Patents

Literature

466results about How to "Improve anti-overturn performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

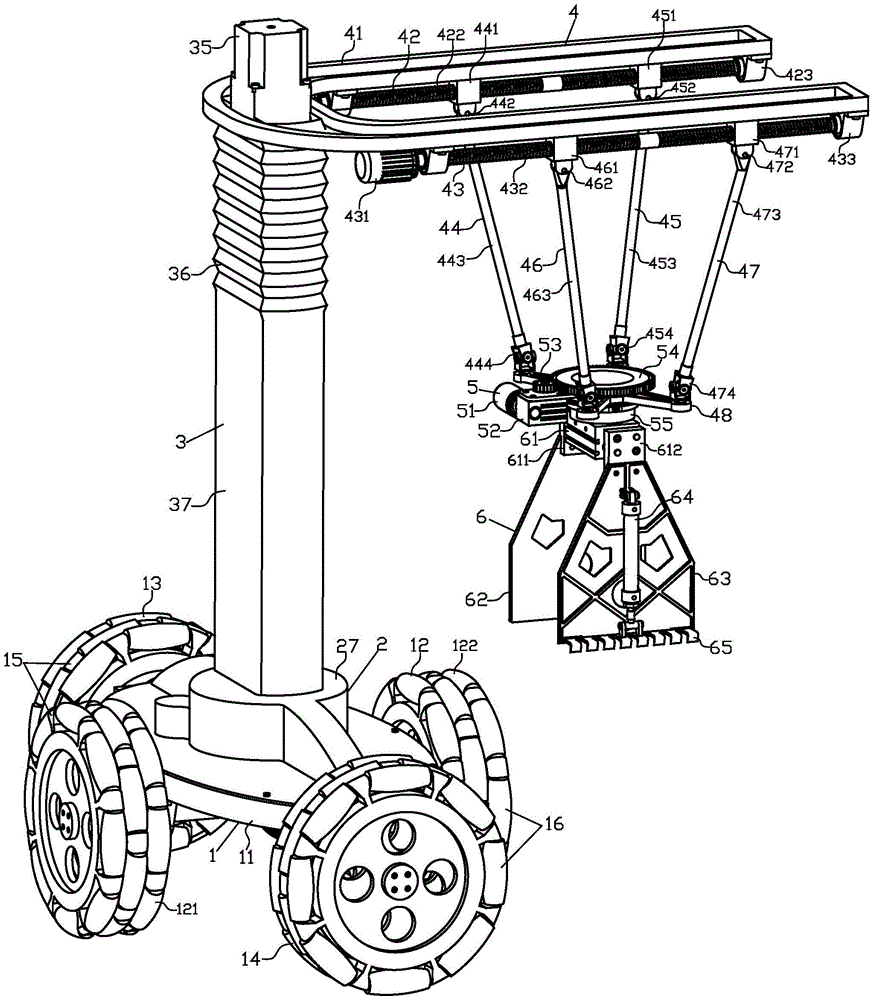

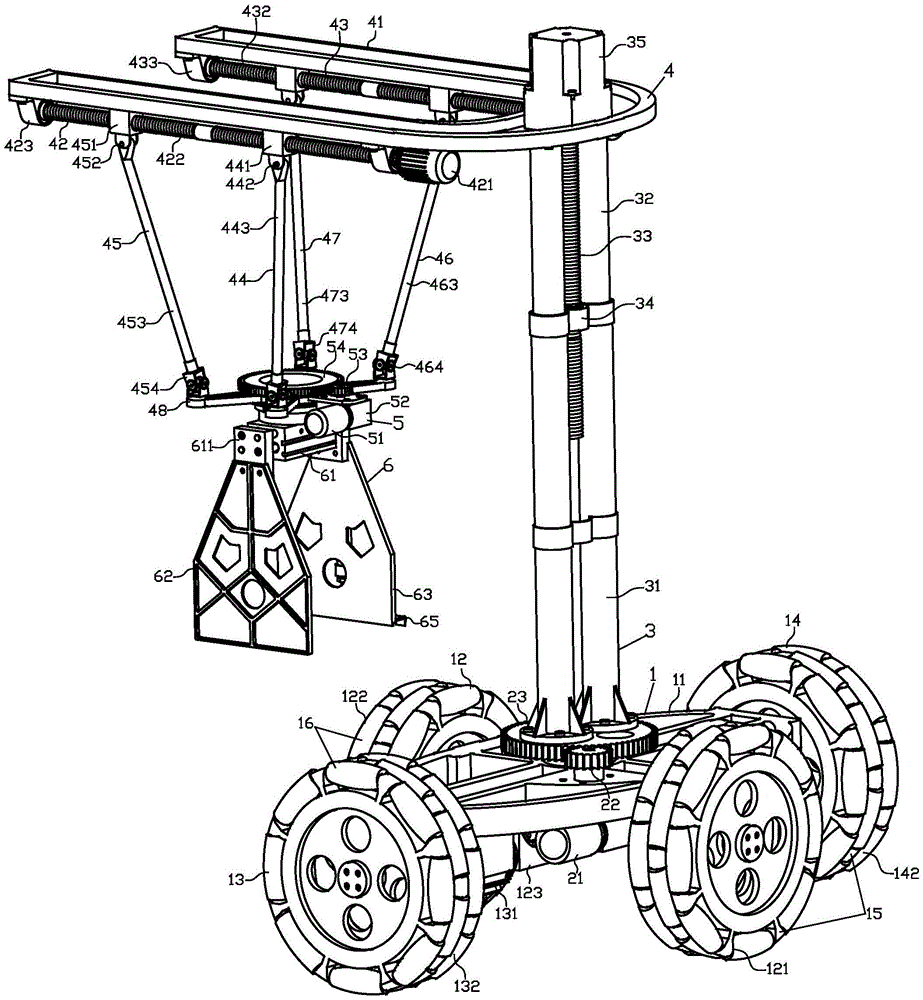

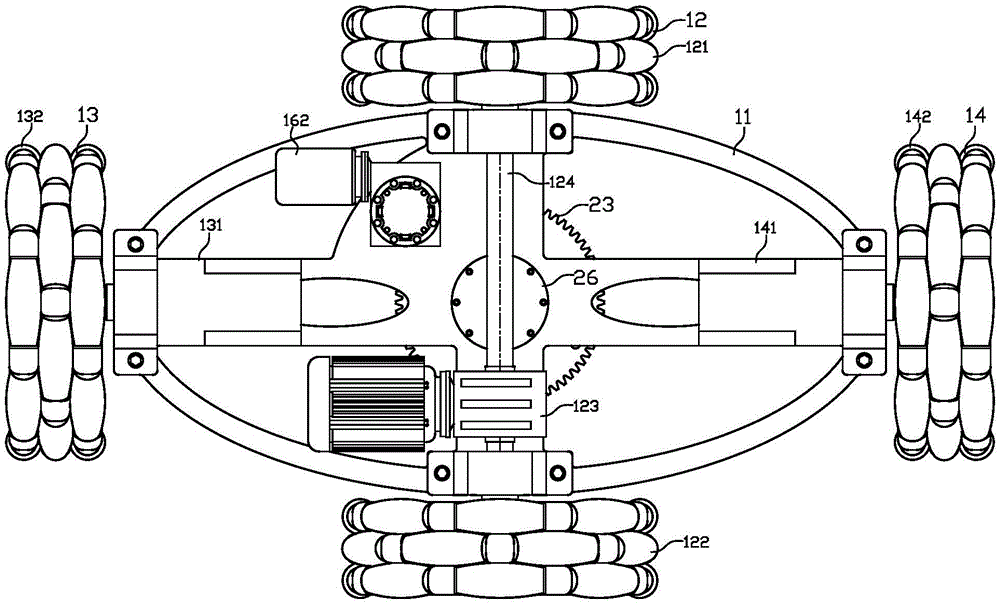

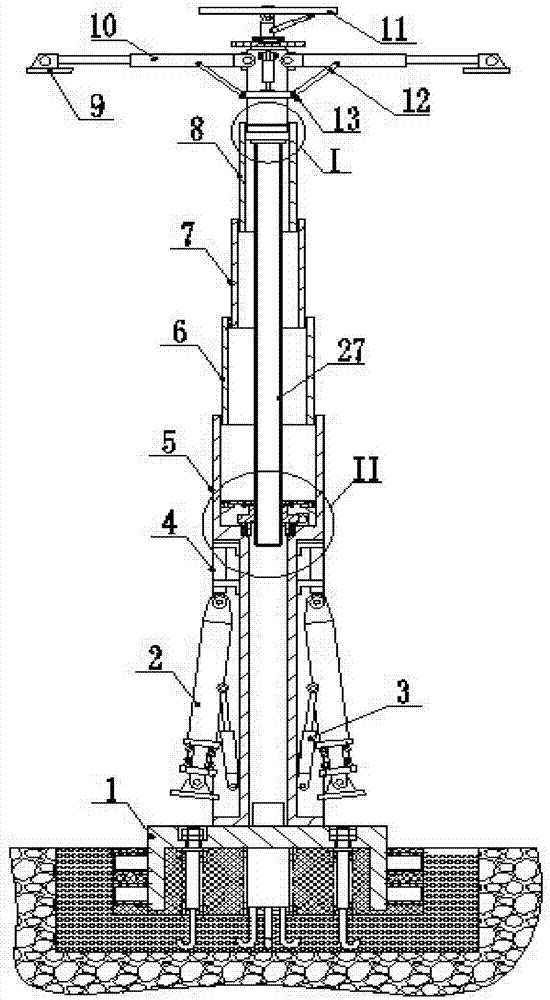

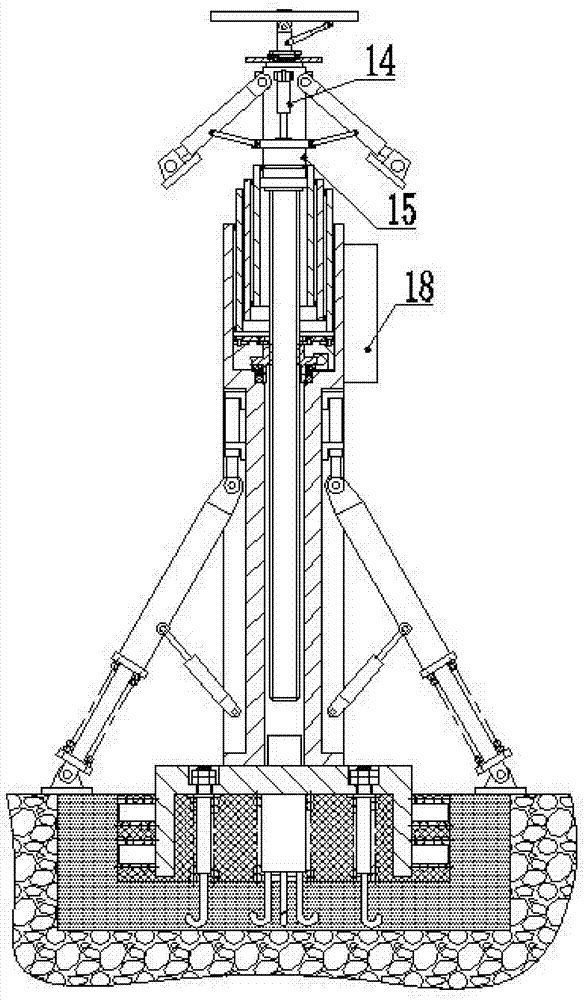

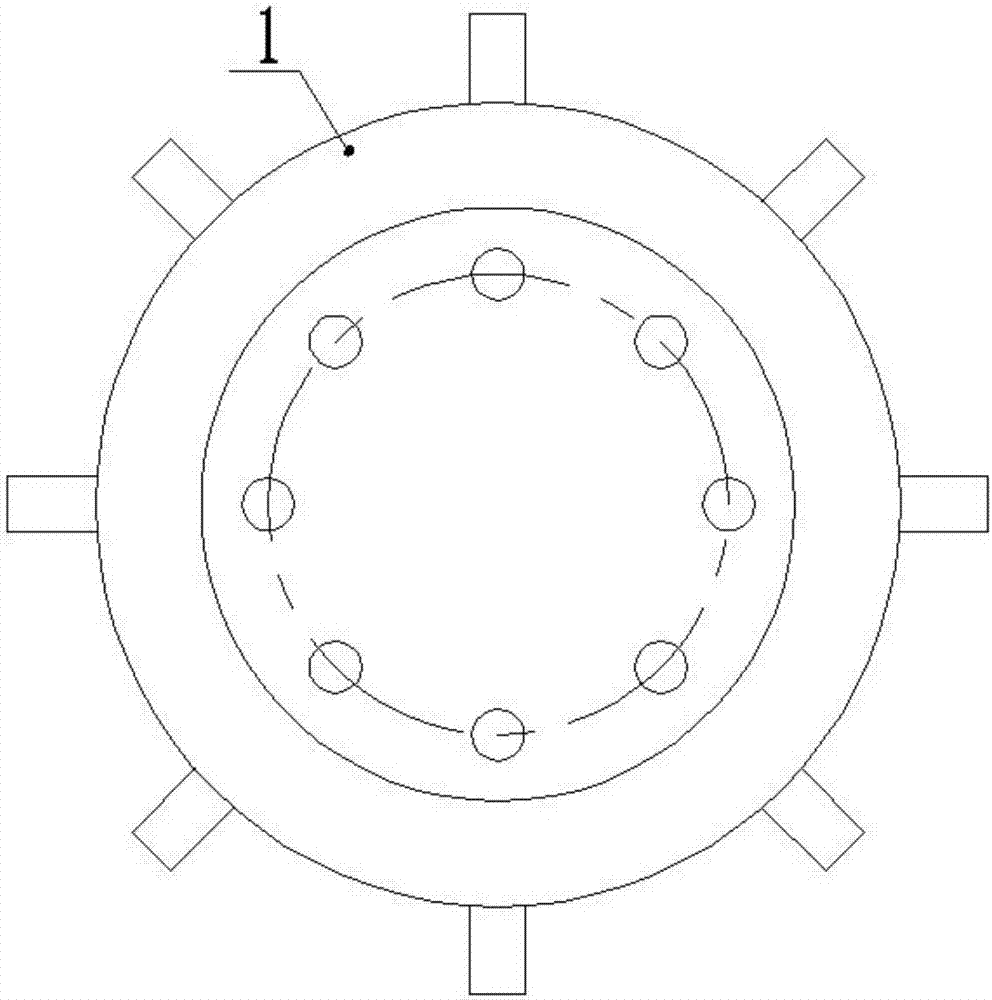

Three-freedom-degree series-parallel omni-directional mobile transfer robot

ActiveCN105459095AIncrease stiffnessImprove carrying capacityProgramme-controlled manipulatorGripping headsIndependent motionCarrying capacity

The invention discloses a three-freedom-degree series-parallel omni-directional mobile transfer robot. The transfer robot comprises an omni-directional mobile chassis, a main slewing gear, a lifting device, parallel working arms, a tail end slewing gear and a clamp holder. The omni-directional mobile chassis is used for executing walking and steering tasks, the lifting device is connected with the omni-directional mobile chassis through the main slewing gear, the parallel working arms installed at the top of the lifting device are connected with the clamp holder through the tail end slewing gear and are used for adjusting the operation posture of the clamp holder. A series-parallel is adopted in a robot body, and the omni-directional mobile transfer robot has the advantages of being high in rigidity, large in carrying capacity, high in motion precision, large in operation space and the like; the clamp holder has six motion ranges and three independent motion freedom degrees and is high in motion flexibility; the tri-drive omni-directional mobile chassis can realize walking tasks of moving forward, or moving backward, or turning left or turning right, and is reasonable in structural design, and high in anti-overturning ability. In addition, the omni-directional mobile transfer robot has the advantages of being convenient to manipulate, and high in adaptability to road conditions.

Owner:ANHUI UNIV OF SCI & TECH

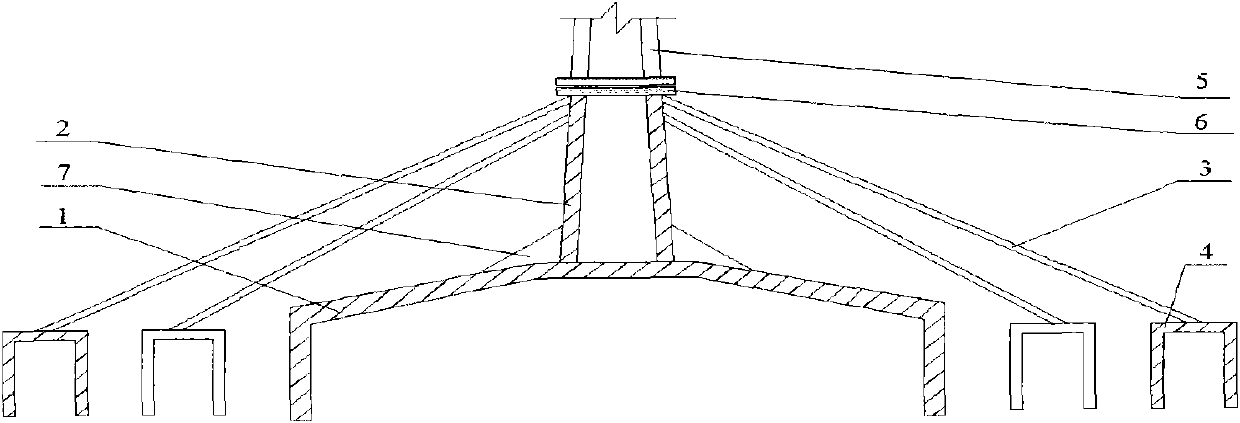

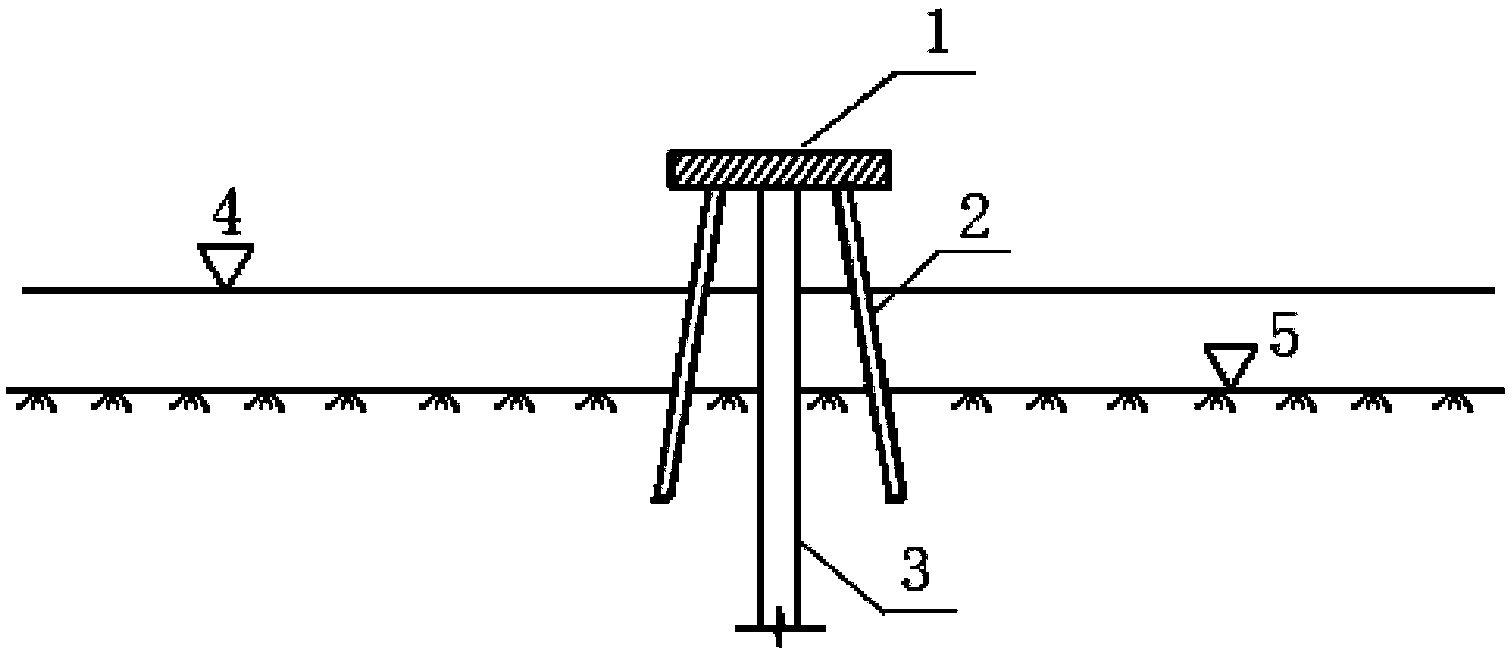

At-sea wind generation unit foundation formed by barrel type foundation and mooring rope anchor

ActiveCN101768978ASimple structureEasy constructionFoundation engineeringEnvironmental geologyOffshore wind power

The invention relates to an at-sea wind generation unit foundation formed by a barrel type foundation and a mooring rope anchor, which is composed of the barrel type foundation, a connection tower barrel, a cable rope and a suction anchor, the barrel type foundation is a steel cylinder structure which is provided with a sealing top cover, the connection tower barrel is a steel conical cylinder shape structure, the connection tower barrel and the barrel type foundation are fixed by welding and are reinforced by a rib plate, and the connection tower barrel and a connection tower barrel tower barrel are fixedly connected by a flange, and two ends of the cable rope are respectively fixed with the connection tower barrel and the suction anchor by welding. The at-sea wind generation unit foundation has the advantages that: the structure is simple, the construction is convenient, the work amount is low and the structure stress is rational. The barrel type foundation of the foundation self-floats to the construction position at sea by traction, the transportation cost can be reduced; a large hoisting ship does not need to be placed at seabed or pile driving construction at sea is not needed, the barrel type foundation can be recycled, thereby being environmental-protection; the load of the foundation structure, especially for moment load, can be effectively dispersed by the suction anchor, so as to improve the antidumping capacity of the single barrel type foundation.

Owner:JLANGSU DAODA OFFSHORE WIND CONSTR TECH

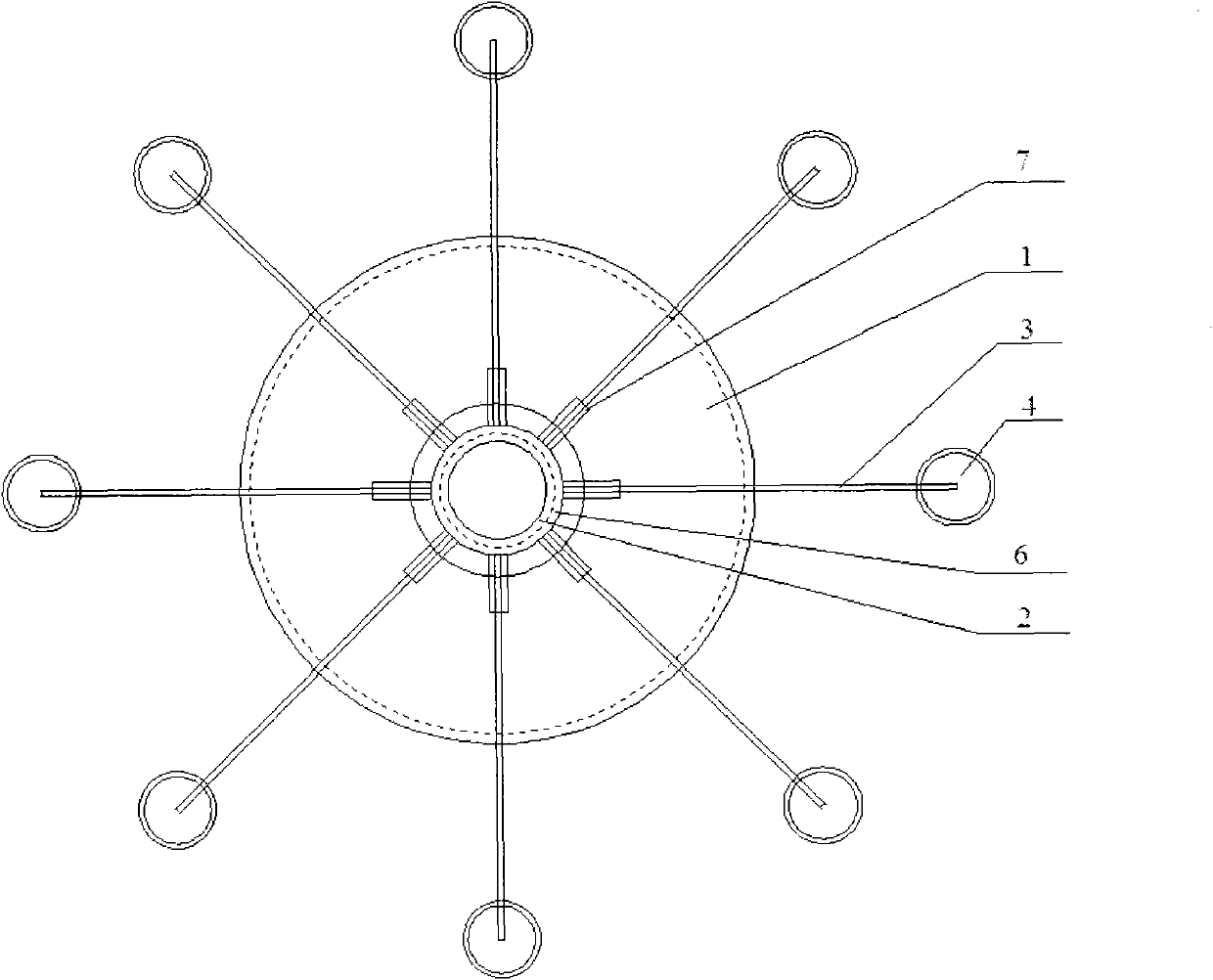

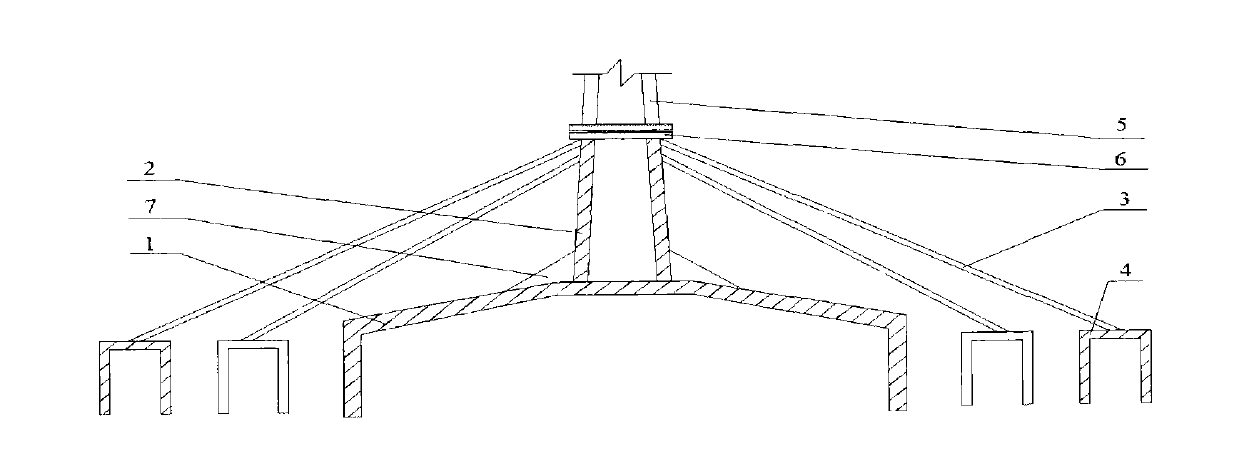

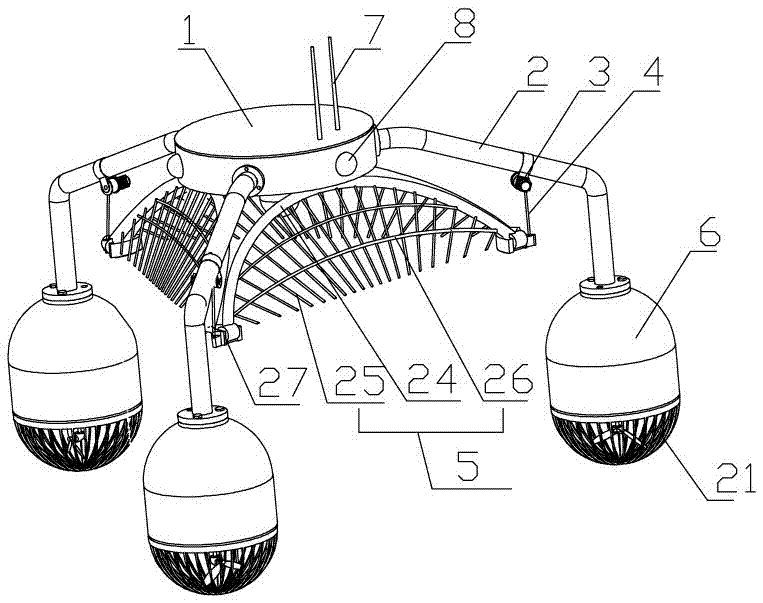

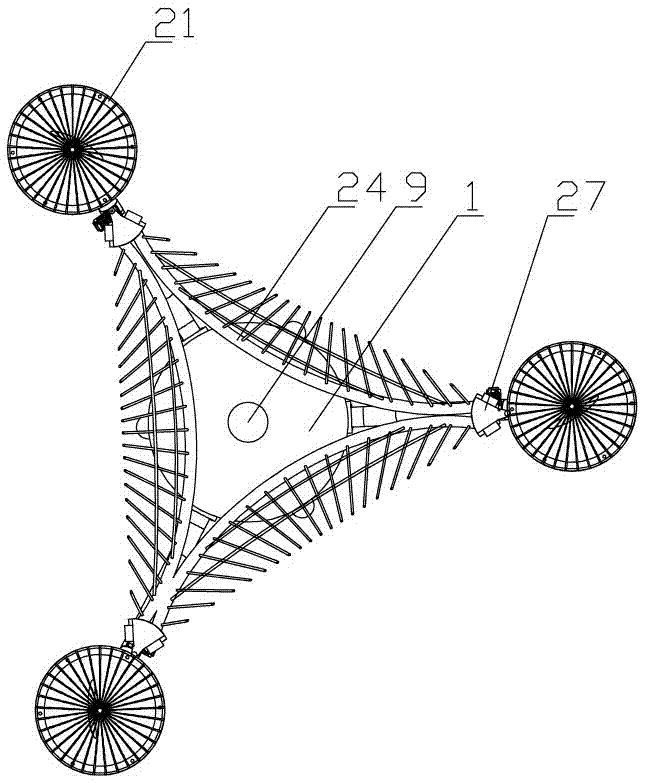

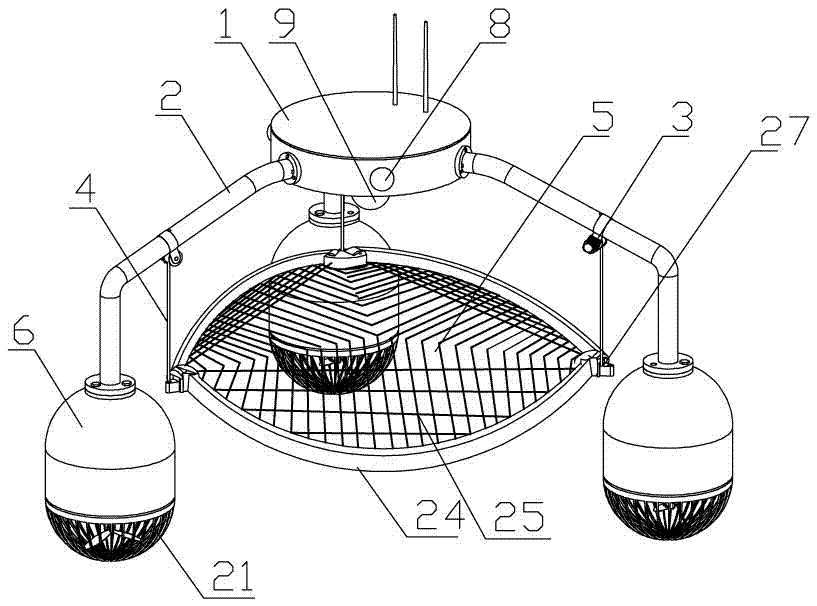

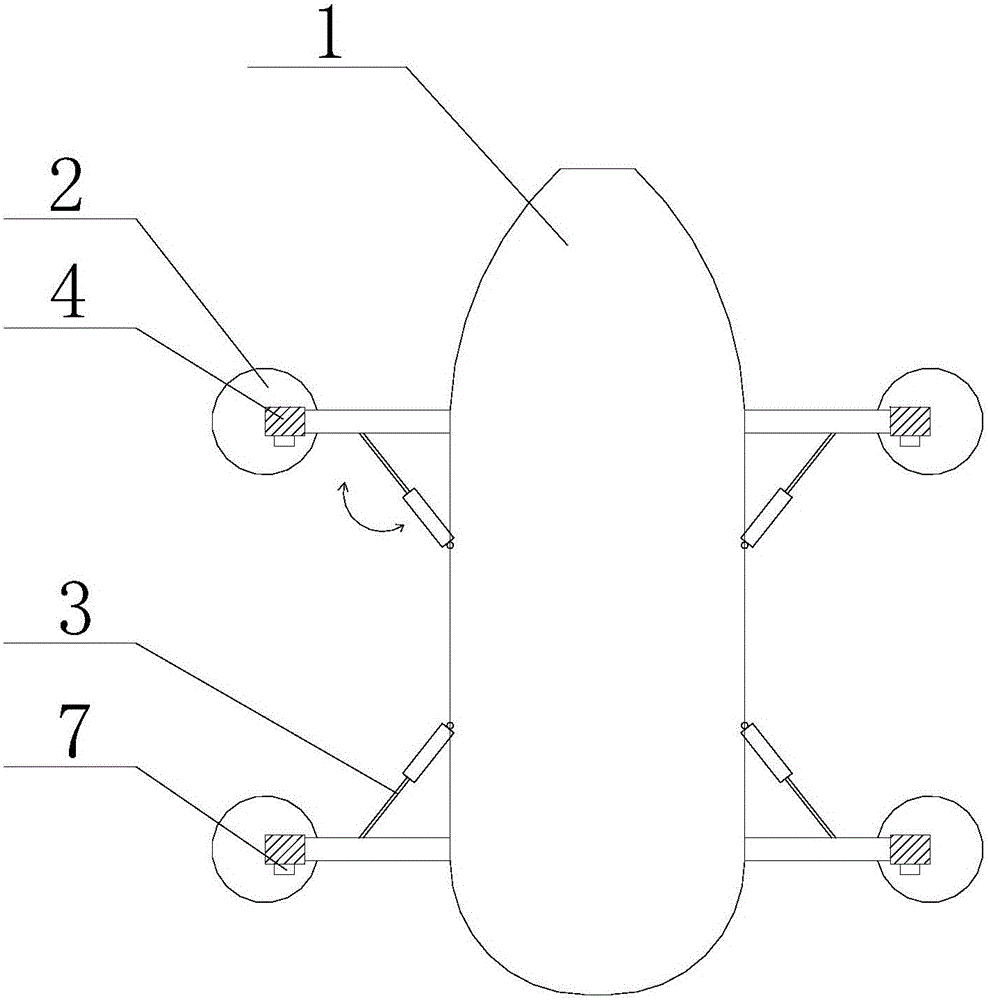

Multi-axis propulsion water search and rescue robot

ActiveCN106926992AAvoid secondary injury and other problemsReduce riskLife-savingUnderwater equipmentRescue robotMarine engineering

The invention relates to the fields of intelligent robot, in particular to a multi-axis propulsion water search and rescue robot. The multi-axis propulsion water search and rescue robot comprises a central control platform, at least three downward projecting brackets are arranged along the circumferential direction of the central control platform, hinge cable devices are arranged on each bracket, hinge cable devices are hoisted with foldable lifesaving net under the central control platform through cables, a power float device is also connected at the lower end of each bracket, a controller is arranged on the central control platform, and the controller is communicated with the hinge cable device and a power float device. The multi-axis propulsion water search and rescue robot has various motion modes, such as hovering, advancing, retreating and 360 DEG free steering in water, has high stability, has high ability to withstand wind and wave, and can be a good alternative to the traditional rescue way; meanwhile the design of the foldable lifesaving net realizes the purpose of fast and safe lifesaving, can realize multiple tasks such as water search and rescue, the water surface monitoring, the water measurement and control and the like in complicated water area and bad weather condition, practicability is high, flexibility is good and popularization prospect is good.

Owner:WUHAN NIWEI INTELLIGENT TECH CO LTD

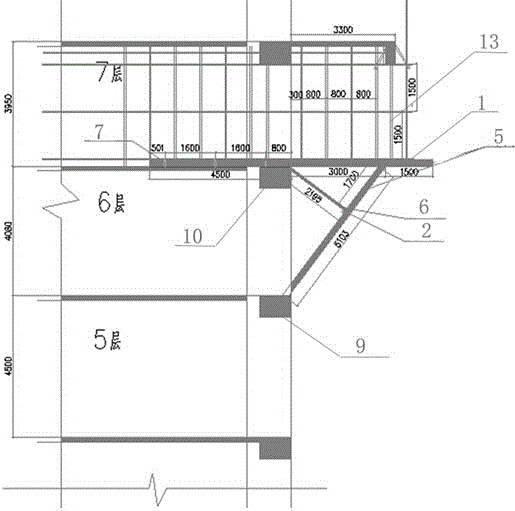

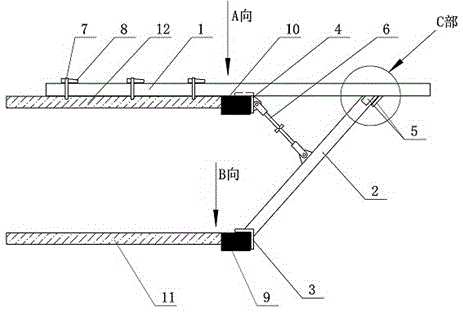

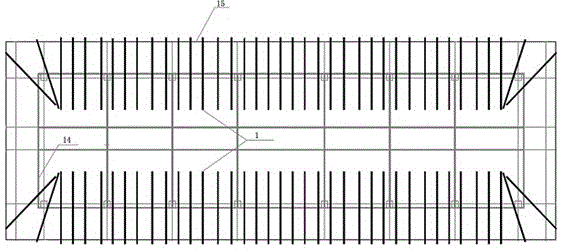

Formwork with high cantilever structure and construction method thereof

ActiveCN105019639ALong cantilever spanImprove overall stability and anti-overturning abilityScaffold accessoriesBuilding support scaffoldsFloor slabStructural element

The invention discloses a formwork with a high cantilever structure and a construction method thereof. The construction method comprises following steps: utilizing angle iron at bottoms fixed at beam corners in a structure with N layers of beams as support points of a braced steel I-beam; welding and fixing top angle iron in middles of a steel I-beam with a cantilever structure; matching and buckling the top angle iron with corners of beams in n+1 layers; welding and fixing a support of the braced steel I-beam at the end portion of the steel I-beam with the cantilever structure or below by closing to the end portion; and pre-burying at least two round steel pressing rings in a floorslab in the N+1 layer during structural construction. Each round steel pressing ring is firmly welded with the steel I-beam with the cantilever structure or plugged and fixed by a wooden wedge. The high cantilever structure is characterized in that positions of cantilever members are high above the ground. The members with cantilever structures are long in cantilever span lengths and great in deflection produced by structural self-weight. The braced steel I-beam and a welding point position of a horizontal steel I-beam cantilever platform can be determined according to cantilever length. An optimal load-carrying position is within the range spacing from the outside of the span edge of the cantilever members.

Owner:HENAN GUOJI CONSTR GRP

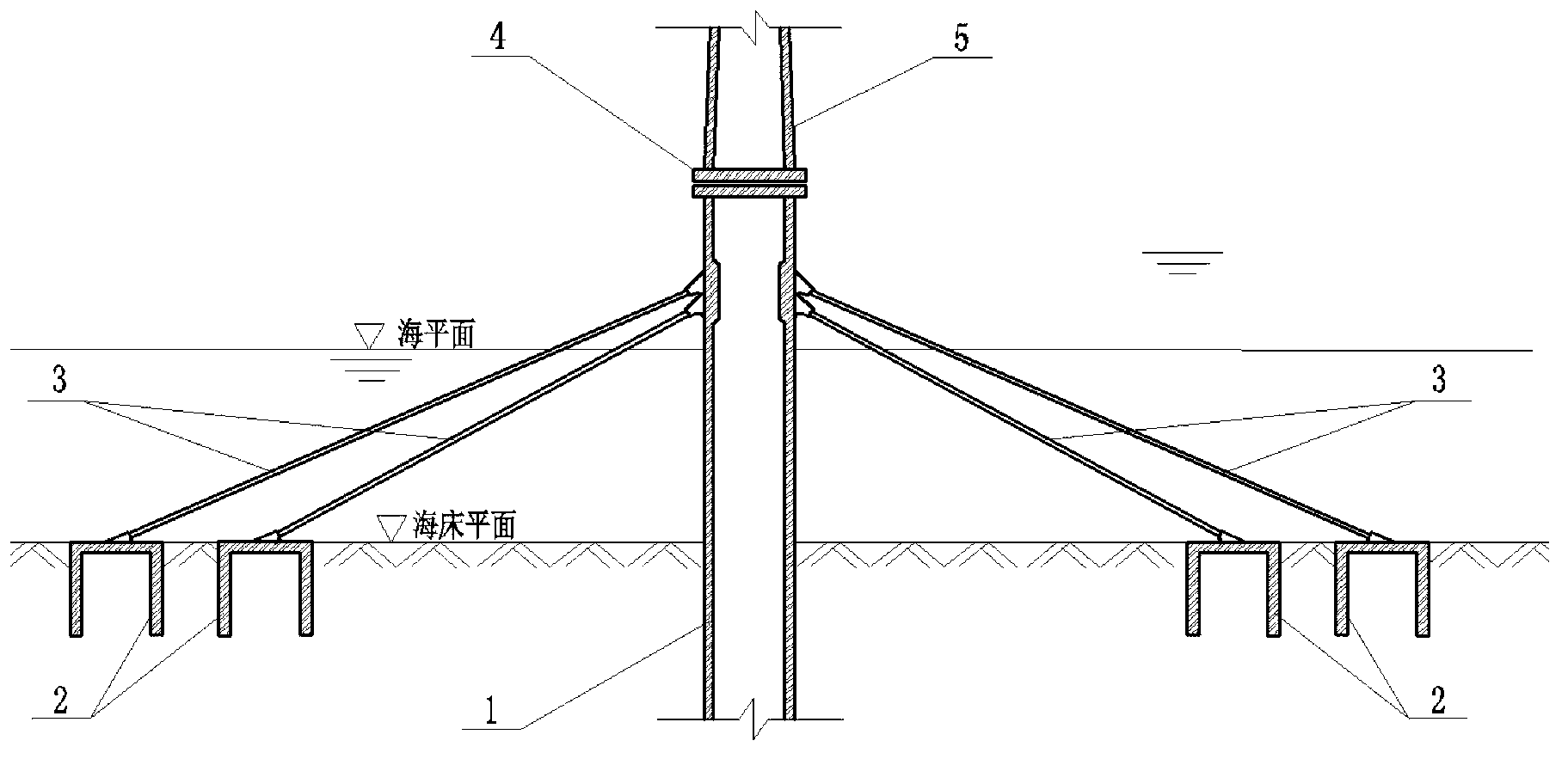

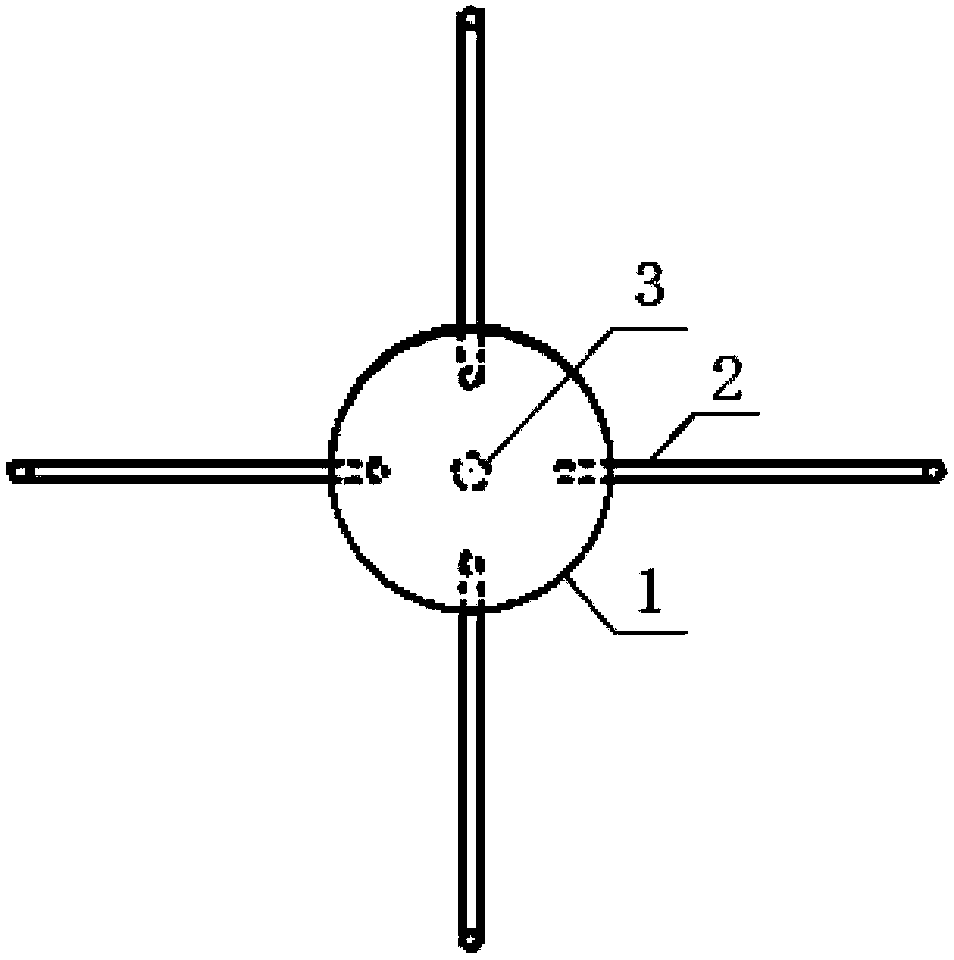

Offshore wind power foundation consisting of single pile, cylindrical foundations and anchor cable

ActiveCN103225315AReduce the overall diameterReduce thicknessBulkheads/pilesElectricityEarth surface

The invention discloses an offshore wind power foundation structure consisting of a single pile, cylindrical foundations and an anchor cable. The offshore wind power foundation structure consists of a single pile, multiple cylindrical foundations and an anchor cable, wherein the cylindrical foundations are uniformly distributed on the circumference which takes the single pile as the center of a circle; the anchor cable is obliquely tensioned and is connected with the cylindrical foundations and the single pile; the anchor cable, the cylindrical foundations and the single pile are connected through welding; the included angle between the anchor cable and the single pile is between 30 and 60 degrees; and the top of the single pile is connected with a wind turbine tower through a flange plate. According to the technical scheme, a novel foundation type consisting of the single pile, the cylindrical foundations and the anchor cable is given, the anchor cable is connected with the cylindrical foundations and the single pile and is obliquely tensioned, the resistance of shallow soil on the earth surface is fully exerted, the bending moment resistance of the structure is enhanced, and the displacement of the pile body is reduced, so that the aim of reducing the diameter and thickness of the single pile is fulfilled.

Owner:TIANJIN UNIV

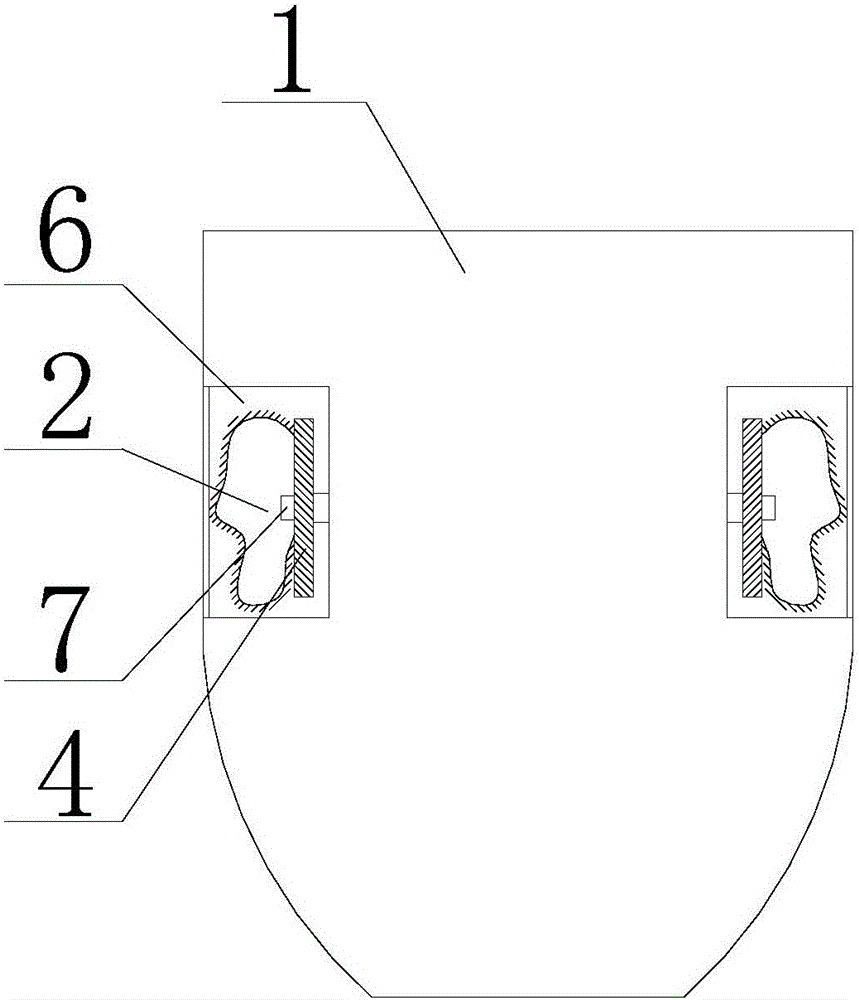

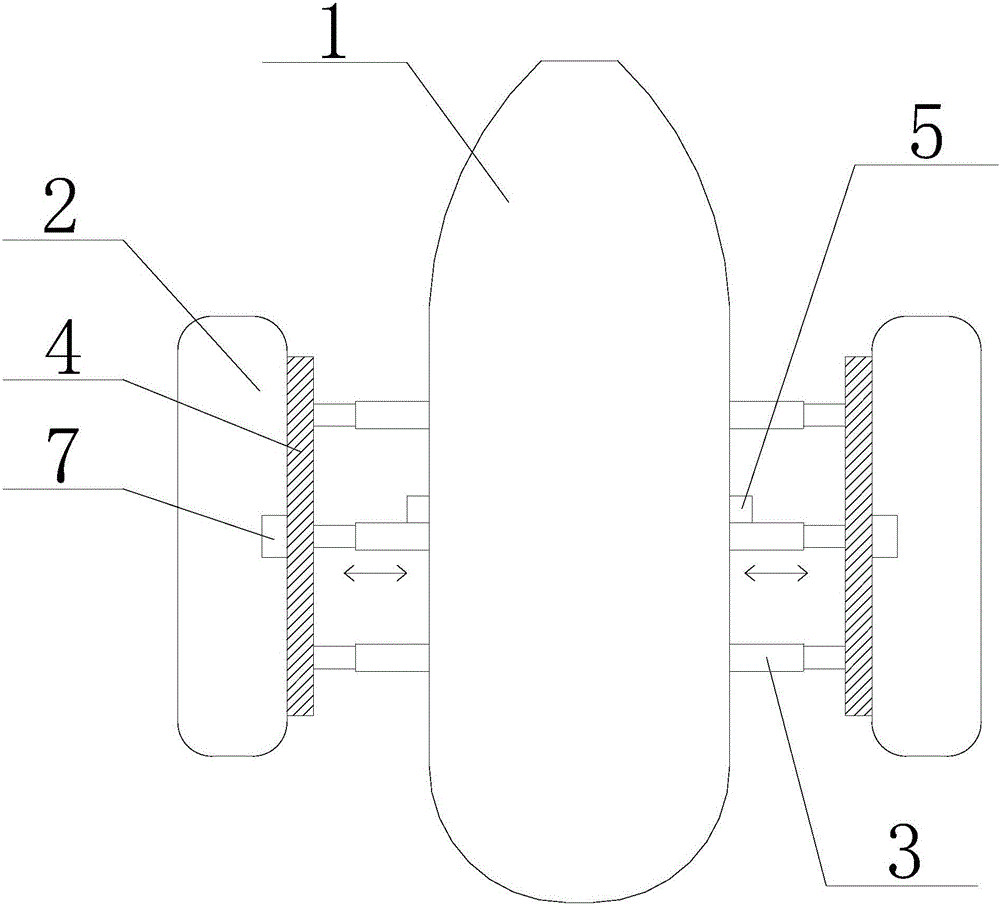

Invisible air sac multi-body overturn-preventing mono-hull ship

InactiveCN106005302AReduce manufacturing costEasy to storeVessel safetyHydrodynamic/hydrostatic featuresMarine engineeringFree state

The invention discloses an invisible air sac multi-body overturn-preventing mono-hull ship. The mono-hull ship comprises a ship body, wherein air bags are arranged on the left side and right side or one of the left side and right side of the ship body, gas generation devices are connected to the air bags, and the air bags are connected to the side edge of the ship body through expansion devices; during normal sailing or berthing, the expansion devices are normally closed, and the air bags are in a gas-free state and put away on the side edge of the ship body; when a capsizing risk exists, the expansion devices expand towards the left side and right side of the ship body manually or automatically so that the air bags can stretch out and be filled with gas through the gas generation devices, and a multi-hull ship structure is formed by the air bags and the ship body through a support formed by the expansion devices. Conversion between a mono-hull ship structure and a multi-hull ship structure can be achieved conveniently, the mono-hull ship structure is obtained during normal sailing or berthing, occupied space is small, and sailing flexibility is high; when a capsizing risk exists, the air bags expand to form a multi-hull ship structure, the stability of the ship body is improved, an inclined ship body can restore quickly, anti-capsizing performance is improved, and life and property safety of people on the ship is effectively guaranteed.

Owner:甘勇

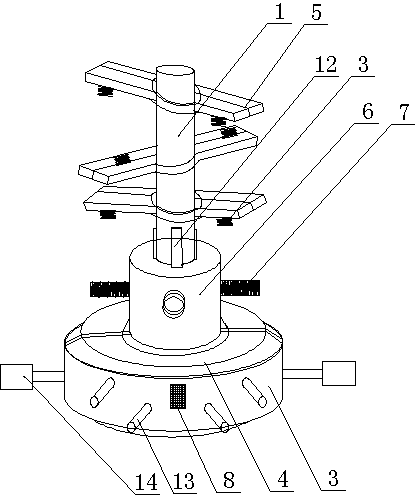

Earthquake self-adaptation-type pole and tower device

ActiveCN103437585AImprove performanceImprove structural stabilityFoundation engineeringTowersPower gridTower

The invention discloses an earthquake self-adaptation-type pole and tower device which comprises a pole and tower body, a self-adaptation-type positioning base and pieces of concrete tower footing. Supporting stand columns are arranged at the bottom of the pole and tower body. The self-adaptation-type positioning base and the pieces of concrete tower footing are laid underground. The self-adaptation-type positioning base comprises base plates and a plurality of layers of pole holding devices, wherein the lower portions of the base plates are precast on the pieces of concrete tower footing, and the pole holding devices are arranged in a spatial-crossing mode. Bearing positioning components of the supporting stand columns are arranged in the middles of the base plates. Self-reset springs are arranged on the peripheral sides of the bearing positioning components and / or the lower portions of the pole holding devices, and positioning reference modules are arranged in the pieces of concrete tower footing. A position collection module connected with a controller is arranged at the upper portion of the pole and tower body. The controller is connected with an alarming module. According to the earthquake self-adaptation-type pole and tower device, the self-adaptation-type positioning base and the pieces of concrete tower footing are laid underground in an embedded mode, the foundation intensity, the structural stability and the earthquake-proof capacity are improved, foundation cracking and uneven settlement are effectively prevented, the controller of the pole and tower body is utilized for collecting position information and timely giving an alarm, the early warning and the outage are carried out before the maximum damage of the disaster is reached, and large-area damage and power failures of a power grid are avoided.

Owner:STATE GRID CORP OF CHINA +1

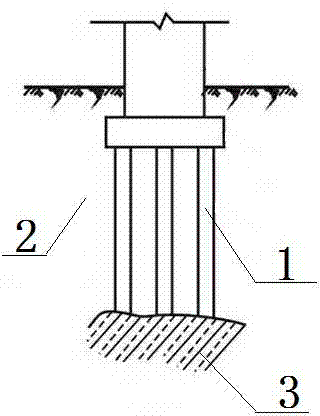

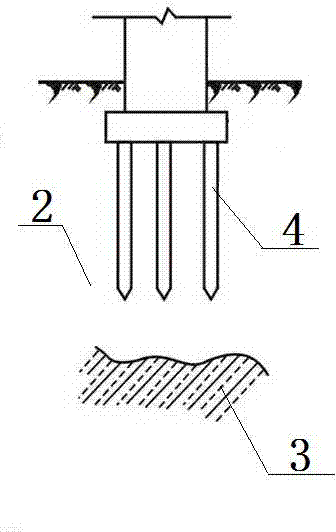

Method for improving pile group bearing capacity by means of reticular pile foundations

InactiveCN103669385AIncrease the carrying areaImprove carrying capacityFoundation engineeringBearing capacity

The invention relates to a method for improving the pile group bearing capacity by means of reticular pile foundations. A pile group is composed of a plurality of sets of reticular pile foundations, each reticular pile foundation is formed by arranging a plurality of single piles which vertically penetrate into a soil body, and the method comprises the following steps: arranging the single piles in the reticular pile foundations in each set according to a certain shape, and respectively arranging a pile beam for connecting every two adjacent piles at the bottom and middle positions of the adjacent single piles so as to increase the bearing areas of the reticular pile foundations and enable the pile beam and the single piles to be of an integral structure. The method has the advantages that the pile group is simple in structure, the pile beam for connecting the adjacent single piles is additionally arranged at the bottom and middle positions of the pile foundations so as to form the whole stable pile group structure, pile feet are additionally arranged on each single pile so as to increase the whole bearing areas of the reticular pile foundations, the whole bearing capacity and the anti-toppling capacity of the pile group are effectively improved, and in addition, compared with a conventional pile group with the same bearing capacity, the length of the pile group is greatly shortened.

Owner:CHINA RAILWAY 24TH BUREAU GRP

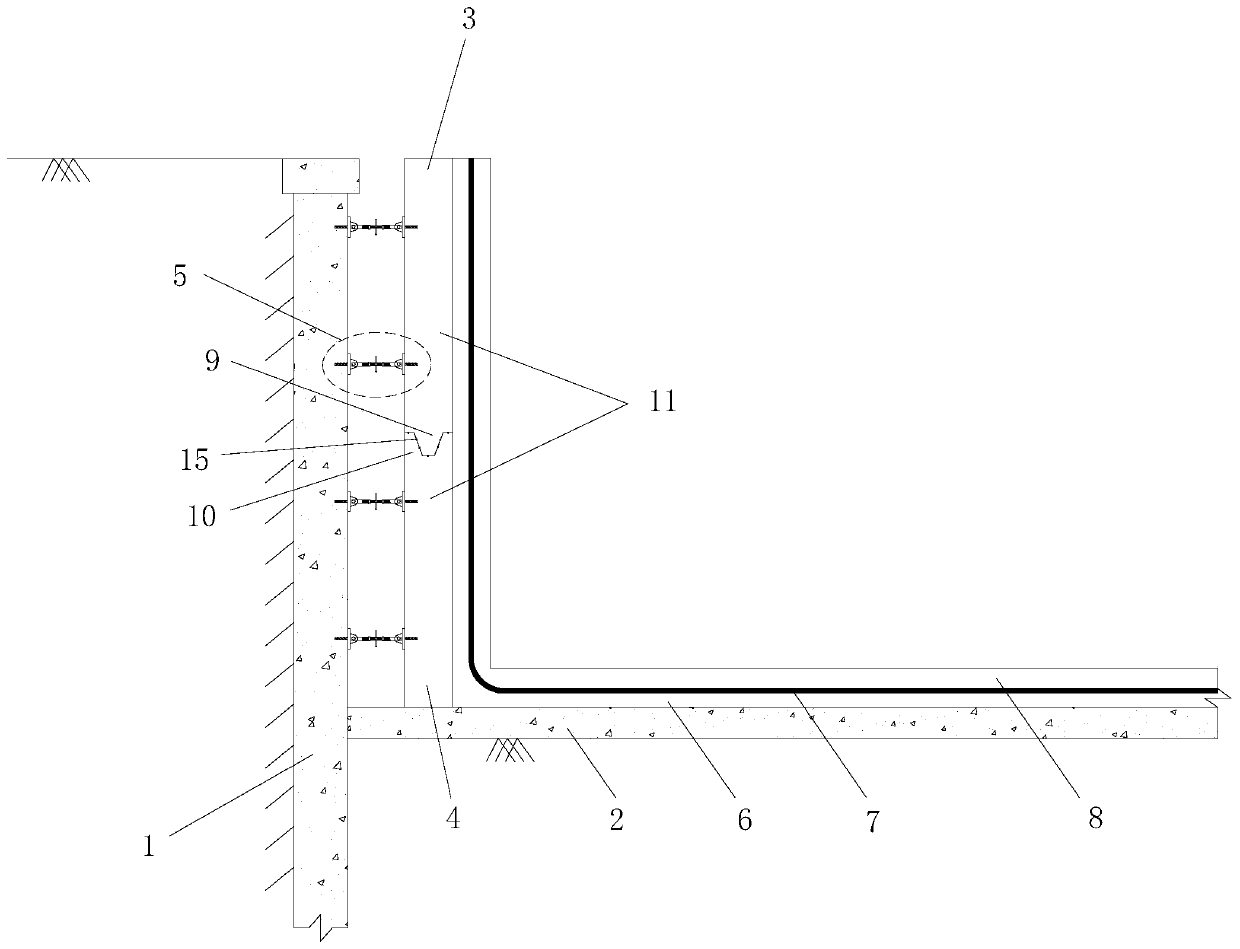

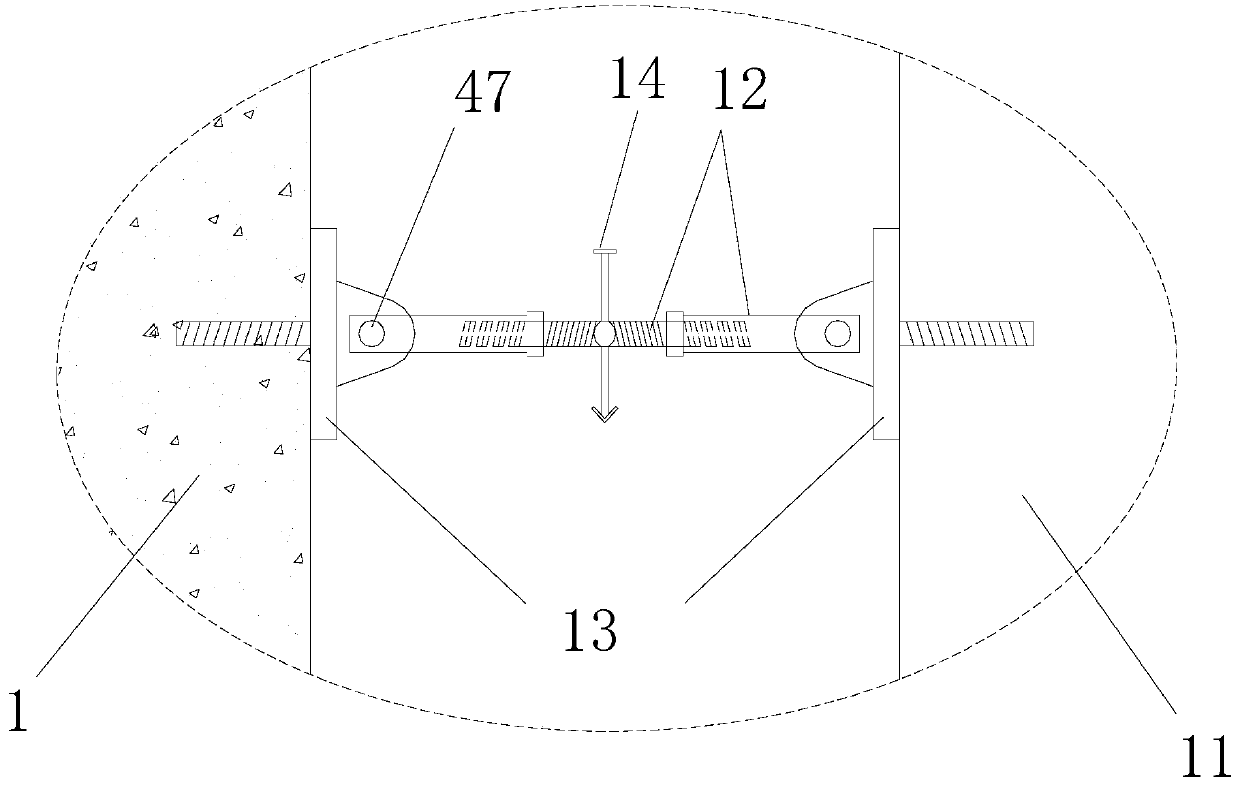

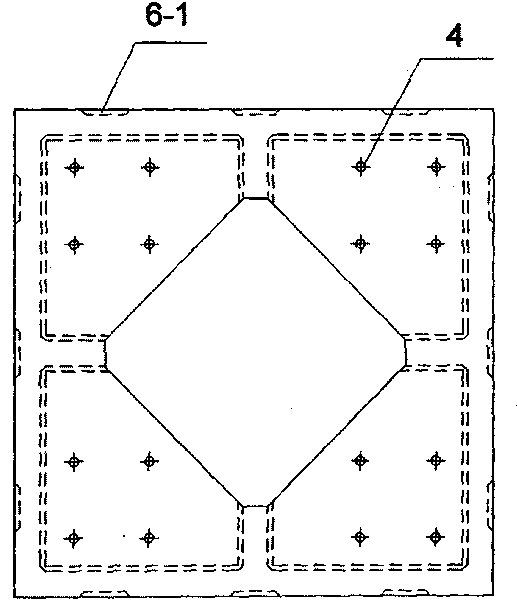

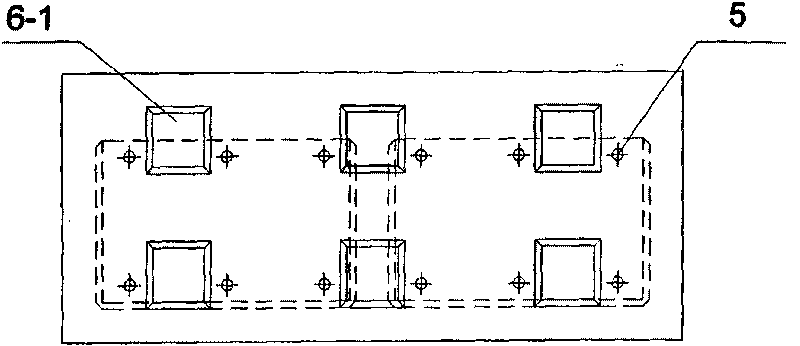

Construction method of composite unilateral formwork deep foundation pit basement exterior wall

ActiveCN109736353AImprove construction efficiencyGood waterproof performanceArtificial islandsProtective foundationFertilizerSteel tube

The invention relates to a construction method of a composite unilateral formwork deep foundation pit basement exterior wall. The construction method comprises the steps of: firstly, a composite waterproof layer of the deep foundation pit basement exterior wall is adopted for waterproof treatment of the basement exterior wall; secondly, a basement bottom plate and an outer wall guide wall are poured; thirdly, aiming at different working conditions with limited fertilizer tank space, three different unilateral formwork systems are adopted for carrying out unilateral formwork on the basement exterior wall, and each unilateral formwork system comprises an exterior wall frame opposite-supporting unilateral formwork system, an exterior wall steel pipe fastener inclined-supporting unilateral formwork system and an exterior wall profile steel support inclined-supporting unilateral formwork system; and fourthly, a basement exterior wall is poured. The method the following beneficial effects: aprotection wall adopts segmented prefabricated hoisting rear tenon type waterproof inserting connection to replace a traditional masonry or cast-in-place concrete structure; the construction efficiency is high, and the waterproof performance is good; and meanwhile, adjustable pull-connection pieces connected with the prefabricated protection wall sections are pre-buried in the foundation pit enclosure structure, so that the perpendicularity of the prefabricated protection wall sections is guaranteed, and the construction quality is high.

Owner:SHENZHEN JIANAN GRP

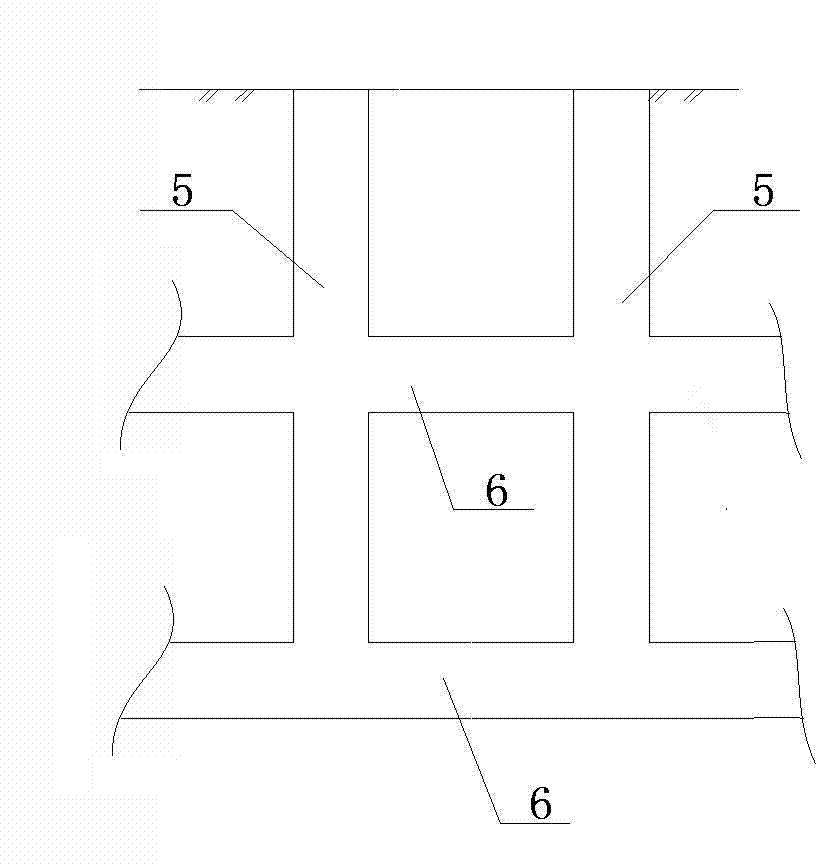

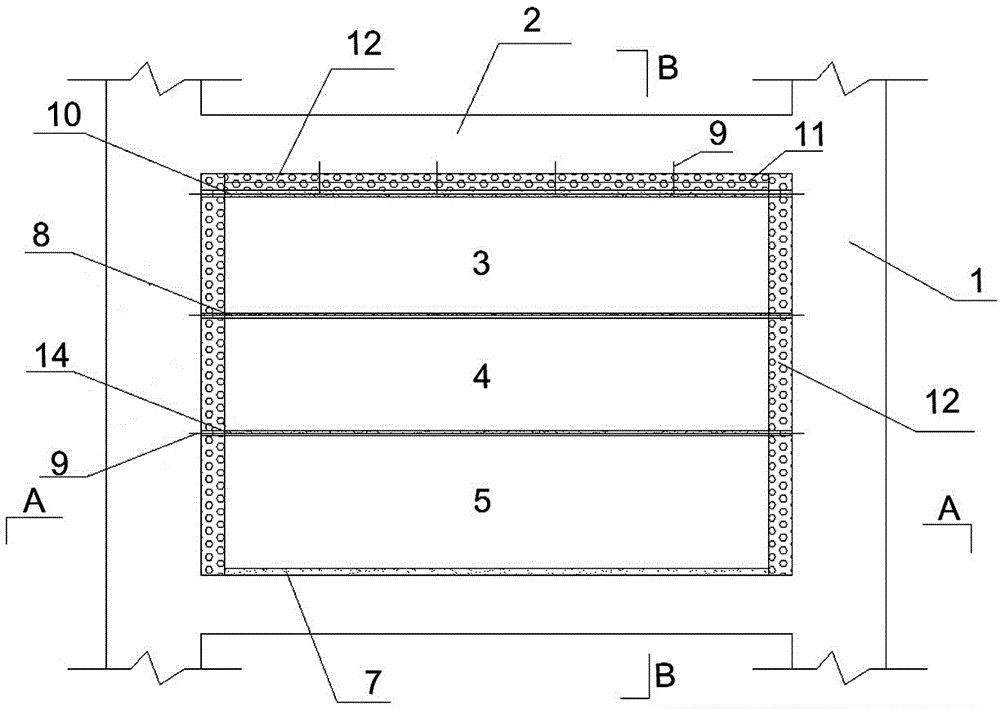

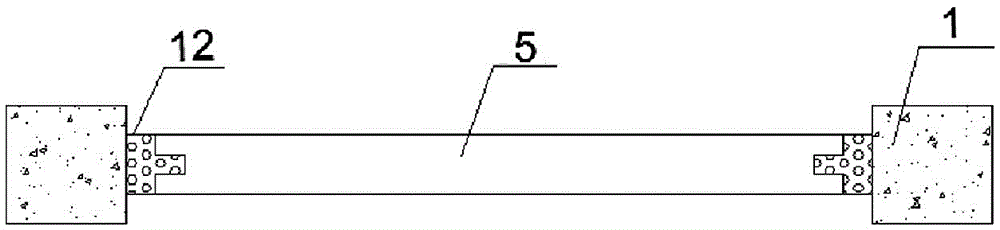

Prefabricated precast concrete tower crane foundation in the shape of bolt connecting box

InactiveCN101718097AEasy to manufactureEasy to assemble and disassembleFoundation engineeringWhole bodyTower crane

The invention relates to a precast concrete tower crane foundation, in particular to a prefabricated precast concrete tower crane foundation in the shape of a bolt connecting box, belonging to the technical field of the constructional machinery. The prefabricated precast concrete tower crane foundation in the shape of a bolt connecting box comprises a plurality of box-shaped components in three structural forms. The box-shaped components are connected into a whole body by bolts. Solid or liquid is filled in the box-shaped components so as to be used weight balancing material. The prefabricated precast concrete tower crane foundation can be installed conveniently and constructed easily on the site and has low manufacturing cost. The weight balancing material can be filled and removed conveniently. The prefabricated precast concrete tower crane foundation can meet the requirement of the tower cranes of various types and models, has similar stability in all directions, has no weak axis and has good overturning resisting ability. The bolts for connecting the box-shaped components can be used repeatedly.

Owner:JIANGSU WANRONG ENG TECH CO LTD

Intelligent anti-seismic streetlamp pole

InactiveCN107388145ASlow down fluctuating energyImprove connection strengthLighting support devicesElectric circuit arrangementsEngineeringUltimate tensile strength

The invention discloses an intelligent anti-seismic streetlamp pole. The intelligent anti-seismic streetlamp pole comprises a base, wherein the base is provided with eight supporting columns with buffer springs in a sleeving manner; a first foundation bolt and a second foundation bolt are arranged in a cavity of each supporting column; the first foundation bolts and the second foundation bolts are mounted on a foundation; gaps are filled with cushion rubber; the base is a supporting seat; a first electric push rod, a supporting electric push rod and a second electric push rod are arranged on the outside of the base; a worm-wheel shaft, a worm motor, a supporting rack, a pressure plate, a matching plate and an ejector rod are arranged in a square hole of the base; a first retractable sleeve, a second retractable sleeve, a third retractable sleeve and a top seat are arranged on the supporting seat; a lamp electric push rod, a lamp ejector rod, a sliding sleeve, a lamp assembly and a solar panel assembly are arranged on the top seat; and a controller is further arranged on the outside of the supporting seat. The fluctuation energy of the ground can be greatly reduced, the strength of connection between the intelligent anti-seismic streetlamp pole is improved, four supporting legs can be added automatically, the center of gravity of a streetlamp is reduced, the intelligent anti-seismic streetlamp pole has a remote monitoring ability, the light collecting rate is guaranteed automatically, and electric energy is saved.

Owner:薛迪宋

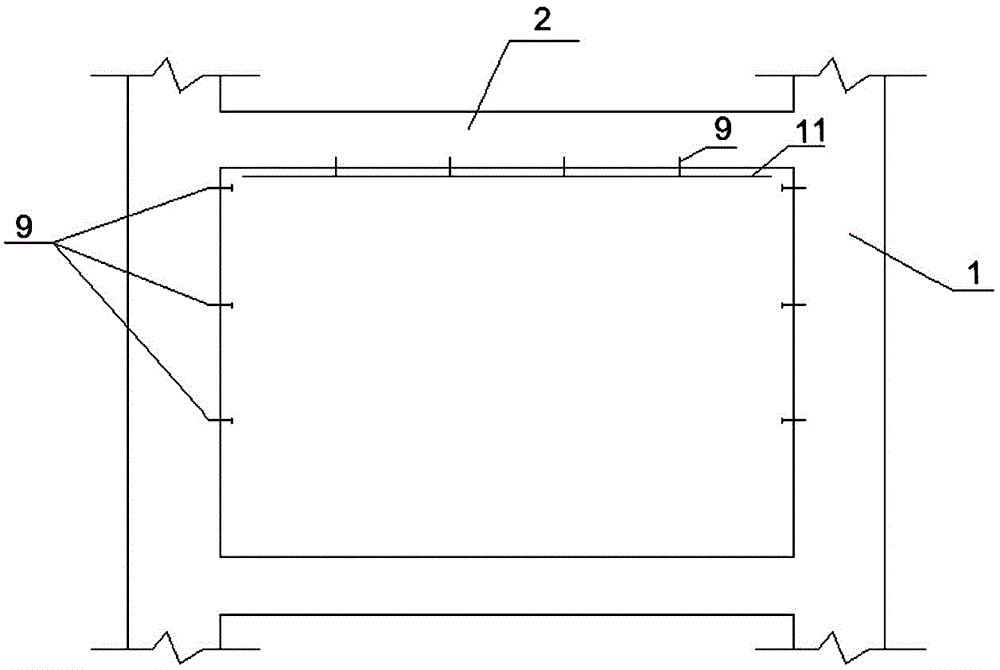

Prefabricated concrete frame infill wall system and construction method thereof

ActiveCN105937278AReduce investmentImprove construction efficiencyWallsUltimate tensile strengthInfill wall

The invention provides a prefabricated concrete frame infill wall system and a construction method thereof. The system comprises a rectangular concrete frame which is formed by concrete frame columns and concrete frame beams in an enclosing mode and an infill wall infilling the frame, anchoring ribs are implanted into the left frame columns in a uniformly spaced mode, the right frame columns and the upper frame beam on a frame inner ring, and the tail end of the anchoring rib on the upper frame beam is horizontally connected with a horizontal through long rib. According to the prefabricated concrete frame infill wall system and the construction method thereof, early cracking and corner damage of the frame infill wall are controlled by changing the structural form of the infill wall to improve the ductility of the wall and the overall anti-seismic property of the frame structure, and the anti-seismic property of the system is guaranteed by serving as the first anti-seismic defense line; in addition, the construction efficiency is high, the anti-dumping capacity is good, and the labor intensity is low. The construction method can be widely applied to concrete frame infill wall construction.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

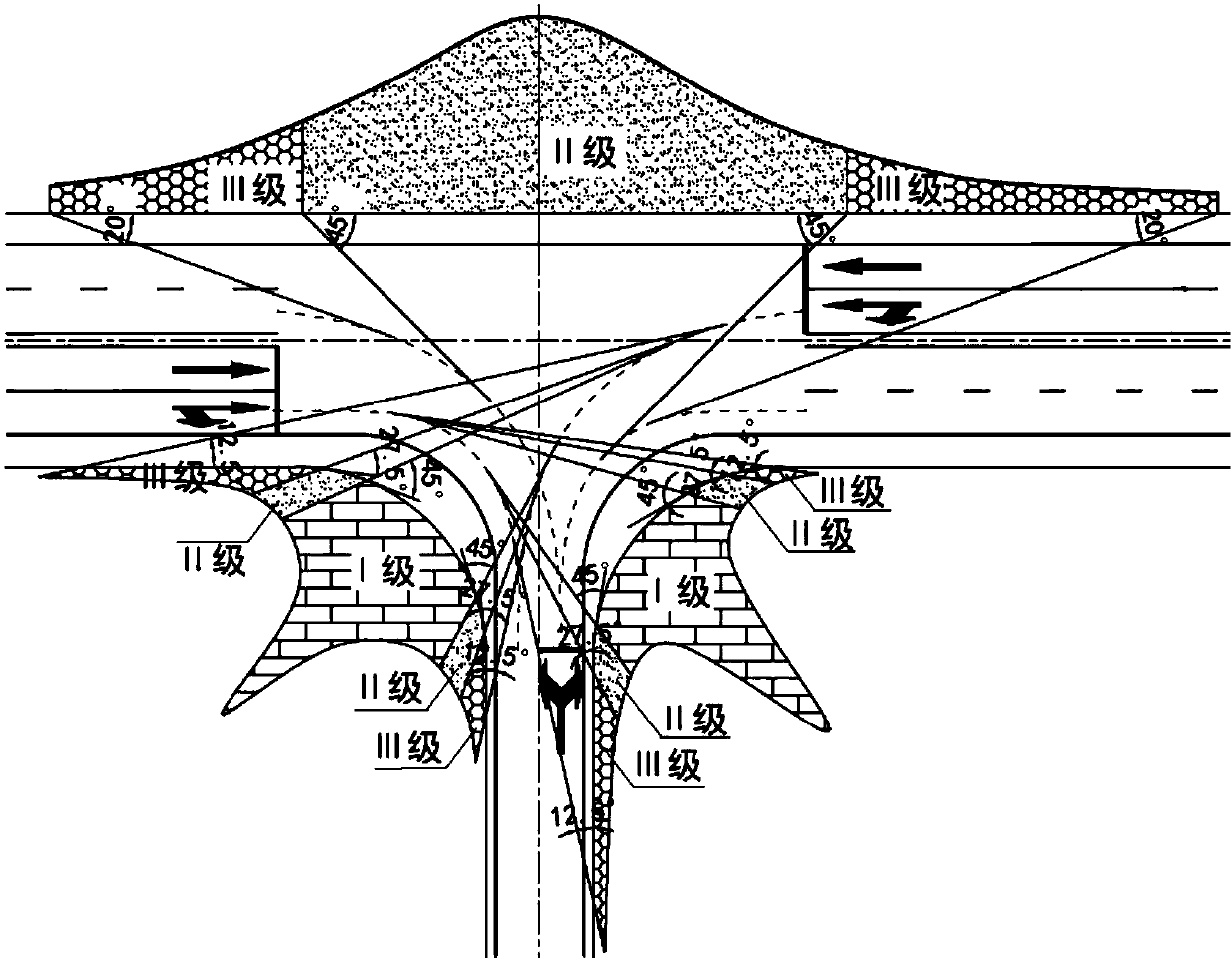

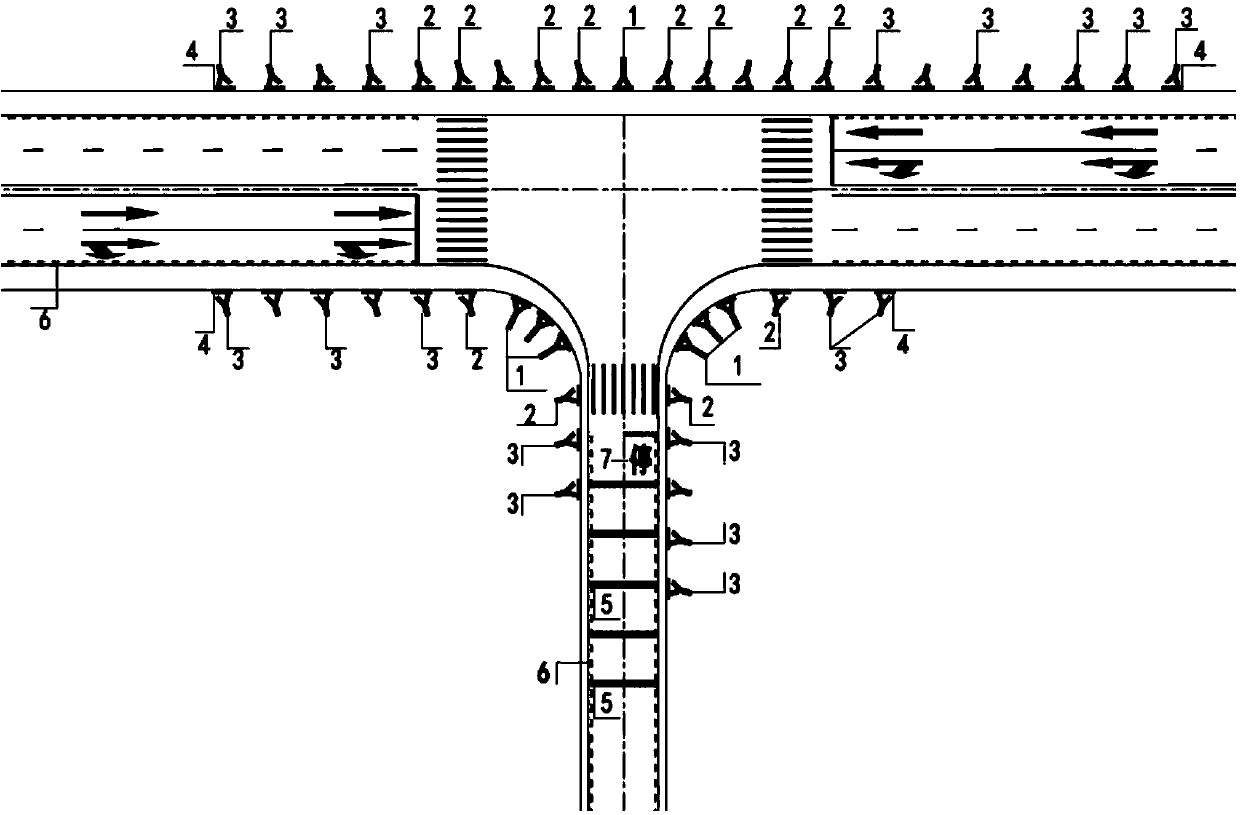

Design method of T-shaped intersection of arterial highway in mountain area for traffic safety

InactiveCN103437255ALow occlusion heightGood permeabilityRoadway safety arrangementsSafety designVisibility

The invention relates to a design method for a T-shaped intersection of an arterial highway in a mountain area for traffic safety. Roadside protections are graded according to the collision energy of vehicles steering at the roadside of the intersection, and corresponding novel concrete guard bar structures are arranged; guard bars comprise herringbone collision posts and independent concrete short bases, the requirements of different protection levels of the roadside at the intersection are met by regulating the spaces, sizes and the depth embedded into a roadbed of the herringbone collision posts, and the purpose of protecting the vehicles steering at the intersection is achieved; the included angle between the herringbone collision posts and the edge line of a lane is 5-15 degrees, so that the protection area for steering vehicles is increased; PVC (poly vinyl chloride) pipes are sheathed on the outer layers of the collision posts, red-and-white retroreflection vertical face mark lines are arranged on both the collision posts and the concrete short bases, so that the visibility of the intersection is improved; 3-4 groups of vibration deceleration zones are arranged on the crossed road 3-6m away from the intersection; vibration side lines are additionally arranged at the roadside in the range of 30-50m in all the directions of the intersection. The design method is applicable to controlling the T-shaped intersection in the mountain area without signal control, and the primary road is a second-class highway or a first-class highway.

Owner:WUHAN UNIV OF TECH

Adjustable tower crane steel platform foundation

InactiveCN103866784ATake advantage ofLow costFoundation engineeringChinese charactersStress conditions

The invention discloses an adjustable tower crane steel platform foundation which comprises a foundation platform and latticed columns. The foundation platform is fixedly connected with a tower crane foundation section, and the latticed columns are fixedly connected with the foundation platform. The latticed columns are fixedly arranged in foundation piles of a tower crane. The foundation platform is a steel platform base welded by H-type steel and comprises steel beams of a two-layer structure, the steel beams are fixedly connected up and down, the auxiliary steel beam is arranged on the lower layer and formed by four pieces of H-type steel in a fixedly-connected mode, and the four pieces of H-type steel are distributed to be shaped like the Chinese character 'kou'. The supporting steel beam is arranged on the upper layer and formed by two pieces of H-type steel in a combined mode, and the two pieces of H-type steel are arranged in parallel. The supporting steel beam is fixedly connected to the top face of the auxiliary steel beam in a centered mode. The top ends of the latticed columns are provided with connecting column caps. The bottom face of the auxiliary steel beam is fixedly connected to the top faces of the connecting column caps, and the tower crane foundation section and the supporting steel beam are welded or connected through high-strength bolts. The double-layer adjustable structure steel beams are used as the steel platform base of the tower crane, a pile foundation is easily and sufficiently used, the same platform base is suitable for installing tower cranes in different types, the construction cost is further reduced, and the stress conditions and the anti-dumping capacity of the tower crane foundation can be greatly improved.

Owner:SHANGHAI GREENLAND CONSTR GRP

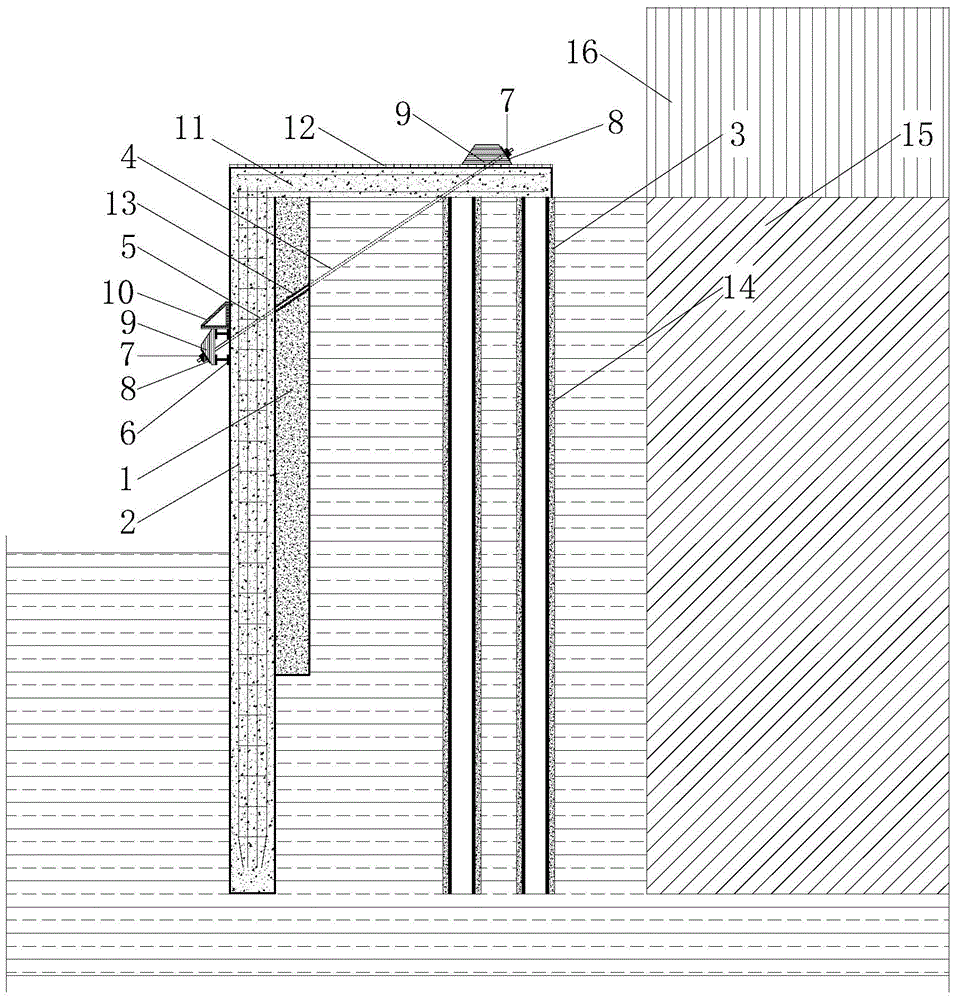

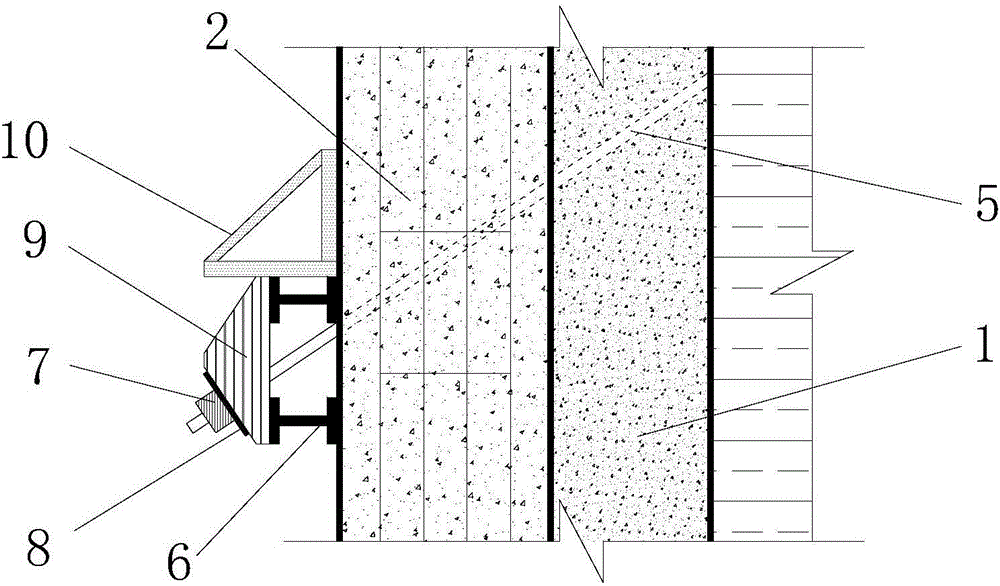

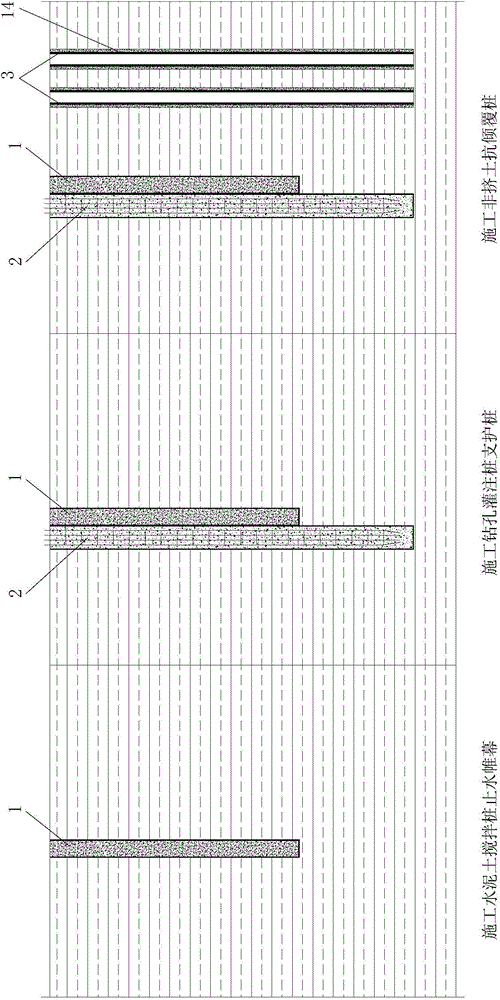

Maintenance structure for foundation pit next to existing building and construction method

ActiveCN104612160AEnsure safetyEnsure stabilityExcavationsArchitectural engineeringEconomic benefits

The invention relates to a maintenance structure for a foundation pit next to an existing building. The maintenance structure is characterized by mainly comprising a cement mixing pile water stop curtain, a cast-in-situ bored pile support pile, non-soil-squeezing anti-overturning piles and a slant pull rod, wherein the cast-in-situ bored pile support pile, the cement mixing pile water stop curtain and the non-soil-squeezing anti-overturning piles are sequentially arranged on the outer side of a foundation pit excavation side boundary from inside to outside; a raft plate is arranged in a pile body top area from the non-soil-squeezing anti-overturning piles to the cast-in-situ bored pile support pile, and a continuous perforated steel plate is arranged on the top of the raft plate; the upper portion of the slant pull rod is arranged on the continuous perforated steel plate on the tops of the non-soil-squeezing anti-overturning piles, the lower portion of the slant pull rod is arranged on the outer side of the cast-in-situ bored pile support pile, and the two ends of the slant pull rod are each fixed with an anchorage device, a base plate and a pedestal. The foundation pit maintenance structure effectively solves the technical problem that the foundation pit next to the existing building is hard to support, and has good technical and economical benefits.

Owner:ZHONGDA CONSTR

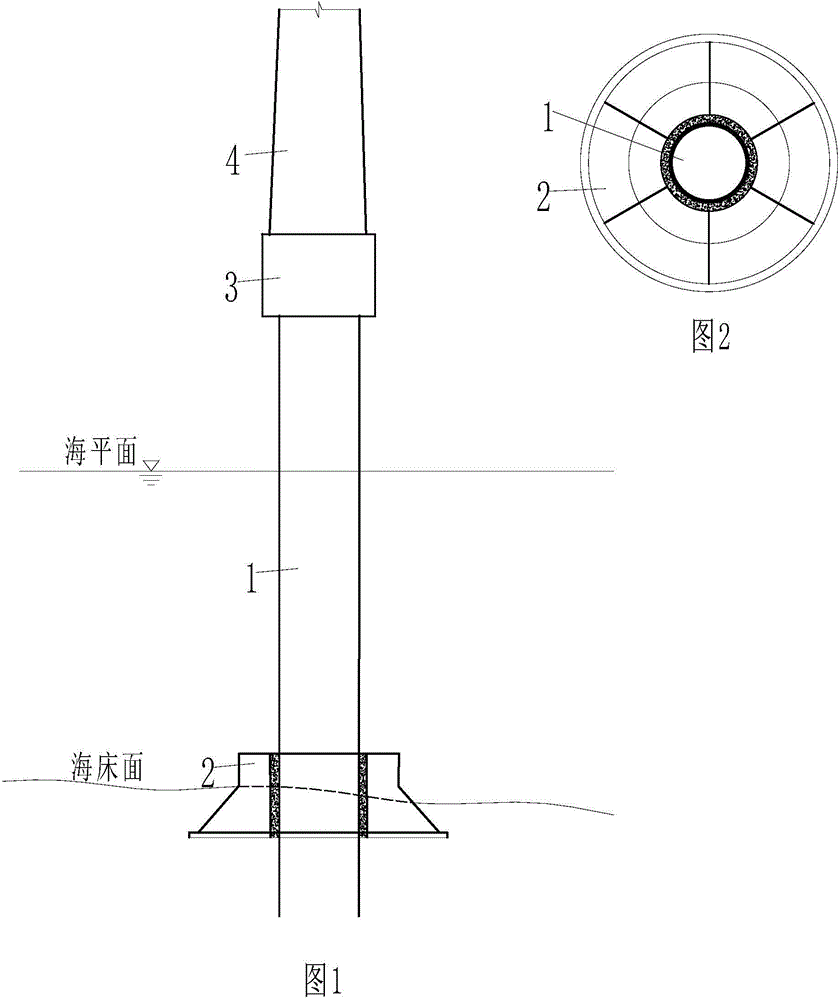

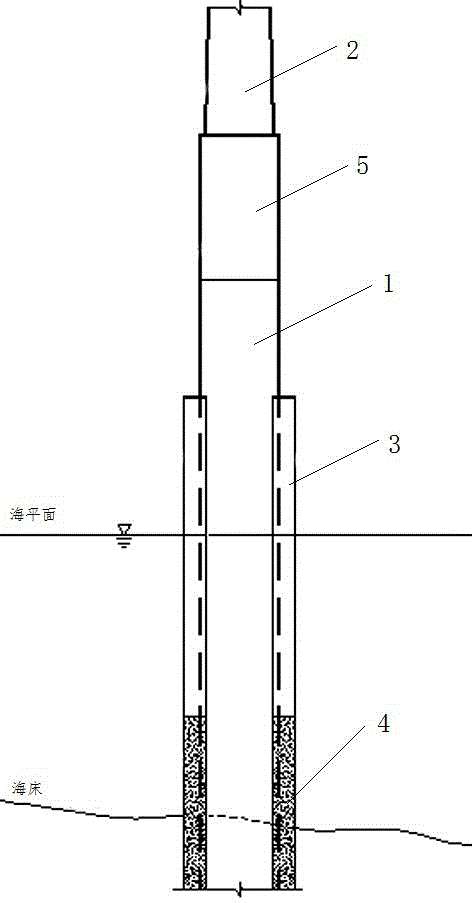

Single pile and gravity combined offshore wind power foundation

InactiveCN104818727AImprove anti-overturn performanceReduce horizontal displacementFoundation engineeringOffshore wind powerTower

The invention discloses a single pile and gravity combined offshore wind plant blower foundation. The foundation comprises a steel pipe pile vertically inserted to a seabed; the upper end of the steel pipe pile is connected with a transition section, and the upper end of the transition section is connected with a blower tower cylinder; the lower end of the steel pipe pile is anchored on the seabed by crossing through a gravity type foundation. The technical scheme of the single pile-gravity combined offshore wind plant blower foundation provides a novel foundation model formed by combining a single pile and the gravity; through adding an additional hollow gravity type foundation at the position of the steel pipe pile closing to the seabed, the rigidity of the single pile foundation closing to the seabed face is enhanced, advantages of two foundations are combined, and the using scale of a single-pile foundation is enlarged. The scheme increases the ability of resisting bending torque of the single-pile foundation, reduces the displacement of the pile body, and decreases the diameter and the thickness of the steel pipe pile.

Owner:FUJIAN YONGFU POWER ENG +1

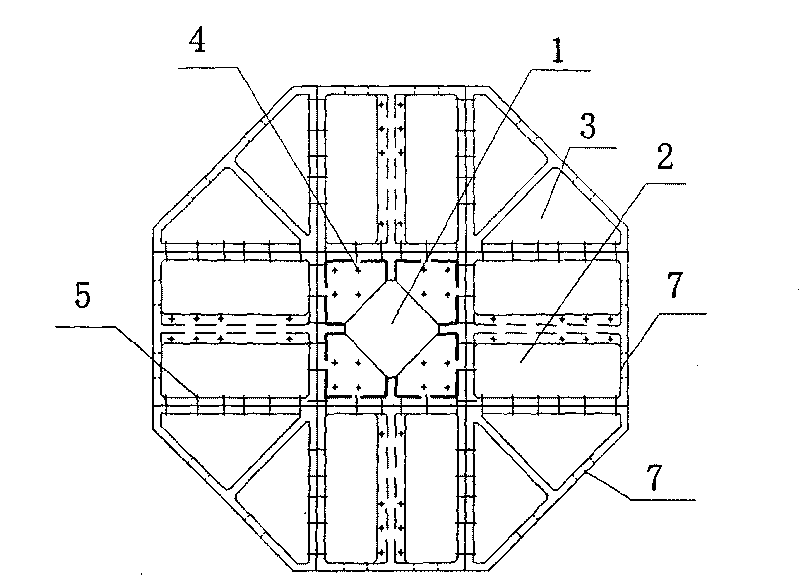

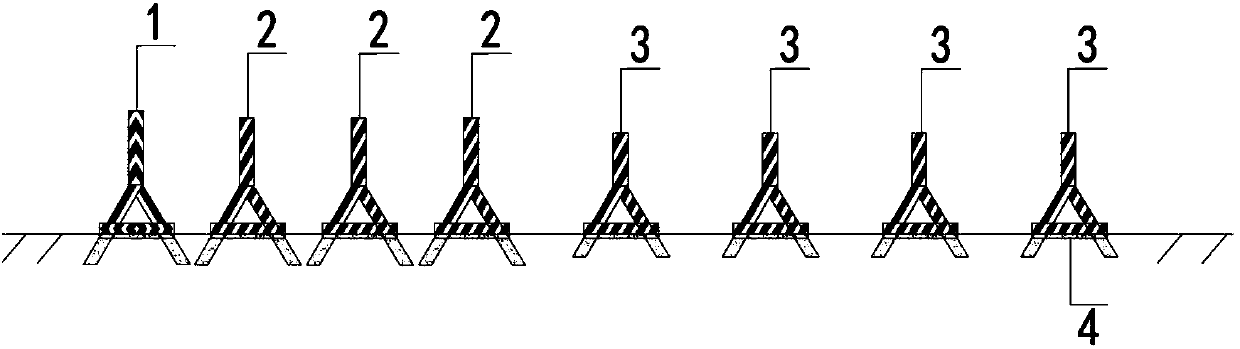

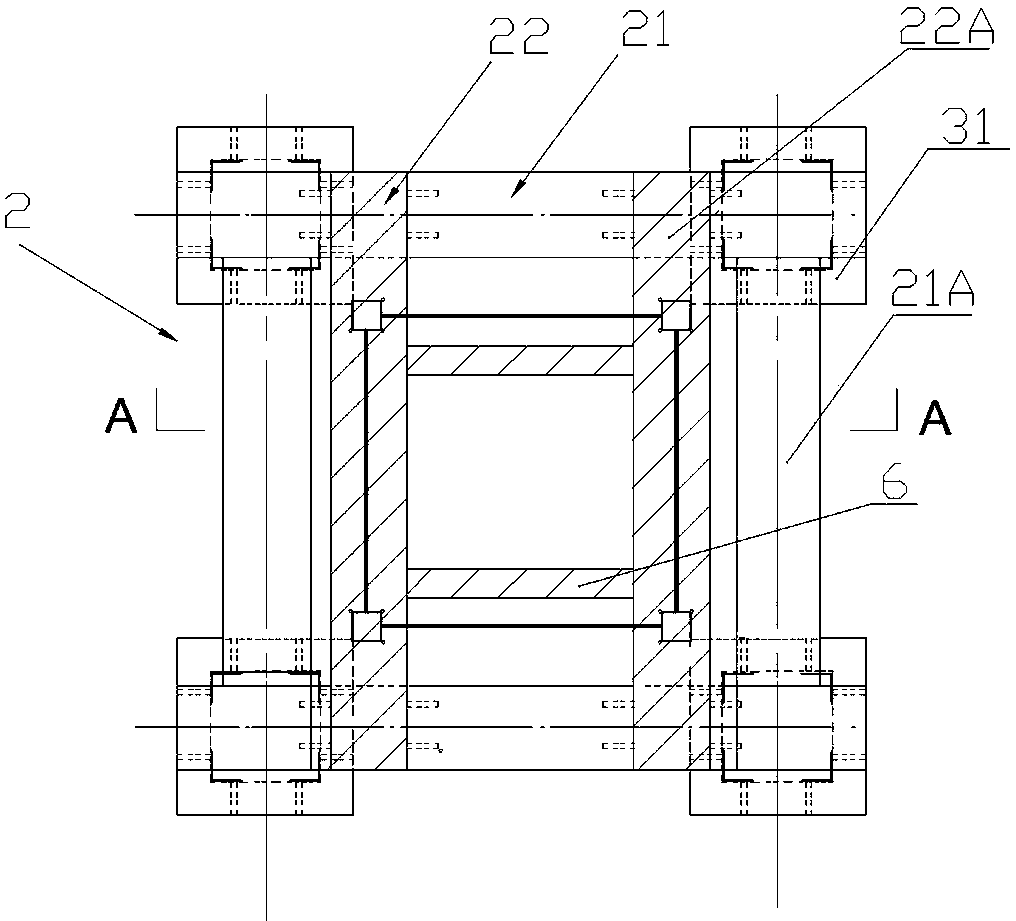

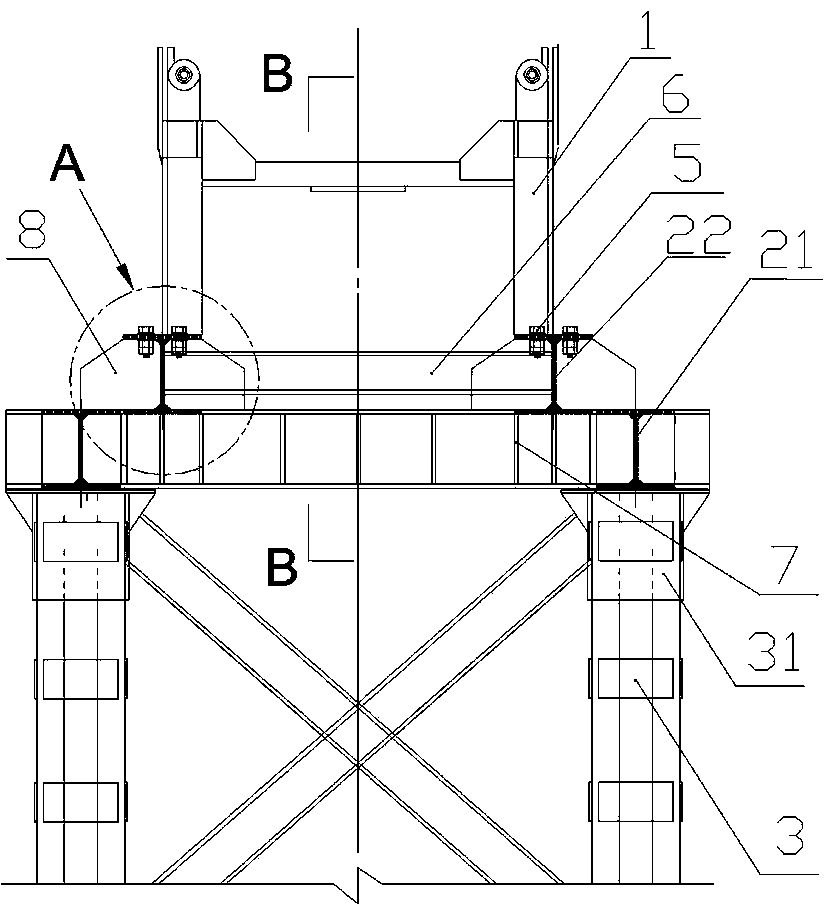

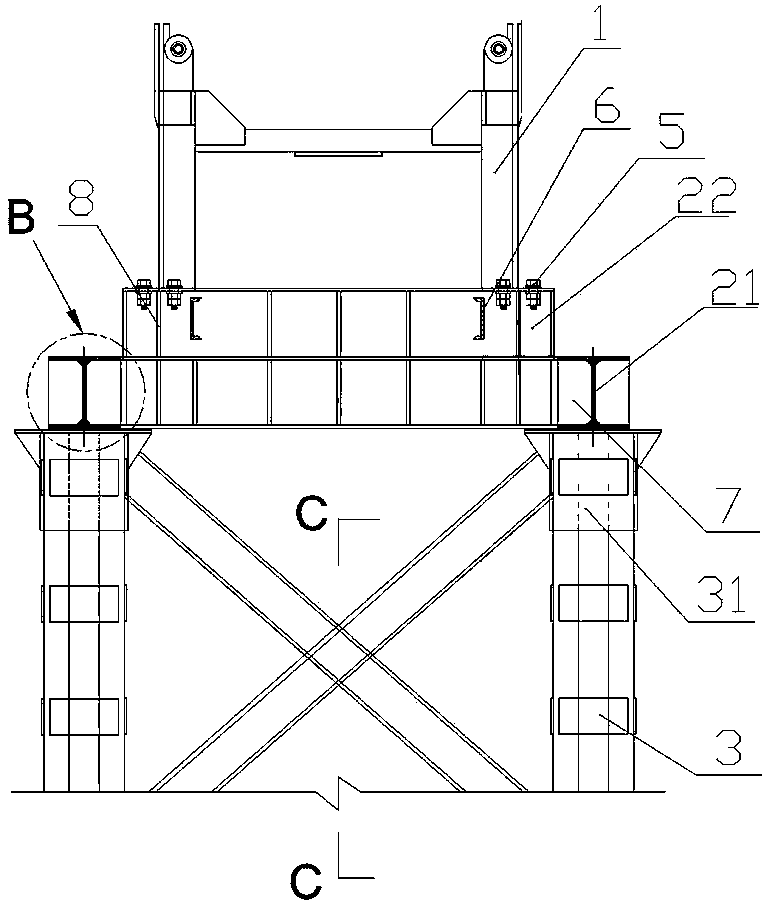

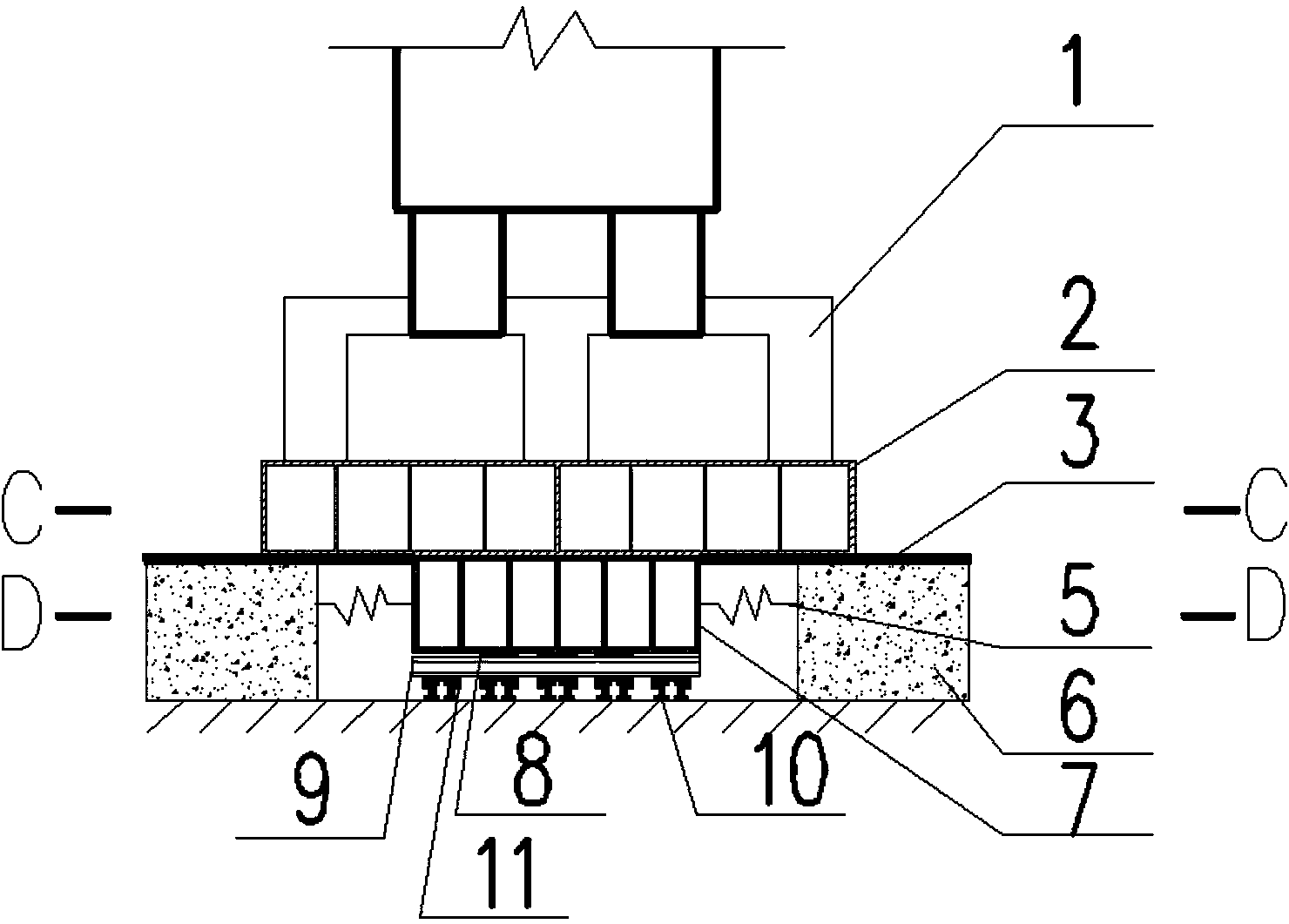

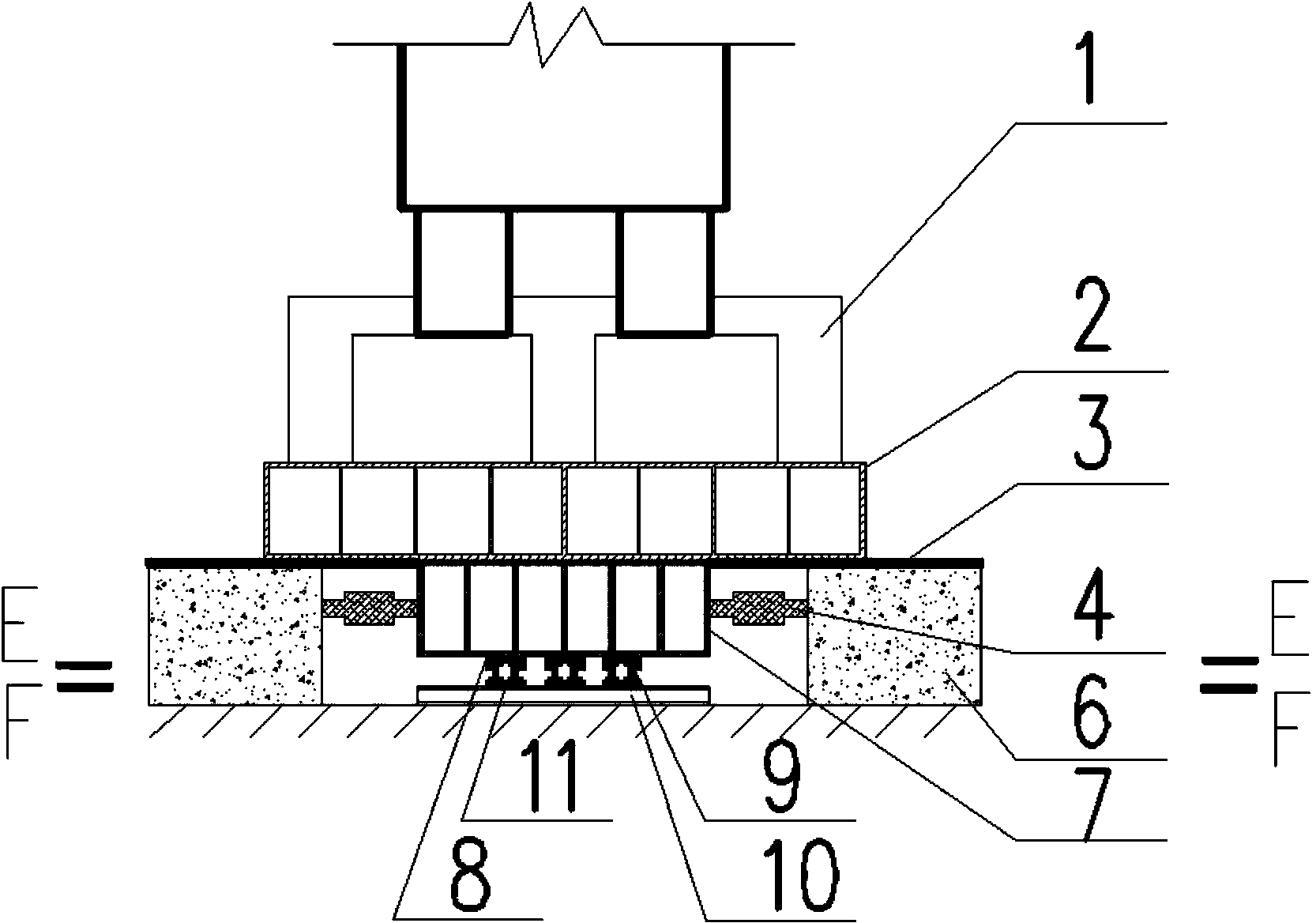

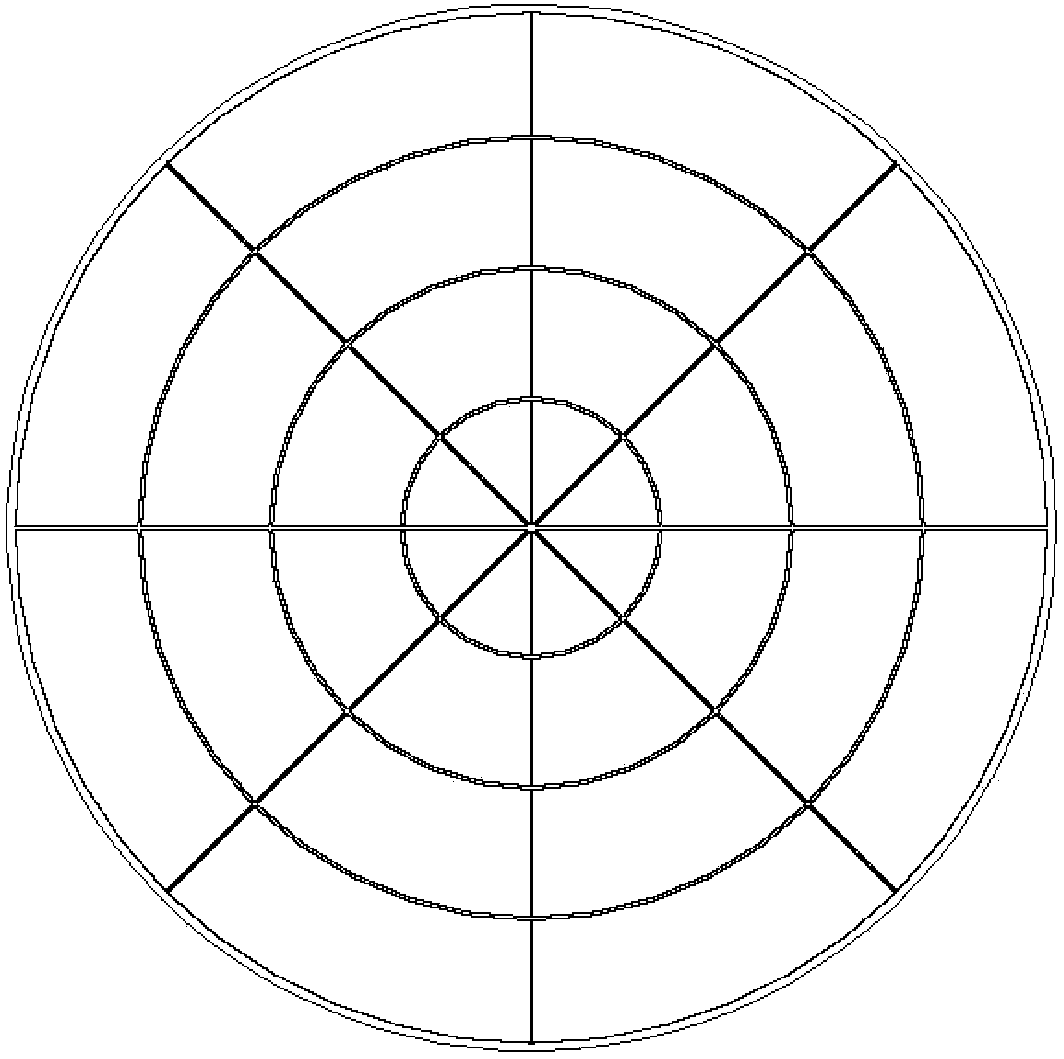

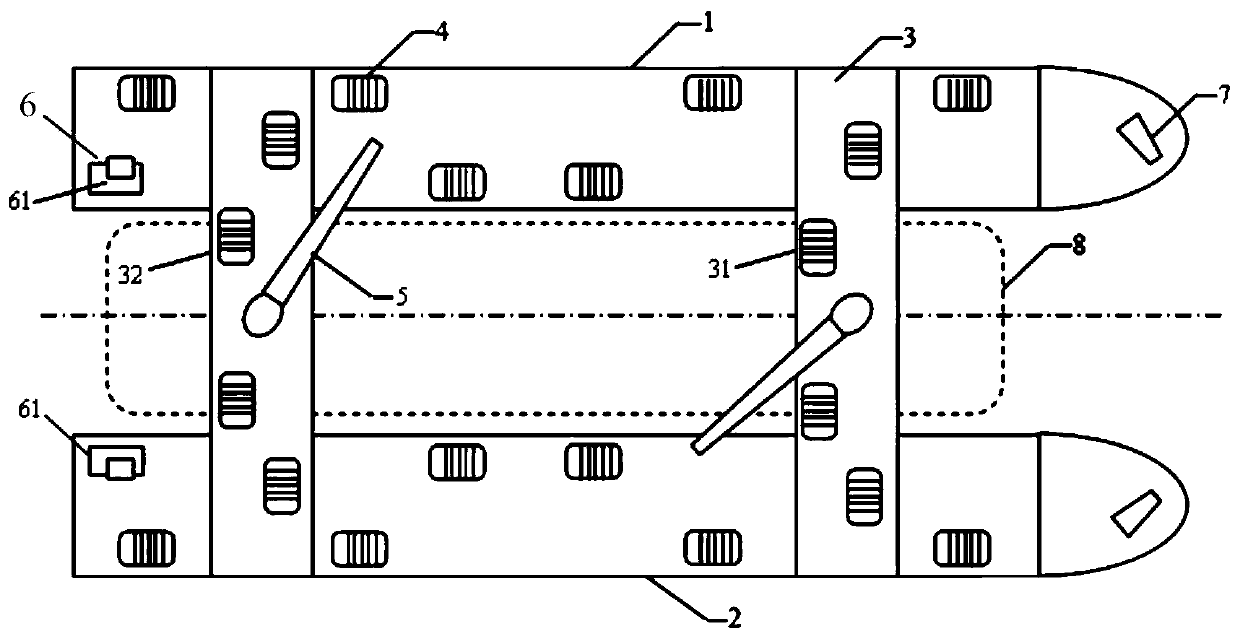

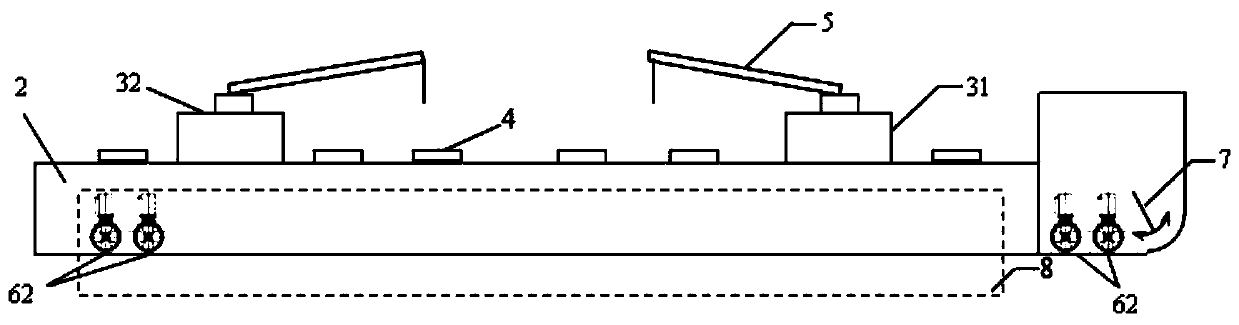

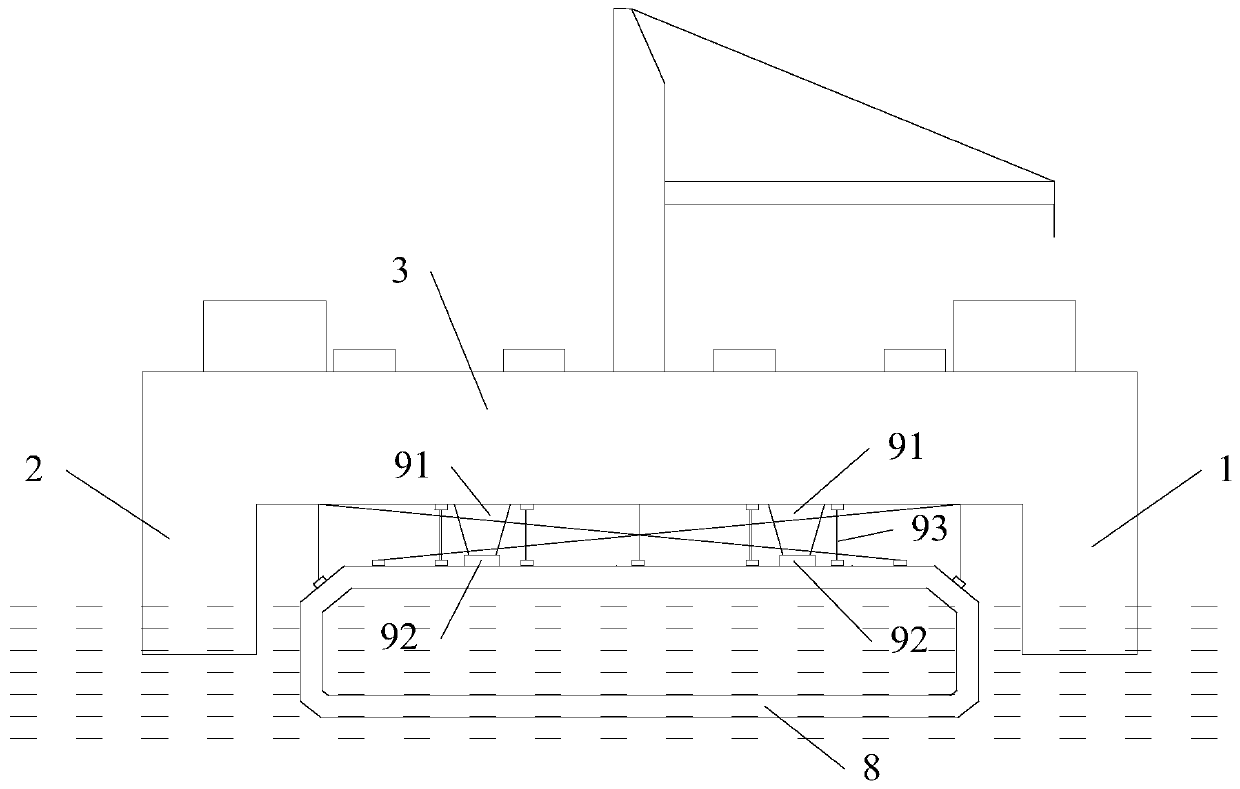

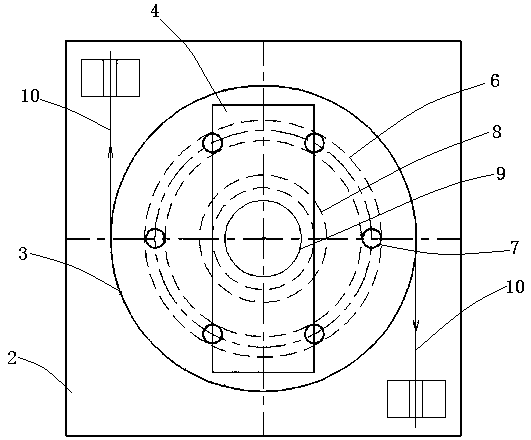

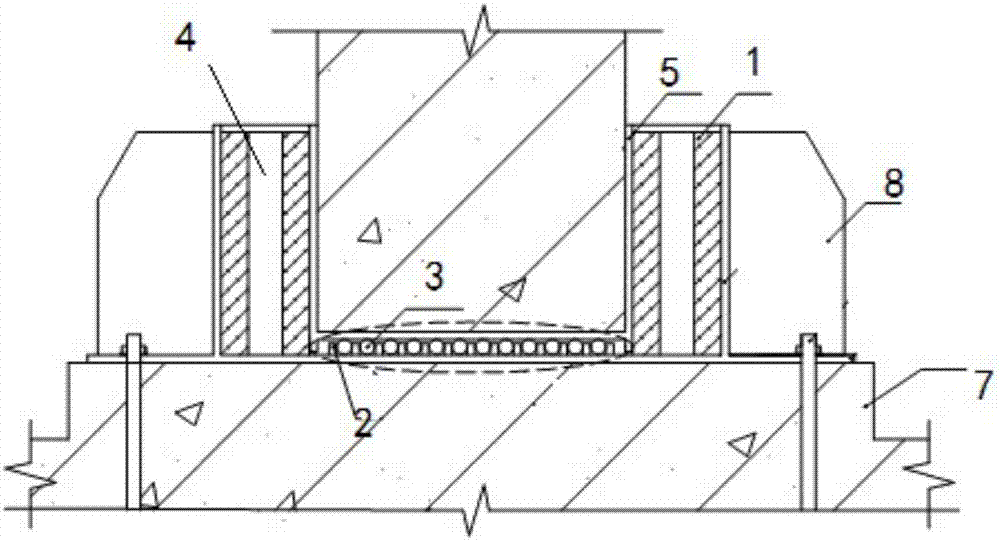

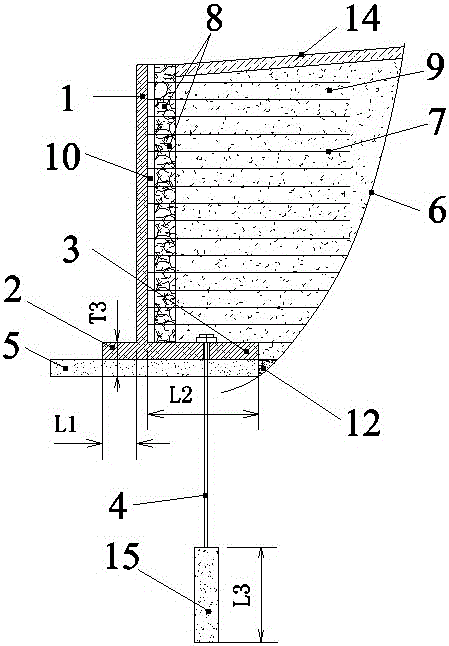

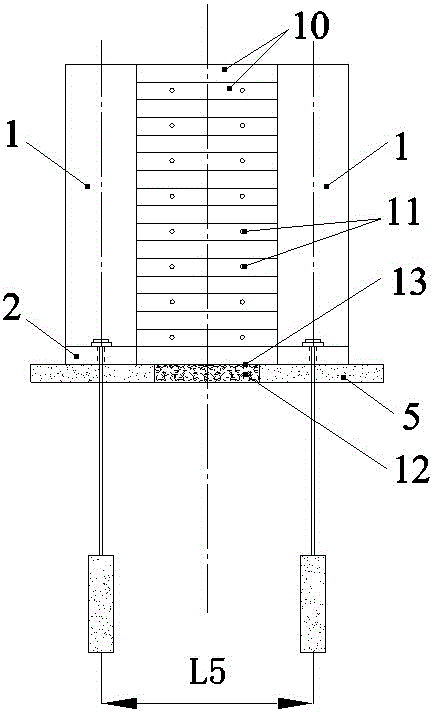

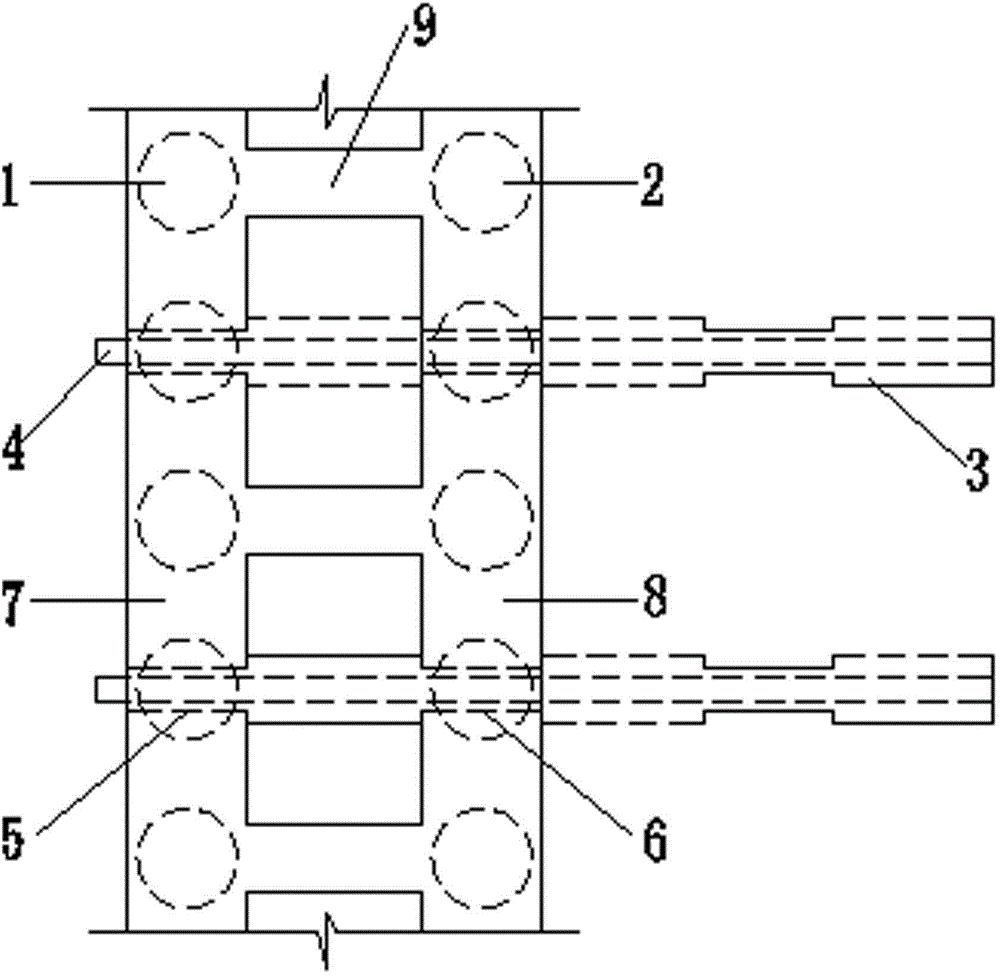

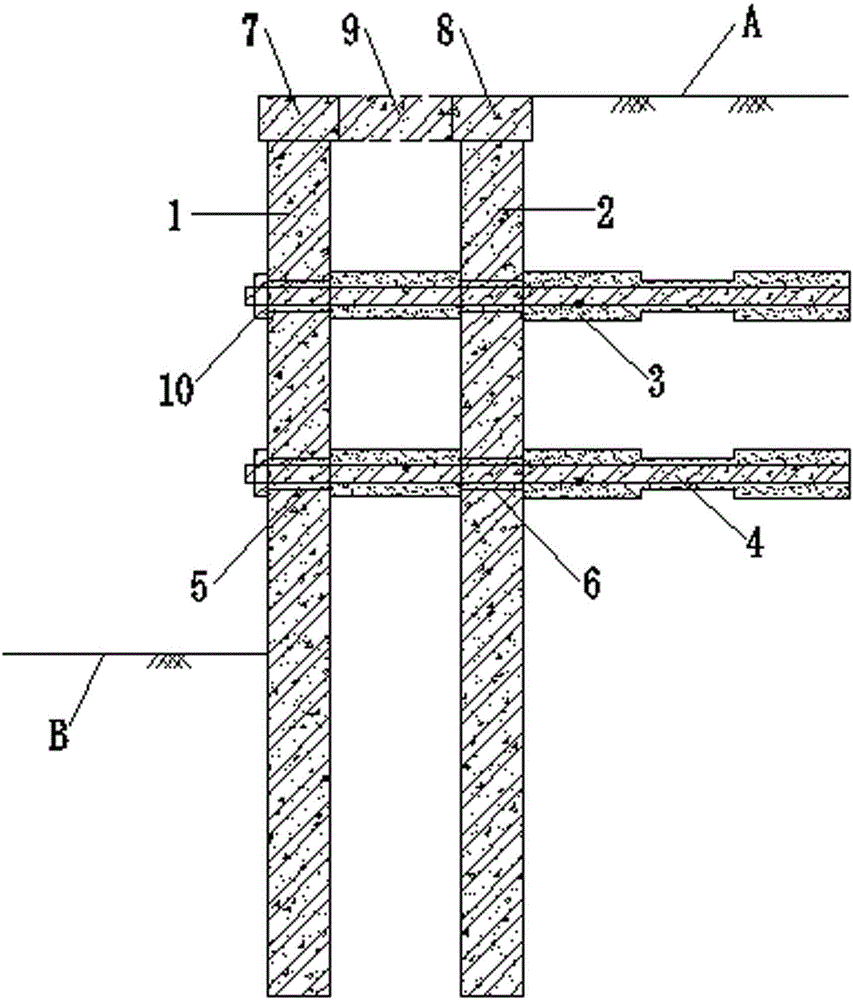

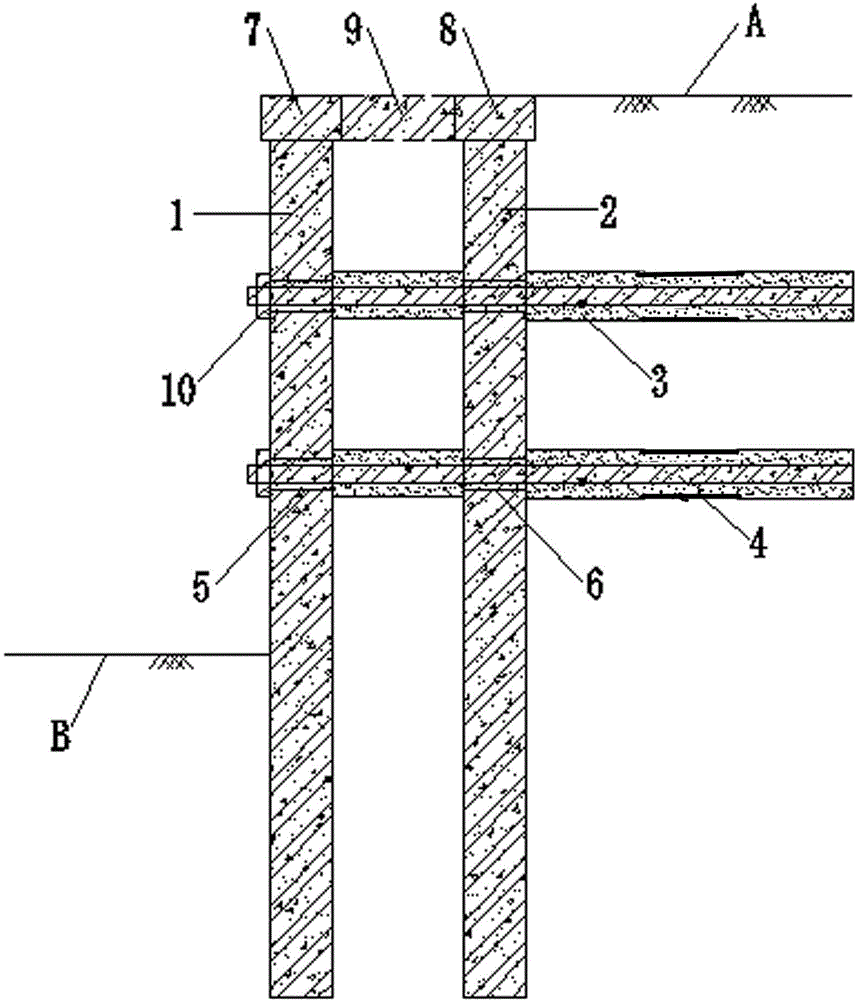

Shock insulating device resistant to pulling and twisting

InactiveCN103669633AWide range of stiffness adjustmentSignificantly prolonged periodShock proofingShock resistanceHigh rise

The invention discloses a shock insulating device resistant to pulling and twisting and belongs to the technical field of building shock resistance. The shock insulating device is mainly composed of a high-rise structure (1), an upper-portion rigid pedestal (2) with high rigidity and bearing capability, a base heat-insulating layer (3), viscous dampers (4), damping springs (5), springs, a damper supports (6), a lower-portion rigid pedestal (7) with high rigidity and bearing capability, horizontal limiting sliders (8), bottom horizontal shock-insulating linear guide rails (9), bottom longitudinal shock-insulating linear guide rails (10) and longitudinal limiting sliders (11). The shock insulating device is low in cost, simple in structure, convenient to construct, high in pulling resistance and twisting resistance and obvious in shock-insulating effect.

Owner:BEIJING UNIV OF TECH

Rock-socketed single pile foundation through offshore wind power and construction method of rock-socketed single pile foundation

ActiveCN105862905AIncrease stiffnessImprove carrying capacityFoundation engineeringBedrockOffshore wind power

The invention relates to a rock-socketed single pile foundation through offshore wind power and a construction method of the rock-socketed single pile foundation. The rock-socketed single pile foundation comprises a steel pipe single pile which is positioned in the center, wherein the lower end of the steel pipe single pile is inserted into a seabed, and the upper end of the steel pipe single pile is positioned above the sea level; a fan tower cylinder is mounted at the upper end of the steel pipe single pile, and a plurality of steel pipe grouting piles which are fixedly connected to the steel pipe single pile are arranged at intervals at the internal circumambient part or the periphery in the steel pipe single pile; the lower ends of the steel pipe grouting piles are inserted into the seabed, and the upper ends of the steel pipe grouting piles are positioned above the sea level; the inner parts of the lower ends of the steel pipe grouting piles are grouted with concrete socketed piles of which the lower ends penetrate through the lower ends of the steel pipe grouting piles to be embedded and fixed in a baserock layer of the seabed. According to the rock-socketed single pile foundation disclosed by the invention, the difficult problem that at current, in China, full cut-off sock-socketed construction of large diameter pile foundation cannot be realized is effectively solved, and besides, the horizontal load bearing capacity and the antidumping capacity of the pile foundation are improved; the dynamic response of infrastructures is reduced, the application scope of the single pile foundation is enlarged, and the single pile foundation disclosed by the invention has a high application value.

Owner:FUJIAN XINNENG OFFSHORE WIND POWER R & D CENT CO LTD +1

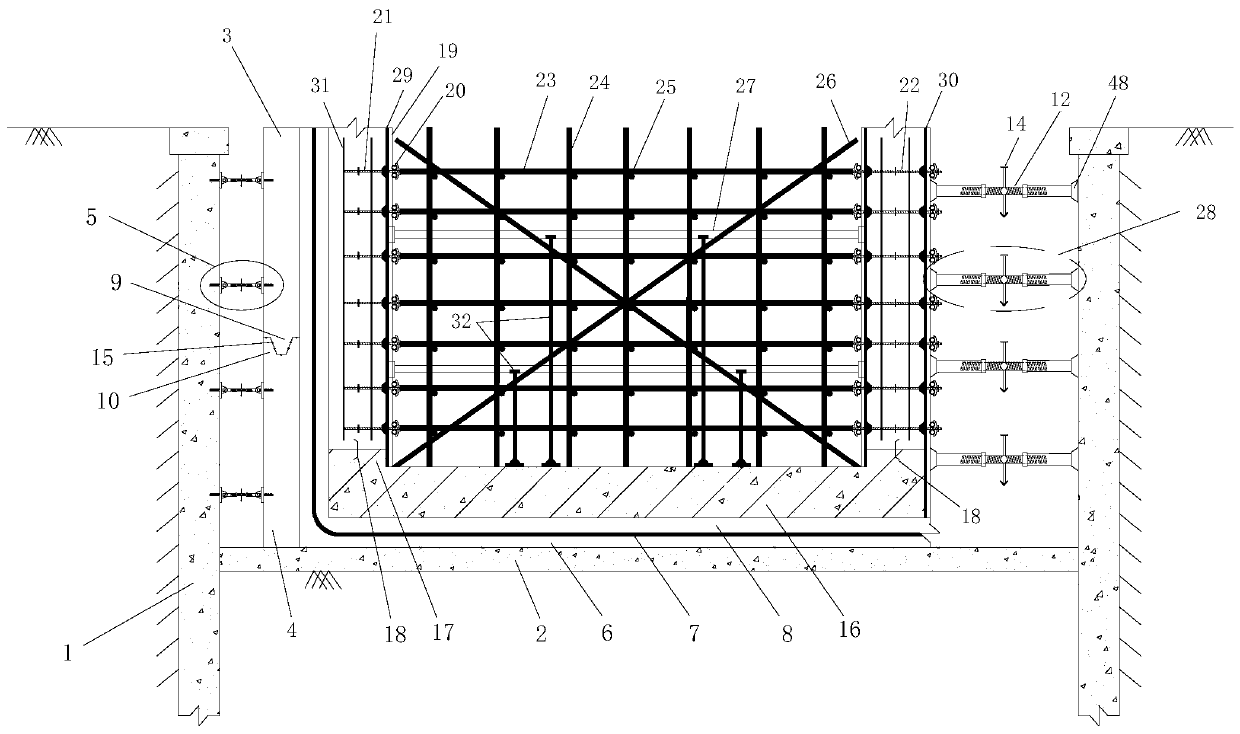

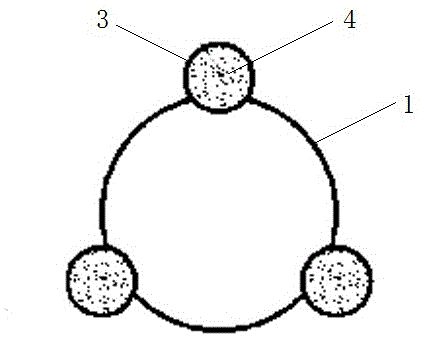

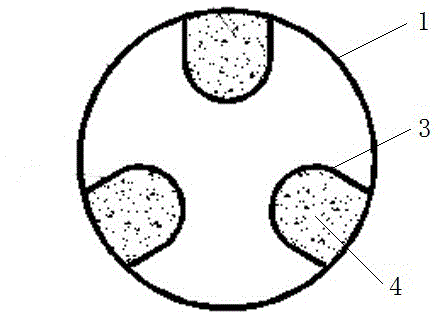

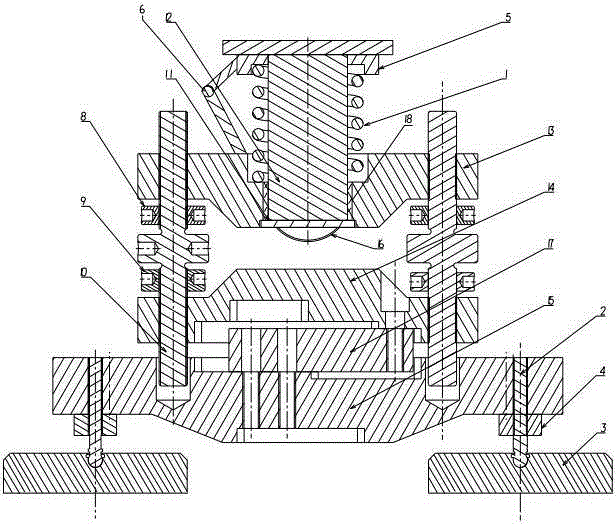

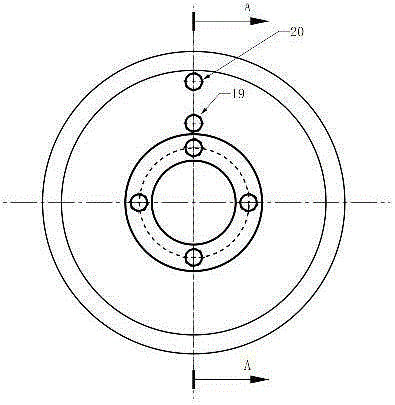

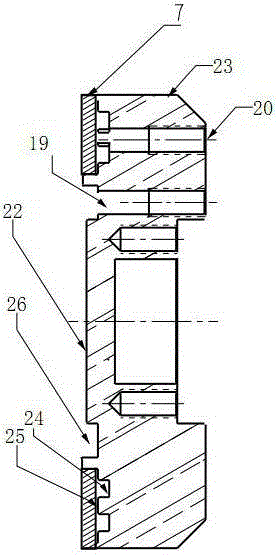

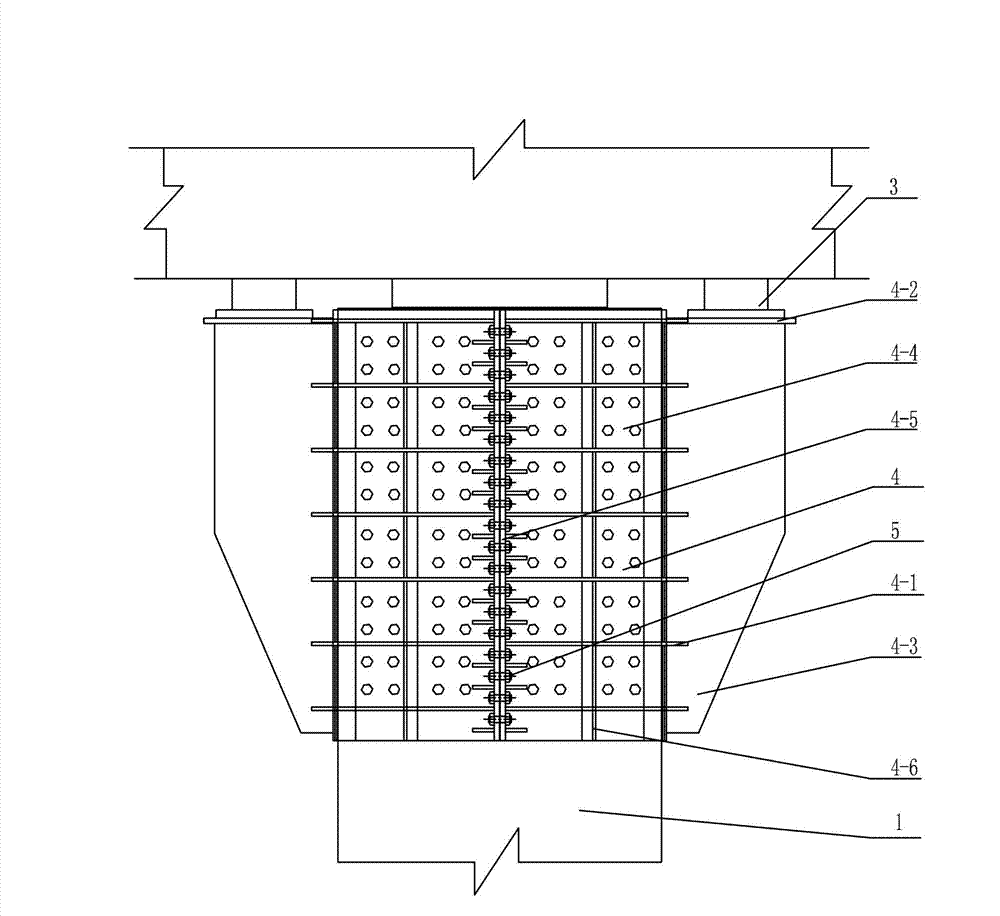

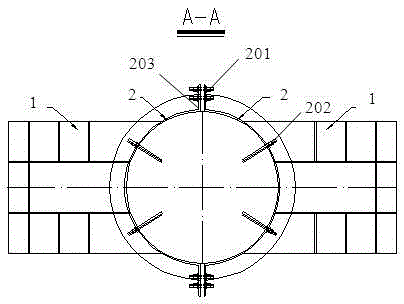

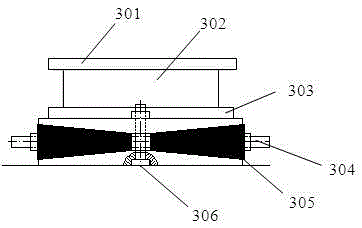

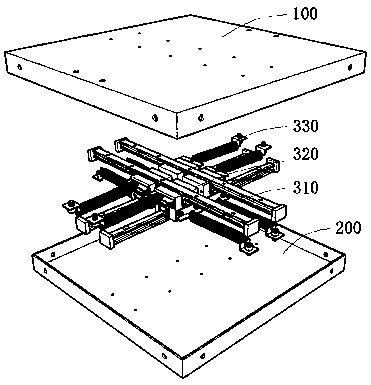

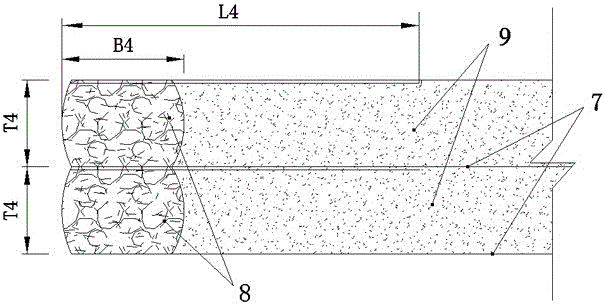

Porous air-suspending supporting system applied to full physical simulation

The invention relates to a porous air-suspending supporting system applied to full physical simulation. According to the air-suspending supporting system, a vacuum pre-load with volume reduction hills is adopted for being combined with a porous flow controller; and the porous air-suspending supporting system mainly comprises a vertical guide mechanism, an adjustable supporting transverse beam, a bearing sensor (17) and an air-suspending supporting mechanism (3), wherein the air-suspending supporting mechanism (3) is formed by an air-suspending supporting shell (23), air nozzles (19 and 20) and the porous flow controller (7). The air-suspending supporting shell (23) is formed by air-suspending pressure-sharing structures (7, 22, 24, 25 and 26), a negative pressure vacuum cavity (26) and the volume reduction hills (22). According to the porous air-suspending supporting system applied to full physical simulation, the anti-dumping force is increased so that the system can be more stable; and the system stability is further improved.

Owner:北京太和科技有限公司 +1

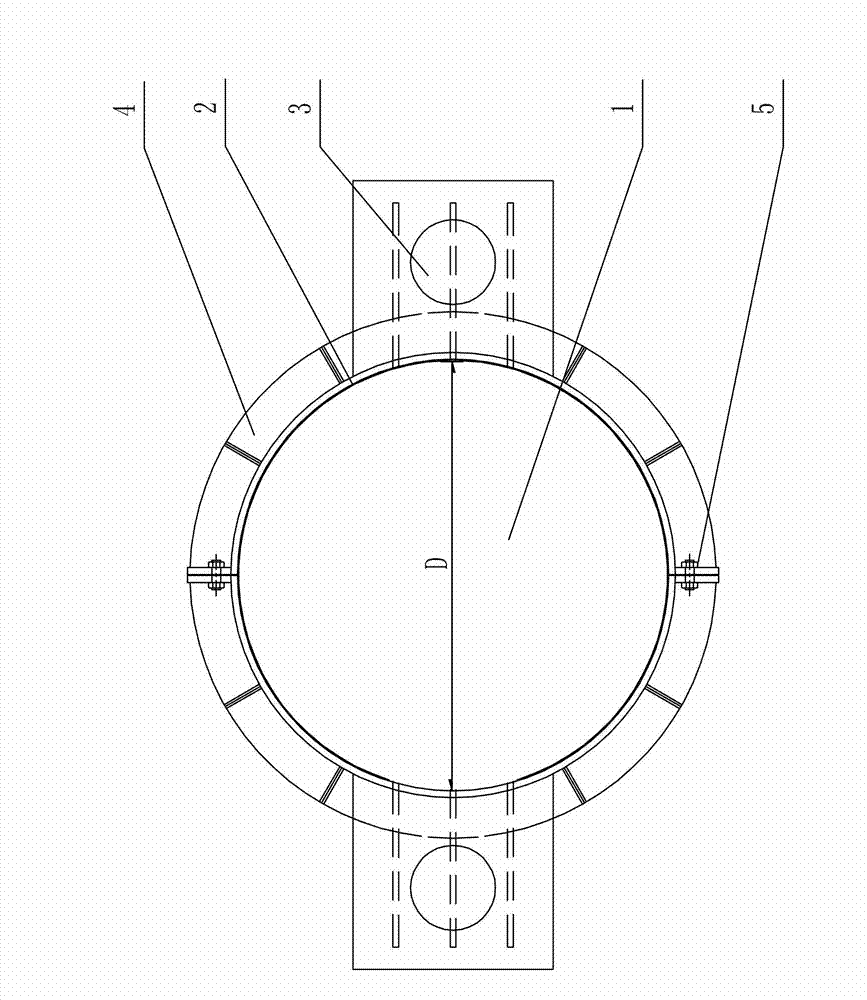

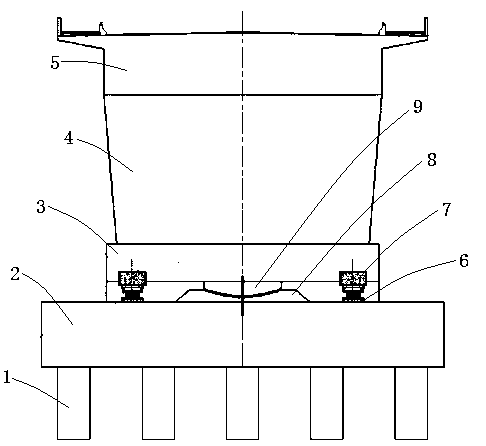

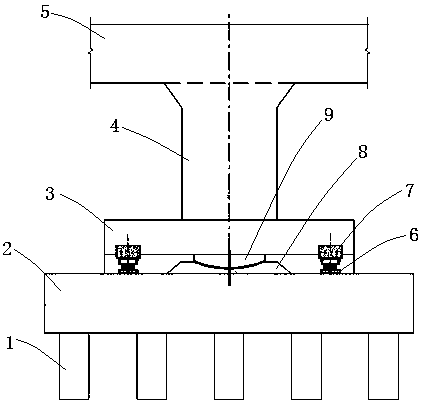

Anti-overturning bridge pier supporting mechanism

InactiveCN103205927AImprove the state of stressImprove anti-overturn performanceBridge structural detailsFiberStructural engineering

The invention relates to an anti-overturning bridge pier supporting mechanism, in order to solves the problem that a single-column pier bridge easily causes disconnection of a supporting seat and even capsizing cases as adopting a single-point supporting beam in the prior art. The supporting mechanism comprises a pier column, carbon fiber cloth, a steel hoop component and two supporting seats, the steel hoop component comprises two horizontal support plates, two semicircular cylinders and four connectors, the two semicircular cylinders form a circular cylinder through the four connectors, one supporting seat is arranged on the upper surface of each horizontal support plate, the two horizontal support plates are arranged on the upper surface of the circular barrel horizontally and linearly, the carbon fiber cloth is wound at the top end of the pier column, and the circular cylinder is sleeved on the carbon fiber cloth on the outer side of the pier column. The anti-overturning bridge pier supporting mechanism is used in the field of bridge reinforcing.

Owner:NORTHEAST FORESTRY UNIVERSITY

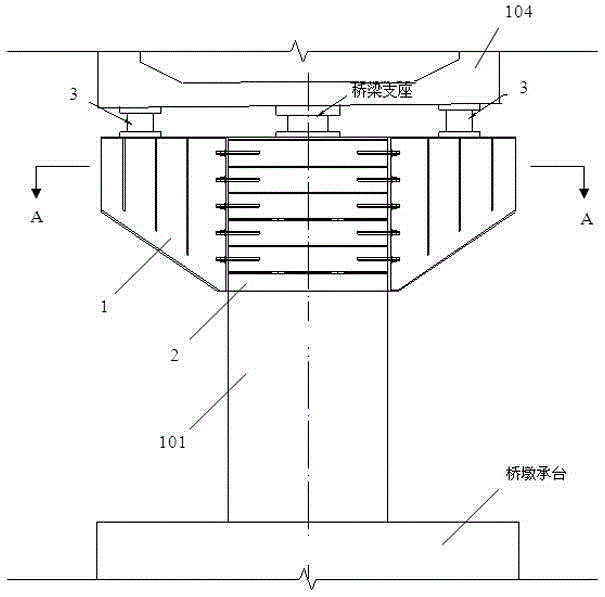

Anti-overturning structure for single-pier bridge girder

InactiveCN105421250AImprove anti-overturn performanceGood construction convenienceBridge structural detailsBridge erection/assemblyMaterials scienceBuilding construction

The invention discloses an anti-overturning structure for a single-pier bridge girder. The anti-overturning structure comprises a steel girdle structure arranged on a pier stand column in a sleeving mode. The steel girdle structure comprises two steel girdles with the same structure, a plurality of opposite-pulling high-strength bolts arranged on the joints of the steel girdles and a plurality of anchor bolts arranged in preformed holes in the steel girdles. The opposite-pulling high-strength bolts enable the steel girdles to be combined into the integral steel girdle structure. The steel girdle mechanism and the pier stand column are fixed through the anchor bolts. Two steel brackets are welded to the two steel girdles. The height of an intelligent supporting base arranged between the steel brackets and the bottom of the bridge girder is adjustable, and it is ensured that the upper surface of the intelligent supporting base is tightly attached to the bottom of the bridge girder and the lower surface of the intelligent supporting base is tightly attached to the steel brackets. According to the anti-overturning structure for the single-pier bridge girder, the anti-overturning performance of the single-pier bridge girder is improved; the anti-overturning structure has good construction convenience, wide applicability and excellent economy.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

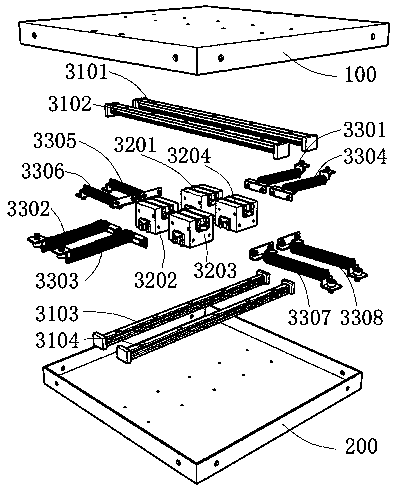

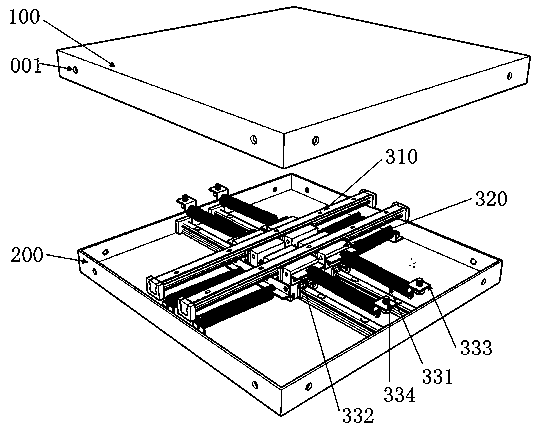

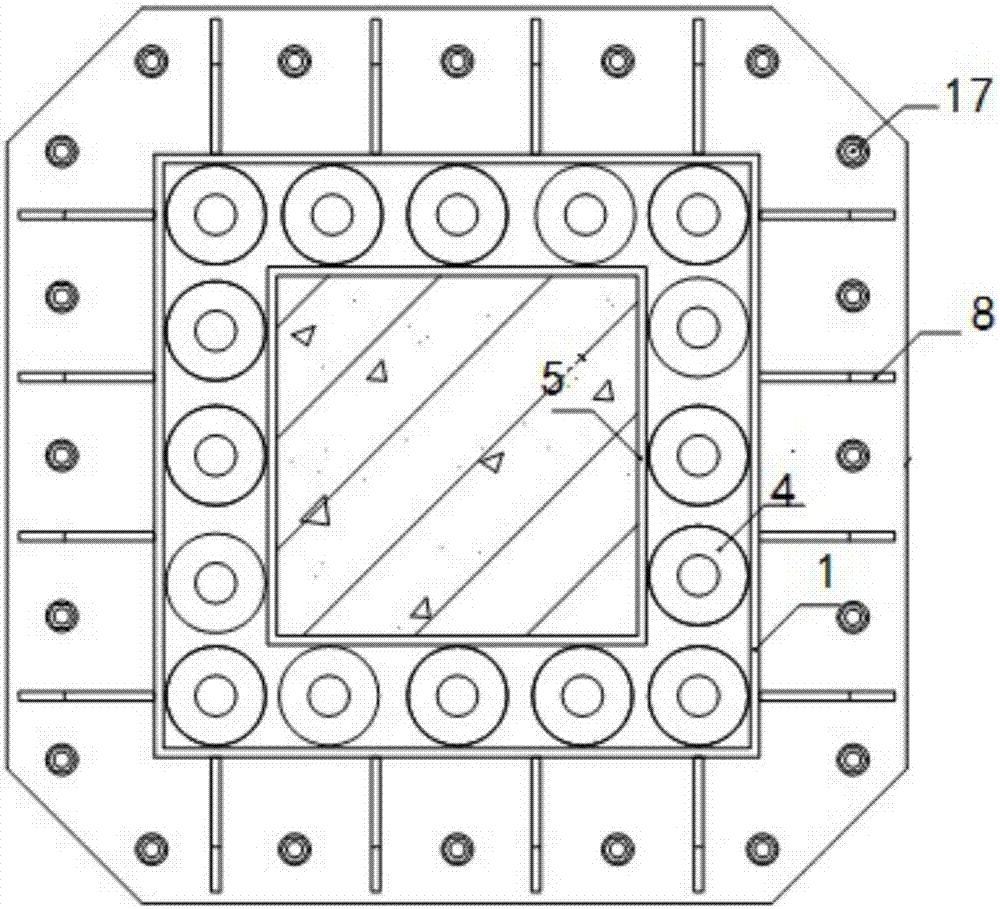

Shock isolation device with orthogonal guide rails, and design method thereof

PendingCN110513434AImprove anti-overturn performanceCompact structureNon-rotating vibration suppressionShock absorbersEngineeringGravity center

The invention discloses a shock isolation device with orthogonal guide rails. The shock isolation device with the orthogonal guide rails comprises an upper plate, a lower plate, two shock isolation flat plates arranged at the top and the bottom, and a shock isolation assembly, wherein the shock isolation assembly comprises two groups of linear guide rail assemblies, a group of slide seats, and twogroups of return connection elements; the two groups of linear guide rail assemblies installed on the two shock isolation flat plates separately are orthogonally arranged; one slide seat is connectedwith the two groups of linear guide rail assemblies at the top and the bottom simultaneously, and connected with floating ends of the two groups of return connection elements simultaneously, and fixed ends away from a slide assembly, of the two groups of return connection elements, are installed on two shock isolation plate assemblies separately; and in a normal working state, the shock isolationassembly limits the gravity center of each shock isolation flat plate to be always located in an area where the two shock isolation flat plates are mutually superposed. According to the shock isolation device with the orthogonal guide rails, the overall anti-overturning capacity of the shock isolation device is improved; and the shock isolation device with a new structure can be independently used.

Owner:四川省龙丹纳科技有限公司

Self-propelled underwater tunnel immersed tube carrying and mounting integrated ship and construction process

InactiveCN110877666ADoes not affect trafficEasy to installArtificial islandsCargo handling apparatusBuoyant flowMechanical engineering

The invention discloses a self-propelled underwater tunnel immersed tube carrying and mounting integrated ship. The ship comprises a first ship body and a second ship body which are parallel, a connecting structure is arranged between the first ship body and the second ship body, and traction hoisting equipment arranged on the first ship body, the second ship body and the connecting structure. A carrying space is formed between the first ship body and the second ship body below the connecting structure, a component to be installed is arranged in the carrying space and connected with the ship bodies, and a propelling power device and a power positioning system are arranged on the first ship body and the second ship body. The lower portion of the integrated ship is provided with the carryingspace. Goods to be transported are placed in the carrying space and float in water. Most weight of goods is shared by buoyancy. The goods are transported to the designated position, and precise installation work is completed. Underwater tunnel immersed tubes or similar large components of various sizes can be independently transported and installed through one self-propelled ship body successfully, other ships do not need to be used for dragging, channels do not need to be sealed for other ships in the transportation process, and passing of other ships is not affected.

Owner:CCCC FIRST HARBOR ENG

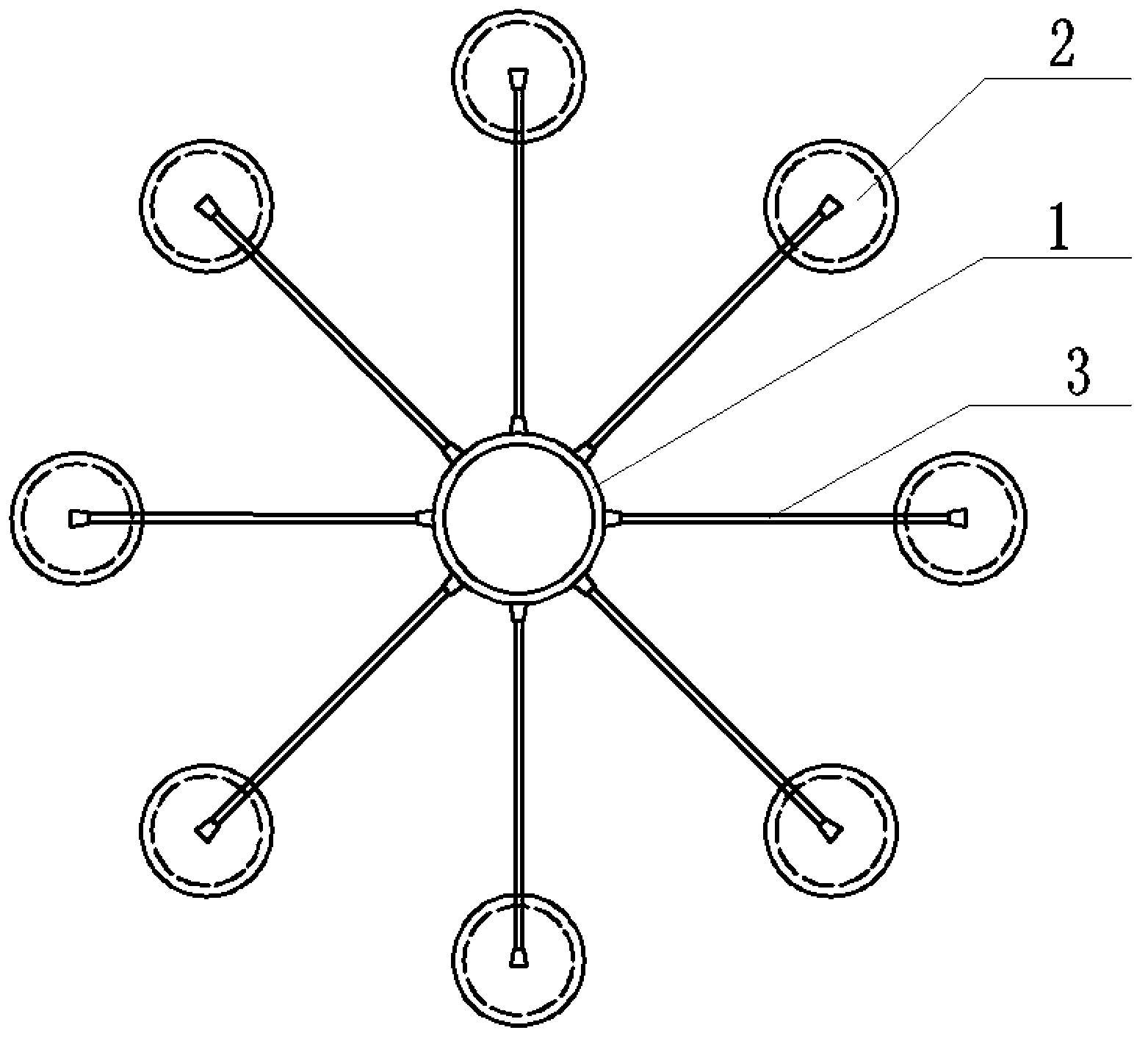

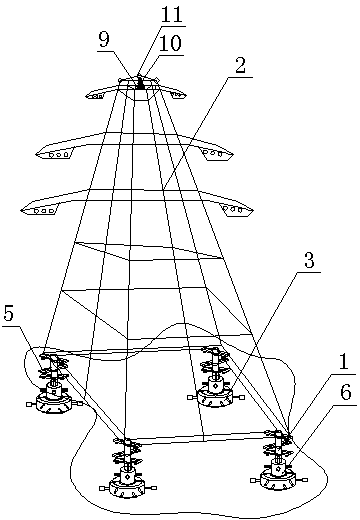

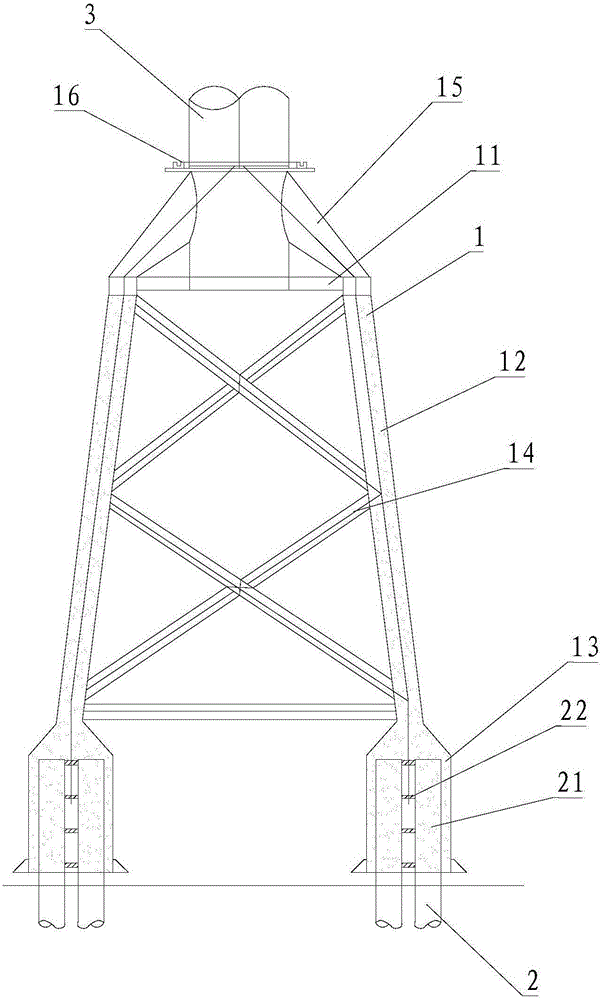

High-rise pile cap offshore wind power foundation combining vertical single pile and multiple raking piles

InactiveCN103352474AImprove horizontal carrying capacityImprove anti-overturn performanceFoundation engineeringSea levelHigh rise

The invention discloses a high-rise pile cap offshore wind power foundation combining a vertical single pile and multiple raking piles. The foundation comprises a bearing platform, the multiple raking piles and the single pile, wherein the upper ends of the raking piles and the upper end of the single pile are positioned above the sea level, the lower ends of the raking piles and the lower end of the single pile are inserted below the sea level, the multiple raking piles are uniformly distributed on a circumference with the single pile serving as a circle center, and the top ends of the multiple raking piles and the top end of the single pile are fixedly connected onto the lower end surface of the bearing platform. Besides, the upper end surface of the bearing platform is connected with a blower tower through a flange; and the number of the raking piles is 3-8, and the multiple raking piles are radially and uniformly distributed on the circumference with the single pile serving as a circle center. With the adoption of the high-rise pile cap offshore wind power foundation combining the vertical single pile and the multiple raking piles, the defect of a single pile foundation in the aspect of resisting to great horizontal force and bending moment load is overcome, the problem that a pile group foundation has more foundation piles and larger diameters can be effectively solved, and meanwhile, the construction difficulty and the construction cost are low; soil mass in larger range can be enabled to be involved in resistance to horizontal force and bending moment, horizontal resistance of the foundation soil mass can be sufficiently played, the horizontal bearing performance of a foundation pile is improved, and the antidumping capacity of the foundation is improved.

Owner:TIANJIN UNIV

Composite support bridge plane rotating system

PendingCN110130231AOvercome uneven stressThe supporting structure is stable and reliableBridge erection/assemblyTravel modeStructural engineering

The invention provides a composite support bridge plane rotating system. The composite support bridge plane rotating system comprises a lower bearing platform structure, a center spherical hinge, a rotary table for supporting a to-be-rotated bridge, and a power mechanism for driving the rotary table to rotate, a supporting platform for supporting the center spherical hinge is arranged on the lowerbearing platform structure, the center spherical hinge is rotatably installed at the bottom of the rotary table, and arranged corresponding to the central area at the bottom of a pier of the to-be-rotated bridge, a ring-shaped track is arranged on the position, on the outer side of the supporting platform, of the lower bearing platform structure, and a plurality of idler wheel trolleys for supporting the rotary table are arranged on the ring-shaped track in a travelling mode. According to the composite support bridge plane rotating system, the center spherical hinge and the idler wheel trolleys are used for being subjected to force bearing jointly, multi-point support is formed on the to-be-rotated bridge, the problem that the loads of existing single-spherical-hinge rotating bodies are all centralized near the center spherical hinge to be transferred, and consequently the lower bearing platform structure is unevenly stressed is solved, and the anti-overturning stability in the rotating process is greatly improved.

Owner:CREEC WUHAN SURVEY DESIGN & RES

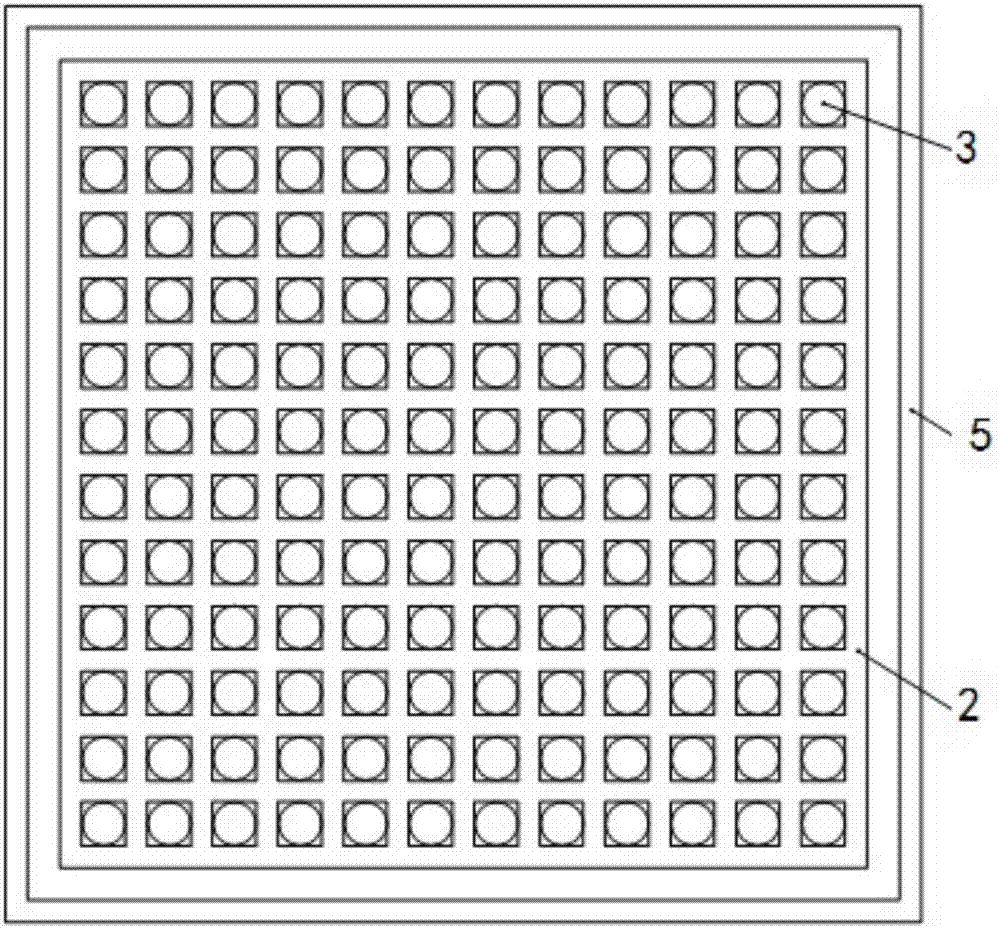

Rubber tube rolling shock insulation support for shock insulation of building structure foundation

PendingCN107190878AImprove earthquake resistanceMeet earthquake resistance requirementsProtective buildings/sheltersShock proofingEarthquake resistantInsulation layer

The invention provides a rubber tube rolling shock insulation support for shock insulation of a building structure foundation. The rubber tube rolling shock insulation support comprises a limiting seat, a ball limiting rack, multiple balls, multiple rubber tubes, a concrete column-column foot lining plate and a limiting stay rope. An upper-portion structure can produce a certain amplitude of horizontal displacement with respect to the shock insulation support fixed to the foundation through matching of the limiting seat, the rubber tubes, the balls and the ball limiting rack when horizontal shock occurs, the power effect of shock on the upper-portion structure is reduced, deformation of a shock insulation layer during earthquake can be limited, the support has a certain reset capability, the limiting stay rope can ensure that the upper-portion structure and the foundation do not produce overlarge displacement, the shock resistance capability of the structure is improved, and the shock resistance demand is met.

Owner:GUANGZHOU UNIVERSITY

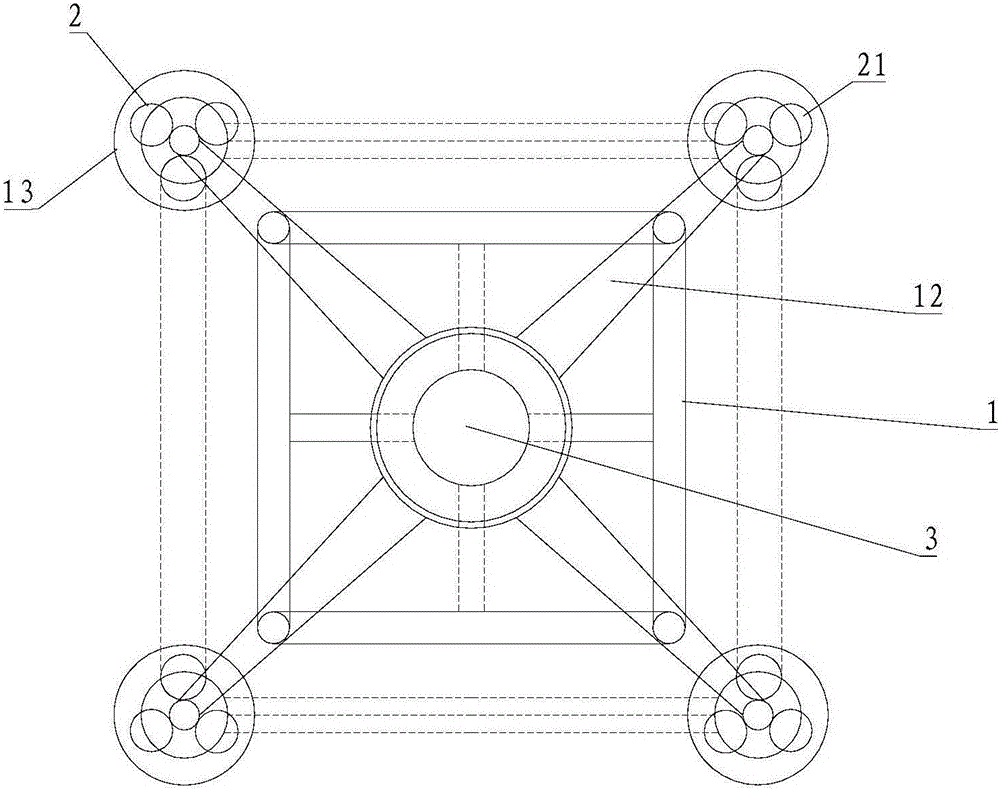

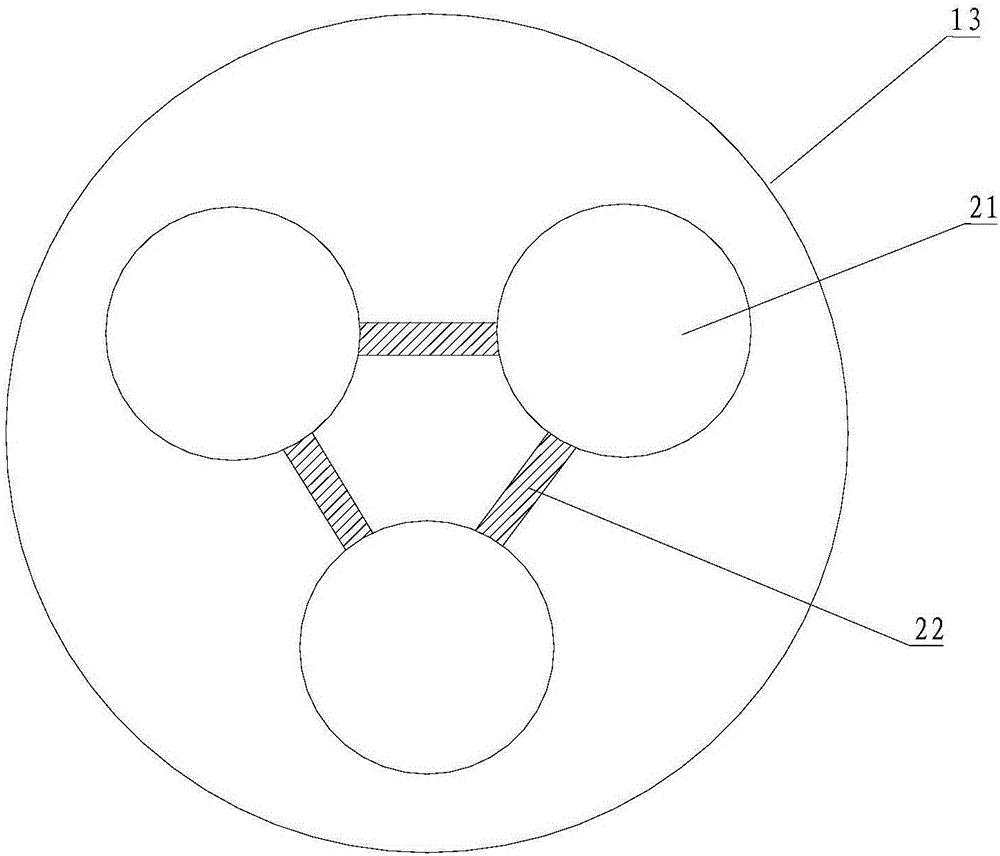

Offshore wind turbine tower foundation structure and installation method

ActiveCN106013212AIncrease the moment of inertia of the structureEnhance overall rigidity and horizontal bearing capacityFoundation engineeringElectricityOffshore wind power

The invention relates to the field of offshore wind power mechanisms and aims to provide an offshore wind turbine tower foundation structure and an installation method. The offshore wind turbine tower foundation structure comprises an offshore jacket and a column pile component, wherein the offshore jacket comprises one or more cylinders arranged on the bottom, the column pipe component comprises one or more parallel column piles, the top of the column pile component is arranged in the cylinders, the portions, in the cylinders, of the column piles are connected through connectors, and the cylinders are grouted to enable the column pile component to be connected with the cylinders. The offshore wind turbine tower foundation structure has the advantages that the column piles can be small-diameter steel pipe piles, the multiple column piles are mutually connected through the connectors and connected with a sleeve on the bottom of a main conduit of the offshore jacket through grouting, so that a grid structure is formed by the column piles, structure inertia moment is increased, the overall rigidity and horizontal bearing capacity of the structure are improved, horizontal displacement of the bodies of the column piles is reduced, and the anti-topple capacity of a foundation is improved.

Owner:FUJIAN YONGFU POWER ENG

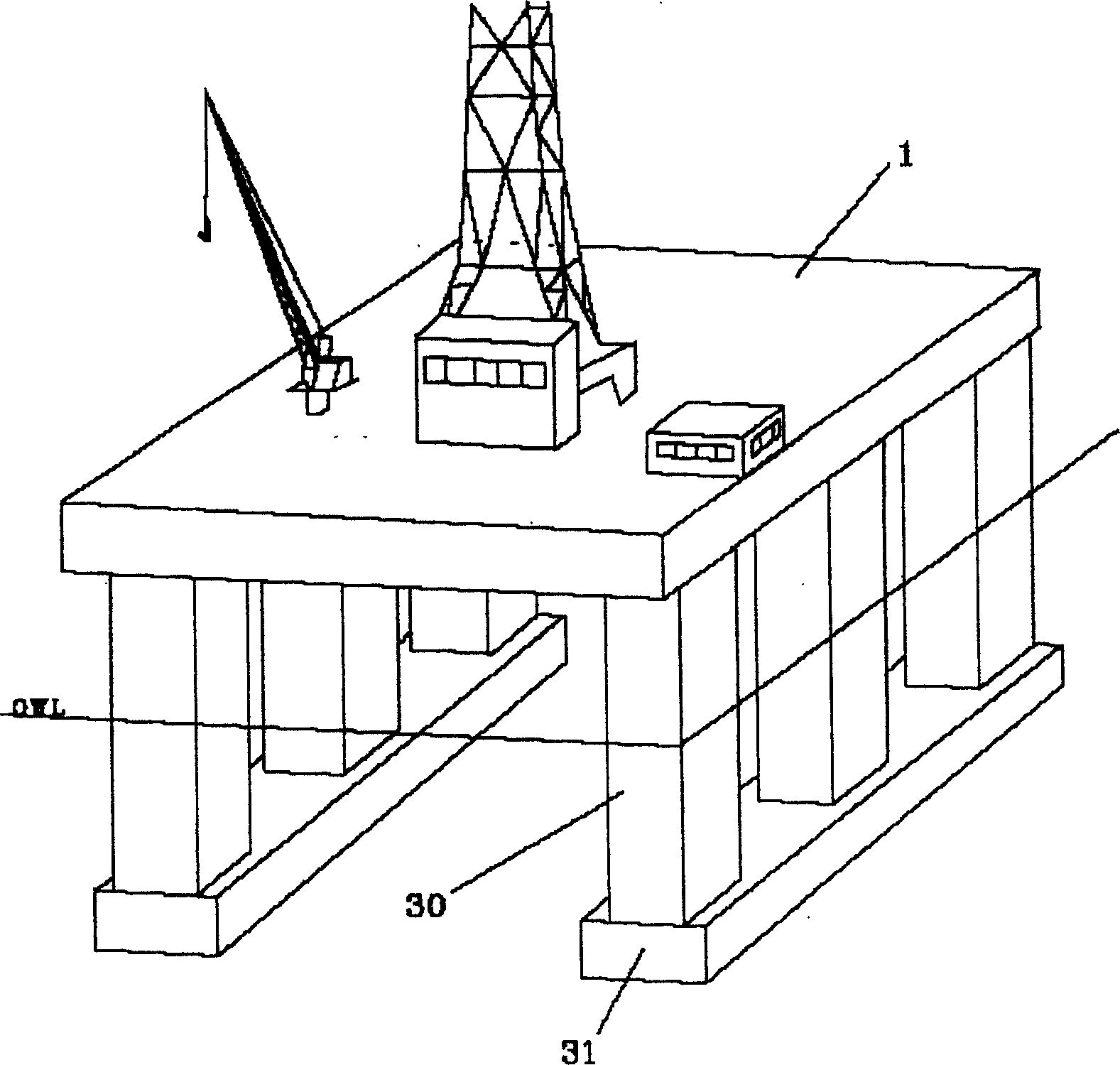

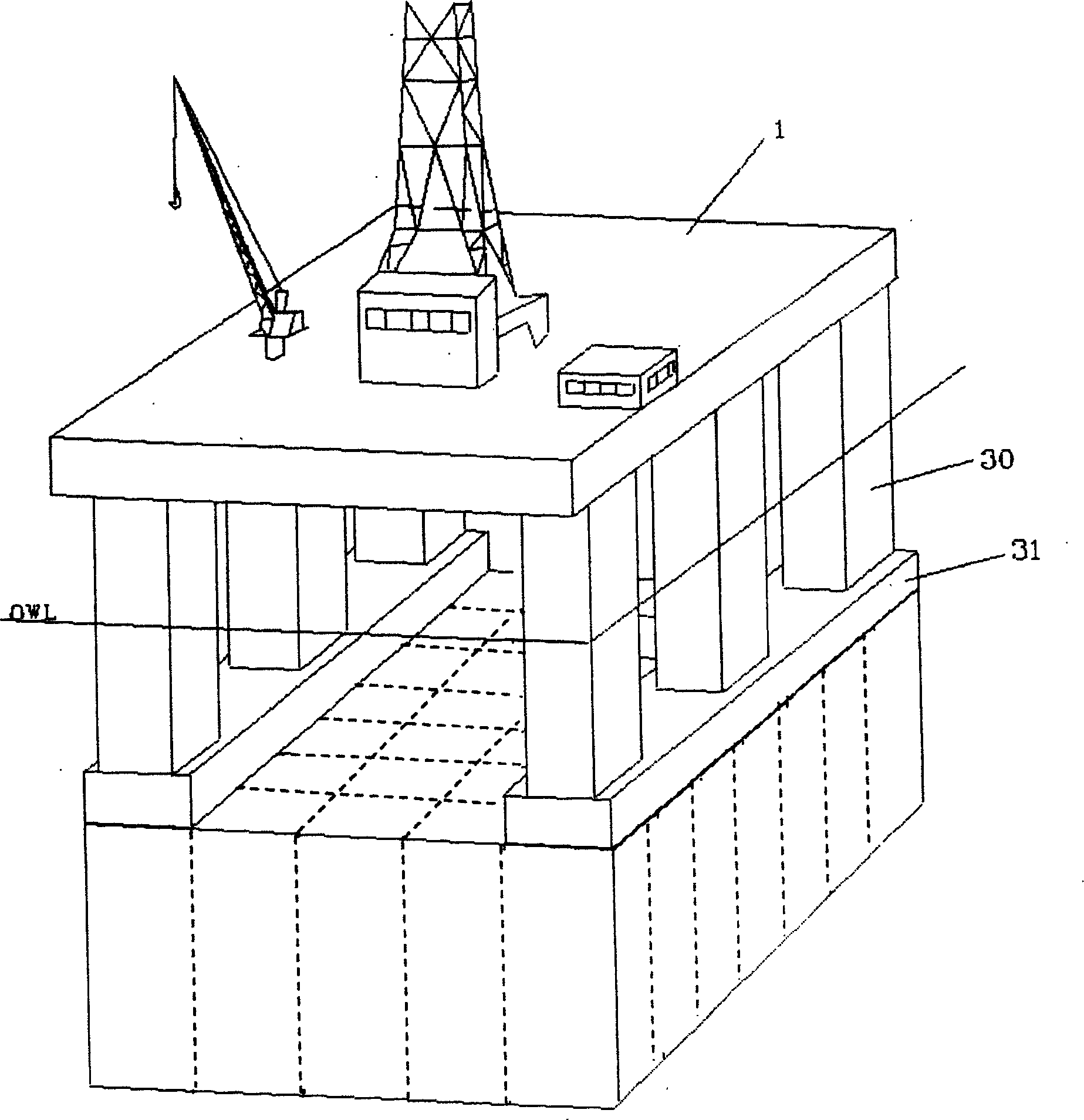

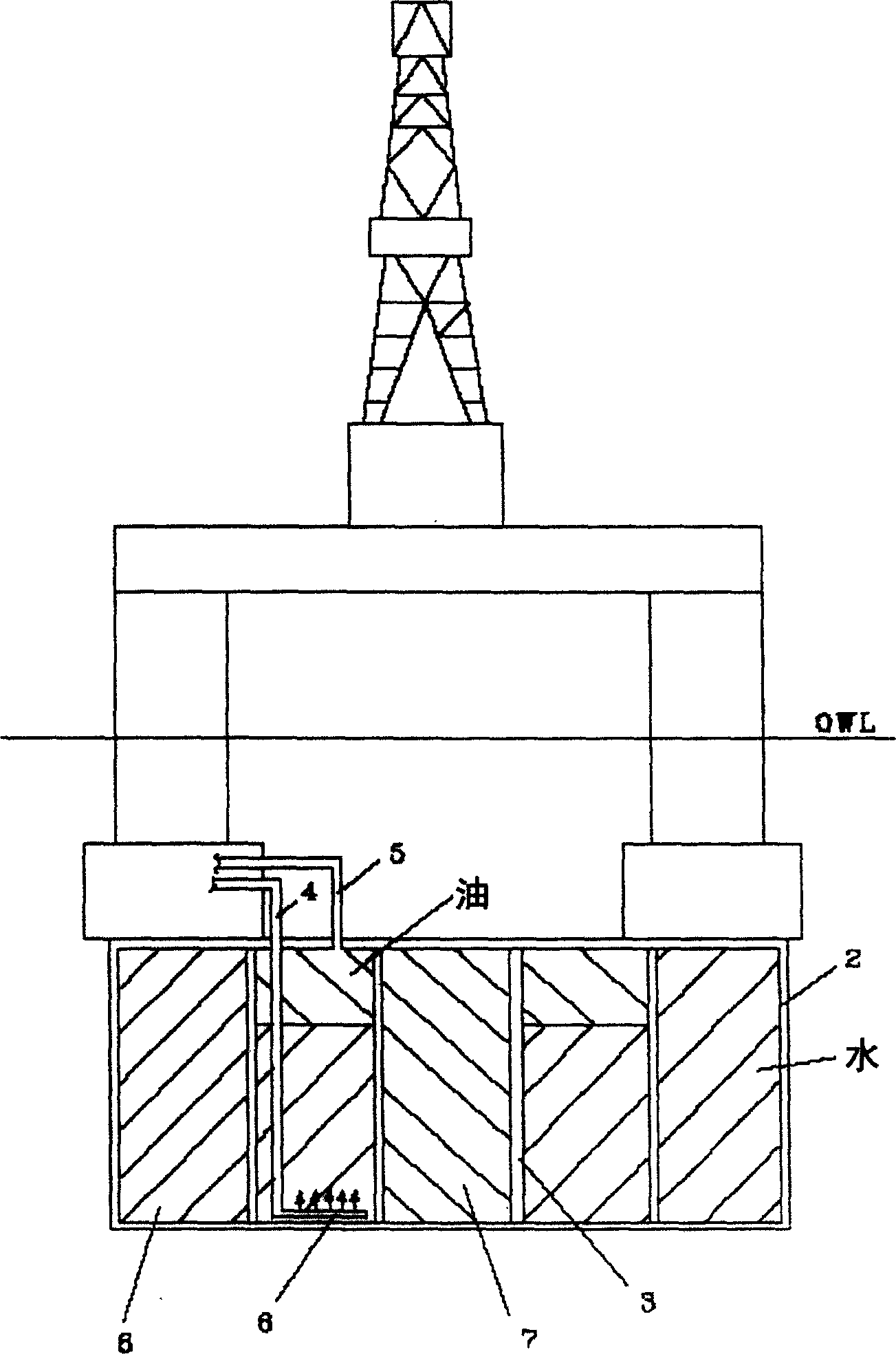

Floating semi-submersible oil production and storage arrangement

InactiveCN1646362AImprove anti-overturn performanceEasy maintenanceWaterborne vesselsFloating buildingsGravity centerOil production

An arrangement for the storage of marketable quantities of crude oil at a semi-submersible floating production vessel. The storage is achieved by hanging a segmented reinforced concrete tank (2) to the underside of the semi-submersible vessel. The semi-submersible vessel can be an existing semi-submersible drilling rig. By maintaining the mass of the tank and contents slightly greater than the displacement of the tank and by arranging the centre of gravity of the tank below its centre of buoyancy, the metacentric height of the semi-submersible vessel is approved. The storage arrangement for the oil provides the necessary maintenance of mass by either storing approximately 4 / 5 of the oil in oil-over-water chambers and approximately 1 / 5 in gas-over-oil chambers or by using a gas-over-oil-over-water arrangement in all the chambers. The piping arrangements minimize the free surface of liquids in the tank. The design ensures the internal pressure in the tank can be less than the external pressure which minimizes required reinforcement. The design provides a net positive suction head to oil export pumps located above the storage tank in a location which allows easy maintenance. The design allows all pumps, valves and instrumentation necessary for handling ballast water to be maintained within the hull of the semi-submersible where they can be easily maintained. The design allows all the valves, pumps and instrumentation necessary for handling oil to be in locations where they can be easily maintained.

Owner:PS COMTEK LTD

Construction method of combined supporting and retaining structure

ActiveCN106638673AReduce excavationReduce lateral deformationArtificial islandsUnderwater structuresReinforced concretePre stress

The invention discloses a construction method of a combined supporting and retaining structure, and relates to the technical field of civil construction. The method includes the steps of surveying and setting-out, mountain slope treatment, manufacturing of prefabricated reinforced concrete breast boards, foundation surface cleaning and replacement filling, construction of a cast-in-place concrete foundation, construction of a cantilever type structure, construction of pre-stressed anchor cables, masonry installation of the prefabricated reinforced concrete breast boards, and construction of a wrapped face reinforced soil structure and a covering layer. By using the vertical pre-stressed anchor cables, the workload can be reduced, the construction period can be shortened, the anti-overturning capacity and anti-slippage capacity of the combined supporting and retaining structure can be improved, and the overall stability and anti-lateral-deformation capacity of the whole combined supporting and retaining structure can be improved; by adopting the prefabricated reinforced concrete breast boards, the construction progress can be accelerated, and the project quality can be ensured; by using the wrapped face reinforced soil structure, the strength and integrity of a filling part can be improved, and the lateral soil pressure on the panel of the supporting and retaining structure can be reduced. By means of the method, the overall stability is improved, occupation of land is reduced, construction is simplified, and the construction cost is reduced; the method is especially suitable for roadbed construction in mountainous and hilly regions.

Owner:SOUTHWEST JIAOTONG UNIV +4

Double-row pile structure with cored horizontal rotary jet grouting pile on pile body

ActiveCN104563129AImprove anti-overturn performanceIncrease stiffnessExcavationsBulkheads/pilesReinforced concreteRebar

The invention discloses a double-row pile structure with a cored horizontal rotary jet grouting pile on the pile body, and belongs to the field of building foundation pit engineering. A first crown beam and a second crown beam are respectively arranged at the top ends of the front-row pile and the rear-row pile, and are connected by a connecting beam. During the construction process of the front-row pile and the rear-row pile, first embedded pipes with the same diameters are respectively embedded at the positions with the same depths in the reinforcement cages; after the pile-forming construction is completed, when the foundation pit is excavated to the depth position of the embedded pipes, the horizontal rotary jet grouting pile is constructed along the embedded pipes in the front-row pile body and the rear-row pile body. The rotary jet grouting pile is constructed by rotary jet grouting segment by segment, the positions between the front-row pile and the rear-row pile completely subjected to rotary jet grouting and solidified, and the rotary jet grouting diameter of the tail position is correspondingly increased to form an anchor body with an enlarged head. After the construction of the rotary jet grouting pile completed, before the pile body quality is stable, a prefabricated reinforced concrete square pile is inserted into the pile body, and thereby the double-row pile structure with the cored horizontal rotary jet grouting pile on the pile bodies is formed.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com