Pneumatic tire and method of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

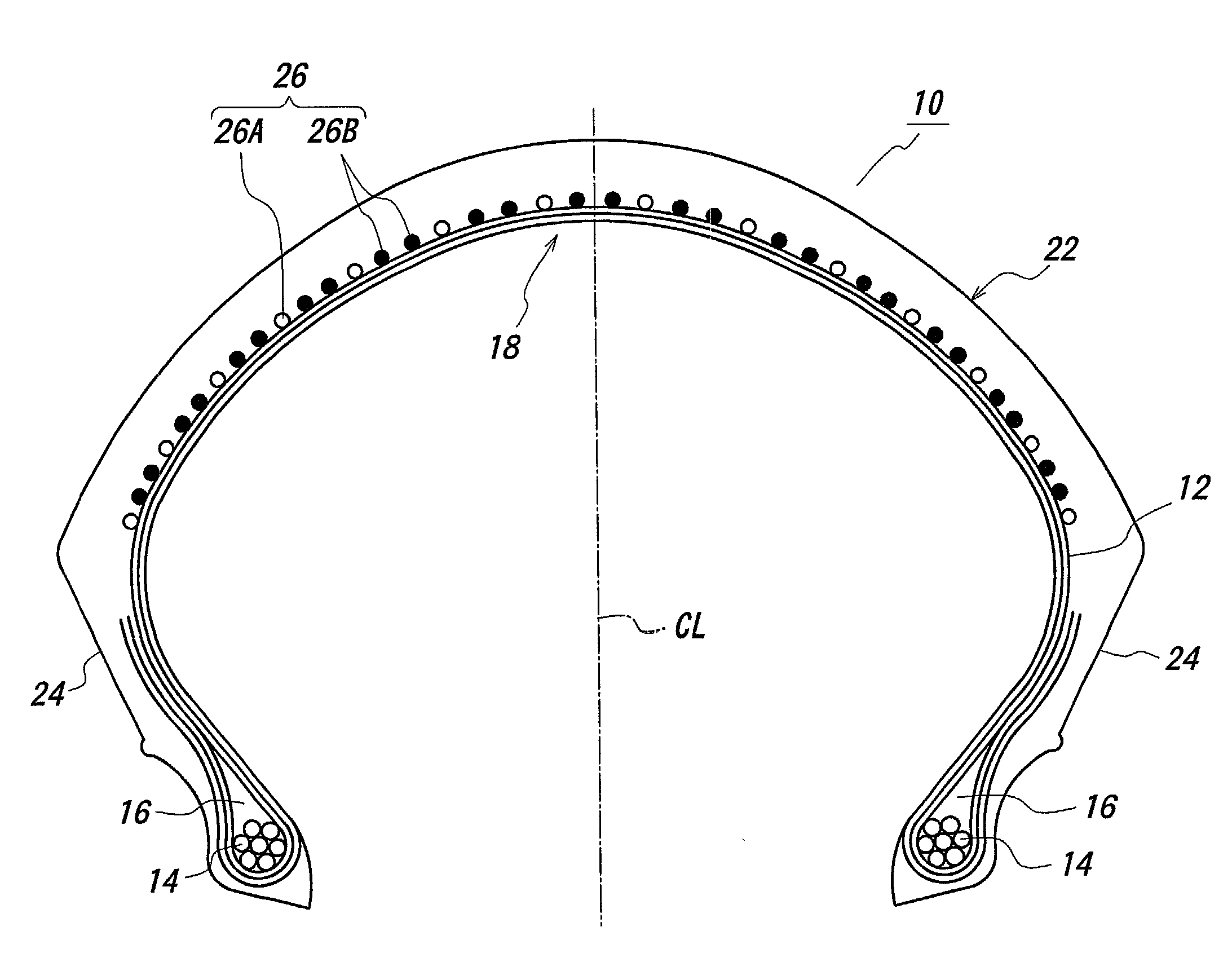

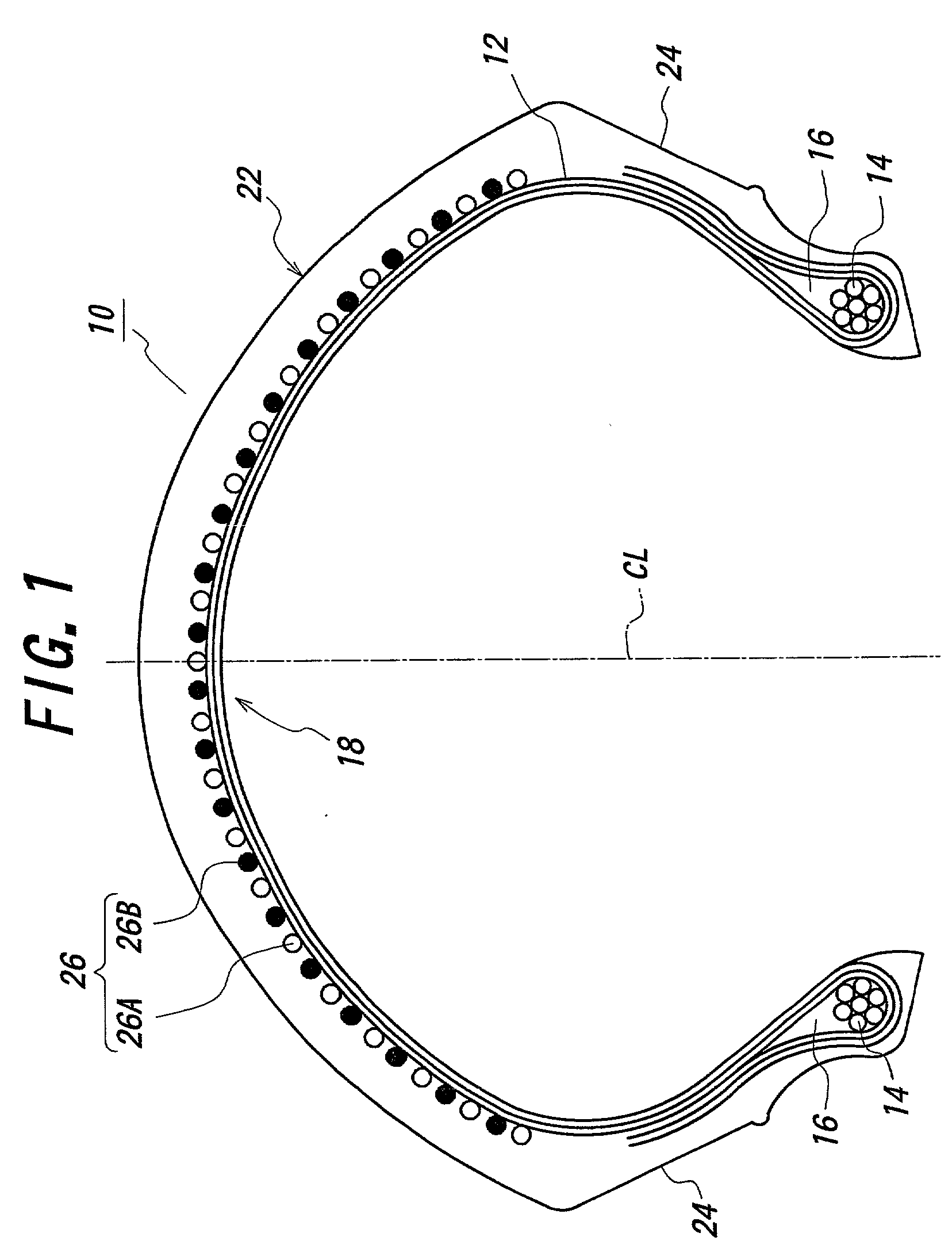

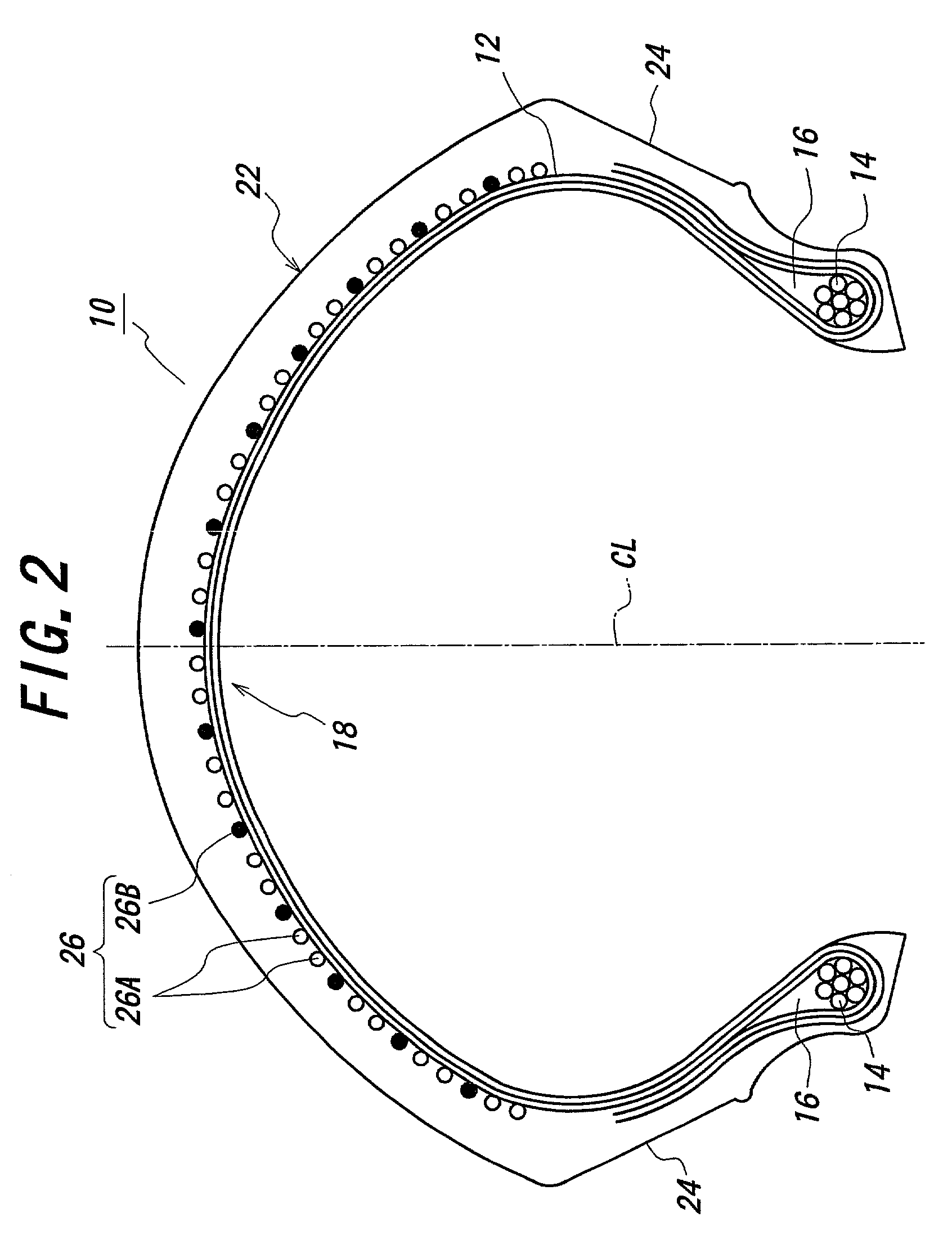

Image

Examples

example 2 example 1

Hydraulic burst pressure (KPa) 250 150 250 High-speed stability 100 120 120 Light feeling and responsibility 100 120 120 Gripping force in cornering 100 110 120 Ride comfort 100 80 90

[0054] As seen from Table 1, when the tire of Example 1 is compared with the tire of Conventional Example 1, the hydraulic burst pressure is equal to and the ride comfort is somewhat low, but the other running performances are higher than those of the conventional tire. And also, the running performances in the tire of Example 1 are equal to or more than those of the tire of Conventional Example 2.

[0055] On the other hand, each of these tires is subjected to a running test by mounting onto a motorcycle as a front tire in addition to a hydraulic burst pressure test to obtain results as shown in Table 2. In this case, a radial tire comprising a circumferential belt of KEVLAR is used as a rear tire.

2 TABLE 2 Conventional Conventional Example 1 Example 2 Example 1 Example 2 Hydraulic burst 250 150 250 220 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com