Flexible high-tensile-strength and anti-corrosion integrated shock insulation rubber support

A technology of shock-isolation rubber and high tensile strength, which is applied in the direction of shock-proof, building types, buildings, etc., and can solve problems such as poor tensile performance of shock-isolation rubber bearings, inability to achieve integrated anti-corrosion, and potential safety hazards of shock-isolation structures. , to achieve the effect of improving the anti-overturning ability, improving the isolation efficiency and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

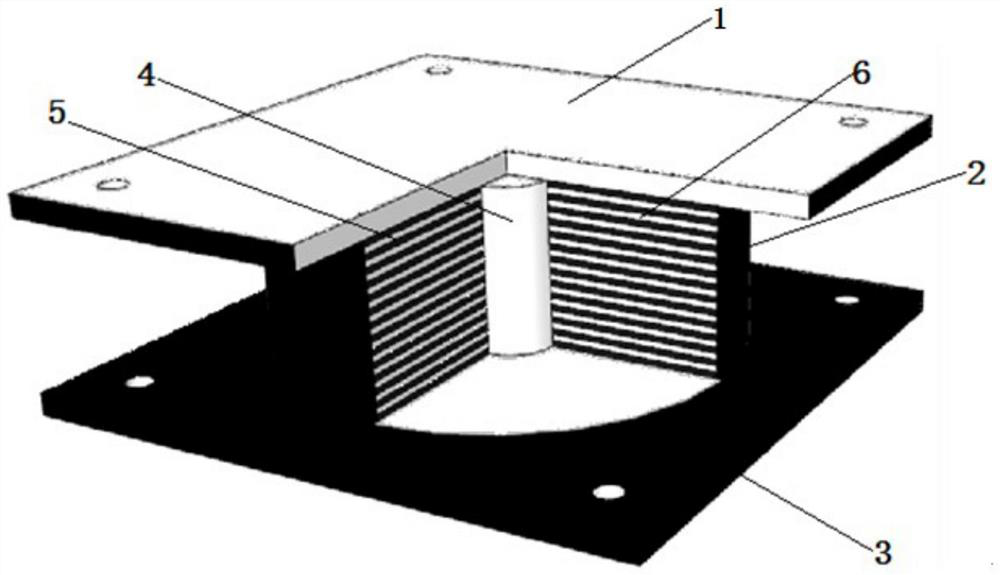

[0026] A flexible high-tensile anti-corrosion integrated shock-isolation rubber bearing, such as figure 1 As shown, it includes an upper flange plate 1, a support body, and a lower flange plate 3; the support body includes a protective rubber 2, a lead core 4, an internal rubber layer 5, and a skeleton plate 6, and the upper flange plate 1 is set on the support Above the body, the lower flange plate 3 is arranged under the support body; the inner rubber layer 5 and the skeleton plate 6 are alternately stacked, the center holes of the inner rubber layer 5 and the skeleton plate 6 are equal in size, and the protective glue 2 is wrapped in the inner rubber layer 5 and On the side of the frame plate 6, the lead core 4 is set at the center of the support body, its outer diameter is closely matched with the inner rubber layer 5 and the center hole of the frame plate 6, and its two ends bear on the upper flange plate 1 and the lower flange plate 3. The upper flange plate 1 and the lo...

Embodiment 2

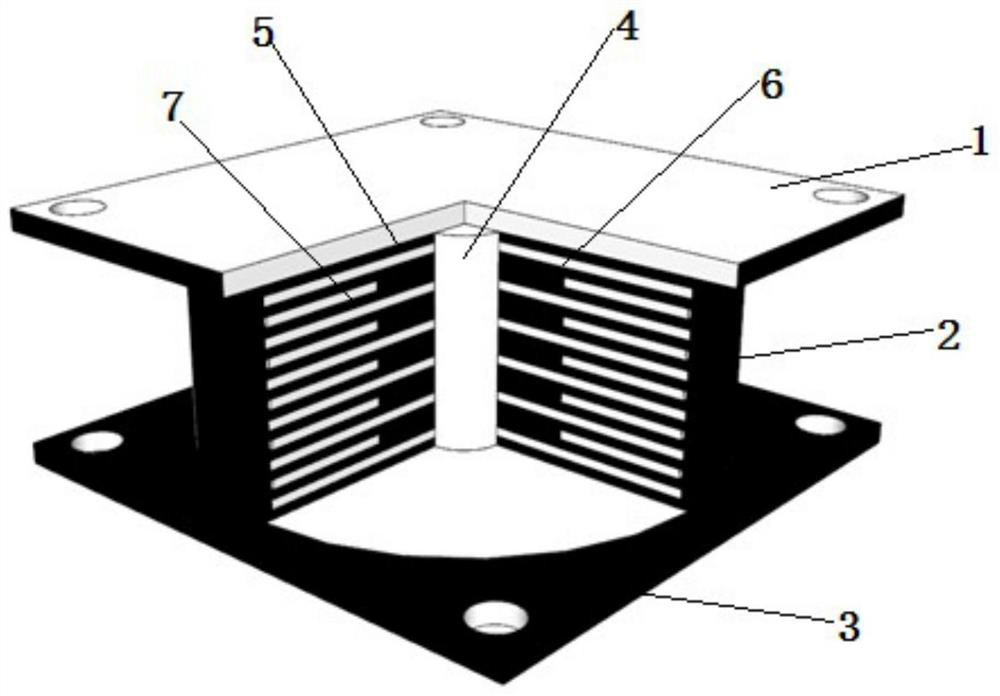

[0030] A flexible high-tensile anti-corrosion integrated shock-isolation rubber bearing, such as figure 2 As shown, on the basis of Embodiment 1, part of the skeleton plate 6 is set to a large-hole skeleton plate 7, and the center hole of the large-hole skeleton plate 7 is larger than the center hole of the inner rubber layer 5, that is, the center hole of the large-hole skeleton plate 7 Larger than the central hole of the conventional skeleton plate 6, the central hole of the conventional skeleton plate is as large as the central hole of the inner rubber layer 5, the conventional skeleton plate 6 and the large-hole skeleton plate 7 are arranged alternately, and six conventional skeleton plates 6 are arranged in this embodiment and five large-hole skeleton plates 7 are alternately superimposed on the inner rubber layer 5, and other components and connection relations are the same as in embodiment 1.

[0031] It is also possible to replace all conventional skeleton plates 6 wi...

Embodiment 3

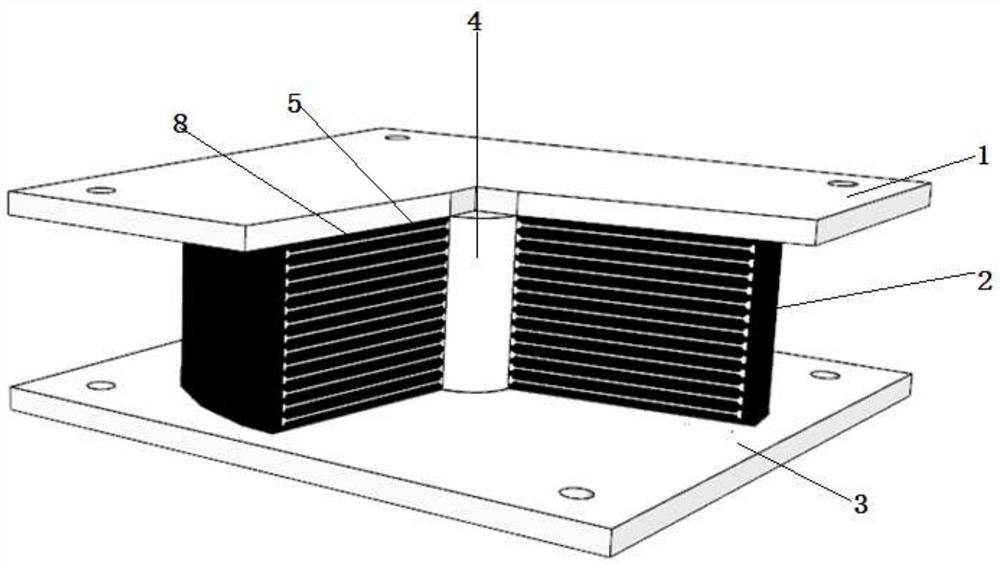

[0034] A flexible high-tensile anti-corrosion integrated shock-isolation rubber bearing, such as image 3 Shown, on the basis of embodiment 1, skeleton board 6 (such as Figure 4 The conventional skeleton board shown) is processed into a special-shaped skeleton board with edges, that is, as Figure 5 As shown in the special-shaped frame plate I8, protrusions are provided on the edge of the special-shaped frame plate I8. The edges include the edge of the center hole and the outer edge. The protrusions are raised on both sides of the frame plate.

[0035] It is also possible to process a part of the skeleton board 6 in Embodiment 1 into a special-shaped skeleton board with edges according to the method of Embodiment 3, and the remaining part is a conventional skeleton board 6. The two kinds of skeleton boards are used in combination, and other components and connection relations are the same as those in the embodiment 3 same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com