Method for improving pile group bearing capacity by means of reticular pile foundations

A pile foundation and bearing capacity technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of huge length requirements of the pile body, increase the difficulty of construction, and high cost, improve the overall bearing capacity and anti-overturning capacity, and increase the overall The effect of shortening the bearing area and the length of the pile group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

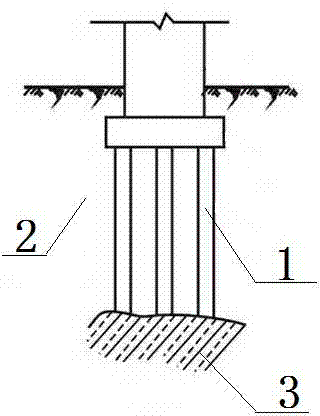

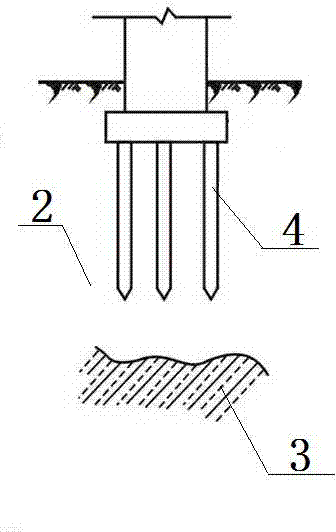

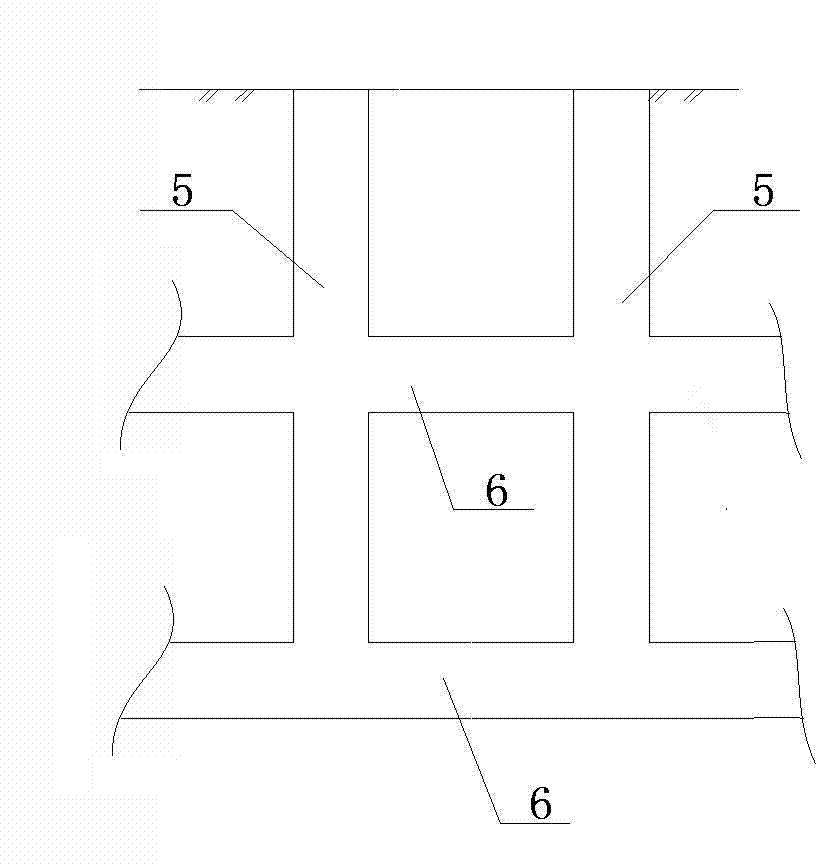

[0027] Embodiment 1: A common problem existing in pile group foundations currently used to provide sufficient bearing capacity for the superstructure is that the bearing capacity is small and the length of the pile body is relatively large. Such as Figure 5 , 6 As shown, in order to improve this phenomenon, the present embodiment provides a method for improving the bearing capacity of the pile group by utilizing the networked pile foundation. The pile group is composed of multiple groups of networked pile foundations 7, and each group of networked piles The foundation is composed of a number of single piles 5. The mesh pile foundation 7 has a rectangular shape as a whole. Most of the pile bodies of each single pile 5 are located in the soil. Compared with the ordinary pile foundation, the bearing capacity of the pile group can be improved. According to the method, two pile beams 6 are arranged at the bottom and the middle of the net pile foundation 7, so that the single pile...

Embodiment 2

[0036] Embodiment two: if Figure 7 , 8 As shown, compared with the method of using the mesh pile foundation to improve the bearing capacity of the pile group described in Embodiment 1, the mesh pile foundation in this embodiment has additional strip footings 8 at the bottom and middle of each single pile 5 , in order to further increase the load-bearing area on the basis of the mesh pile foundation described in the first embodiment, and improve the anti-overturning capability of the pile group.

[0037] Such as Figure 7 , 8 As shown, the netted pile foundation 7 in this embodiment is specifically a rectangular outline-shaped pile group composed of several single piles 5 arranged deep into the soil, and the method for improving the bearing capacity of the pile group by using the netted pile foundation specifically includes the following measure:

[0038] (1) Two pile beams 6 are arranged between adjacent single piles 5 to connect them to each other. The monopile 5 connec...

Embodiment 3

[0050] Embodiment three: as Figure 9 , 10 As shown, compared with the method of using the mesh pile foundation to improve the bearing capacity of the pile group described in the first embodiment, the mesh pile foundation in this embodiment adds semicircular pile feet at the bottom and middle of each single pile 5 9, to further increase the bearing area on the basis of the mesh pile foundation described in Embodiment 1, and improve the overturning resistance of the pile group.

[0051] Such as Figure 9 , 10 As shown, the netted pile foundation 7 in this embodiment is specifically a rectangular outline-shaped pile group composed of several single piles 5 arranged deep into the soil, and the method for improving the bearing capacity of the pile group by using the netted pile foundation specifically includes the following measure:

[0052] (1) Two pile beams 6 are arranged between adjacent single piles 5 to connect them to each other. The monopile 5 connected to it is integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com