Method for realizing automatic over-pressure piling and compaction in holes

A piling and dense method technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of re-creation of value without comprehensive utilization, water source, air pollution, and no re-creation of value, etc., to improve work efficiency. Efficiency and depth of foundation treatment, solving pollution problems, and reducing labor intensity of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

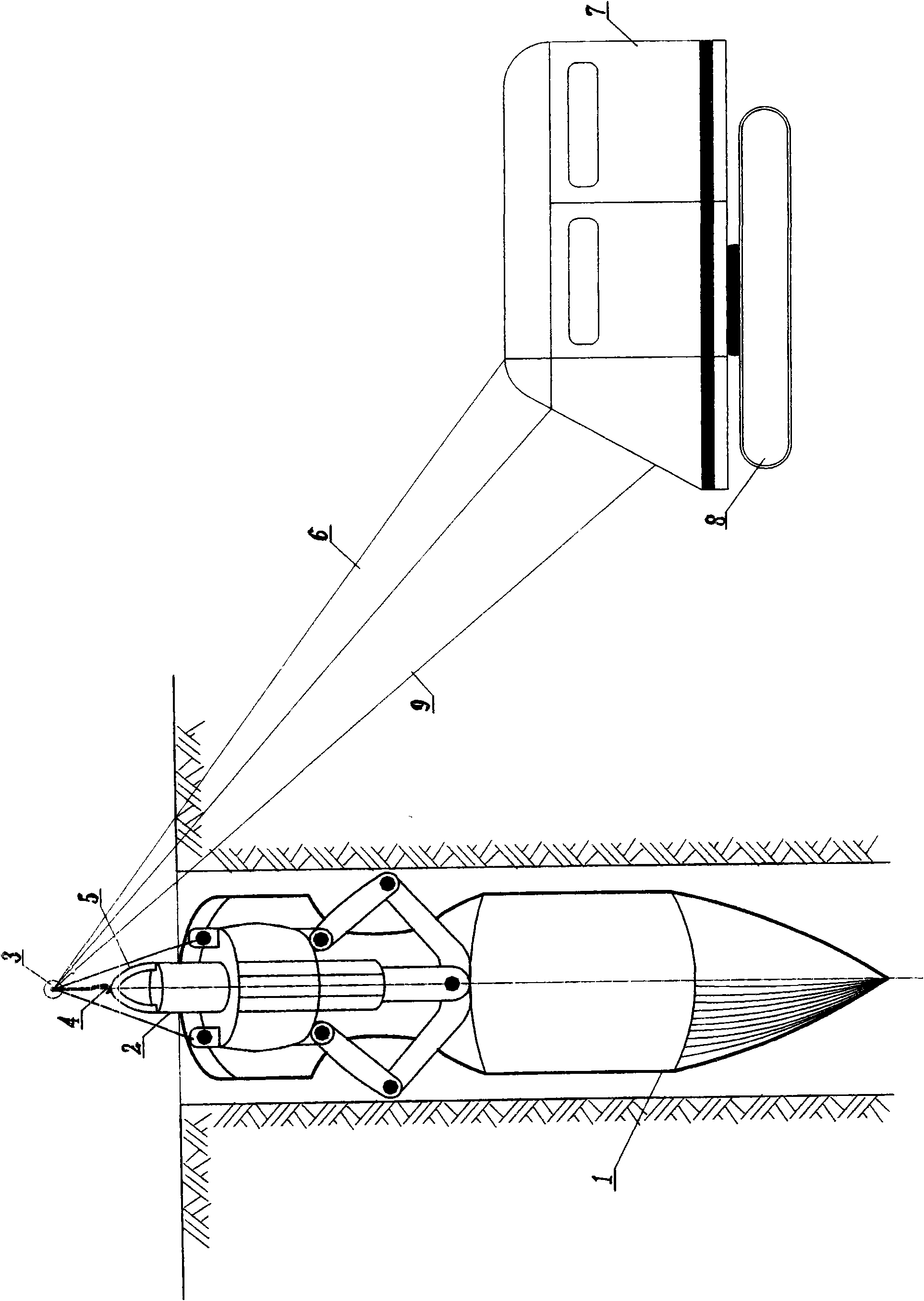

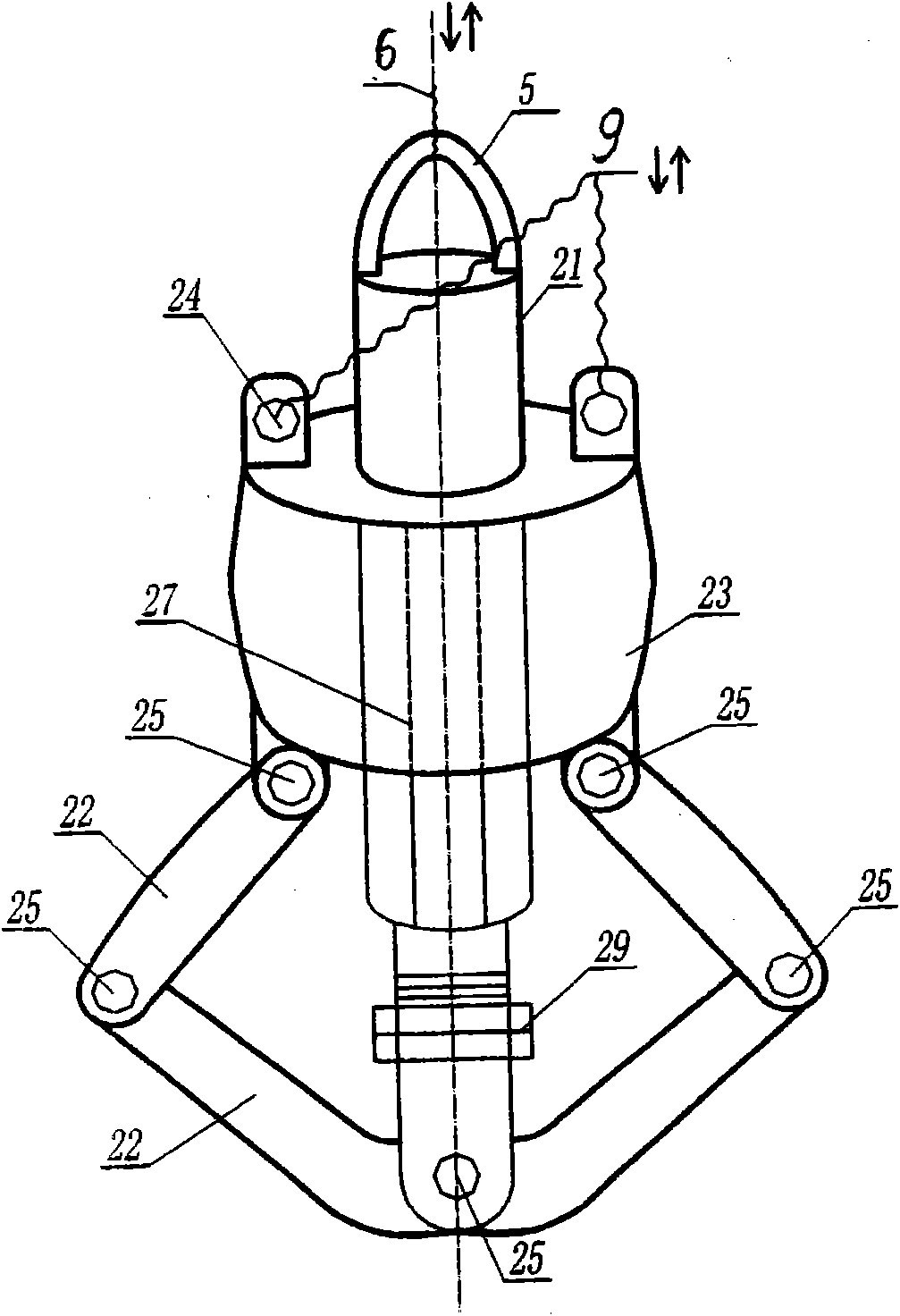

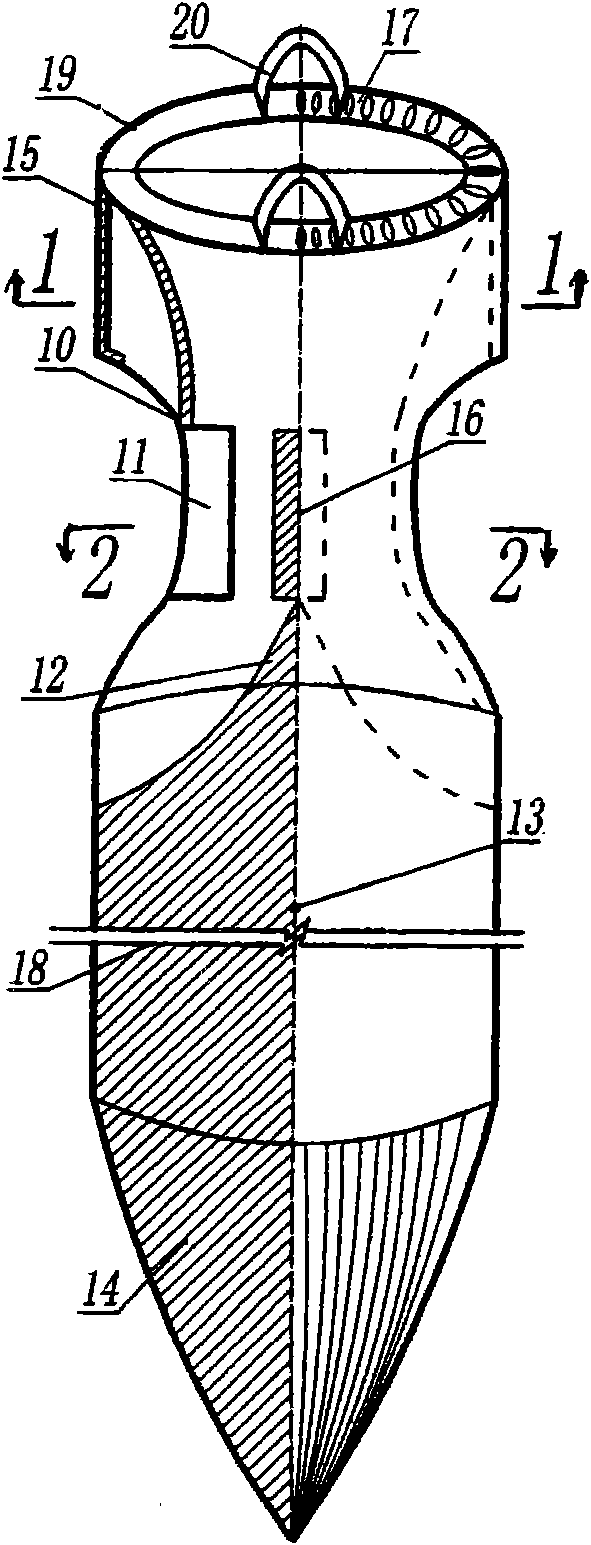

[0023] Referring to the accompanying drawings, the automatic overpressure pile compaction method in the hole of the present invention is based on the characteristics of the foundation soil, on-site materials and the design requirements for treating the foundation, and designs an overpressure heavy hammer 1 with a slenderness ratio λ=1~10 And an automatic decoupling device 2 that hooks, lifts and unhooks the hammer body under the action of the crane roller 7. During construction, the automatic decoupling device 2 repeatedly hooks, lifts and releases the overpressure heavy hammer 1 for many times. Unhook and release, so that the hammer body of the super-pressure hammer repeatedly uses the super-pressure kinetic energy E=6×10 4 ~1.53×10 8 KNM / m 2 The foundation and sanitation projects are punched, smashed, squeezed, pressed, and split with high kinetic energy, overpressure, and strong compaction. During the period, various fillers (ballast soil, plain soil, lime soil, etc.) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com