Self-anchored suspension bridge bearing bottom sliding support device and longitudinal displacement adjustment method

A technology for self-anchored suspension bridges and supporting devices, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of affecting the normal working state of bearings, expensive large bearings, and damage to bearings, and achieves easy adjustment methods operation, improving the stress condition of longitudinal shear deformation, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

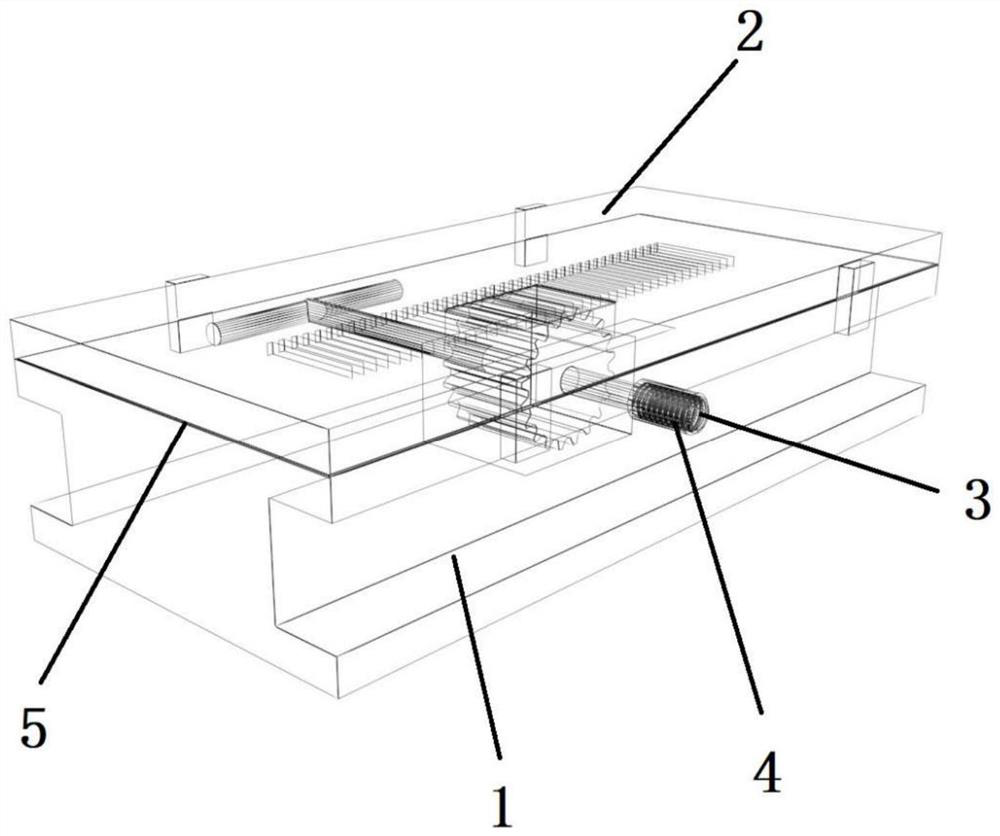

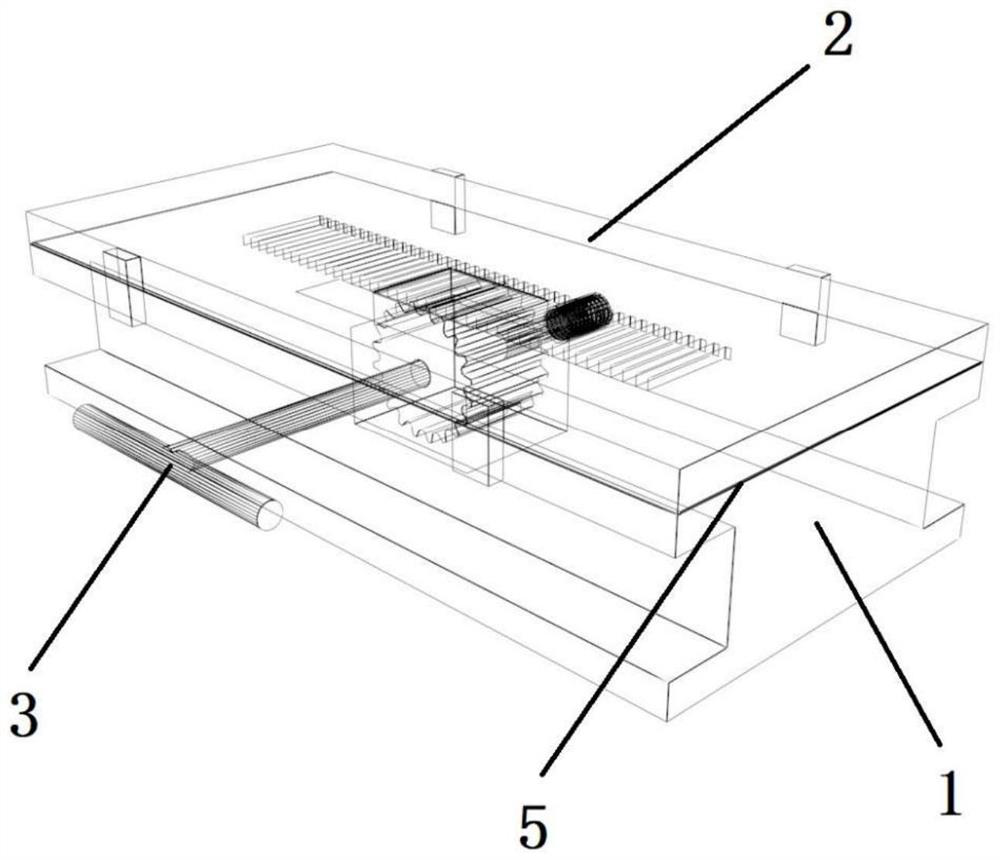

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

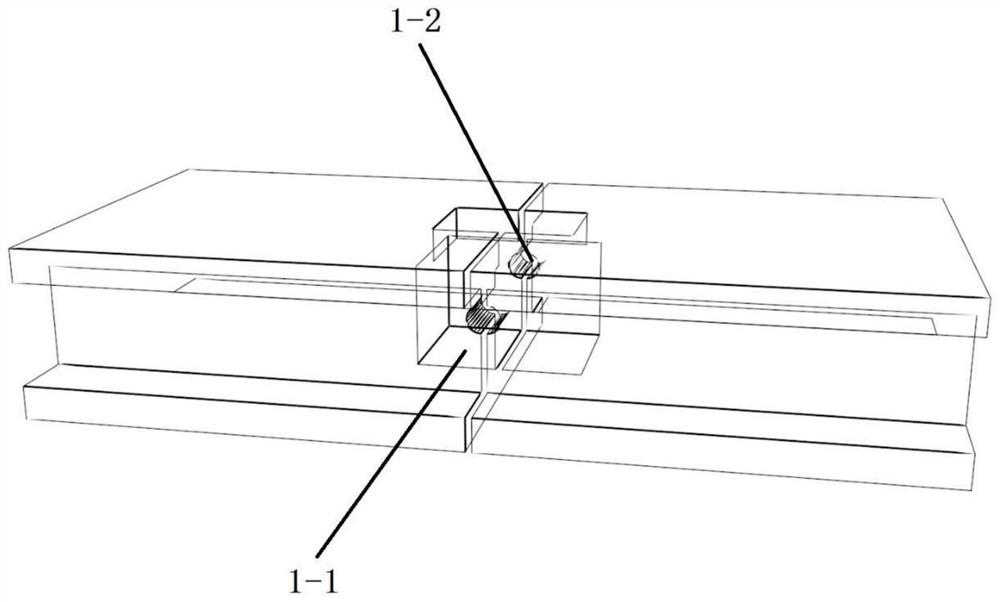

[0028] see Figure 1-2 , The self-anchored suspension bridge bearing bottom sliding support device of the present invention structurally includes a support guide rail 1, a sliding plate 2, a transmission spur gear shaft 3, a fixed nut 4, a sliding washer 5 and a temporary jack. Such as image 3 As shown, the sliding plate 2 is installed on the supporting guide rail 1, and the supporting guide rail 1 is provided with a cavity 1-1, and the two sides of the cavity 1-1 communicate with the hole 1-2 that runs through the supporting guide rail 1 transversely, and the supporting guide rail 1 is composed of It is assembled from two parts separated longitudinally from the cavity 1-1. see Figure 4 , the lower surface of the sliding plate 2 is processed with equally spaced grooves 2-2, and the two sides of the sliding plate 2 are symmetrically provided with four lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com