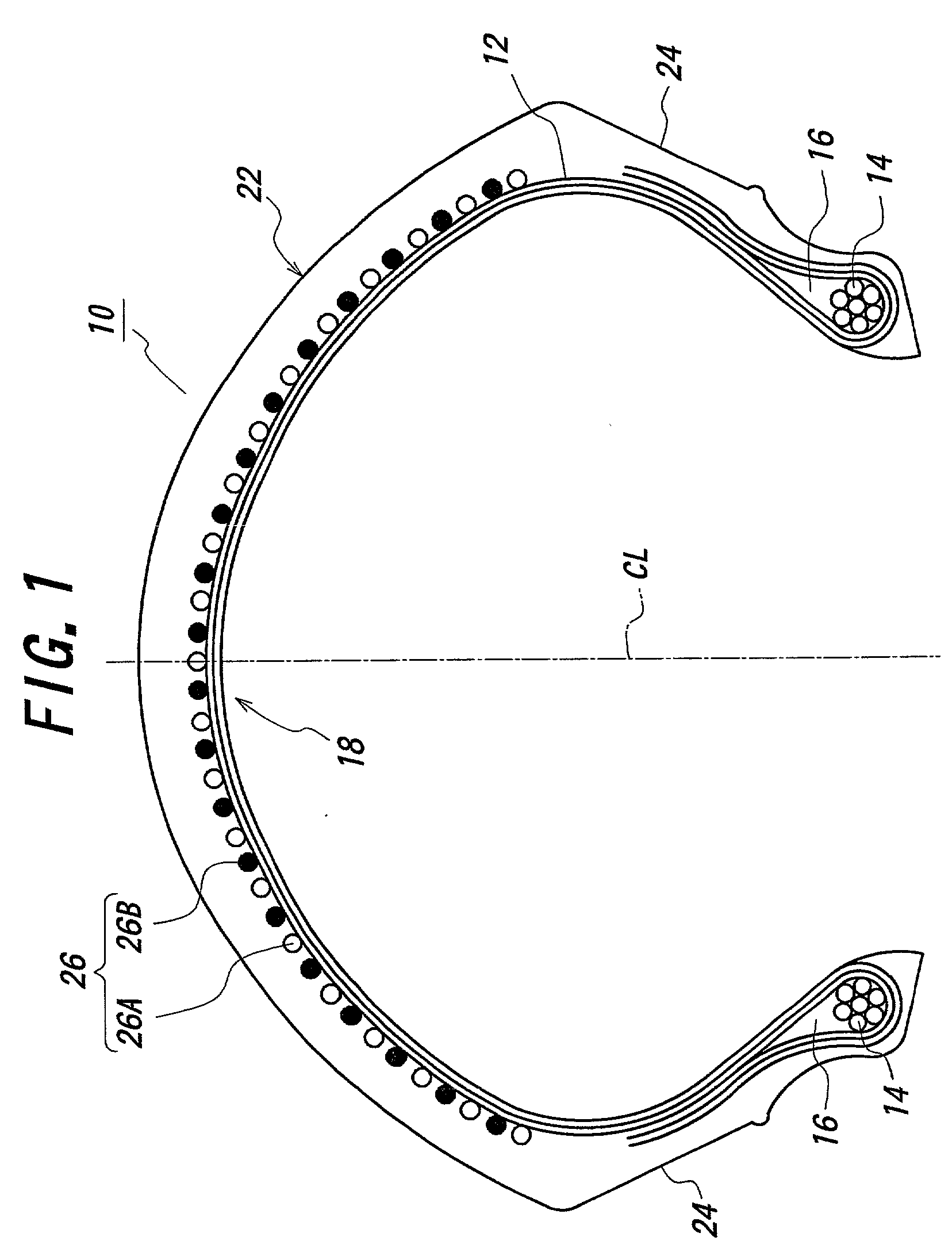

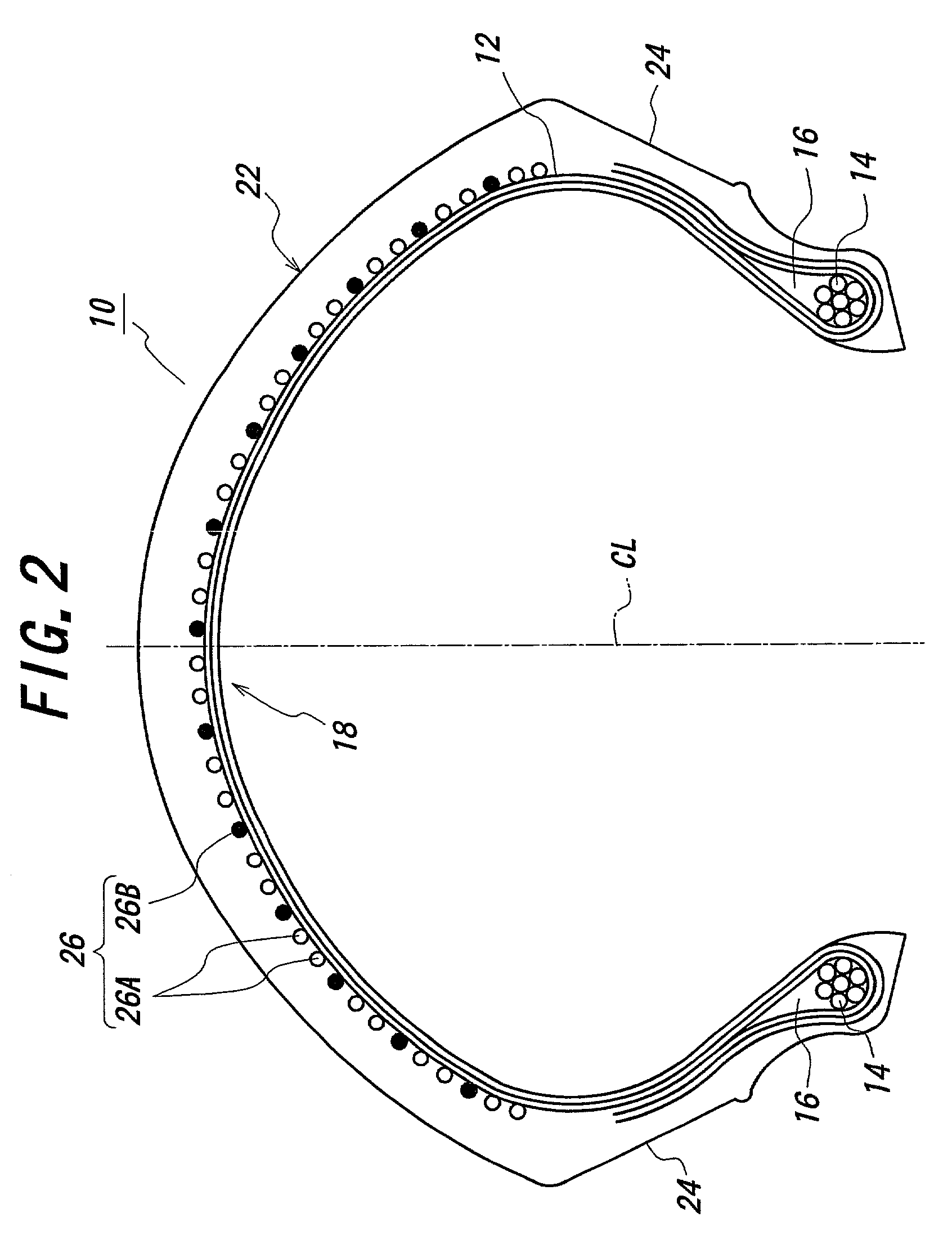

Balloon catheter having a shaft with a variable stiffness inner tubular member

ActiveUS7273485B2Reduce wall thicknessIncrease wall thicknessStentsBalloon catheterVariable stiffnessAxial compression

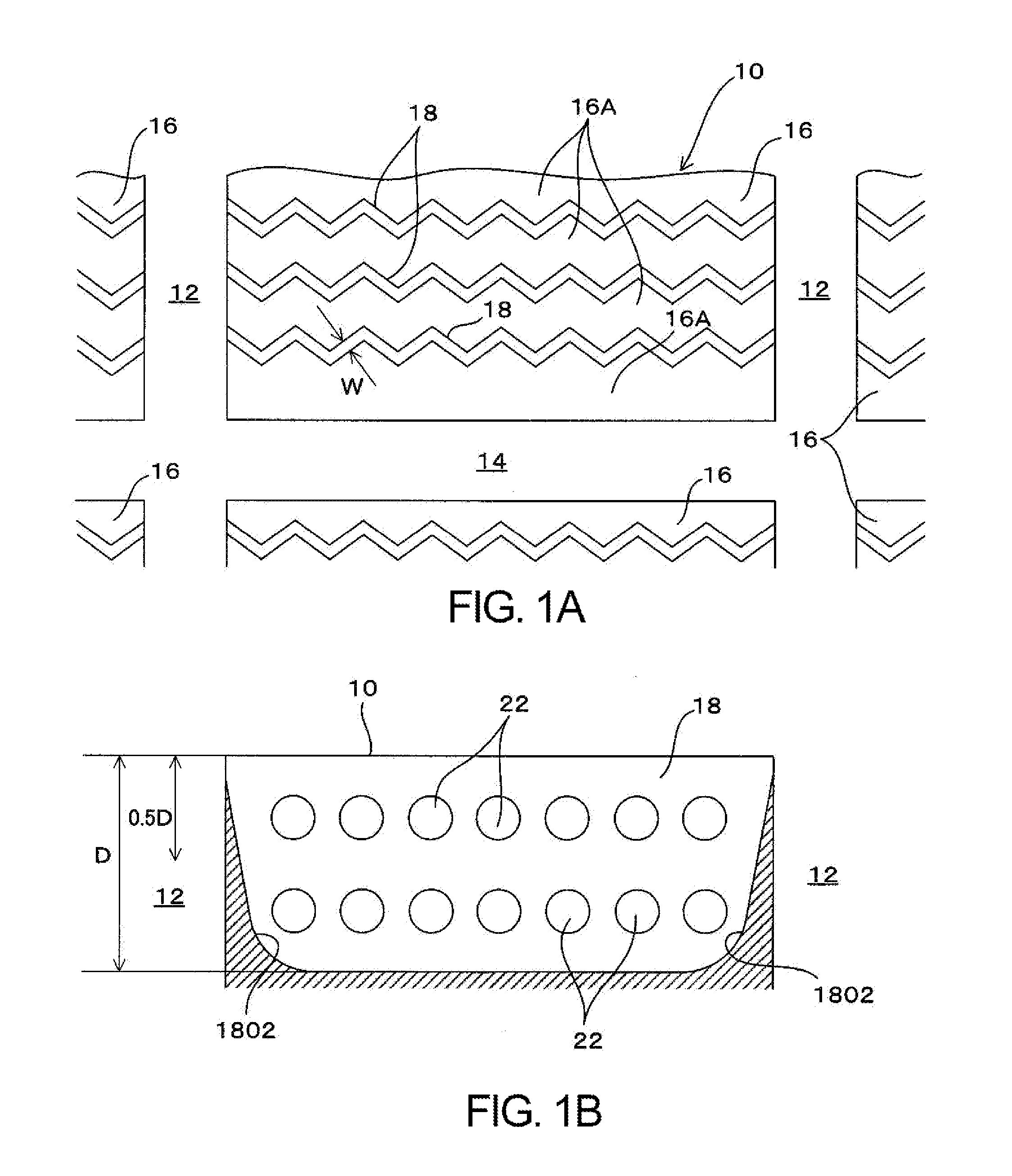

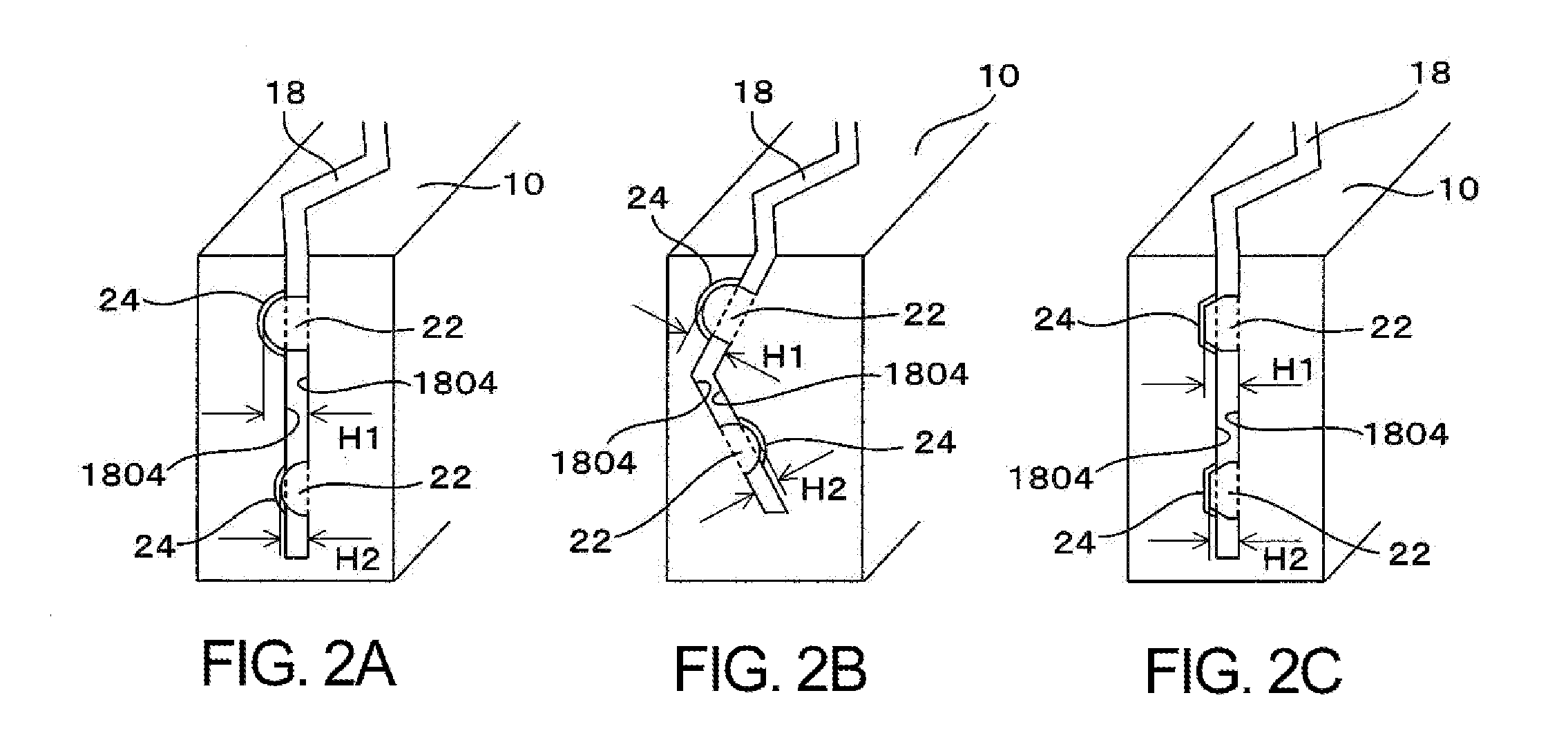

A catheter having an elongated shaft and a balloon on a distal shaft section, the elongated shaft comprising an outer tubular member, and an inner tubular member which has a bonded portion along which an outer surface of the inner tubular member is bonded to an inner surface of the outer tubular member. The inner tubular member has a proximal portion proximal to the bonded portion, and a distal portion distal to the bonded portion with higher axial compression stiffness and column strength than the proximal portion thereof. The catheter has improved traceability, axial collapse resistance, pushability, and crossability, for improved ability to position the balloon at a desired location in a patient's body lumen.

Owner:ABBOTT CARDIOVASCULAR

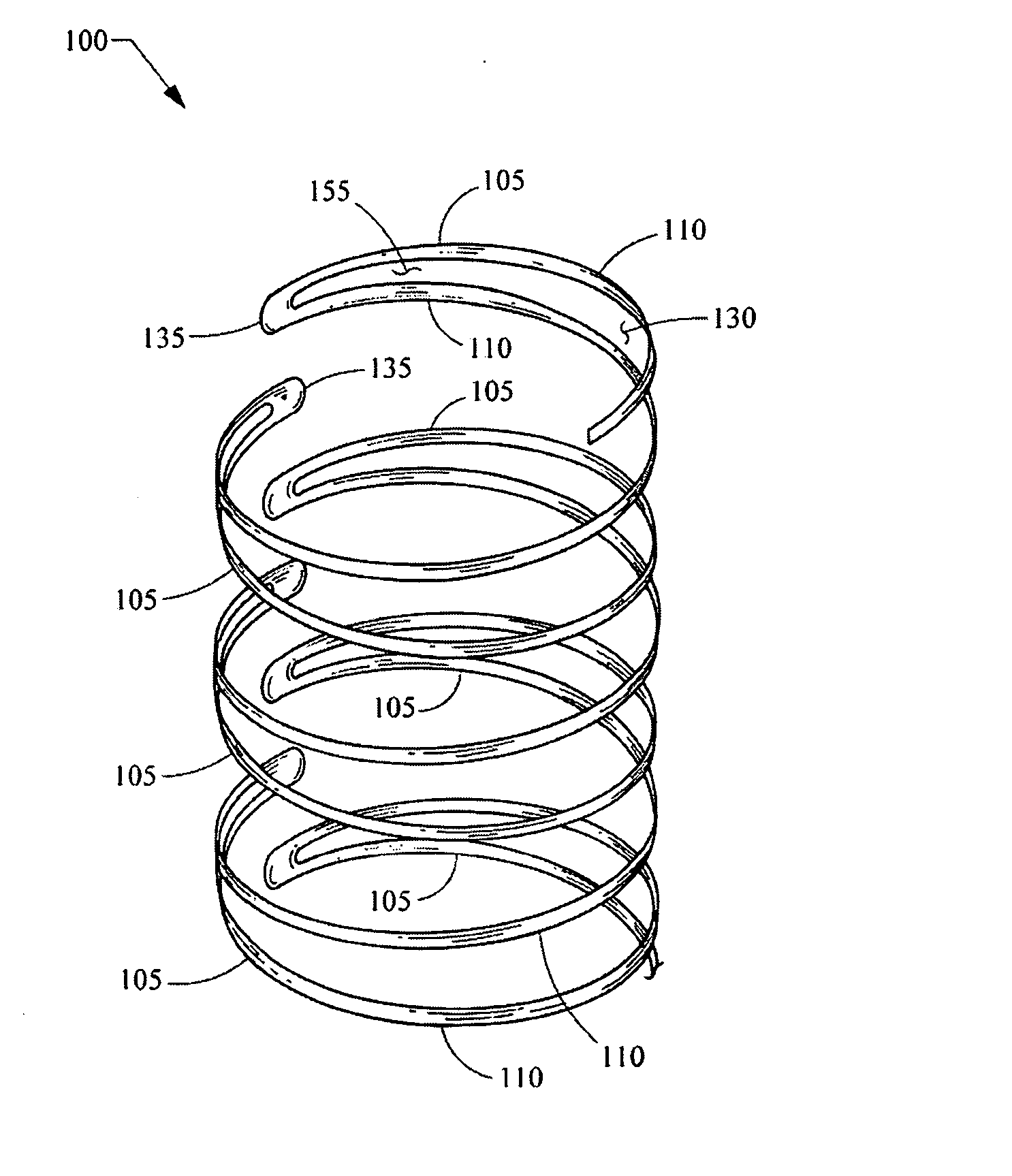

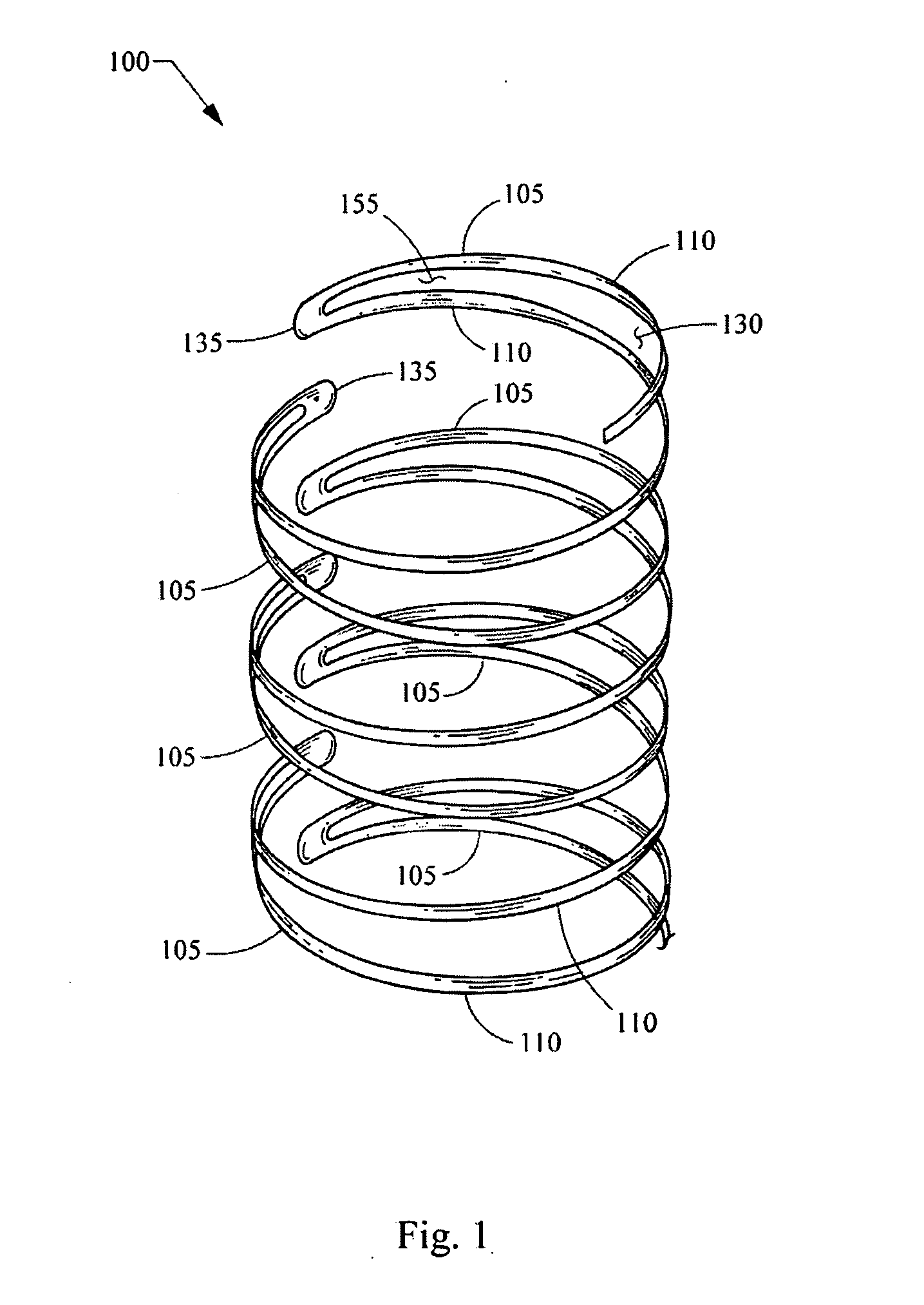

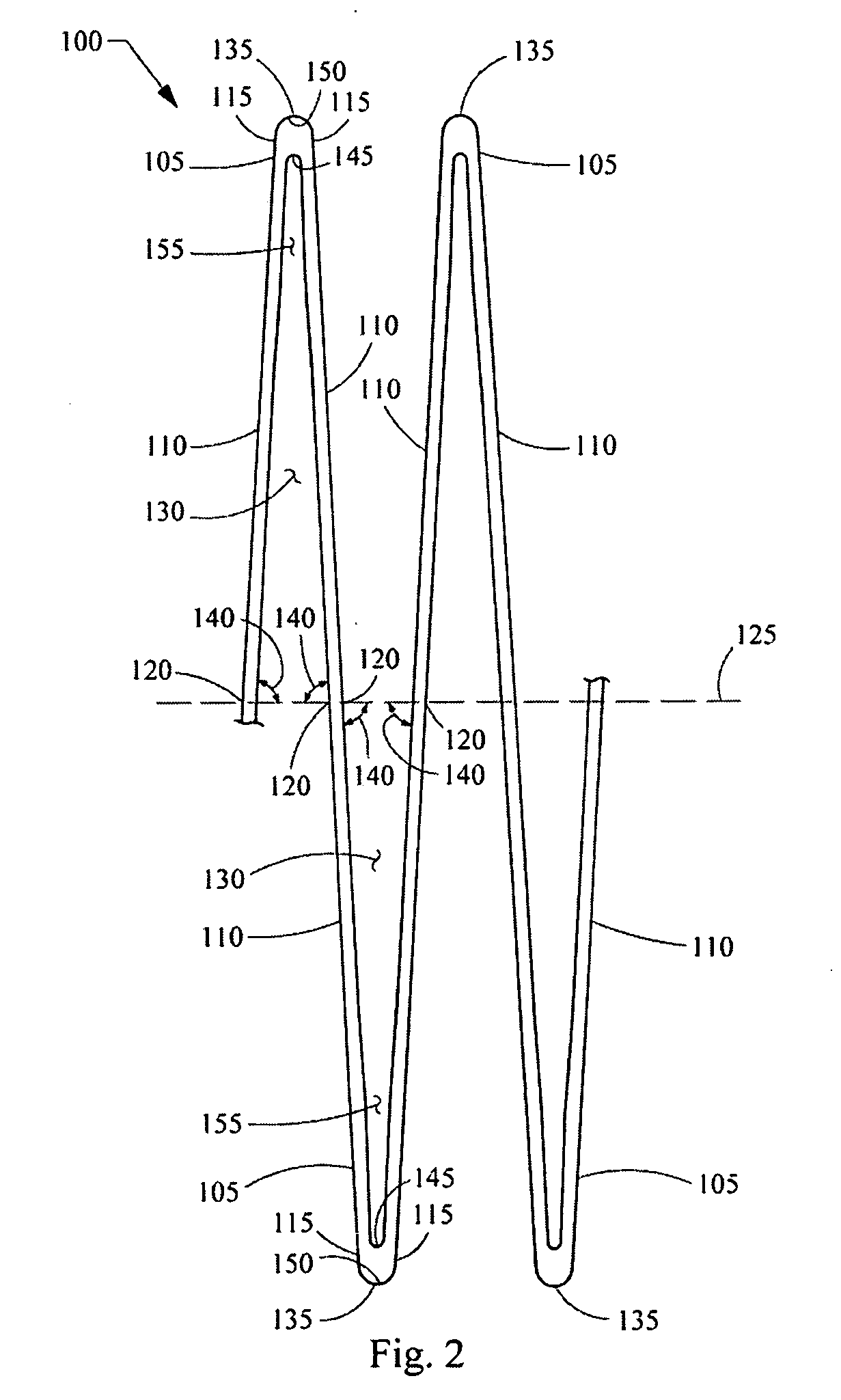

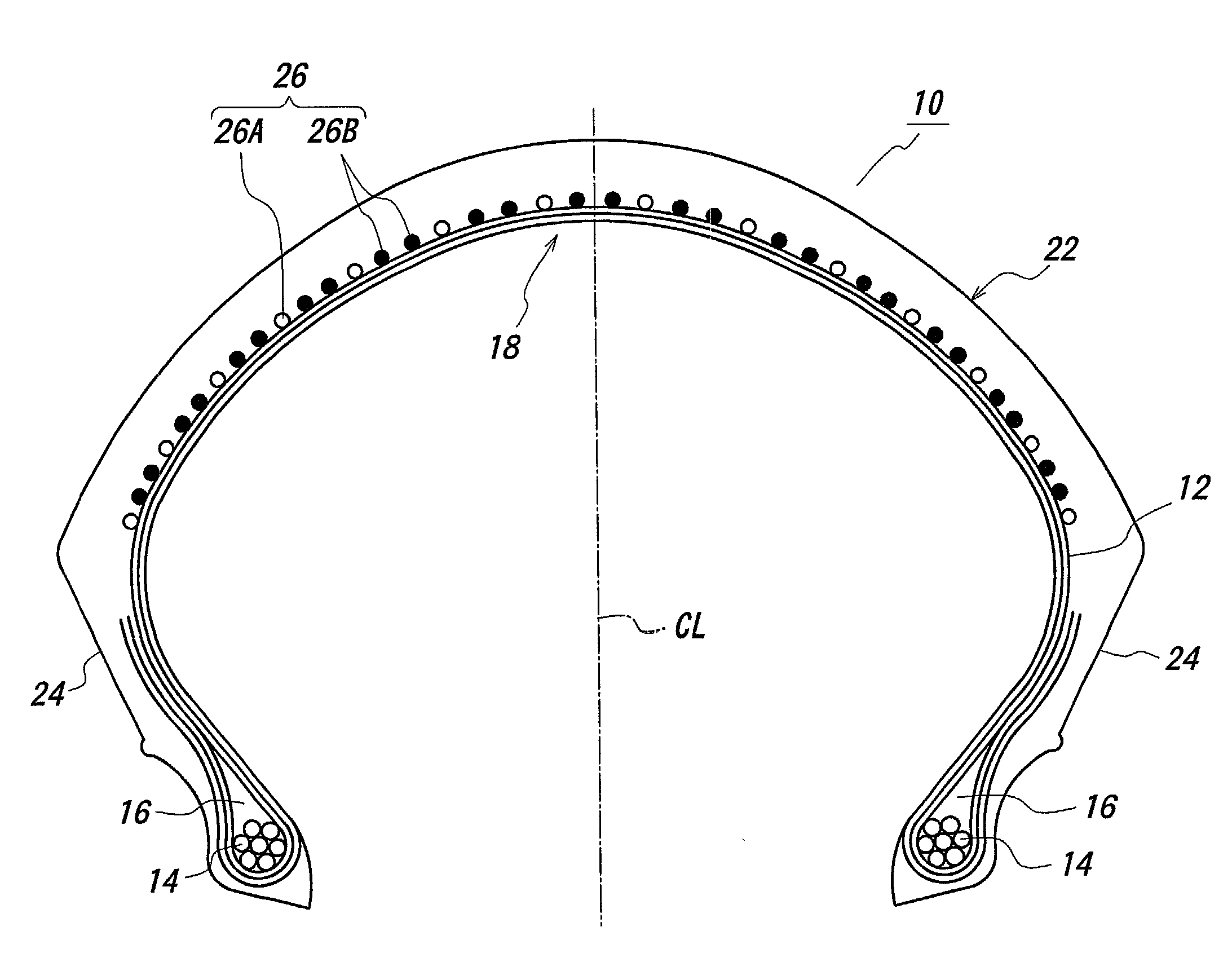

Expandable stent

InactiveUS20070185560A1High and uniform radial forceImprove fatigue lifeStentsBlood vesselsInsertion stentBiomedical engineering

An expandable stent for medical implantation is described which has a generally cylindrical structure with a central longitudinal axis. At least a portion of the generally cylindrical structure is formed from an arrangement of circumferentially curved structural members. The portion expands from a compressed state to an expanded state by a spiraling motion of each of the structural members about the central longitudinal axis. In the compressed state, each of the structural members may nest within an open region formed by segments composing the structural member, such that the portion of the generally cylindrical structure has no overlapping regions. A ratio of a circumferential length of each structural member to a spacing between adjacent structural members may be in the range of about 1.8 to about 2.3.

Owner:MED INST INC

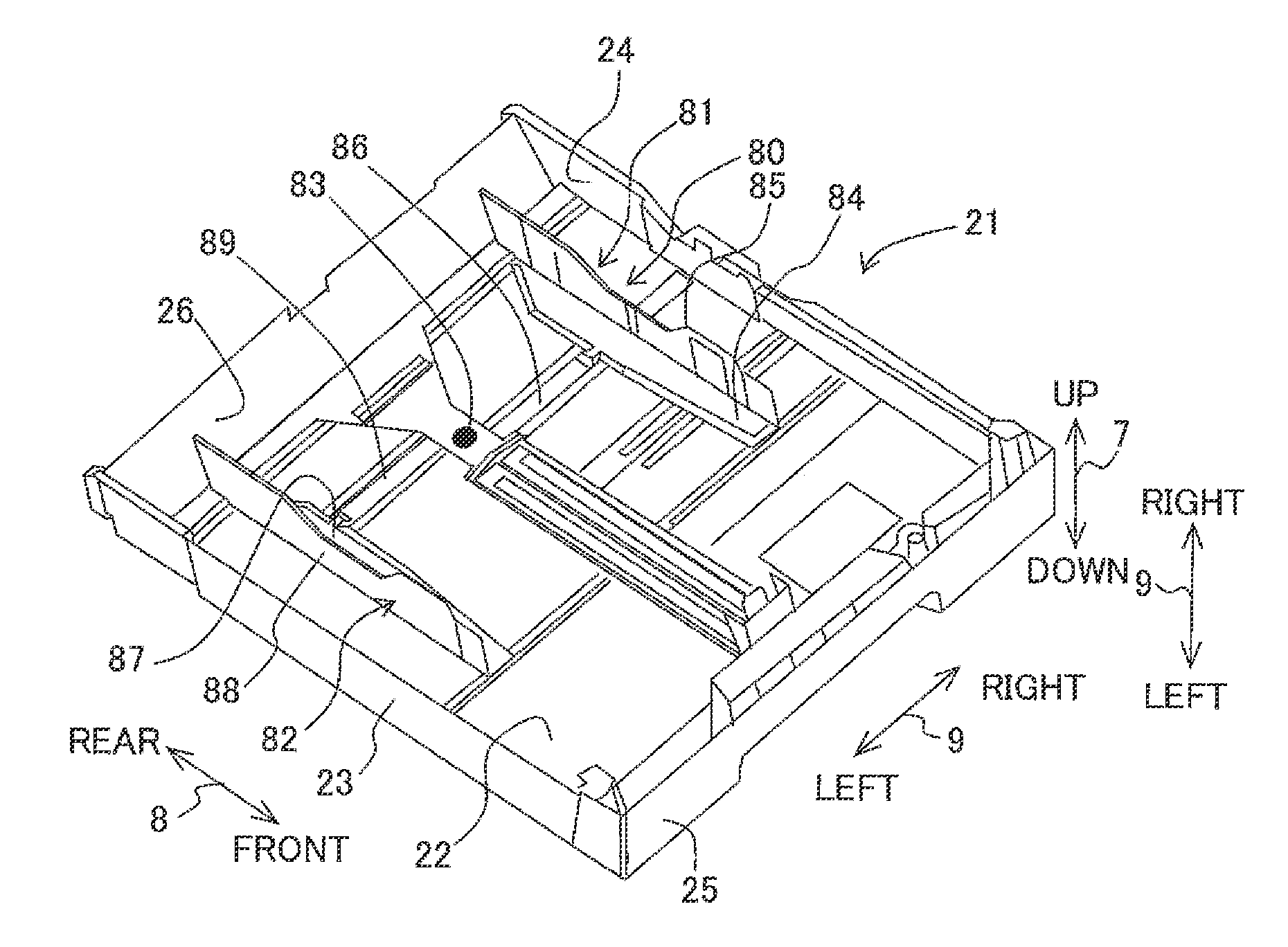

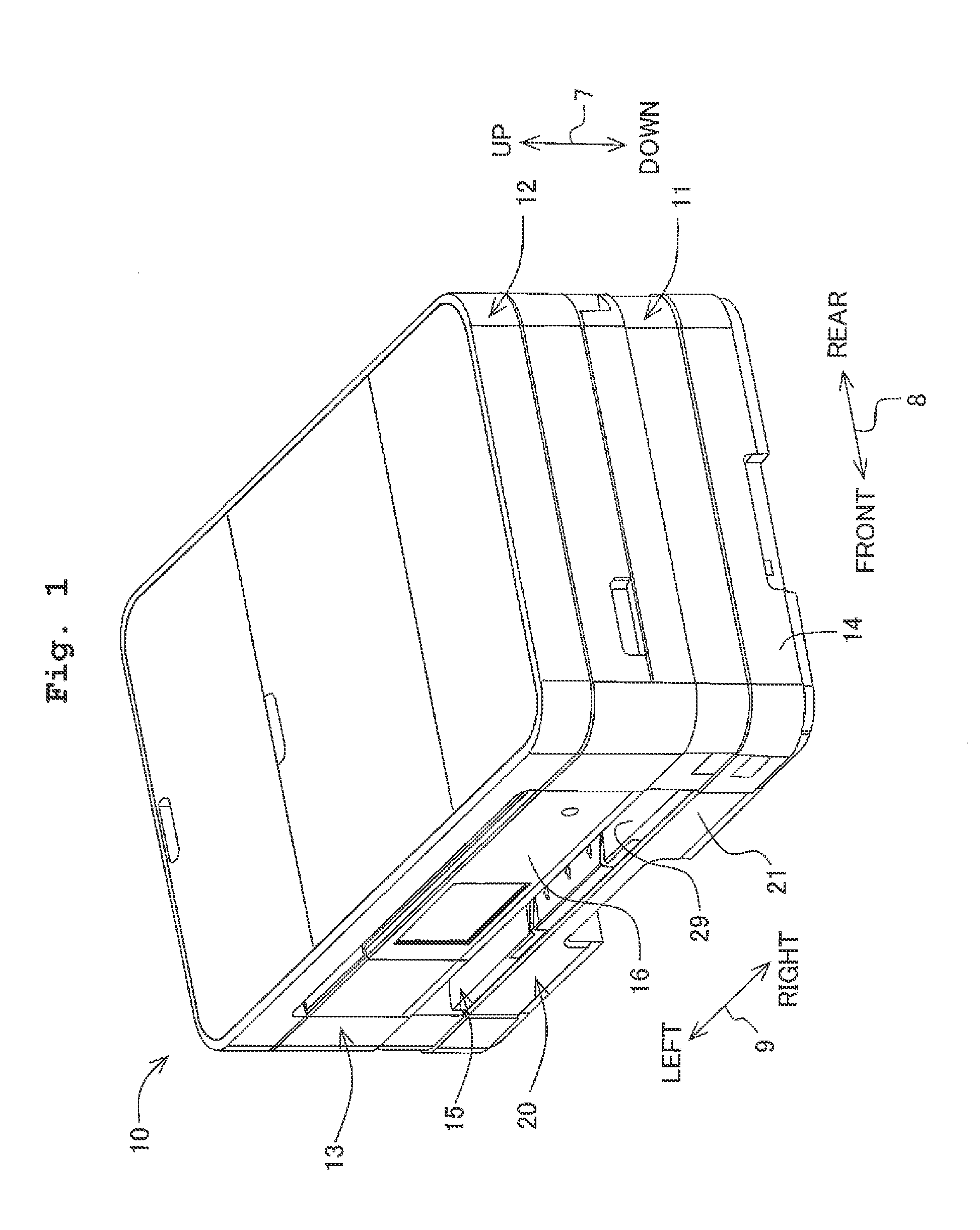

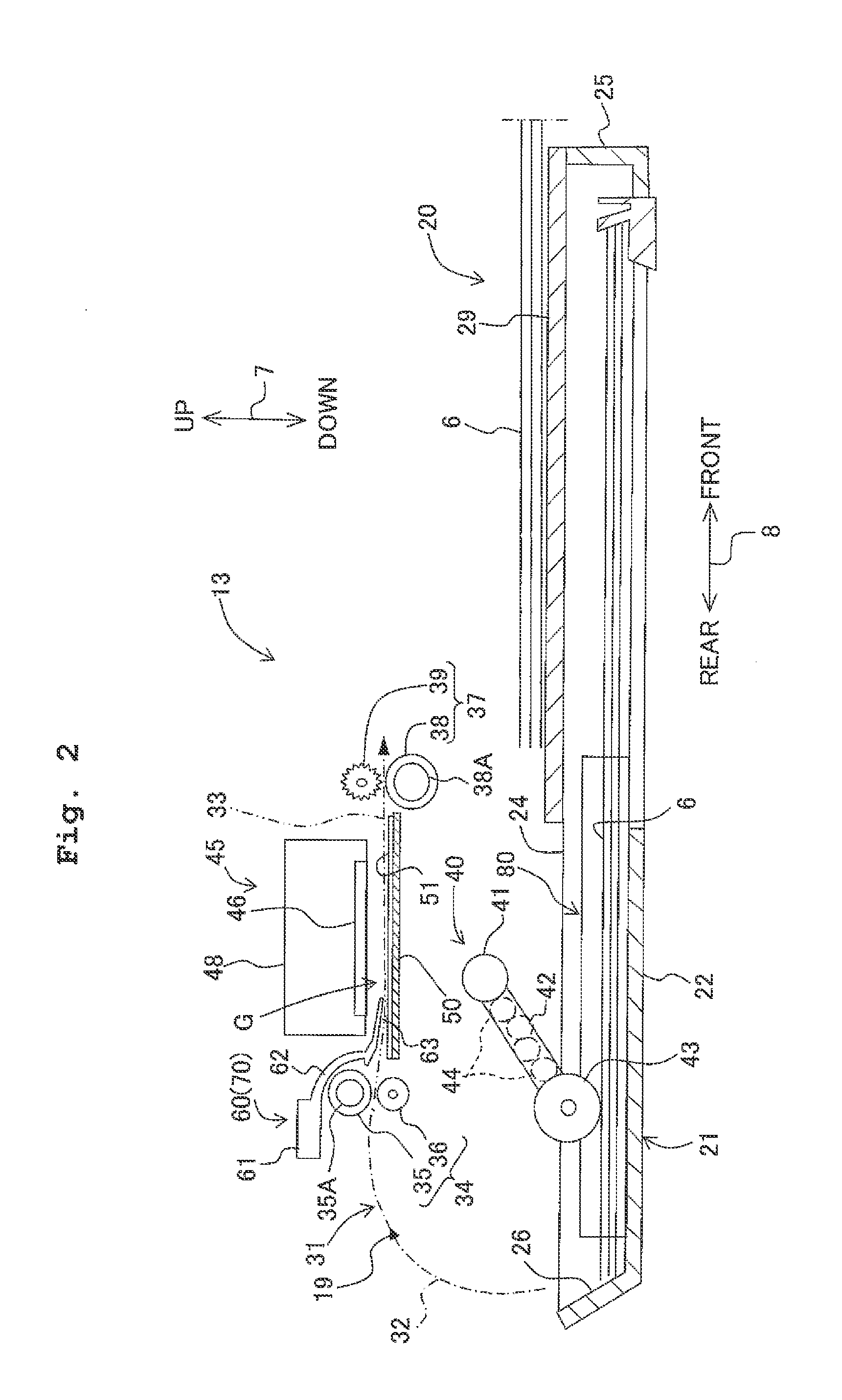

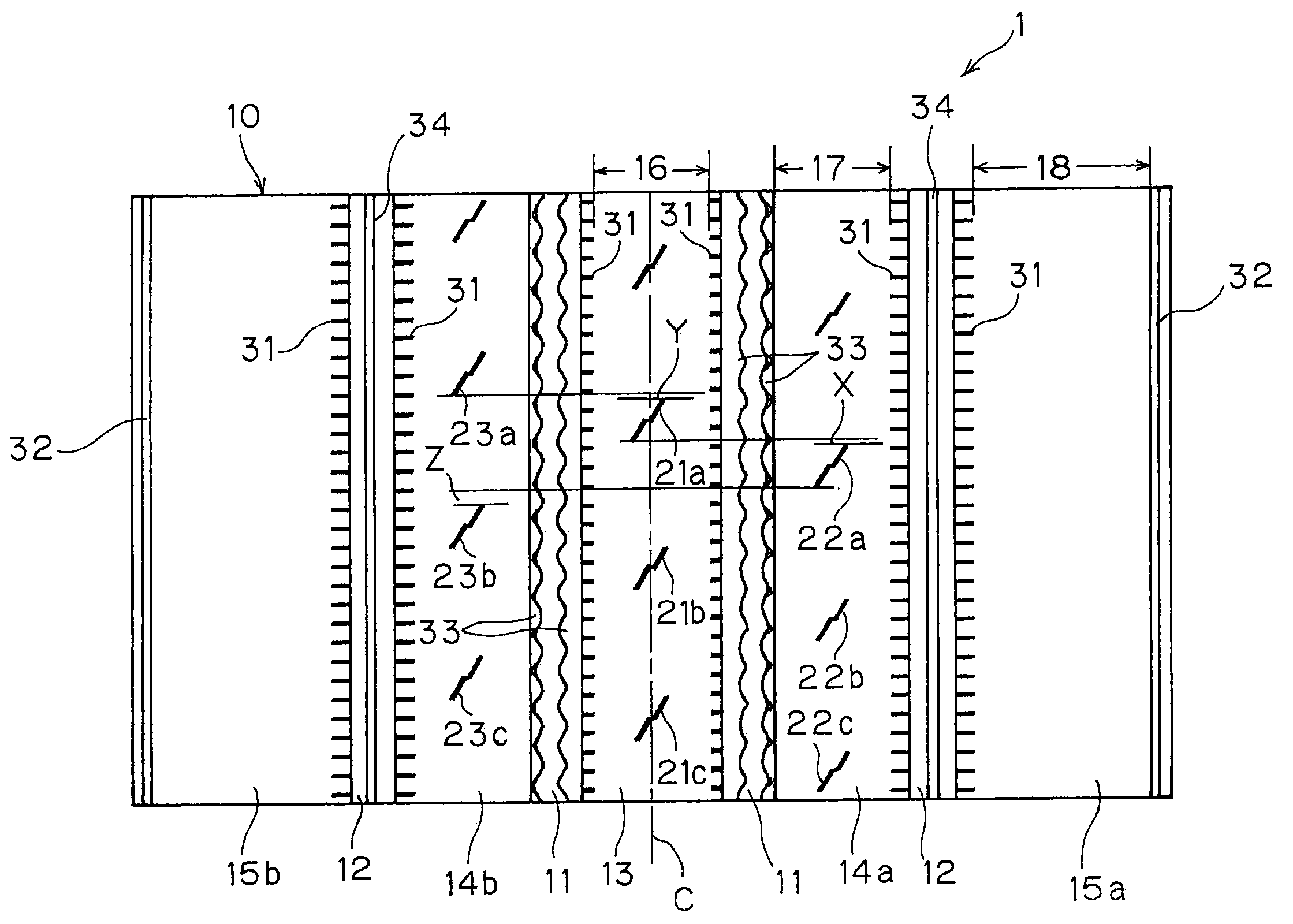

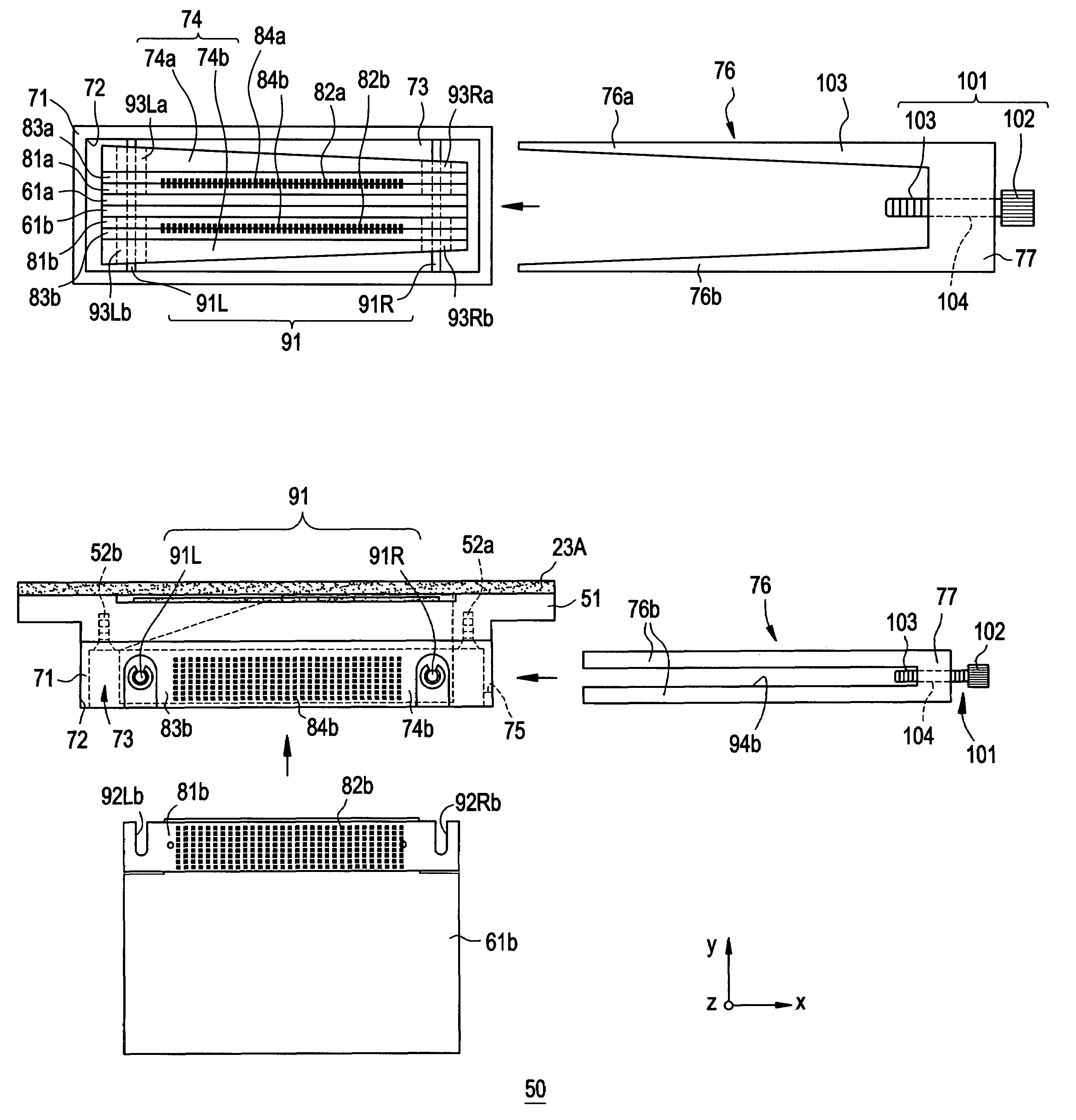

Ink-Jet Recording Apparatus and Platen Apparatus

ActiveUS20130135413A1Improve rigidityImproving Imaging AccuracyOther printing apparatusPositioning apparatusMechanical engineeringSecond rib

There is provided an ink jet recording apparatus including: a platen, a contact portion disposed between a pair of first ribs of the plurality of first ribs with respect to a scanning direction. A lower end of the contact portion is located lower than each upper end of the pair of first ribs. The platen includes a second rib disposed between one first rib of the pair of first ribs and the contact portion with respect to the scanning direction, and an upper end of the second rib is located lower than the upper end of the one first rib of the pair of first ribs and higher than the lower end of the contact portion.

Owner:BROTHER KOGYO KK

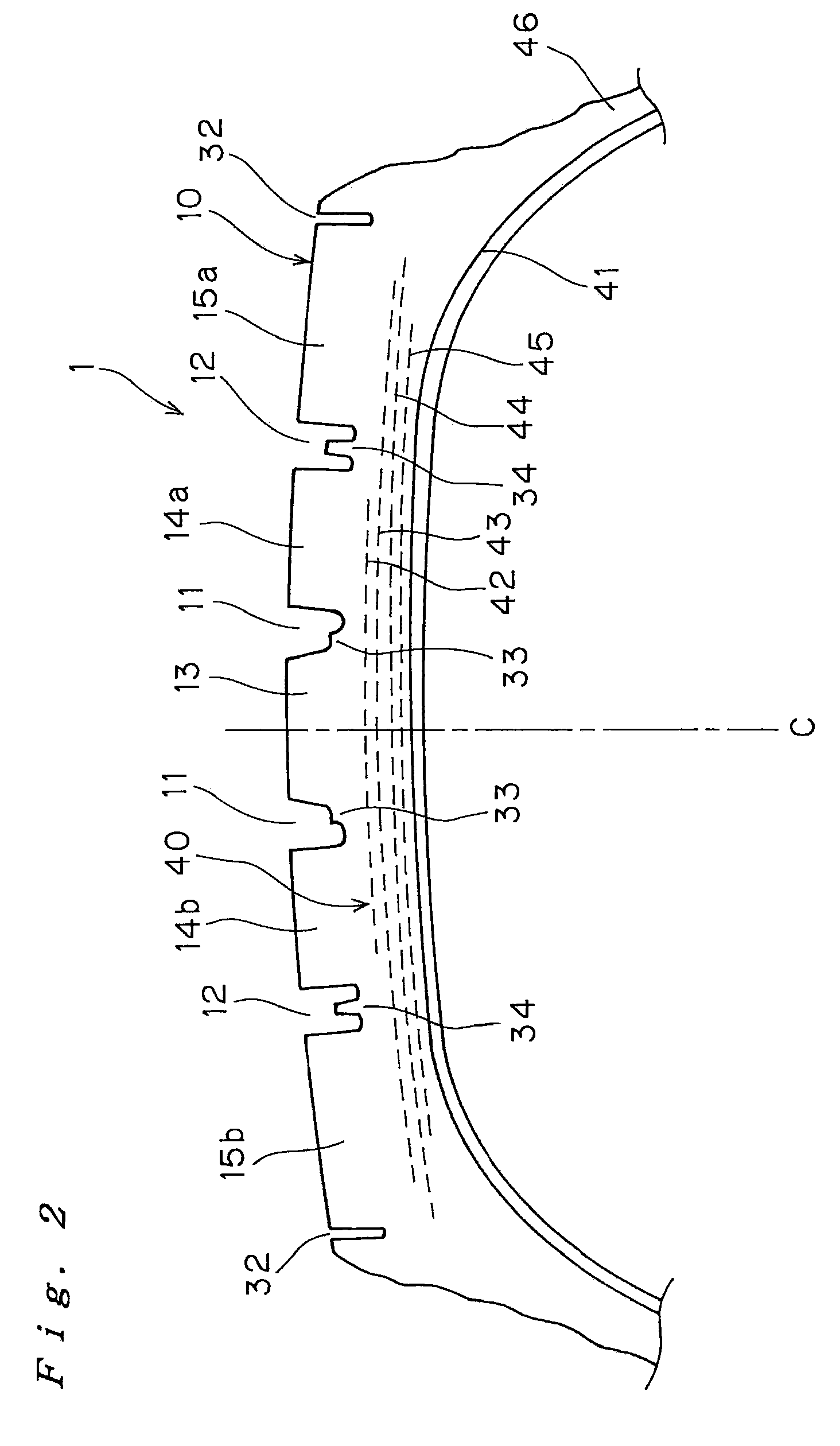

Balloon catheter having a shaft with a variable stiffness inner tubular member

InactiveUS20080045895A1High axial compression stiffness and column strengthImproved crossabilityStentsBalloon catheterVariable stiffnessDistal portion

A catheter having an elongated shaft and a balloon on a distal shaft section, the elongated shaft comprising an outer tubular member, and an inner tubular member which has a bonded portion along which an outer surface of the inner tubular member is bonded to an inner surface of the outer tubular member. The inner tubular member has a proximal portion proximal to the bonded portion, and a distal portion distal to the bonded portion with higher axial compression stiffness and column strength than the proximal portion thereof. The catheter has improved trackability, axial collapse resistance, pushability, and crossability, for improved ability to position the balloon at a desired location in a patient's body lumen.

Owner:ABBOTT CARDIOVASCULAR

Sports board with integral laminated stiffening element

InactiveUS7246568B1Uniform stiffnessImproves compression resistanceNon-magnetic metal hullsWater sport boardsPolyolefinPliability

A sport board for snow sledding or surf body boarding comprises a multi-layered laminated composite foam core coupled with stiffening elements for mechanical strengthening of the board. The composite foam core comprises laminates of polyolefin foam base and stiffening elements composed of substantially polymer foam and has substantial higher compressive strength and flexural strength than the foam base. A front section may be made of the same blank material as the low density polyolefin foam base and is bonded to the front end of the foam core complex to give a full frontal flexibility for a higher directional control by the rider and improved shock absorbing property. Upper and lower polyethylene foam sheets wrap the foam core complex subassembly and head section for sled integrity and graphic film finishes the sled top, the bottom is also finished with a polyethylene sheet for slickness.

Owner:CHEUNG WAH KAN

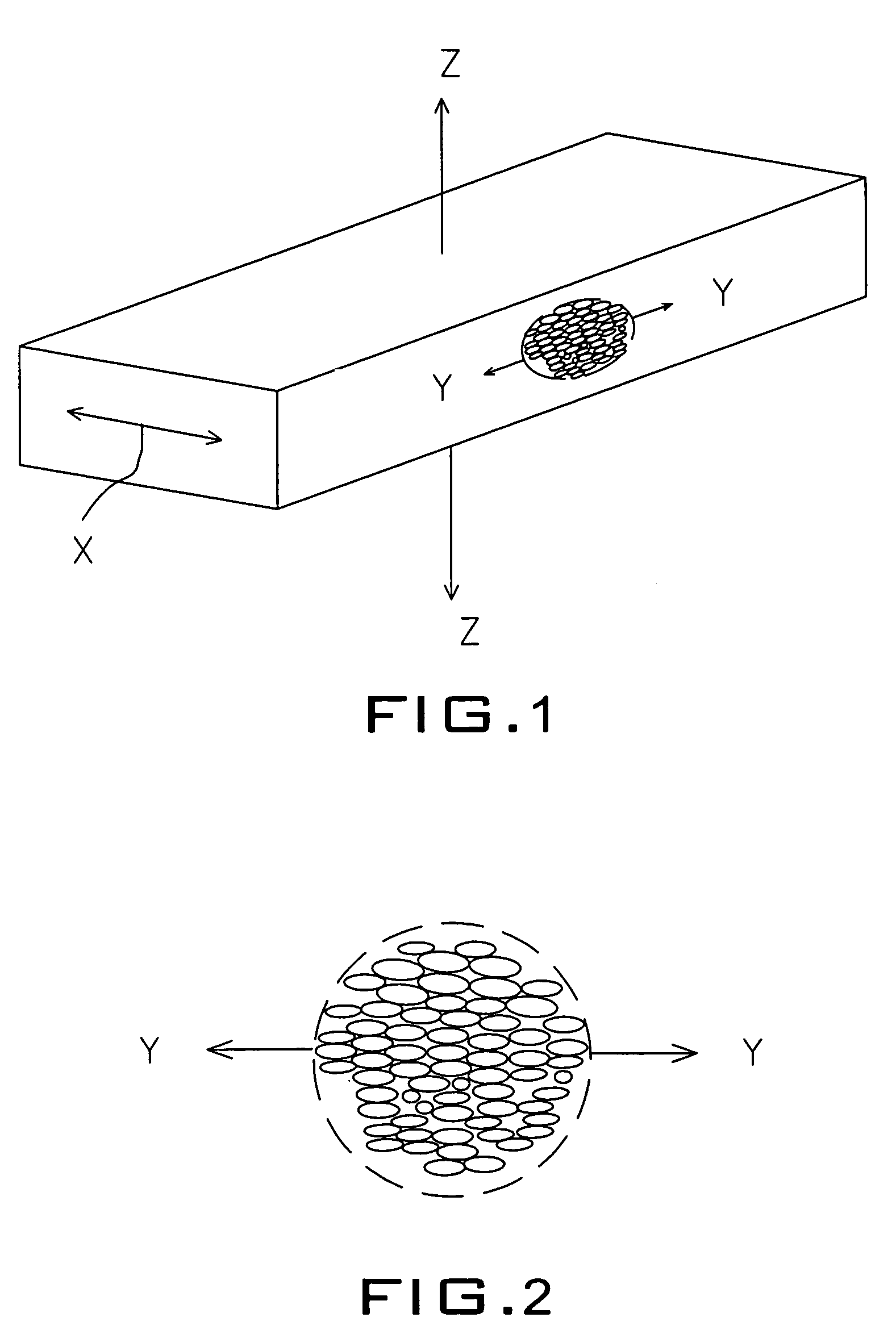

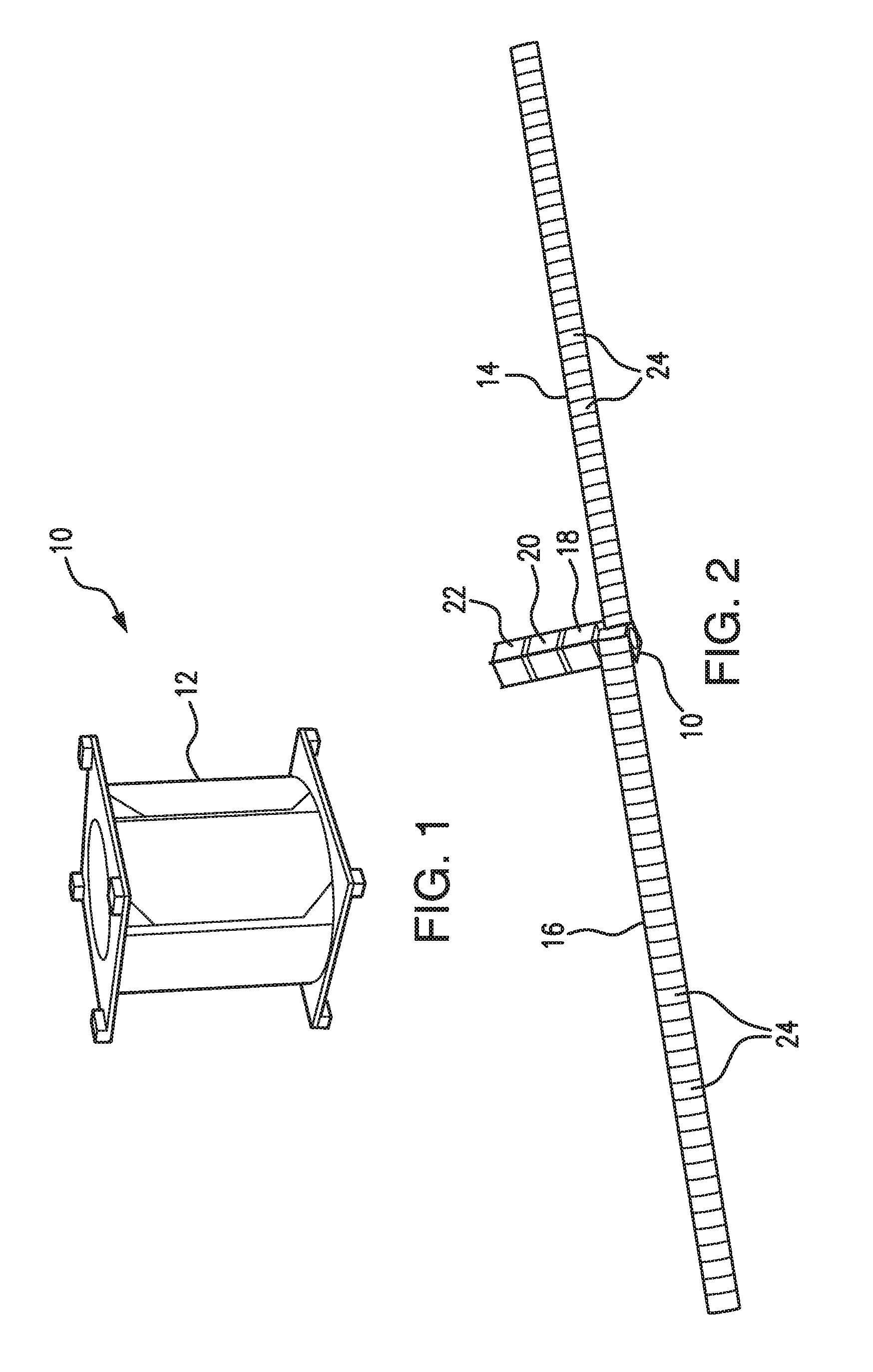

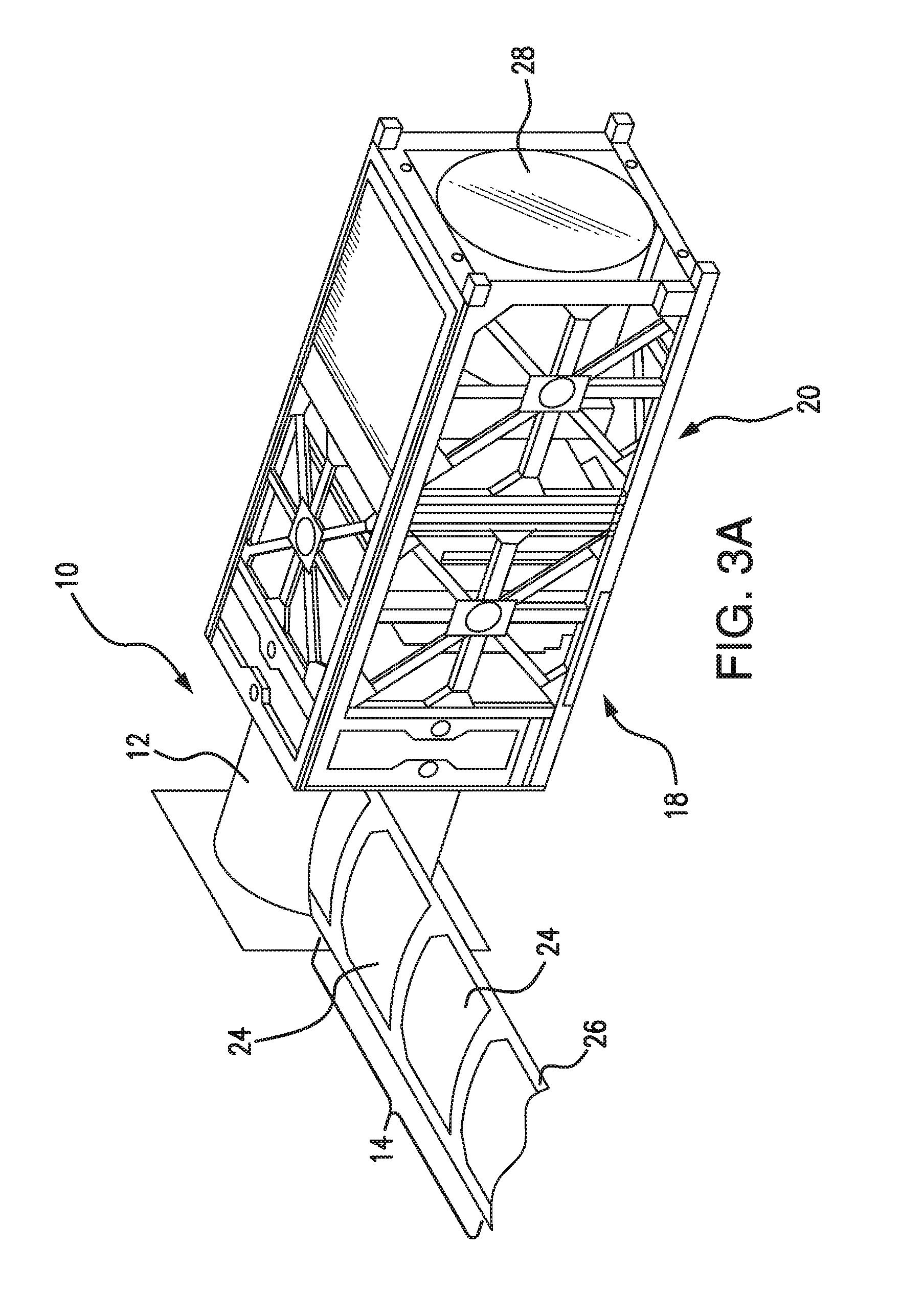

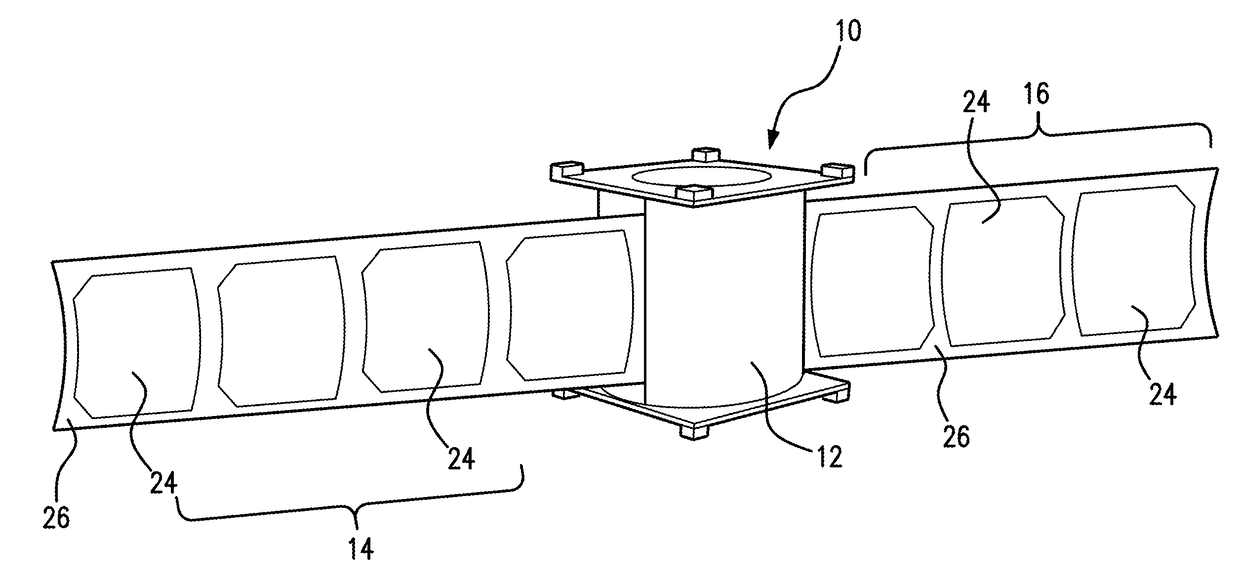

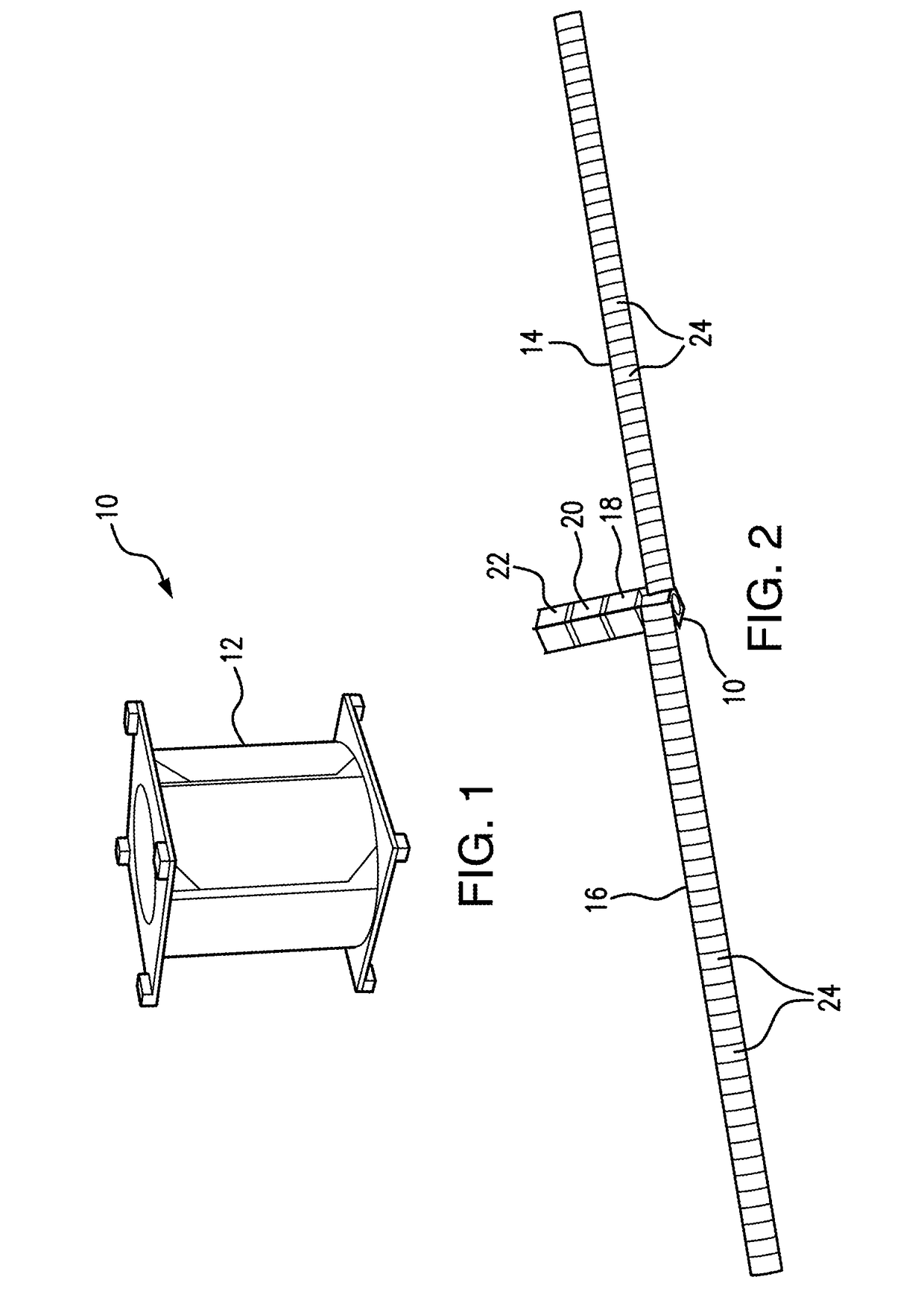

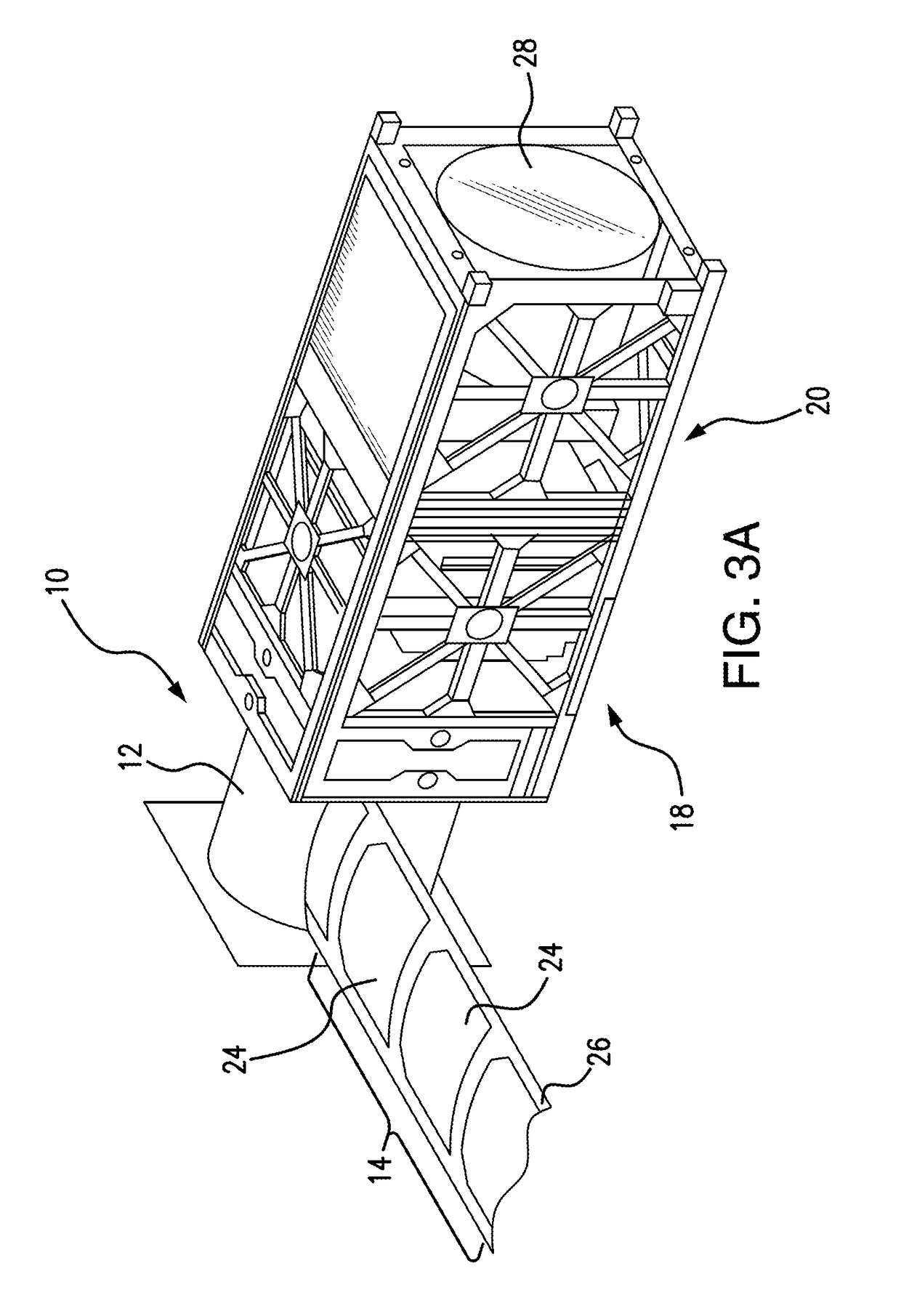

Method for releasing a deployable boom

InactiveUS20160137319A1Uniform flexibilityUniform stiffnessCosmonautic environmental control arrangementCosmonautic vehiclesFiberComposite laminates

The present disclosure provides, among other things, a deployable solar array comprising: an array of photovoltaic devices; and a flexible, elongated, rectangular sheet for supporting the array of photovoltaic devices composed of a composite laminate having a predetermined pattern of graphite fiber plies which impart a predefined tension in the planar surface of the sheet so that it curls into a planar sheet with a uniform radius of curvature along its major axis.

Owner:SOLAERO TECH CORP

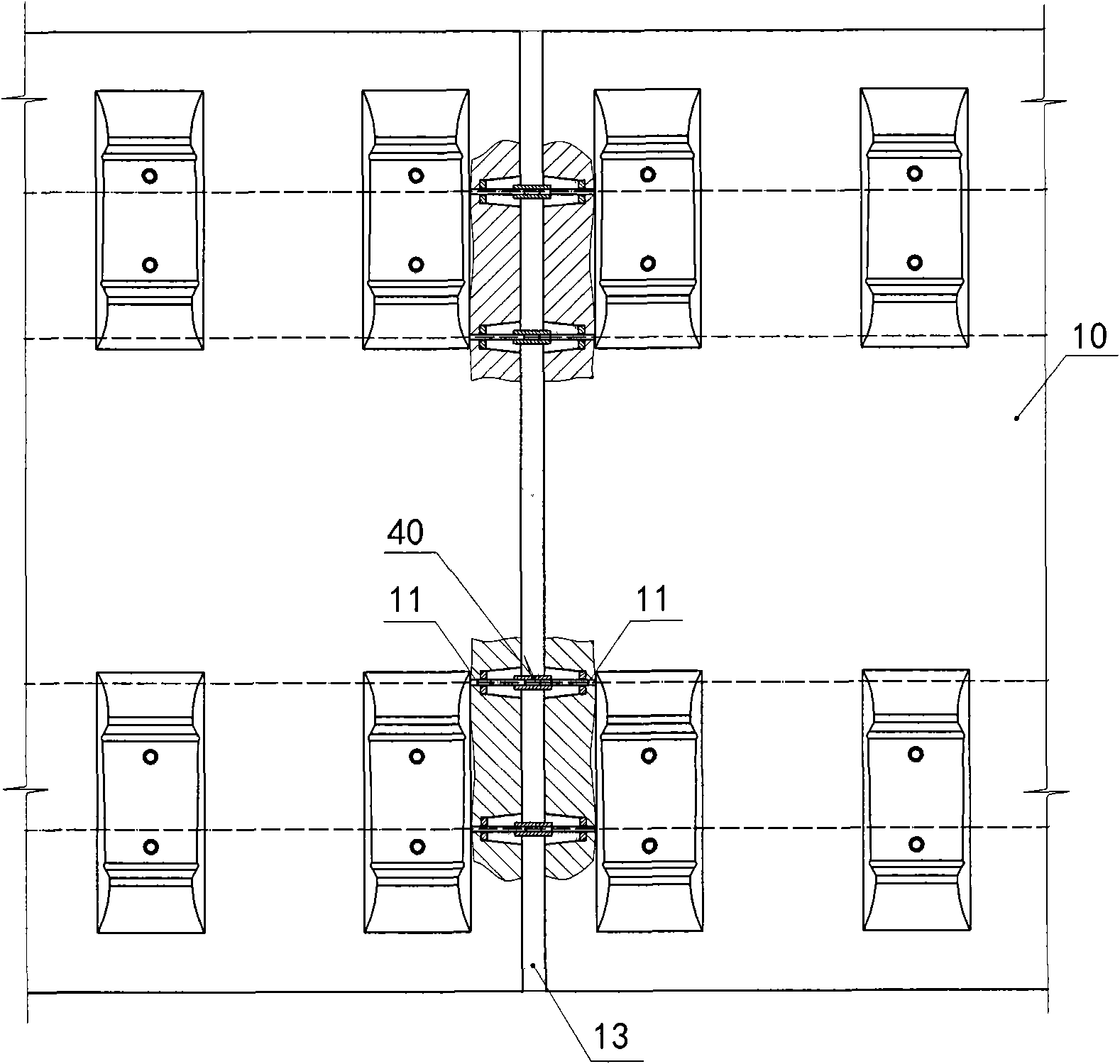

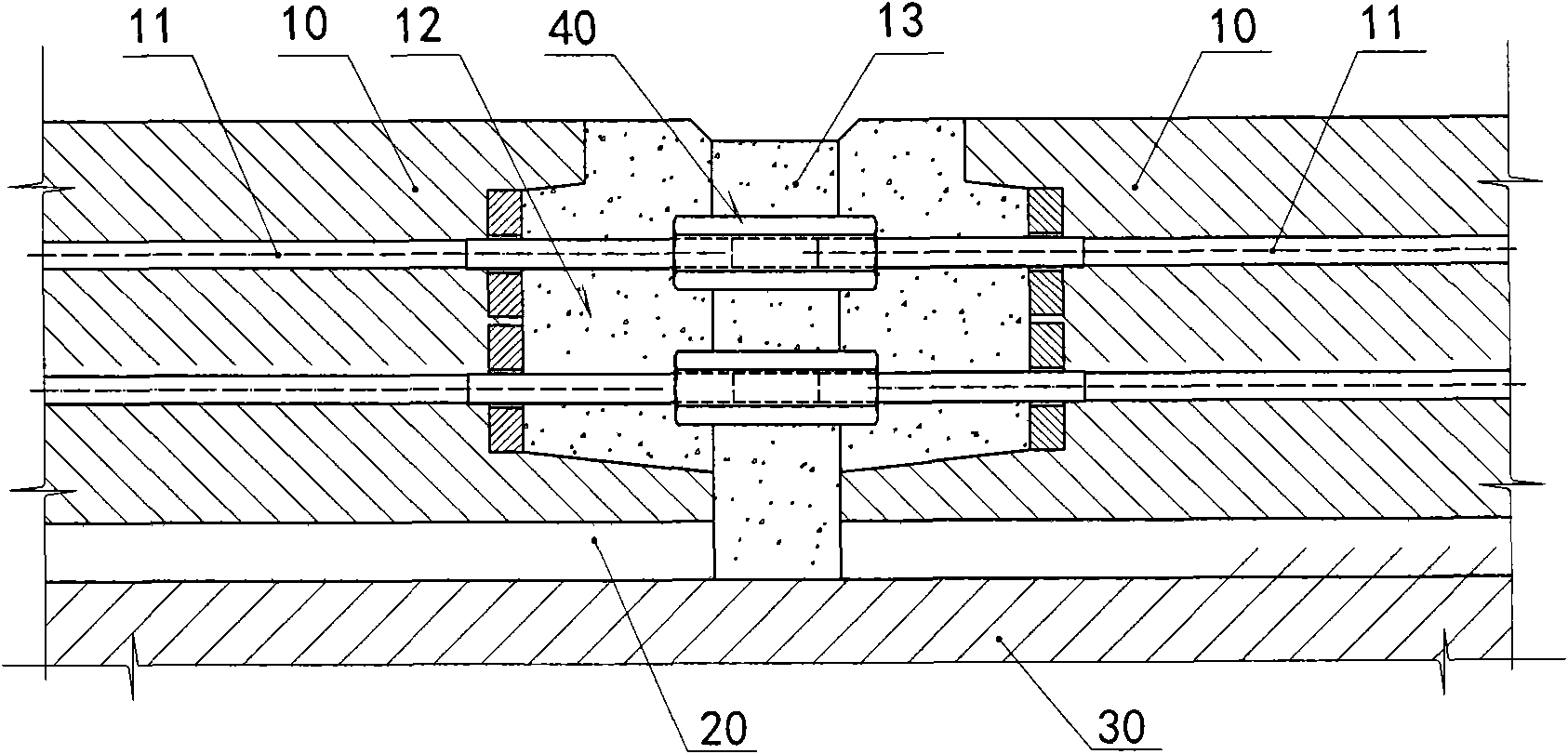

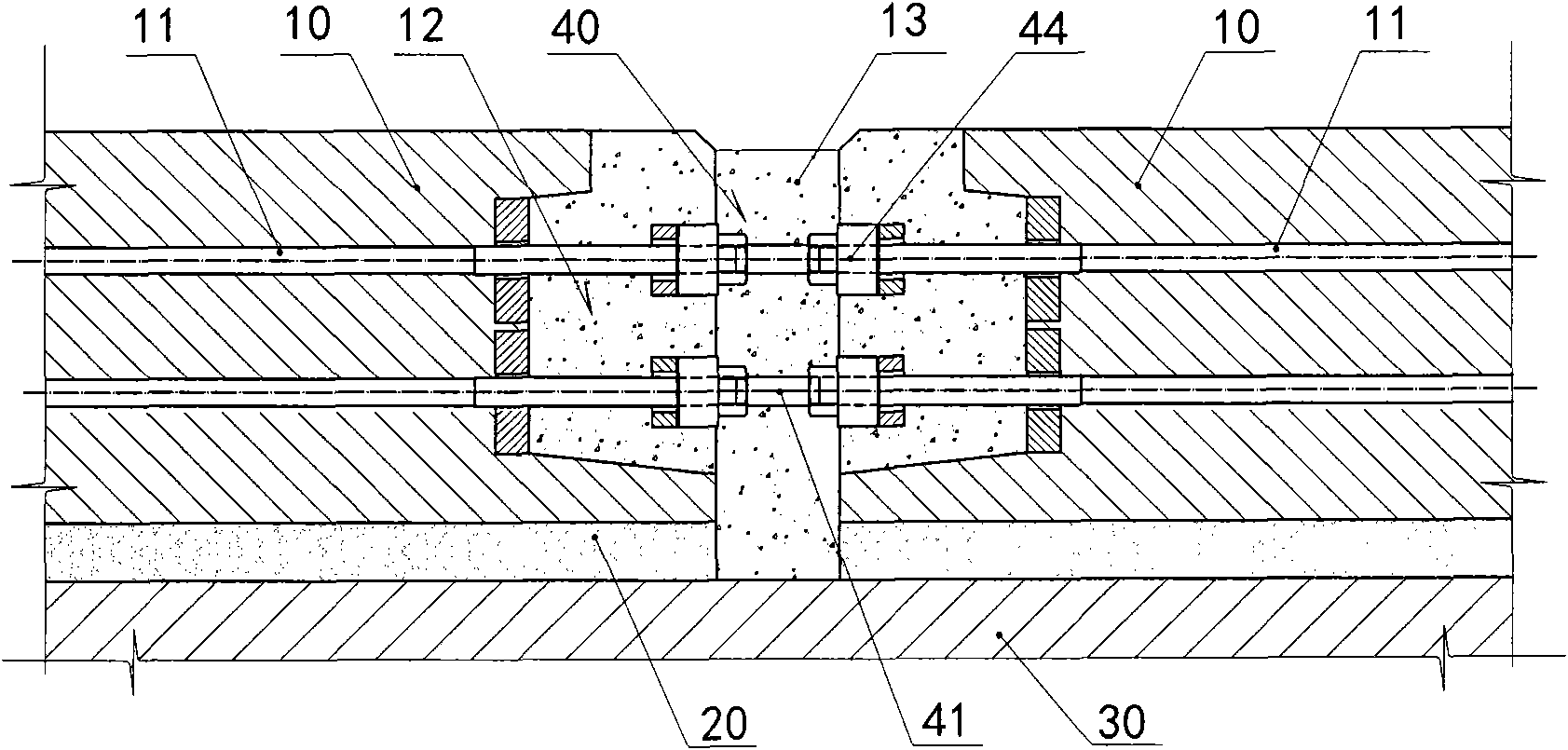

Integral ballastless track

ActiveCN101603281AImprove integrityUniform stiffnessBallastwayRailway track constructionPre stressPre stressing

The invention discloses an integral ballastless track, aiming to prolong the service life of a track structure and meet the requirement of the ballastless track on stability and comfort. The track comprises a track slab (10), an adjusting layer (20) and a supporting layer (30), wherein the track slab (10) is paved on the adjusting layer (20) along the line extending direction; multigroup pre-stressed steel bars (11) are distributed transversely in the body of each track slab (10) at intervals; a filling layer (13) is arranged in a seam between two adjacent track slabs (10); the pre-stressed steel bars (11) corresponding to the track slabs (10) are vertically connected and apply pre-stress in segment to form the integral track slab. The integral ballastless track has the advantages of track integration improvement, even track rigidness, fulfillment of requirements of the ballastless track on the stability and comfort. The ballastless track effectively solves the problems that the filling layer between track slabs is easily cracked, and vertical ends of the track slabs are easily warped, can reduce the workload for maintaining and repairing the track structure, and improve the service life of the track structure.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

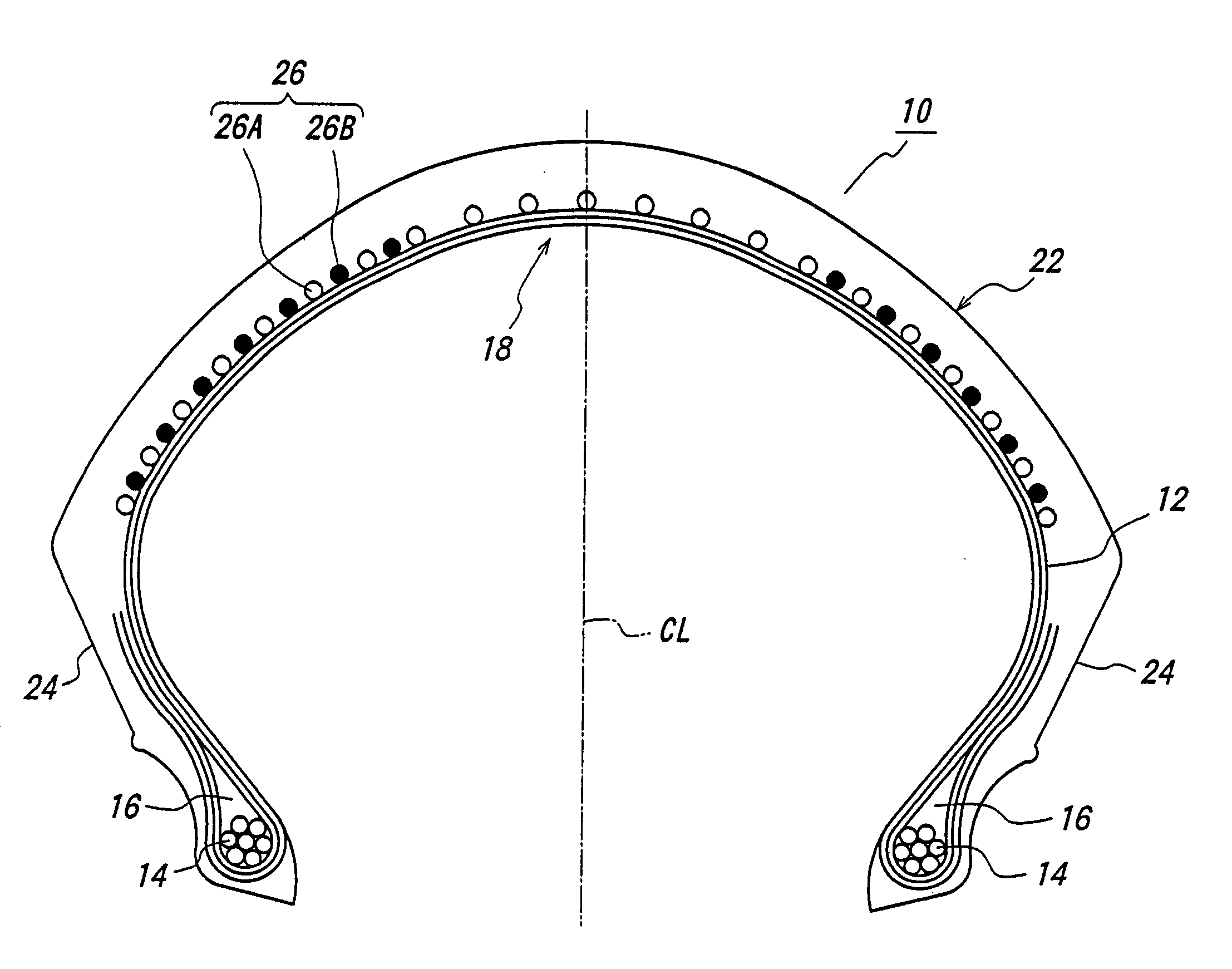

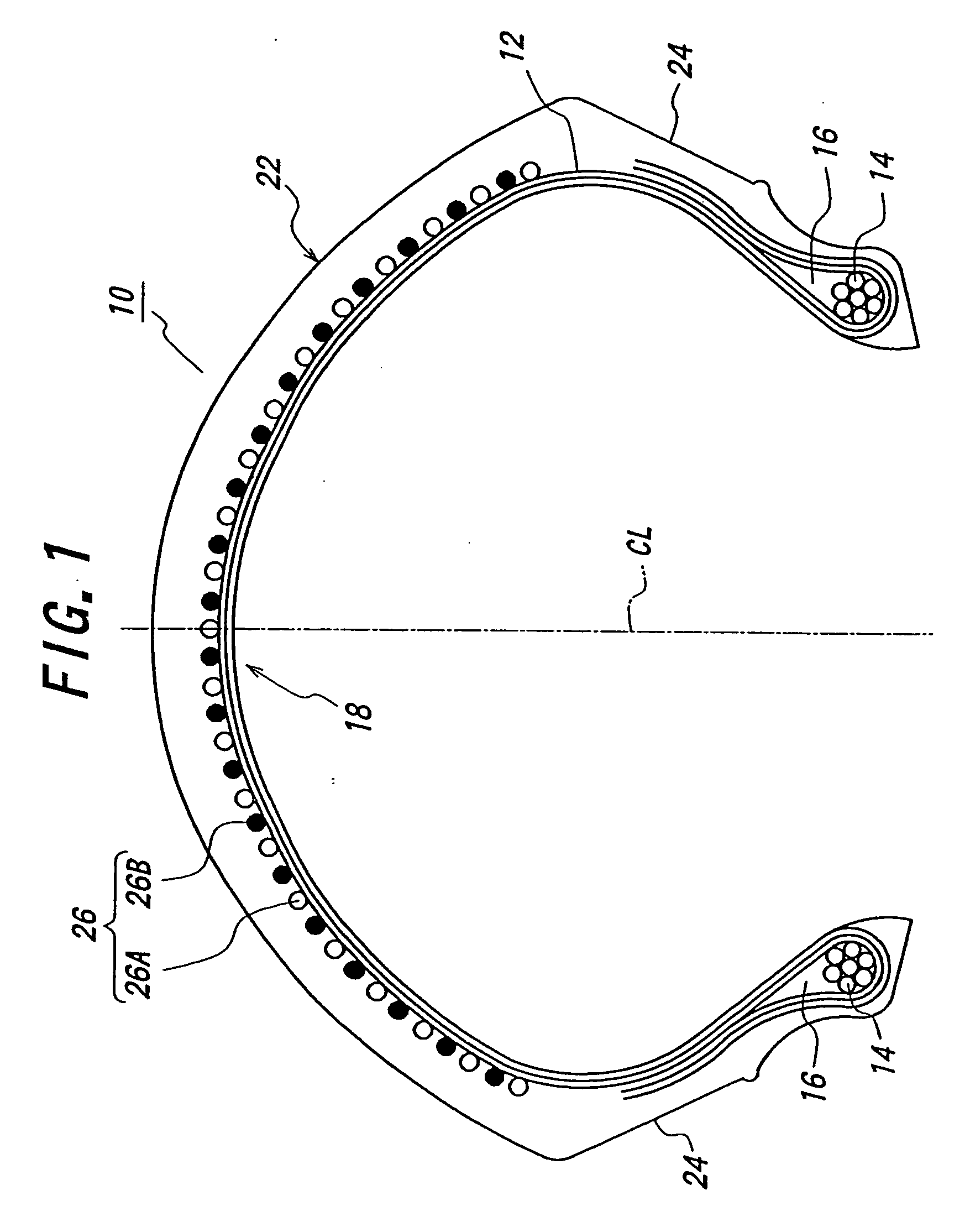

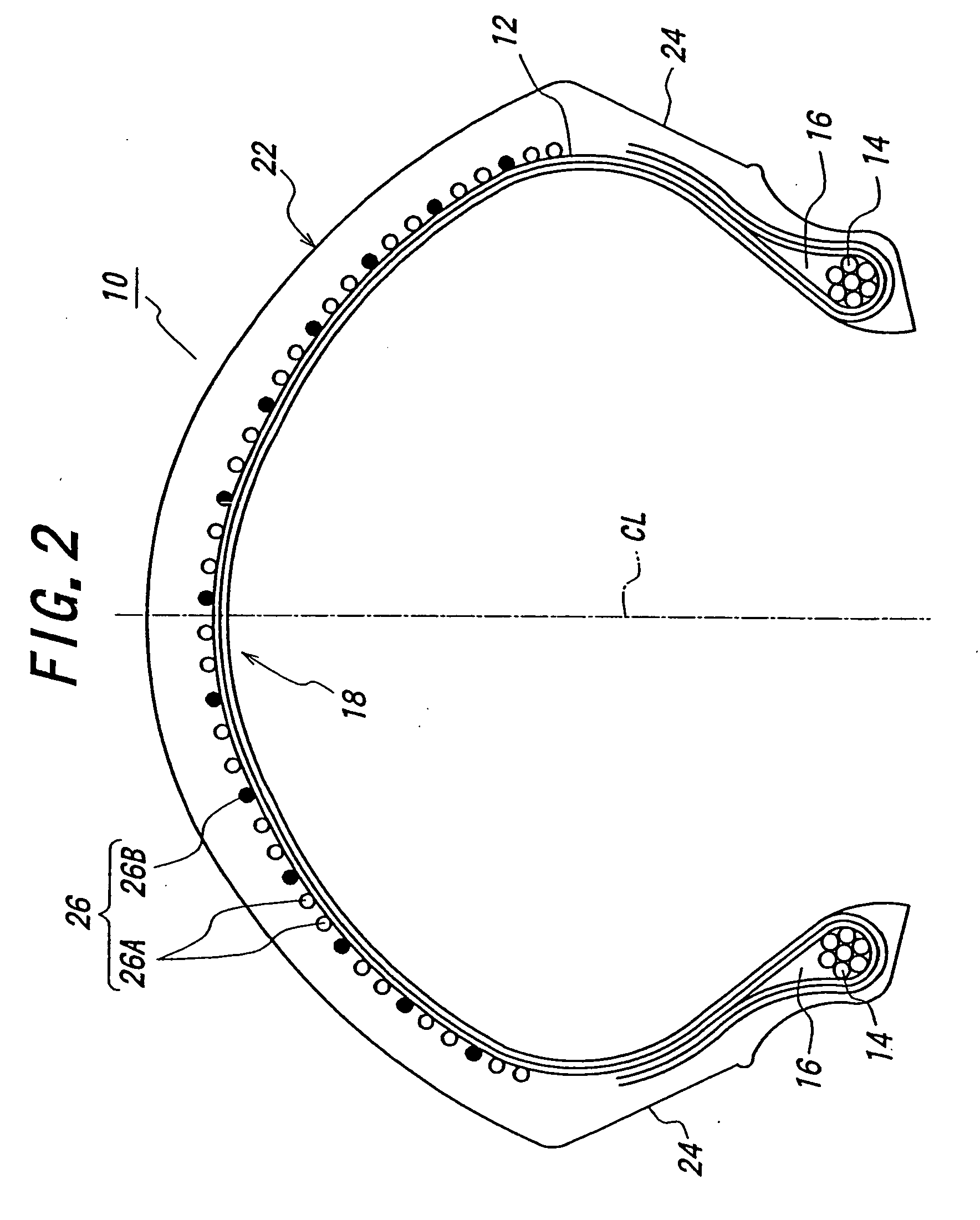

Pneumatic tire and method of producing the same

InactiveUS20040123930A1Improve compressive stiffnessReduce rigidityTyresPneumatic tyre reinforcementsEngineeringTread

A pneumatic tire comprises a spiral belt formed by spirally winding a cord(s) along a circumferential direction of a torus tread, wherein the spiral belt is comprised of at least one layer constructed with a combination of two different cords each having an initial tension of not less than 50 cN / cord.

Owner:BRIDGESTONE CORP

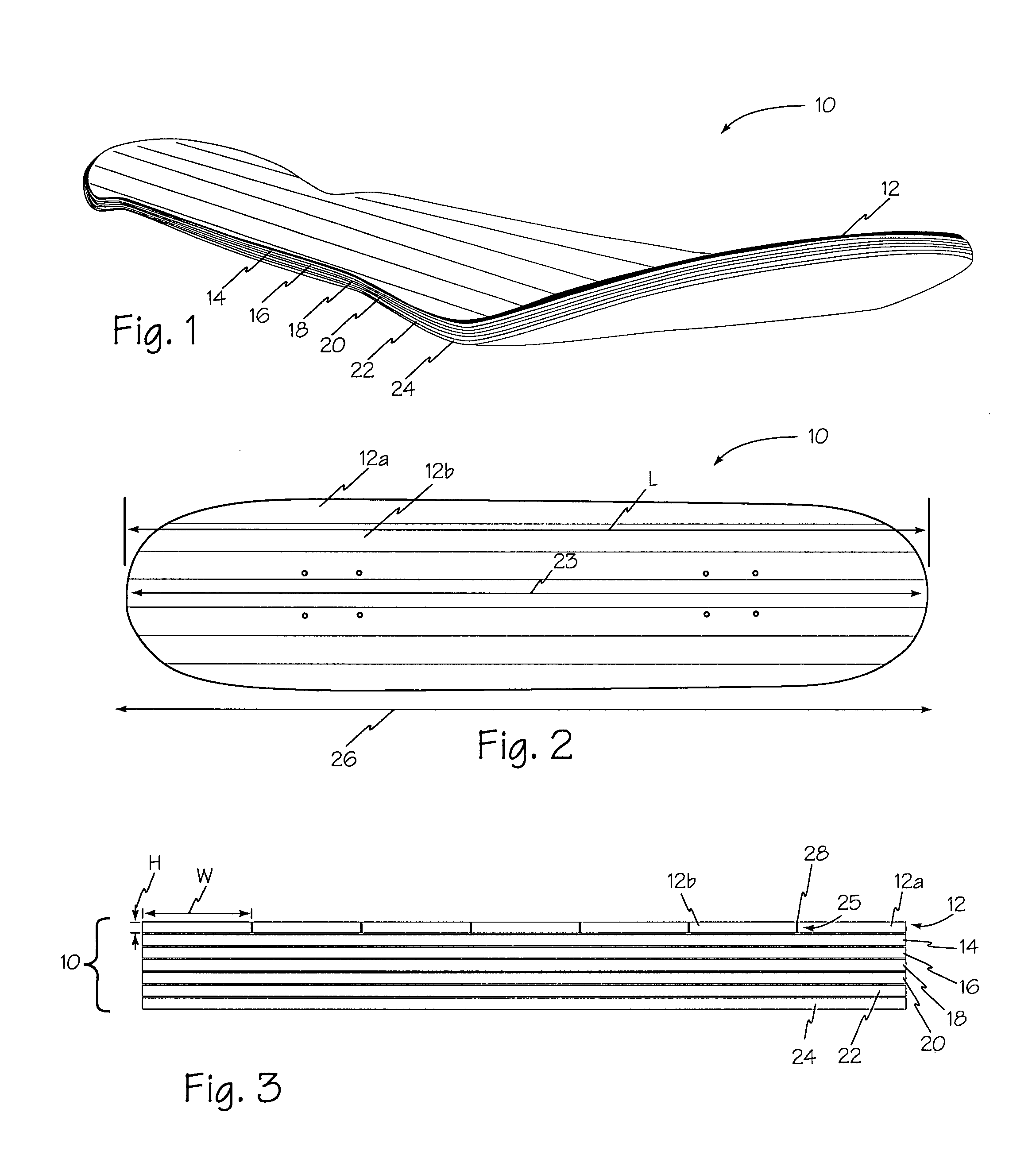

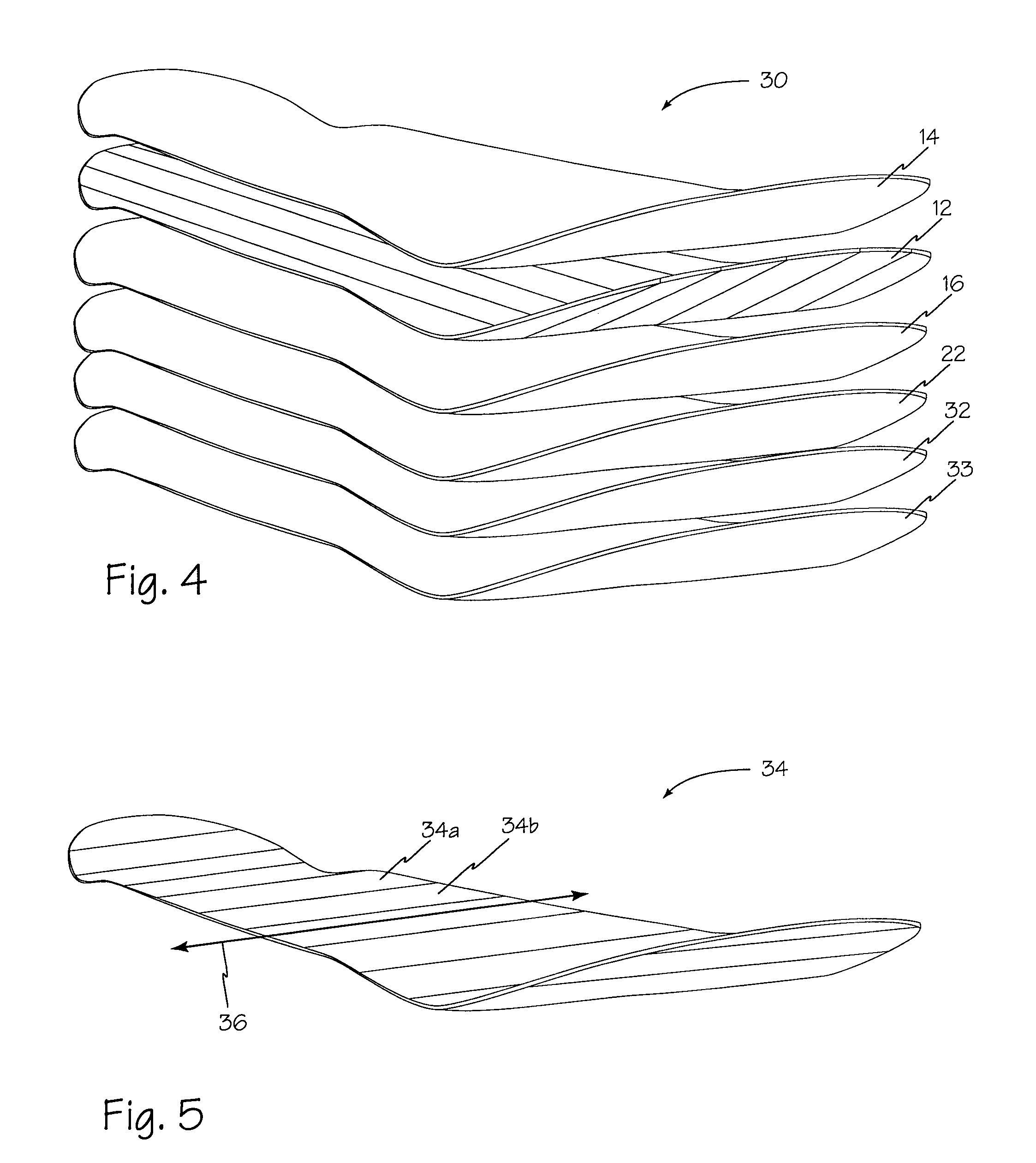

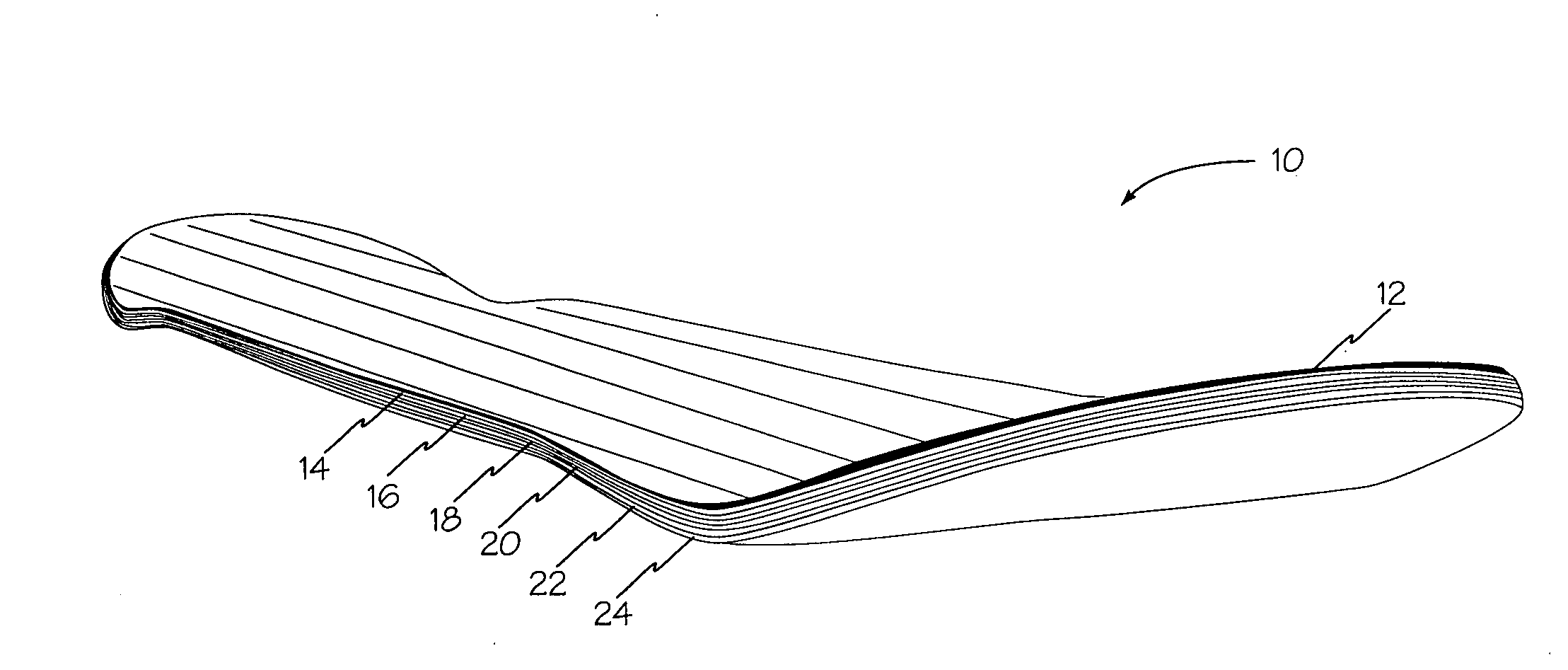

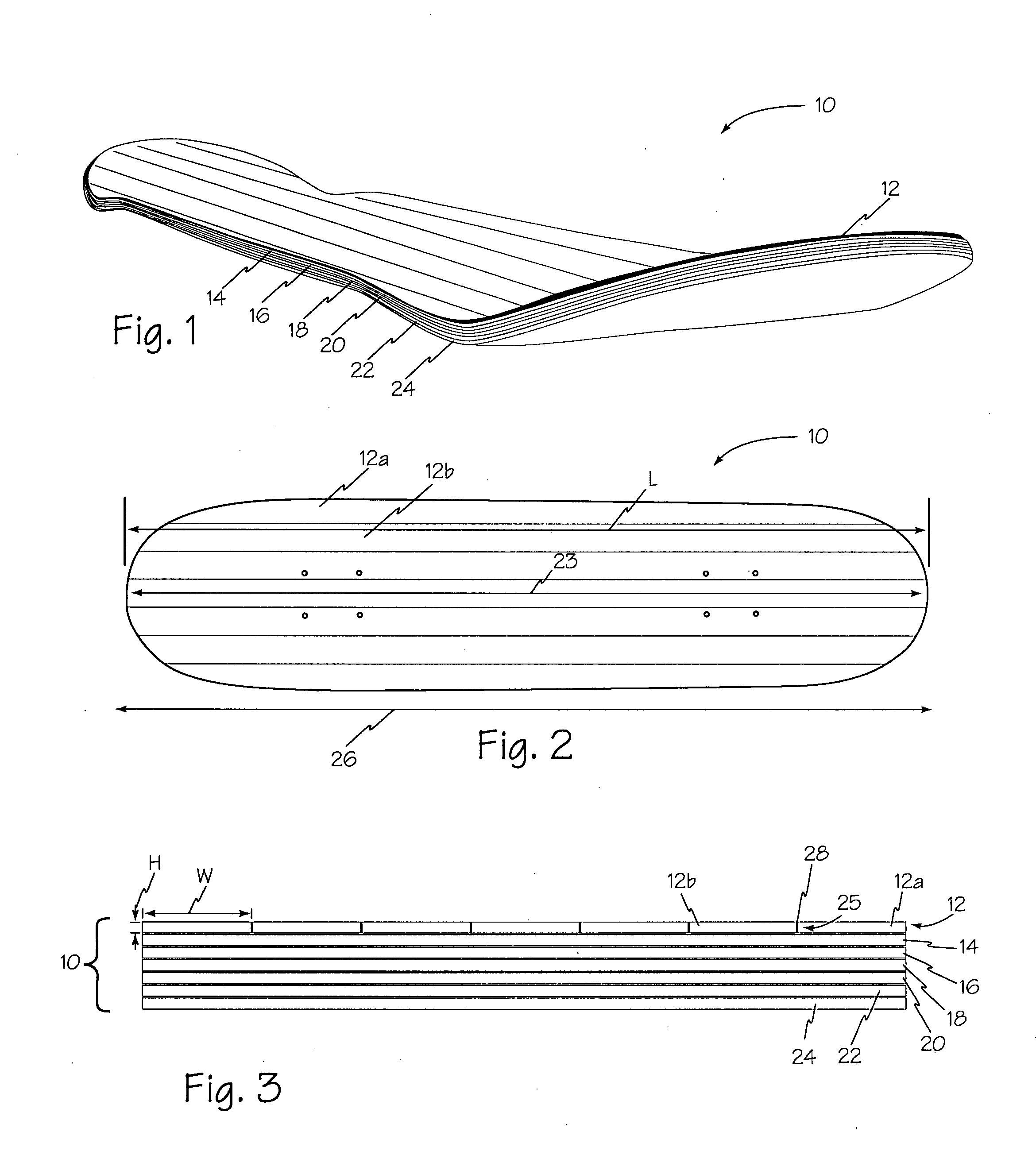

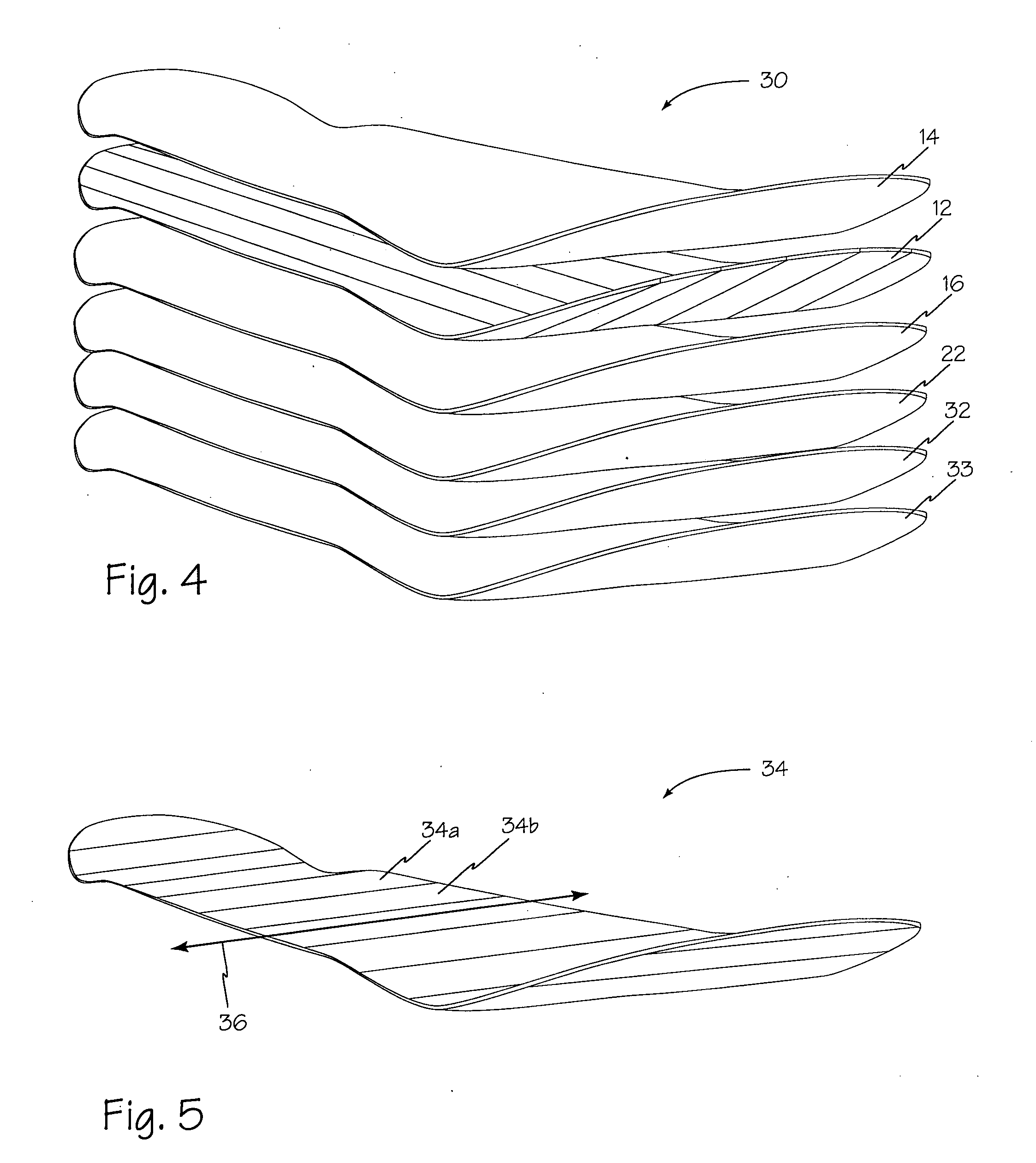

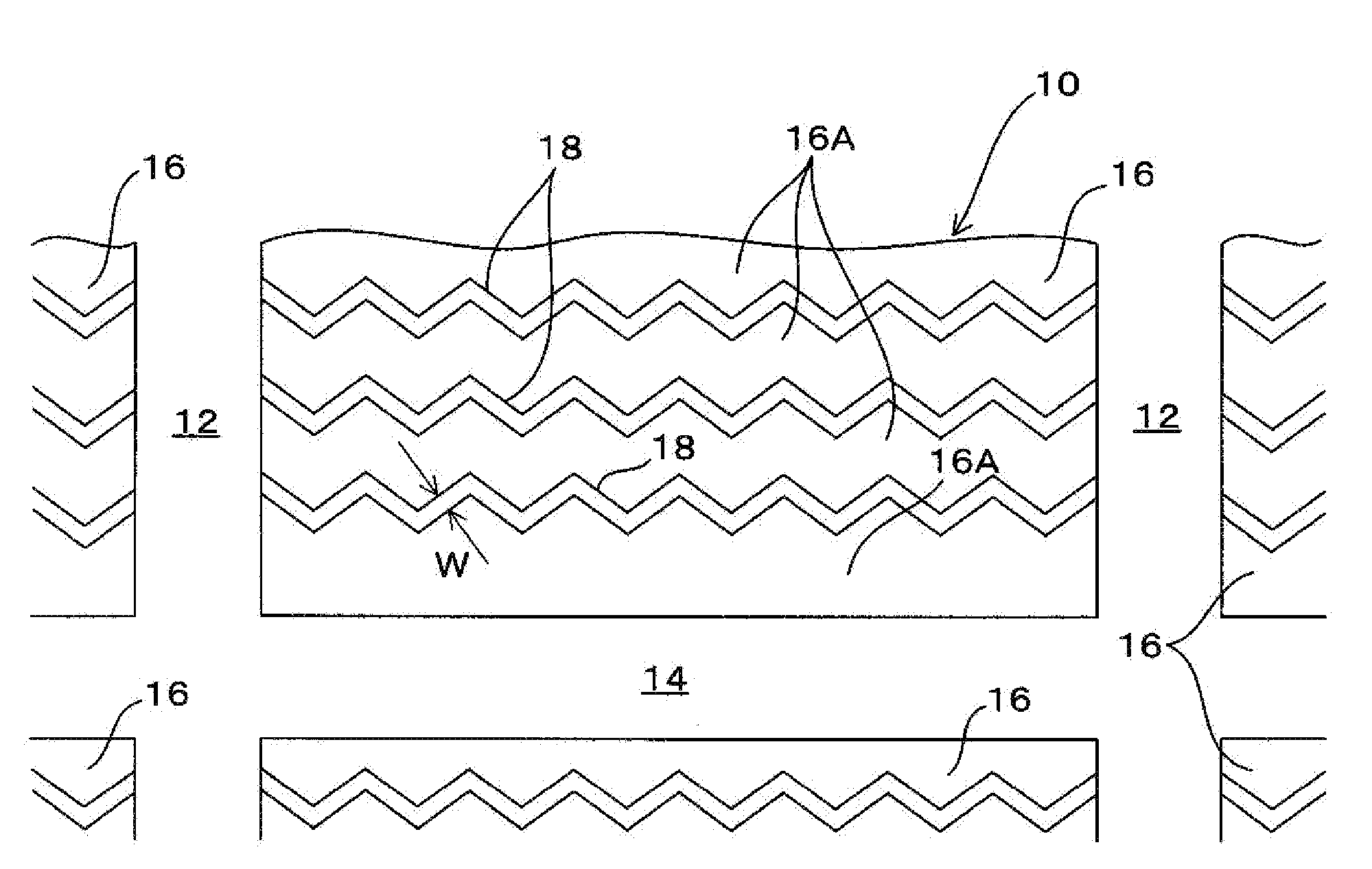

Bamboo core hybrid skateboard deck

InactiveUS7506880B2Easy to FeedbackHigh strengthGuiding agricultural machinesThin material handlingEngineeringSlide plate

A hybrid skateboard deck combines at least one layer of bamboo with one or more layers of any suitable wood to form a multi-ply deck. A hybrid skateboard deck combines at least one layer of bamboo sandwiched between at least two layers of conventional hardwood such as maple. The addition of a bamboo layer in the core of the laminated deck provides superior strength relative to conventional plywood decks. The bamboo core laminate also provides superior feedback to a rider as well as uniform stiffness.

Owner:BURWELL SCOTT

Pneumatic Tire

ActiveUS20080099115A1Improve wear resistanceRigidityTyre tread bands/patternsNon-skid devicesEngineeringWear resistance

A pneumatic tire having improved wear resistance, especially improved uneven wear resistance (such as river wear), is offered. The tire that is a rib-pattern tire has five ribs extending circumferentially of the tire. The ribs include a center rib and intermediate ribs located on the opposite sides of the center rib that is located on the equator line of the tire. Closed sipes are formed at least in the center rib and in the intermediate ribs. Each sipe is located in the lateral center of the corresponding rib. Both ends of each sipe terminate within the corresponding rib. The closed sipes are successively offset circumferentially among the ribs and arranged in a periodic pattern on the outer surface of the tire. The closed sipes in the ribs are so arranged that when they are optically projected onto the equator line of the tire, the sipes do not overlap circumferentially of the tire among the ribs.

Owner:TOYO TIRE & RUBBER CO LTD

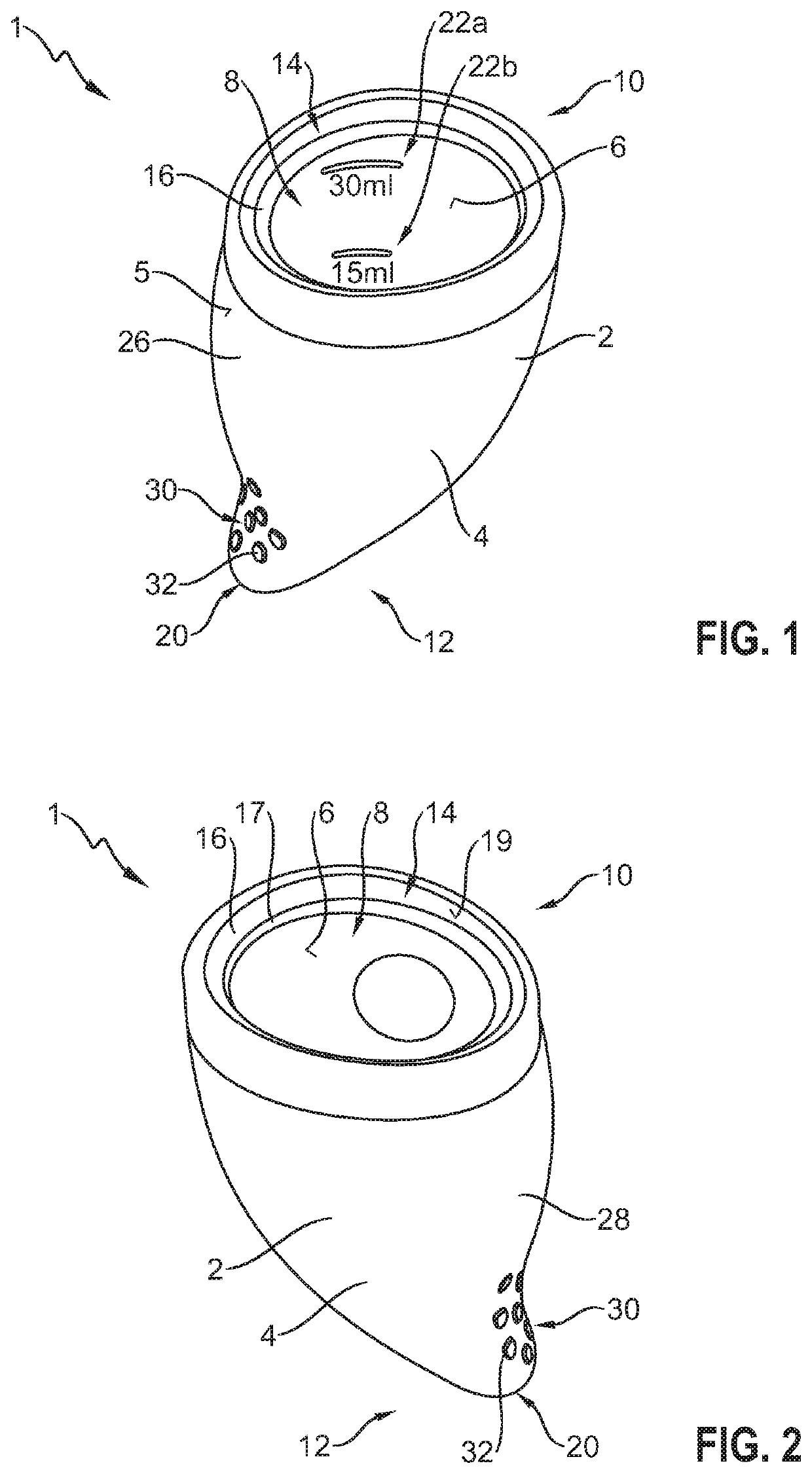

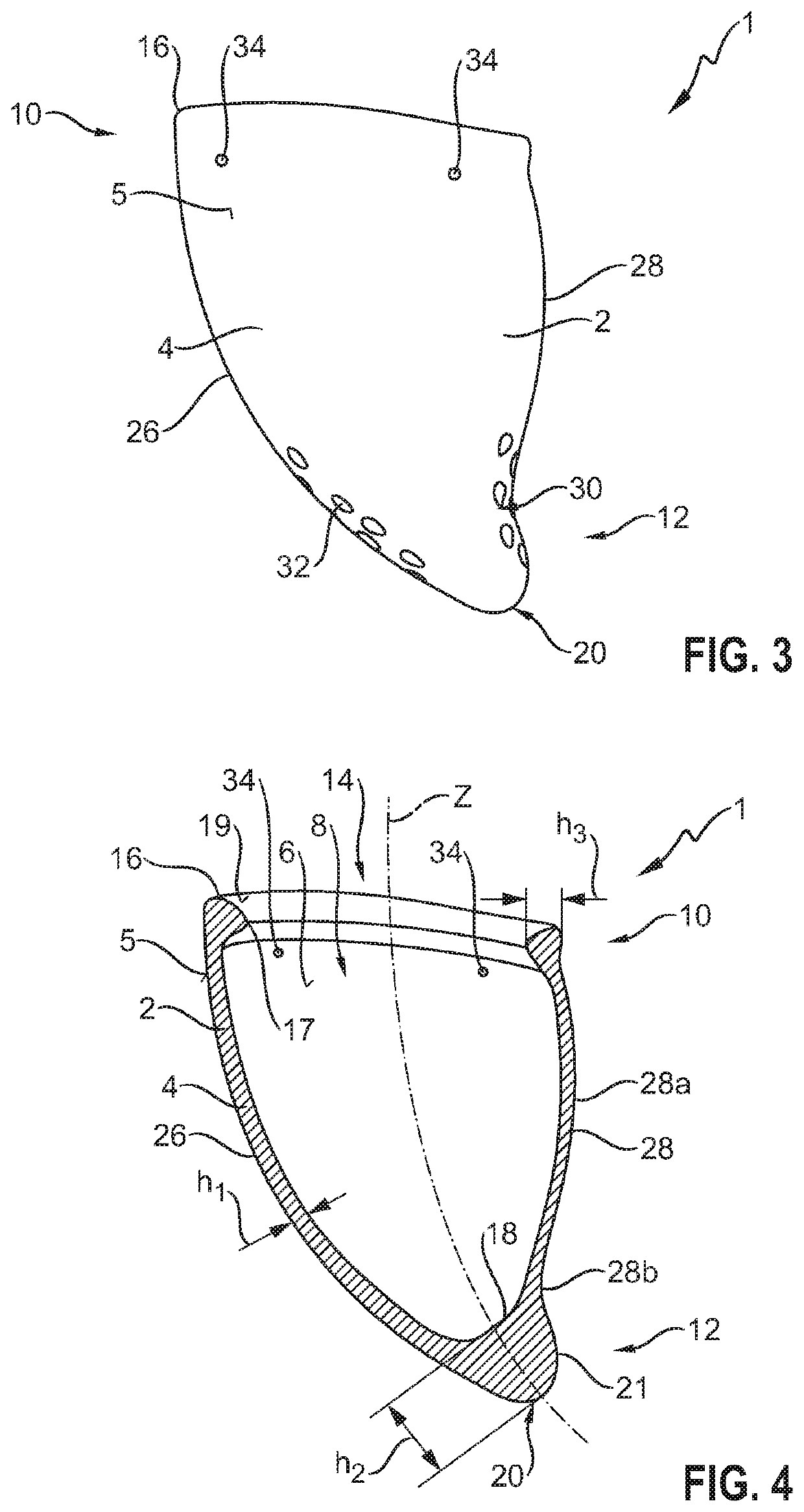

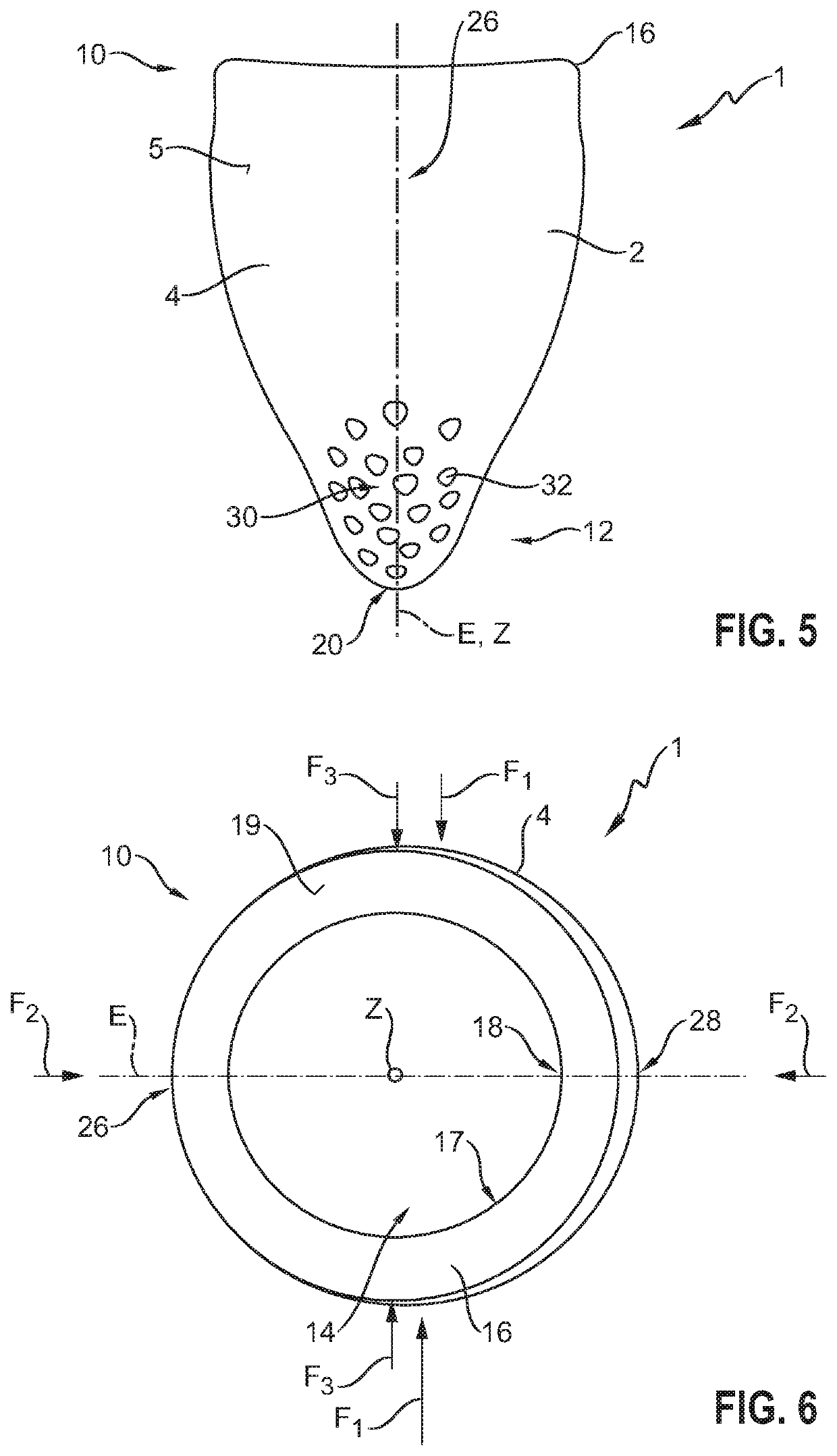

Hygiene product, in particular menstrual cup with an ergonomic shape

ActiveUS20190358077A1Improved fluid receptionImprove wearing comfortMedical devicesBodily discharge devicesBiomedical engineeringHygiene

The disclosure relates to a hygiene product, in particular a menstrual cup, having a cup body comprising a cup wall defining a receiving space using an inner surface, the cup body comprising on a first end an opening into the receiving space, the opening having an edge, and at a second end, a bottom opposite the opening, and the cup body comprising a generally conical shape, tapering towards the bottom and terminating in a tip. The hygiene product is characterized in that the cup body is rotationally asymmetric and a central axis of the cup body runs curved.

Owner:FUN FACTORY

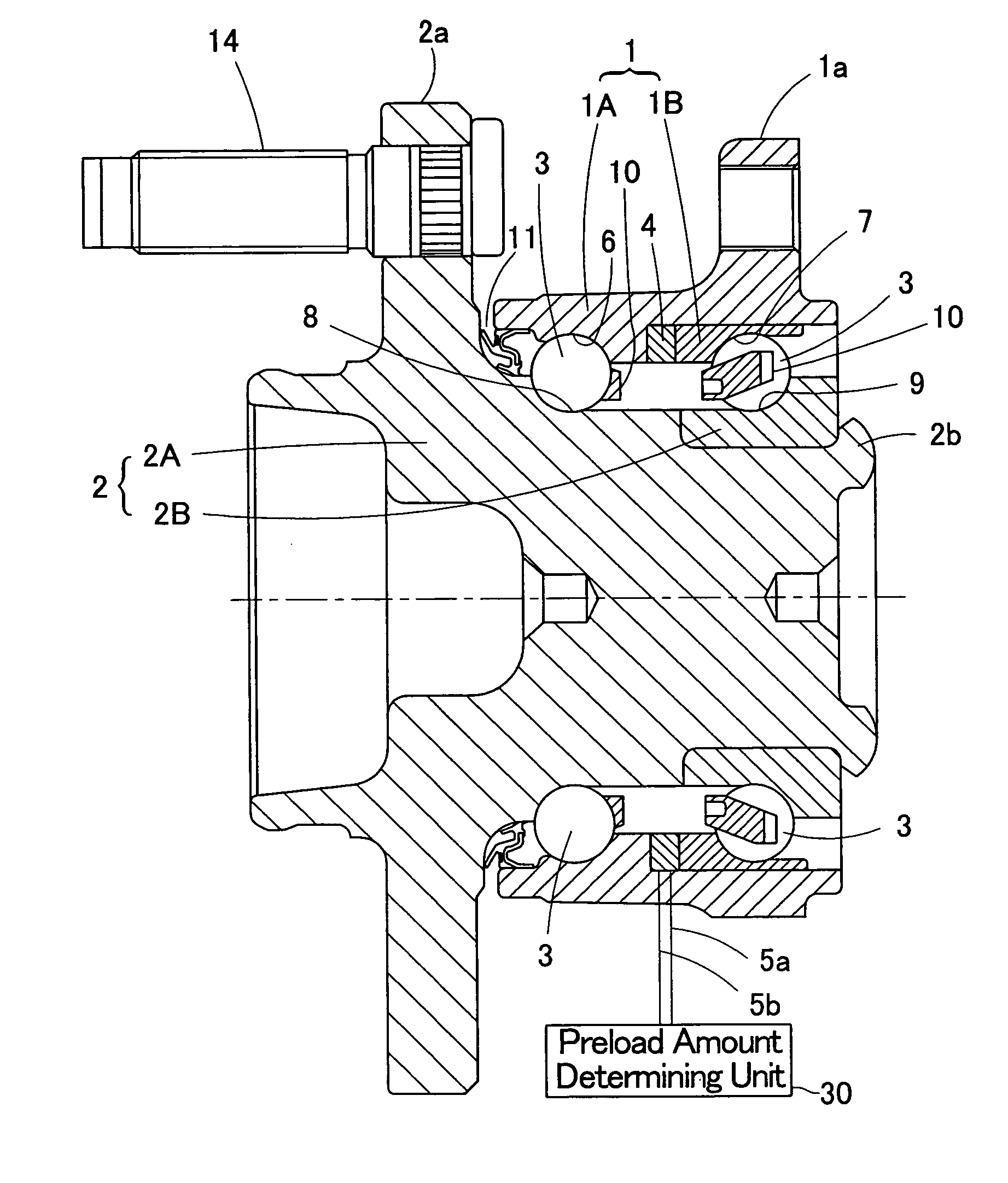

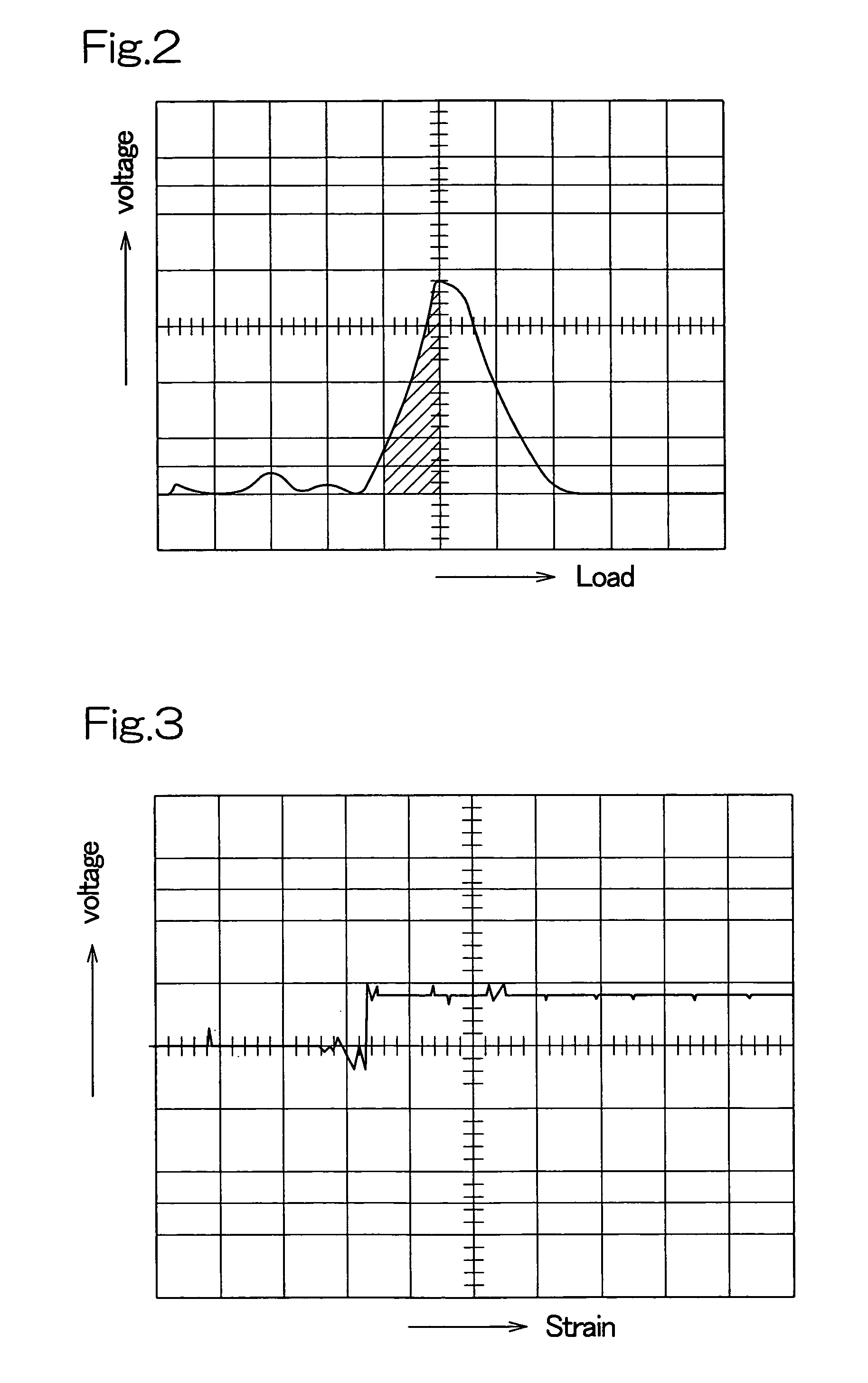

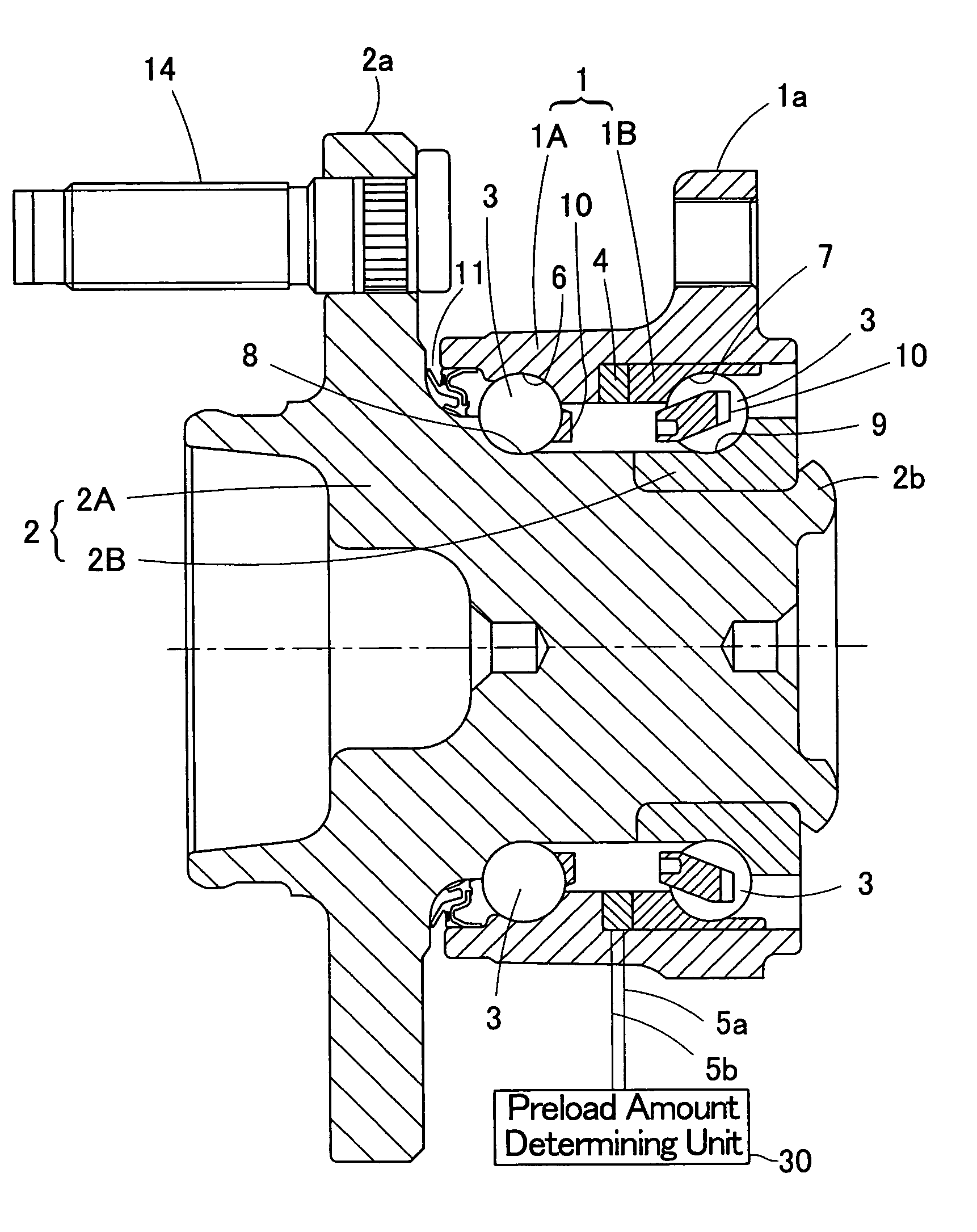

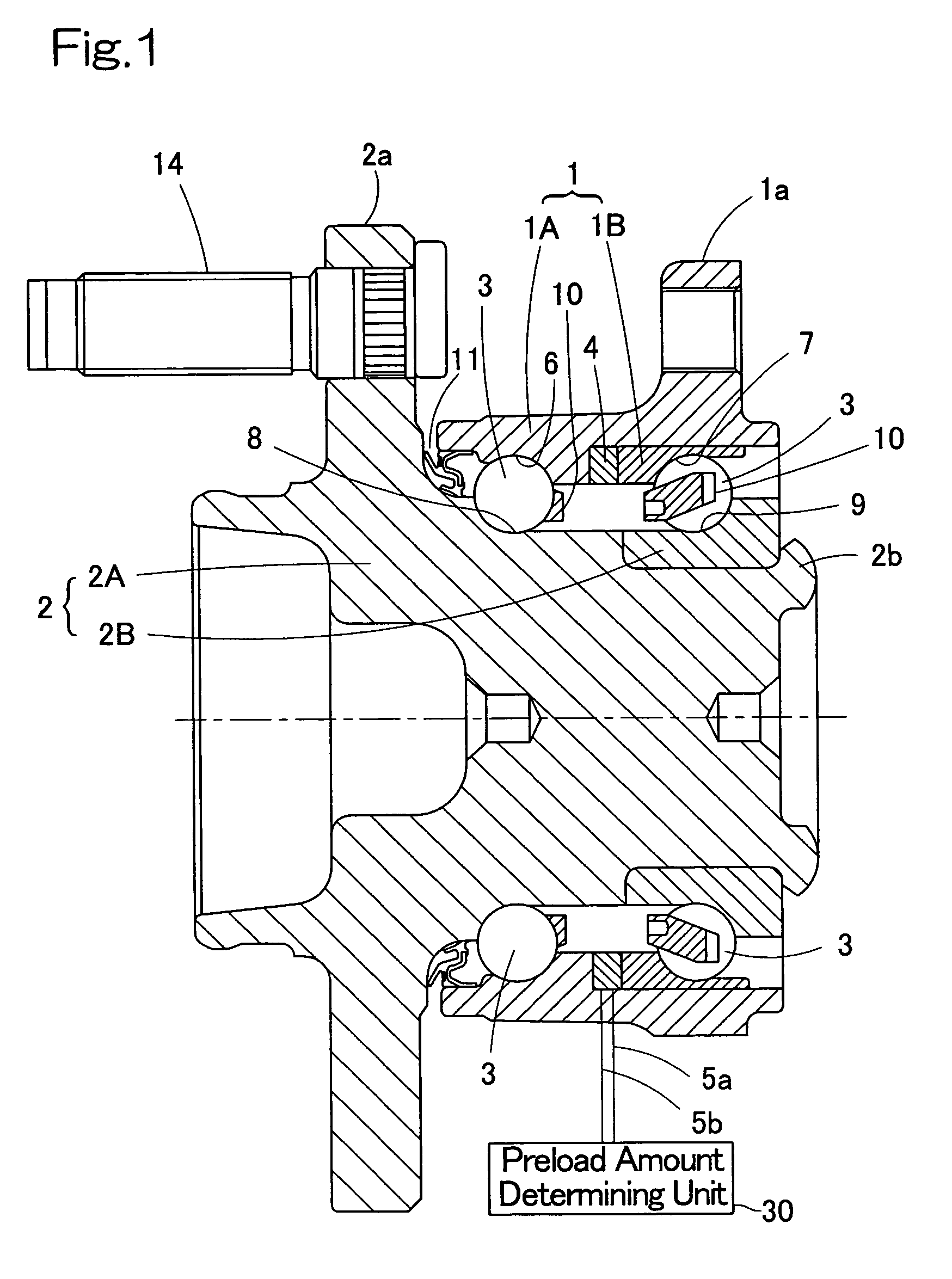

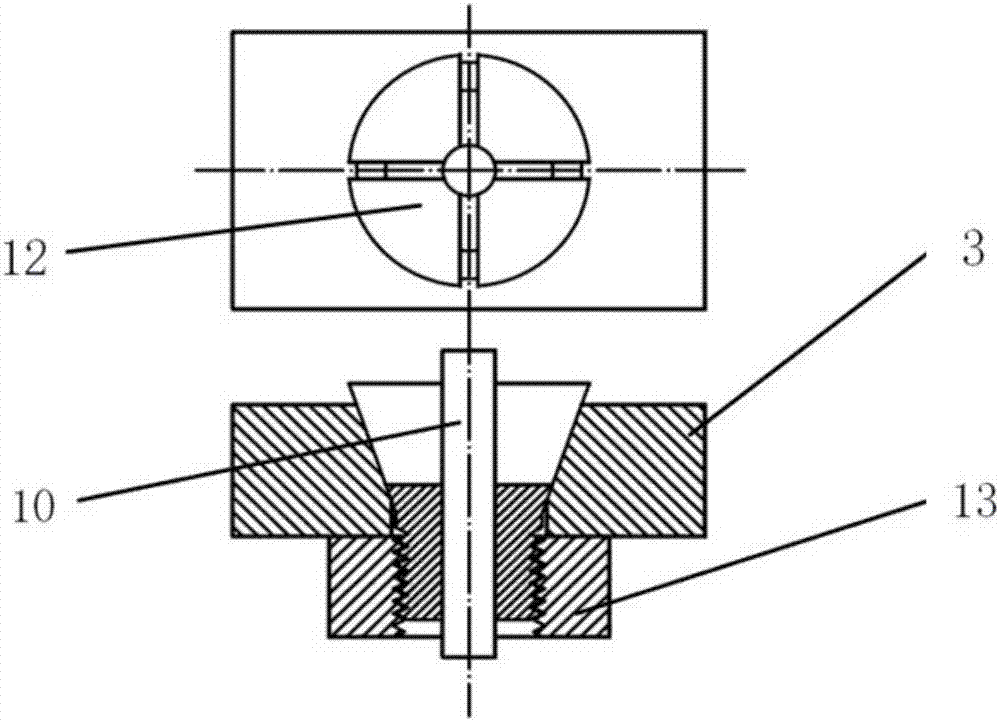

Bearing device for wheel

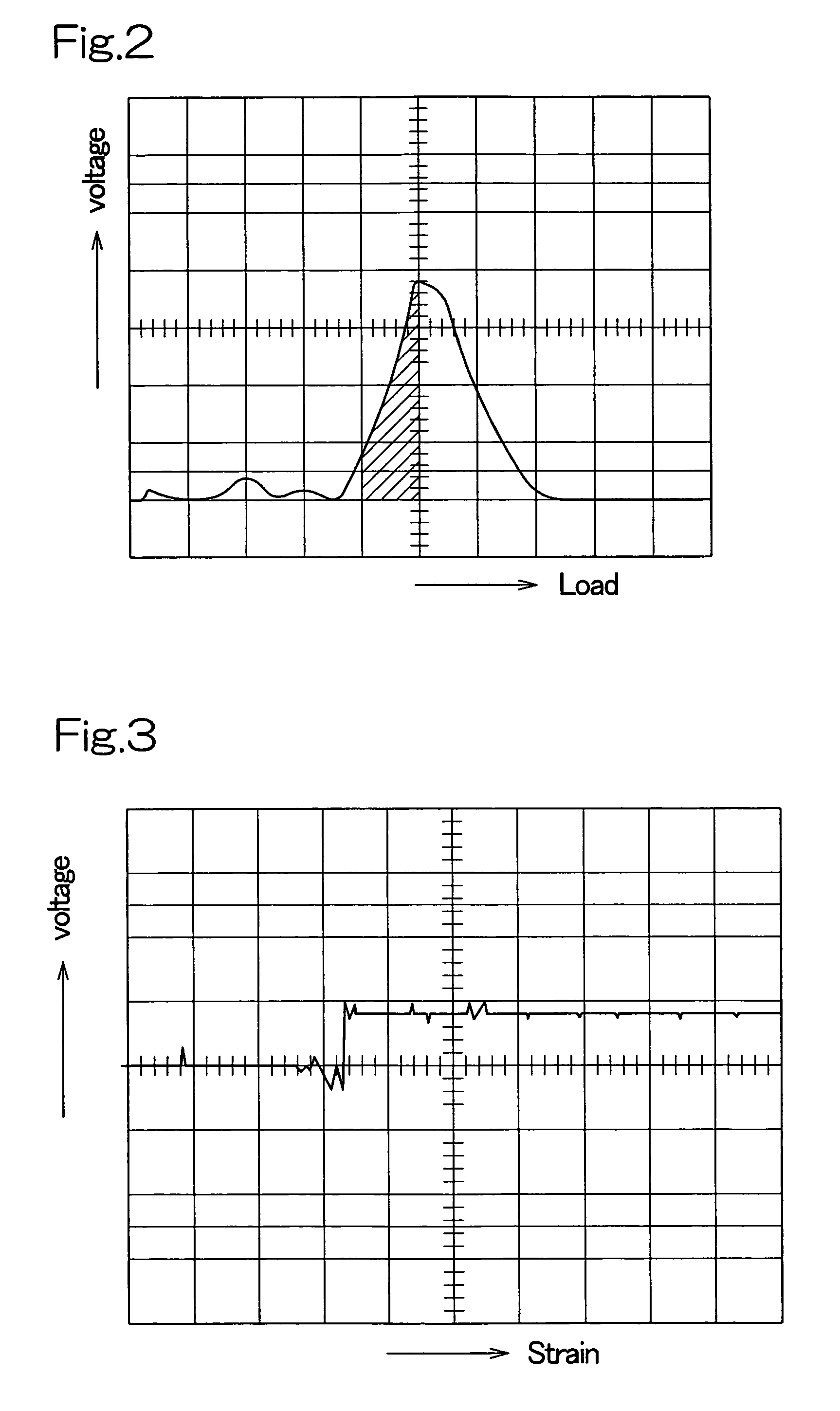

InactiveUS20070014500A1Suppress mutationSimple to executeRolling contact bearingsBearing assemblyEngineeringFlange

To provide a bearing device for a wheel, in which a preload control is easy and a uniform amount of preload can be applied with a bearing seal being mounted, the bearing device for the wheel includes an outer member, an inner member and double rows of rolling elements interposed between the outer member and the inner member. The outer member has a flange on an outer periphery thereof and also has an inner periphery formed with two rolling surfaces. The inner member is formed with rolling surfaces opposed to the rolling surfaces of the outer member. The double rows of the rolling elements are interposed between the rolling surfaces of the outer member and the inner member. A sensor for detecting the amount of preload of the bearing is provided in one of the outer and inner members.

Owner:NTN CORP

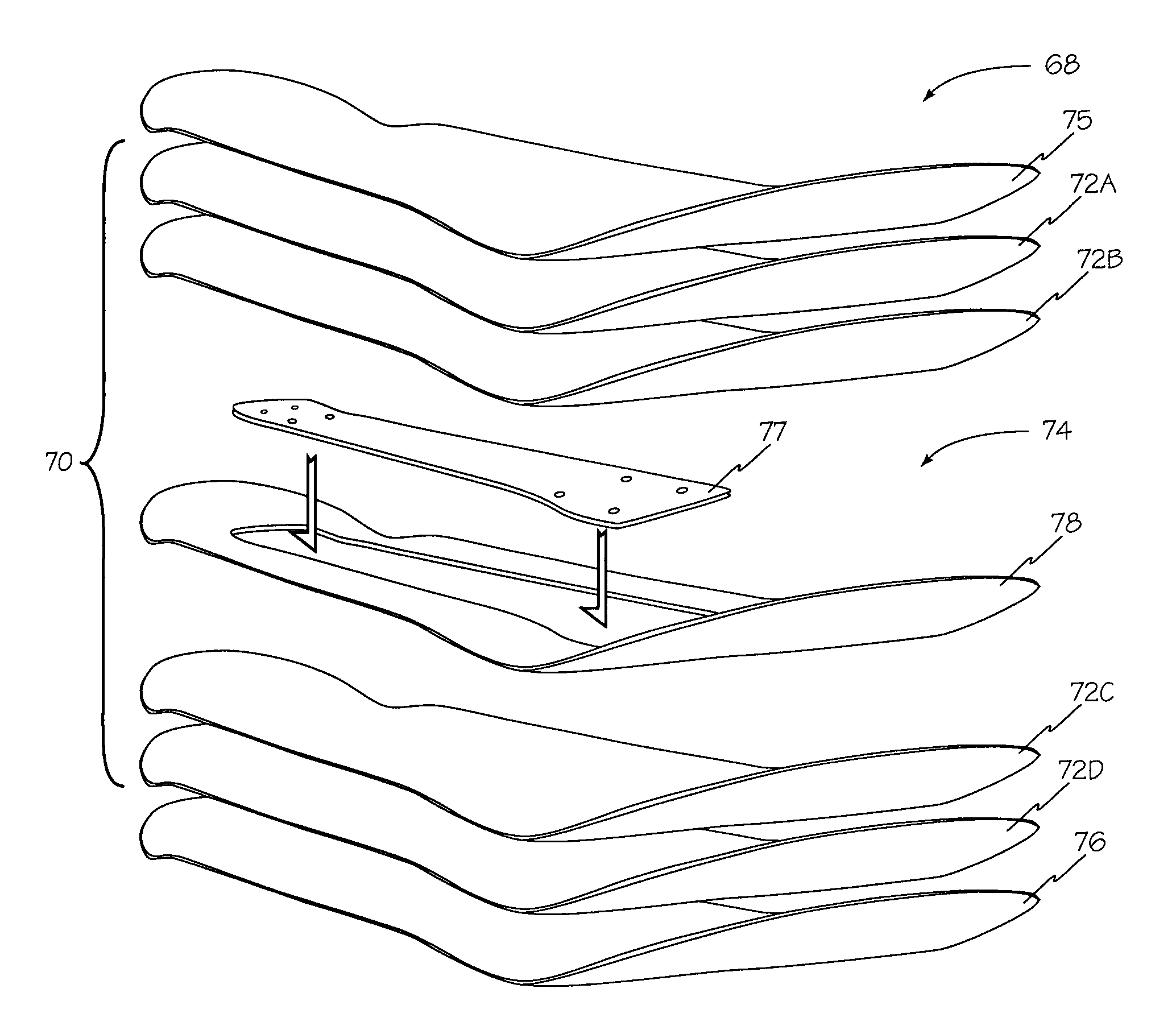

Bamboo core hybrid skateboard deck

InactiveUS20080296858A1Superior strengthUniform stiffnessGuiding agricultural machinesThin material handlingEngineeringMultiple layer

A hybrid skateboard deck combines at least one layer of bamboo with one or more layers of any suitable wood to form a multi-ply deck. A hybrid skateboard deck combines at least one layer of bamboo sandwiched between at least two layers of conventional hardwood such as maple. The addition of a bamboo layer in the core of the laminated deck provides superior strength relative to conventional plywood decks. The bamboo core laminate also provides superior feedback to a rider as well as uniform stiffness.

Owner:BURWELL SCOTT

Pneumatic tire

InactiveUS20110277896A1Suppressing excessive rigidityImprove braking effectTyre tread bands/patternsNon-skid devicesDepth directionMechanical engineering

A plurality of sipes extending in a tire width direction are provided in a tread surface of a block. In the sipes, protrusions are formed on a first sipe wall surface of mutually opposing sipe wall surfaces and recesses that engage with the protrusions are formed on a second sipe wall surface. Collapse of portions of the block sandwiched by the sipes is suppressed due to engagement of the protrusions and the recesses. A height of protrusions positioned on an upper portion in the depth direction of the sipes is greater than a height of protrusions positioned on a lower portion.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire with tread including ribs having closed sipes

ActiveUS7980280B2Improve wear resistanceRigidityTyre tread bands/patternsNon-skid devicesEngineeringWear resistance

A pneumatic tire having improved wear resistance, especially improved uneven wear resistance (such as river wear), is offered. The tire that is a rib-pattern tire has five ribs extending circumferentially of the tire. The ribs include a center rib and intermediate ribs located on the opposite sides of the center rib that is located on the equator line of the tire. Closed sipes are formed at least in the center rib and in the intermediate ribs. Each sipe is located in the lateral center of the corresponding rib. Both ends of each sipe terminate within the corresponding rib. The closed sipes are successively offset circumferentially among the ribs and arranged in a periodic pattern on the outer surface of the tire. The closed sipes in the ribs are so arranged that when they are optically projected onto the equator line of the tire, the sipes do not overlap circumferentially of the tire among the ribs.

Owner:TOYO TIRE & RUBBER CO LTD

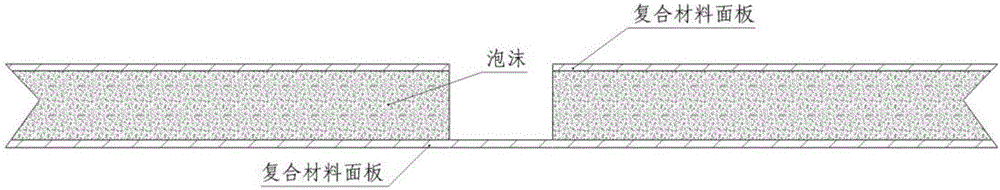

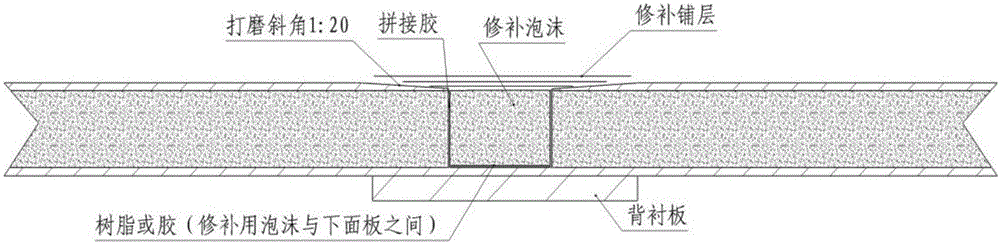

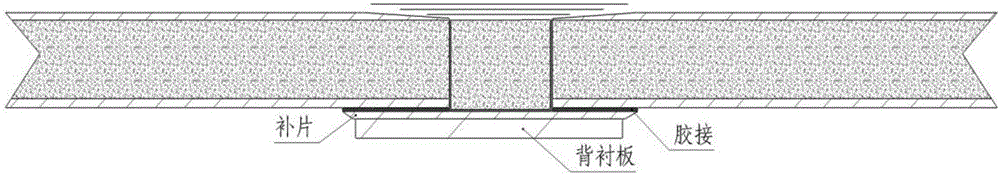

Repairing method of airplane composite material foam interlayer structure

PendingCN106628240AMeet surface quality requirementsEasy to operateAircraft maintainanceEngineeringOblique angle

The invention relates to a repairing method of an airplane composite material foam interlayer structure. The repairing method comprises the following steps that 1, foam and a panel on the damaged portion are removed, and the panel is grinded; 2, a sticking patch is produced by laying a lower panel, and foam is cut and repaired; 3, the sticking patch is glued to the lower portion of the lower panel and supported through a backer board; 4, an upper panel is grinded to form an oblique angle of a certain degree; 5, a glue film is laid on the upper surface of the lower panel; and 6, repairing layers are laid and pasted to the upper panel, the boundary of the first layer needs to be larger than that of the damaged portion, and steps are reserved between every two adjacent repairing layers. The method is easy to implement and can be flexibly applied, the strength and rigidity of the airplane foam interlayer structure can restore, bumping is avoided, and rigidity is uniform.

Owner:R&D INST OF CHINA AVIATION IND GENERAL AIRCRAFT

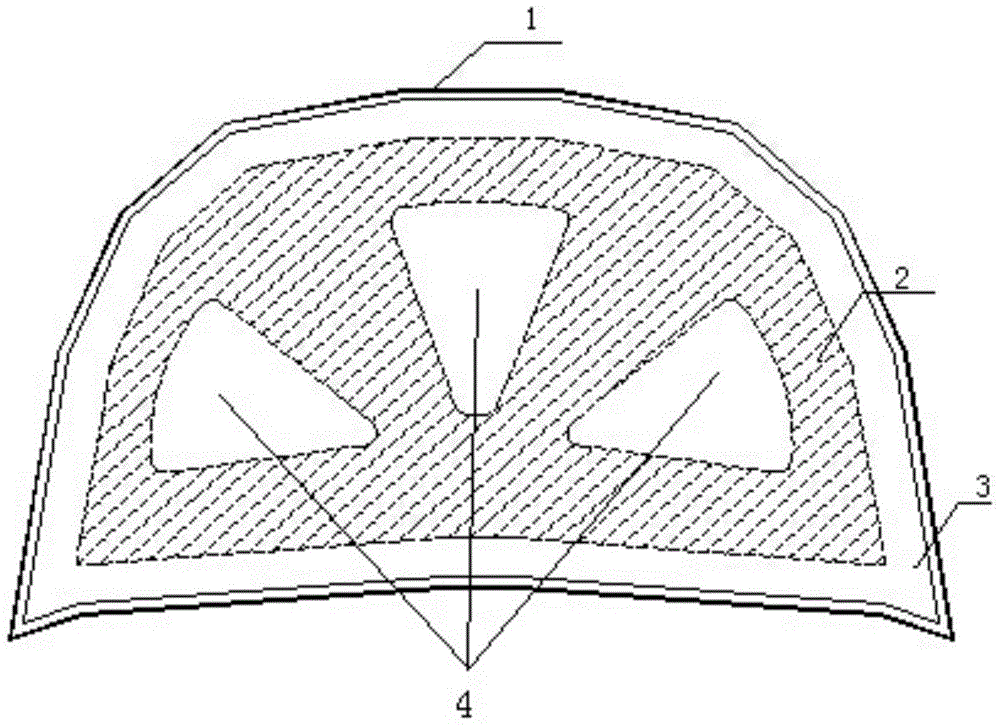

Vehicle engine hood and preparation method thereof

ActiveCN105460082AUniform stiffnessLight in massSuperstructure subunitsCarbon fiber compositePedestrian

The invention discloses a vehicle engine hood which comprises carbon fiber composite layers and a foam sandwich reinforcing layer, wherein the carbon fiber composite layers include an upper layer and a lower layer; the foam sandwich reinforcing layer is arranged between the upper layer and the lower layer; the foam sandwich reinforcing layer is provided with three fan-shaped hollow regions which are arranged at intervals, and the three hollow regions are in axial symmetry along a center line and are concentrically arranged; and the upper layer and the lower layer are made of 6K filament carbon fiber twill / plain fabric. The vehicle engine hood disclosed by the invention solves the problems of overhigh stiffness, overlarge brittleness and unfavorable pedestrian protection of the existing engine hood and has the advantages that the vehicle engine hood is lighter than an engine hood designed by the traditional composite material; the vehicle engine hood is moderate in stiffness, overcomes the defects of overhigh stiffness and overlarge brittleness of the traditional foam sandwich, and has a better pedestrian protection effect; and the vehicle engine hood is simple in molding process and is molded in one step.

Owner:CHERY AUTOMOBILE CO LTD

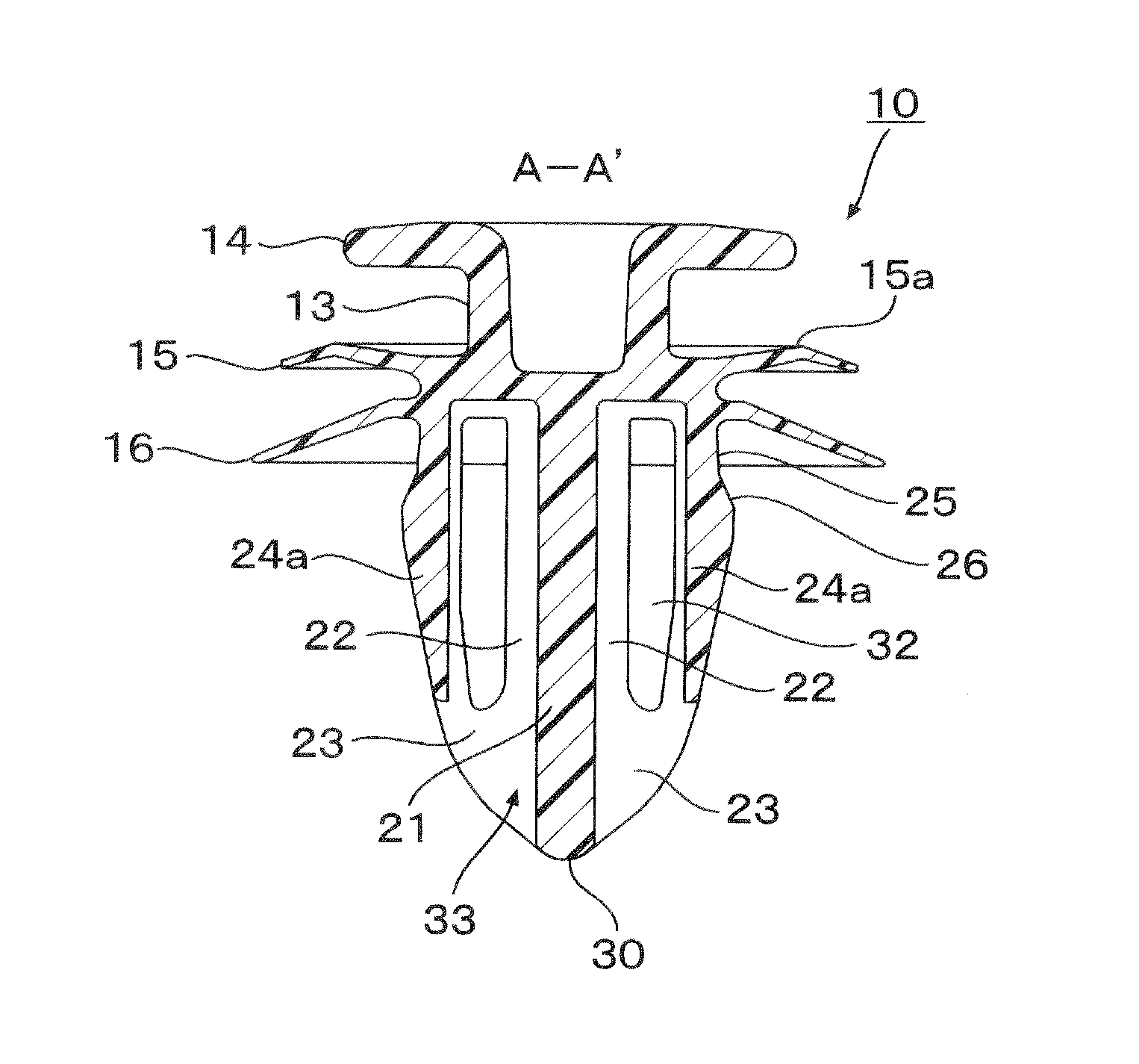

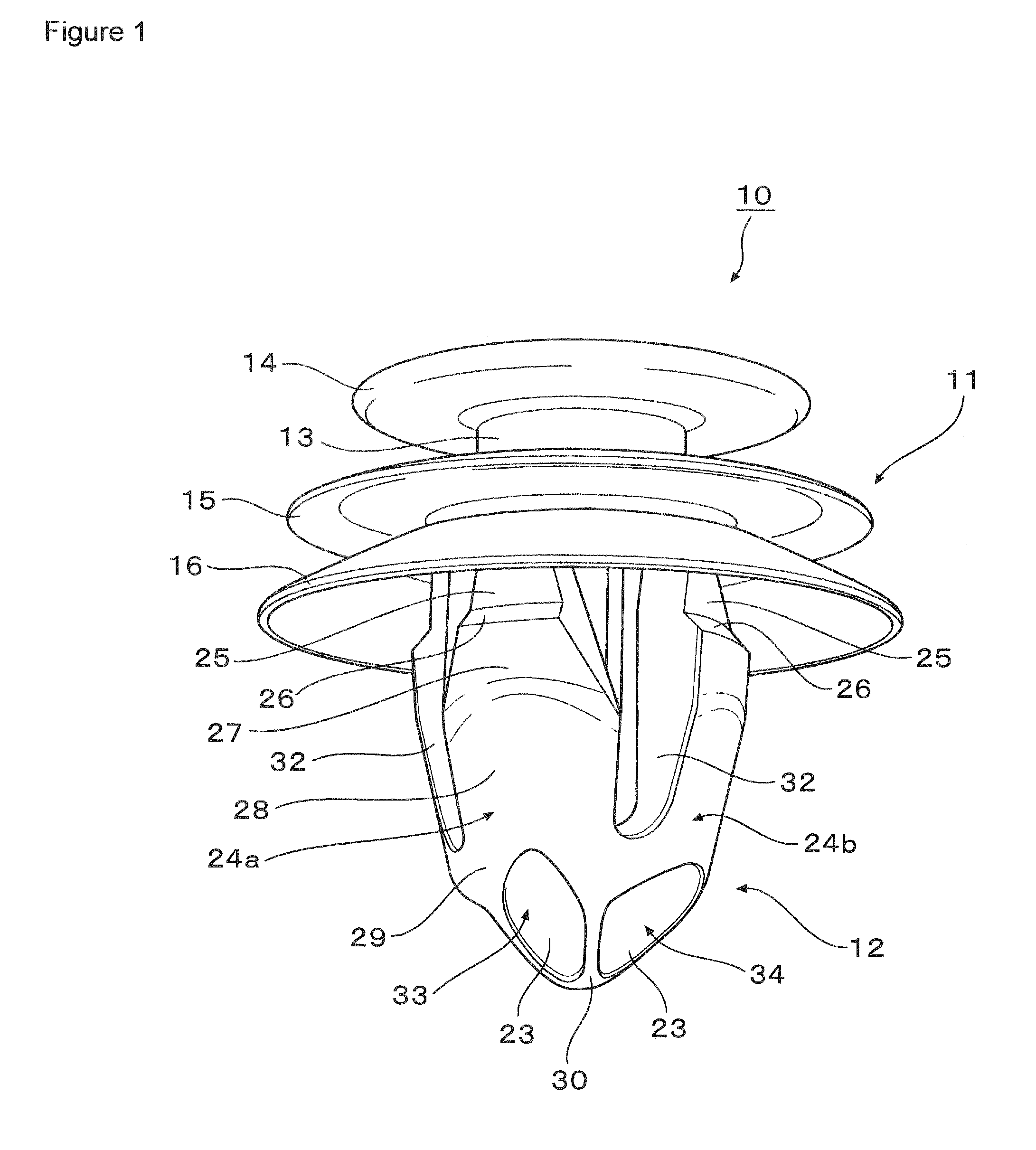

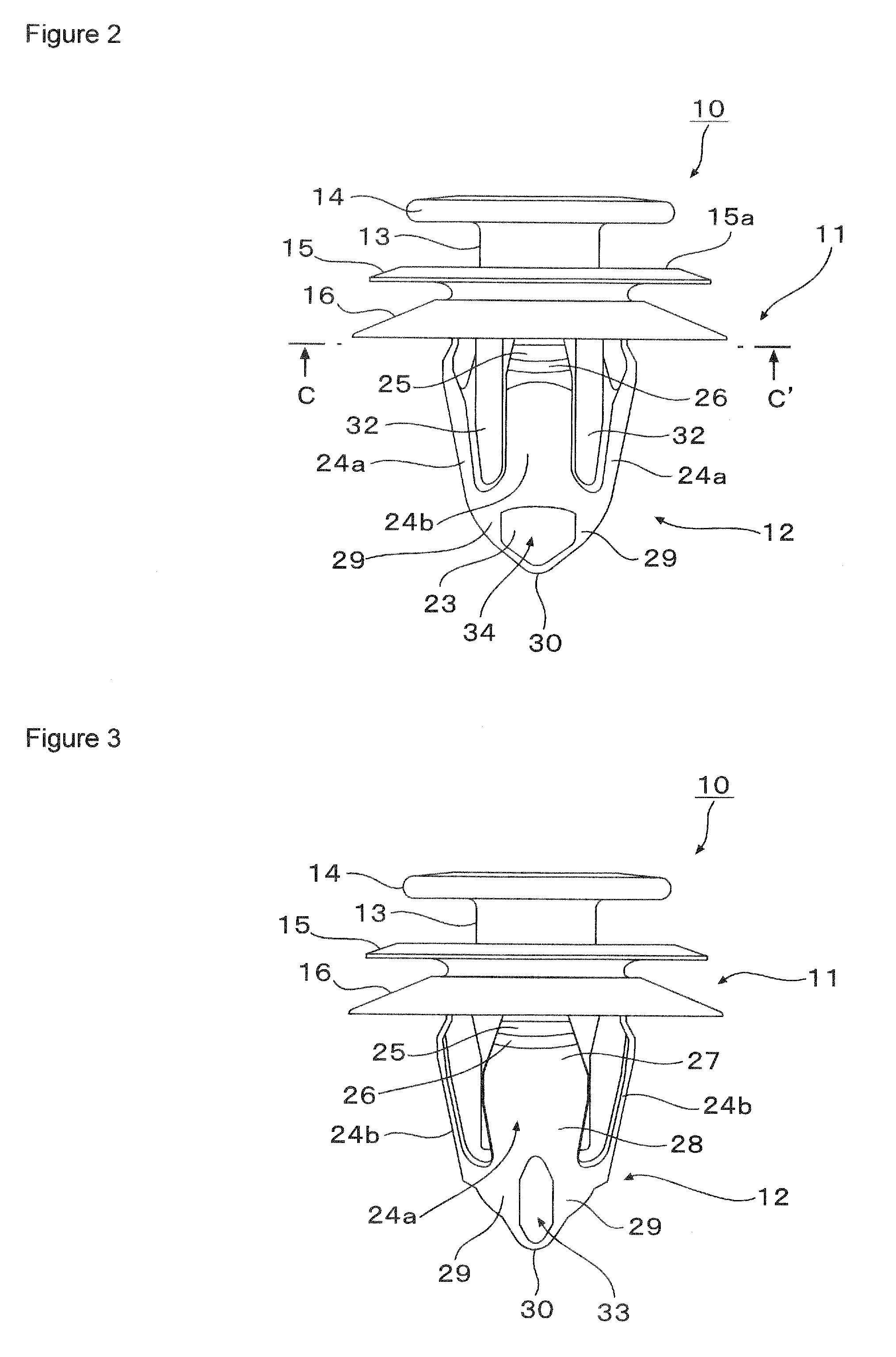

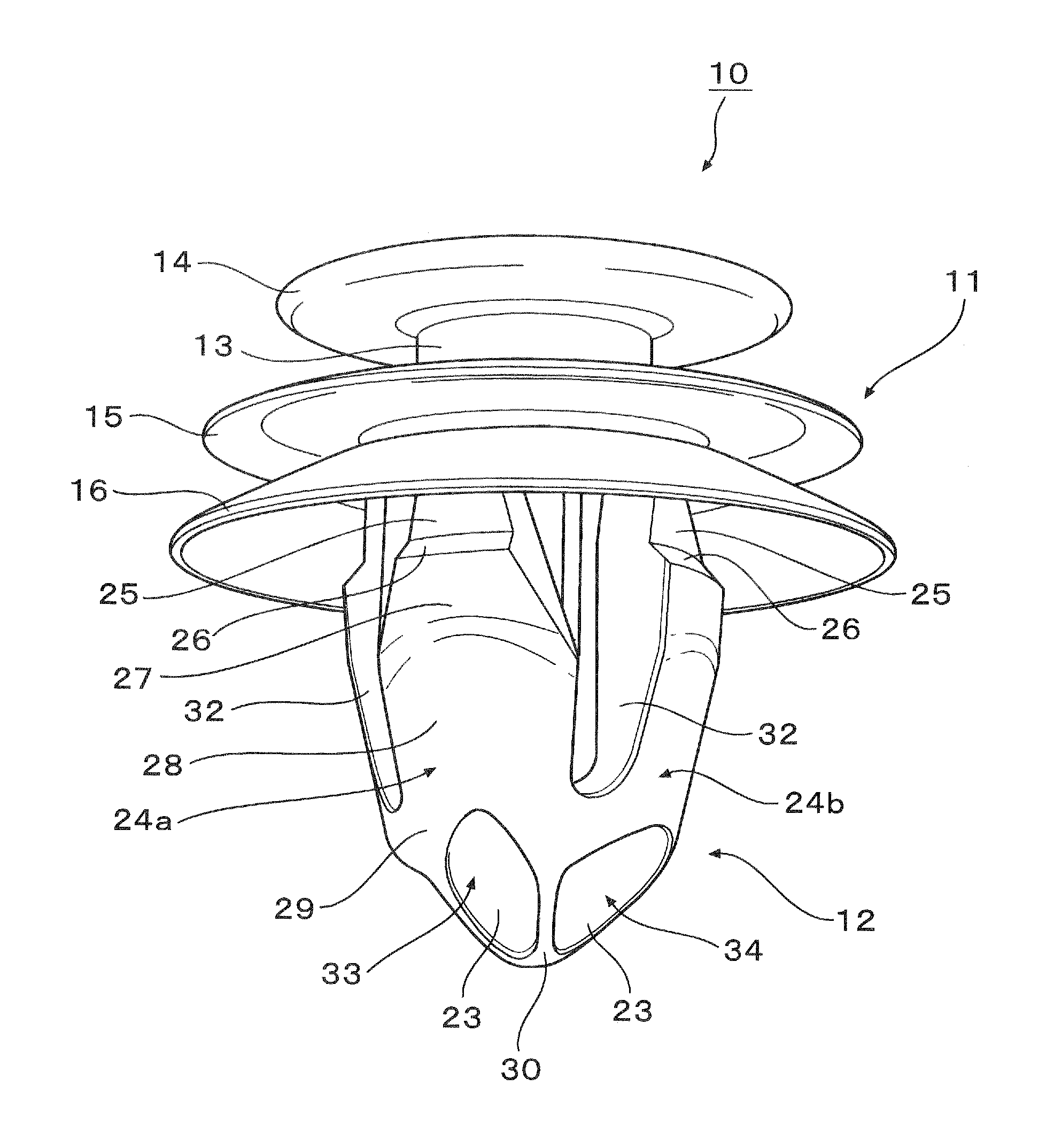

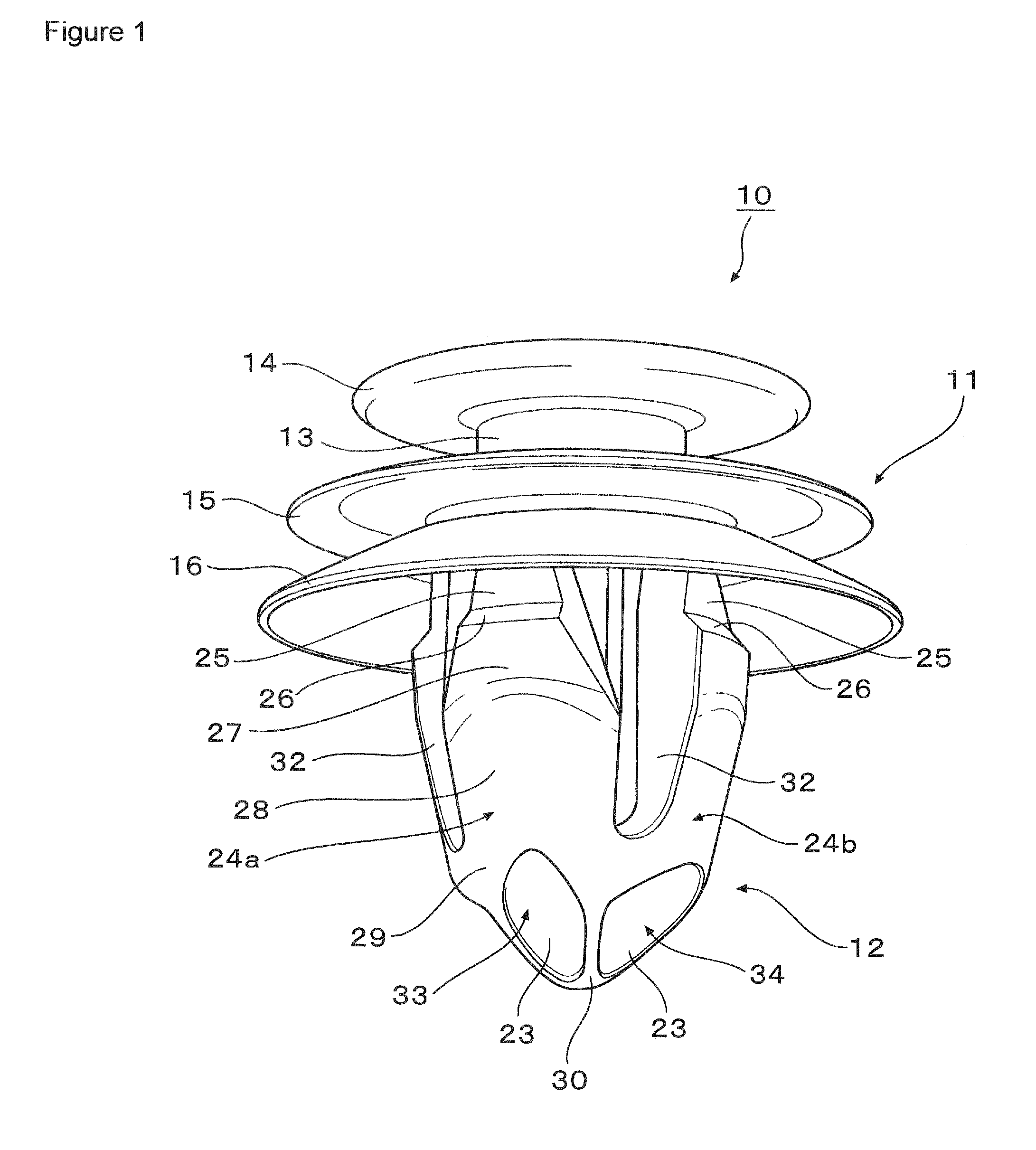

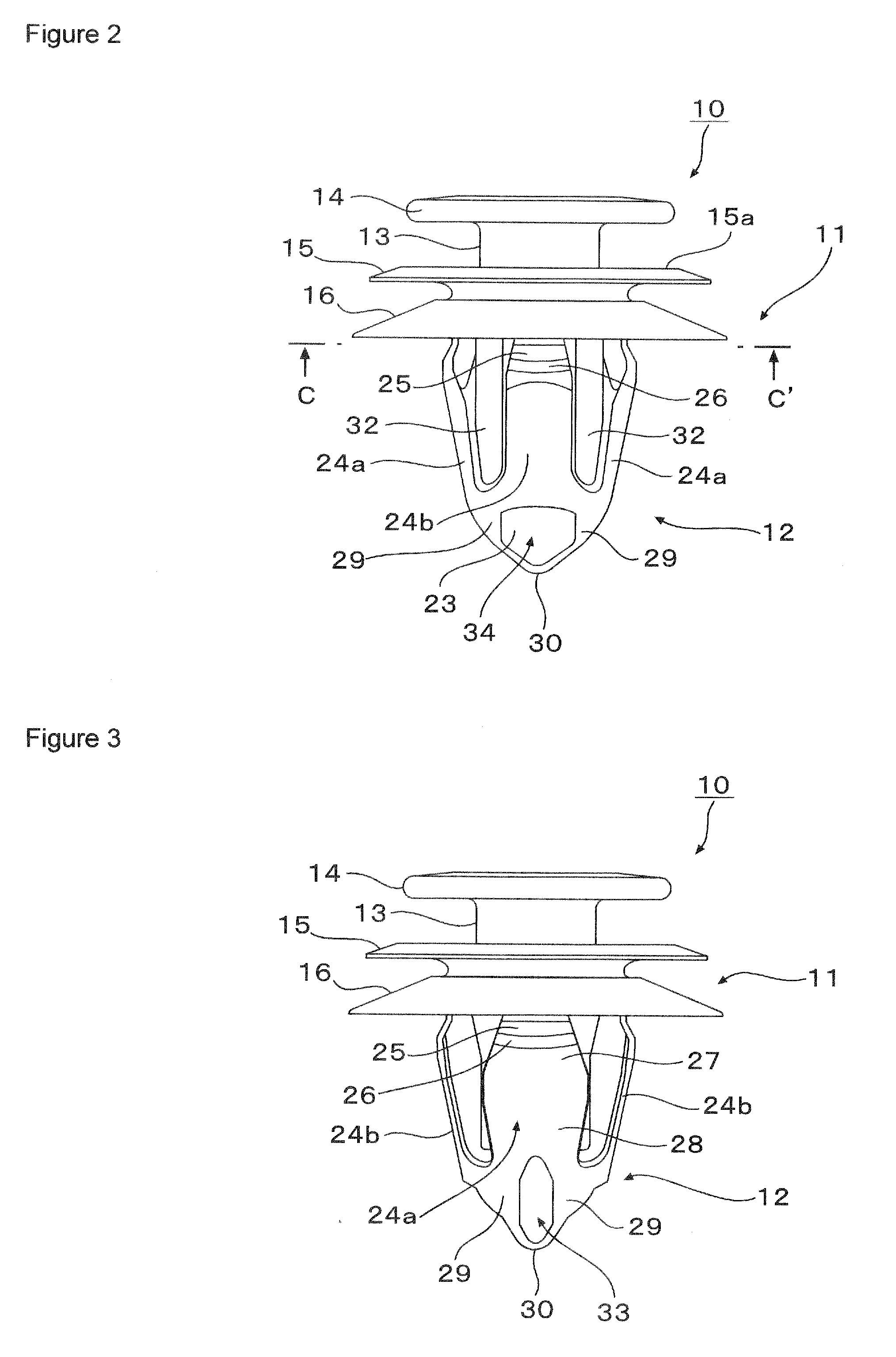

Clip

Owner:PIOLAX CO LTD

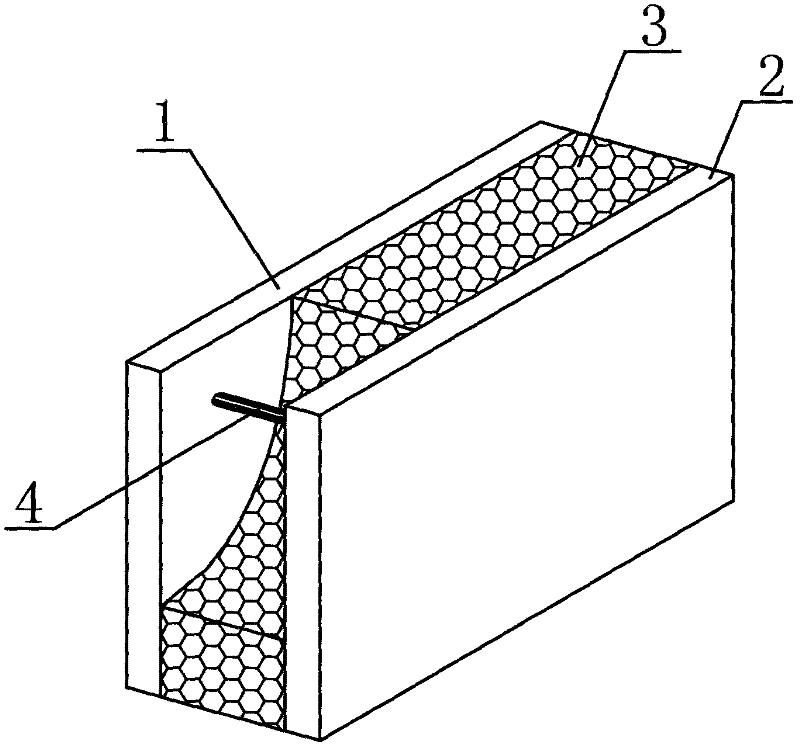

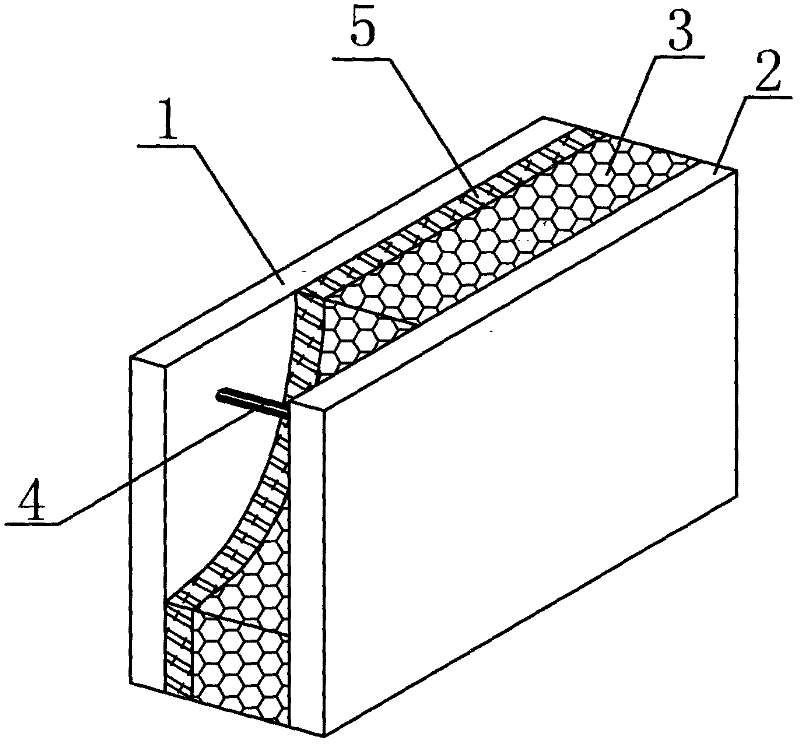

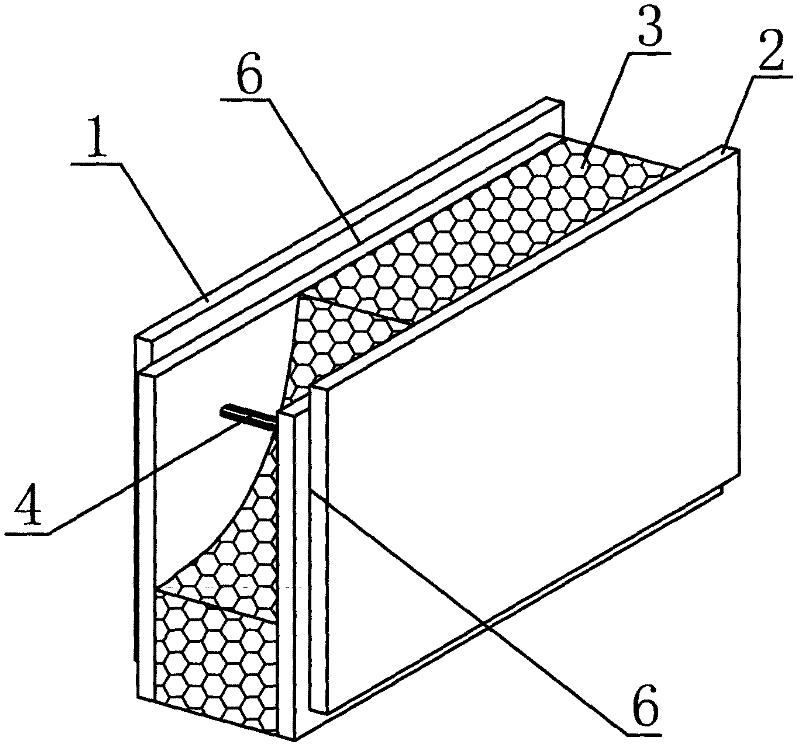

Composite mold clamp building block

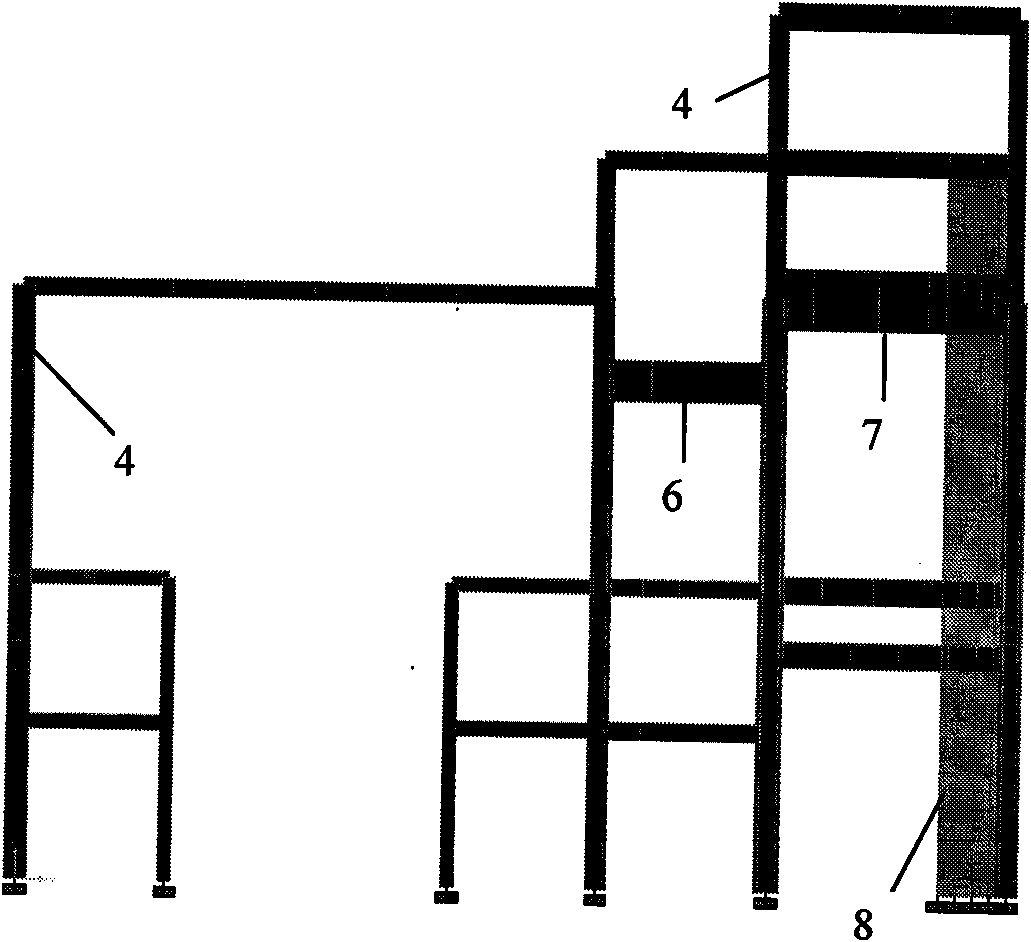

InactiveCN102383521ALow costImprove thermal insulation performanceConstruction materialWallsBrickSlurry

A composite mold clamp building block is characterized by comprising an outer face plate (1) and an inner face plate (2). A heat preservation layer (3) is filled between the outer face plate (1) and the inner face plate (2). The outer face plate (1), the heat preservation layer (3) and the inner face plate (2) are connected to form a whole through connecting pieces (4). The composite mold clamp building block adopts an inner clamp heat preservation layer design, is lighter than a traditional clay brick, and meets the requirements of modern multiple floor buildings and high-rise buildings. A traditional process of on-site slurry wiping and wall building is changed, the building block can be directly installed and fixed, construction is fast, process flow and construction materials are reduced, and construction cost is lowered. After installation, the vertical face of a wall body is even and smooth, strength and rigidity of the vertical face are balanced. The composite mold clamp building block can effectively block heat bridge effect and obviously enhance heat preservation and insulation performance and fire-proof performance, and has good sound insulation effect and better comprehensive performance.

Owner:HUBEI SYNTHETIC SPACE TECH CO LTD

Clip

ActiveUS20090252573A1Reduce widthExcessive increase in insertion resistanceSnap fastenersScrewsEngineeringHead parts

Owner:PIOLAX CO LTD

Bearing device for wheel

InactiveUS7628540B2Simple to executeUniform preloadRolling contact bearingsBearing assemblyEngineeringFlange

A bearing device for a wheel, where preload control is easy and a uniform amount of preload can be applied even if a bearing seal is installed in the bearing device. The bearing device rotatably supports a wheel and has an outer member 1, an inner member 2, and rolling elements 3 interposed between both members. The outer member 1 has on its outer periphery a vehicle body installation flange 1a, and double row rolling surfaces 6, 7 are formed on the inner peripheries of the outer member. Rolling surfaces 8, 9 facing the rolling surfaces 6, 7 of the outer member 1 are formed in the inner member 2. Between the rolling surfaces of both members 1, 2 are interposed the rolling elements 3. A sensor 4 for detecting the amount of preload of the bearing is provided on either the outer member 1 or the inner member 2.

Owner:NTN CORP

Method for releasing a deployable boom

ActiveUS20170297749A1Uniform flexibilityUniform stiffnessCosmonautic vehiclesCosmonautic power supply systemsAngular momentumEngineering

The present disclosure describes a method of deploying an extensible boom from a housing. Sheets supporting respective arrays of photovoltaic devices are deployed substantially simultaneously so that a first sheet is deployed in a first direction from the housing and a second sheet is deployed in an opposite direction from the housing. Angular momentum imparted by deploying the first sheet is canceled by angular momentum imparted by deploying the second sheet. The housing can be part of a space satellite, such that the first and second sheets are deployed without causing the satellite to move out of its orbit.

Owner:SOLAERO TECH CORP

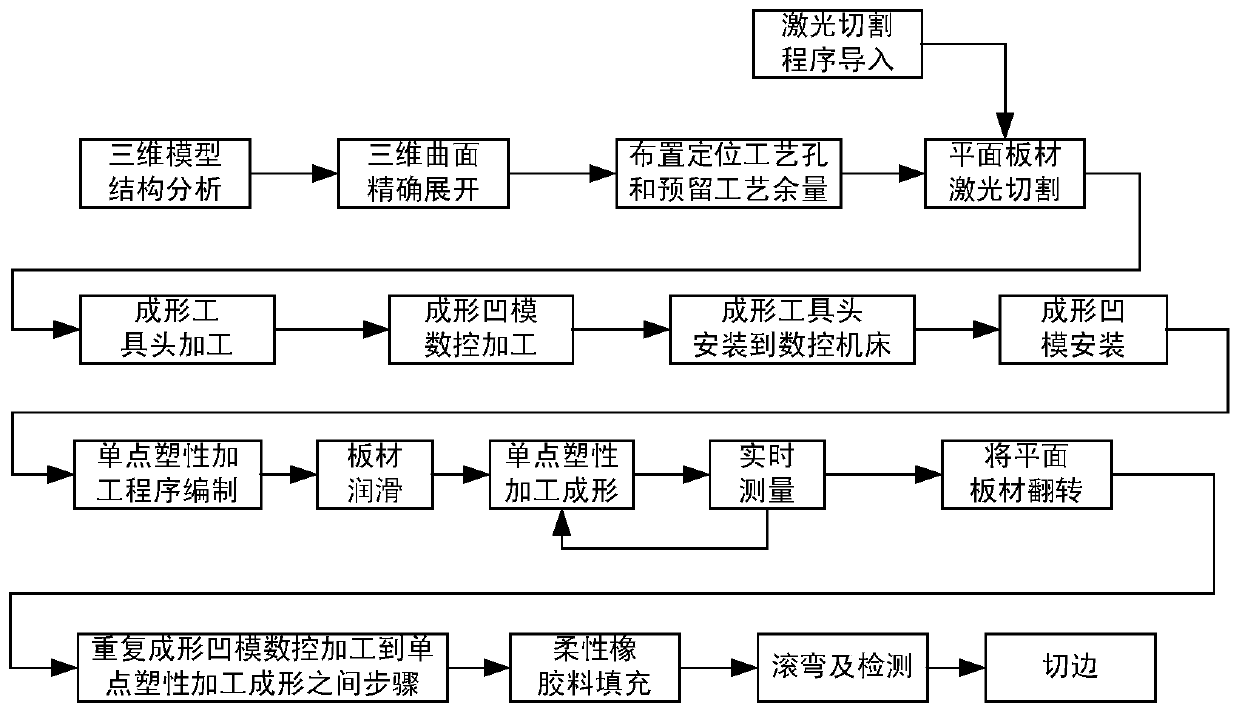

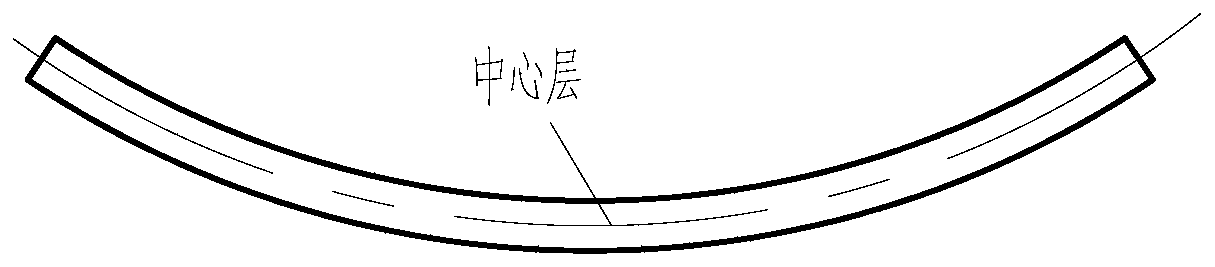

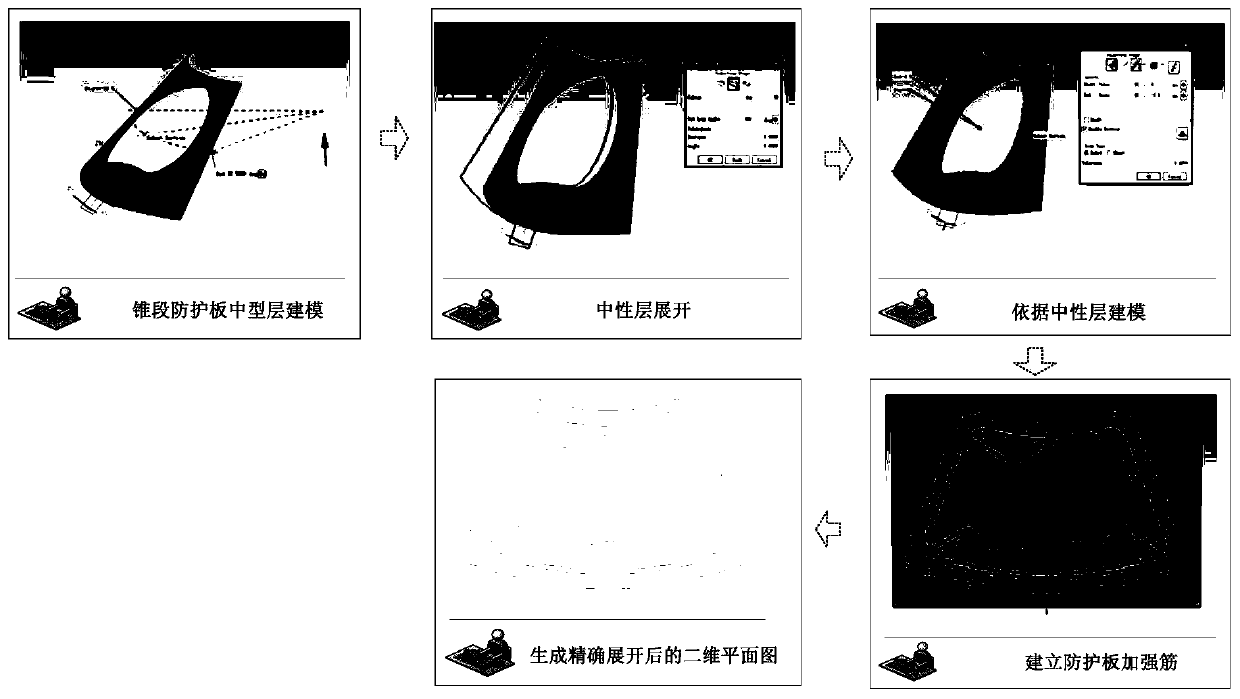

Forming method of spatial curved surface protective plate with internal and external bidirectional stiffener

ActiveCN109955043AHomogenization of stiffnessImprove the overall stiffness and anti-instability abilitySingle pointEngineering

The invention discloses a forming method of a spatial curved surface protective plate with internal and external bidirectional stiffener. Firstly the model of the spatial curved surface protective plate is accurately expanded into a two-dimensional plane model, a corresponding CAD model is obtained, and a panel is processed according to the two-dimensional plane model, and a two-dimensional planepanel after the spatial protective plate being expanded and modified is obtained, then a forming die for processing one side stiffener is designed and manufactured, the plane panel is formed by singlepoint plastic processing, and the plane panel including single surface qualified stiffener is obtained, then the plane panel with the formed single surface stiffener is turned over and placed on theforming die for processing the other side stiffener, single point plastic forming is conducted, and an aluminum alloy spatial curved surface protective plate with the internal and external bidirectional stiffener is obtained, finally, a rubber plate is filled with the inner and outer stiffeners of the curved surface protective plate for equal thickness treatment and fixedly sealing, the plane panel is rolled and bended by a three-axis rolling and bending machine, then trimming and polishing are conducted, and thus forming of the spatial curved surface protective plate with the internal and external bidirectional stiffener is completed.

Owner:BEIJING SATELLITE MFG FACTORY

Pneumatic tire and method of producing the same

InactiveUS20020050314A1Improve compressive stiffnessReduce rigidityTyresMotorcycle tyresEngineeringHelix

A pneumatic tire comprises a spiral belt formed by spirally winding a cord(s) along a circumferential direction of a torus tread, wherein the spiral belt is comprised of at least one layer constructed with a combination of two different cords each having an initial tension of not less than 50 cN / cord.

Owner:BRIDGESTONE CORP

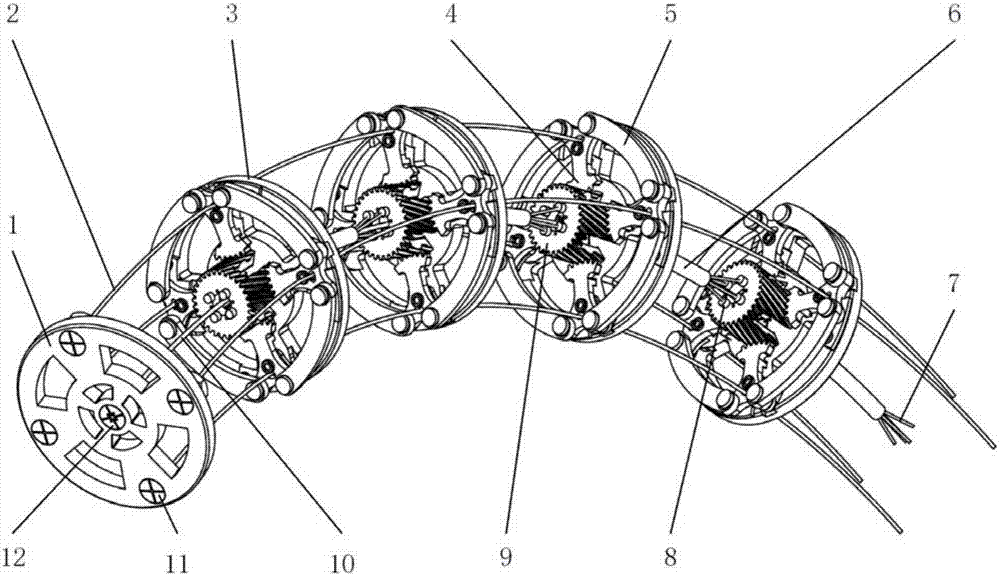

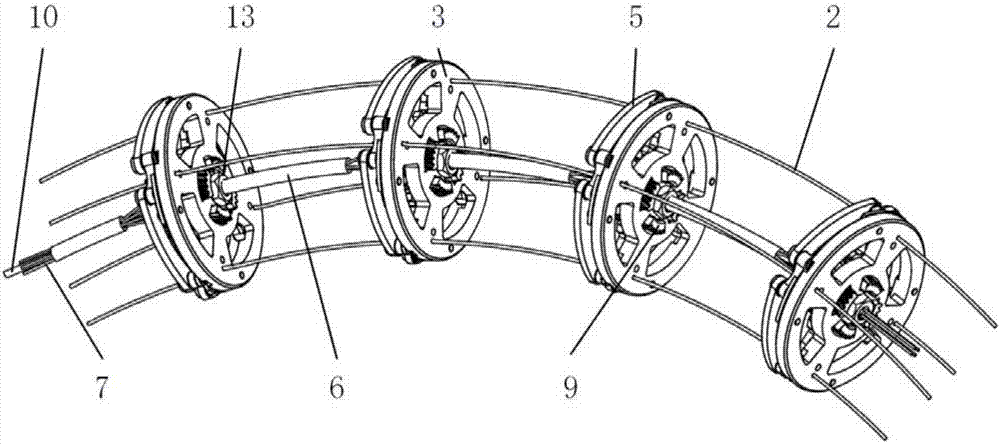

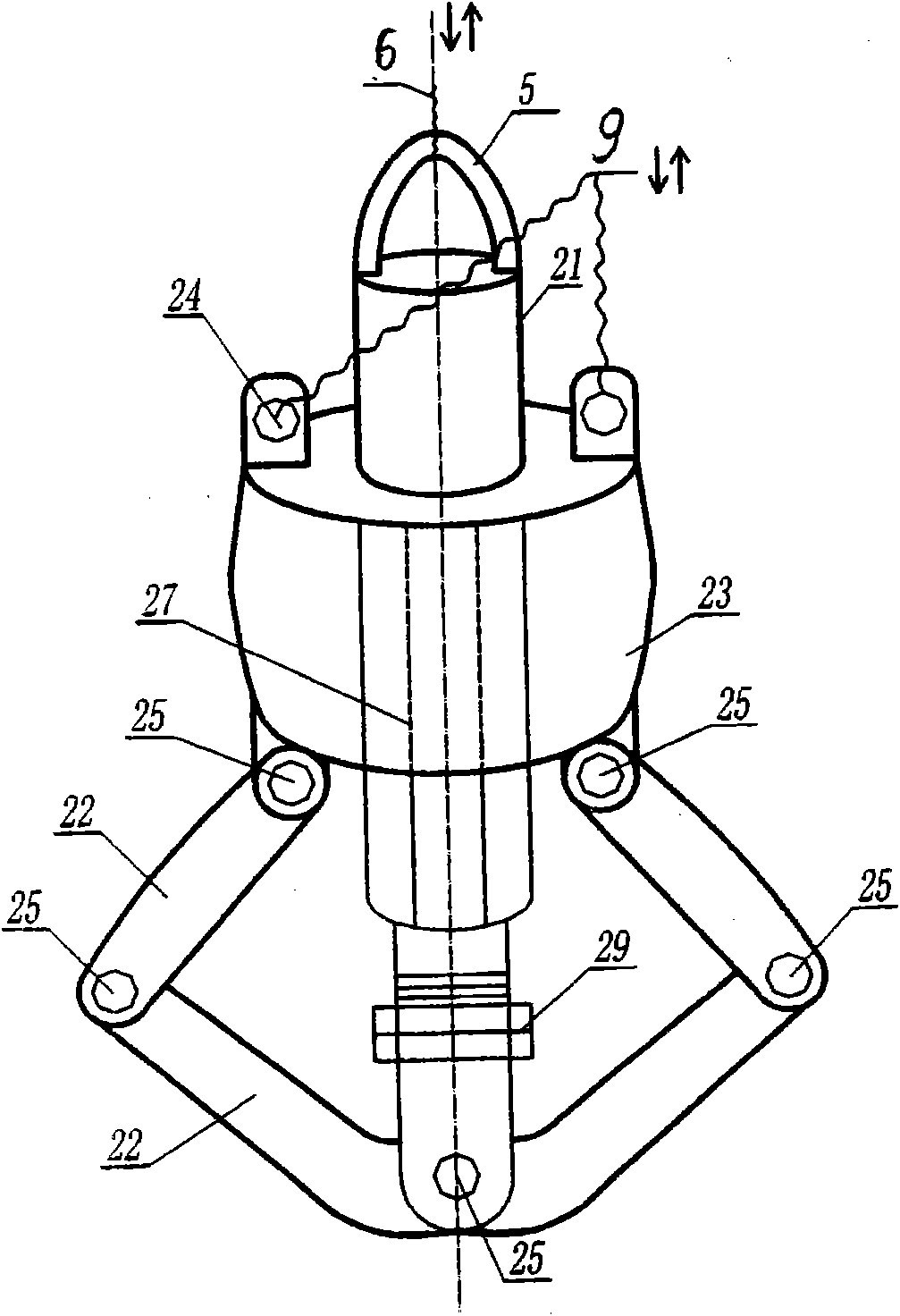

Mechanical-locking-based wire traction variable stiffness mechanism

ActiveCN107097218ASimple structureSimple designProgramme-controlled manipulatorVariable stiffnessGear wheel

The invention discloses a mechanical-locking-based wire traction variable stiffness mechanism. The mechanism comprises a continuum robot basic structure, variable stiffness locking mechanisms and a variable stiffness traction mechanism. The continuum robot basic structure is composed of connection disks, a central wire and four driving wires distributed circumferentially. The connection disks include the middle connection disks and the tail end connection disk. The tail end connection disk is fixed to the tail end of the central wire and the tail ends of the driving wires through a wedge-shaped locking mouth. The middle connection disks are fixed to the central wire through wedge-shaped locking mouths. Each variable stiffness locking mechanism is a single-degree-of-freedom mechanism composed of sliding bevel wheels, springs, incomplete gears, connecting rods and inlaid metal sheets with each middle connection disk as a rack. The variable stiffness traction mechanism is composed of wire guide sheaths, a tensile metal wire and metal wire lock pieces. The wire guide sheaths and the central wire are concentric. The tensile metal wire penetrates through the wire guide sheaths and the wedge-shaped locking mouths of the central wire and is fixed to the sliding bevel gears through the metal wire lock pieces. The mechanical-locking-based wire traction variable stiffness mechanism is fast in rigid and flexible state switching and high in positioning rigidity.

Owner:TIANJIN UNIV

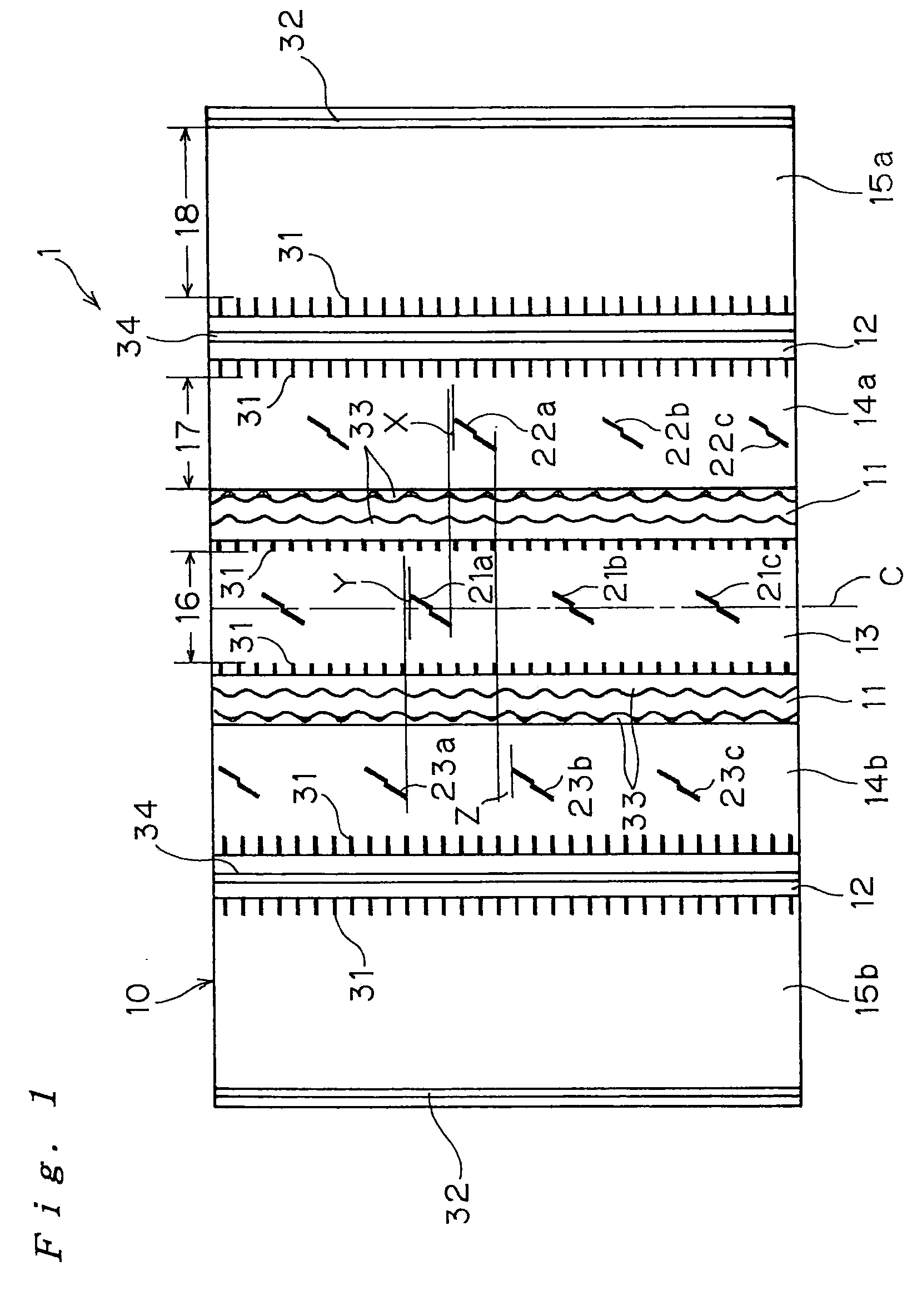

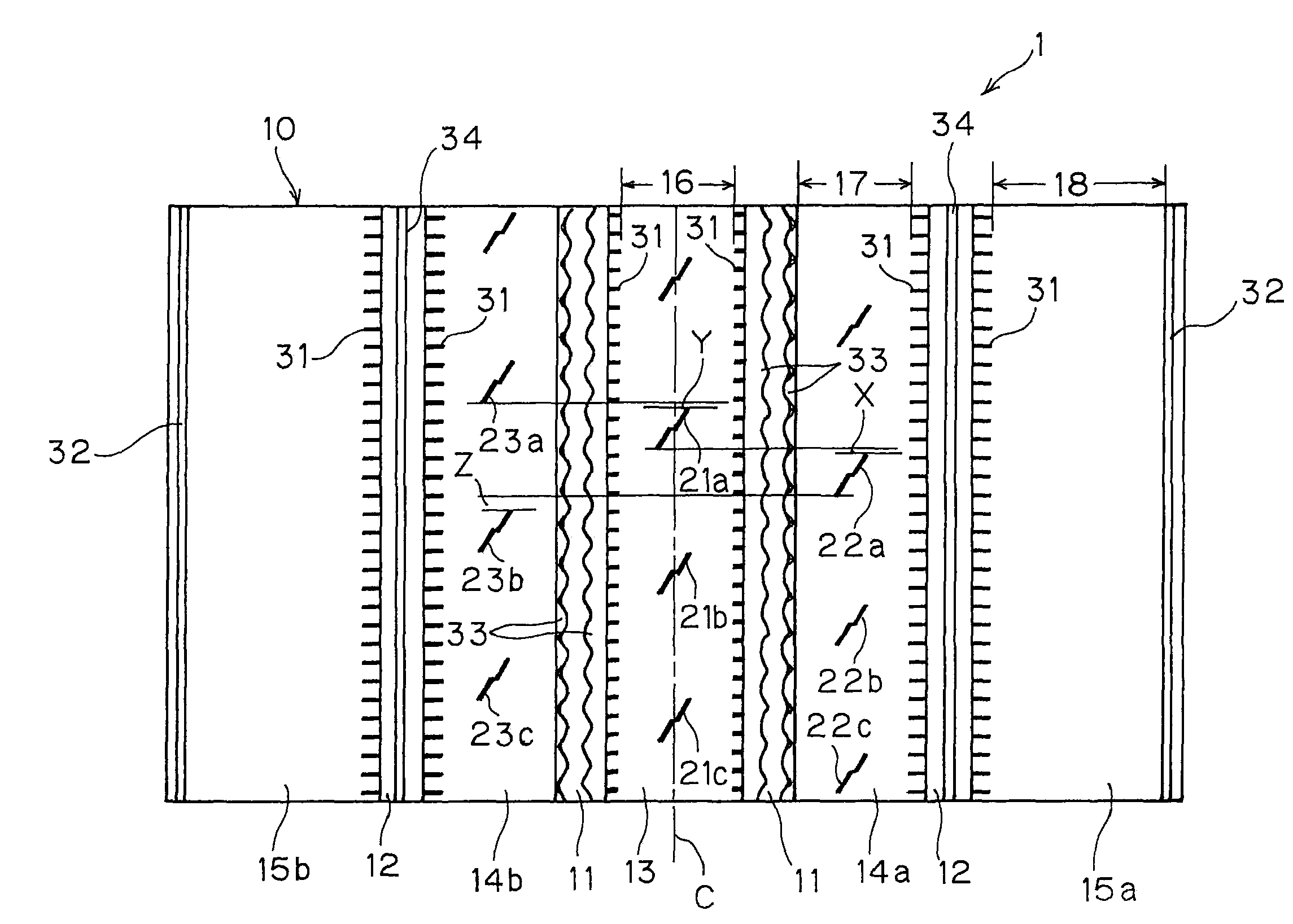

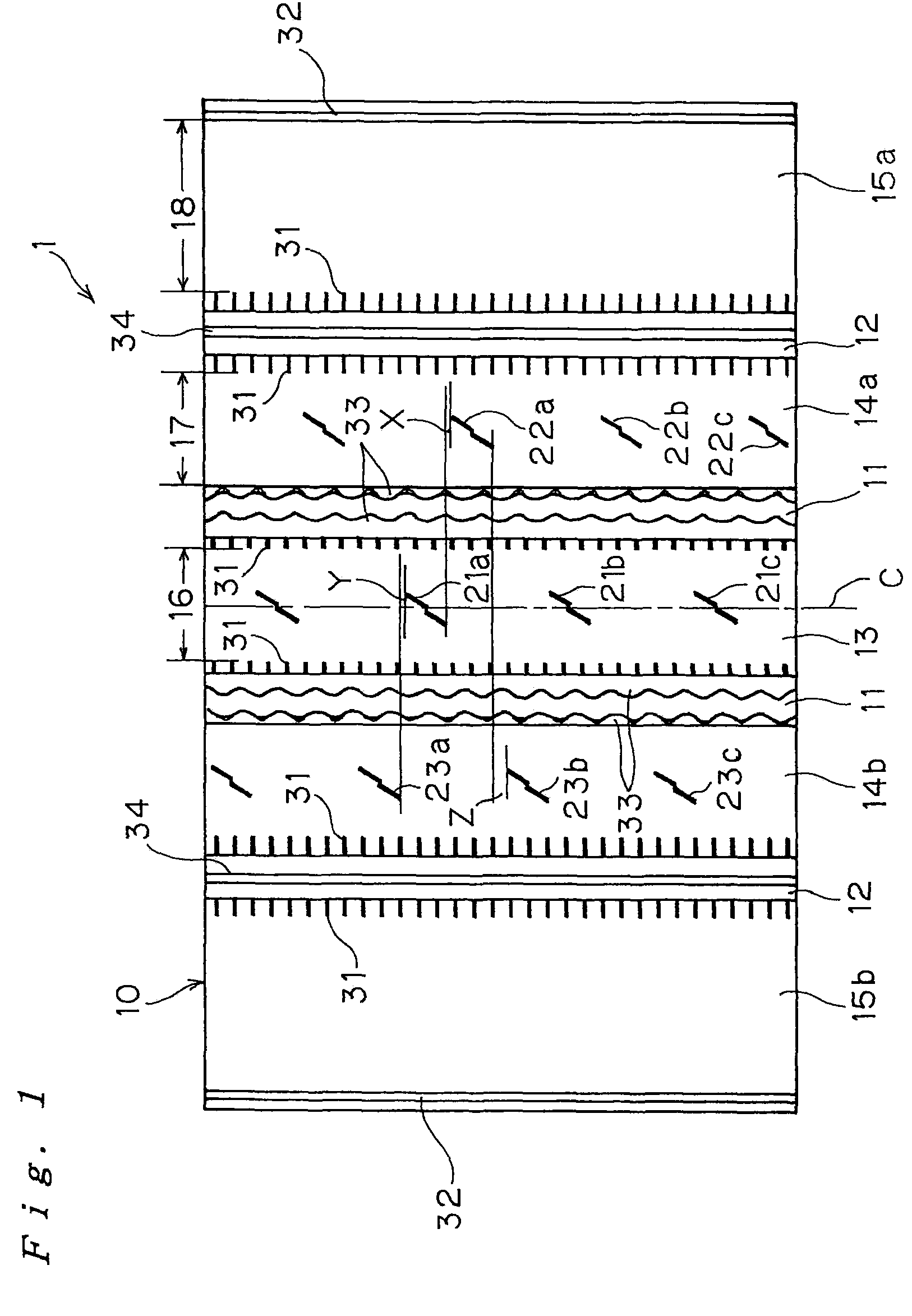

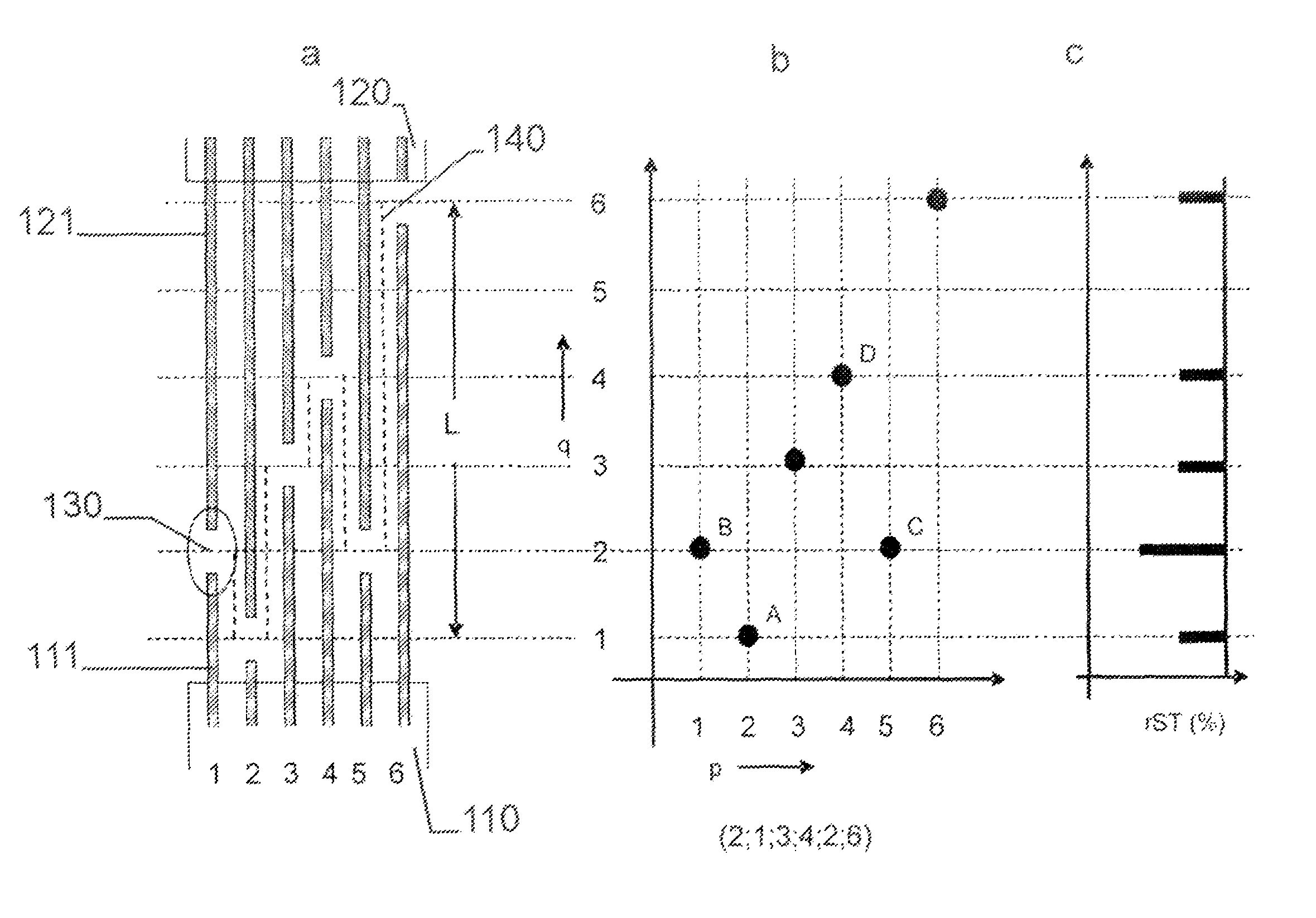

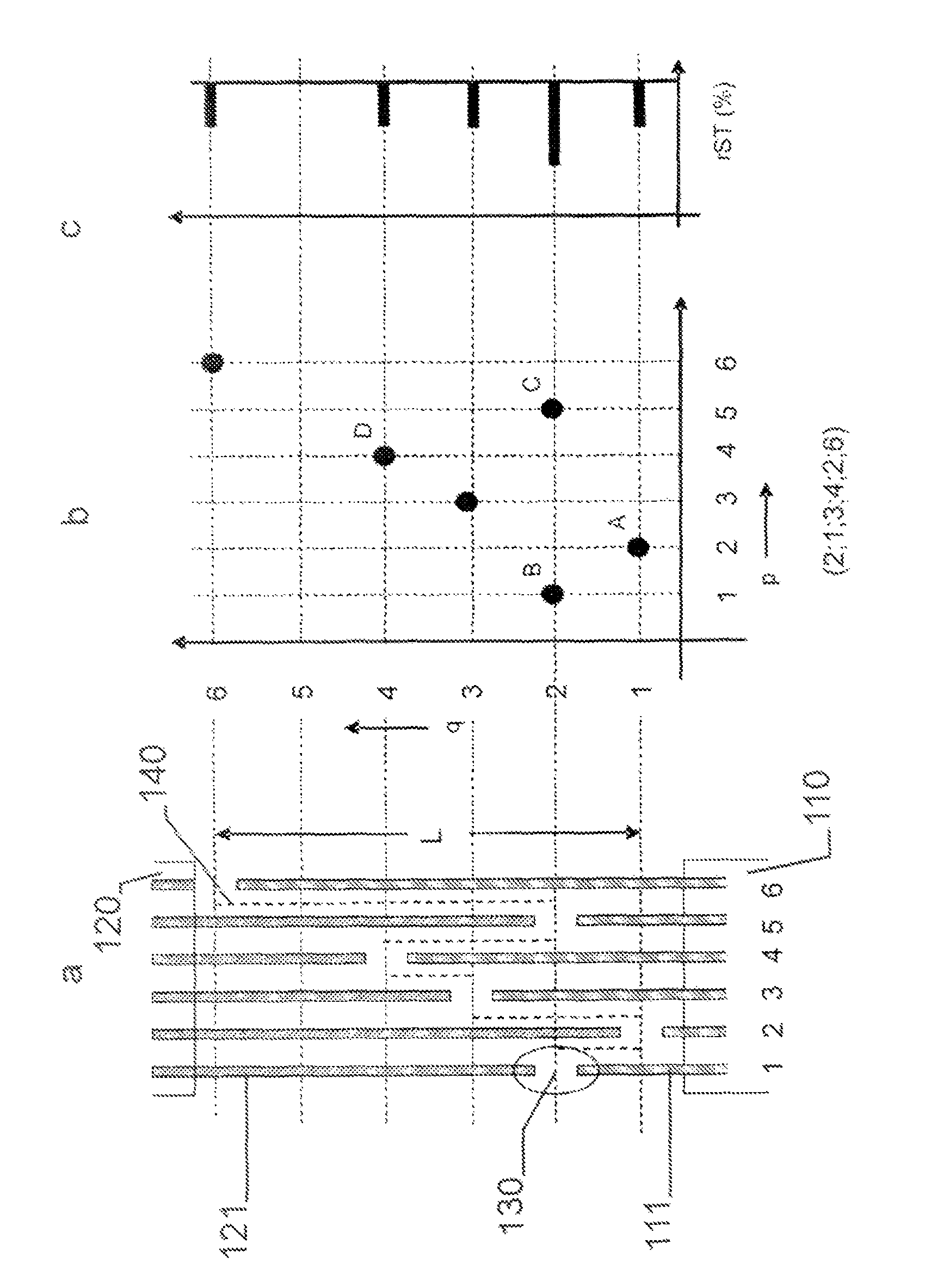

Lay-out for splicing strips comprising cords

ActiveUS8910462B2Uniform stiffnessSufficient strength retentionV-belt fasteningsBelt fasteningsTransmission beltEngineering

A plain stepped splice lay-out scheme is presented that can be used for splicing strips to one another that comprise longitudinally arranged cords. The strips can take the form of a conveyor belt, transmission belt, timing belt, elevator belt, a rubber track or a reinforcing strip. The splice is optimised for uniform bending stiffness and maximum strength retention. The cross section of the strip and the splice are substantially equal: there is no increase in thickness or width at the splice. The splice lay-out is characterised by the fact that the abutments (130)—those positions where cord ends (111, 121) meet—are positioned sufficiently far away from one another and by preference as far away from one another as possible. Preferred embodiments in terms of length common between cords of the different strips and local strength are given.

Owner:BEKAERT ADVANCED CORDS AALTER NV

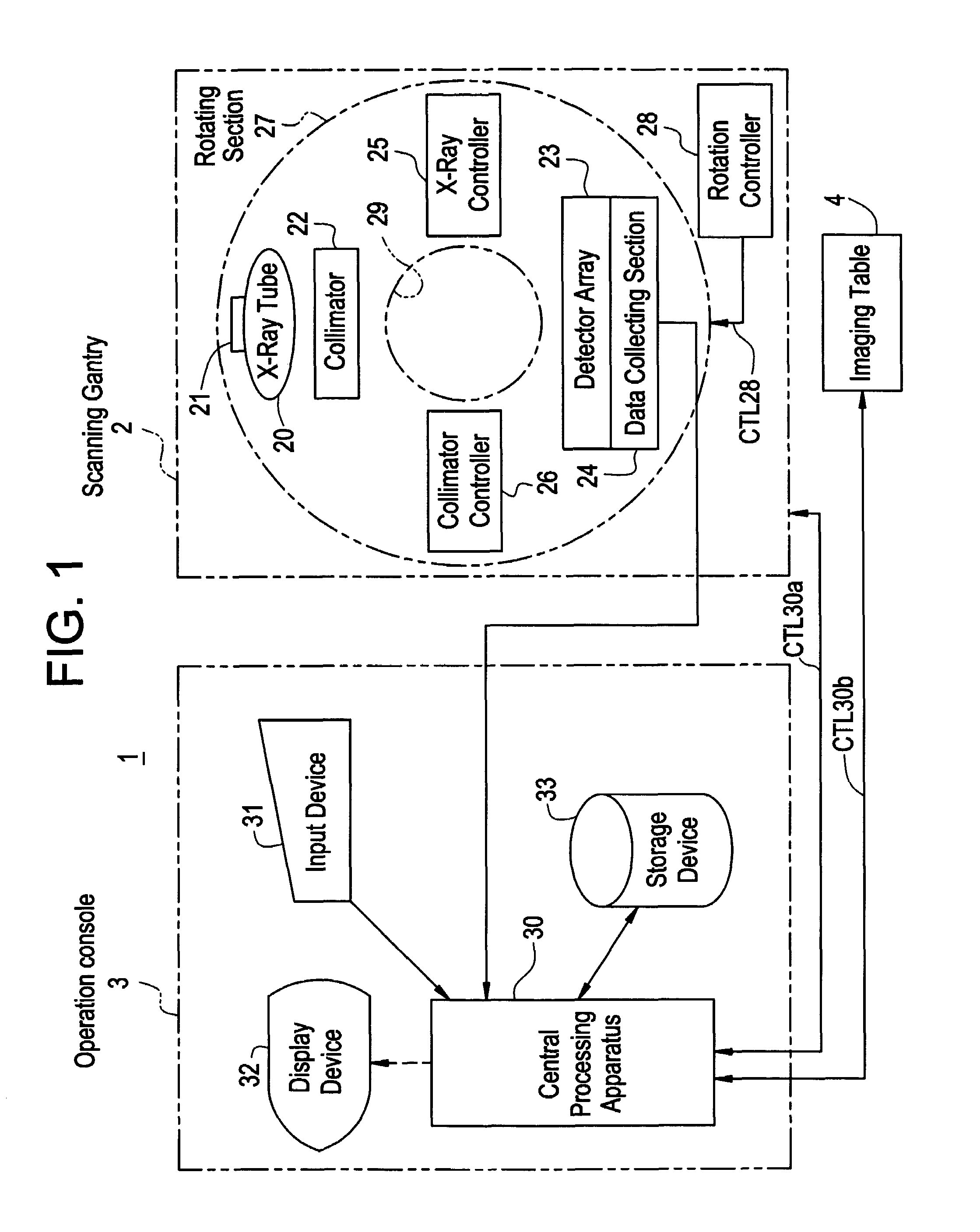

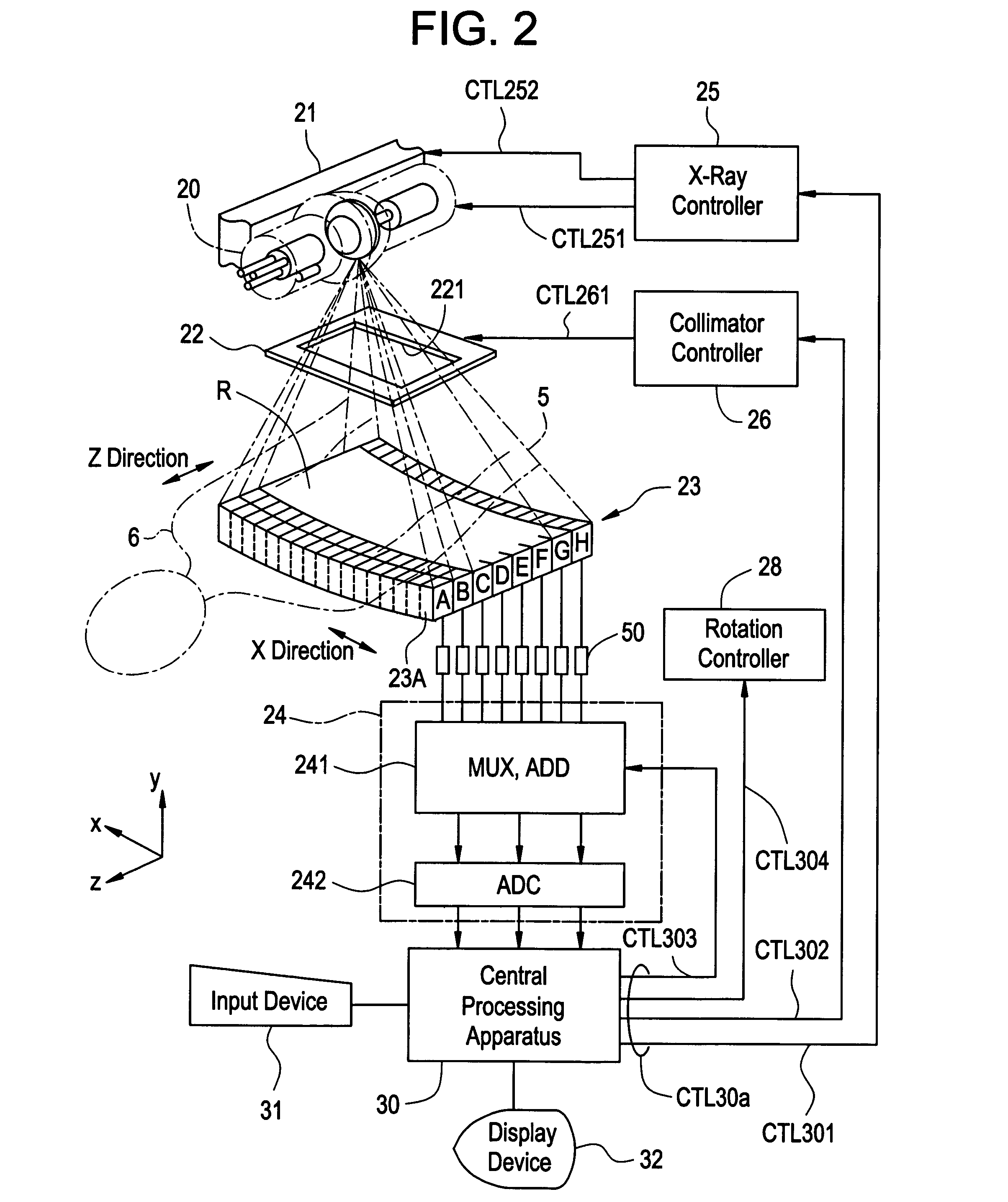

Connector and radiation tomographic imaging apparatus

InactiveUS7029302B2Promote repairRigid enoughEngagement/disengagement of coupling partsTomosynthesisEngineeringImaging equipment

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

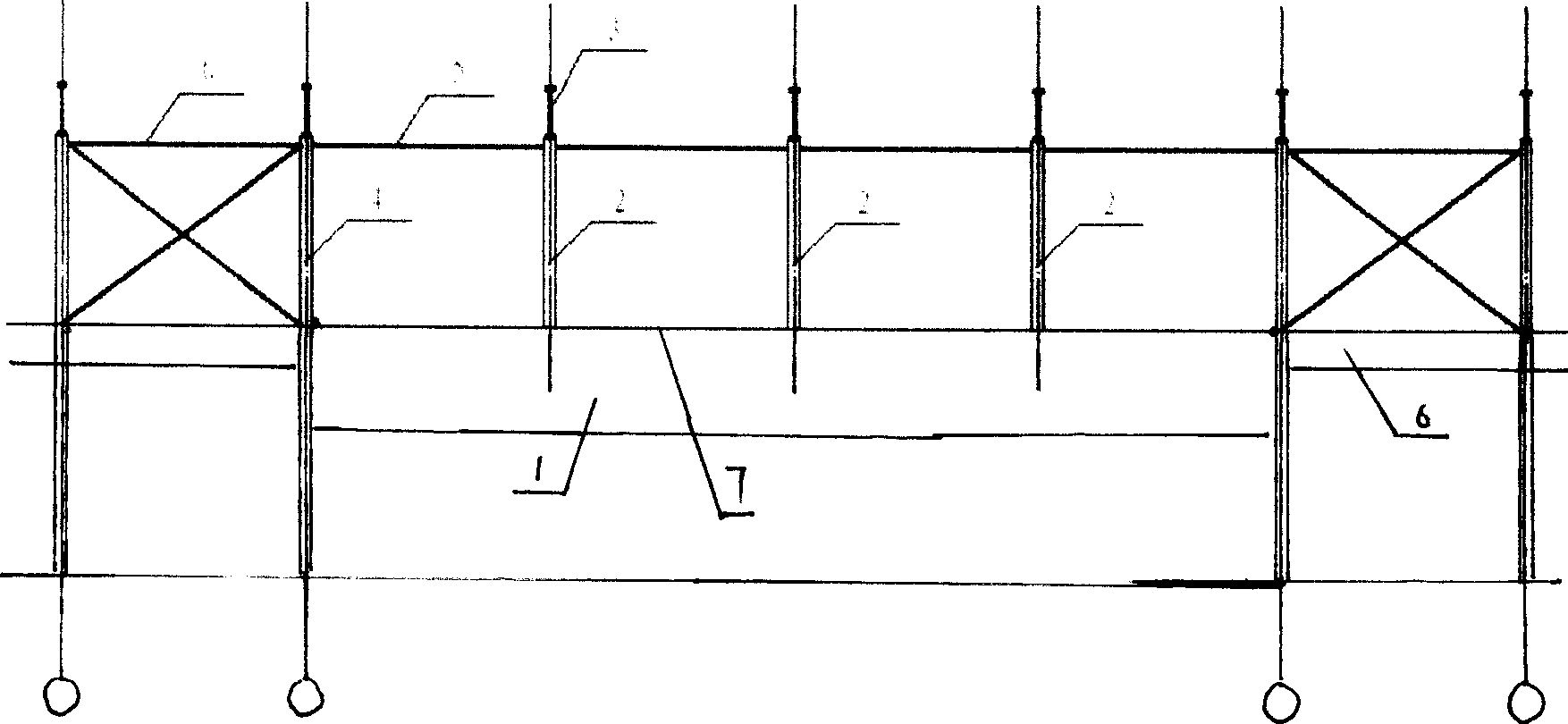

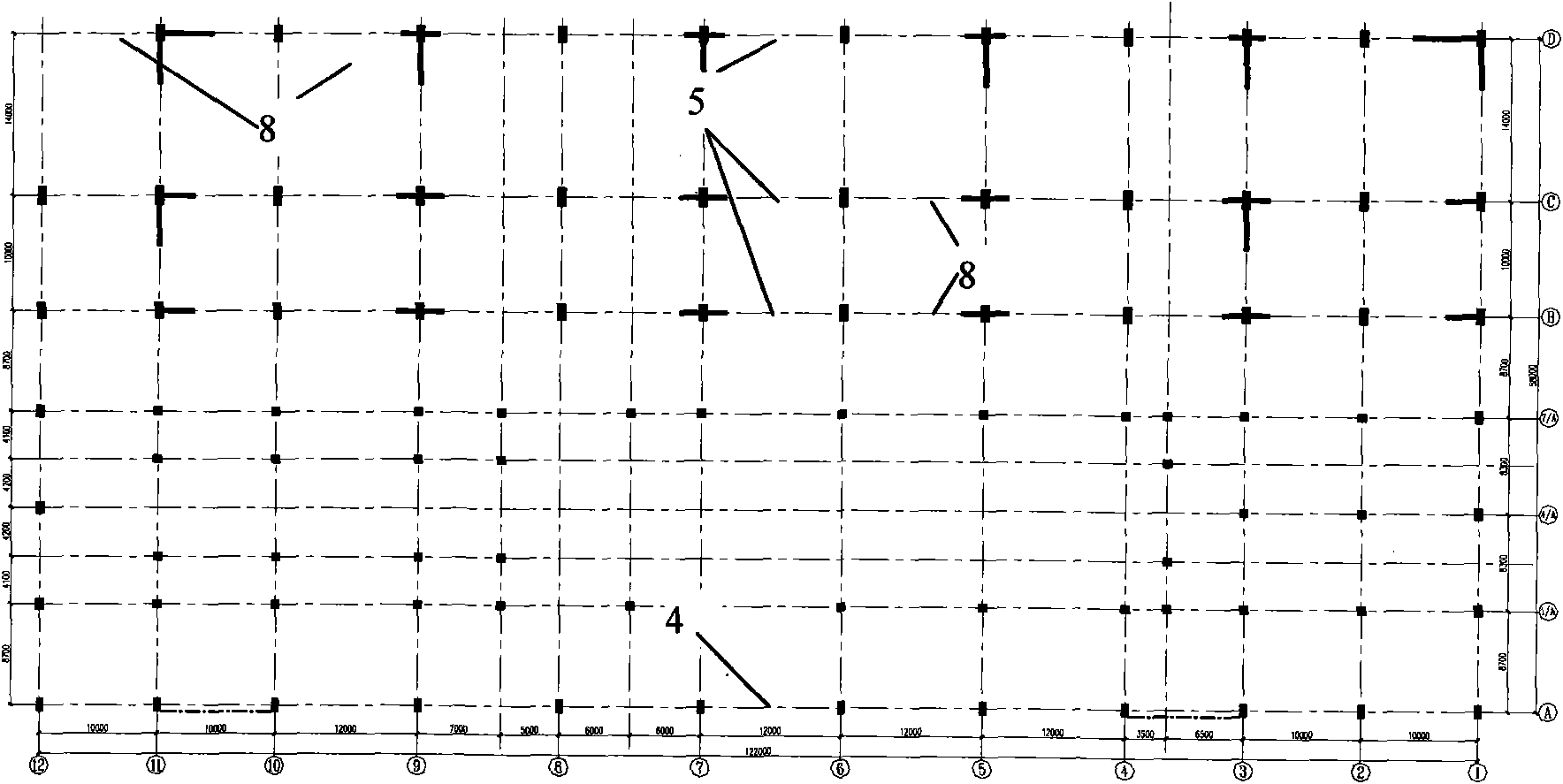

Supporting method of factory building roof system at super large column-removed spacing

InactiveCN101397814AUniform stiffnessUnified layoutBuilding roofsEconomic benefitsStructural engineering

The invention discloses a method for supporting a factory-building roofing system at a huge pumping column space, which relates to the technical field of construction structure design. According to normal column space (6), an on-beam steel column (2) is added in corresponding position on the top surface of a large box-shaped crane beam (1) at the huge pumping column space (7); the top of the on-beam steel column (2) is articulated with a steel roof truss (3), and the foot of the on-beam steel column (2) is articulated with the large box-shaped crane beam (1). The method effectively solves the problem of how to support a factory-building roofing system at a huge pumping column space and causes the arrangement of the roofs to be more unified and the whole rigidity of the factory buildings to be evener, thereby achieving good technical effect and economic benefits. The method is mainly used for the design of the supporting of a factory-building roofing system at a huge pumping column space.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

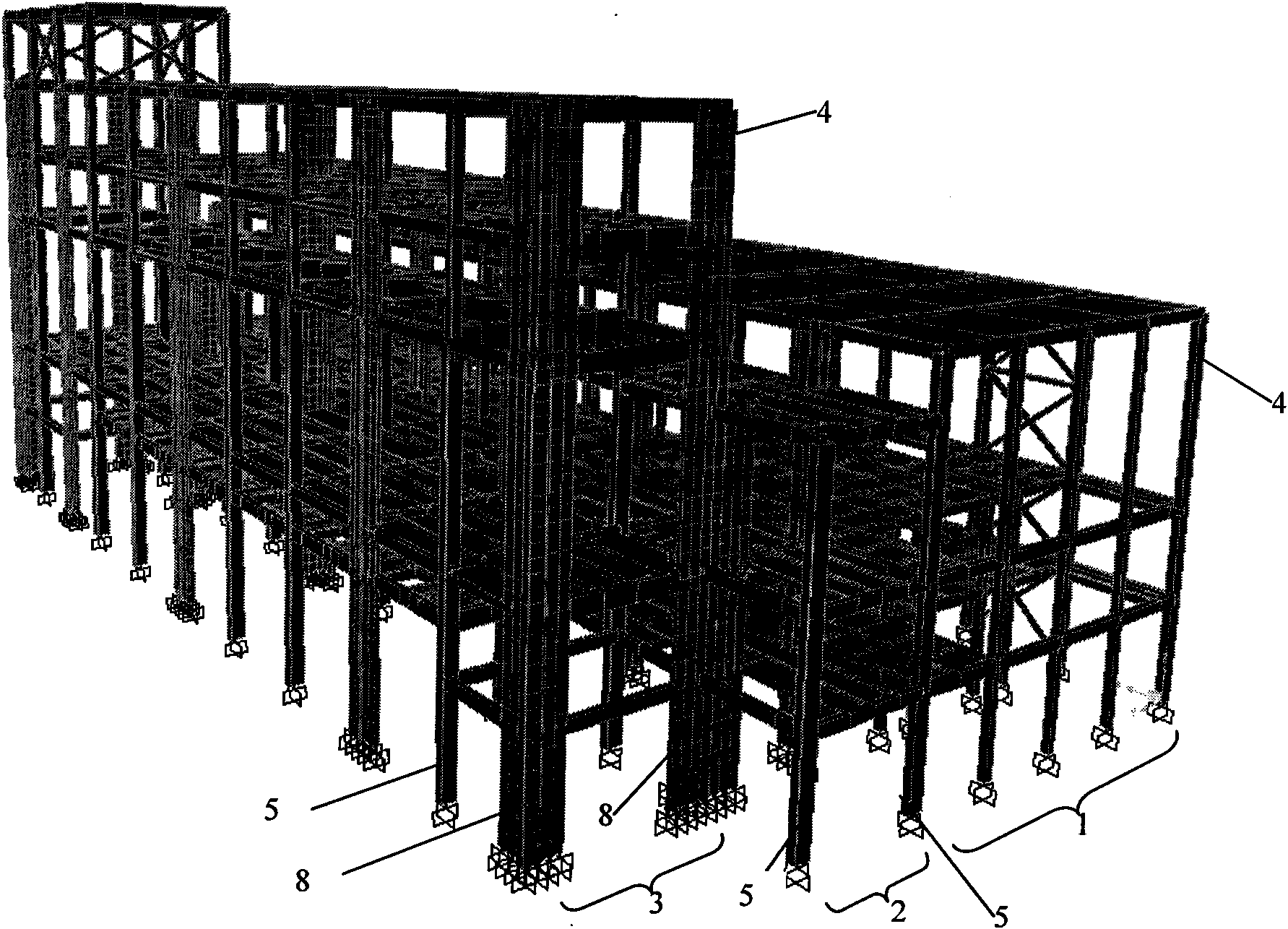

Main workshop structure of large heat power plant

ActiveCN101672118AImprove seismic performanceEasy to useBuilding constructionsIndustrial buildingsEngineeringHigh intensity

The invention relates to a main workshop structure of a large heat power plant, which comprises a turbine house, a deoxidizing bay and a bunker bay, wherein one side of the deoxidizing bay is adjacentto the turbine house, and the other side of the deoxidizing bay is adjacent to the bunker bay; a transverse shearing force wall and a longitudinal shearing force wall are dispersed at the circumferences of the bunker bay and the deoxidizing bay; frame columns of the deoxidizing bay and the bunker bay are profile steel concrete columns under the coal bucket layer; and the turbine house, the deoxidizing bay and the bunker bay integrally form a profile steel concrete frame-dispersed shearing force wall structure. The main workshop structure of the heat power plant is a main workshop structural system which is suitable for a high-capacity unit in an earthquake high-intensity area and has favorable structure performance and relatively low cost. Compared with the traditional system, the invention has the advantages of better quaking resistance, column section reduction, more convenient space process arrangement, low maintenance cost in later period, and the like.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP +1

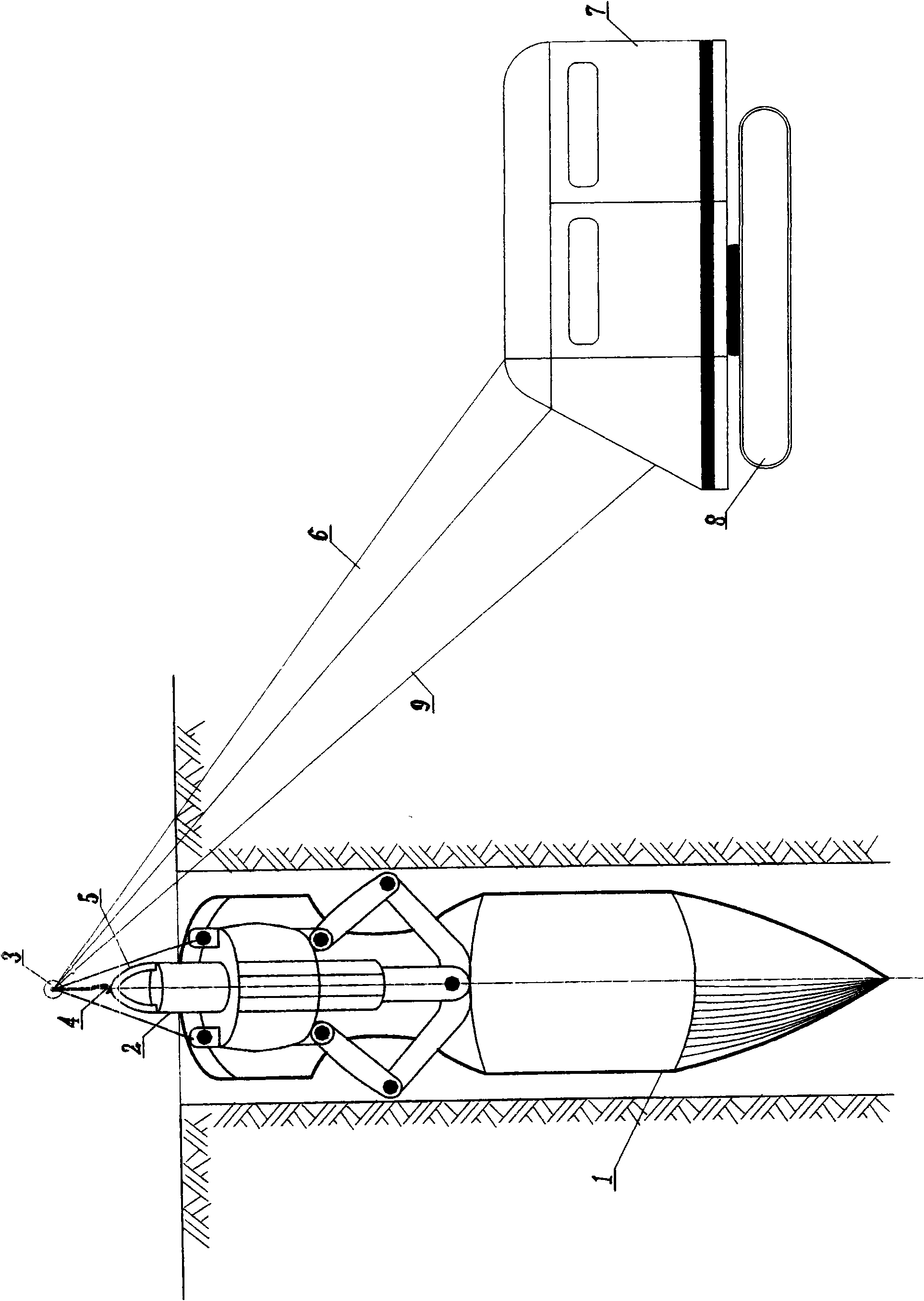

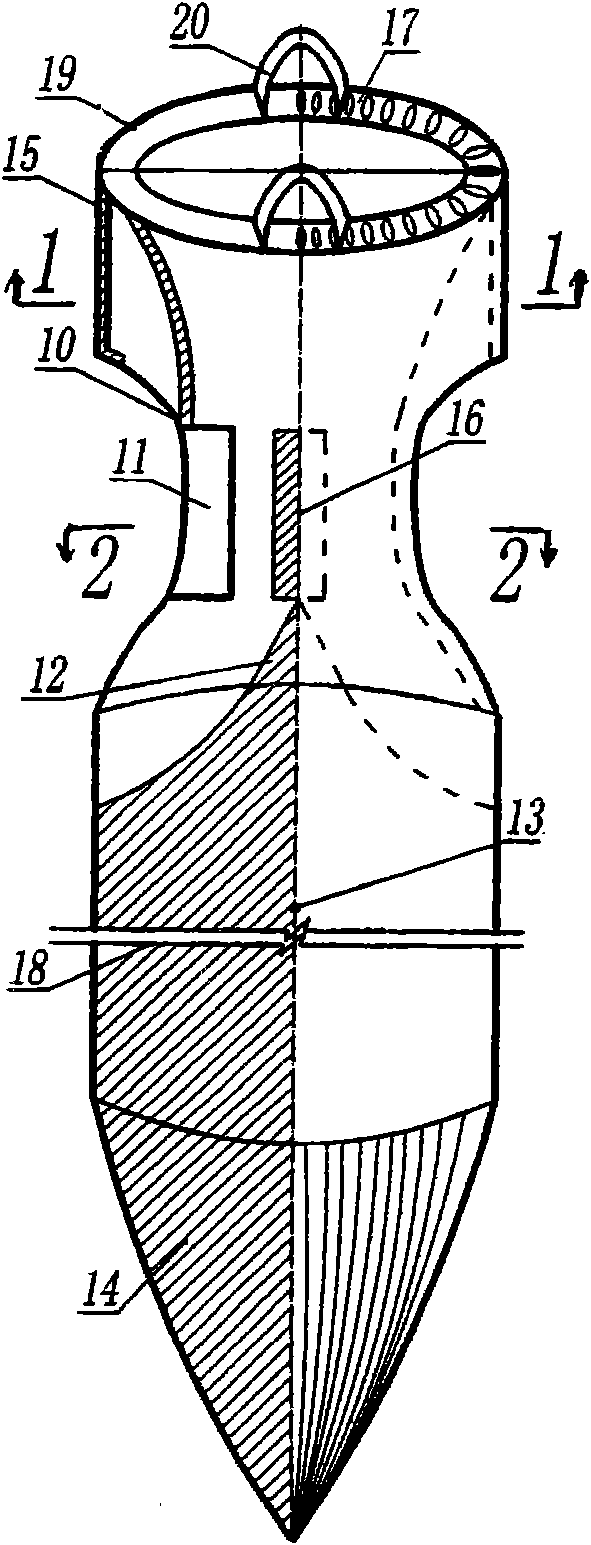

Method for realizing automatic over-pressure piling and compaction in holes

The invention relates to a method for realizing automatic over-pressure piling and compaction in holes, which comprises the following steps: making an automatic unhooking and hooking device controlled by a crane fall off and pierce a bell mouth on the upper part of an over-pressure counter weight by utilizing self weight; under the action of forces of vertical and transverse counter-force points, making the unhooking and hooking device hook hooking holes of a weight body; hoisting the counter weight to designed elevation in the air by using the crane and then making the unhooking and hooking device unhook the hooking holes of the weight body, so that the freely-falling weight body pierces a foundation hole; making the unhooking and hooking device fall off to drill and hook the weight body; repeatedly performing the steps of the hoisting of the weight body, the unhooking of the weight body, the falling-off of the weight body, the automatic weight body hooking of the unhooking and hooking device and the hoisting of the weight body, and then filling a filler with high design requirements into the foundation hole; and then repeatedly performing the steps and finally obtaining the deep foundation of a composite foundation, specific pile foundations and pre-expanded ecological pile bodies with high bearing capacity so as to fulfill the aims of processing the foundation into piles and the composite foundation and eliminating garbage contaminants.

Owner:司利利 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com