Railway high-fill embankment box structure

A high filling and railway technology, applied in roads, buildings, tracks, etc., can solve problems that have not been reported, and achieve the effects of simple construction technology, reducing compressive stress, and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

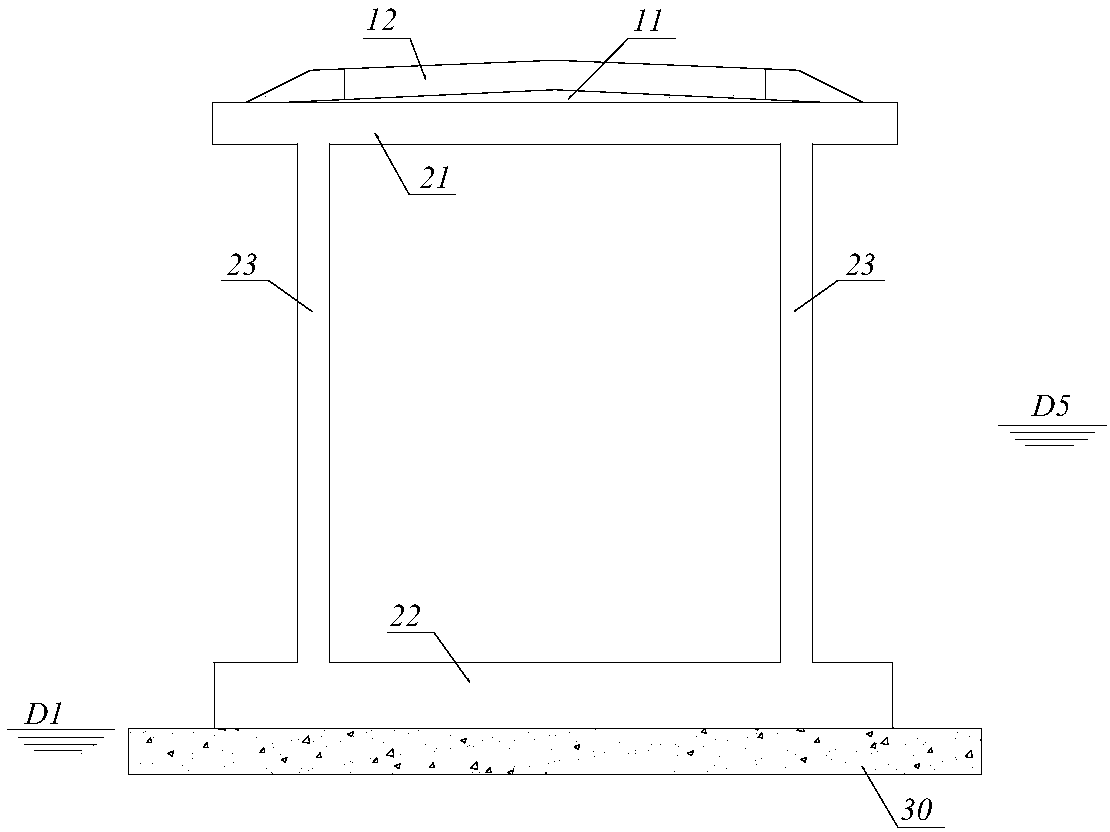

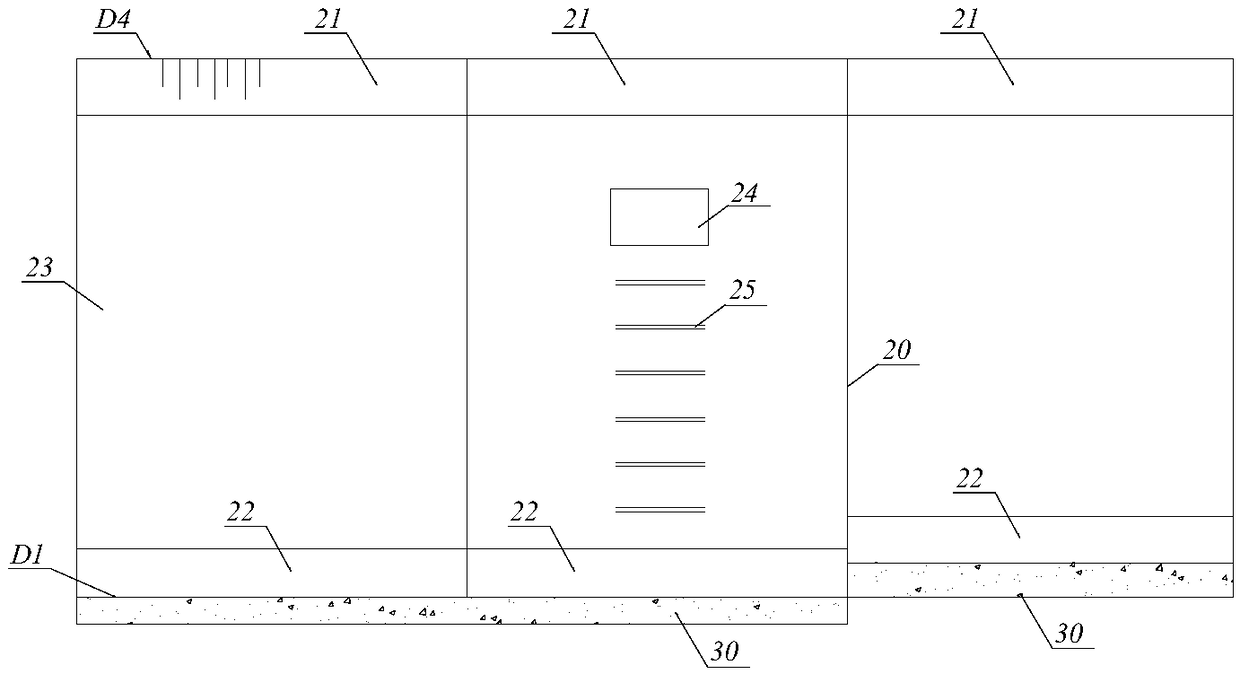

[0018] refer to figure 1 , the railway high-fill embankment box structure of the present invention includes reinforced concrete box-shaped segments arranged continuously along the embankment extension direction, and each reinforced concrete box-shaped segment is integrally poured from a top plate 21, a bottom plate 22, and two side webs 23 , the base plate 22 sand is located on the cushion layer 30; the lateral ends of the top plate 21 and the bottom plate 22 respectively extend out from the webs 23 on the same side to form an overhang structure, and the width of the bottom plate 22 and the top plate 21 exceeds the width of the webs 23 on both sides. spacing. On the top plate 21, the bottom layer 11 of the foundation bed and the surface layer 12 of the foundation bed are sequentially constructed from bottom to top.

[0019] refer to figure 1 , Compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com