Vehicle engine hood and preparation method thereof

A hood and automobile technology, which is applied to vehicle components, superstructure, and sub-assembly of the upper structure, etc., can solve the problems of not taking into account the rigidity, deformation capacity and pedestrian protection of the hood, the complex preparation method of the hood, and the disadvantage of pedestrian protection. , to achieve the effect of good pedestrian protection, moderate stiffness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

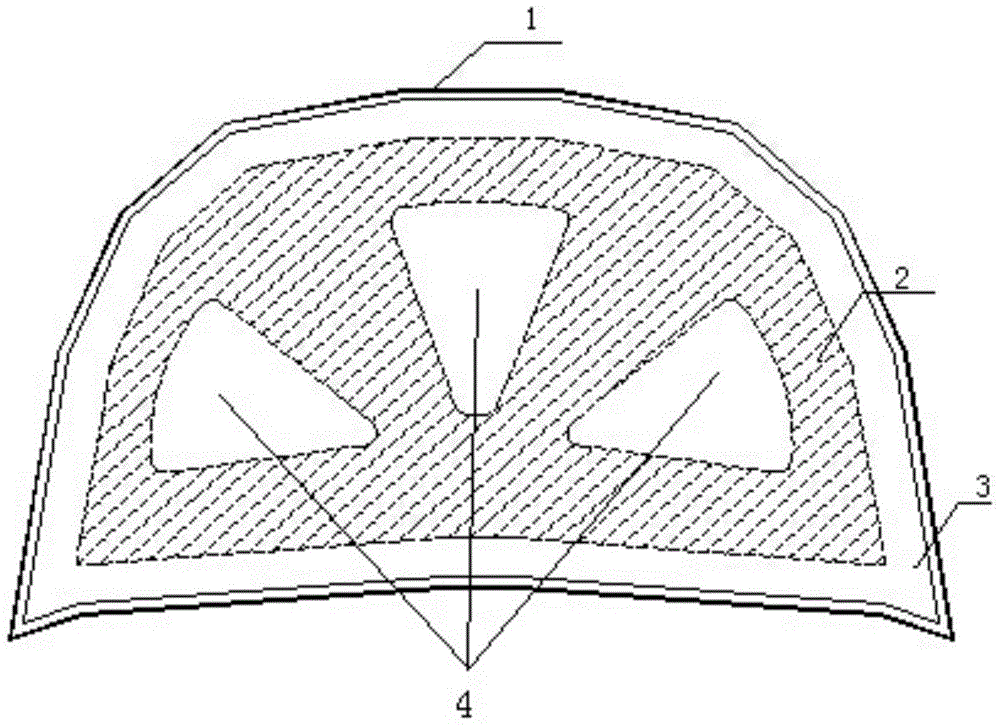

[0019] see figure 1 , a car engine cover includes a carbon fiber composite material layer and a foam sandwich reinforced layer 2, the carbon fiber composite material layer includes an upper layer 1 and a lower layer 3, the foam sandwich reinforced layer 2 is arranged between the upper layer 1 and the lower layer 3, and other metal locks The accessories can be installed in the form of embedded parts (not shown in the figure). There are also three hollow areas 4 on the foam sandwich reinforced layer 2 . The hollowed out areas 4 are fan-shaped and arranged at intervals, and the three hollowed out areas 4 are arranged axially symmetrically and concentrically along the central line of the hood. By arranging the foam sandwich reinforcement layer into the above-mentioned shape, the rigidity of the engine cover is locally enhanced, and at the same time, the requirements of rigidity, deformation ability and pedestrian protection are balanced.

[0020] Both the upper layer 1 and the l...

Embodiment 2

[0022] The preparation method of automobile engine cover as described in embodiment 1, it comprises the steps:

[0023] (1) First put the prepreg of three layers of 6K tow carbon fiber twill / plain weave into the molding mold; the resin matrix of the prepreg is epoxy resin, and the reinforcing fabric is carbon fiber twill or plain weave;

[0024] (2) Then the 2mm thick foam sandwich reinforcing layer is cut into three fan-shaped hollow areas as described in Example 1, and fixed on the surface of the prepreg in step (1) with 502 quick-drying glue;

[0025] (3) Then lay the prepreg of two layers of 6K tow carbon fiber twill fabric above the foam sandwich reinforcing layer in step (2), and the laying method is preferably [±90°] 2 , that is, the angle between the two layers of fiber plies is preferably ±90°;

[0026] (4) Finally, seal the semi-finished product laid by step (3) with a vacuum bag, vacuumize it, and then heat and solidify it for molding, wherein the heating temperatu...

Embodiment 3

[0028] The preparation method of automobile engine cover as described in embodiment 1, it comprises the steps:

[0029] (1) At first the prefabricated body of three layers of 6K tow carbon fiber twill / plain weave fabric is put into forming mold; Wherein, the reinforced fabric of prefabricated body is carbon fiber twill weave or plain weave;

[0030] (2) Then the 2mm thick foam sandwich reinforcing layer is cut into three fan-shaped hollow areas as described in Example 1, and fixed on the surface of the prefabricated body in step (1);

[0031] (3) Then lay the prepreg of two layers of 6K tow carbon fiber twill fabric above the foam sandwich reinforcing layer in step (2), and the laying method is preferably [±90°] 2 , that is, the angle between the two layers of fiber plies is preferably ±90°;

[0032] (4) Close the mold, inject RTM resin, and cure and form. RTM epoxy resin is generally used, such as EPIKOTE of Momentive Company TM Resin05475, EPIKOTE TM Resin RIMR135, Hun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com