Anti-overturning bridge pier supporting mechanism

An anti-overturning and bridge pier technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as support seat emptying and overturning accidents, and achieve the effects of preventing overturning, improving the stress state, and shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

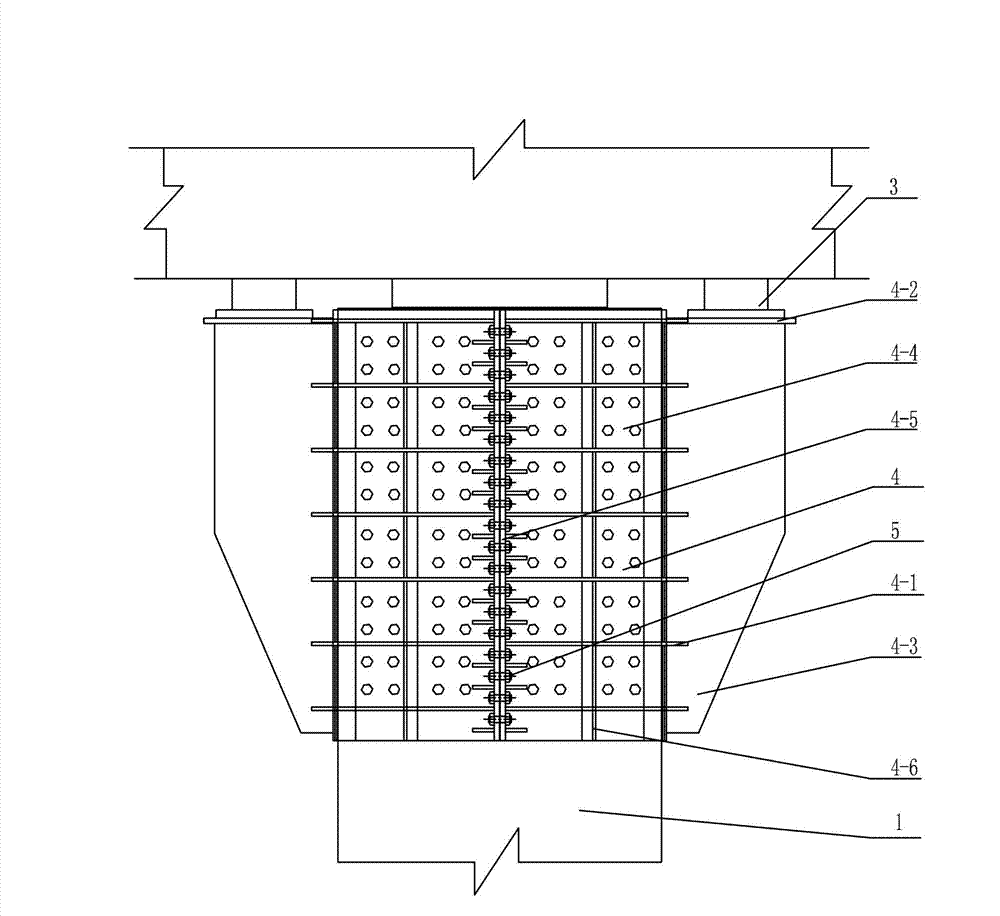

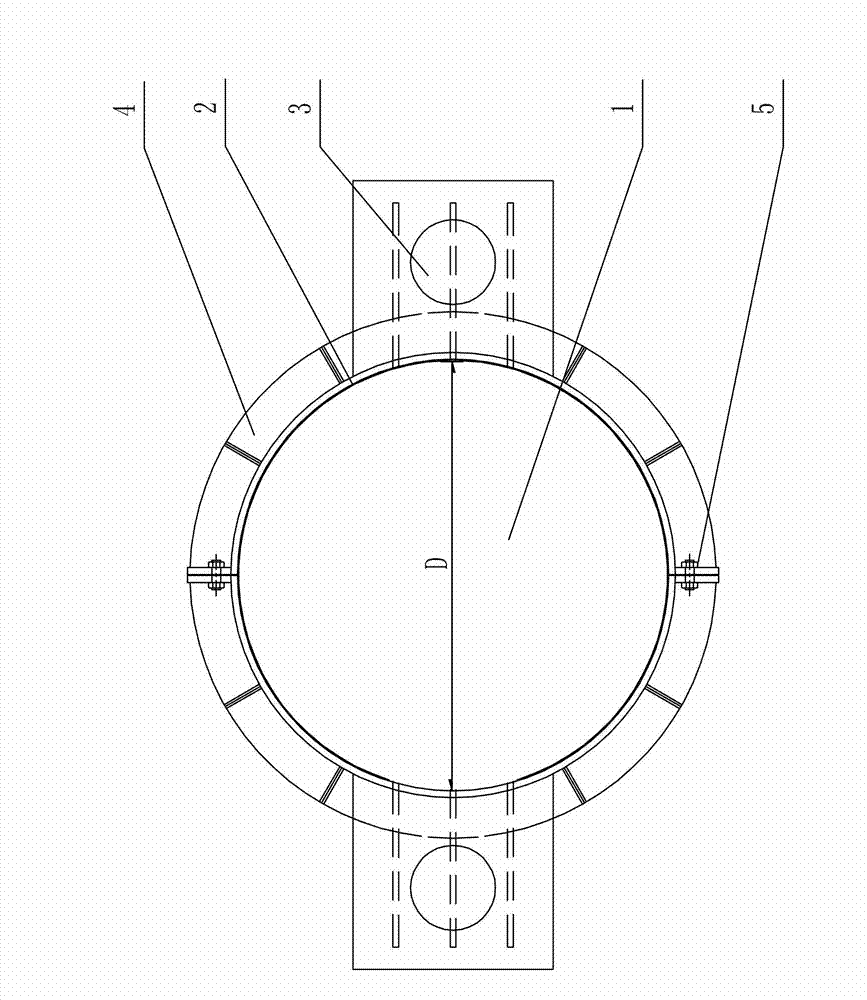

[0007] Specific implementation mode one: combine Figure 1-Figure 2 Describe the support mechanism of a bridge anti-overturning pier in this embodiment. The support mechanism includes a pier column 1, the support mechanism also includes a carbon fiber cloth 2, a steel hoop assembly 4 and two supports 3, and the steel hoop assembly 4 includes Two horizontal support plates 4-2, two semicircular cylinders 4-4 and four connecting pieces 4-5; two semicircular cylinders 4-4 form a circular cylinder through four connecting pieces 4-5 The upper surface of each horizontal support plate 4-2 is respectively provided with a support 3, and the two horizontal support plates 4-2 are horizontally arranged on the upper surface of the circular cylinder in a straight line, and the carbon fiber cloth 2 is wound on the top of the pier 1, and the circular cylinder is set on the carbon fiber cloth 2 on the outside of the pier 1.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 1-Figure 2 To illustrate a support mechanism for bridge anti-overturning piers in this embodiment, the steel hoop assembly 4 also includes a plurality of semicircular ribs 4-1 and a plurality of rectangular ribs 4-6; every two semicircular ribs 4-1 forms a circular rib, a plurality of circular ribs are uniformly set on the outer wall of the circular cylinder, and a plurality of rectangular ribs 4-6 are uniformly arranged on the circular cylinder On the outer wall of the body, and the center line of each rectangular rib plate 4-6 along the length direction coincides with the axial center line of the circular cylinder, the other is the same as the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 1-Figure 2 To illustrate a support mechanism for a bridge anti-overturning pier in this embodiment, the steel hoop assembly 4 also includes a plurality of support ribs 4-3, and the plurality of support ribs 4-3 are uniformly arranged on the circular cylinder On the outer wall, the upper end of each supporting rib 4-3 is connected to the lower surface of the corresponding horizontal supporting plate 4-2, and the other is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com