Patents

Literature

30results about How to "Improve compressive stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

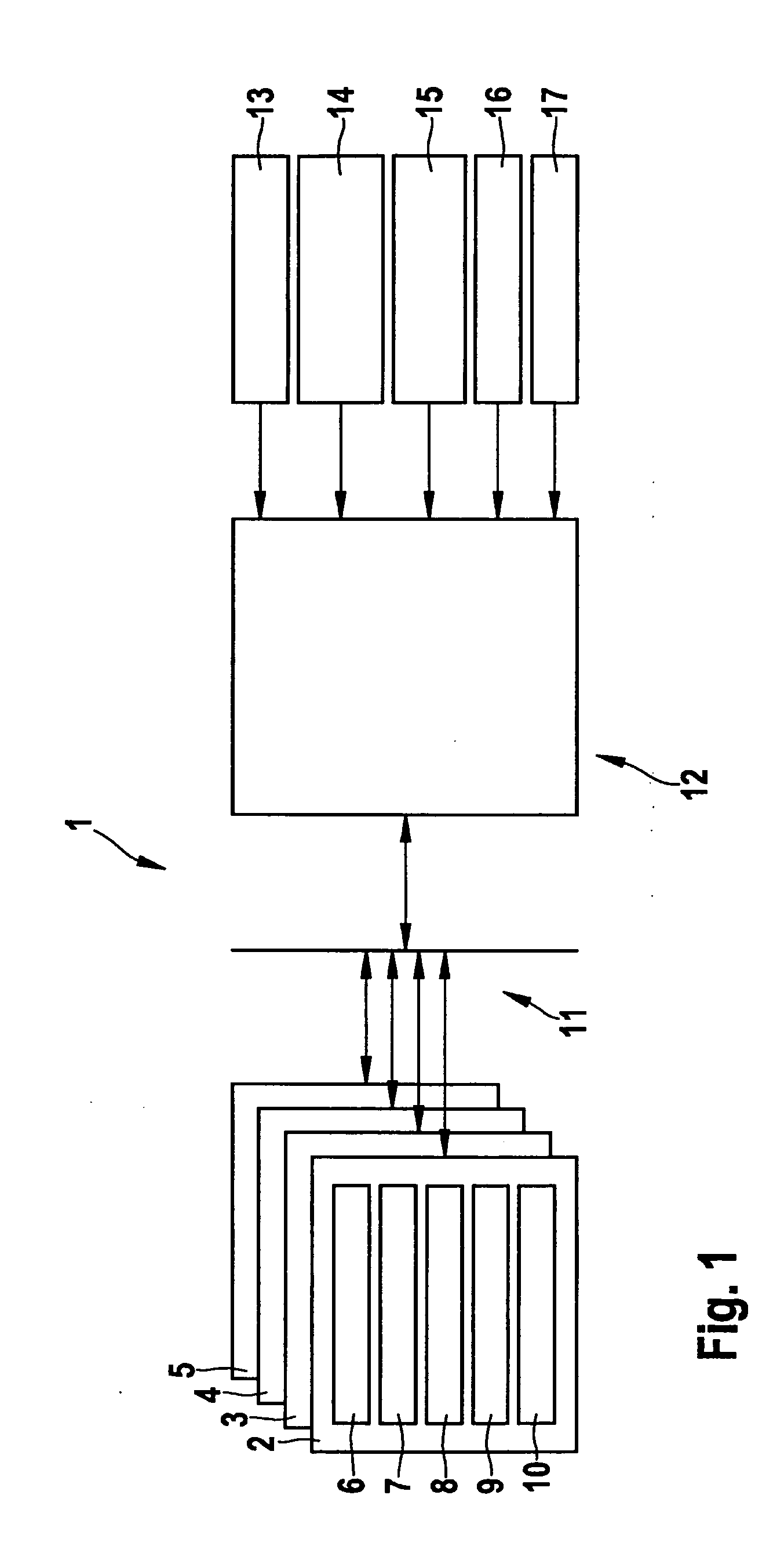

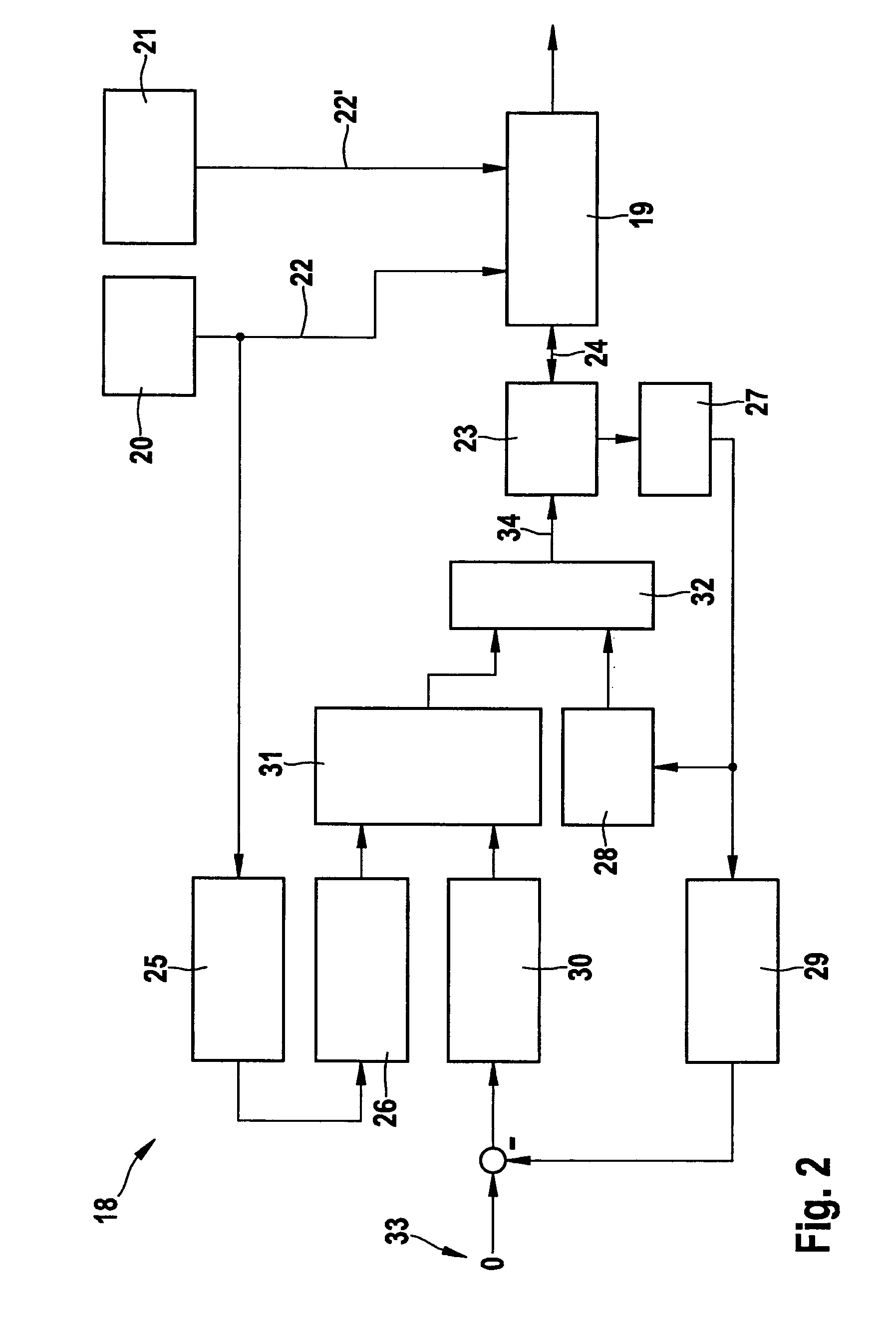

Method for Chassis Control of a Motor Vehicle, and Device for the Performance Thereof

ActiveUS20120055745A1Increase stiffnessAdjust stiffnessSpringsResilient suspensionsCompressive loadMotorized vehicle

In a method for chassis control of a motor vehicle which has at least one wheel suspension, a vehicle body, and a shock absorber having a rebound stage, whose stiffness is adjustable, and a compression stage, whose stiffness is adjustable, the stiffness of the compression stage is changed for a compressive load of the shock absorber generated by a specific vehicle body movement, and the stiffness of the rebound stage is additionally changed for a subsequently following tensile load of the shock absorber generated by the specific vehicle body movement, or the stiffness of the rebound stage is changed for a tensile load of the shock absorber generated by a specific vehicle body movement, and the stiffness of the compression stage is additionally changed for a subsequently following compressive load of the shock absorber generated by the specific vehicle body movement.

Owner:ROBERT BOSCH GMBH

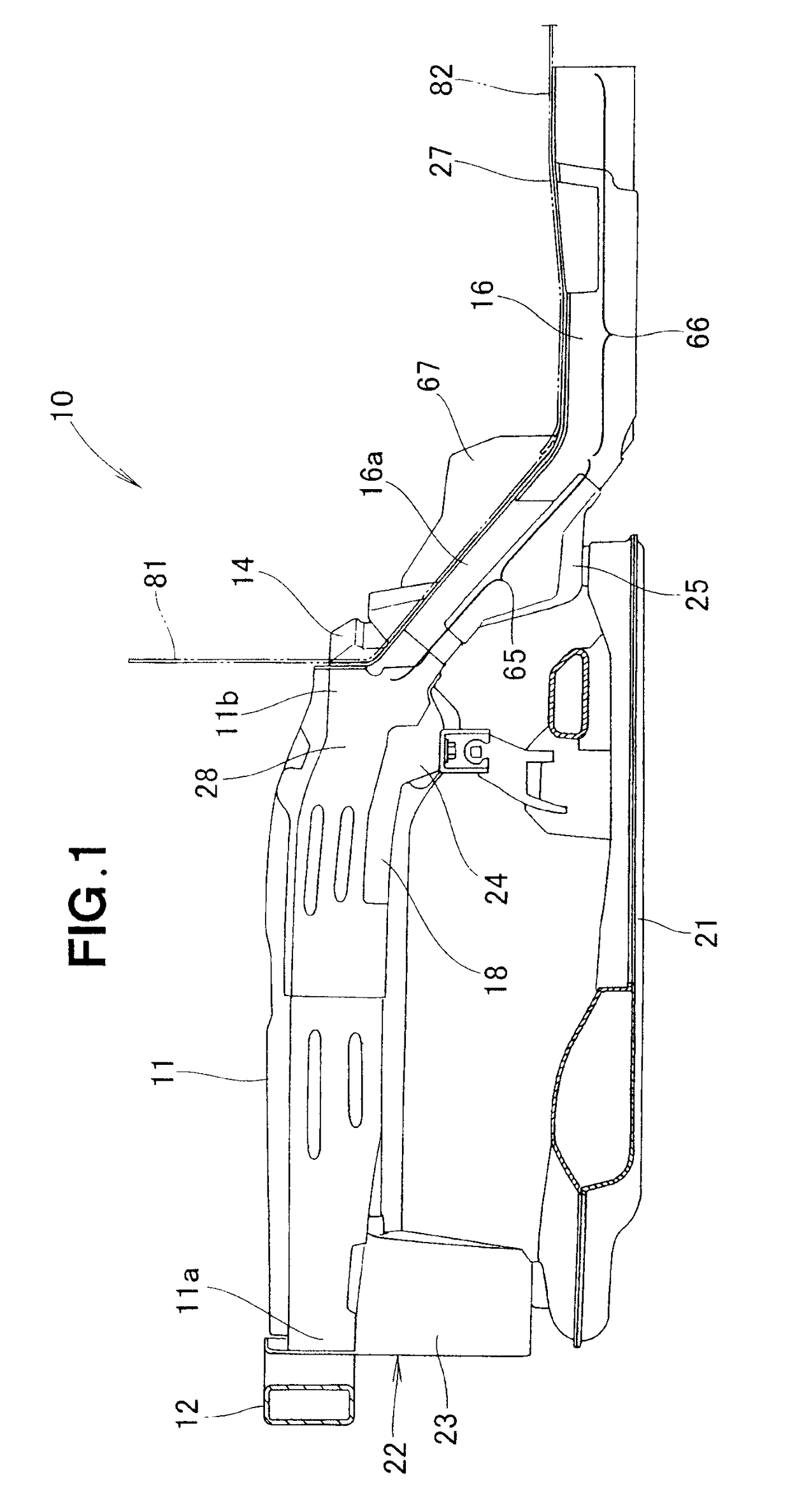

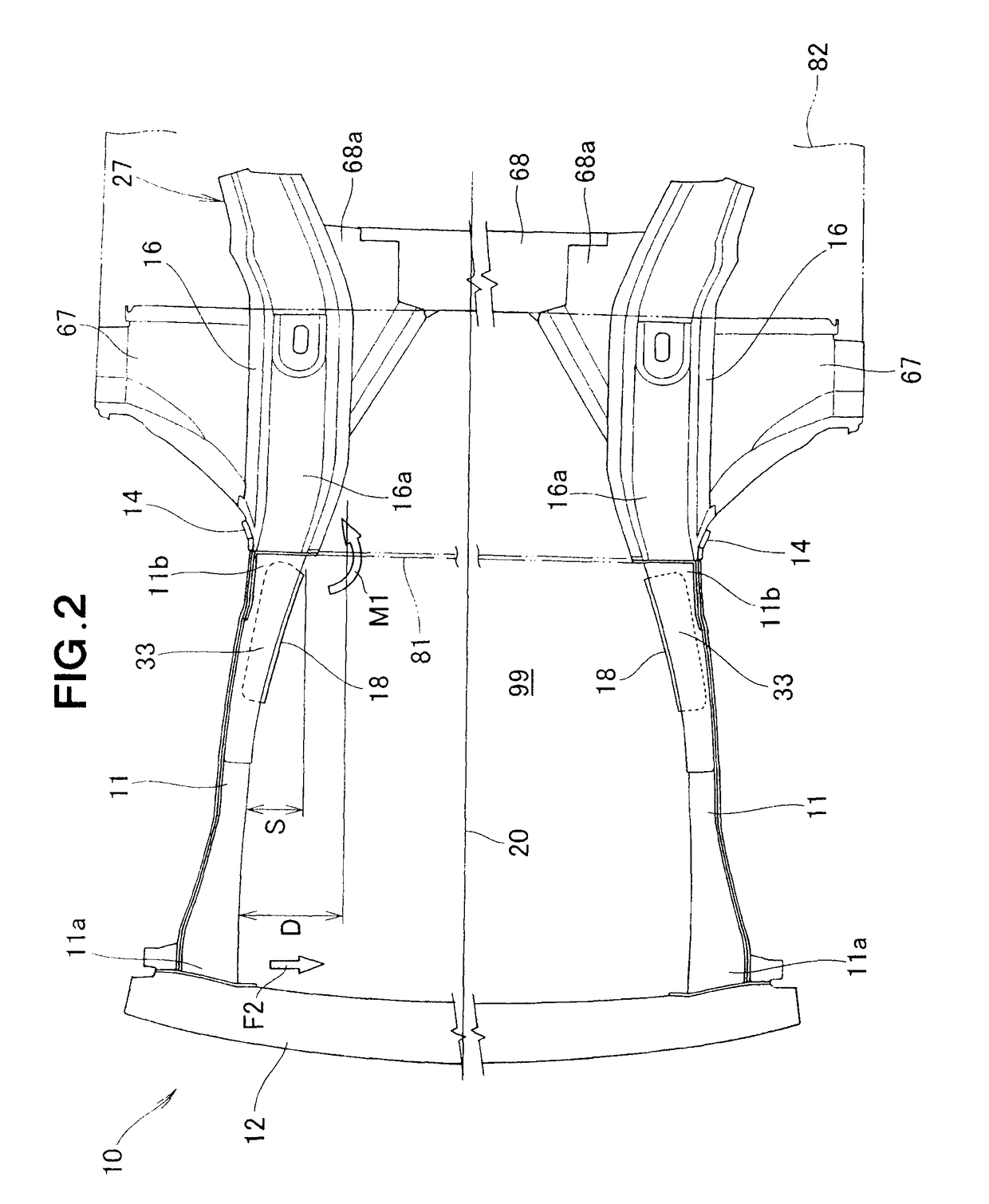

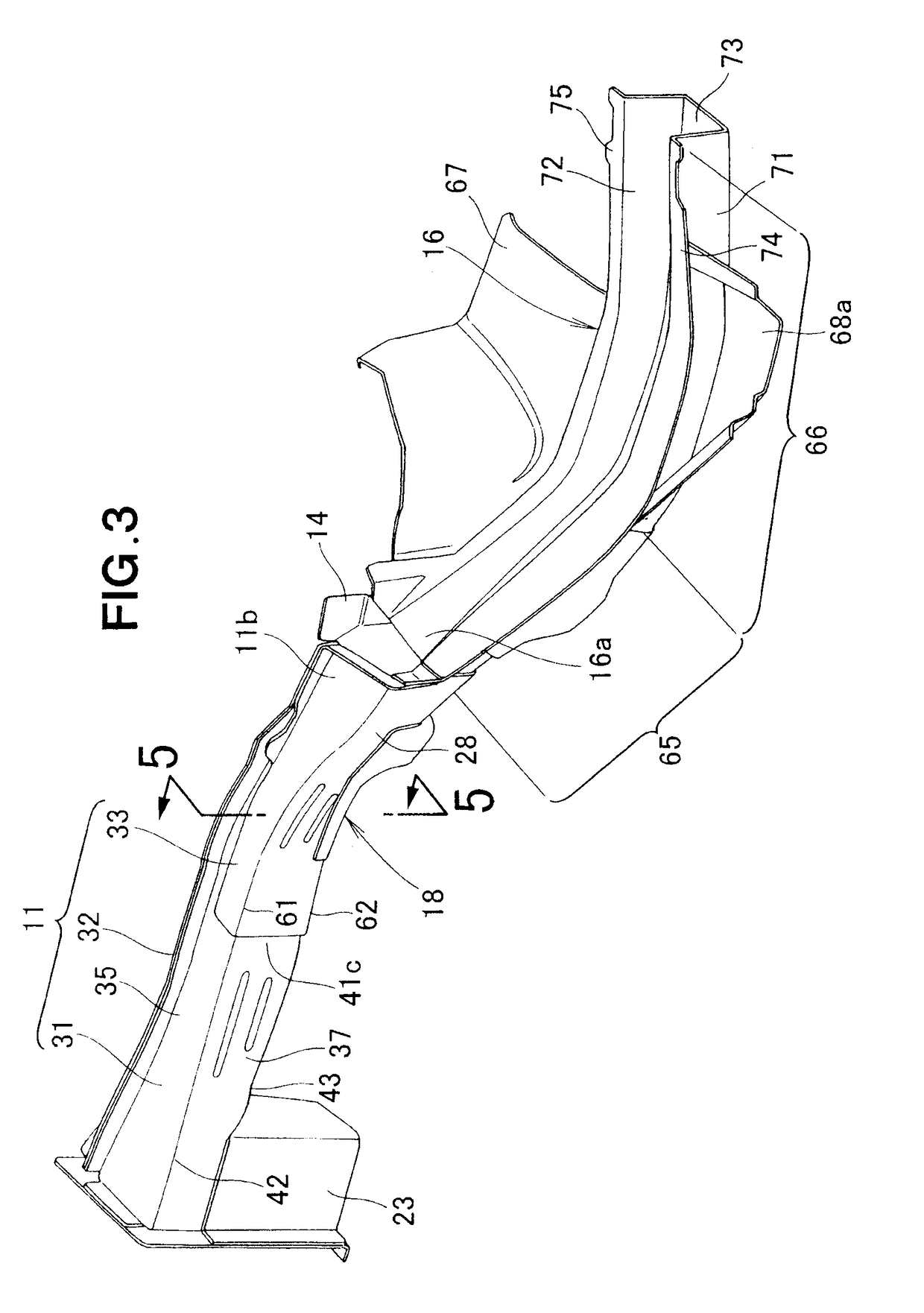

Vehicle body front part structure

ActiveUS8118349B2Firmly connectedImprove rigidityVehicle seatsUnderstructuresEngineeringMechanical engineering

A vehicle body front part structure having a front side frame including a compressive load bearing frame member extending longitudinally of a vehicle body, and a bending load bearing frame member branched from a longitudinally central portion of the compressive load bearing frame member and curved inwardly toward a longitudinal centerline of the vehicle body as extending rearwardly of the vehicle body. The compressive load bearing frame member has a rear end portion curved inwardly toward the longitudinal centerline of the vehicle body, and reinforcement beads formed on a sidewall of the rear end portion of the compressive load bearing frame member.

Owner:HONDA MOTOR CO LTD

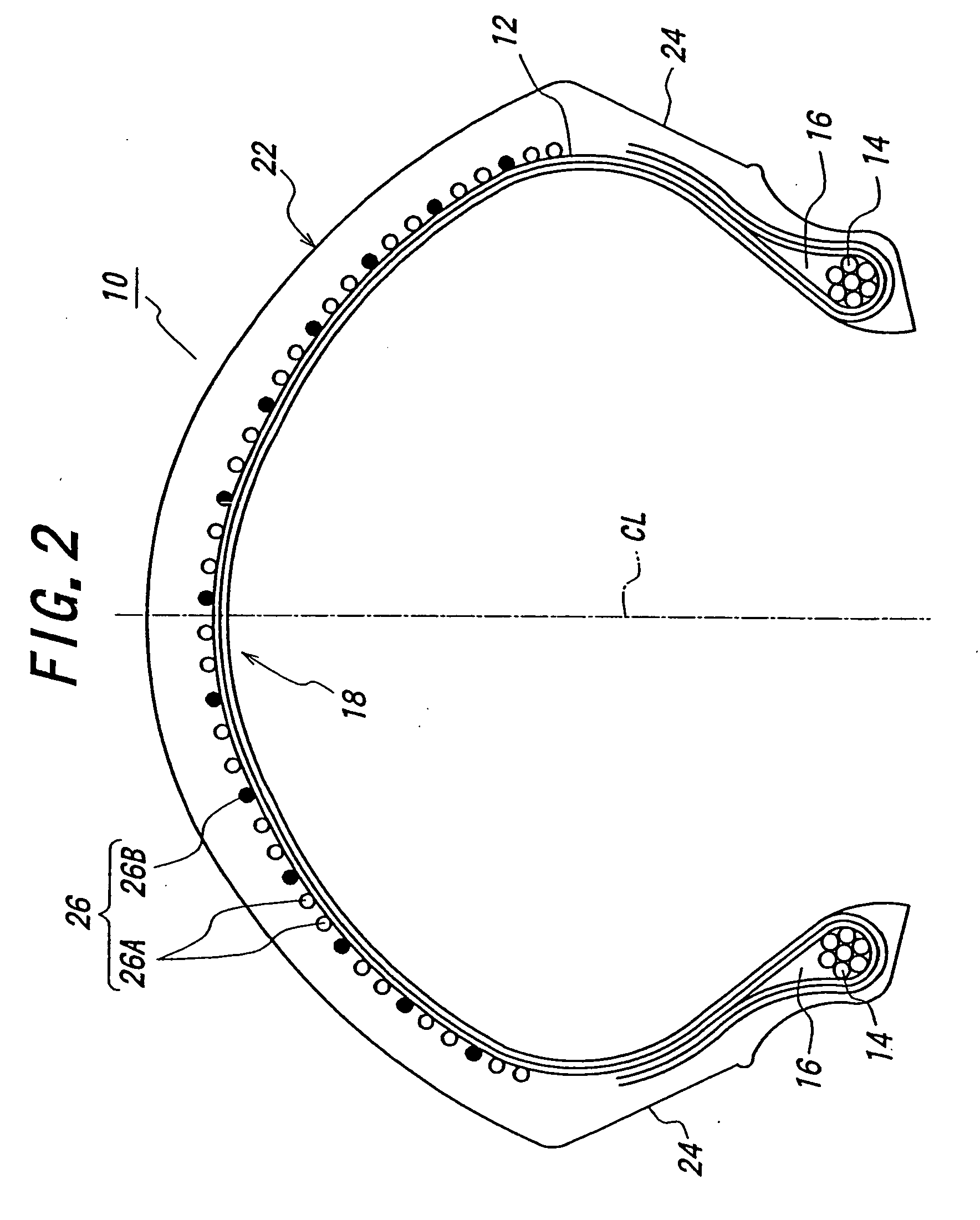

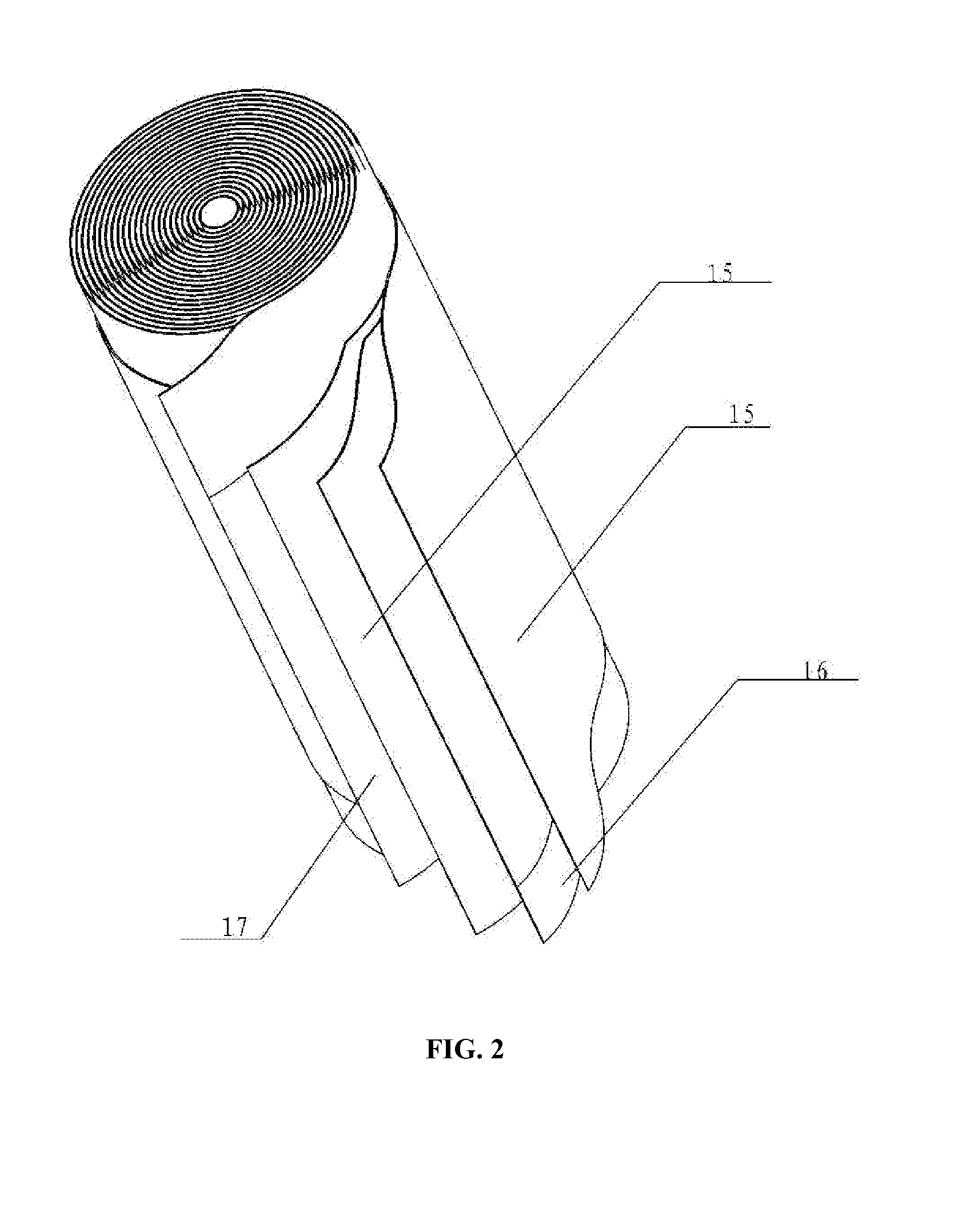

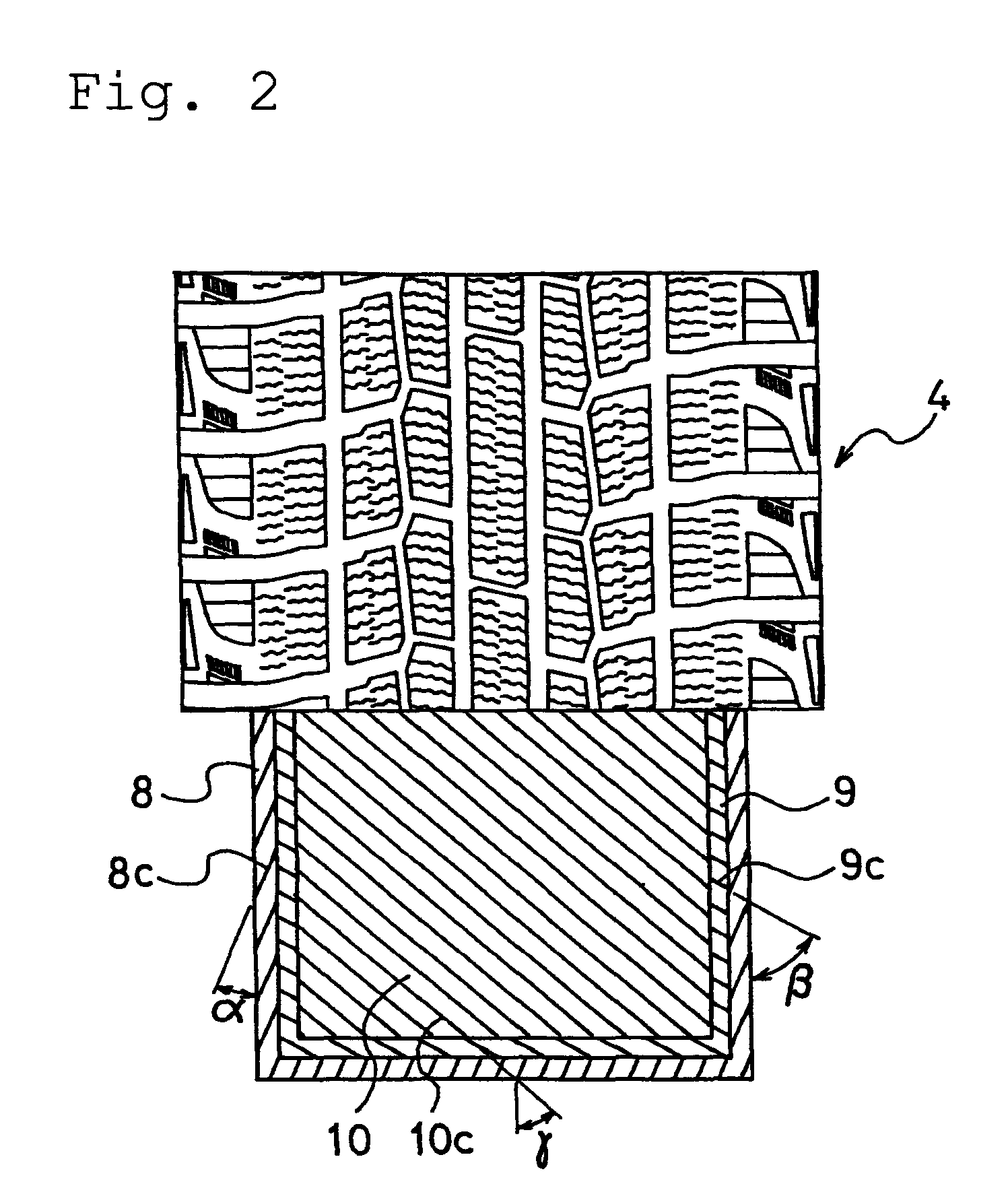

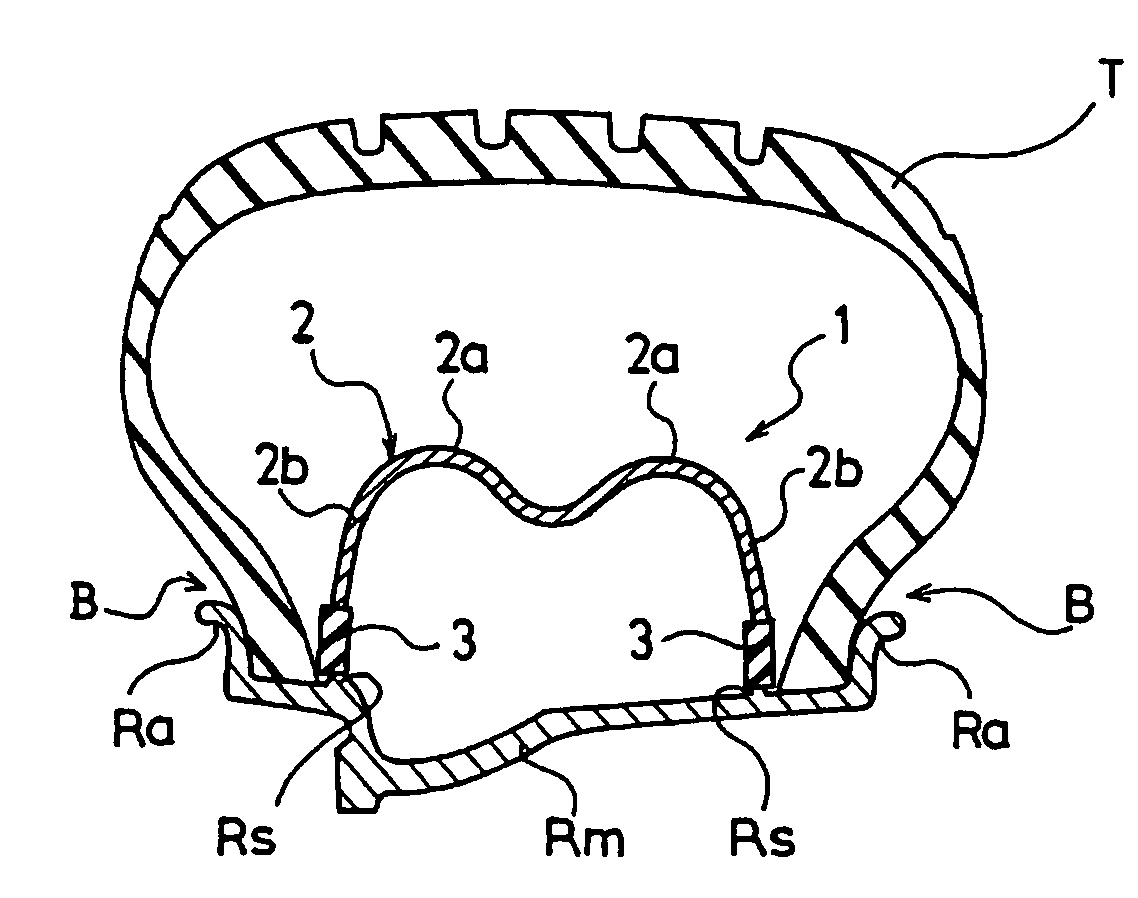

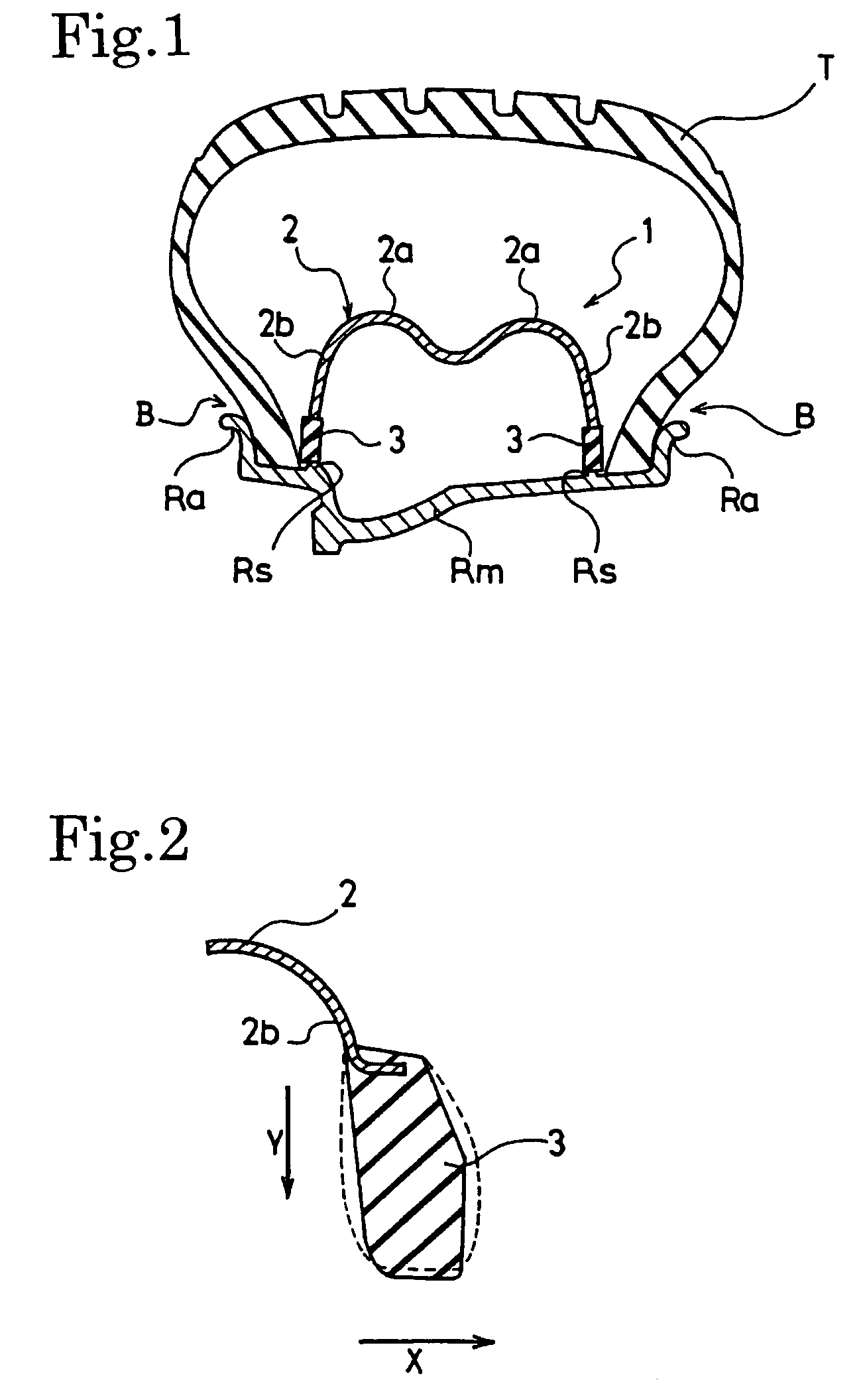

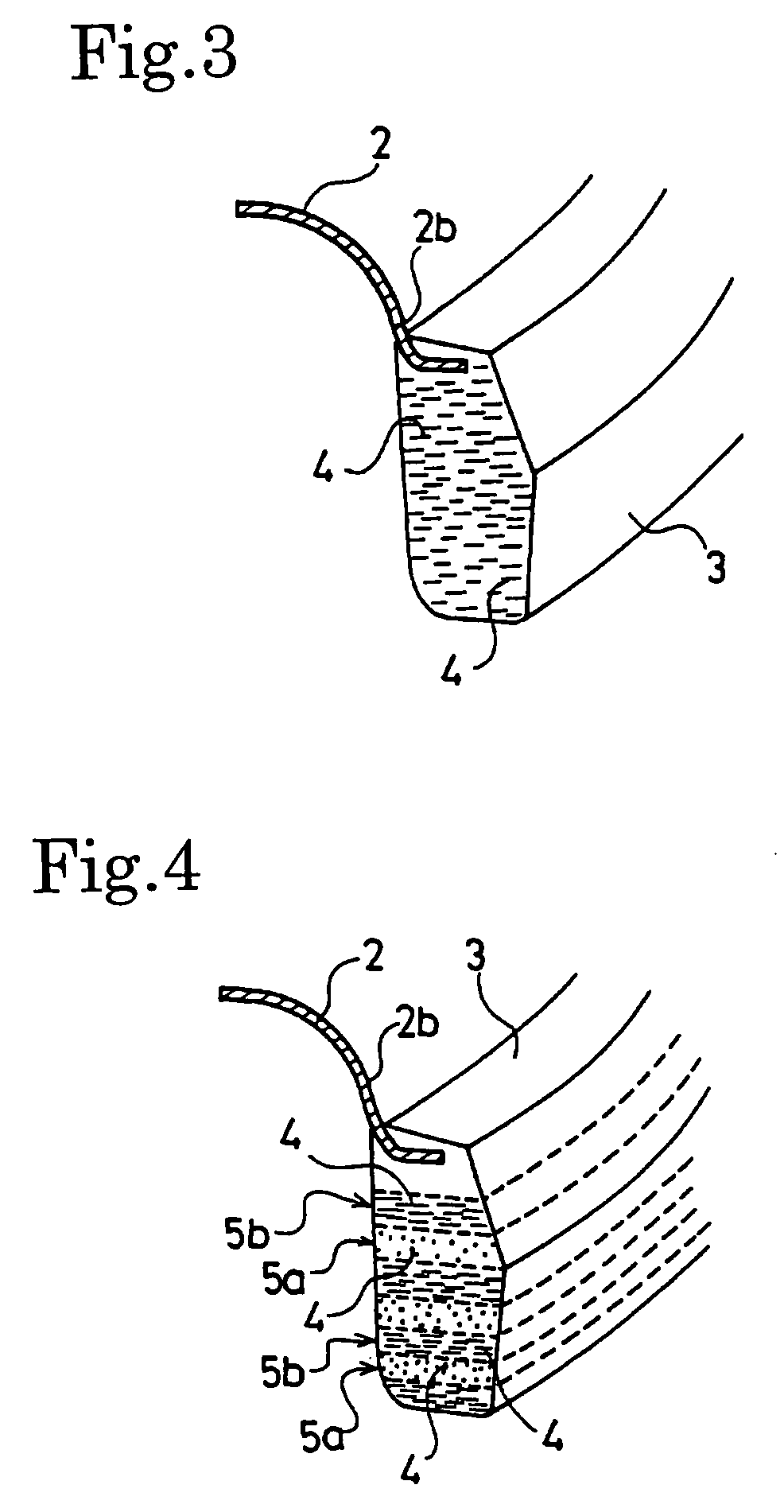

Pneumatic tire and method of producing the same

InactiveUS20040123930A1Improve compressive stiffnessReduce rigidityTyresPneumatic tyre reinforcementsEngineeringTread

A pneumatic tire comprises a spiral belt formed by spirally winding a cord(s) along a circumferential direction of a torus tread, wherein the spiral belt is comprised of at least one layer constructed with a combination of two different cords each having an initial tension of not less than 50 cN / cord.

Owner:BRIDGESTONE CORP

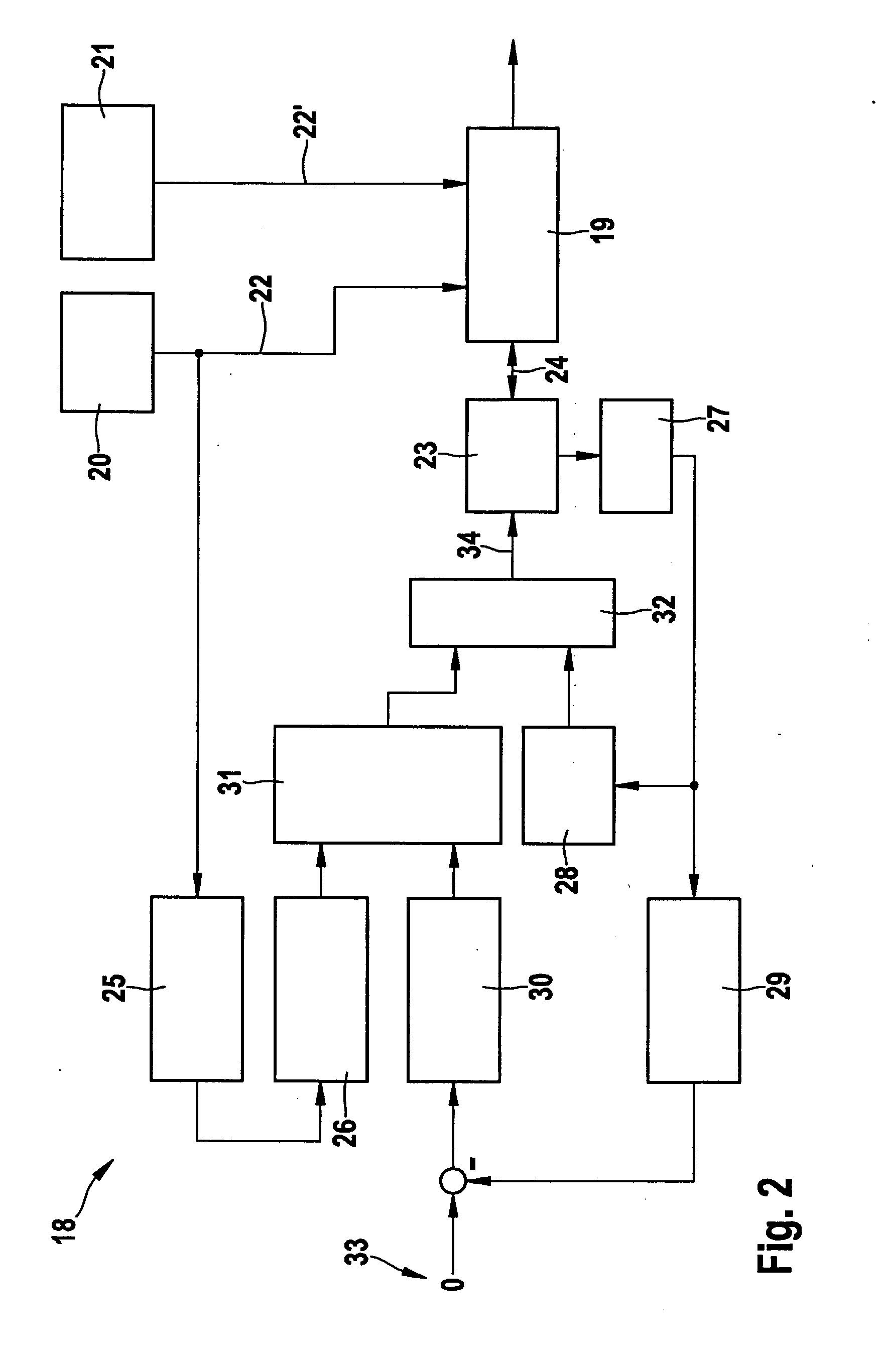

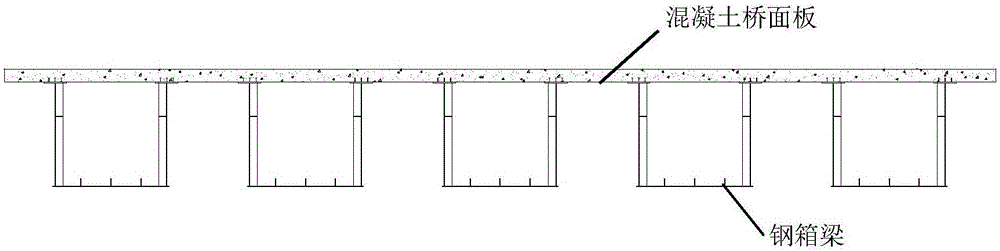

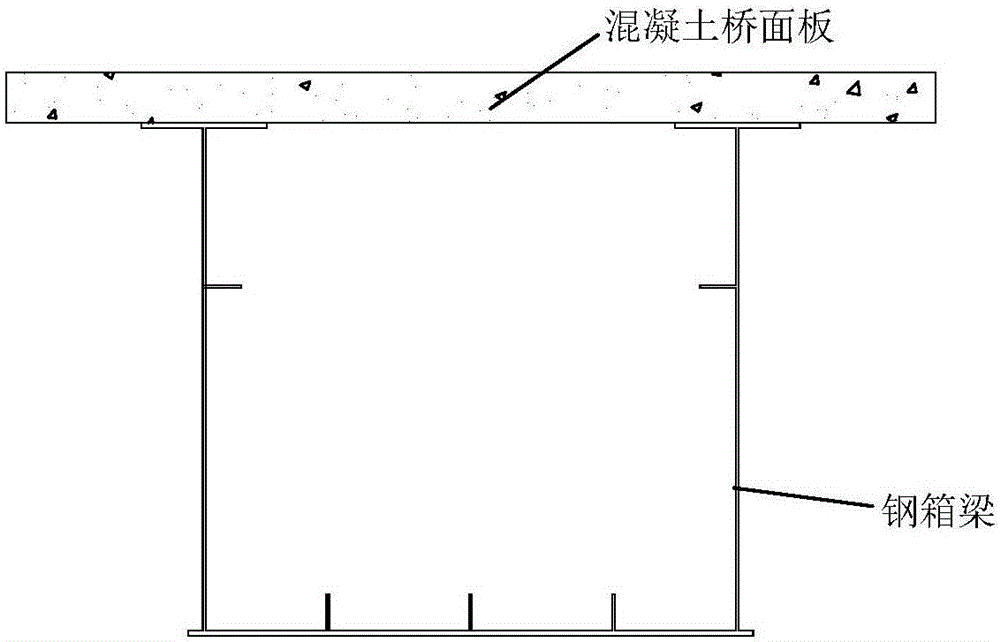

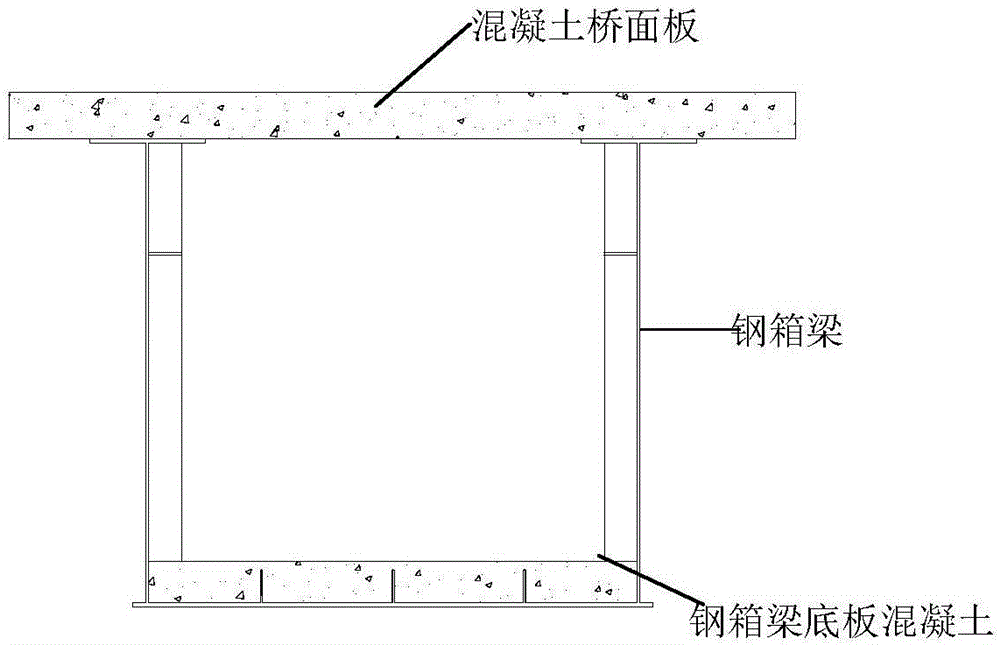

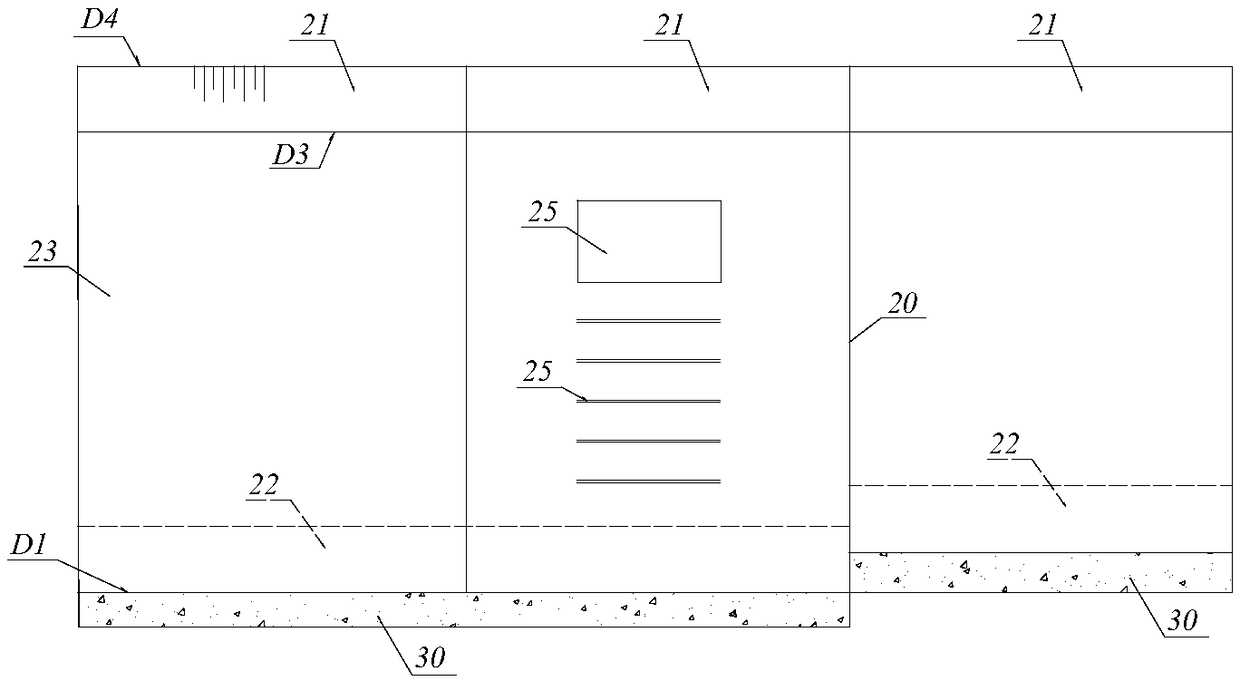

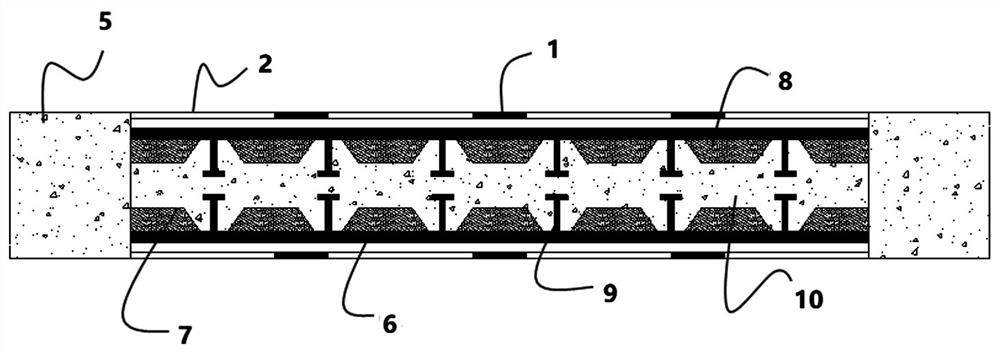

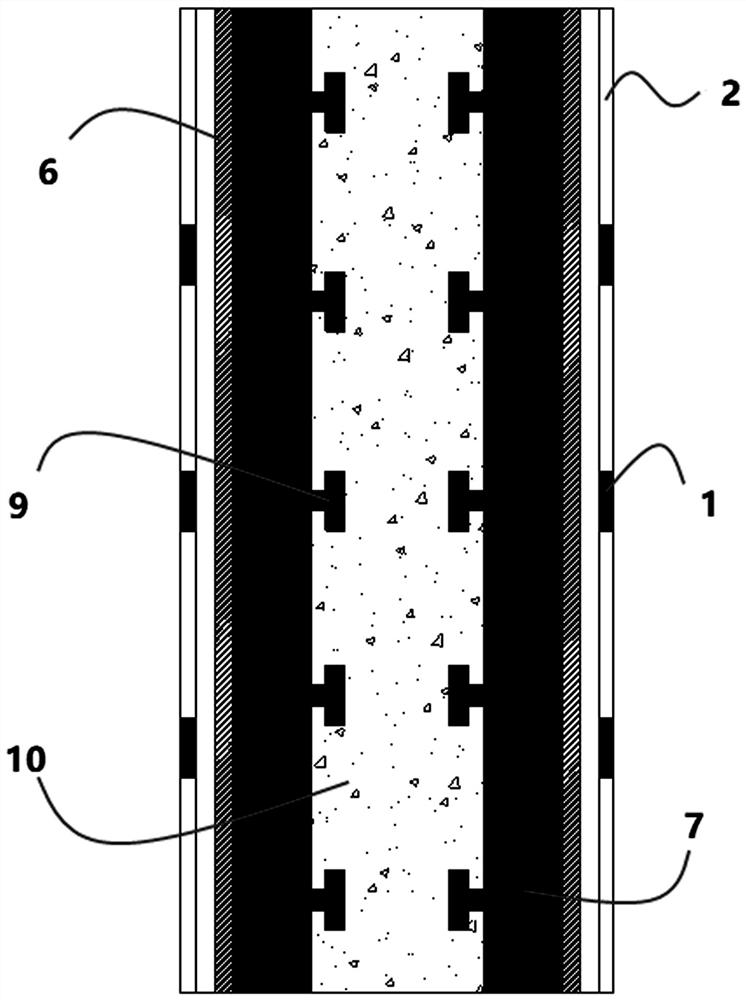

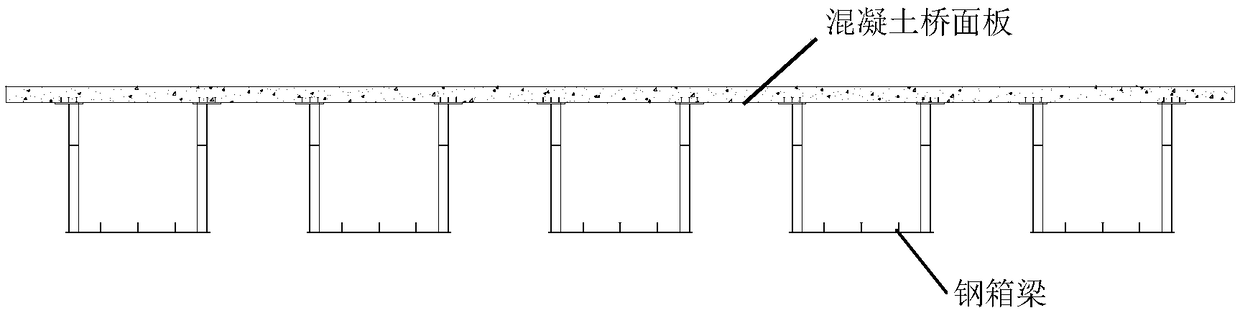

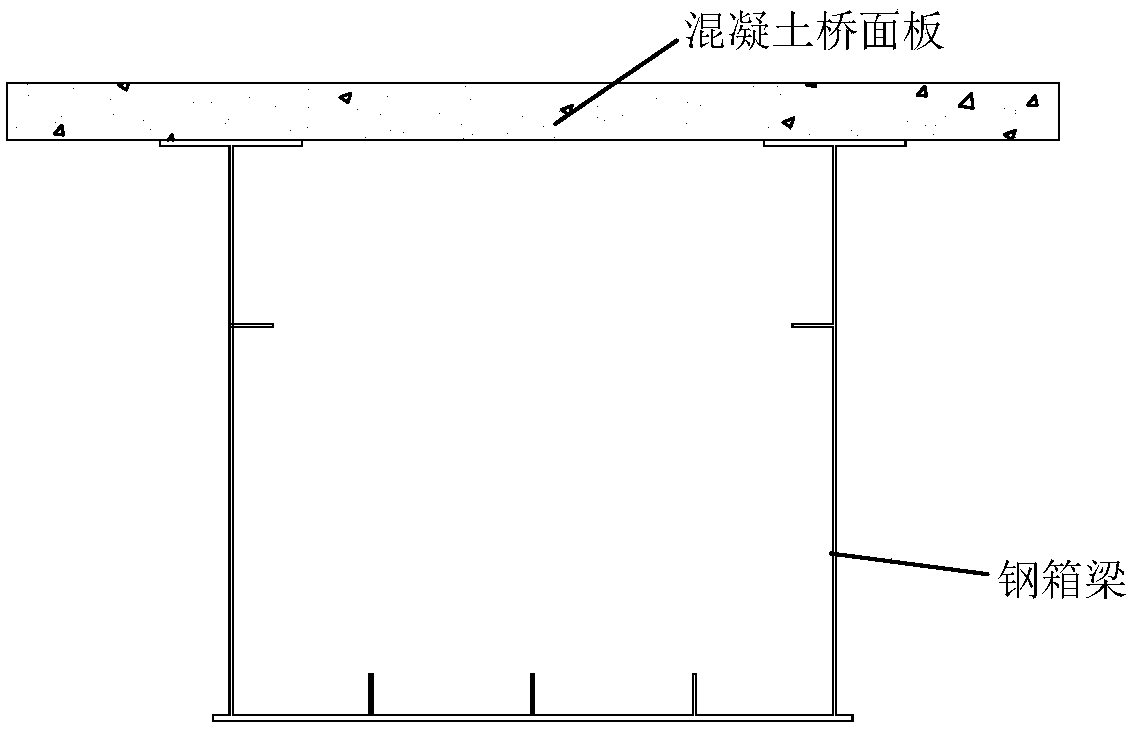

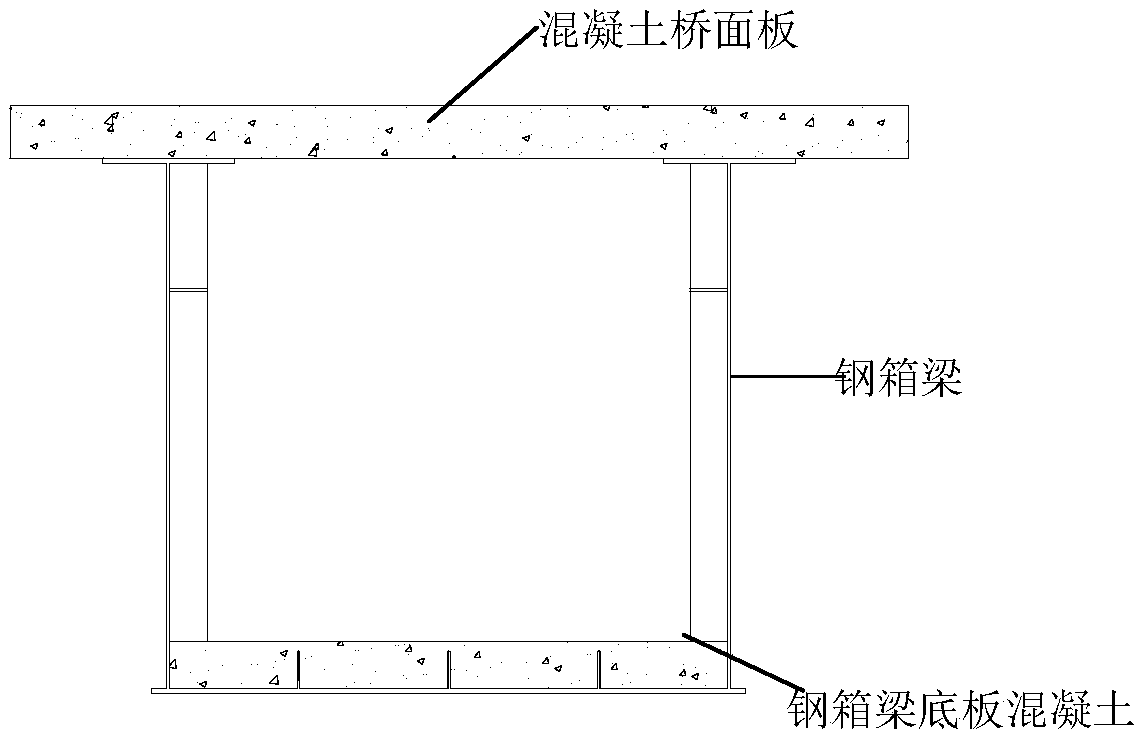

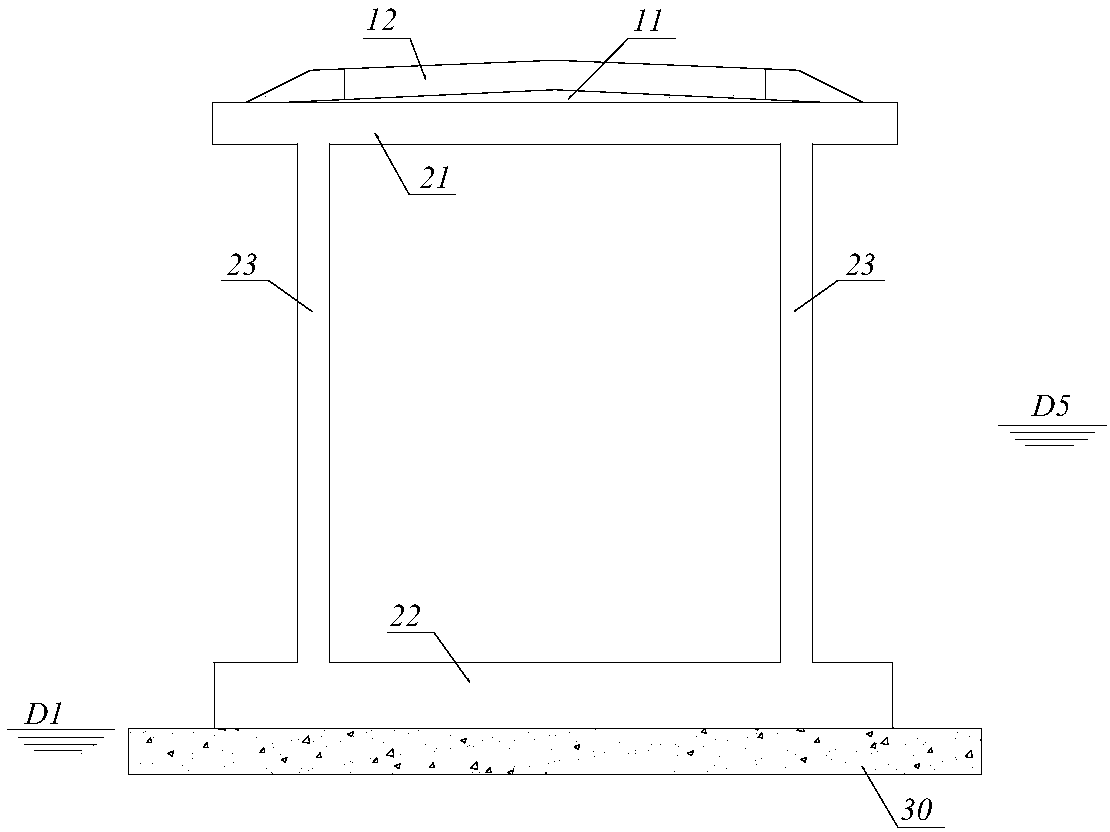

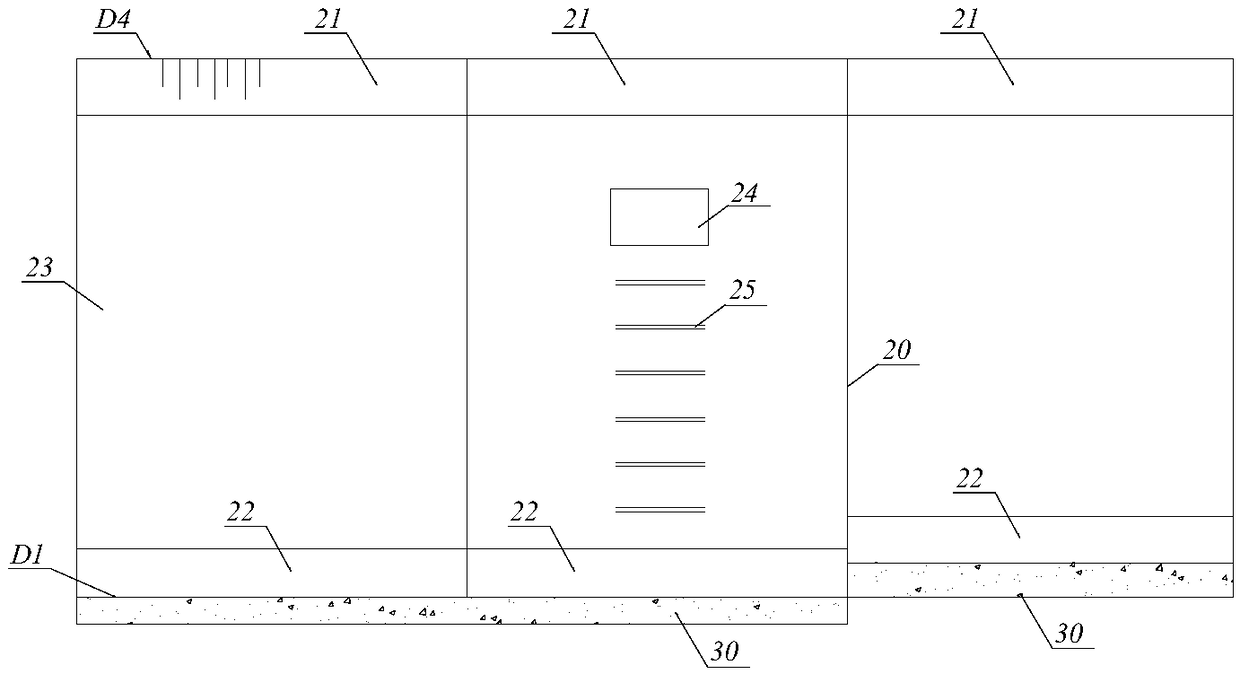

Method for improving stress performance of negative bending moment zone of steel-concrete combined multi-box continuous beam bridge

ActiveCN106758743AImprove compressive stiffnessImprove unfavorable stress situationsBridgesSpecial data processing applicationsStress conditionsContinuous beam

The invention discloses a method for improving stress performance of a negative bending moment zone ofa steel-concrete combined multi-box continuous beam bridge. The continuous girder bridge built by using the method comprises multiple horizontally connected separate small box beams. The upper portion of each small box beam is a concrete bridge surface plate. The lower portion is a steel box beam. The concrete bridge surface plate and the steel box beam are connected into an integral body by the shear force of the top flange of the steel box beam. Normal stress steel bars and constructional steel bars are arranged in the concrete bridge surface plates of the whole bridge. Normal horizontal and longitudinal stiffening ribs are arranged in the steel box beams. The longitudinal stress steel bars in the concrete bridge surface plates of the negative bending moment zone are intensified in density. After the steel box beams is erected, the surface plates are grouted and the preformed holes are prepared, concrete is grouted in the steel beam base plates of the negative bending moment zone through the holes, the concrete grade is identical to the concrete grade of the bridge surface plates. The method can increase the compression strength of the steel box beam base plate, improve the unfavorable stress condition that the steel box beam base plates in the negative bending moment zone is bent by pressure.

Owner:ZHEJIANG UNIV

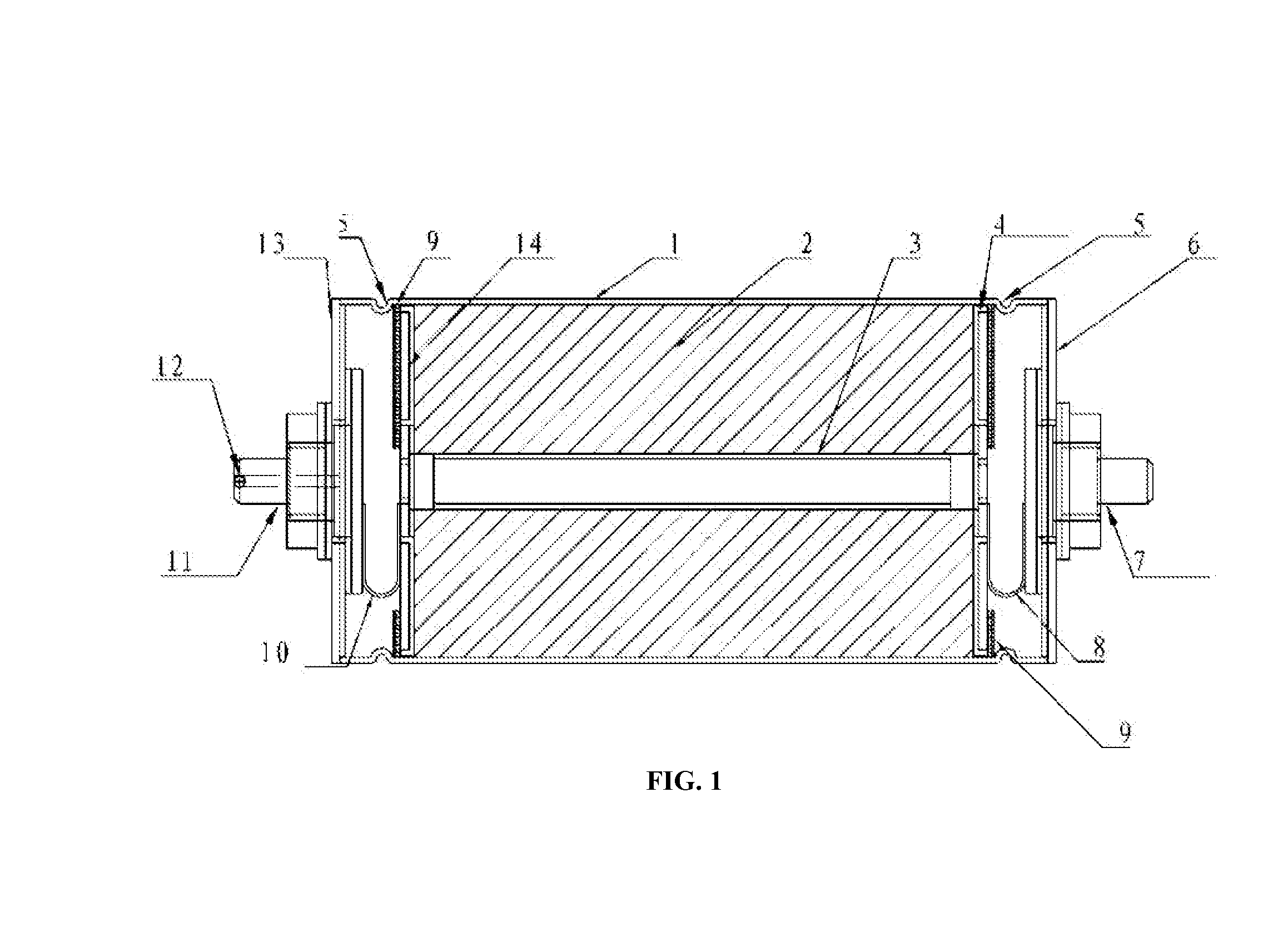

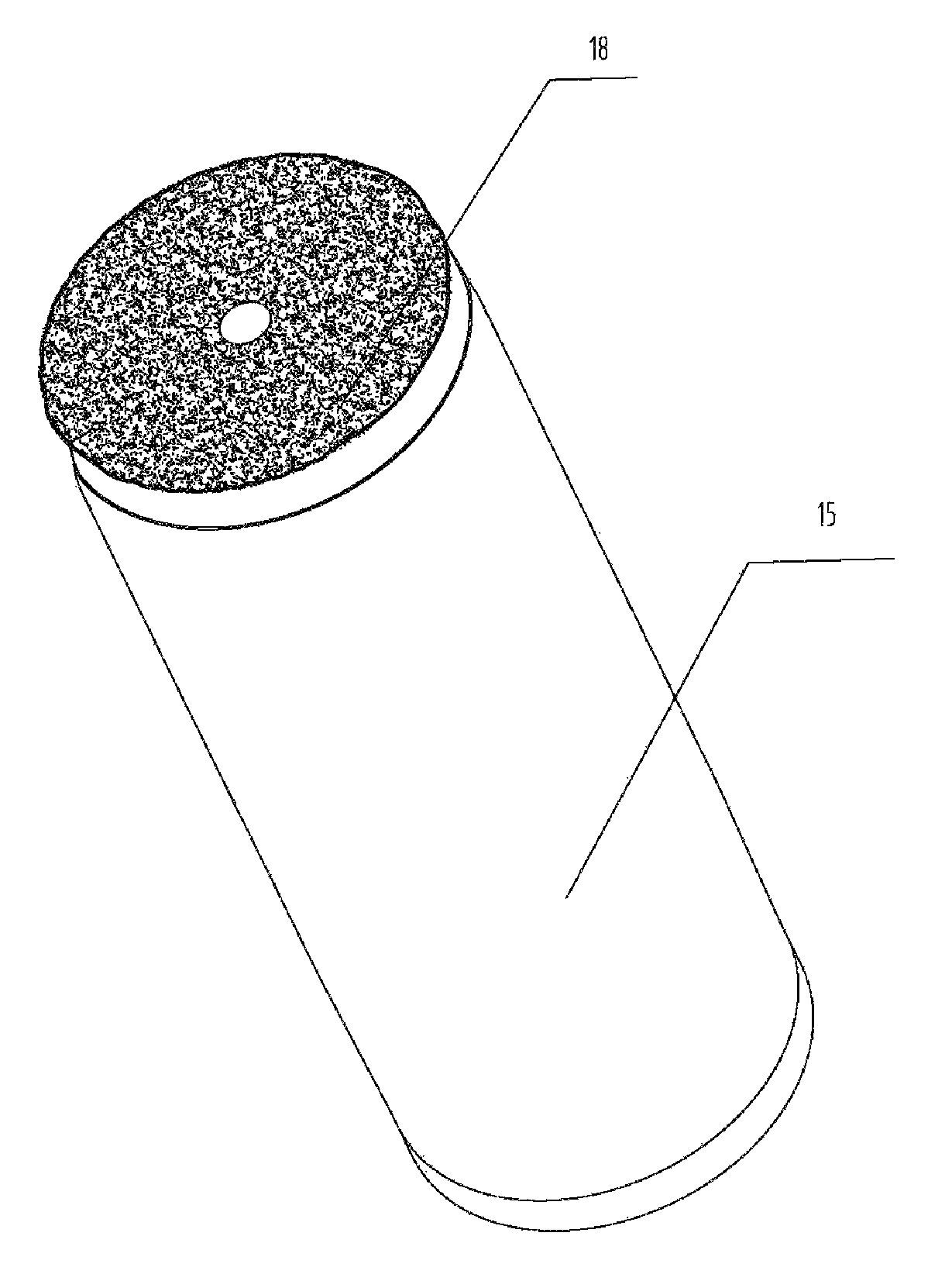

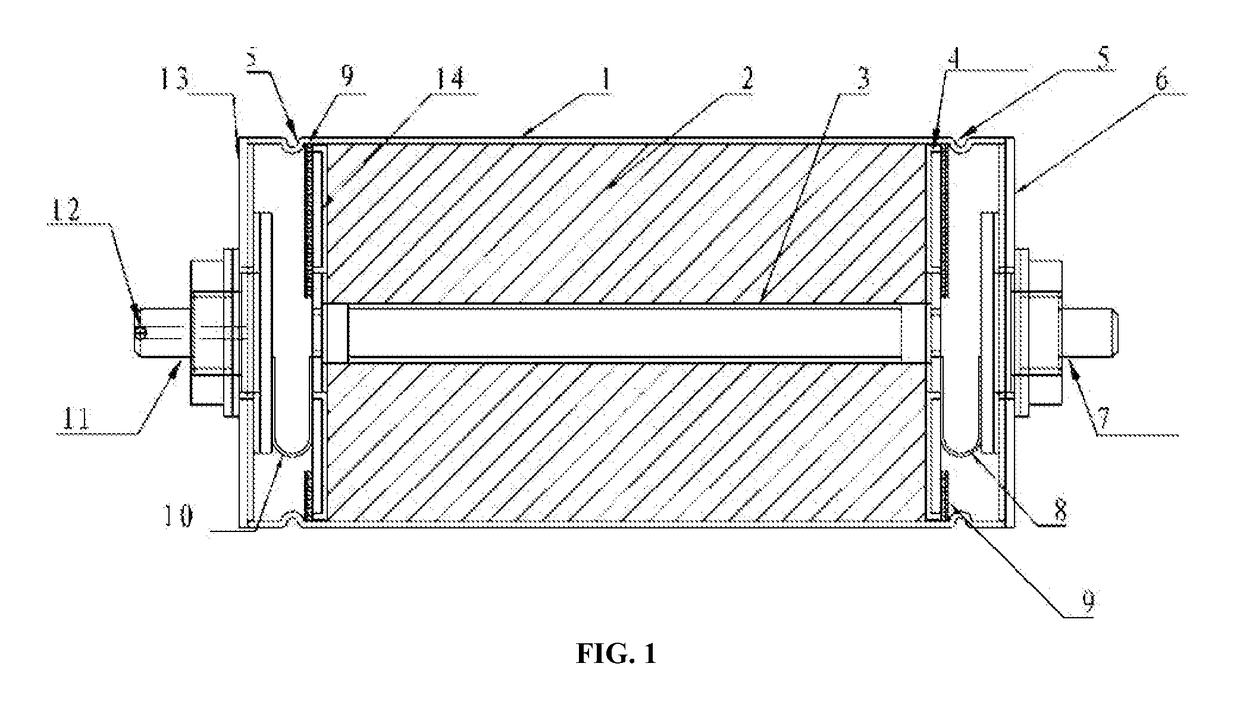

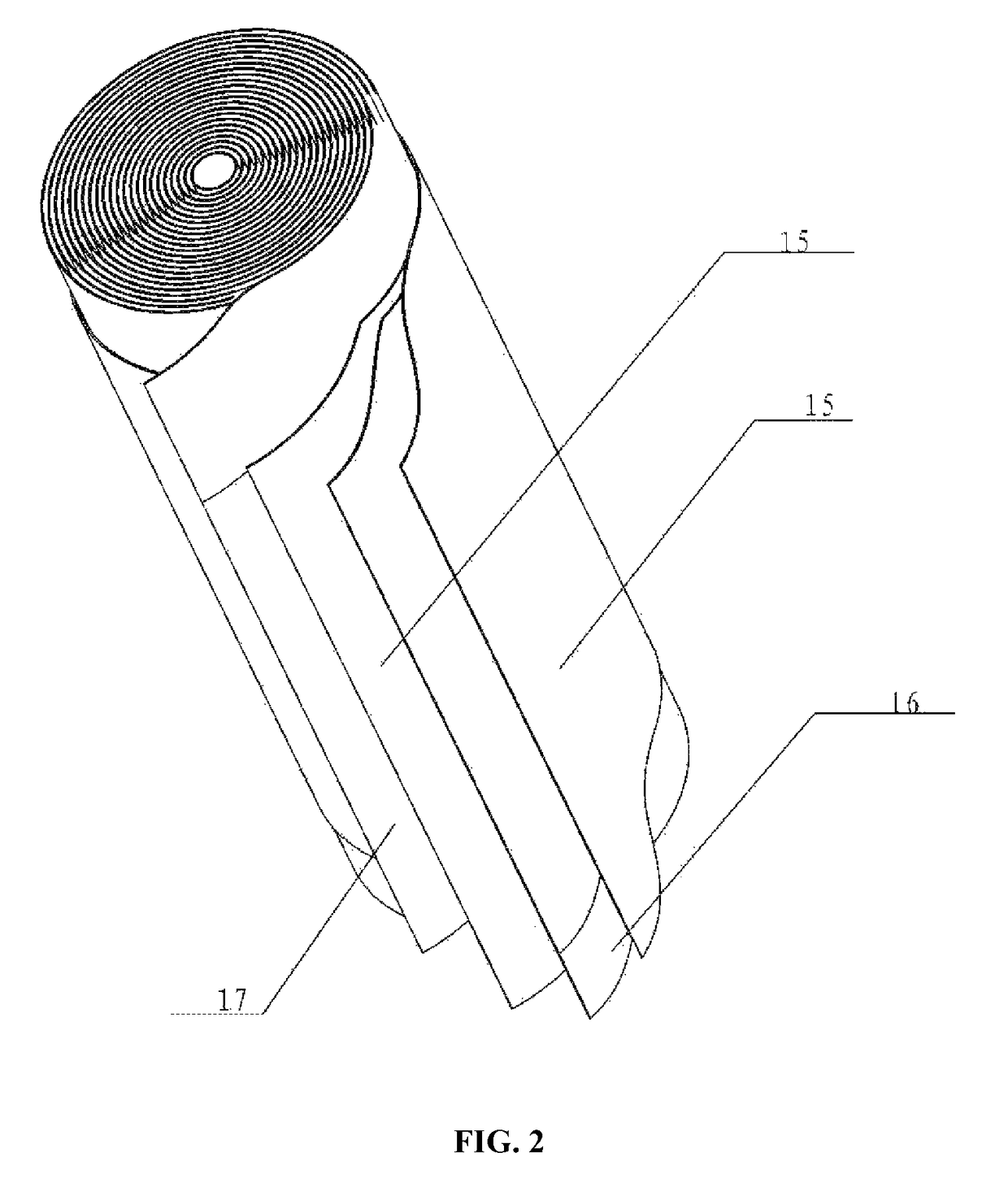

High-capacity Cylindrical Lithium Ion Battery and Production Method Thereof

InactiveUS20140087225A1High densityWeight increaseCell electrodesFinal product manufactureEngineeringWeld strength

The invention discloses a high-capacity cylindrical lithium ion battery. Tab-position end face is shaped; a high frequency oscillation and pressure are applied on to make the foil bodies softened in the scope of 0.1-6.5 mm. At the instant of high-frequency oscillation, the rigidity of the foil body is greatly decreased; and the foil bodies are mutually wound and compressed together, so that the weight density of the foil body in unit volume is increased and meanwhile, the rigidity of the compressed foil body at the Tab-position end face is greatly increased, thereby laying a firm foundation for laser welding of the 1 Tab-position end face and a current collector, increasing a laser welding effective area of the Tab-position end face and the current collector, and improving the welding strength.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

Pneumatic tire and method of producing the same

InactiveUS20020050314A1Improve compressive stiffnessReduce rigidityTyresMotorcycle tyresEngineeringHelix

A pneumatic tire comprises a spiral belt formed by spirally winding a cord(s) along a circumferential direction of a torus tread, wherein the spiral belt is comprised of at least one layer constructed with a combination of two different cords each having an initial tension of not less than 50 cN / cord.

Owner:BRIDGESTONE CORP

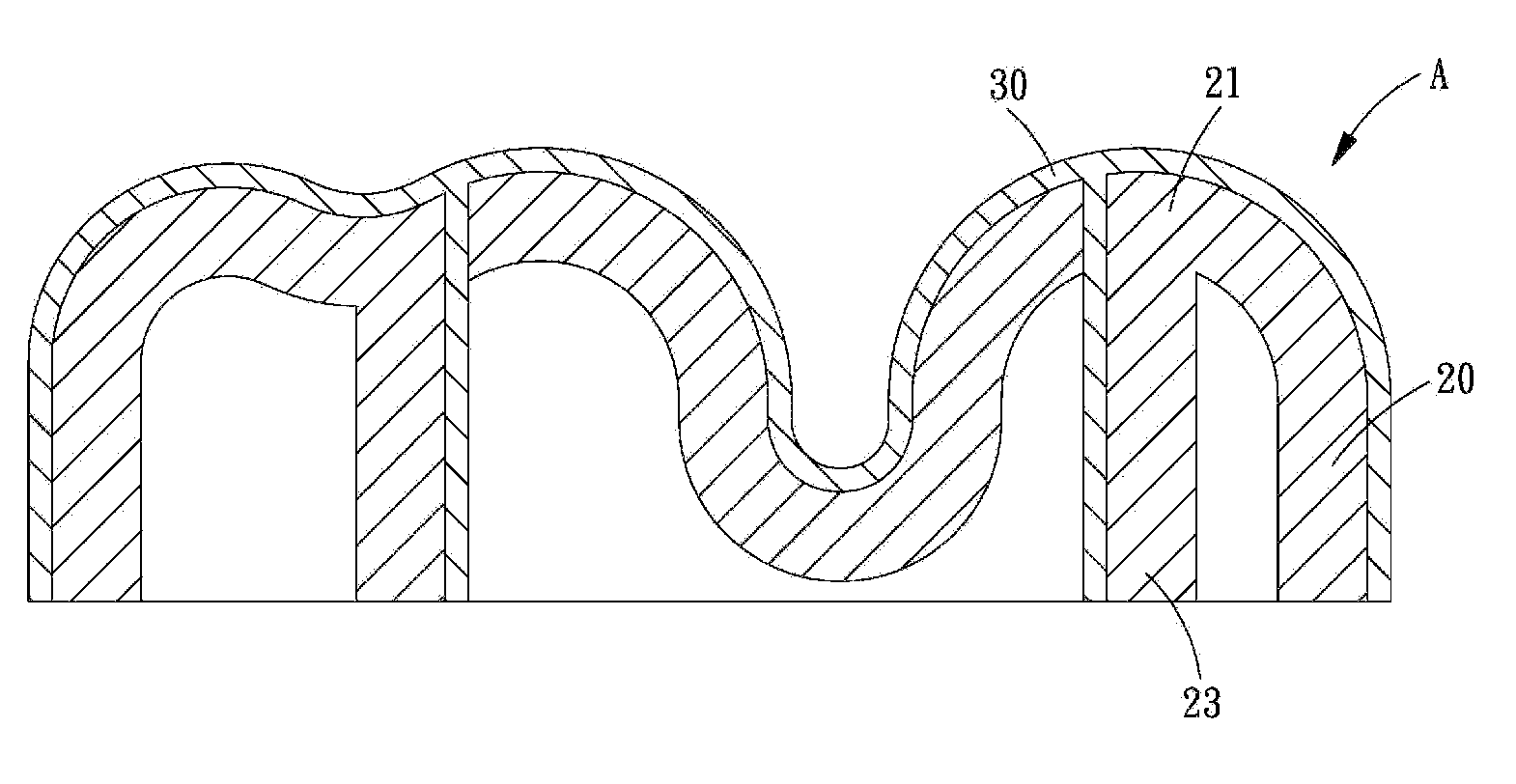

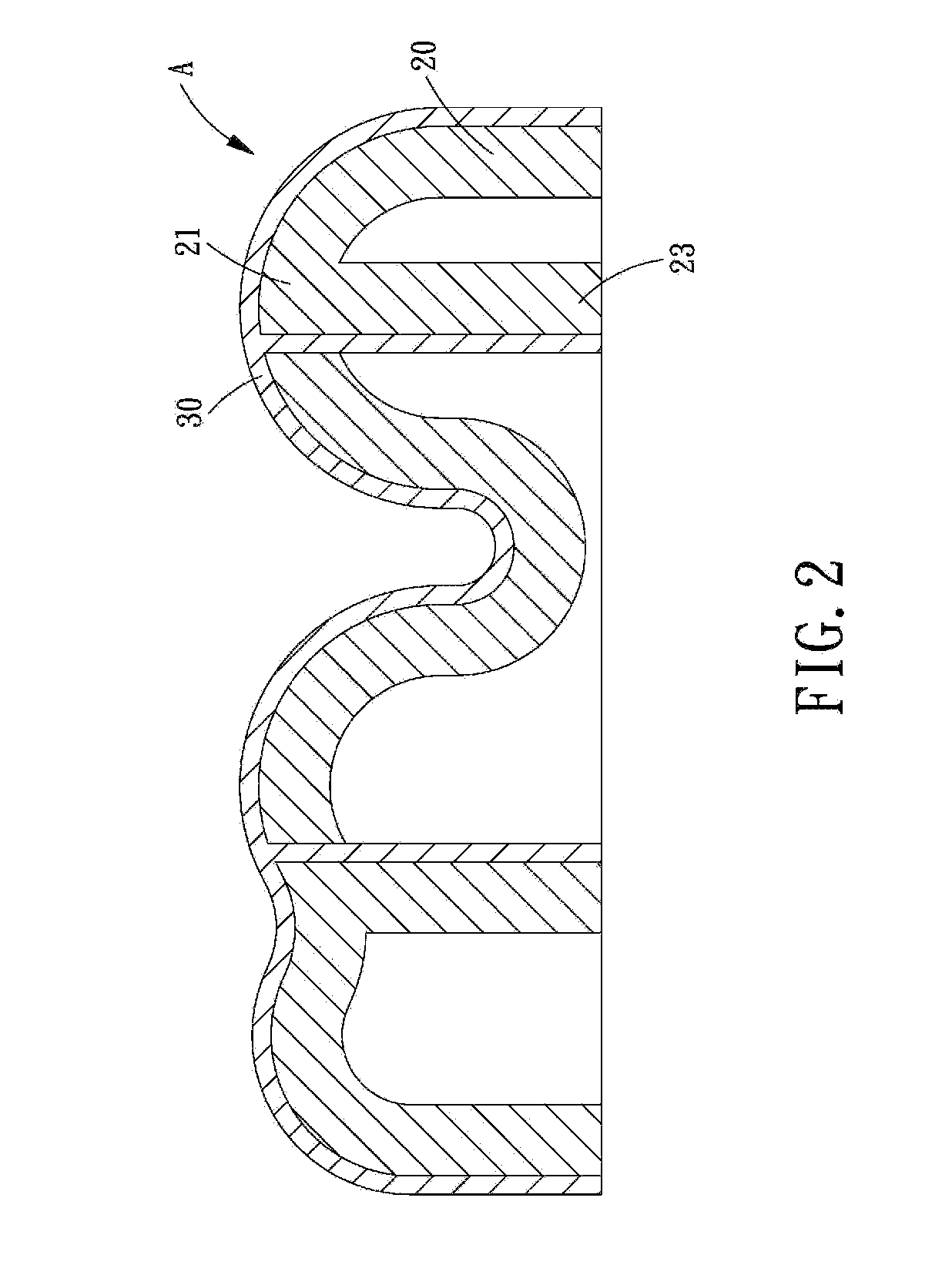

Elastic Deformable Cushion

InactiveUS20090297783A1Improve compressive stiffnessImprove buffering effectSolesLayered productsEngineeringCushion

An elastic deformable cushion comprises: an elastoplastic curved piece made of elastoplastic material, and at least two elastoplastic ribs. At least two grooves are formed in an outer surface of the elastoplastic curved piece, and the grooves are separated from and not in communication with and one another. In an inner surface of the elastoplastic curved piece is formed a groove opening in an opposite direction to and located between the at least two grooves in the outer surface of the elastoplastic curved piece. The at least two elastoplastic ribs are formed in the at least two grooves in the outer surface of the elastoplastic curved piece, the elastoplastic ribs are integral with the elastoplastic curved piece, and each of the two elastoplastic ribs have a curved portion.

Owner:YANG TENG JEN

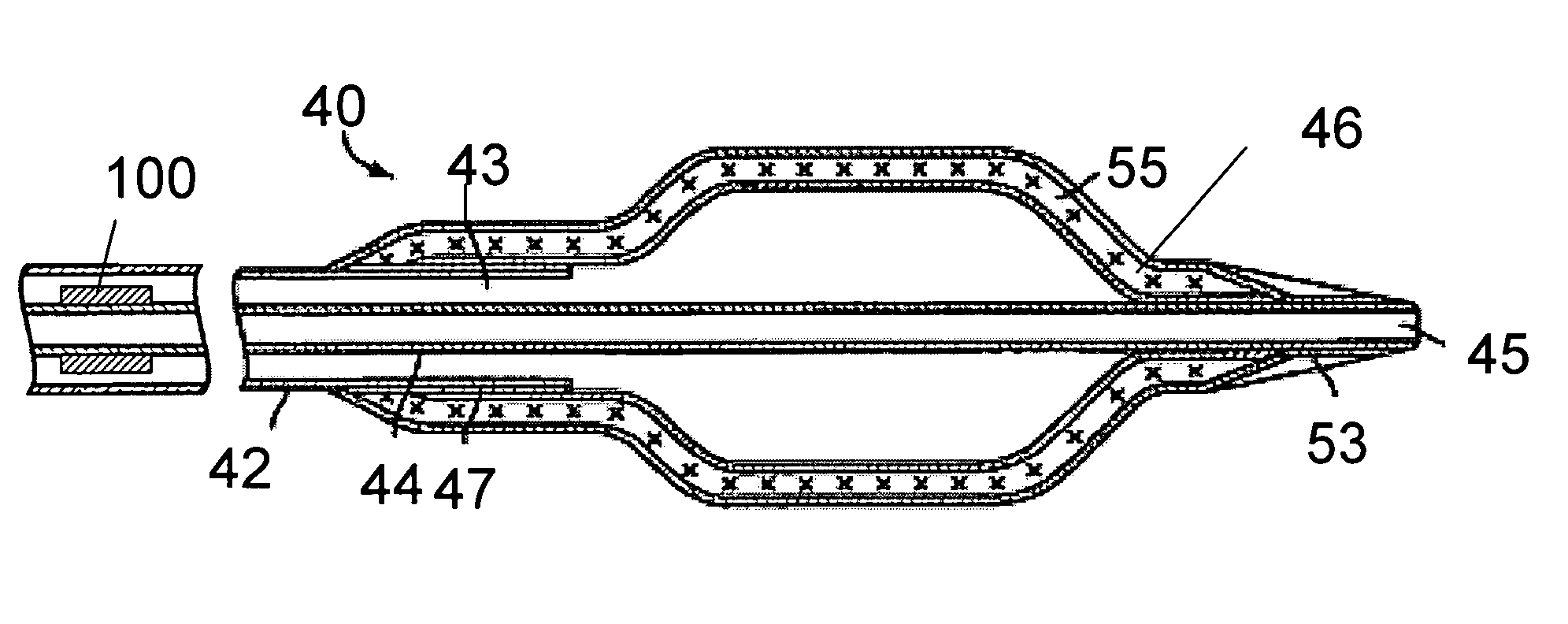

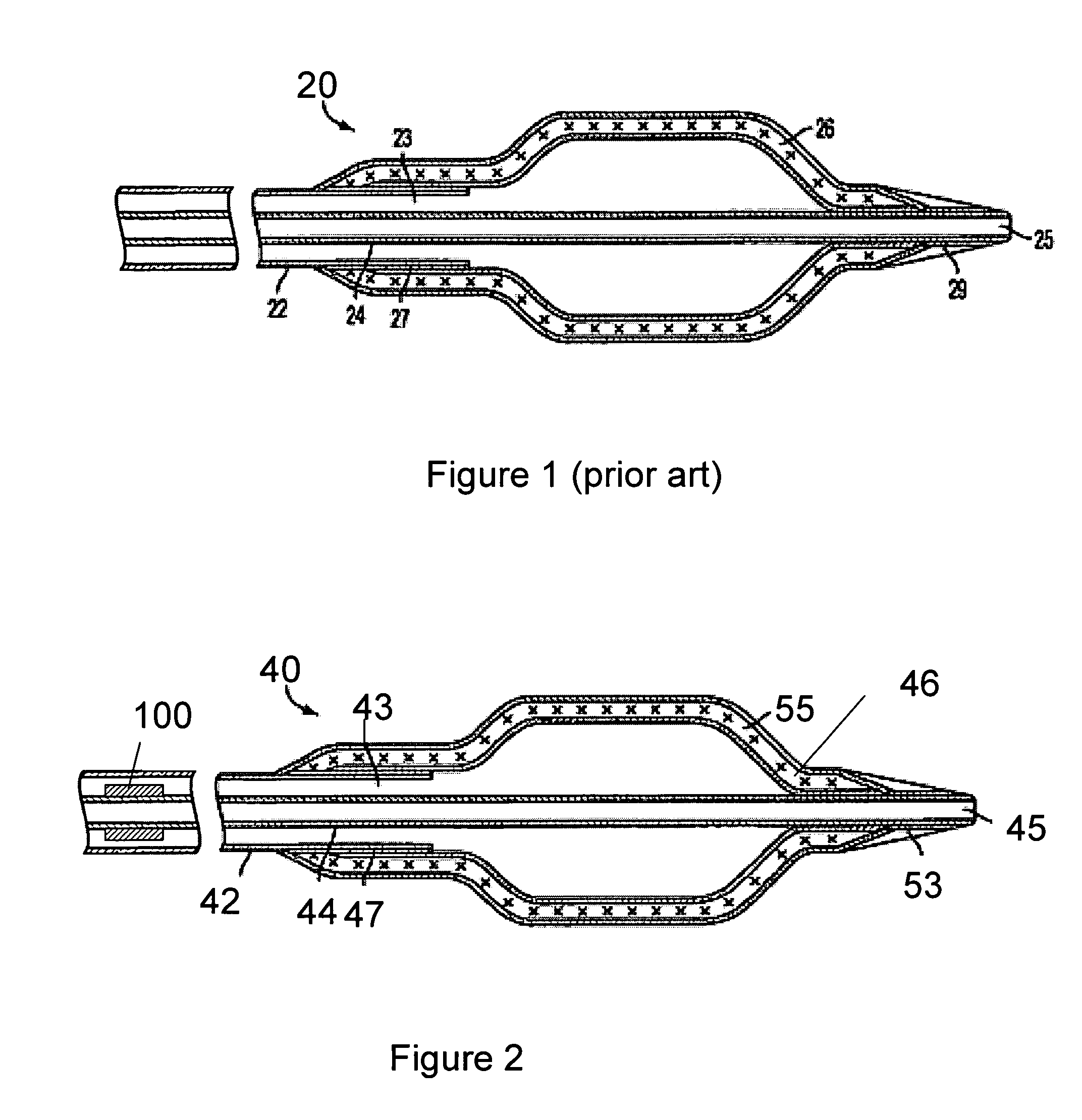

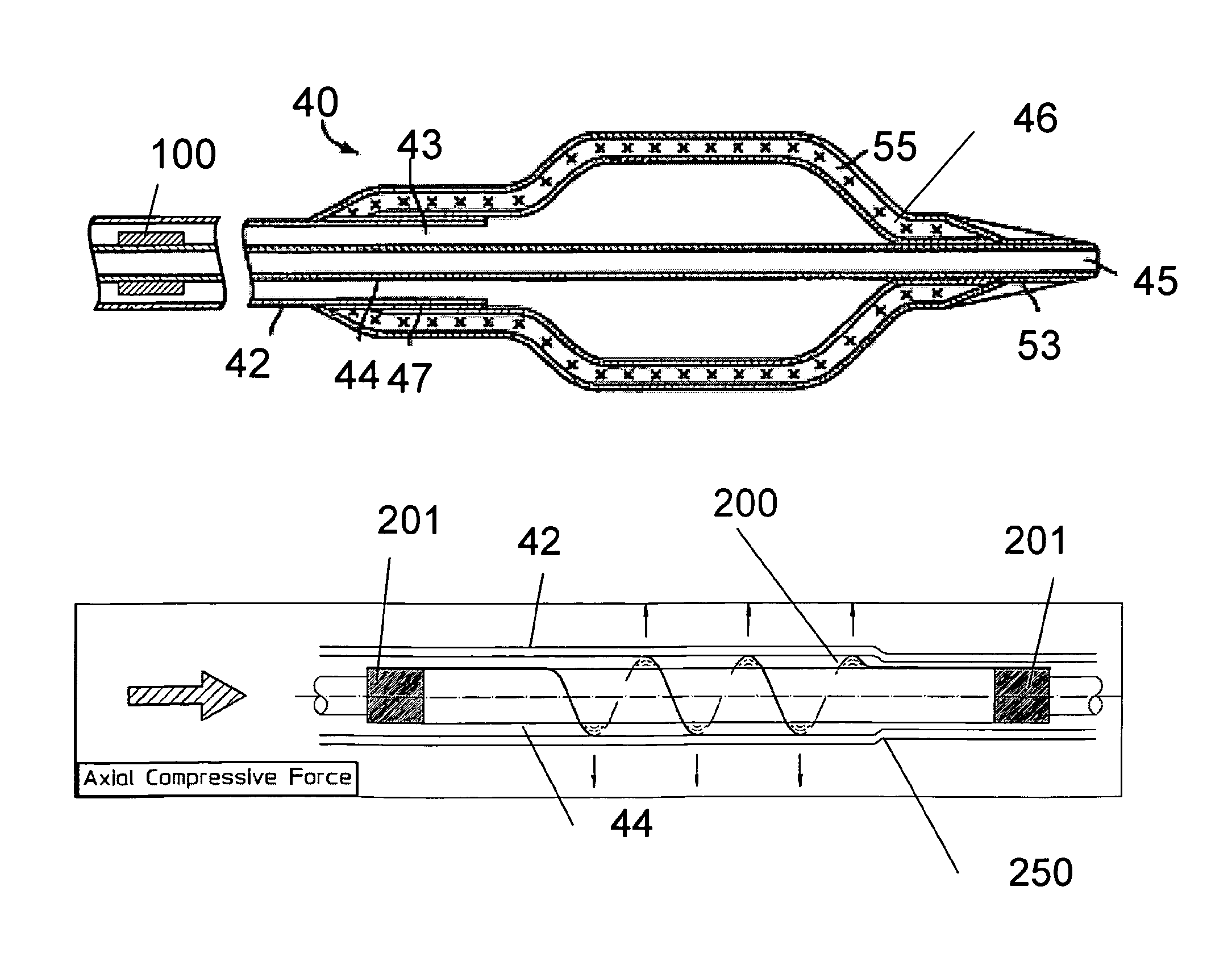

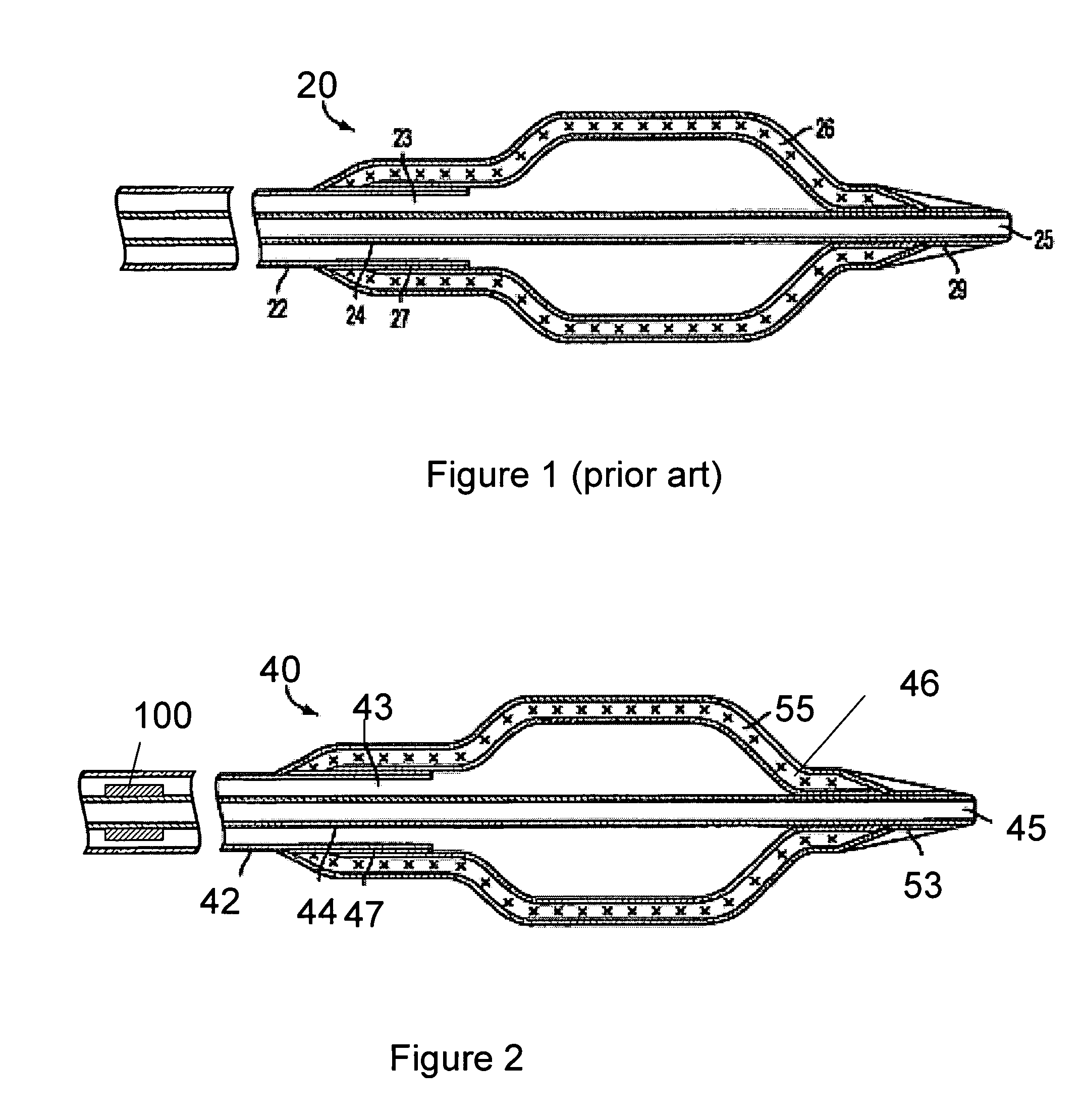

Catheter with enhanced pushability

InactiveUS20120316585A1Increase thrustImprove pushabilityStentsCannulasBalloon catheterLinkage concept

Apparatus for enhancing pushability and minimizing kinking of a balloon catheter is provided, wherein a catheter comprises inner and outer tubes, and a balloon that is proximally affixed to the outer tube and distally affixed to the inner tube. The catheter of the present invention further comprises a tubular member imposed on the inner tube which is configured to form a reversible mechanical linkage between inner tube and outer tube while an axially compressive load is applied to the catheter tip.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

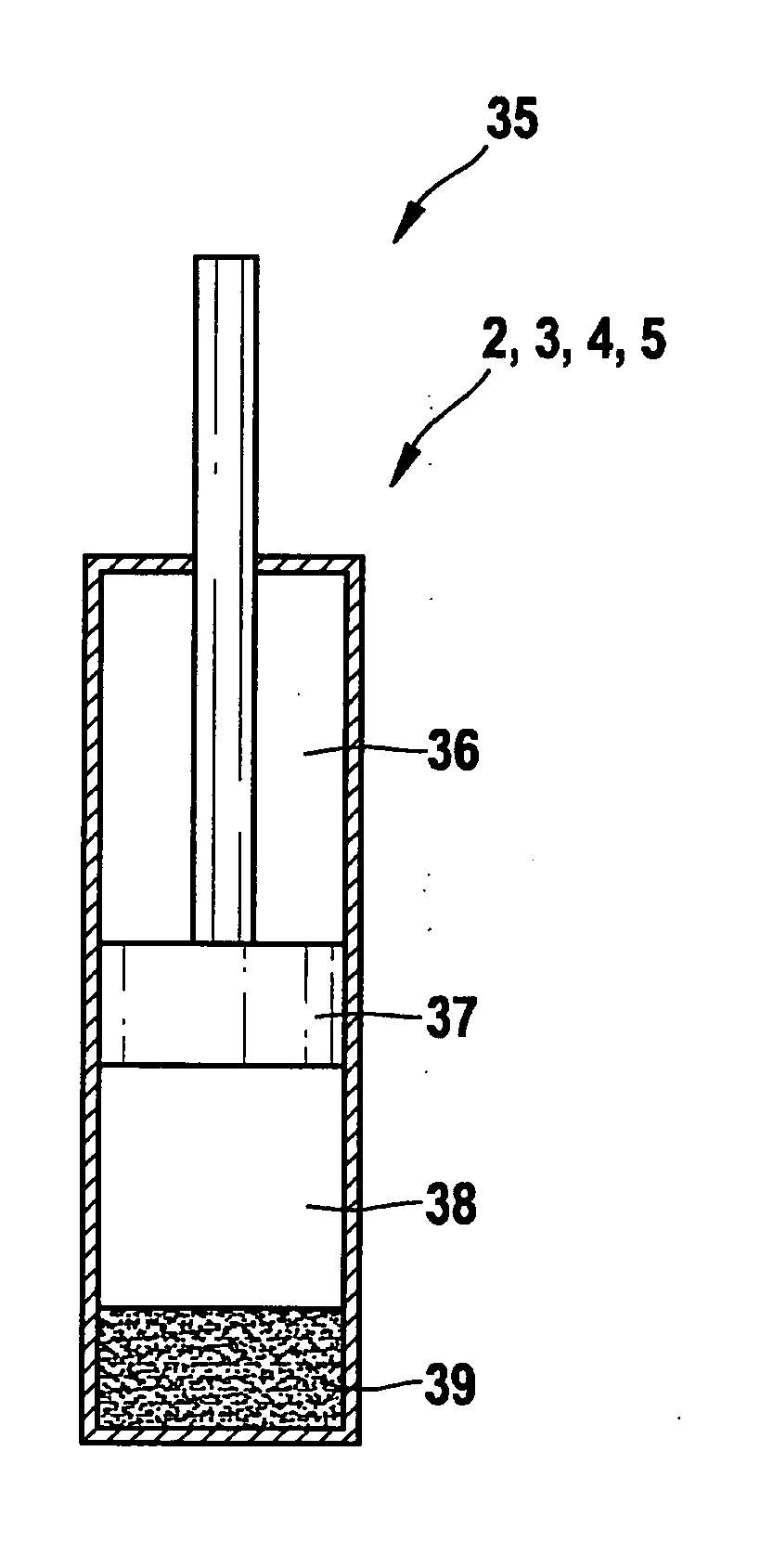

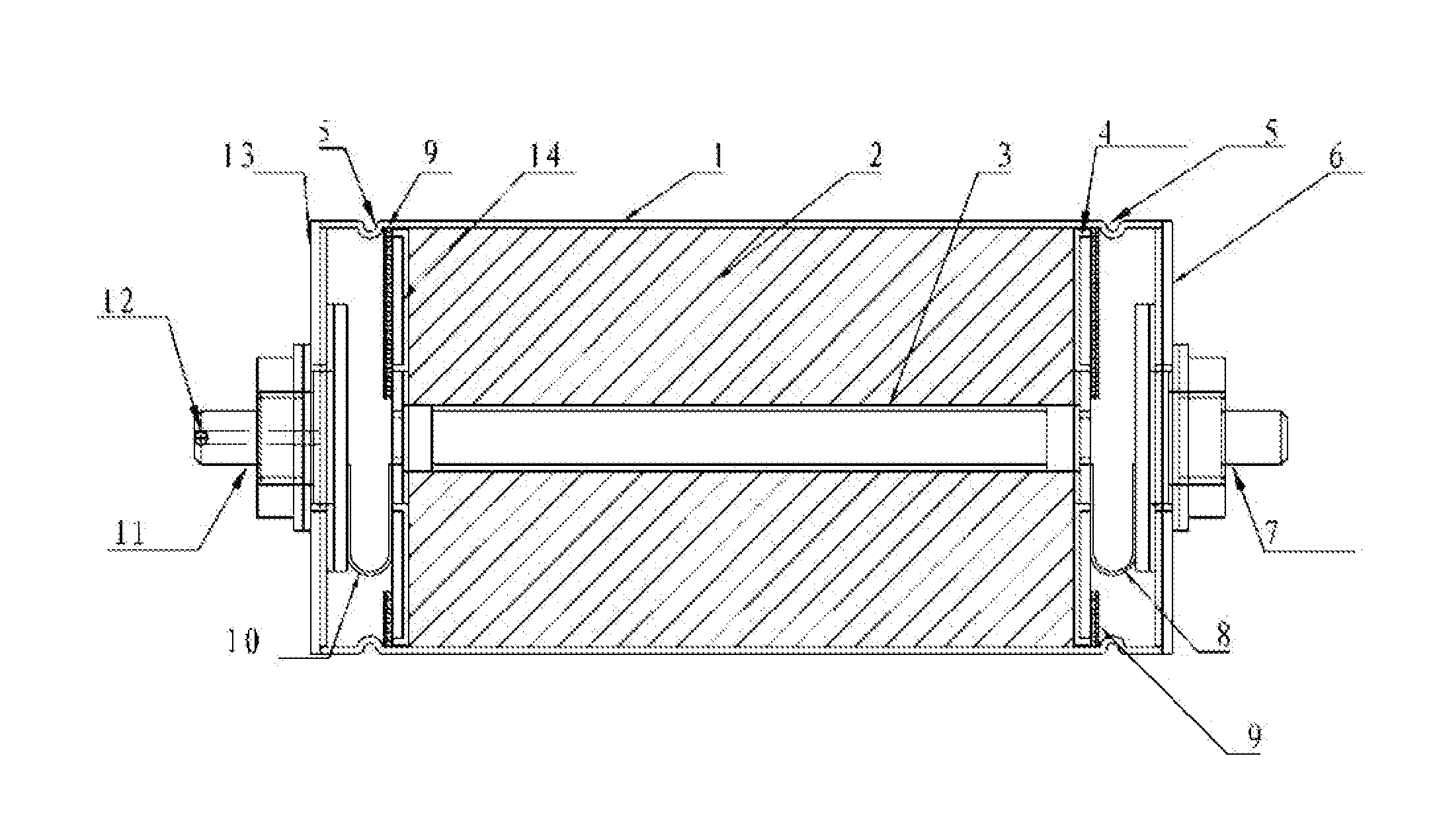

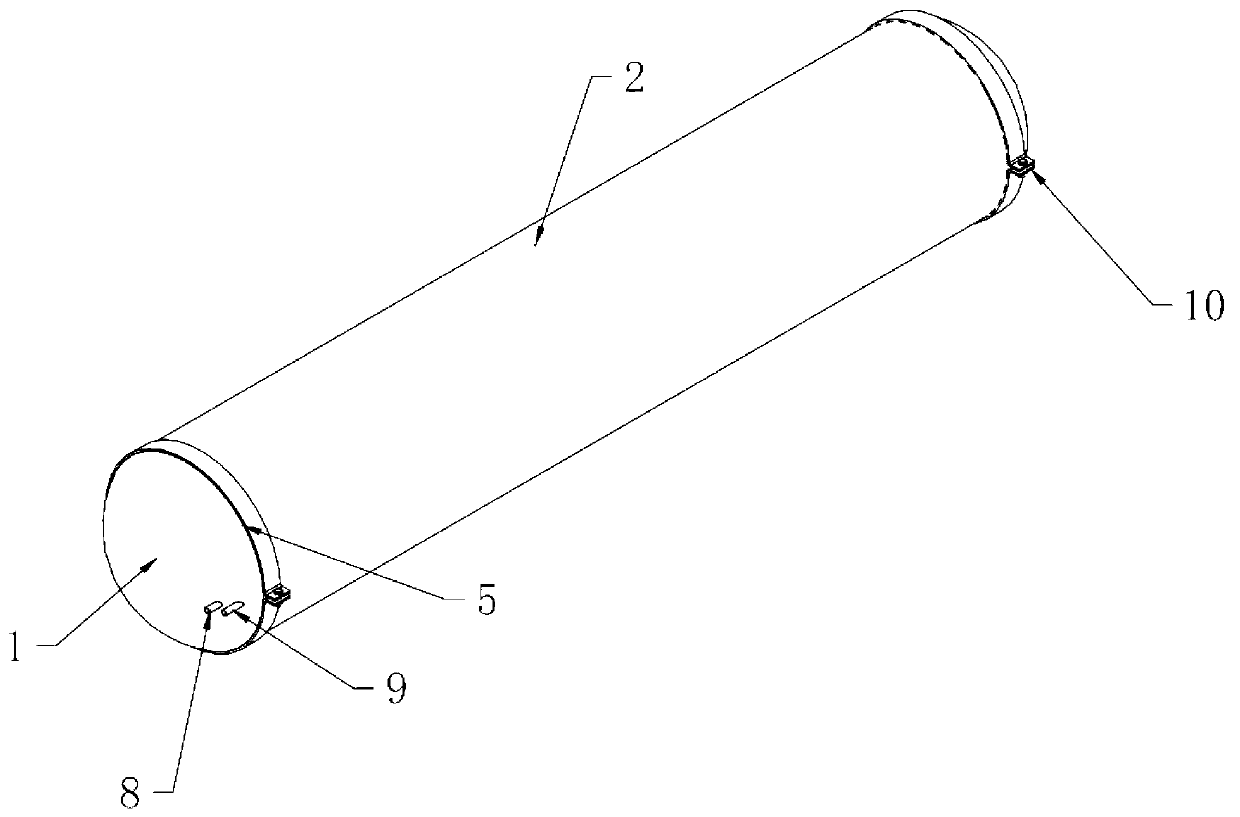

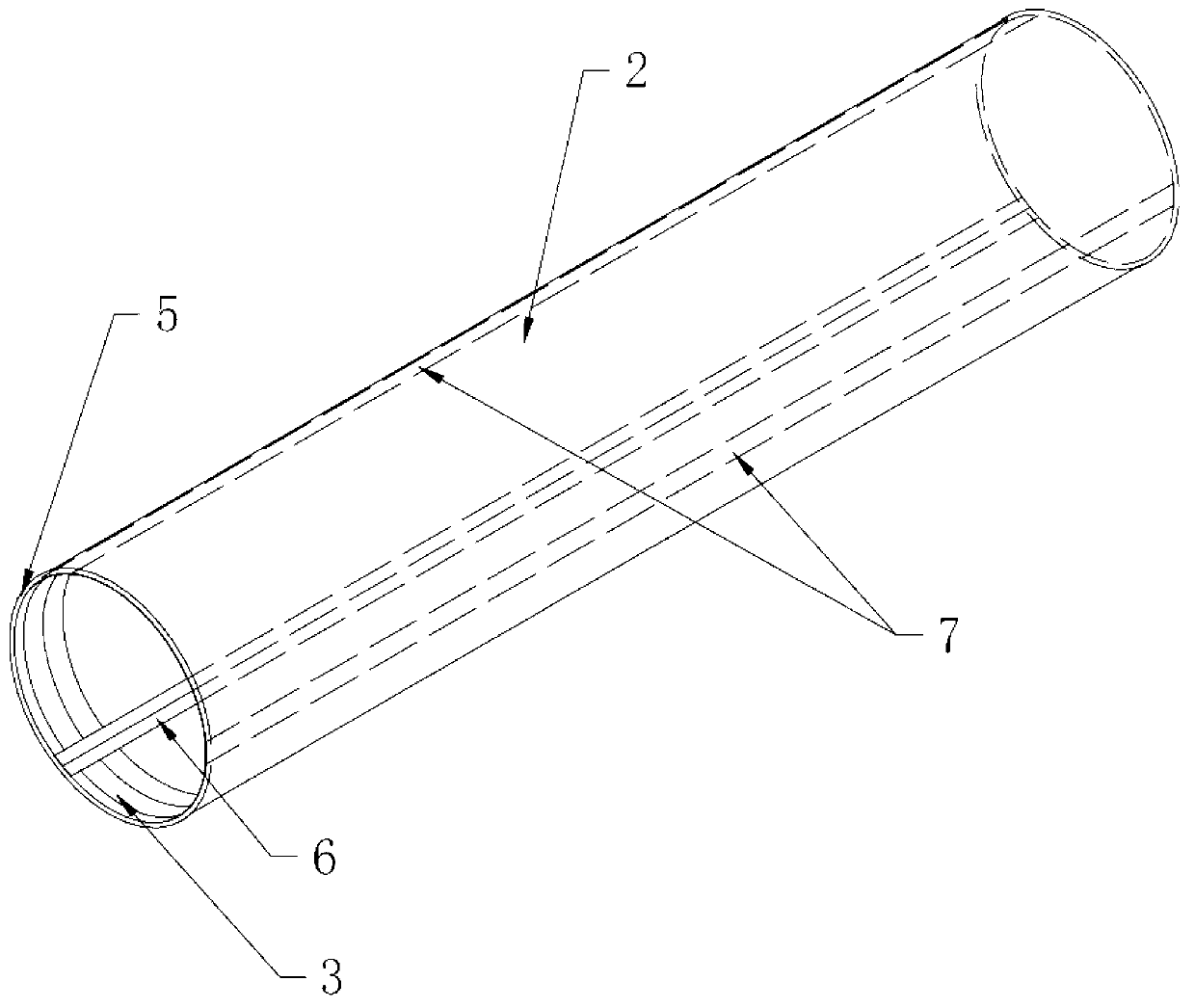

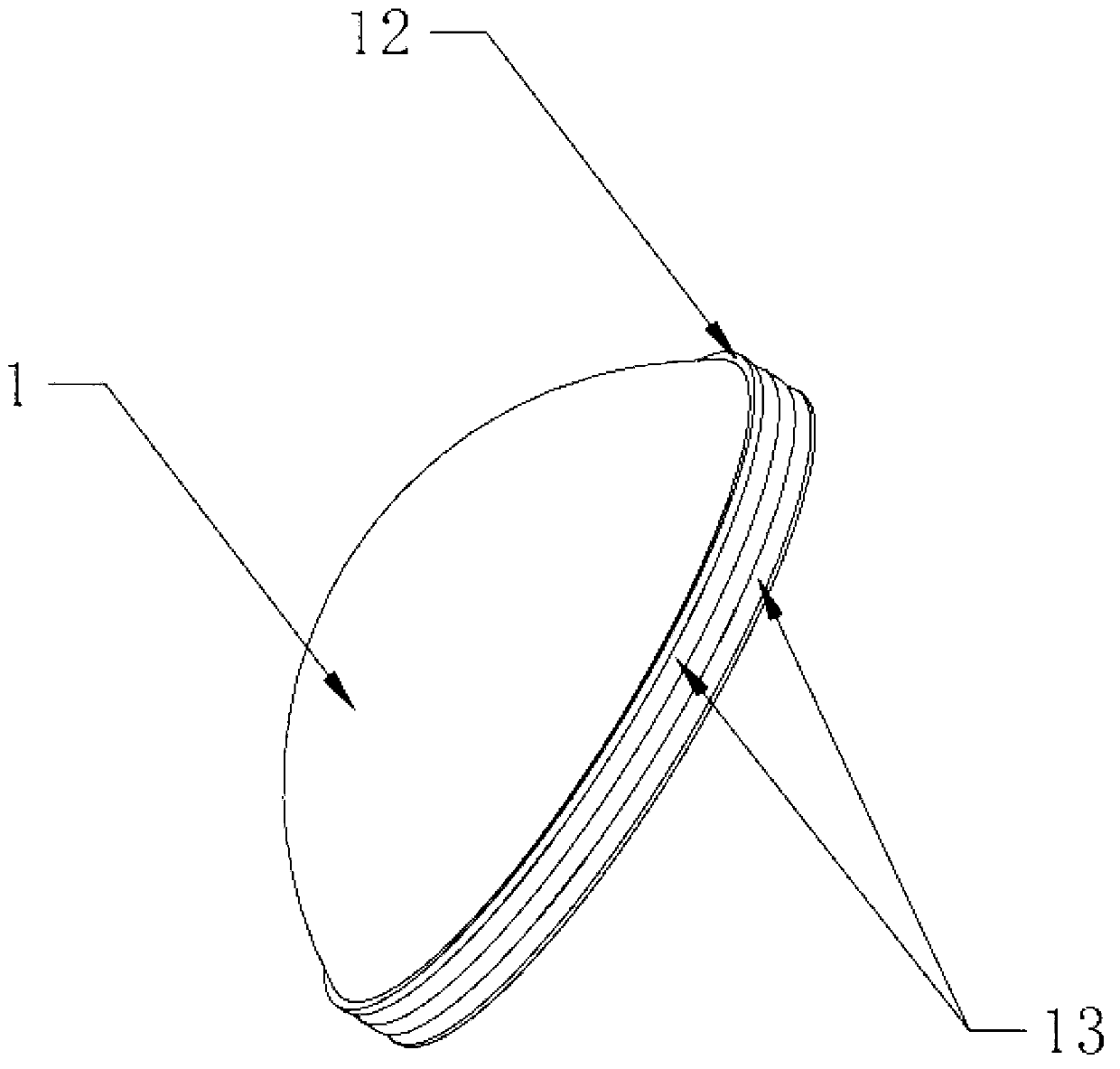

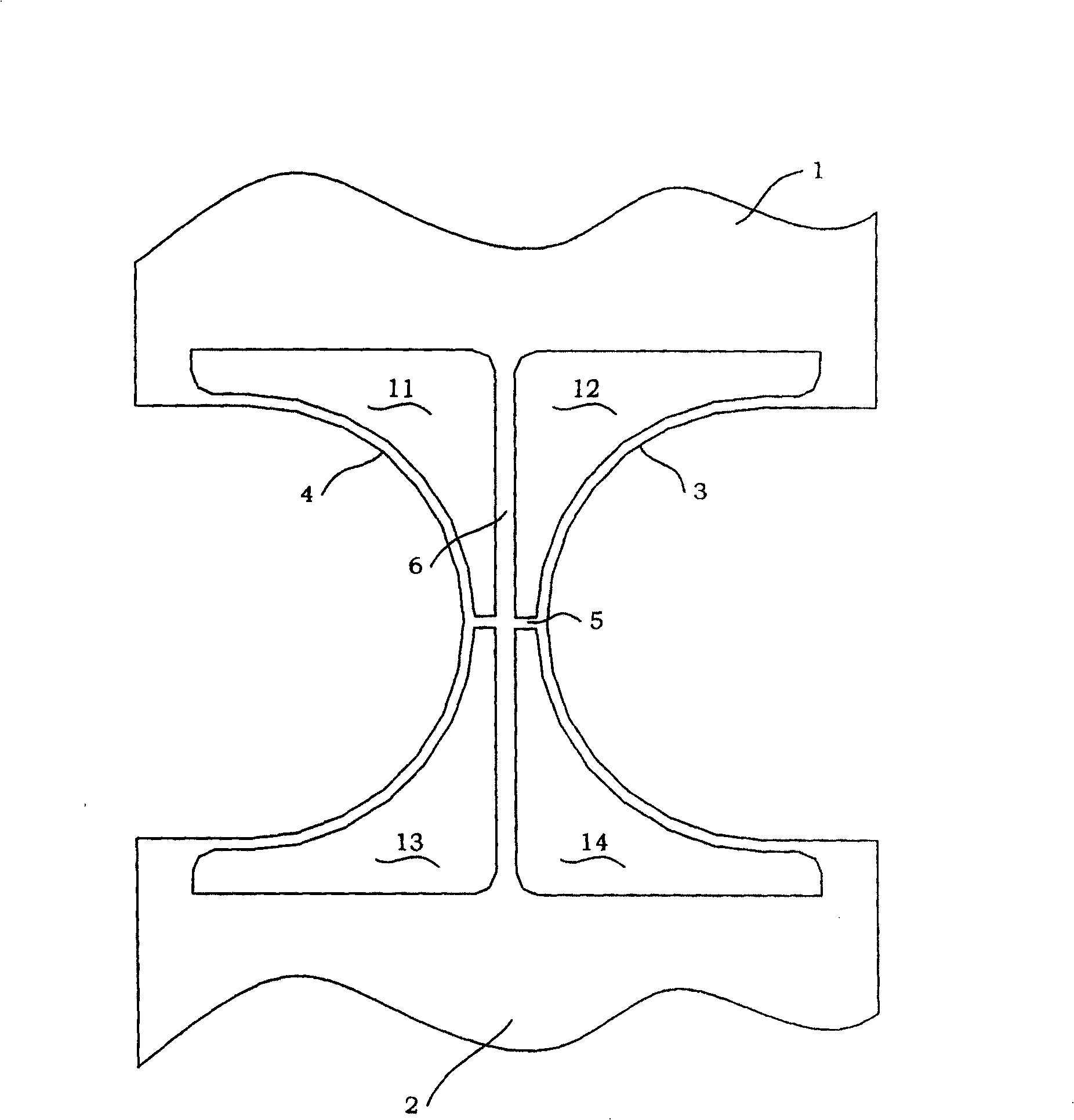

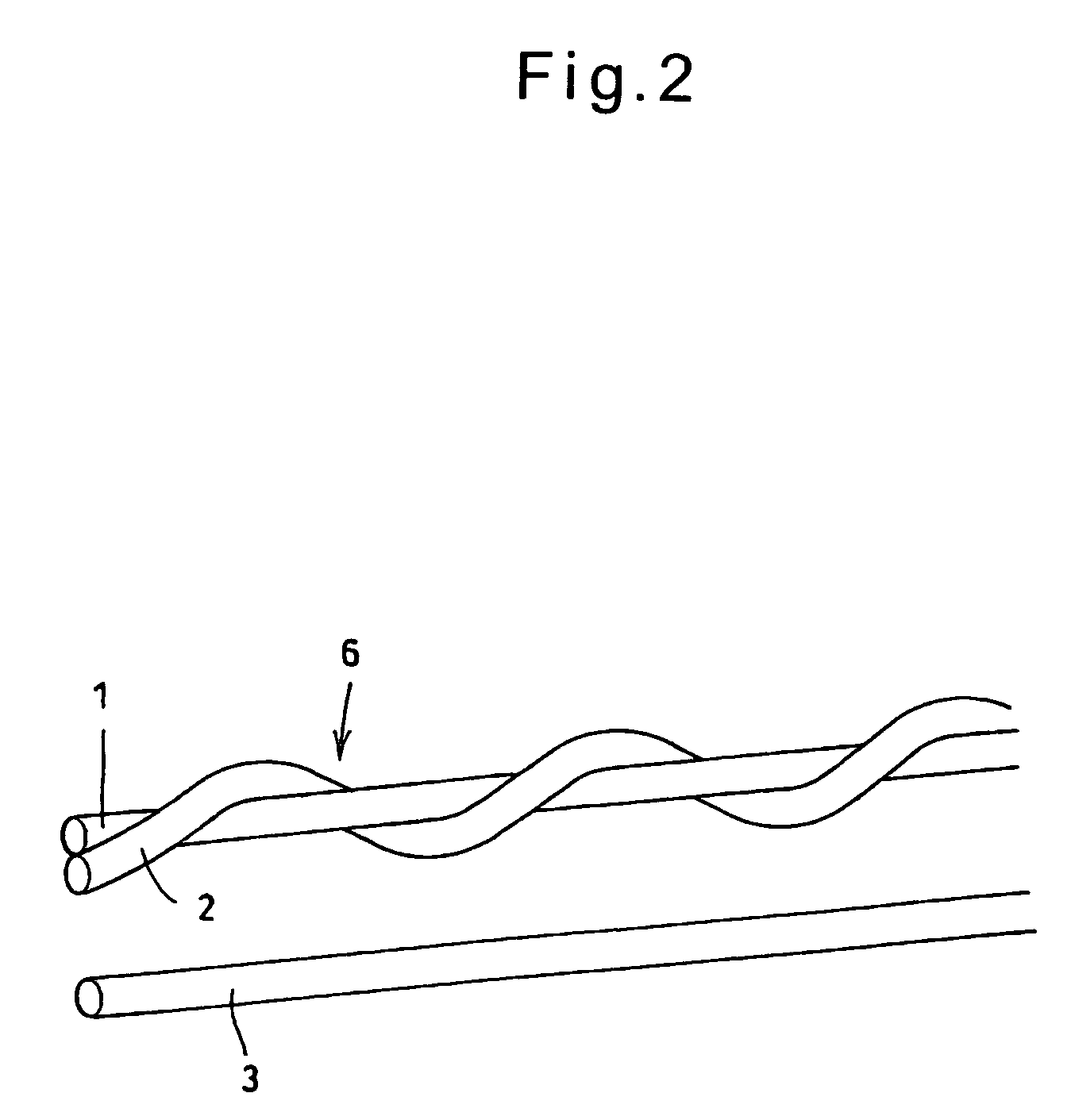

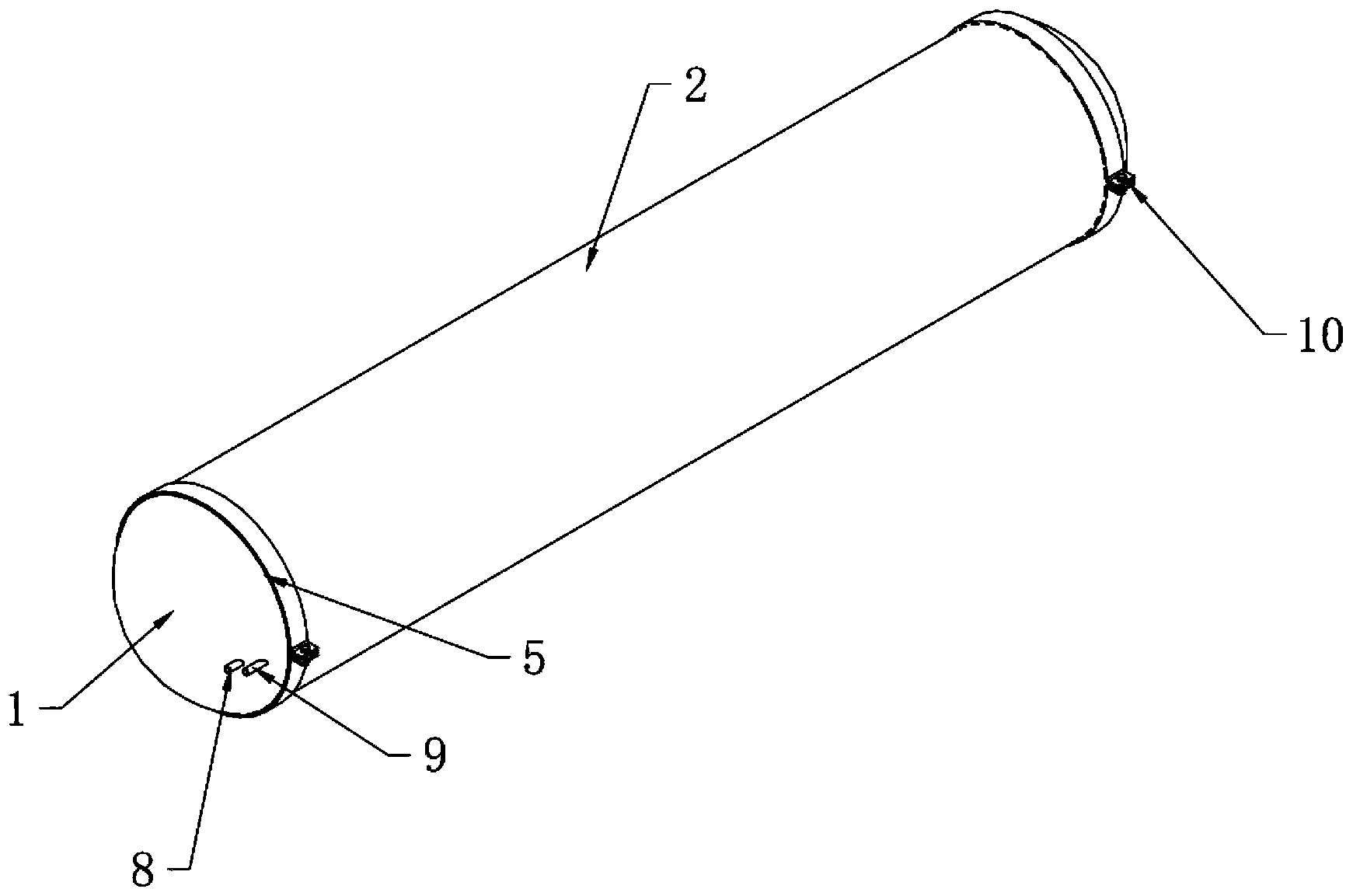

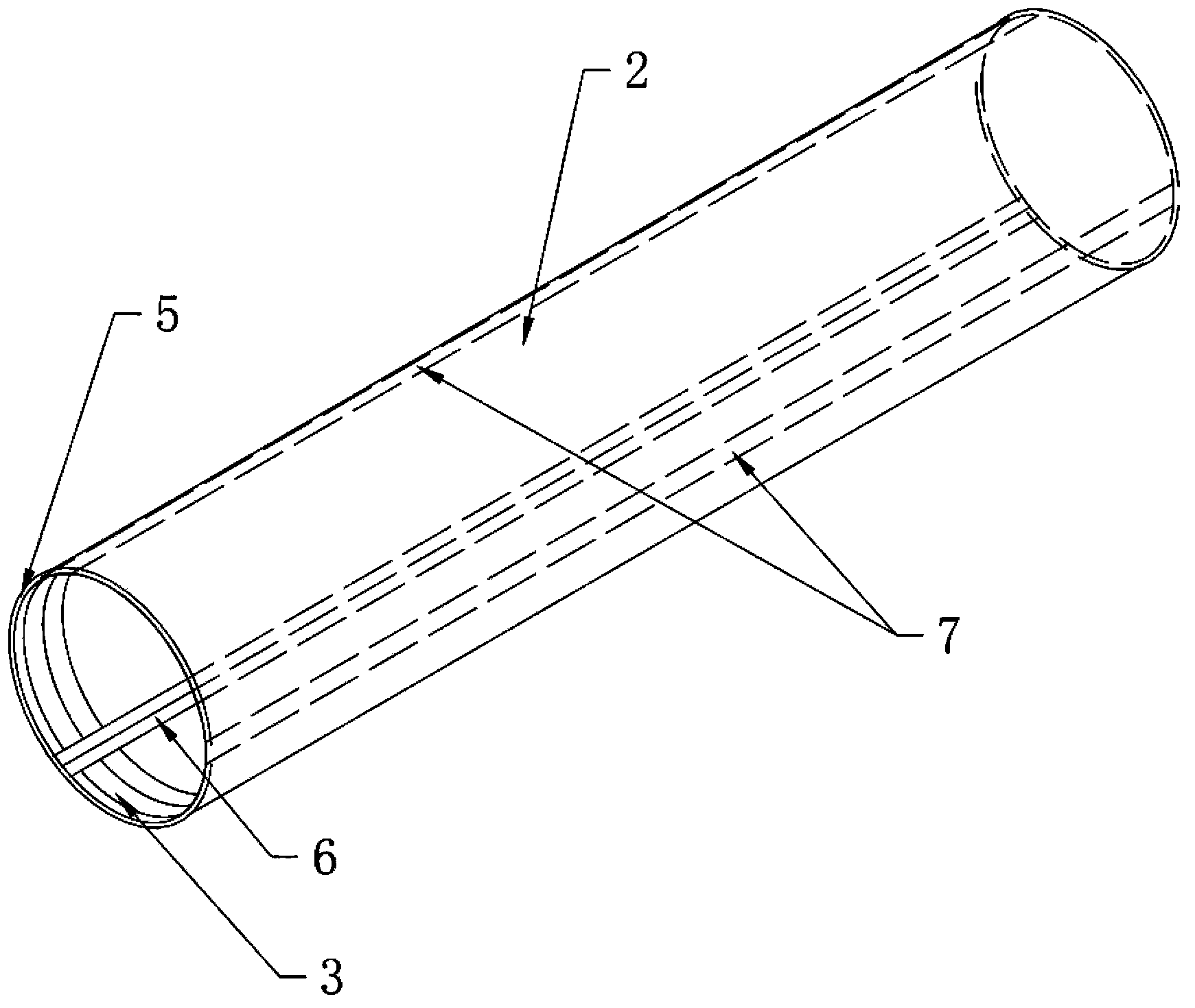

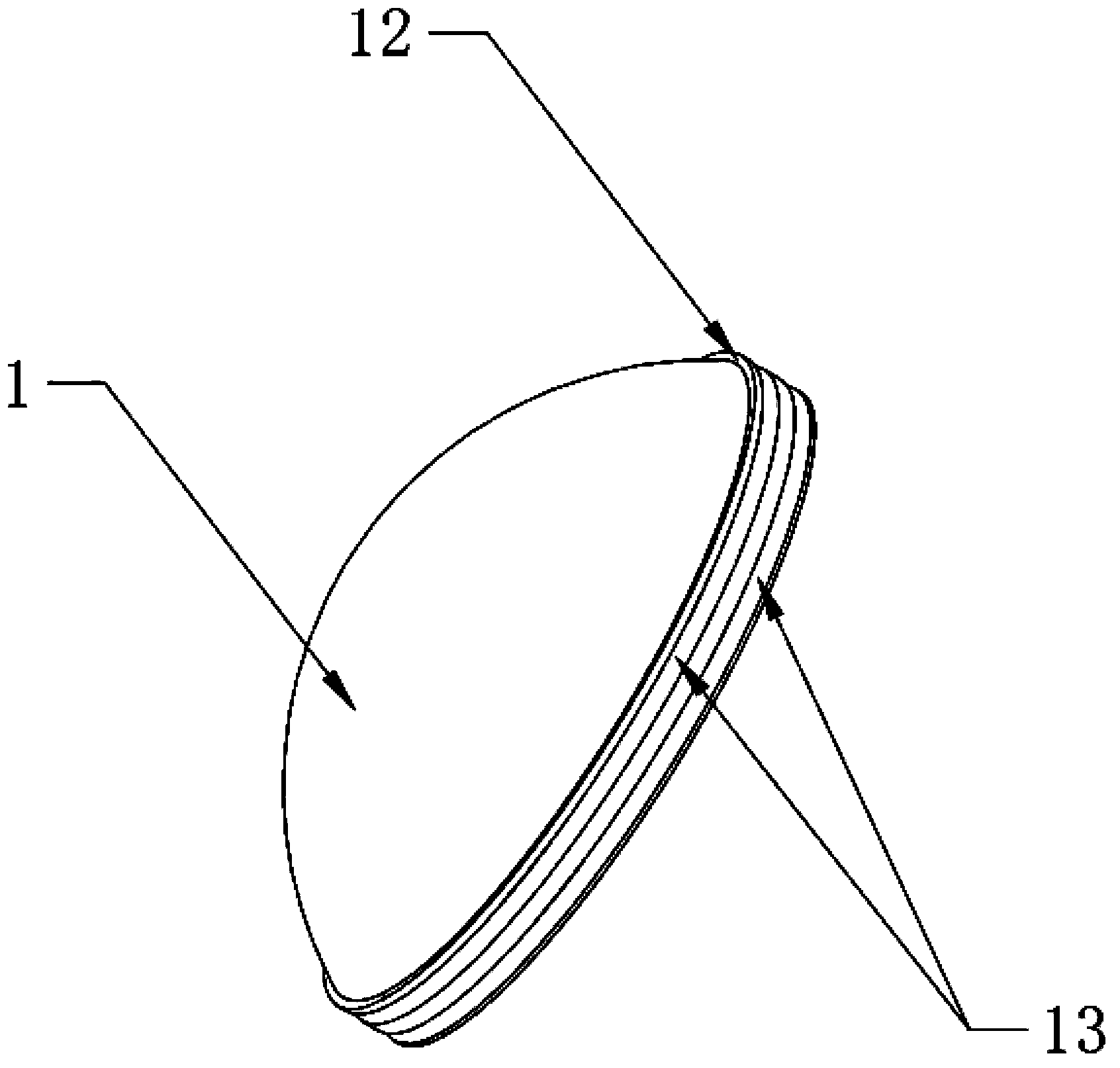

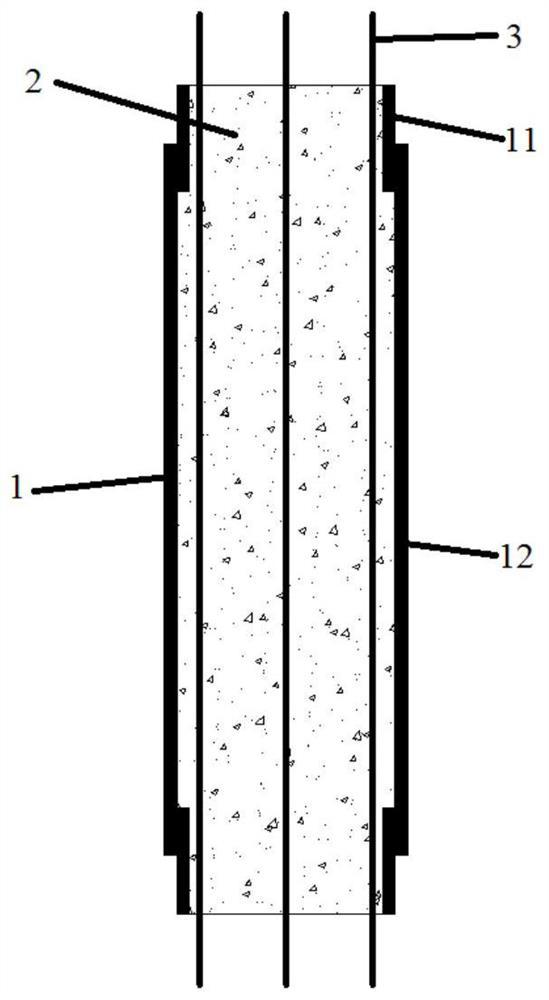

Pneumatic membrane compression bar and manufacturing method thereof

ActiveCN102995748AImprove air tightnessLight in massExtraordinary structuresRubber ringMechanical engineering

The invention discloses a pneumatic membrane compression bar and a manufacturing method thereof and belongs to the field of pneumatic membrane structures. The pneumatic membrane compression bar comprises a bar end enclosure (1), a tubular air bag (2), reinforcing membrane materials (3), a sealing rubber ring (4), buried ropes (5), a thermal bonding seam rib (6), a balancing rib (7), an air inlet (8), an air outlet (9), a bar end steel hoop (10) and a sealing rubber pad (11). The pneumatic membrane compression bar is characterized in that a membrane material and the thermal bonding seam rib (6) are connected to form the tubular air bag (2), and meanwhile, the tubular air bag (2) is internally provided with the balancing rib (7); the inner walls at two ends of the air bag are additionally provided with the reinforcing membrane materials (3), and the buried ropes (5) are embedded in the ends of the air bag; and the tubular air bag (2) is connected with the bar end enclosure (1) by using the bar end steel hoop (10), and meanwhile, construction measures including the sealing rubber ring (4), the sealing rubber pad (11) and the buried ropes (5) are adopted between the tubular air bag (2) and the bar end enclosure (1) so that the pneumatic membrane compression bar is assembled. The pneumatic membrane compression bar has the characteristics of high compression resistant rigidity, light weight, high bearing capability and convenience in deformation compatibility, manufacture and installation.

Owner:BEIJING UNIV OF TECH

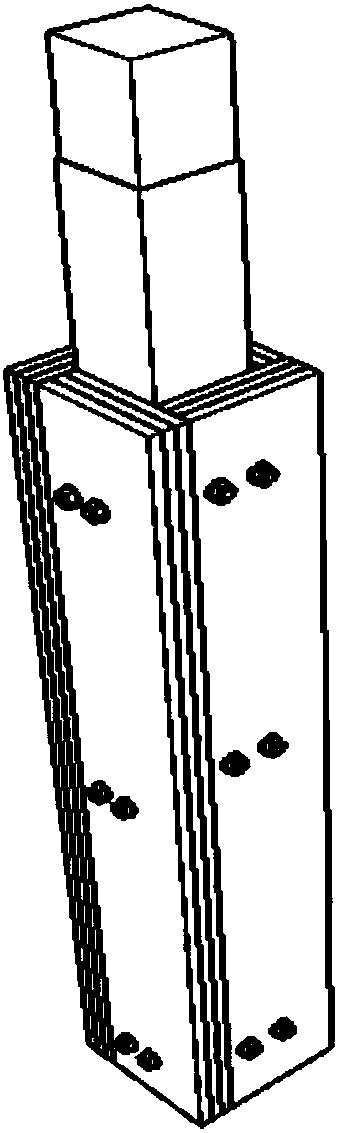

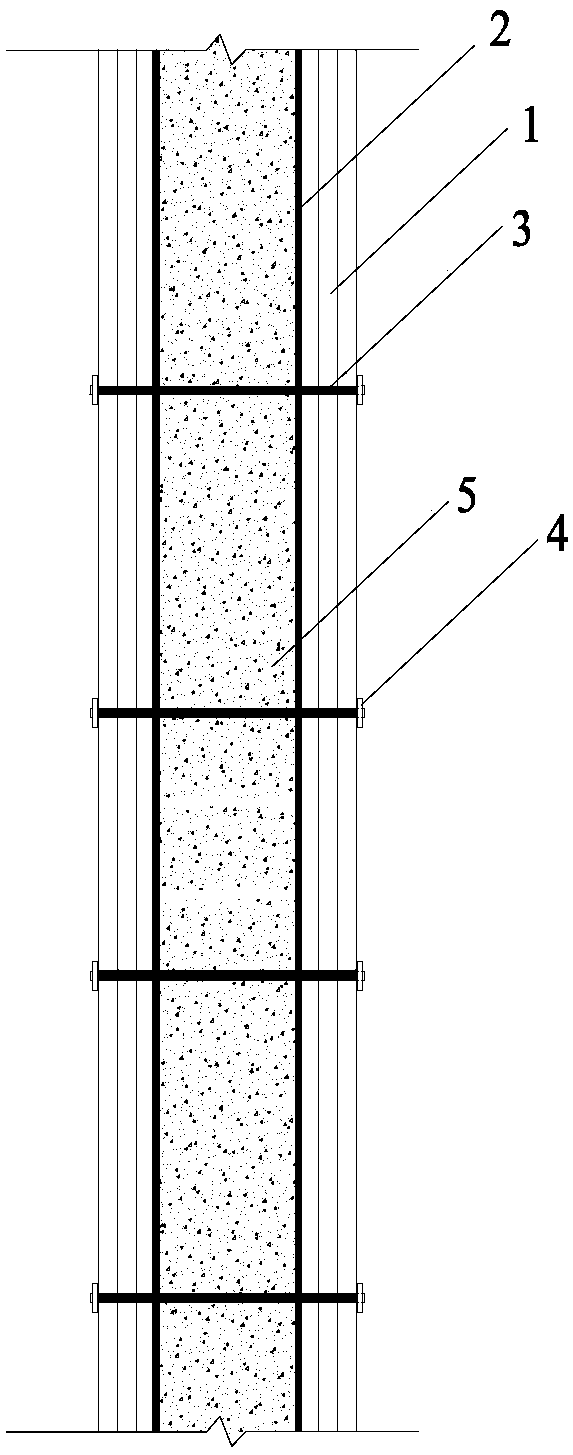

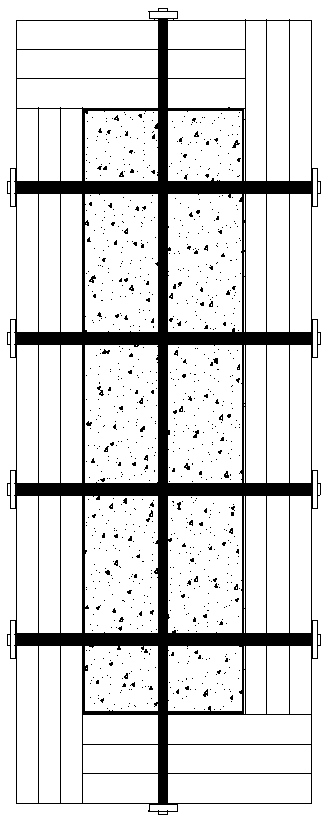

Assembly type prestressed steel pipe concrete column-column connection mode

InactiveCN106812215ASolve the positioning problemFast assemblyBuilding constructionsPre stressShear capacity

The invention provides an assembly type prestressed steel pipe concrete column-column connection mode and belongs to the technical field of structural engineering. A connection device comprises a lower column, an upper column, a lower cover plate, an upper cover plate, lower column lifting hooks and prestressed cables. The lower column is provided with two lower column lifting hooks, and the lower column lifting hooks are welded to the two inner surfaces of the upper end of the lower column respectively, play a positioning role in the lifting process of the upper column and play a role in strengthening a joint area after the upper column is lifted. After lifting is completed, cement paste is pumped upwards through reserved holes in the lower cover plate, so that the upper and lower columns are filled with the cement paste. Connection with certain strength is achieved by filling the columns with the cement paste. The connection part of the columns is located near a contraflexure point so that the shear capacity of the columns can be improved by pouring the cement paste. The prestressed cables are fixed through the upper and lower columns, the deformation performance and the compressional stiffness of the columns are improved, the tensile strength of the columns is obviously improved, assembly between structural die blocks is achieved, assembly speed of the members is increased, the assembly quality of the members is improved, and the connection mode sufficiently meets requirements of an assembly type steel structure system and sufficiently adapts to characteristics of the assembly type steel structure system. Through the assembly type prestressed steel pipe concrete column-column connection mode, the construction speed is greatly increased, the construction quality is greatly improved, and the column-column connection mode adapts to the development of assembly type steel structures.

Owner:BEIJING UNIV OF TECH

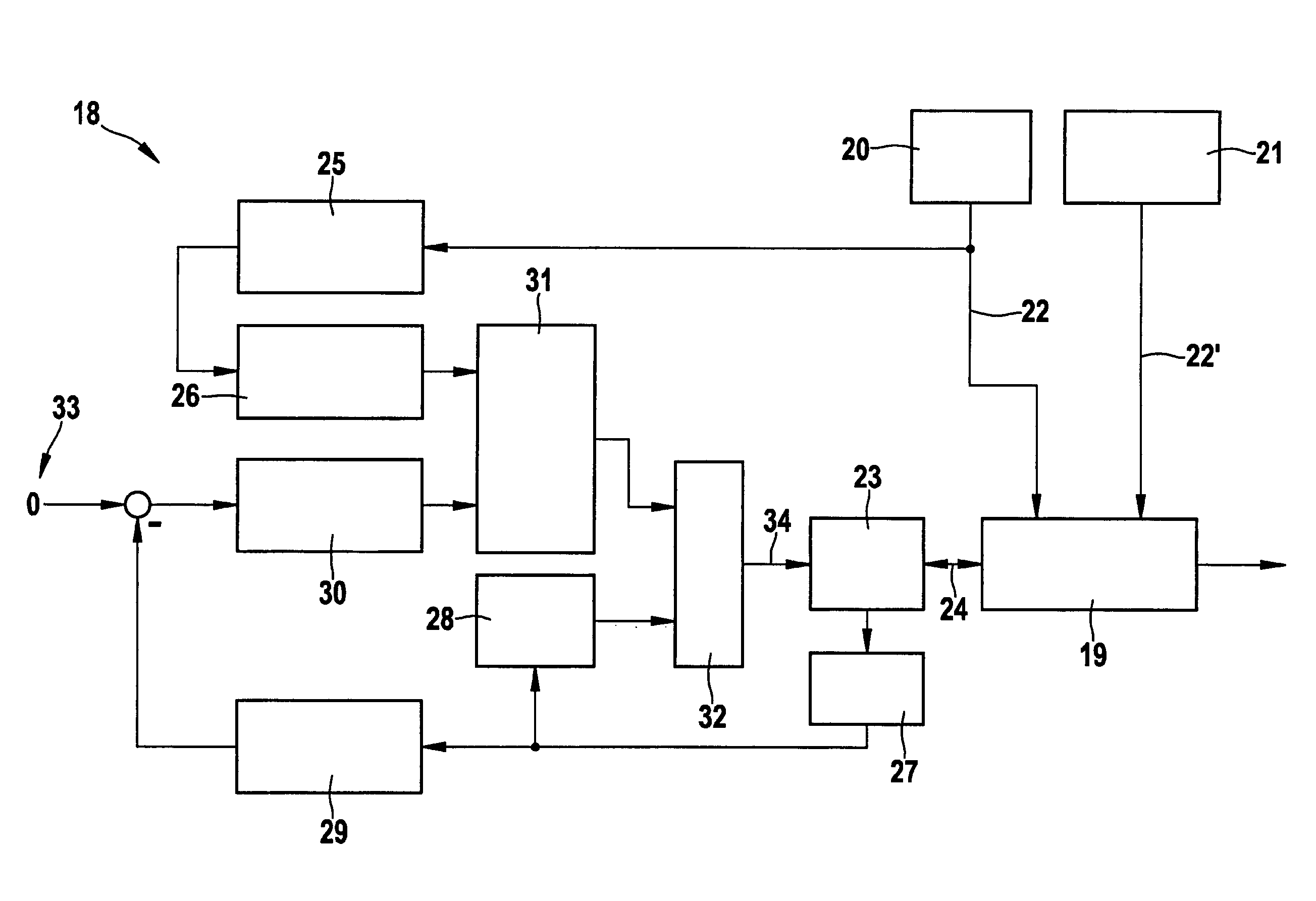

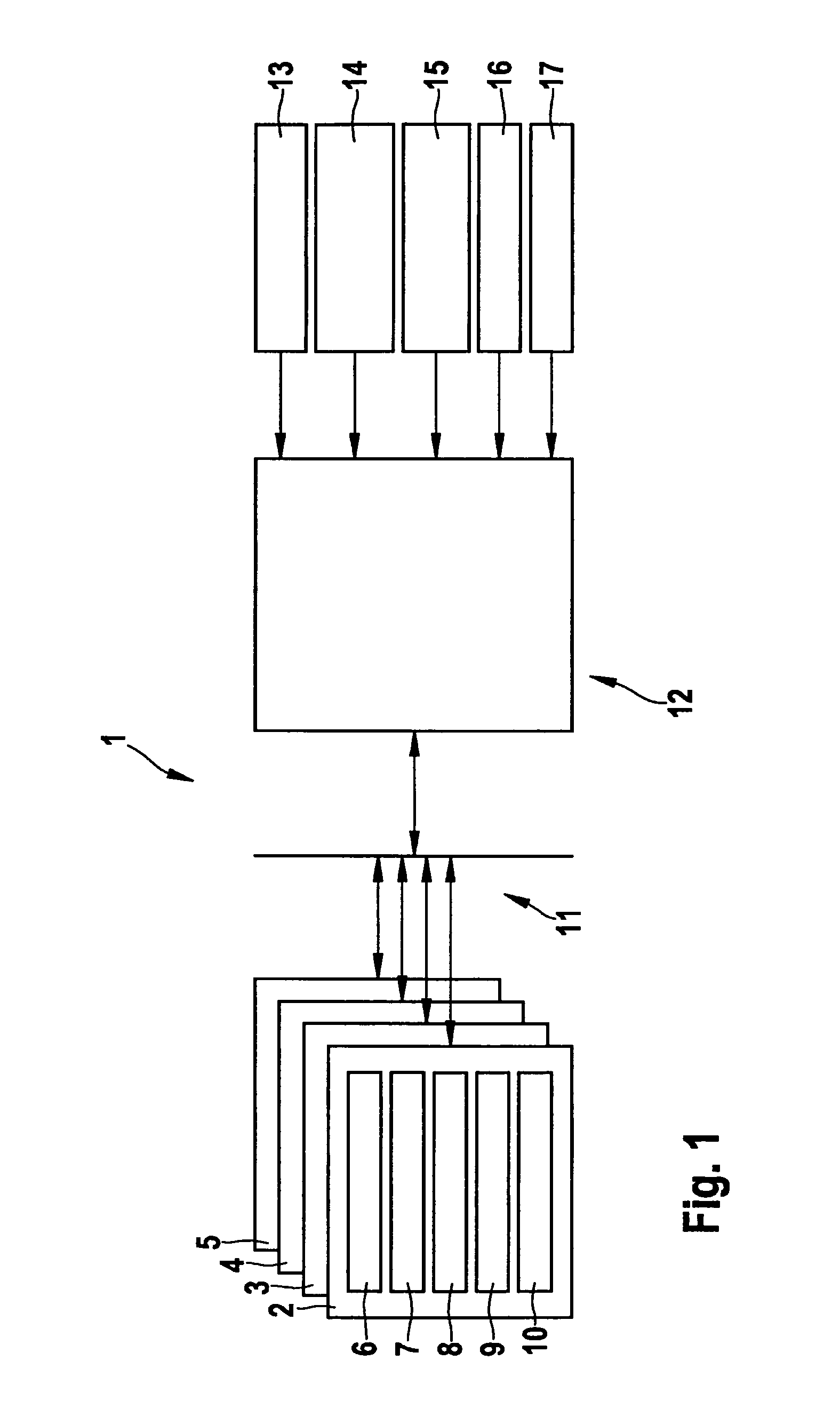

Method for chassis control of a motor vehicle, and device for the performance thereof

ActiveUS9045017B2Improve compressive stiffnessIncrease stiffnessSpringsResilient suspensionsBody movementShock absorber

In a method for chassis control of a motor vehicle which has at least one wheel suspension, a vehicle body, and a shock absorber having a rebound stage, whose stiffness is adjustable, and a compression stage, whose stiffness is adjustable, the stiffness of the compression stage is changed for a compressive load of the shock absorber generated by a specific vehicle body movement, and the stiffness of the rebound stage is additionally changed for a subsequently following tensile load of the shock absorber generated by the specific vehicle body movement, or the stiffness of the rebound stage is changed for a tensile load of the shock absorber generated by a specific vehicle body movement, and the stiffness of the compression stage is additionally changed for a subsequently following compressive load of the shock absorber generated by the specific vehicle body movement.

Owner:ROBERT BOSCH GMBH

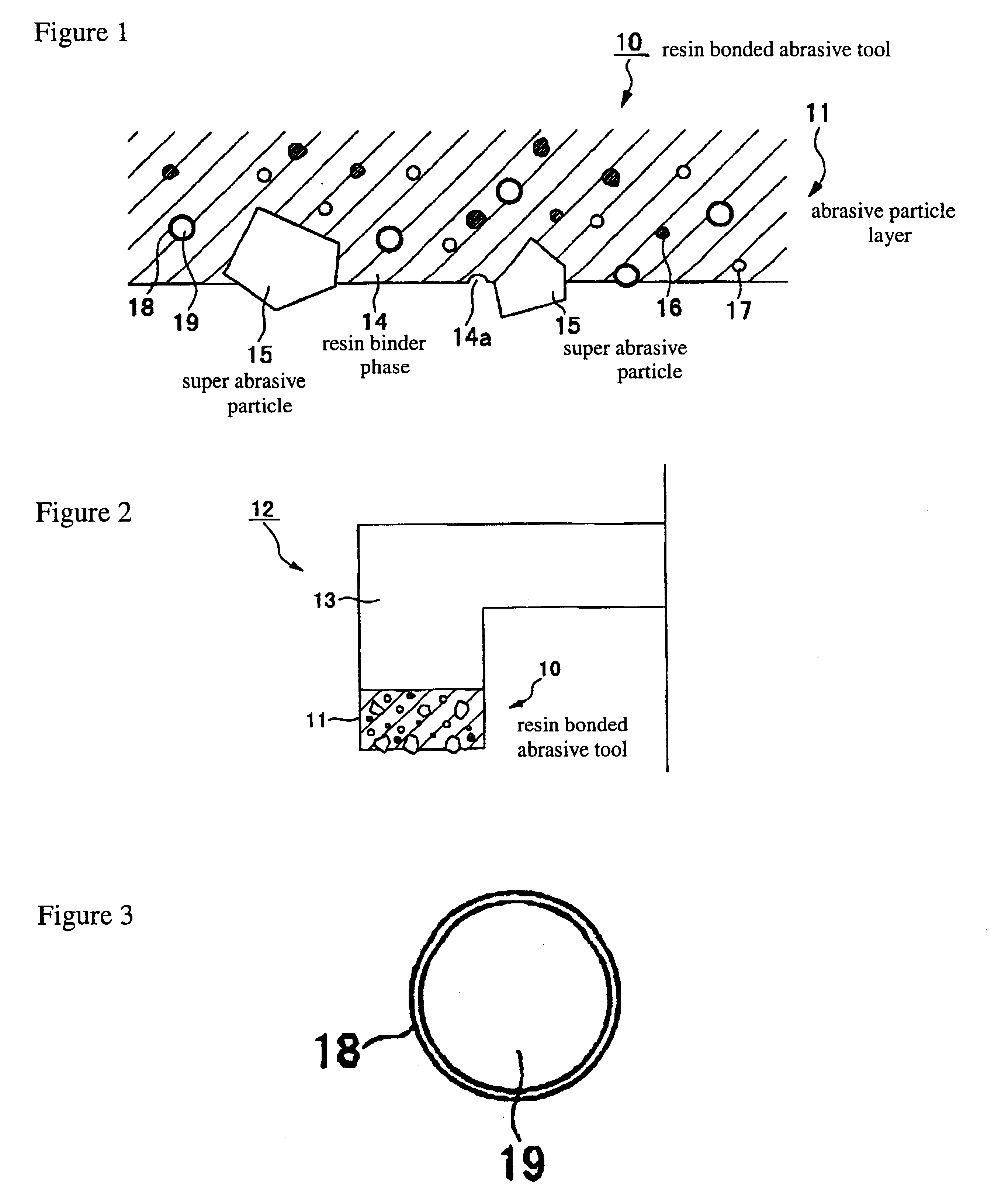

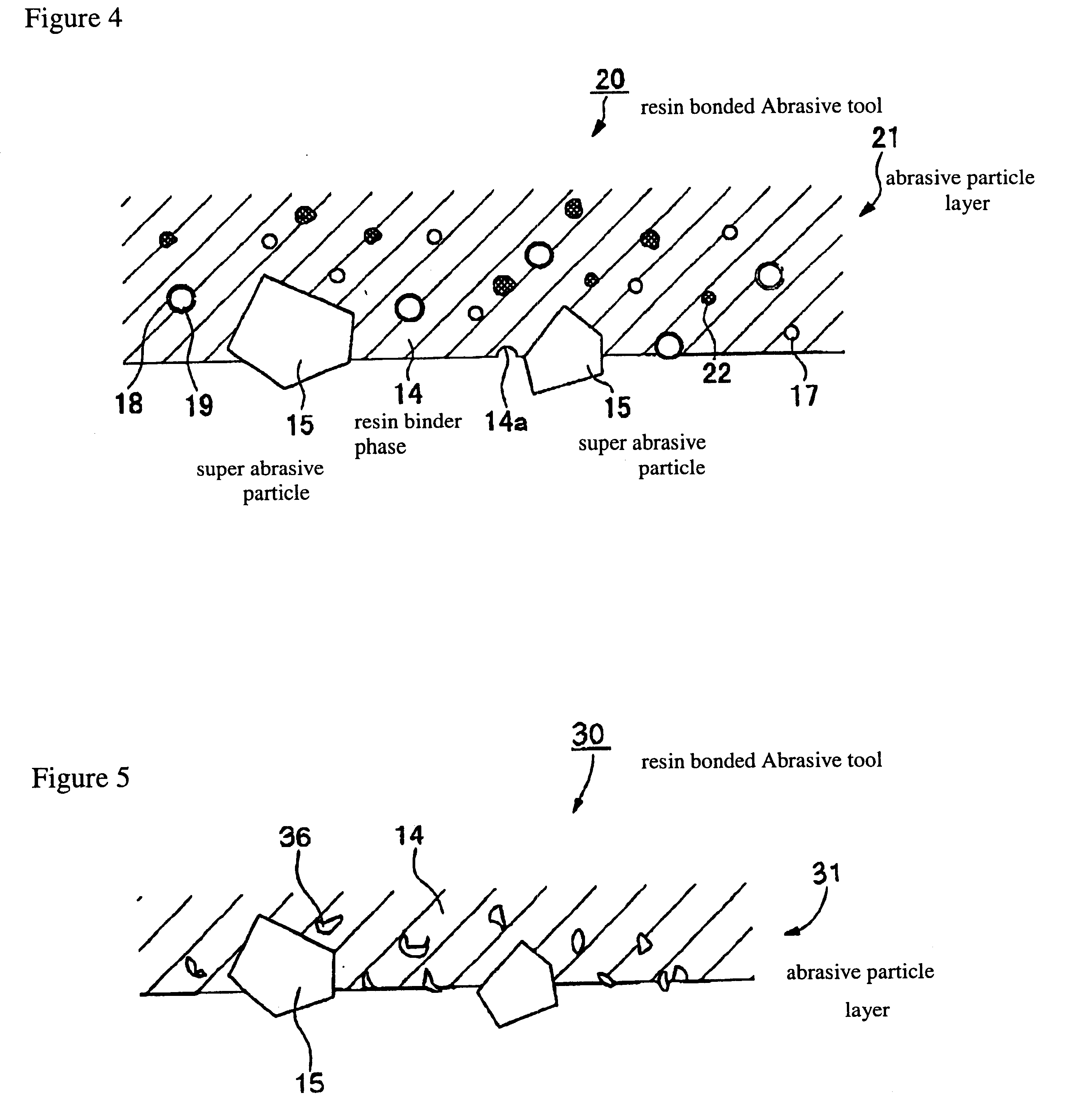

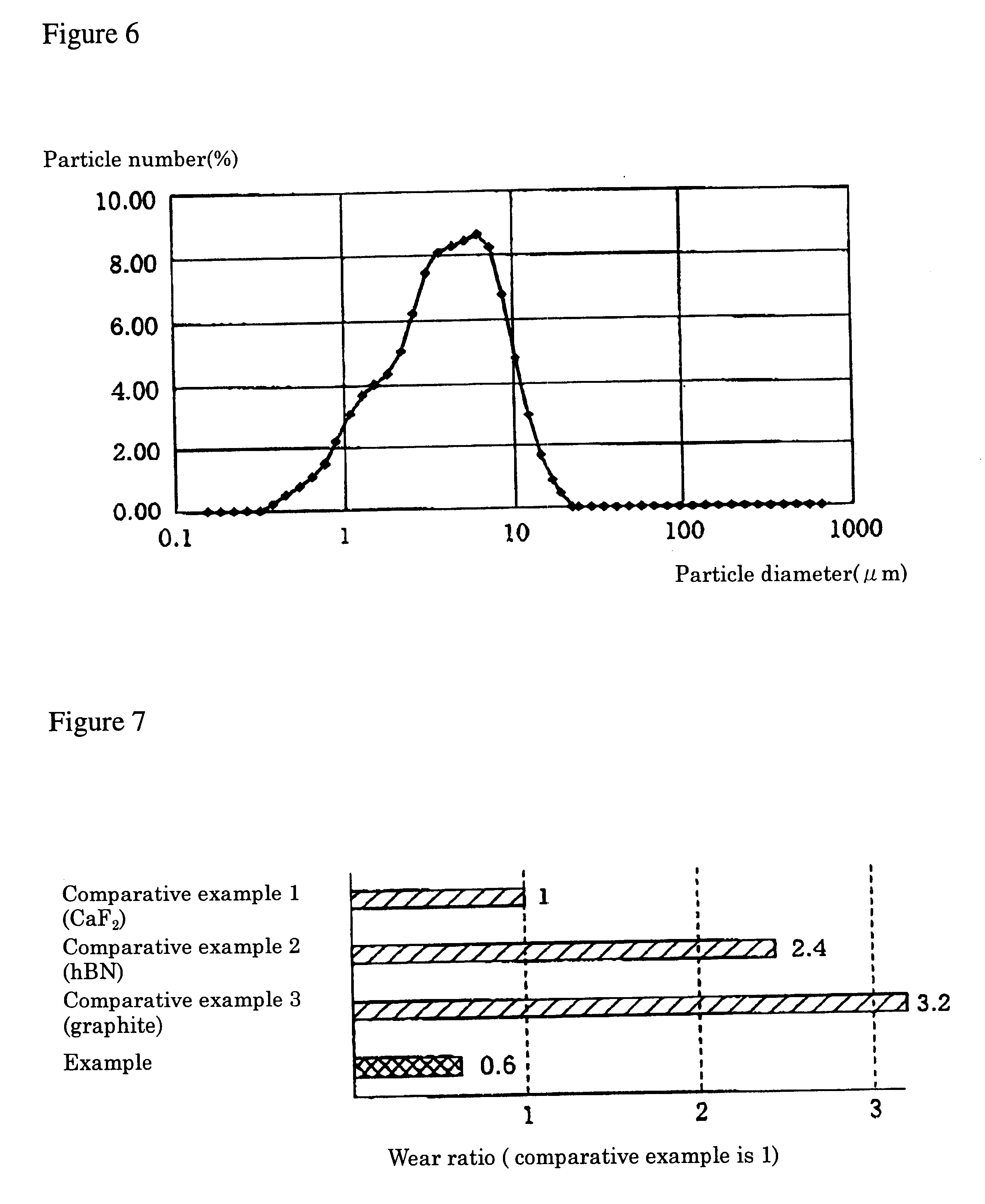

Resin bonded abrasive tool

InactiveUS6383238B1Improve wear resistanceReduce resistancePigmenting treatmentOther chemical processesMetal coatingWear resistant

The abrasive particle layer of resin bonded abrasive tool is constructed by resin binder phase consisting of heat hardening resin, for example, phenol resin etc. and super abrasive particle of diamond (or CBN etc.) distributed in this resin binder phase. The wear resistant filler consisting of SiC, for example, as hard filler and hollow glass and metal coated amorphous carbon is distributed in resin binder phase. The amorphous carbon is made to spherical shape and metal coating layer consisting of Cu, for example, as the metal having high thermal conductivity, is set on a surface of this amorphous carbon.

Owner:MITSUBISHI MATERIALS CORP

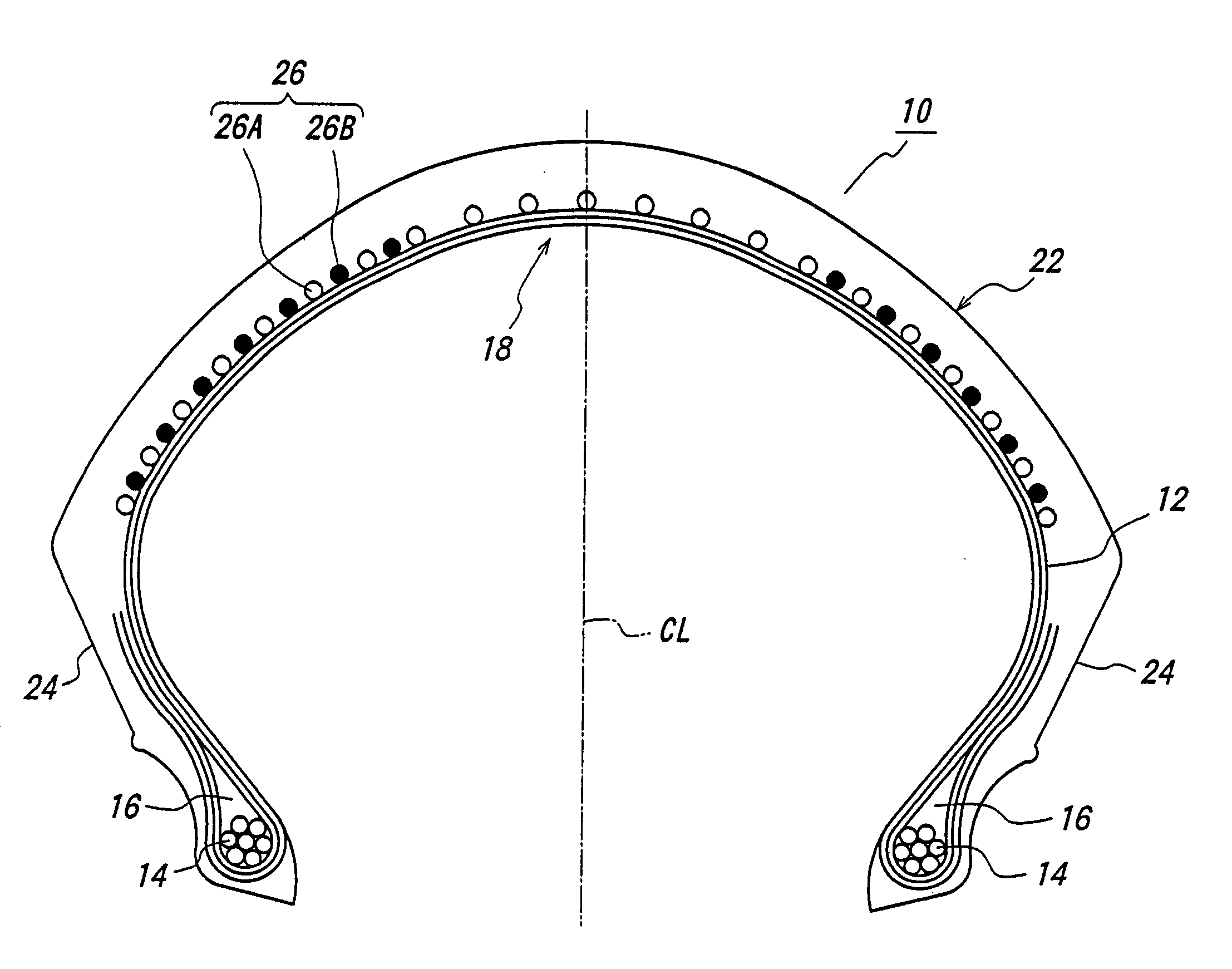

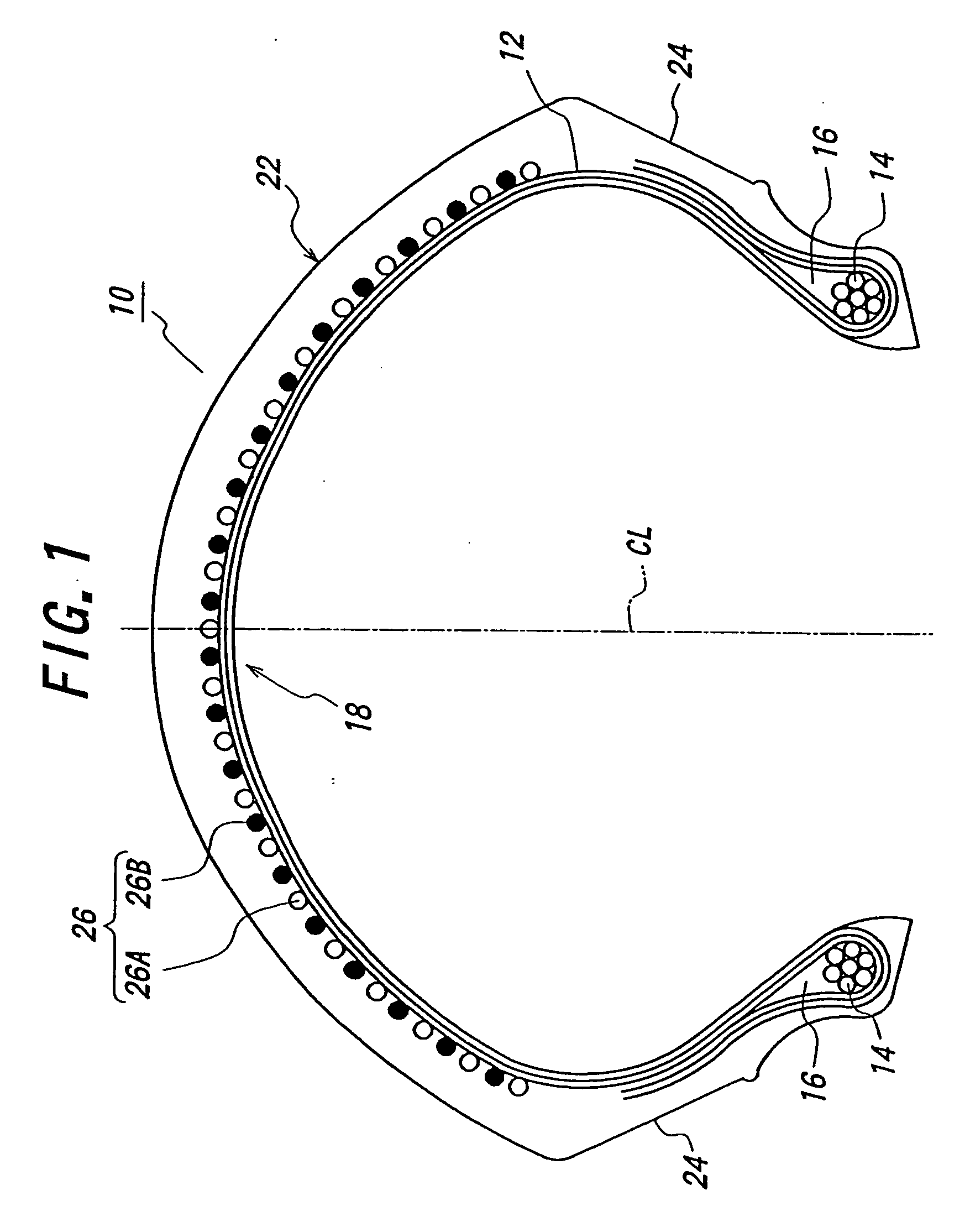

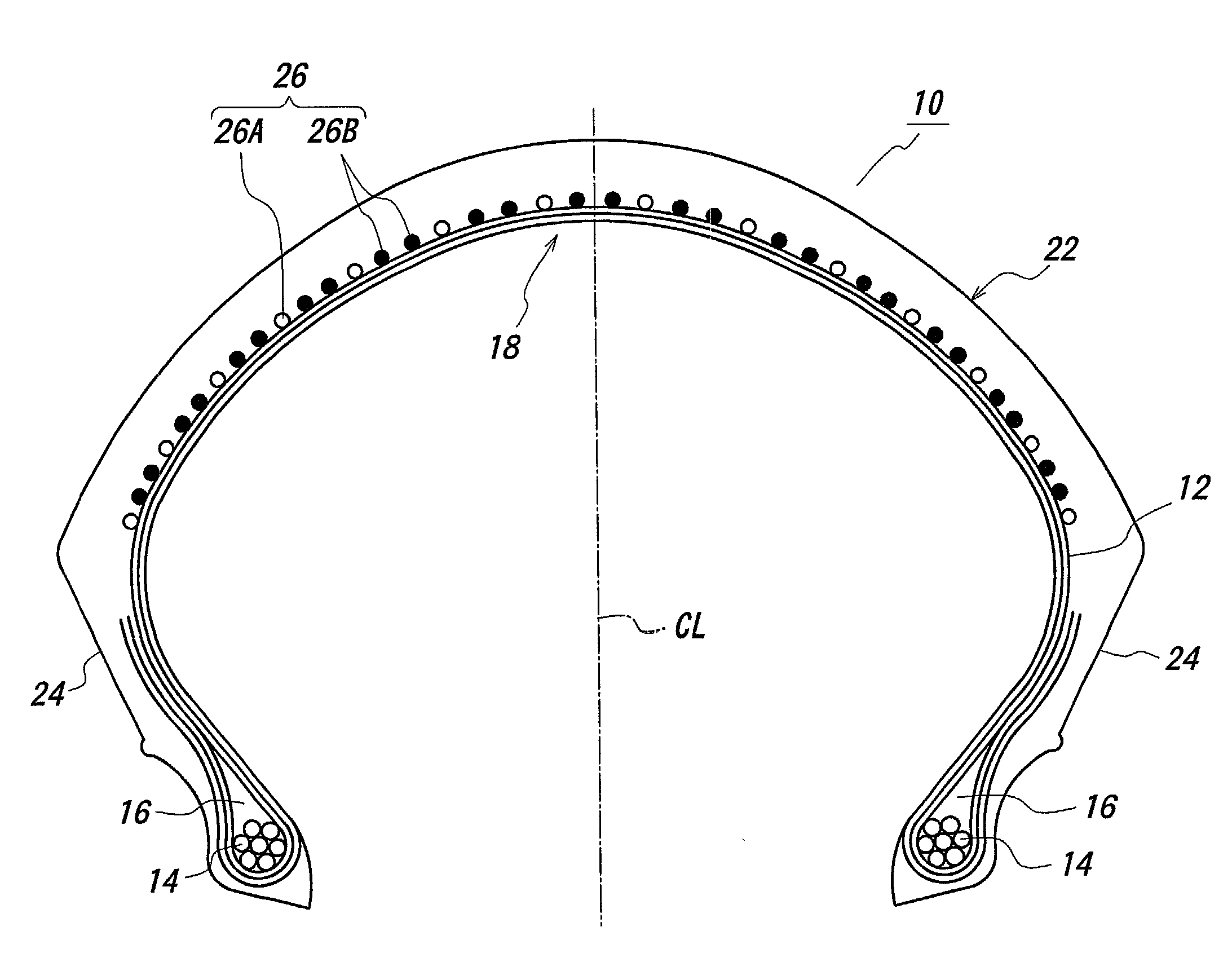

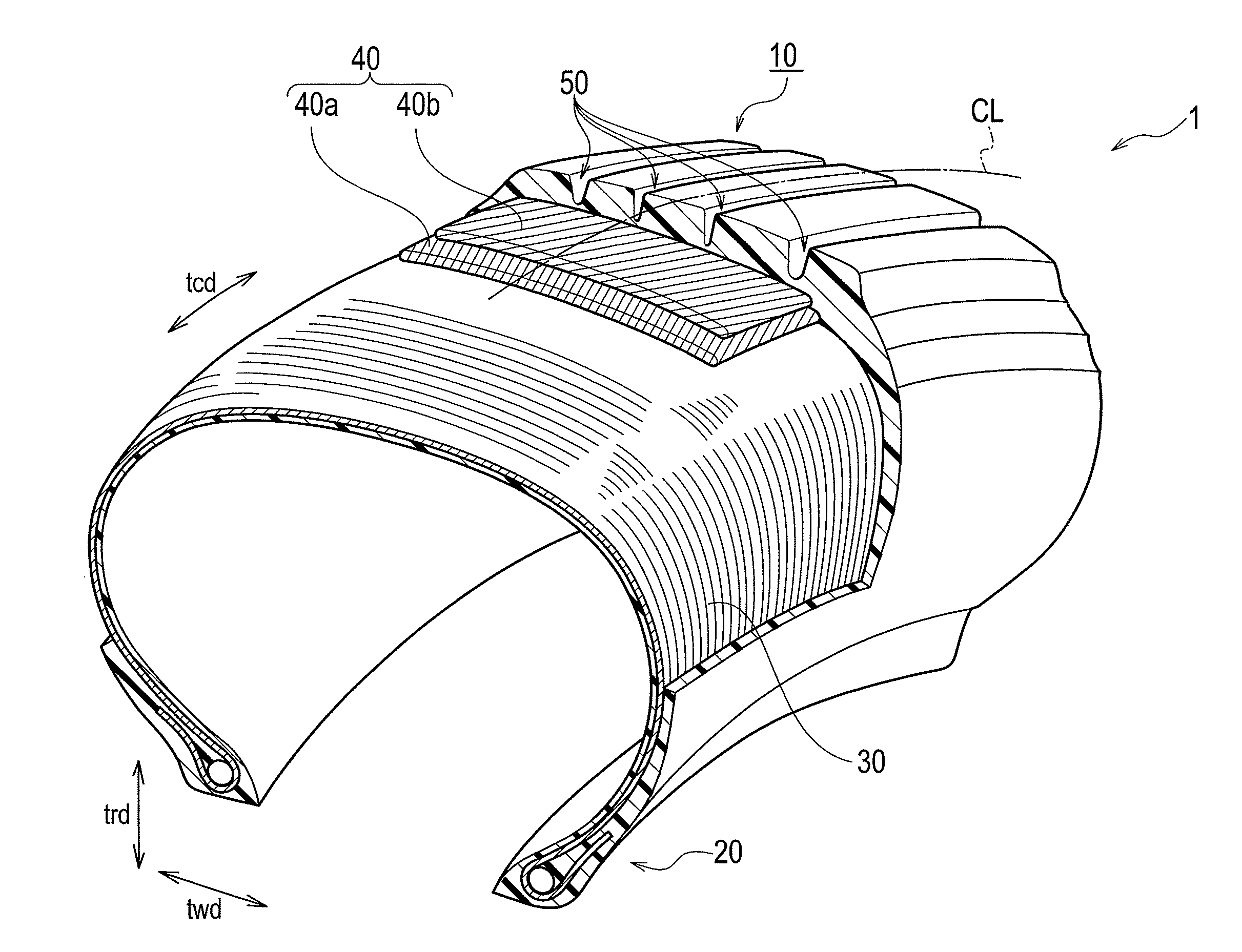

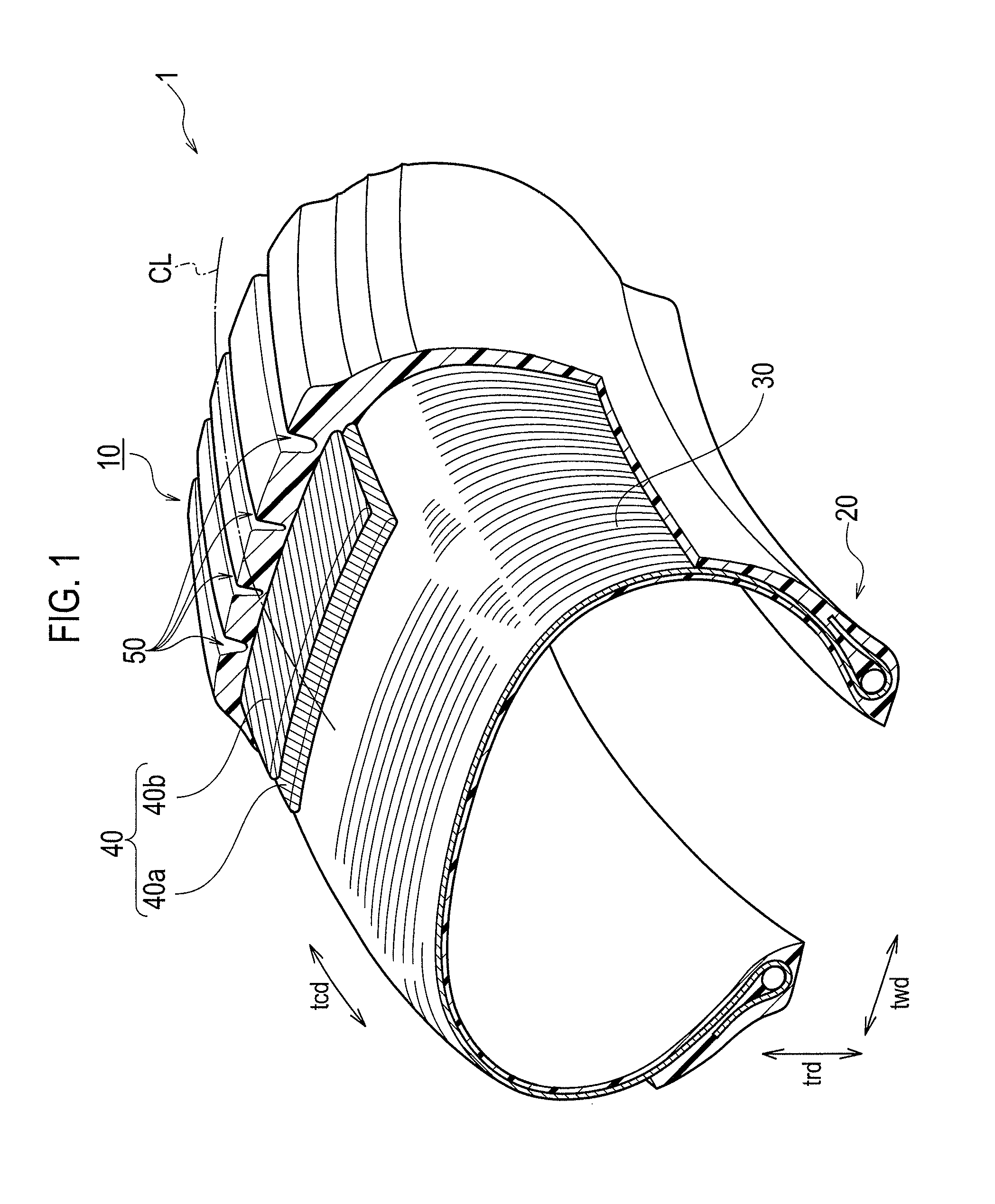

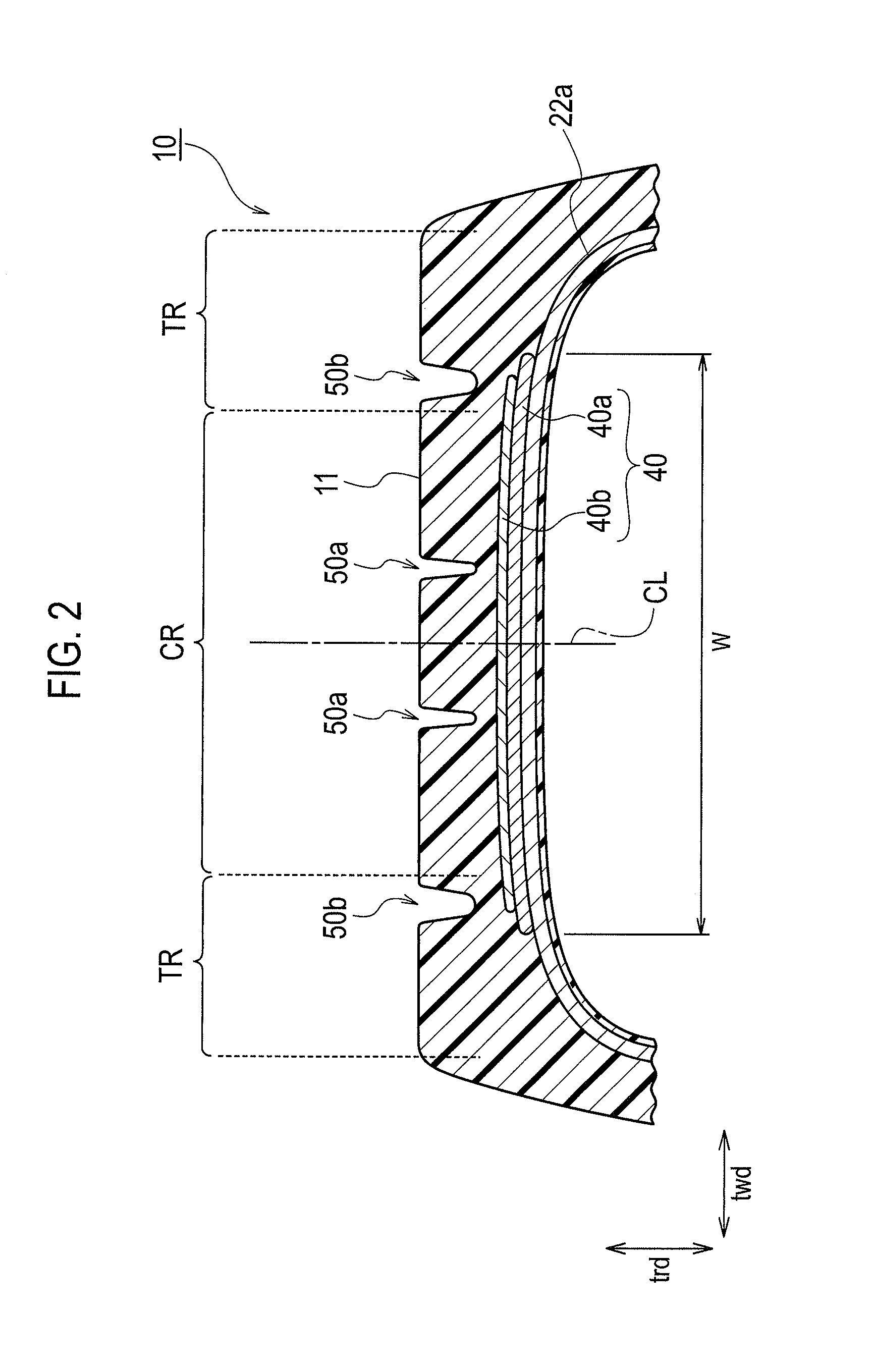

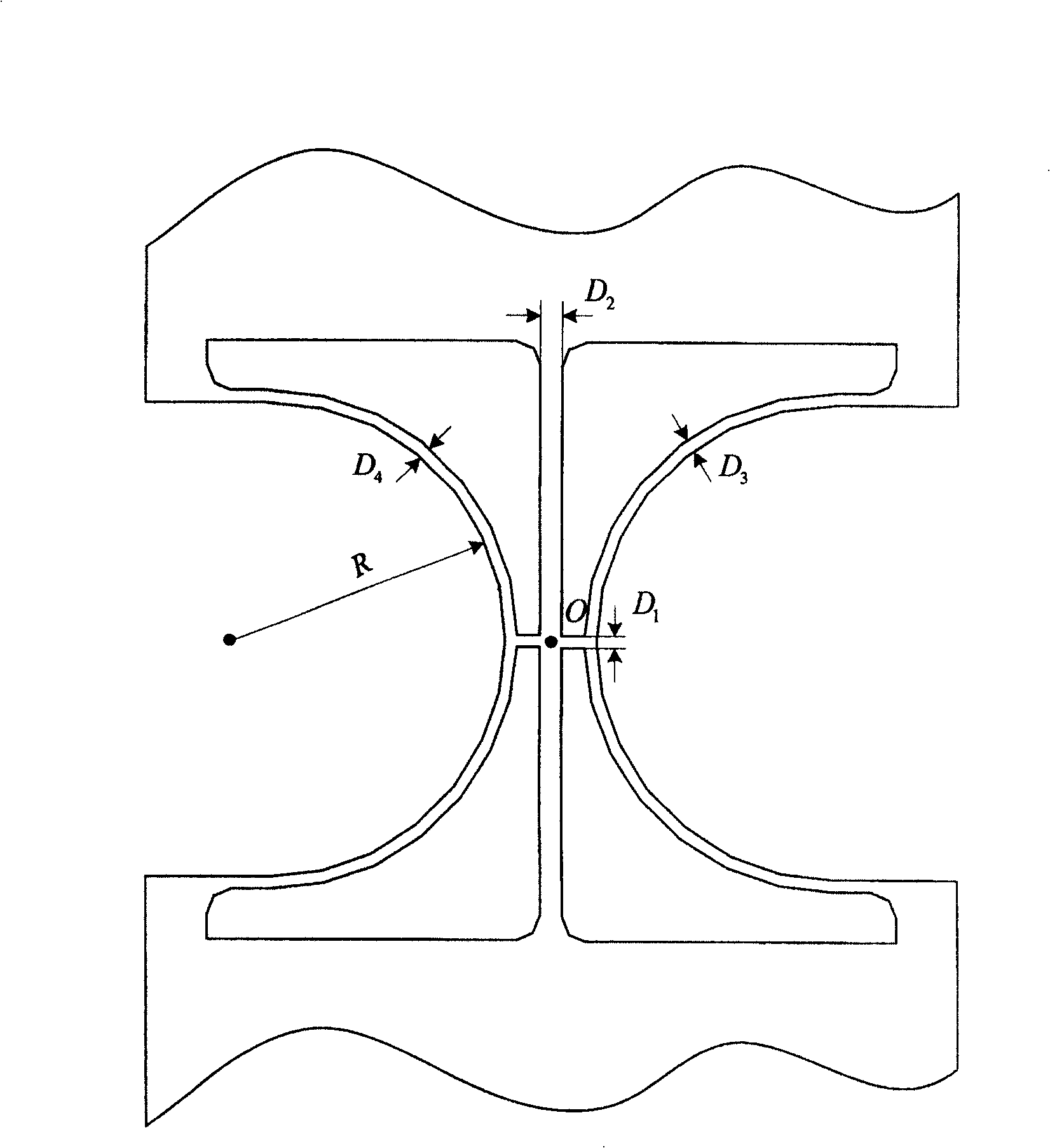

Tire

InactiveUS20130333816A1Reduce rolling resistanceImprove rolling resistanceTyre tread bands/patternsNon-skid devicesMaximum depthTread

In the tire (1), a region of the tread portion (10) overlapping with a range of 80% of a length of the circumferential belt layer (40) in a tread widthwise direction around a tire equator line CL is a central region CR in the tire radial direction trd, and a remaining region of the tread portion (10) is a terminal region TR, a maximum curvature radius of the arc portion of the central circumferential groove 50a is R1, a minimum curvature radius of the arc portion of the terminal circumferential groove 50b is R2, a maximum depth in the tire radial direction trd from the tread surface (11) to a groove bottom 55a of the central circumferential groove 50a is D1, a maximum depth in the tire radial direction trd from the tread surface (11) to a groove bottom 55b of the terminal circumferential groove 50b is D2, and a relationship of R1 / D1≦0.130 and a relationship of R2 / D2>0.195 are satisfied.

Owner:BRIDGESTONE CORP

Semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column and manufacturing method thereof

PendingCN108505685AInhibit or delay glue openingReduce dependenceStrutsPillarsEngineeringEngineering structures

The invention relates to a semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column, further relates to a manufacturing method of the semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column and belongs to the technical field of engineering structure bearing columns. The semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column comprises a bamboo plywood layer, a steel pipe, a dust collection mountain flour concrete column, steel pull rods and nuts. The dust collection mountain flour concrete column is located in the steel pipe, the bamboo plywood layer is bonded on the outer wall of the steel pipe, and dust collection mountain flour concrete is prepared from cement adulterated with dust collection mountain flour. The steel pull rods are arranged perpendicular to the axial direction of the steel pipe in a crossed mode, the two ends of the steel pulling rods are providedwith the nuts, and the nuts are connected with the steel pulling rods through threads. According to the combined column, a steel pipe-dust collection mountain flour concrete reinforcement strategy isadopted, the slender proportion of the combined column can be reduced, anti-compression instable failure of the large-slender proportion combined column is regulated, the anti-compression strength isimproved to reduce anti-compression deformation and creeping, the anti-compression bearing capacity of the combined column is improved, and traditional decoration technological treatment such as embedding, wrapping, riveting, grinding and coating can be adopted on the surface.

Owner:GUANGDONG CONSTR VOCATIONAL TECH INST

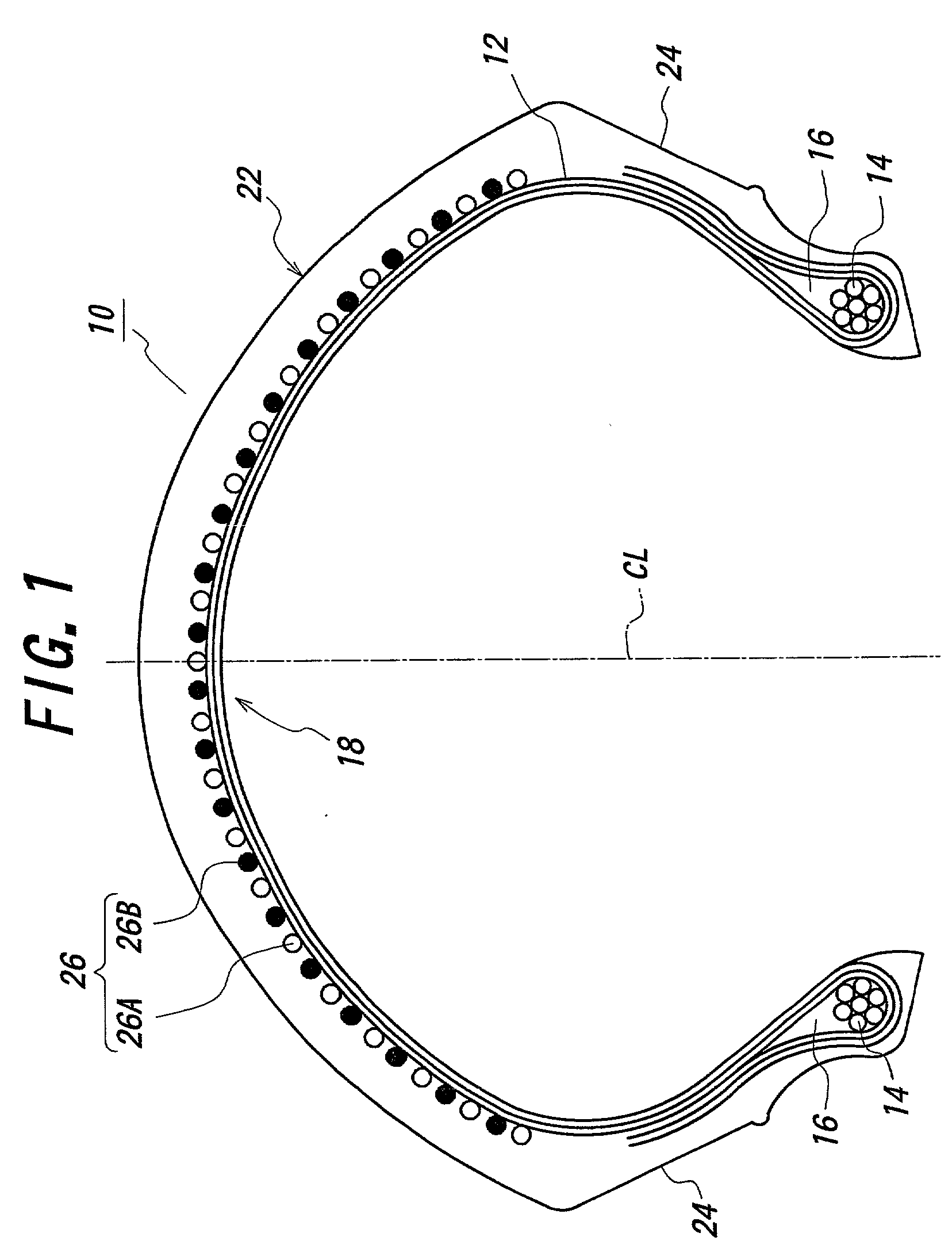

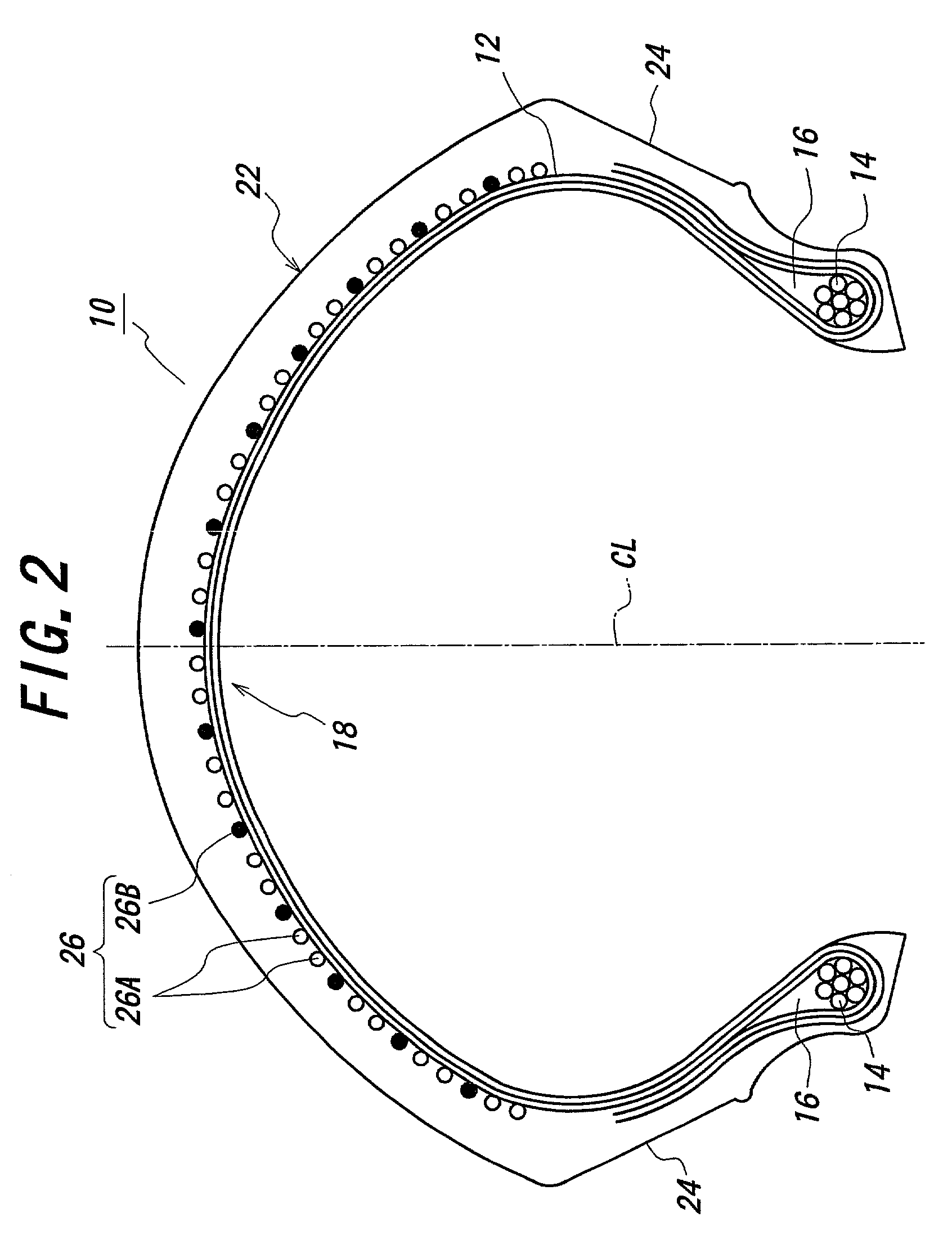

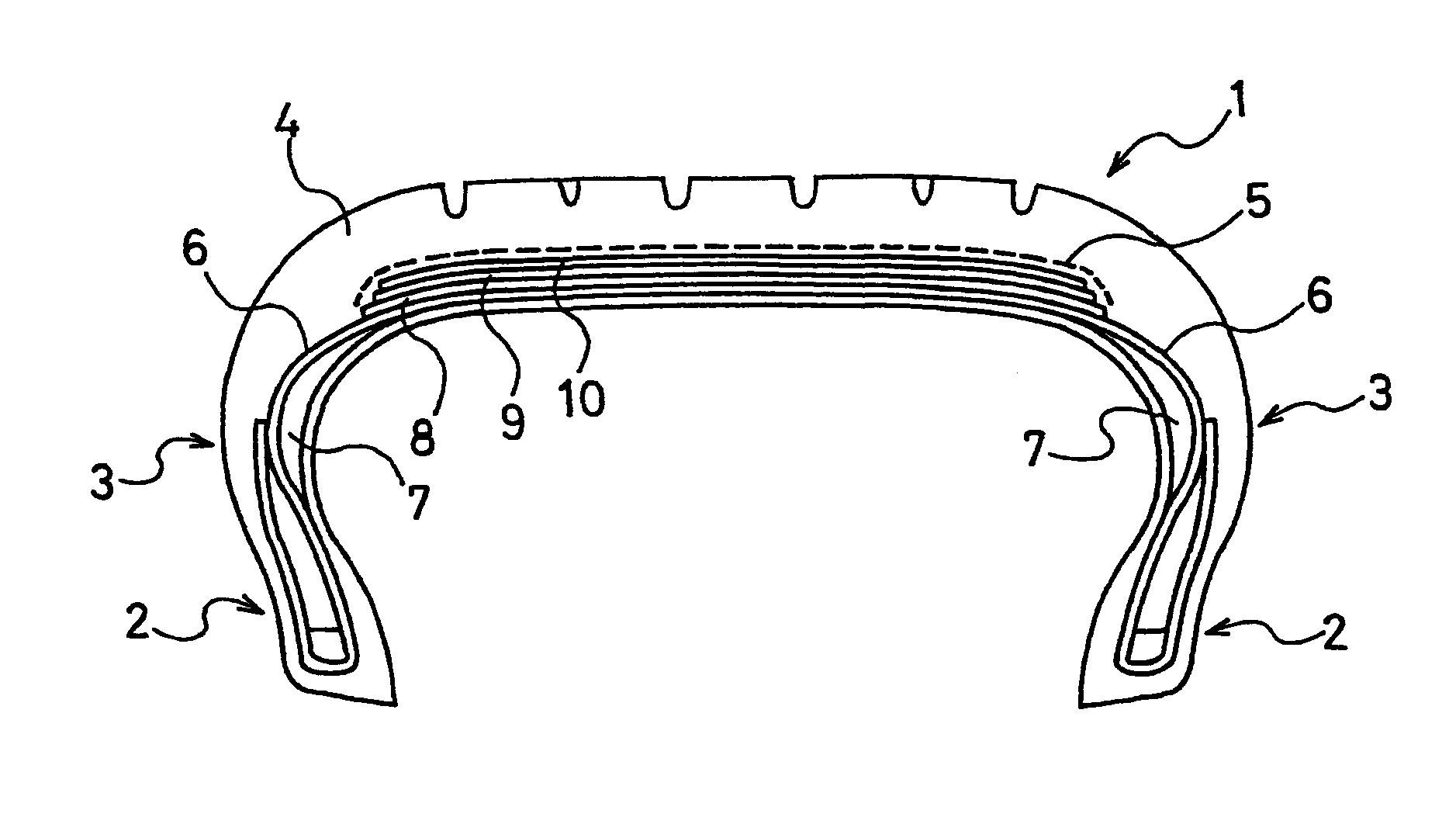

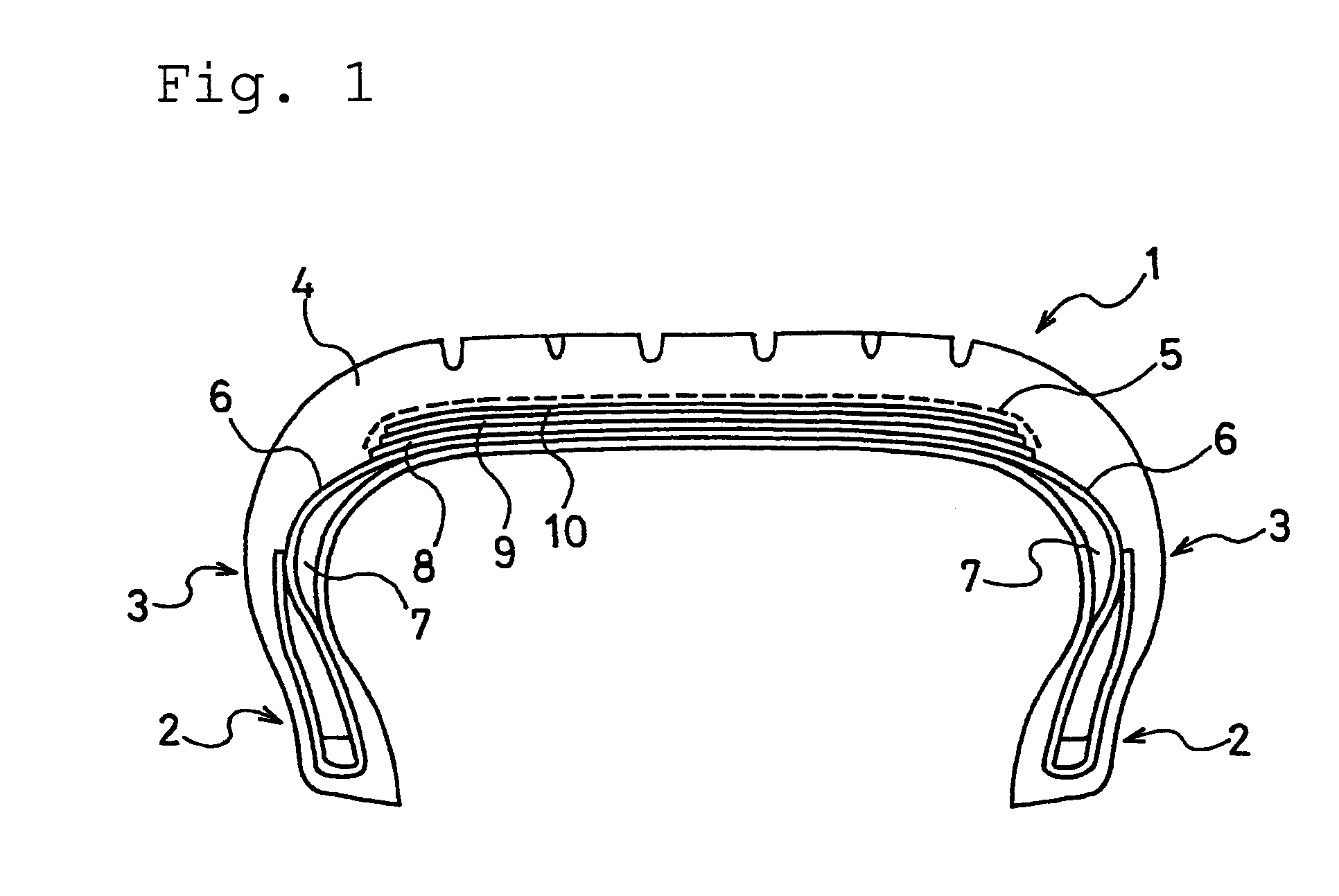

Run flat tire

InactiveUS8281836B2Improve compressive stiffnessIncrease stiffnessPneumatic tyre reinforcementsWheelsRoad surfaceRun-flat tire

Provided is a run flat tire having an enhanced ride comfort in running on general road surfaces and an enhanced driving stability on snowy road surfaces at the time when the tire is not punctured, as well as an enhanced maneuverability, particularly starting ability, on icy road surfaces in run-flat running where the tire is punctured. Three belt layers (8, 9, 10) are disposed on an outer circumferential side of a carcass layer (6) in a tread portion (4). In addition, as to the three belt layers, the cord angle α of the innermost belt layer (8) with respect to a circumferential direction of the tire is set at 15° to 30°, the cord angle β of the intermediate belt layer (9) with respect to the circumferential direction of the tire is set at not less than 40°, and the cord angle γ of the outermost belt layer (10) with respect to the circumferential direction of the tire is set at 35° to 70°.

Owner:THE YOKOHAMA RUBBER CO LTD

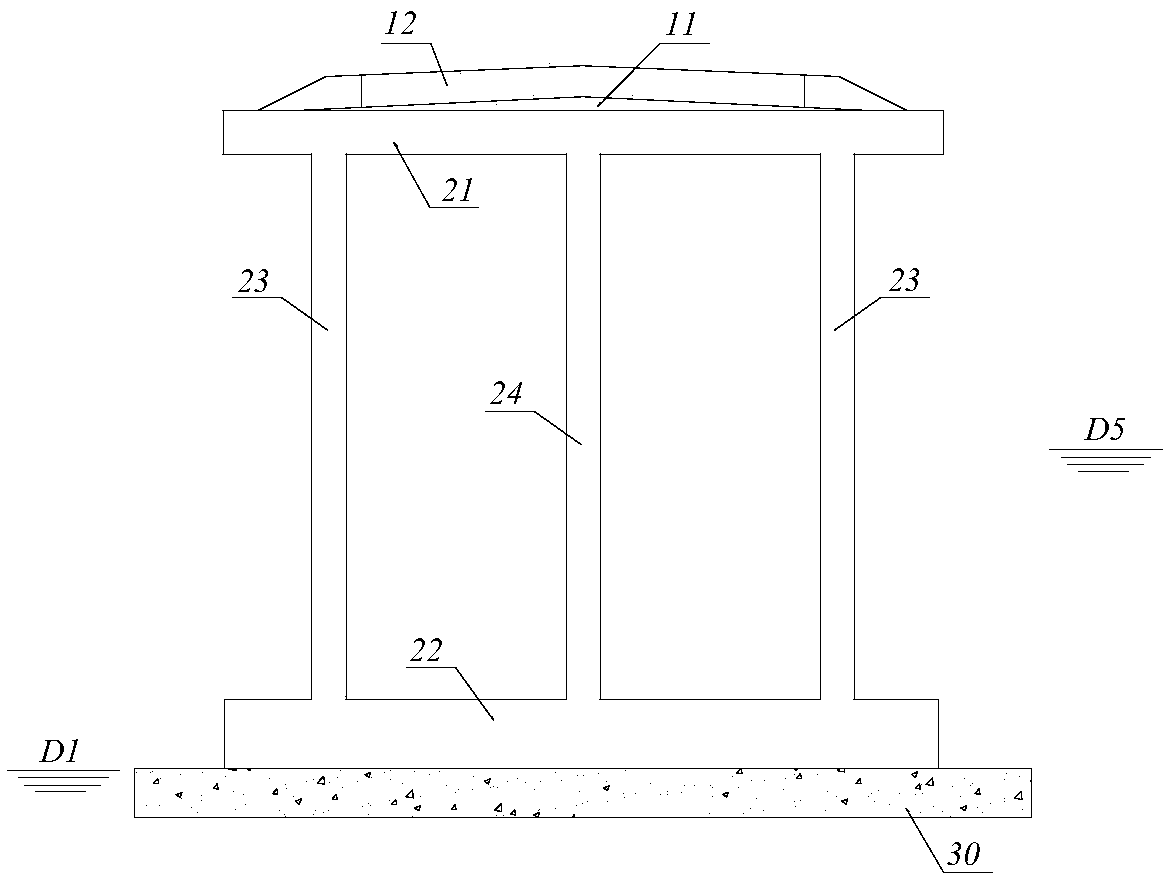

Railway high embankment vertical diaphragm box structure

In order to effectively improve the overall rigidity of the box structure and reduce the stress on the web, the invention provides a railway high embankment vertical diaphragm box structure to meet the safety and stability requirements of the railway high embankment slope and to solve the durability problem of the embankment structure. Comprises continuously arranged reinforced concrete box-shapedsegments along the extension direction of the embankment, wherein each reinforced concrete box-shaped segment is integrally poured by a top plate, a bottom plate, two side webs and a vertical middlepartition plate located between the two side webs; the upper end of the reinforced concrete box-shaped segment is arranged, and the lower end is respectively consolidated with the top plate and the bottom plate into a vertical middle partition plate; The top plate and the transverse two ends of the bottom plate respectively extend out the same side web plate to form an outer overhanging structure,and the bottom plate is seated on the sand cushion layer; A base bed bottom layer and a base bed surface layer are sequentially constructed on the top plate from bottom to top.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Double crank type hollow flexible hinge

The invention discloses a hyperbolic rod-type hollow flexible hinge, symmetrically cutting out left and right reels on the two opposite surfaces of a rectangular cube, cutting out vertical bar in the vertical center of the rectangular cube, cutting out horizontal bar in the horizontal center of the rectangular cube, and the vertical bar, the horizontal bar and the right reel form hollow regions A and C, the vertical bar, the horizontal bar and the left reel form hollow regions B and D; the left and right reels and the horizontal and vertical bars separate the rectangular cube into upper and lower link rods. And the invention adopts hollow design and converts the traditional notched flexible hinge into reel flexible hinge, thus enlarging its rotation range and reducing structural inner stress, and applied to large-travel intelligent control mechanisms.

Owner:BEIHANG UNIV

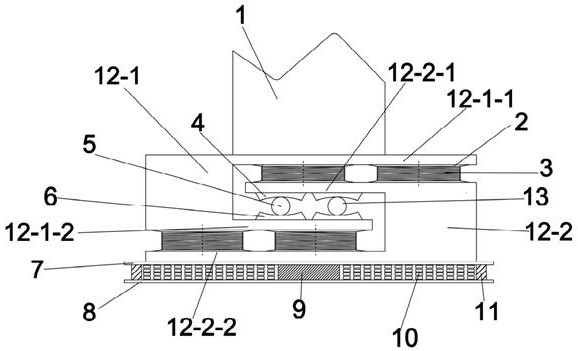

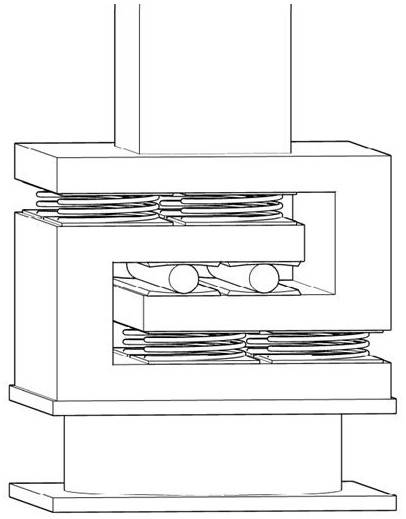

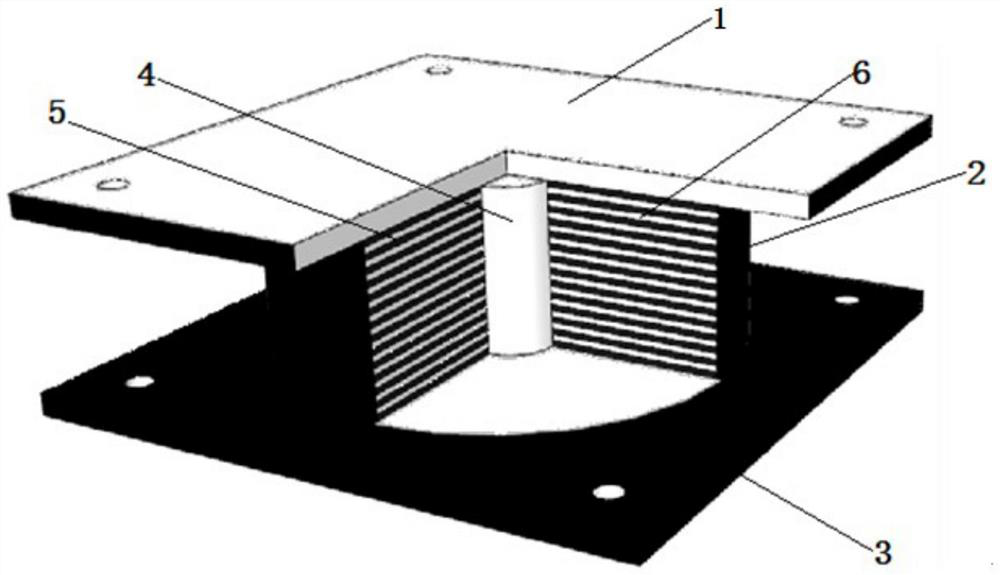

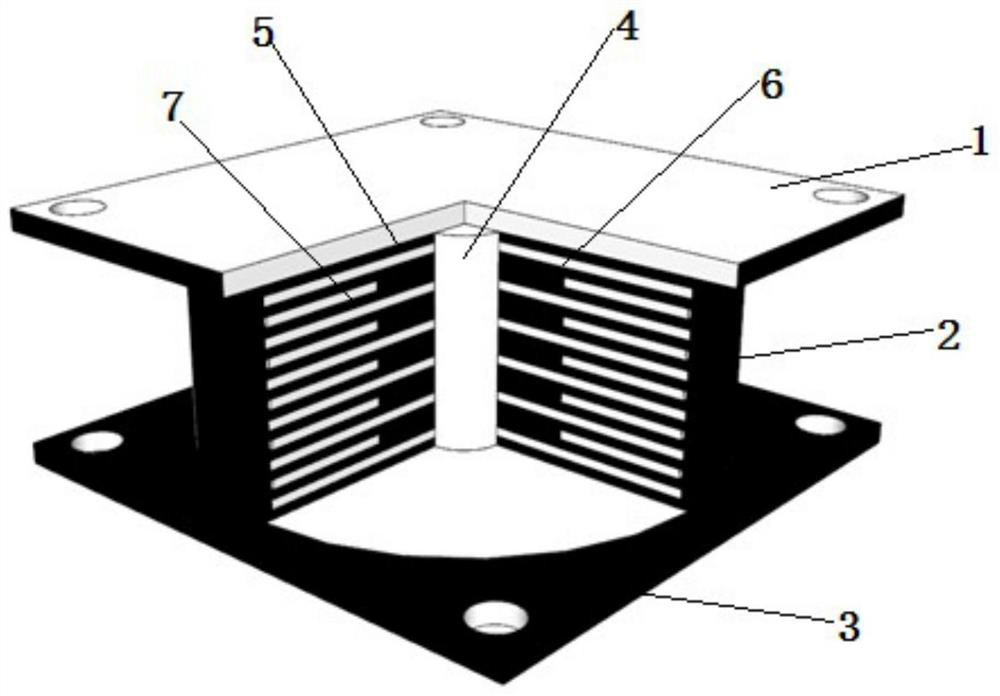

Vibration reduction column composite foundation for subway station and vibration reduction method of vibration reduction column composite foundation

ActiveCN114319415ALow tensile strengthImprove the forceArtificial islandsProtective foundationArchitectural engineeringStructural engineering

The invention discloses a vibration reduction column composite foundation for a subway station and a vibration reduction method thereof, and the vibration reduction column composite foundation comprises a foundation bottom energy dissipation composite structure located at the bottommost part of the whole foundation; the two special-shaped U-shaped supports are arranged on the upper portion of the foundation bottom energy dissipation composite structure and comprise the first special-shaped U-shaped support and the second special-shaped U-shaped support, and the first special-shaped U-shaped support comprises a first upper horizontal supporting plate and a first lower horizontal supporting plate which are arranged in parallel; a lead rod is arranged in the center of the foundation bottom energy dissipation composite structure, and the two sides of the lead rod are each of a multi-layer viscous-elastic material composite steel plate structure. Vibration generated by the whole station can be effectively reduced, the multi-layer and multi-dimensional vibration reduction effect is achieved, the main structure of the station is effectively prevented from cracking due to long-term vibration, and the safety of long-term operation is guaranteed.

Owner:SOUTHEAST UNIV

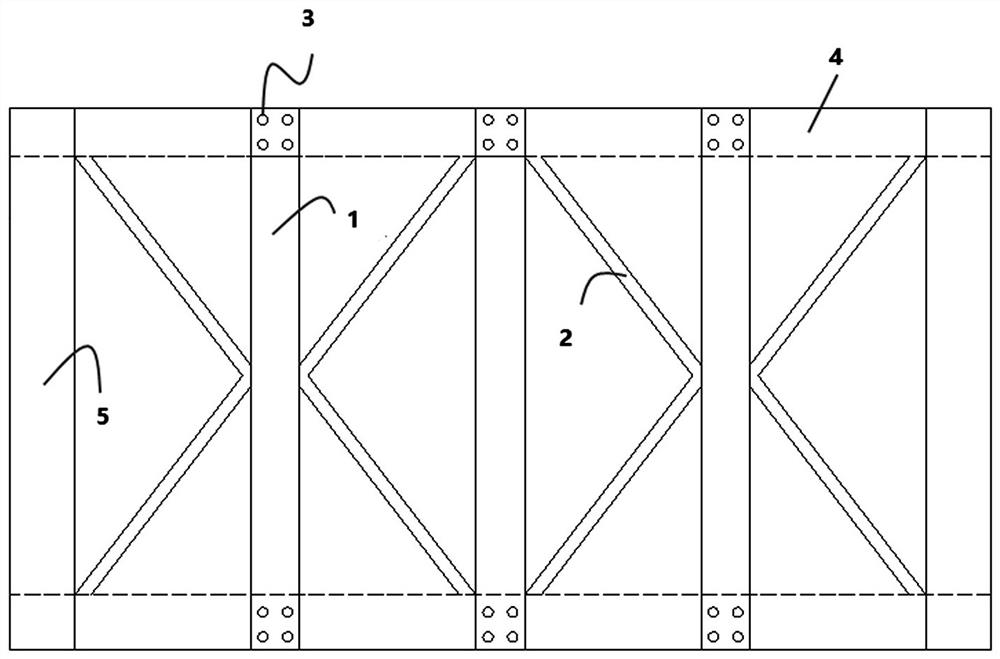

Corrugated steel plate recycled concrete anti-seismic sound-insulation shear wall

InactiveCN111764537AReduce usageShorten the construction periodConstruction materialWallsClassical mechanicsSoundproofing

The invention discloses a corrugated steel plate recycled concrete anti-seismic sound-insulation shear wall. The shear wall comprises an anti-seismic energy consumption structure, a damping sound-insulation structure and a bearing structure, wherein the anti-seismic energy consumption structure comprises a plurality of strip-shaped steel plates, edge beams, edge columns and inclined supports; thedamping sound-insulation structure comprises steel plates, elastic cement gum, corrugated steel plates and steel partition plates; the bearing structure comprises recycled concrete, corrugated steel plates, studs and the like; and the bearing structure, the damping sound-insulation structure and the anti-seismic energy consumption structure are sequentially arranged from inside to outside to formthe shear wall. The shear wall can overcome the defects of an existing steel plate shear wall and has the advantages of being resistant to seismic, insulating sound, reducing construction waste and the like.

Owner:FUZHOU UNIV

A method for improving the mechanical performance of steel-concrete composite multi-box continuous girder bridges in the negative moment zone

ActiveCN106758743BImprove compressive stiffnessImprove unfavorable stress situationsBridgesInformaticsStress conditionsFull bridge

Owner:ZHEJIANG UNIV

High-capacity cylindrical lithium ion battery and production method thereof

InactiveUS9614246B2High densityWeight increaseCylindrical casing cells/batteryWound/folded electrode electrodesWeld strengthUltimate tensile strength

The invention discloses a high-capacity cylindrical lithium ion battery. Tab-position end face is shaped; a high frequency oscillation and pressure are applied on to make the foil bodies softened in the scope of 0.1-6.5 mm. At the instant of high-frequency oscillation, the rigidity of the foil body is greatly decreased; and the foil bodies are mutually wound and compressed together, so that the weight density of the foil body in unit volume is increased and meanwhile, the rigidity of the compressed foil body at the Tab-position end face is greatly increased, thereby laying a firm foundation for laser welding of the 1 Tab-position end face and a current collector, increasing a laser welding effective area of the Tab-position end face and the current collector, and improving the welding strength.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

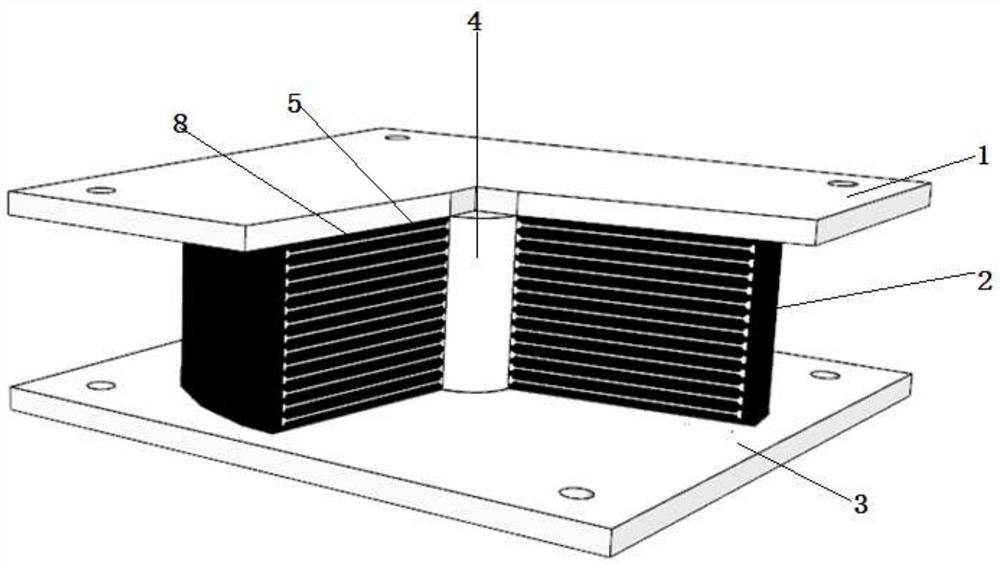

Flexible high-tensile-strength and anti-corrosion integrated shock insulation rubber support

ActiveCN113718977AIncreasing the thicknessImprove anti-overturn performanceProtective buildings/sheltersShock proofingVulcanizationInsulation layer

The invention discloses a flexible high-tensile-strength and anti-corrosion integrated shock insulation rubber support. Integrated vulcanization anti-corrosion layers are arranged on the faces, facing a support body, of an upper flange plate and a lower flange plate and the side faces of the upper flange plate and the lower flange plate; and a framework plate comprises one or more large-hole framework plate bodies. The large-hole framework plate bodies, conventional framework plate bodies or edge special-shaped framework plate bodies are independently used or used in cooperation, on the premise that the lateral restraint of a steel plate on internal rubber is not weakened, the total thickness of a rubber layer is increased, the vertical compressive rigidity and the vertical bearing force of the shock insulation rubber support cannot be reduced, the horizontal rigidity and the vertical tensile rigidity are further reduced, and the shock insulation efficiency and the tensile capacity of a shock insulation layer are improved. The anti-corrosion capacity of the support can be improved through the arrangement of the integrated anti-corrosion layers, the production process is simplified, and the production cost is reduced.

Owner:KUNMING UNIV

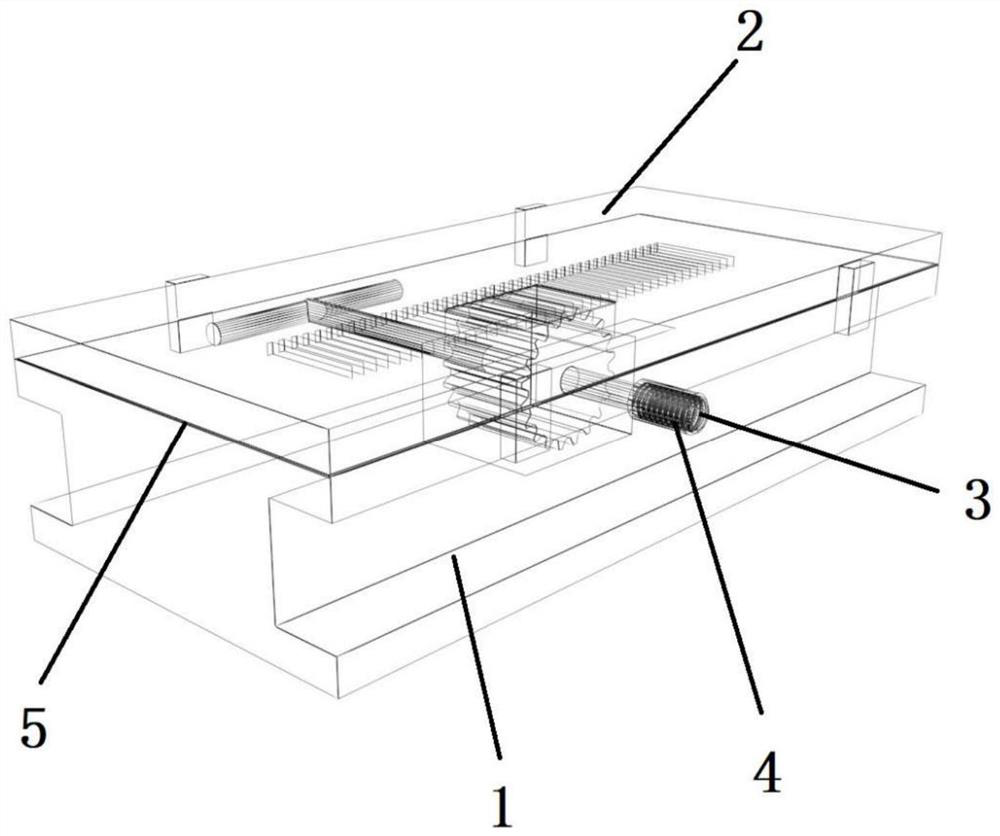

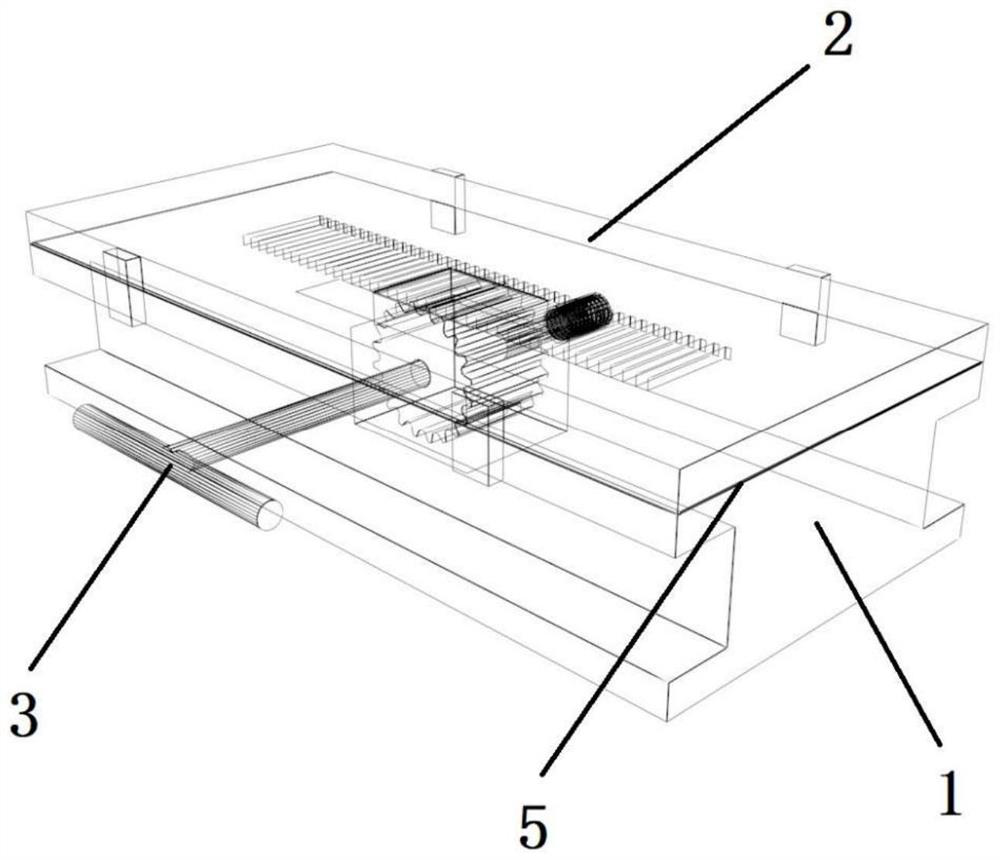

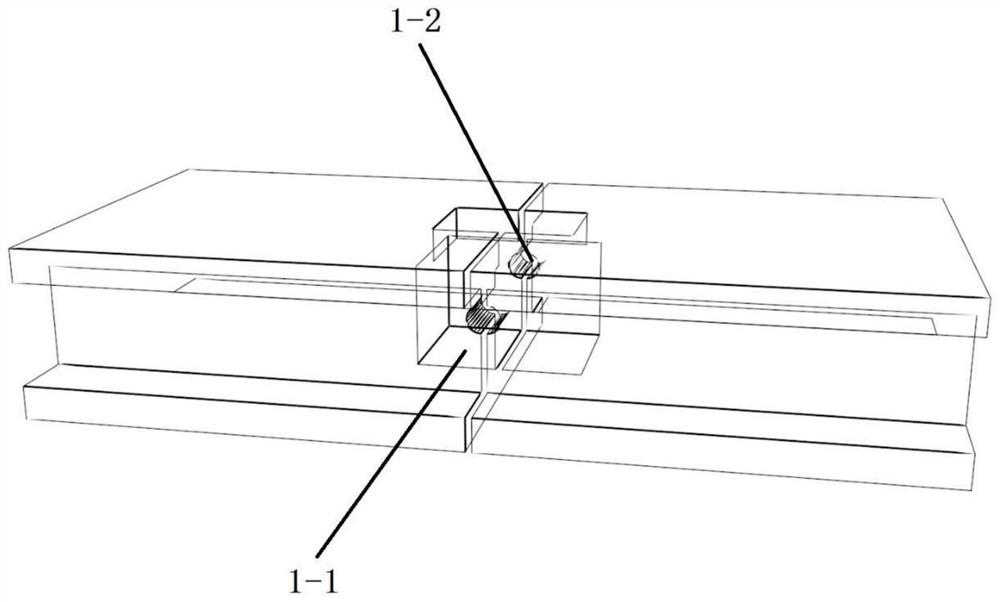

Self-anchored suspension bridge bearing bottom sliding support device and longitudinal displacement adjustment method

InactiveCN109137725BSimple structureEasy to installBridge structural detailsBridge erection/assemblyGear driveDrive shaft

Owner:CHANGAN UNIV

Railway high-fill embankment box structure

The invention provides a railway high-fill embankment box structure, which can effectively improve the overall rigidity of the box structure, effectively meet the safety and stability requirements ofrailway high embankment slope, at the same time, solve the durability problem of embankment structure, reduce the differential settlement of foundation, and adapt to the requirements of foundation bearing capacity. Comprises continuously arranged reinforced concrete box-shaped segments along the extension direction of the embankment, wherein each reinforced concrete box-shaped segment is integrally poured from a top plate, a bottom plate and two web plates on both sides, and the bottom plate sand is seated on a cushion layer; The two transverse ends of the top plate and the bottom plate respectively extend out the same side webs to form an outer overhanging structure, and the bottom layer of the base bed and the surface layer of the base bed are sequentially constructed from the bottom tothe top of the top plate.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

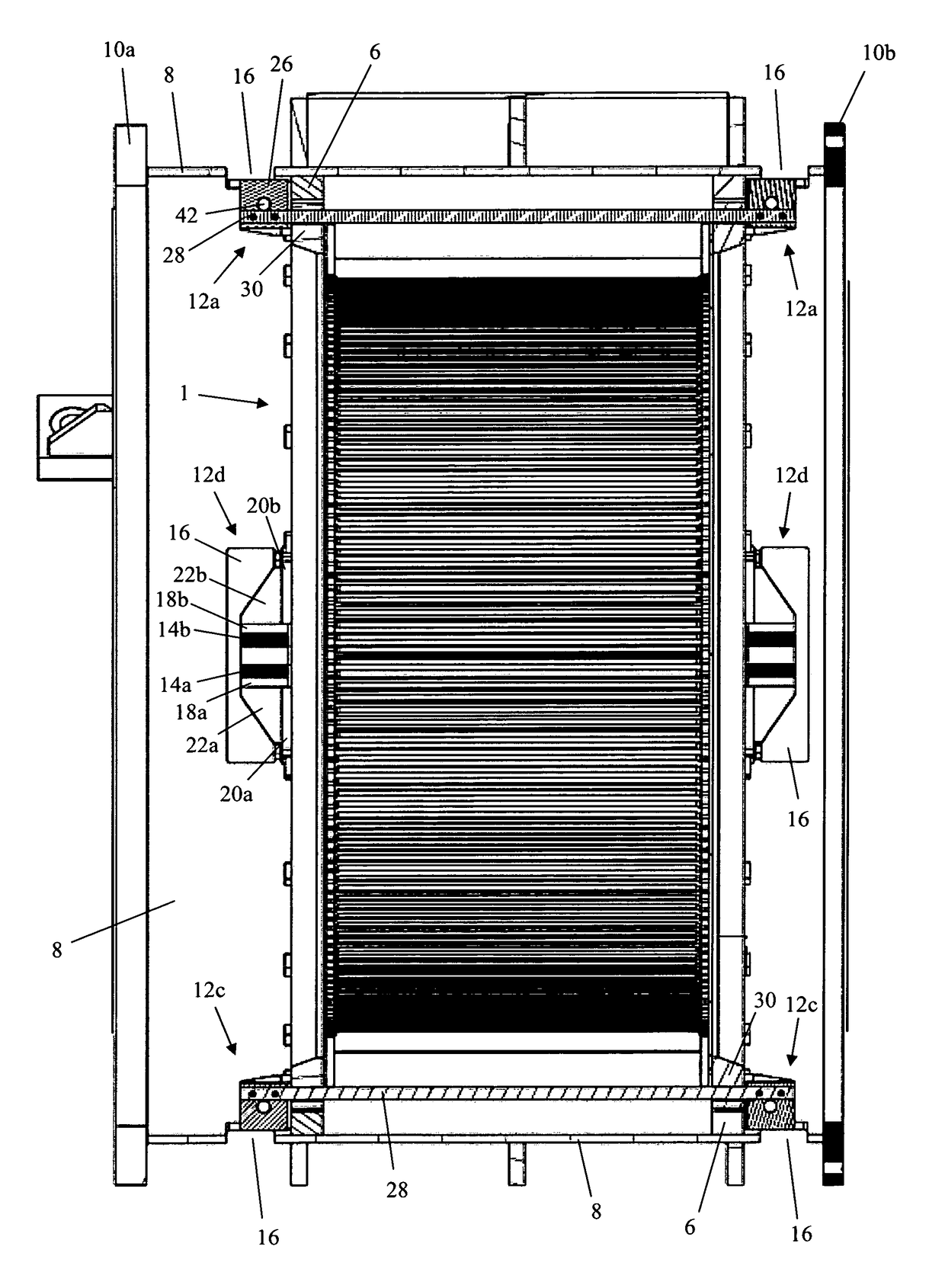

Suspension structures

ActiveUS9692262B2Restrain tangential deflectionAvoid deflectionMagnetic circuit stationary partsSupports/enclosures/casingsHigh stiffnessEngineering

Owner:GE ENERGY POWER CONVERSION TECH

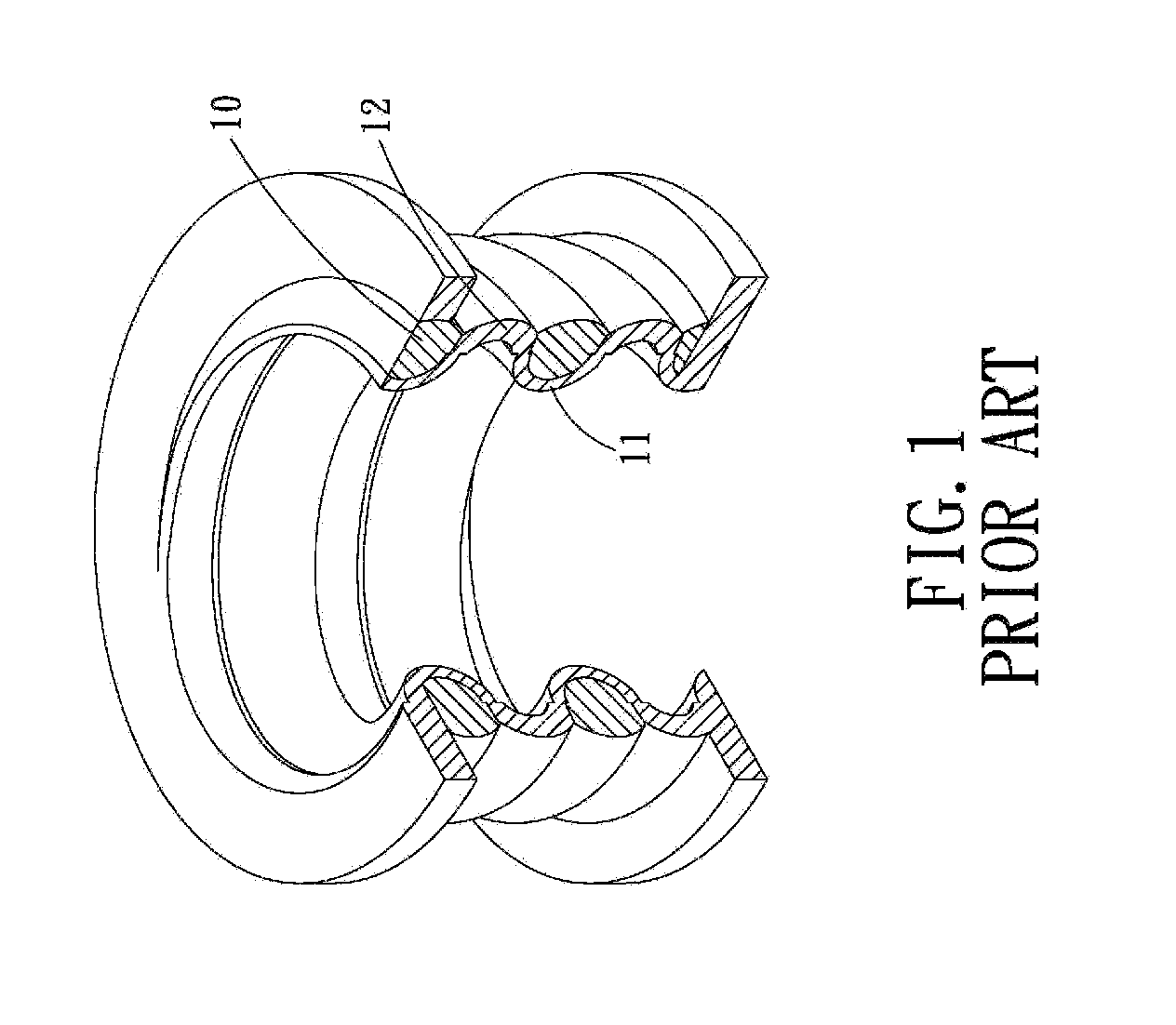

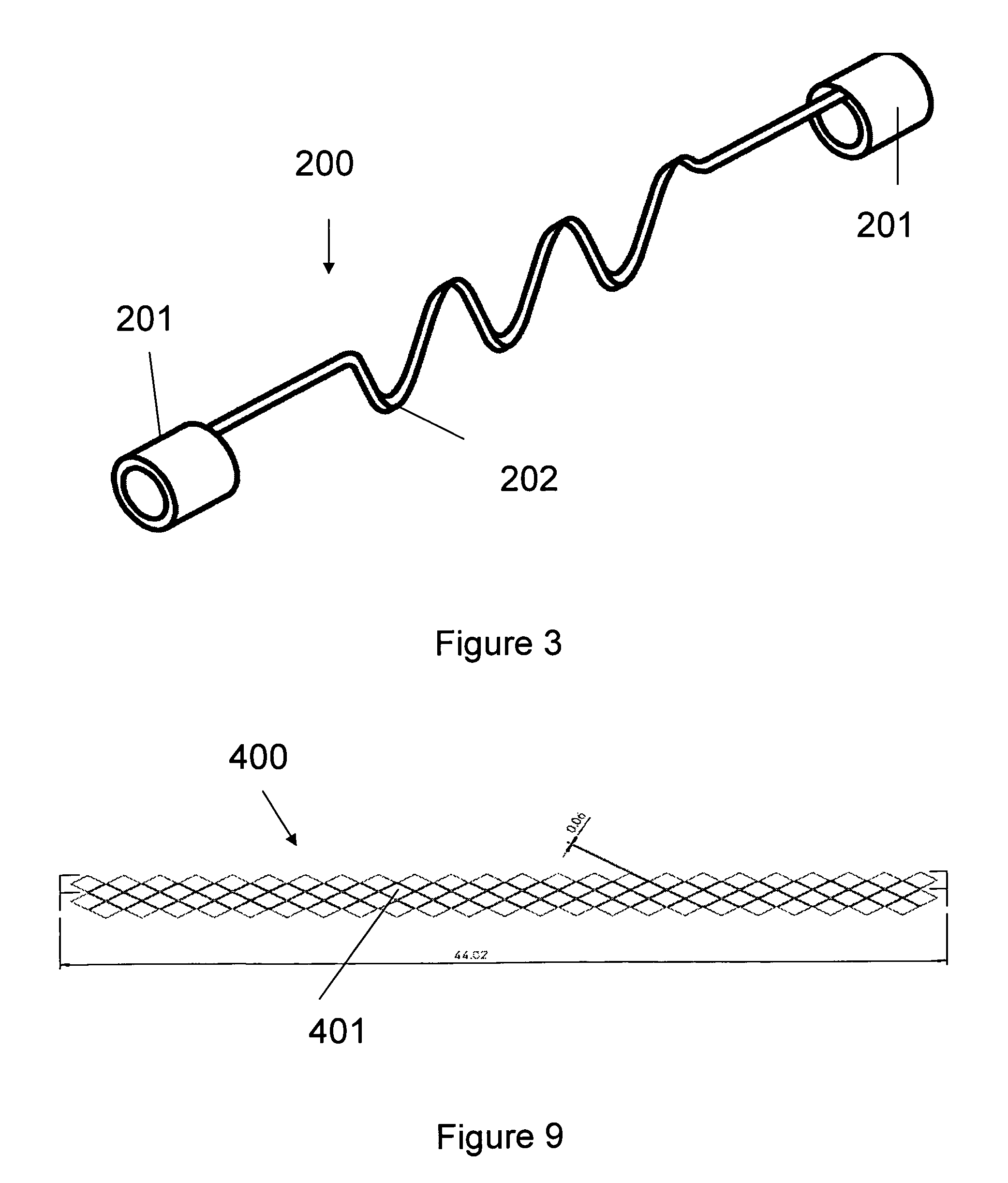

Run flat support body for pneumatic tire

InactiveUS7681614B2Improve machinabilityImproved run-flat durabilityPneumatic tyre reinforcementsWheelsFiberEngineering

Owner:THE YOKOHAMA RUBBER CO LTD

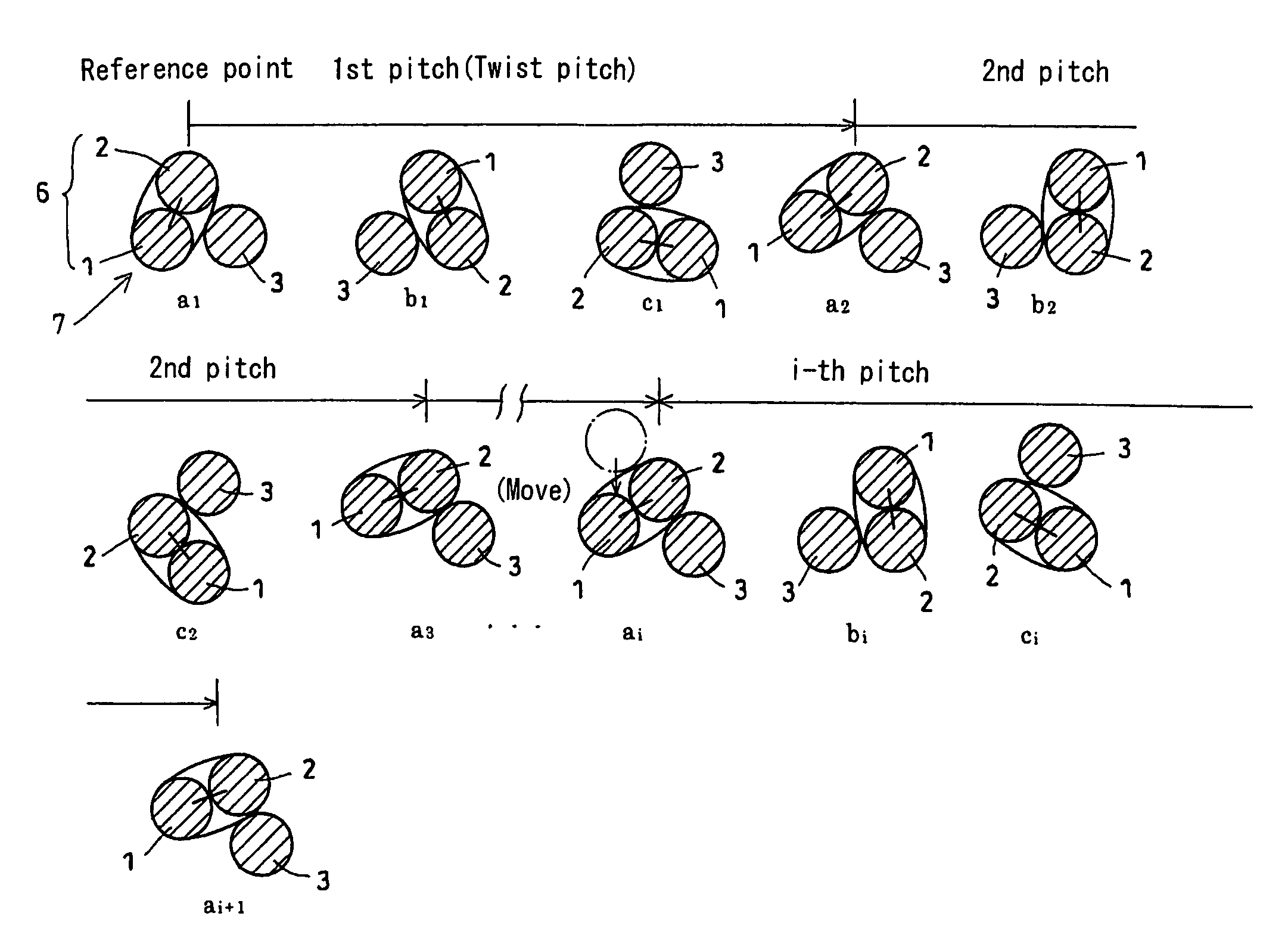

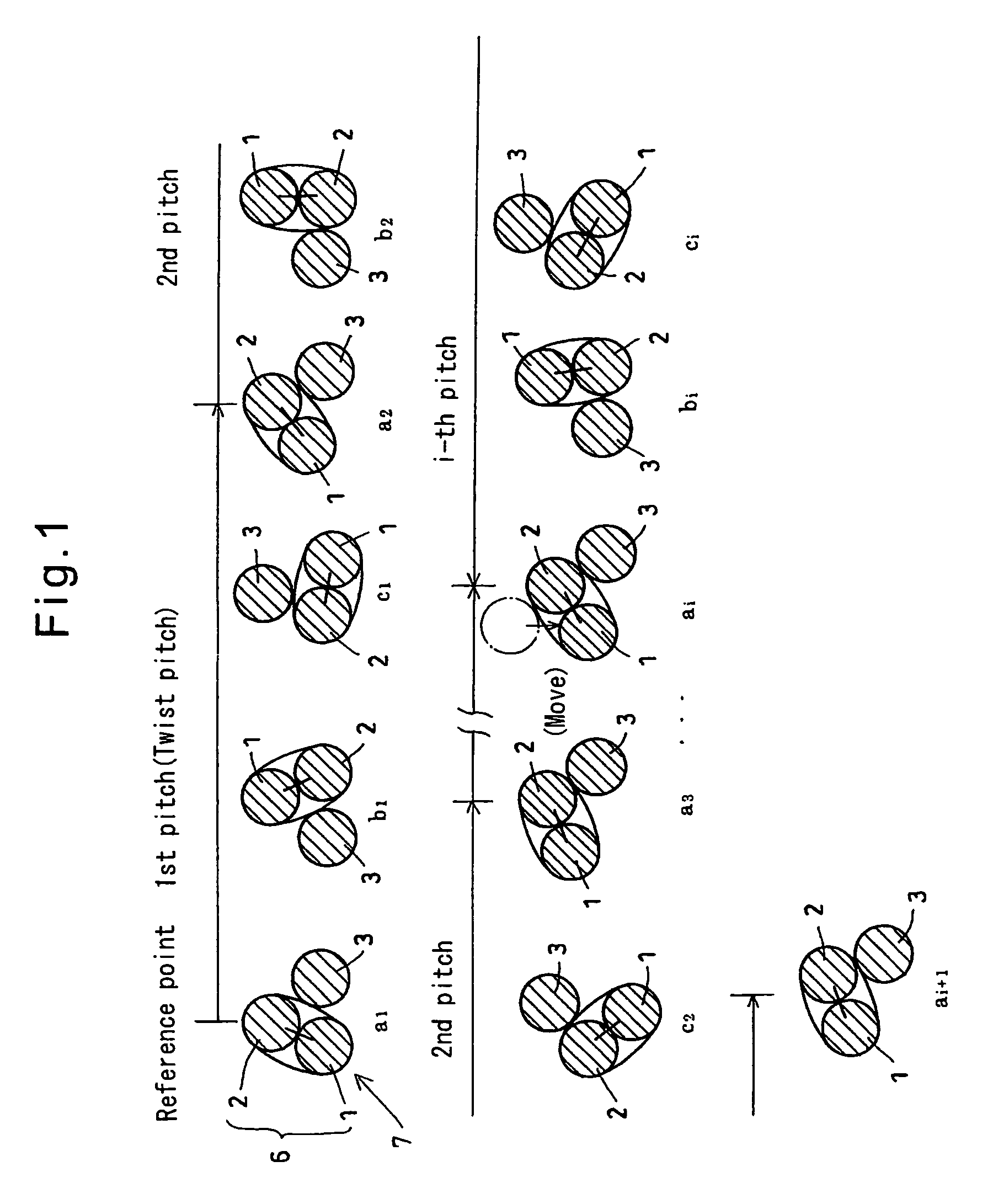

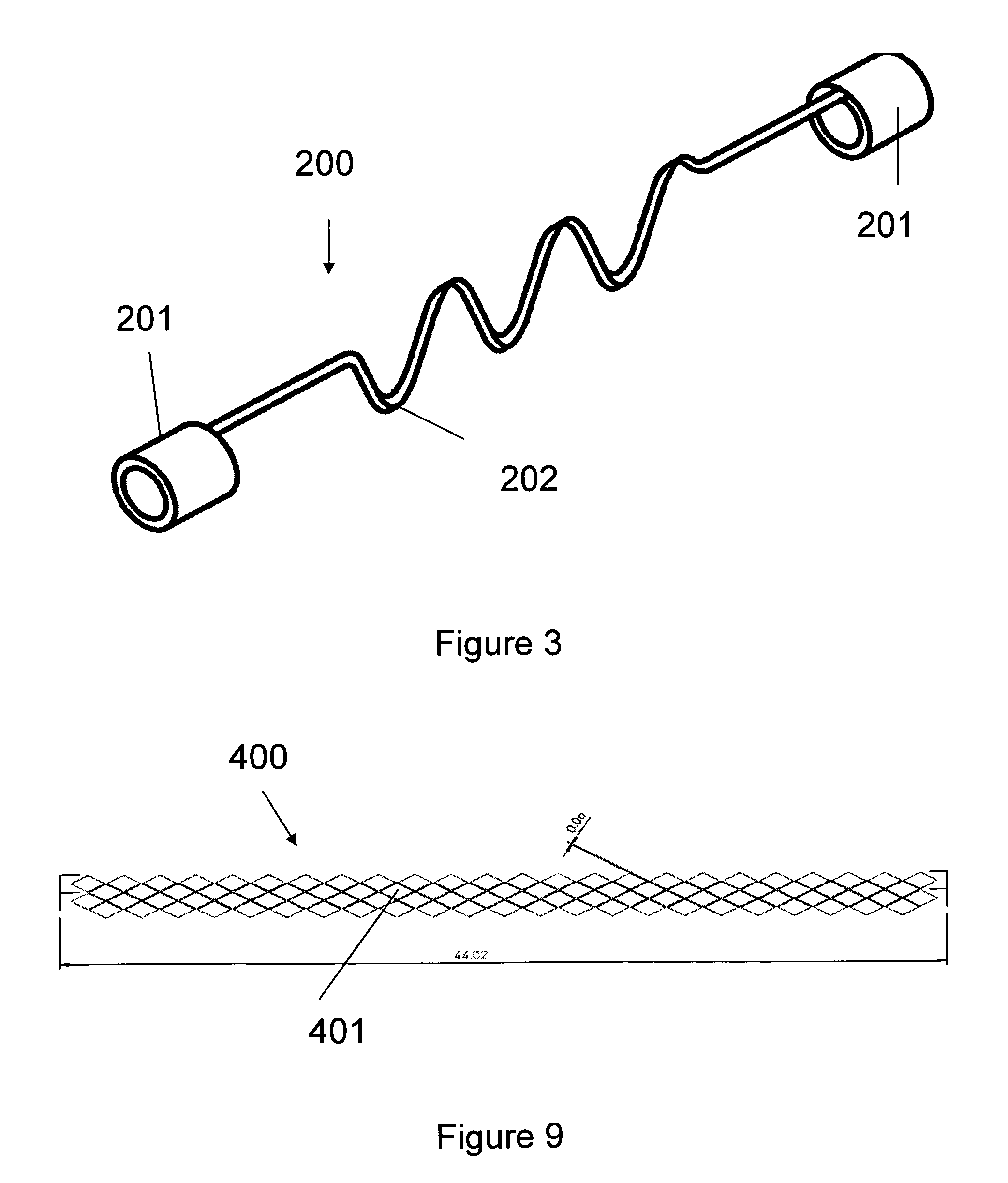

Rubber product-reinforcing metallic cord and method for manufacturing such a cord

InactiveUS7596937B2Smoothly and sufficiently penetrate into cordImprove compressive stiffnessPneumatic tyre reinforcementsRope making machinesMetallurgyHelix

Owner:SUMITOMO (SEI) STEEL WIRE CORP +1

Catheter with enhanced pushability

InactiveUS9352120B2Increase thrustImprove pushabilityStentsBalloon catheterBalloon catheterLinkage concept

Apparatus for enhancing pushability and minimizing kinking of a balloon catheter is provided, wherein a catheter comprises inner and outer tubes, and a balloon that is proximally affixed to the outer tube and distally affixed to the inner tube. The catheter of the present invention further comprises a tubular member imposed on the inner tube which is configured to form a reversible mechanical linkage between inner tube and outer tube while an axially compressive load is applied to the catheter tip.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

Pneumatic membrane compression bar and manufacturing method thereof

Owner:BEIJING UNIV OF TECH

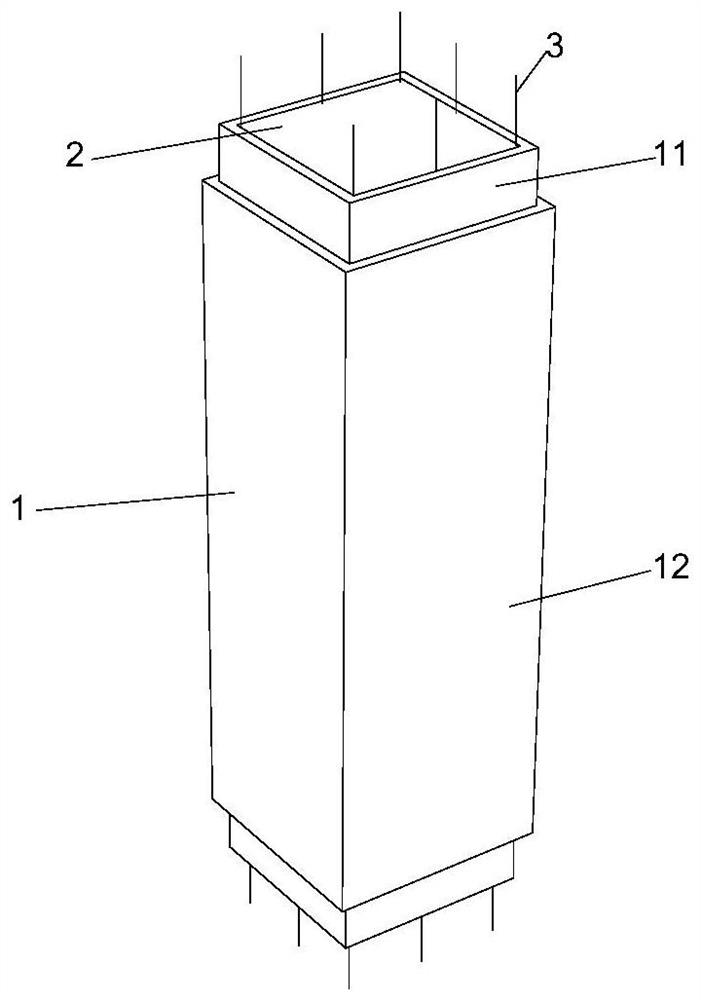

Rectangular steel tube confined ultrahigh-strength concrete column and construction method thereof

PendingCN114000586AImprove carrying capacityImprove compressive stiffnessBuilding reinforcementsBuilding material handlingArchitectural engineeringRebar

The invention discloses a rectangular steel tube confined ultrahigh-strength concrete column and a construction method thereof. The rectangular steel tube confined ultrahigh-strength concrete column comprises a steel tube assembly, ultrahigh-strength concrete and longitudinal reinforcing steel bars, the steel tube assembly comprises a rectangular steel tube and two rectangular steel sleeves, and the outer contours of the two rectangular steel sleeves are matched with the inner contour of the rectangular steel tube; the two rectangular steel sleeves are connected into the two ends of the rectangular steel pipe in a sleeved mode respectively, and the longitudinal ends of the two rectangular steel sleeves correspondingly protrude out of the two ends of the rectangular steel pipe respectively. The ultrahigh-strength concrete and the longitudinal reinforcing steel bars are arranged in the steel pipe assembly, and the ultrahigh-strength concrete is attached to the inner wall of the steel pipe assembly. The bearing capacity of the structure can be effectively improved by adopting the ultrahigh-strength concrete, and the rectangular section has the characteristics of regular arrangement and simple and convenient node construction; the rectangular steel sleeve is additionally arranged at the column end, so that the compressive rigidity of the section of the column end can be improved, and the non-deformability is improved.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com