Main workshop structure of large heat power plant

A technology for factory owners and workshops, applied in building structures, industrial buildings, buildings, etc., it can solve problems such as large stress and deformation anisotropy of nodes, uneven distribution of stiffness and mass, and poor horizontal structural continuity, and achieve later maintenance. And the effect of low cost of use, excellent earthquake resistance and performance, and large space for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

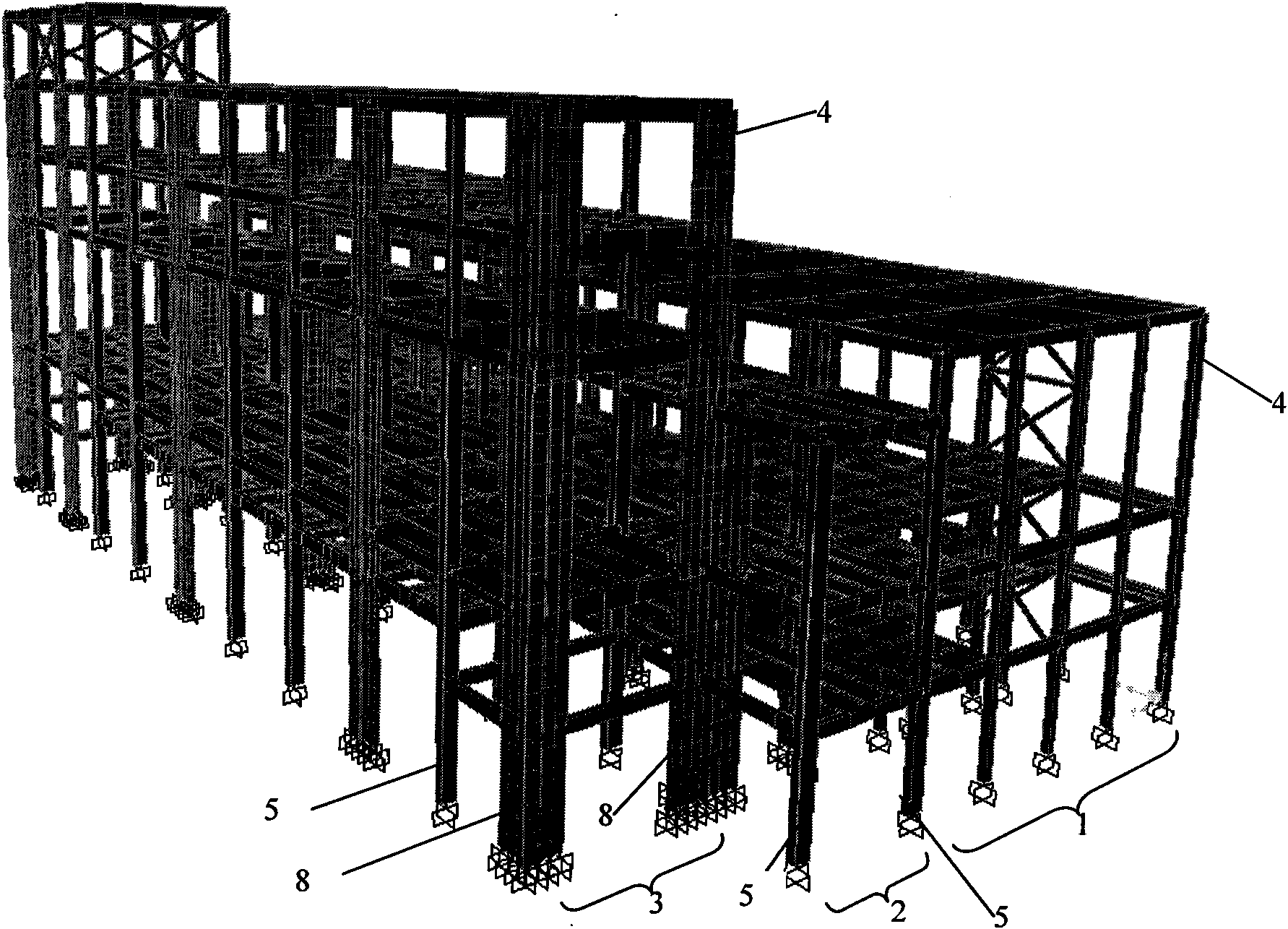

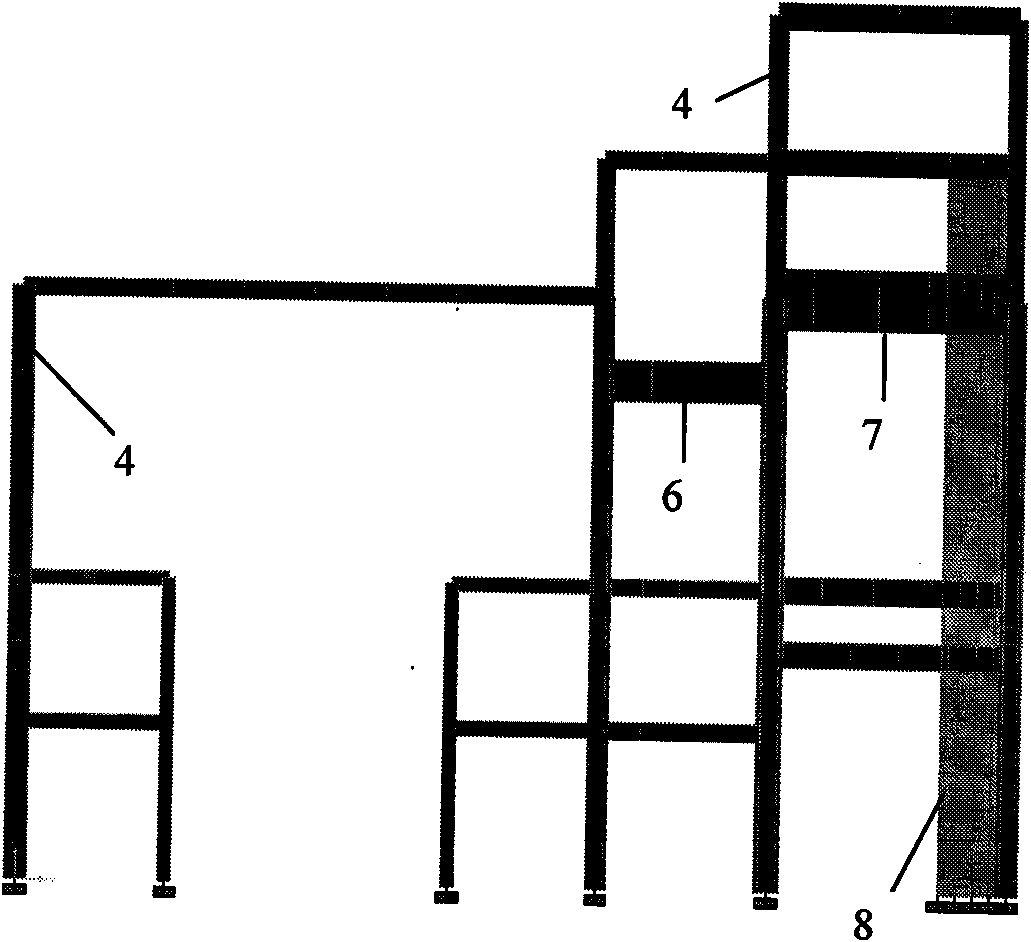

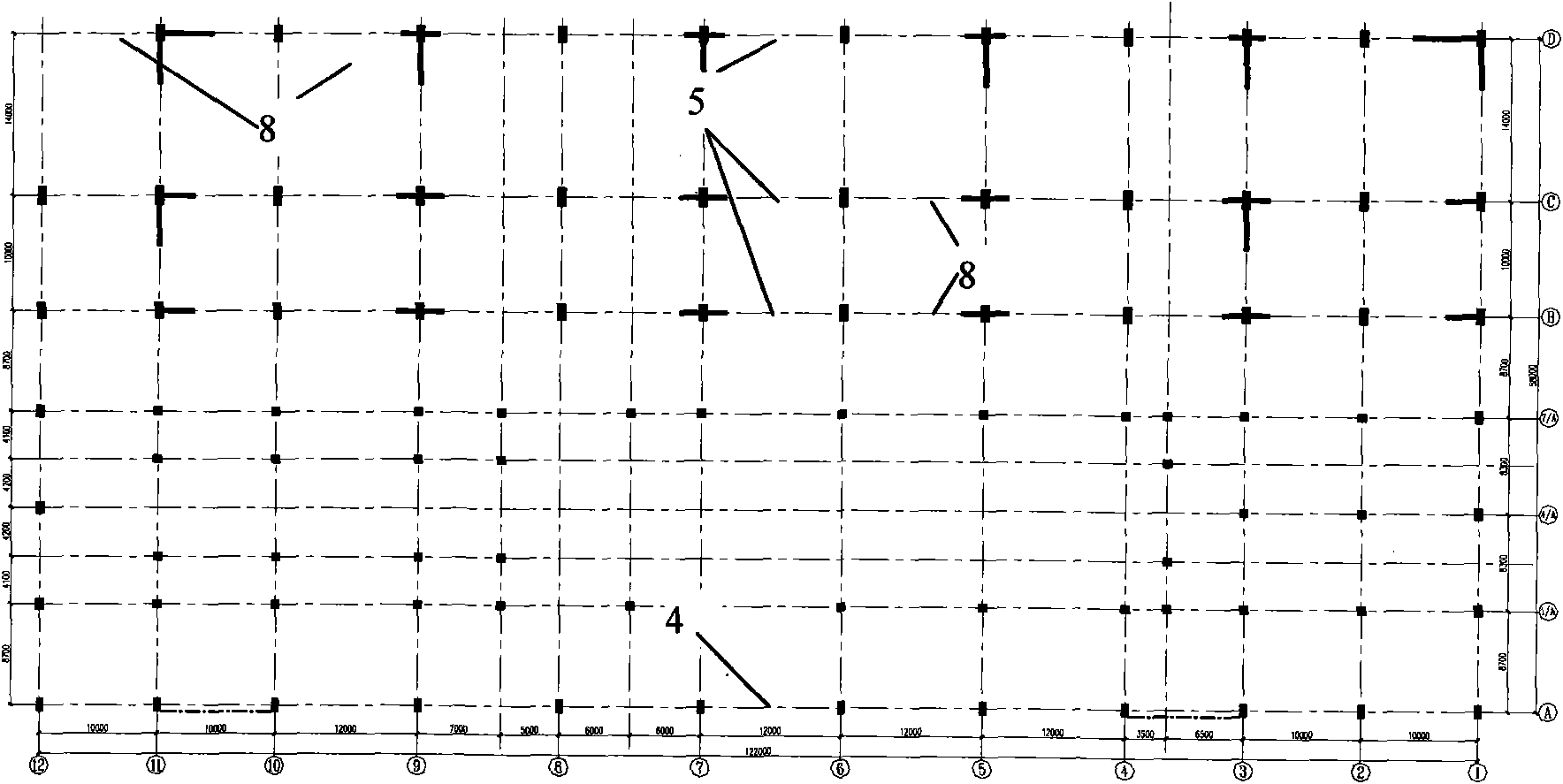

[0031] see figure 1 , 2 And 3, a main building structure of a large-scale thermal power plant, including a turbine room 1, a deaeration room 2 and a coal bunker room 3, characterized in that: one side of the deaeration room 2 is adjacent to the turbine room 1, and the deaeration room 2. The other side is adjacent to the coal bunker room 3; horizontal and vertical shear walls 8 are scattered around the frame of the coal bunker room 3; horizontal and vertical shear walls 8 are scattered around the frame of the deaeration room 2; The frame column between the deaeration room 2 and the coal bunker room 3 is a steel concrete column 5 under the coal bucket layer; the turbine room 1, the deaeration room 2 and the coal bunker room 3 integrally form a steel concrete frame-dispersed shear wall structure .

[0032] The turbine house 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com