Patents

Literature

65results about How to "Wide range of stiffness adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

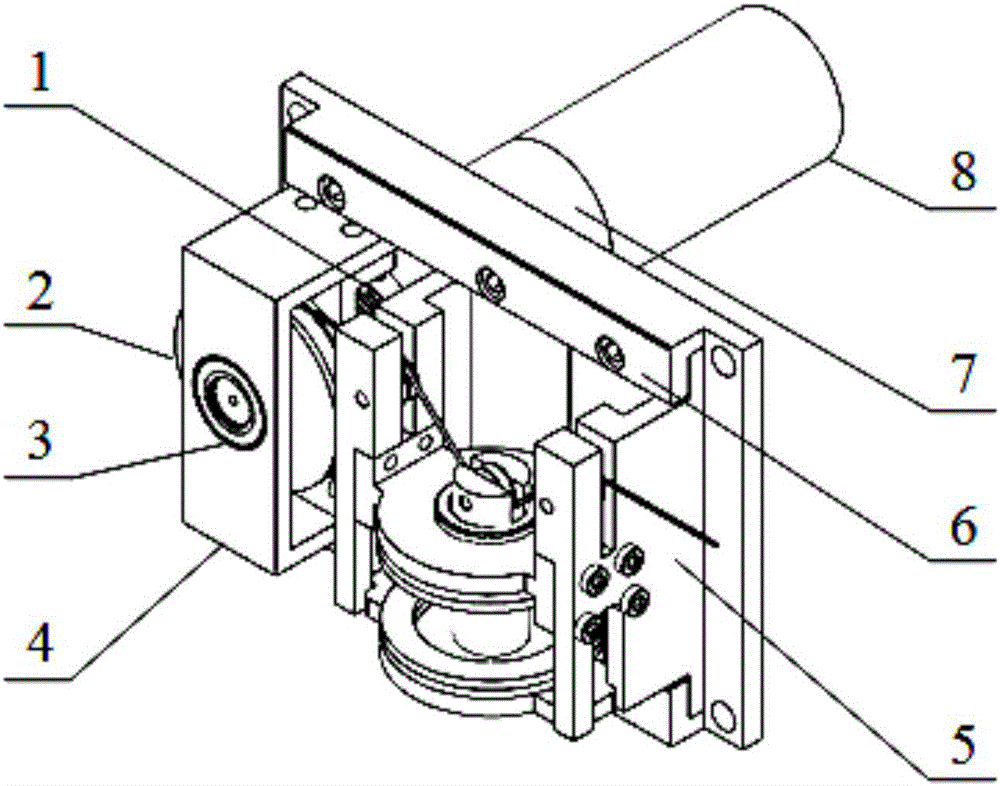

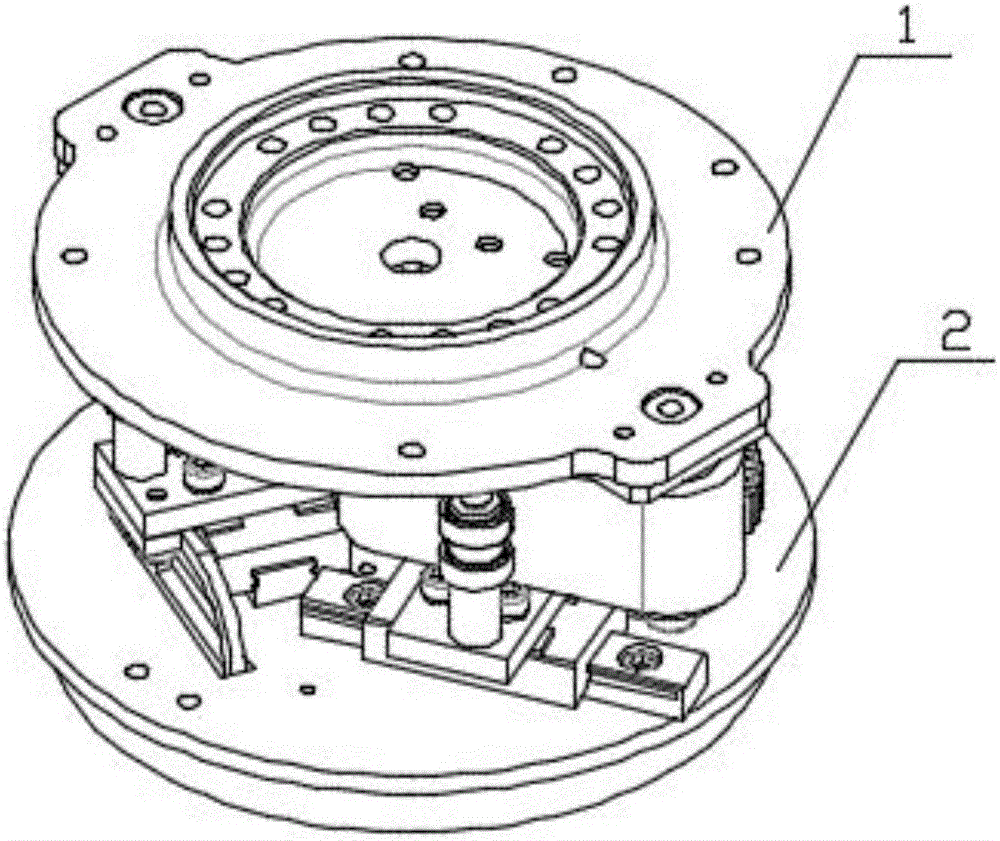

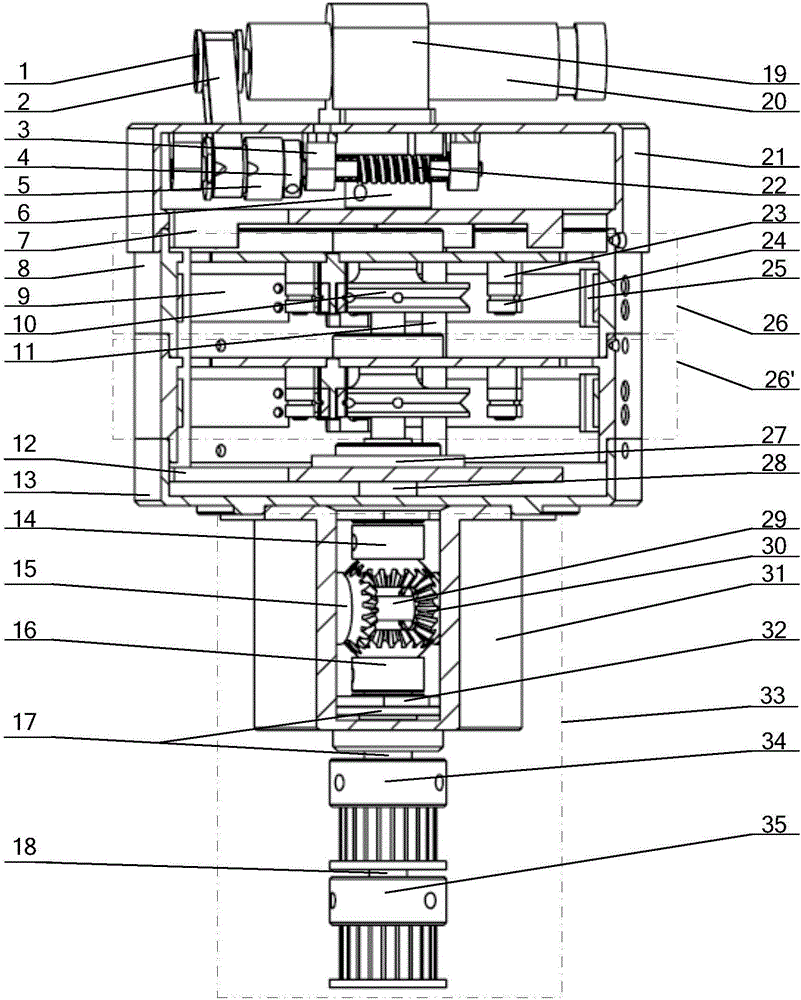

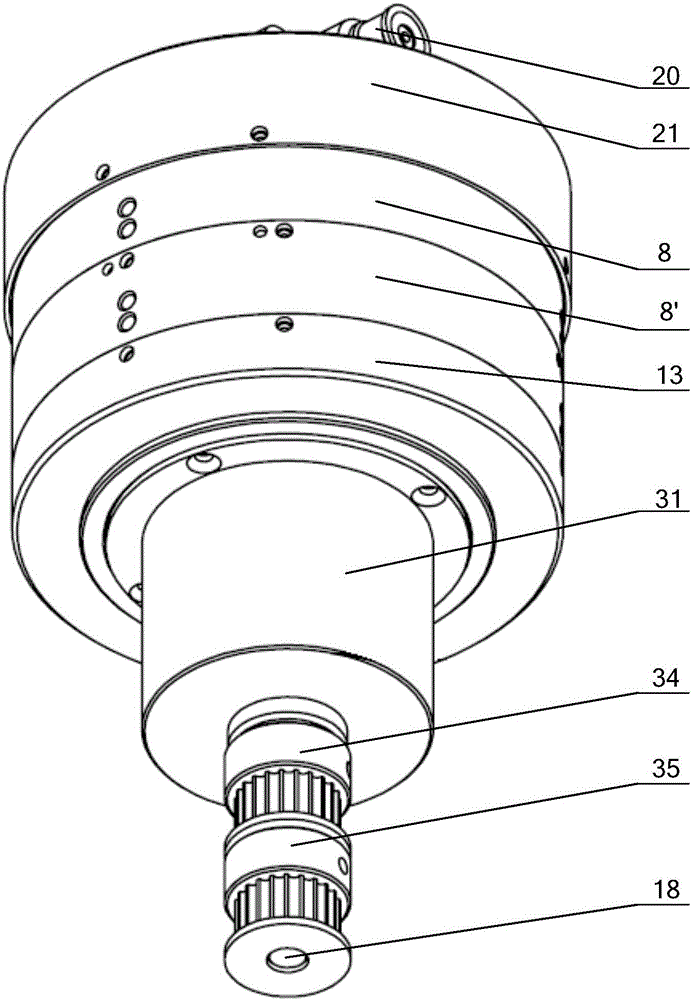

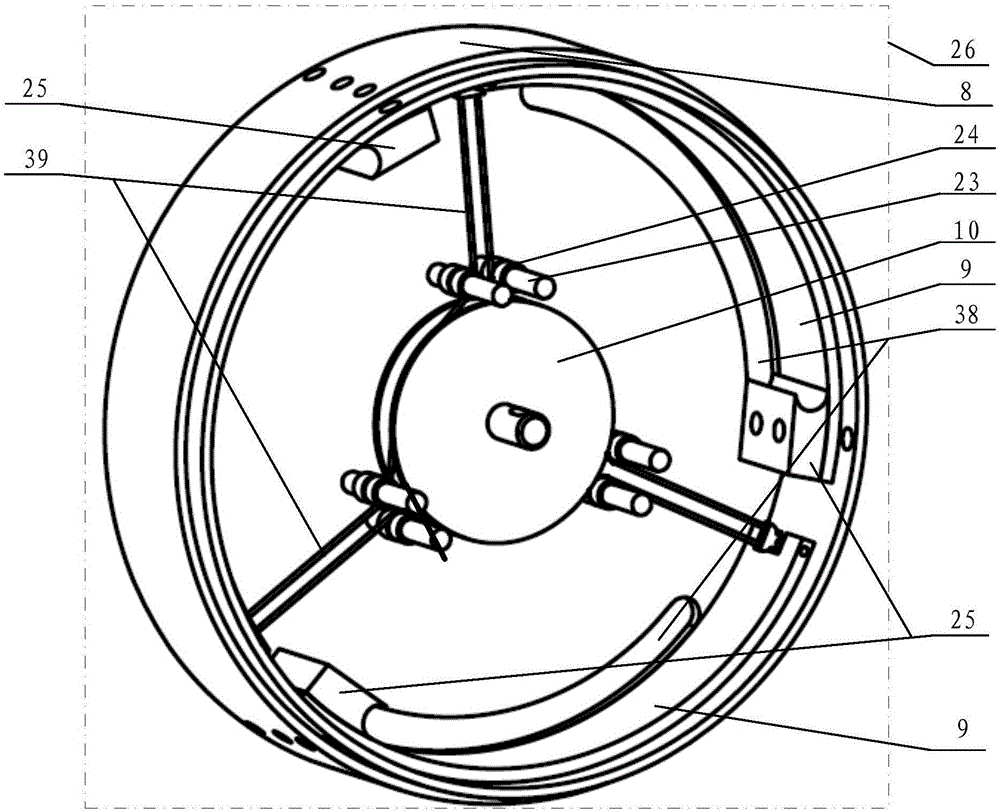

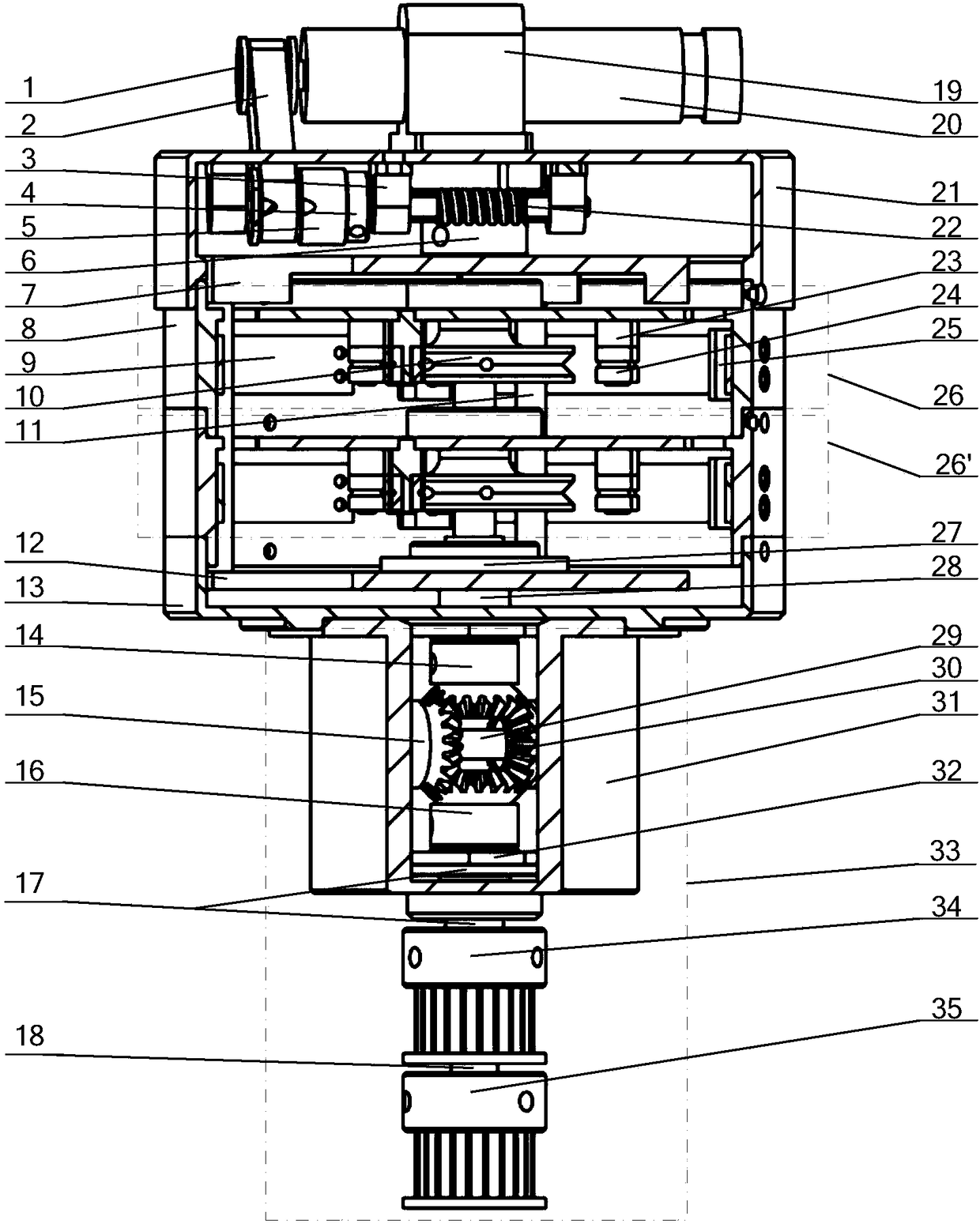

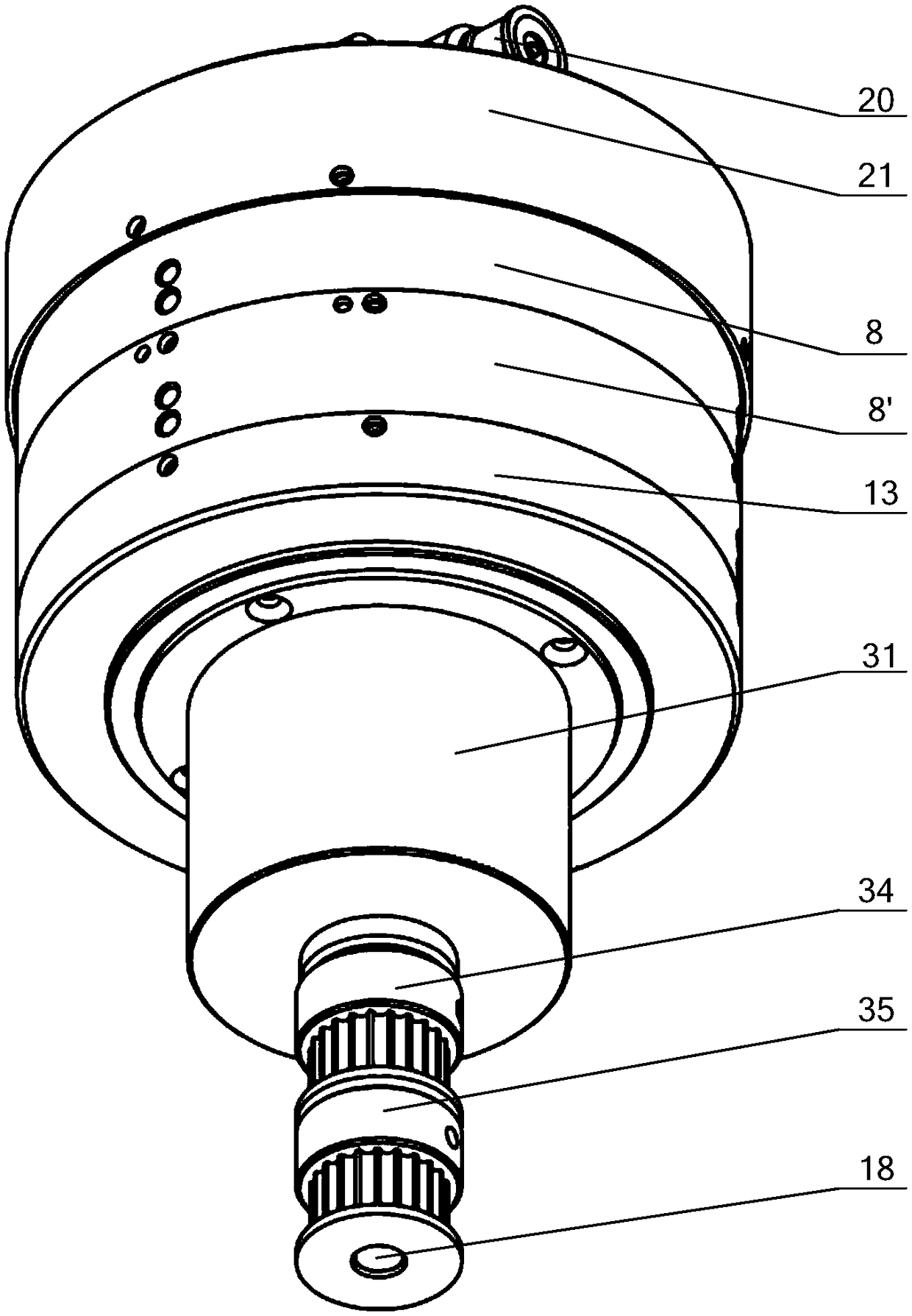

Synchronous displacement adjustment type variable-stiffness joint driver and adjustment method for robot joint stiffness

ActiveCN104669261AEasy to adjustAdjust energy savingProgramme-controlled manipulatorJointsVariable stiffnessEngineering

The invention discloses a synchronous displacement adjustment type variable-stiffness joint driver. The synchronous displacement adjustment type variable-stiffness joint driver comprises a base, a swing arm position control assembly, a variable-stiffness adjustment assembly and an angular deviation measurement assembly, and is characterized in that the swing arm position control assembly is used for moving a swing arm to a specified equilibrium position point; the variable-stiffness adjustment assembly is used for changing the stiffness value of the driver according to the requirement of an actual task; the angular deviation measurement assembly is used for measuring and acquiring angular deviations for subsequent data processing and real-time stiffness control. The synchronous displacement adjustment type variable-stiffness joint driver is used for the variable-stiffness control of a robot joint, and can realize the flexibility of a driving system in terms of control without adding sensors, and thereby human safety is improved in the process of human-machine interaction. In addition, because of the special structural design, the energy consumption of a robot can be reduced, the joint structure is more compact, and good shock resistance and flexible dynamic characteristic lay a solid foundation for the movement of the robot in complex environments.

Owner:BEIHANG UNIV

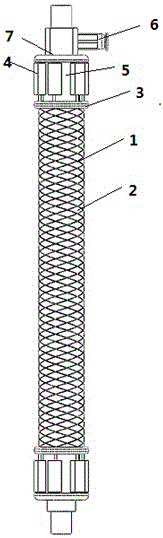

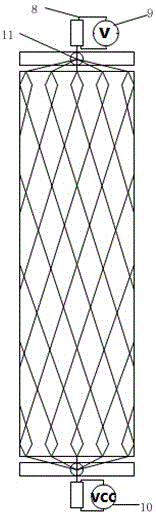

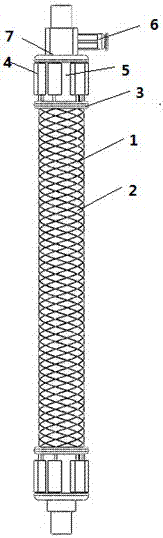

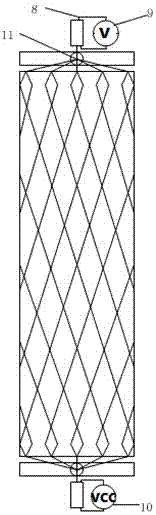

Pneumatic artificial muscle with self-sensing and driving functions

InactiveCN105856219AImprove shrinkageExpand the scope ofProgramme-controlled manipulatorFiberVoltmeter

The invention belongs to the pneumatic artificial technical field and in particular relates to a pneumatic artificial muscle with self-sensing and driving functions. The pneumatic artificial muscle comprises fibers, an elastic hose, a cylindrical sleeve pipe, a fiber collecting hoop, a fiber collecting hole, a piezoelectric body, an electrode, a sensing circuit, a drive circuit, a hoop and an air pipe joint. The pneumatic artificial muscle has the beneficial effects that via the direct piezoelectric effects of the piezoelectric body, the contractility of the fibers can be measured to obtain the external load driving force of the pneumatic muscle; meanwhile, collision of the pneumatic muscle can be self-sensed according to the real-time reading of a voltmeter; via the inverse piezoelectric effects of the piezoelectric body, the amount of contraction of the pneumatic muscle can be increased and the rigidity of the pneumatic muscle can be changed; compared with the same model of pneumatic muscle on the market, the pneumatic muscle provided by the invention can achieve the effects of detecting the external load driving force, self-sensing collision, increasing the amount of contraction of the pneumatic muscle and changing the rigidity of the pneumatic muscle; the properties of the pneumatic muscle are improved and enriched; and the pneumatic muscle has function innovation and extension and is worthy to be applied.

Owner:CHINA JILIANG UNIV

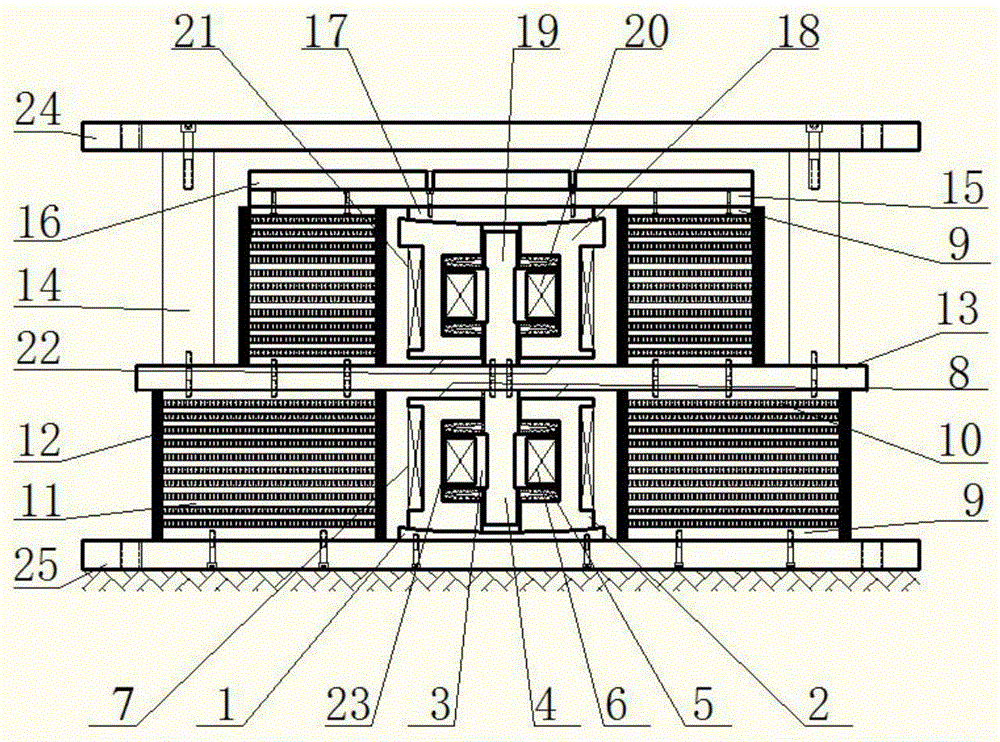

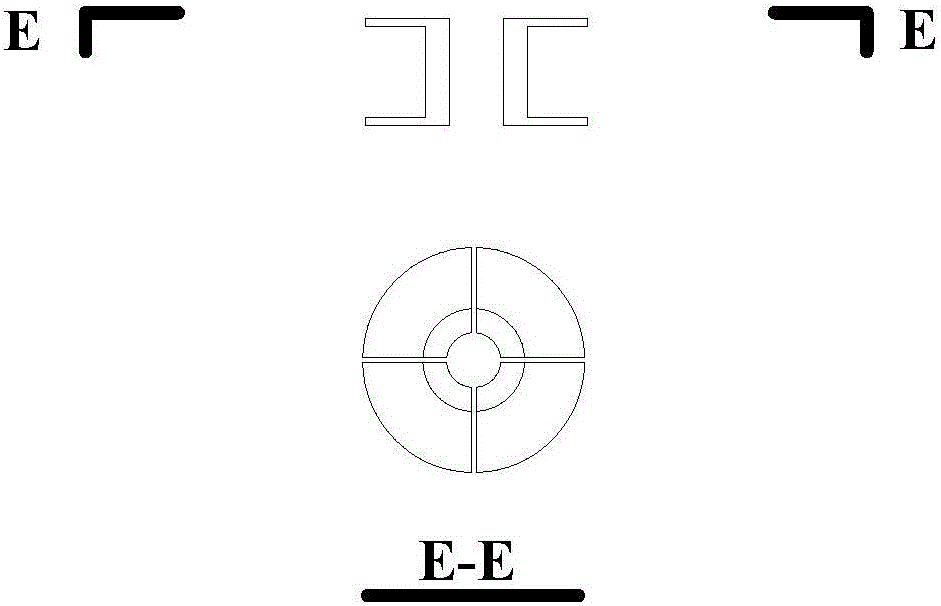

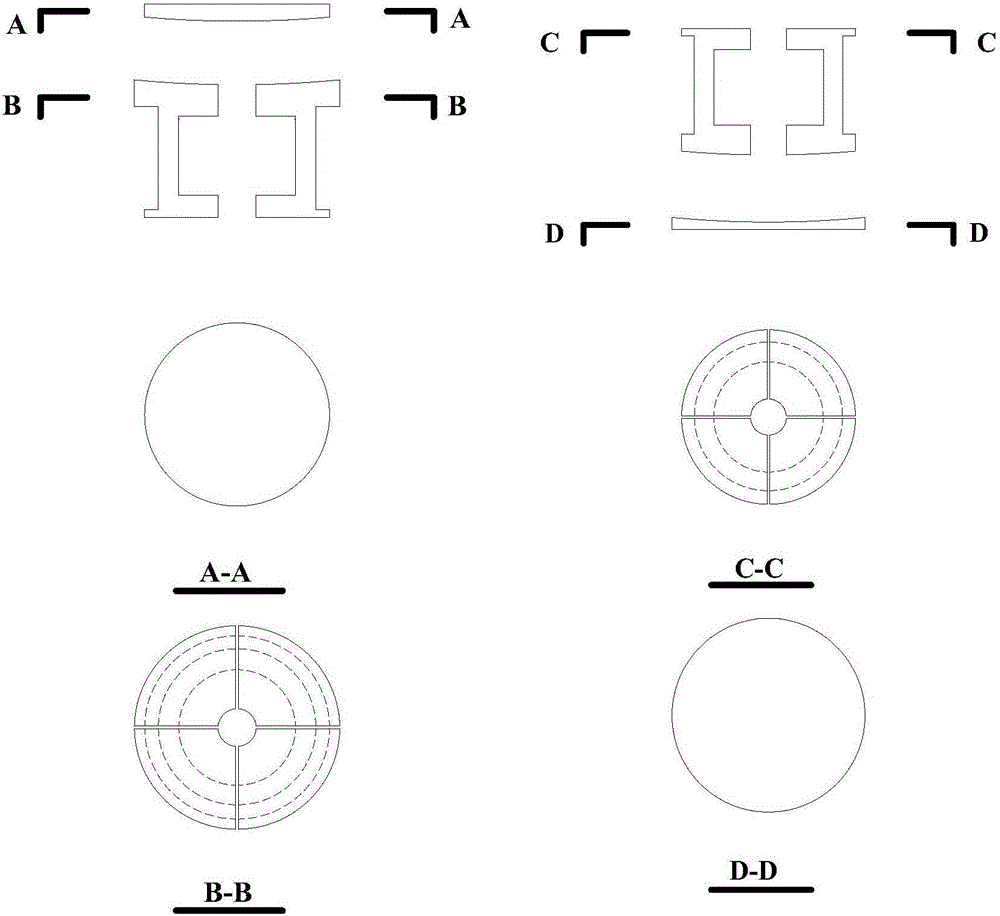

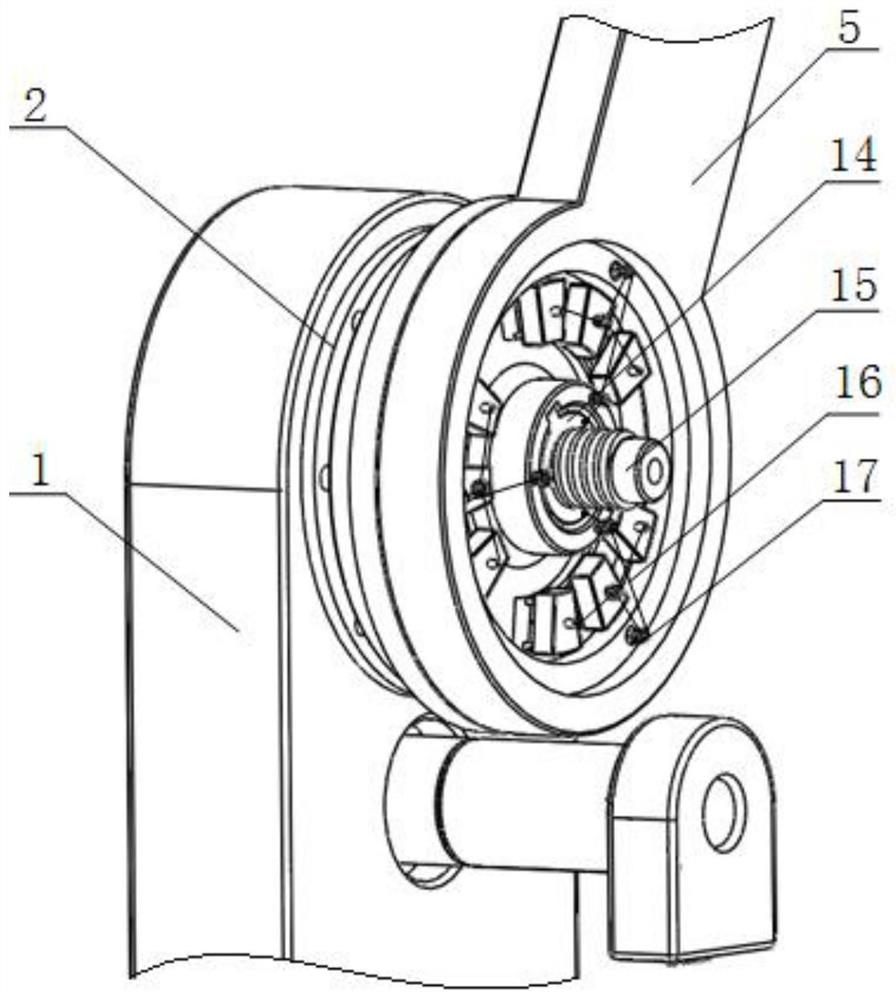

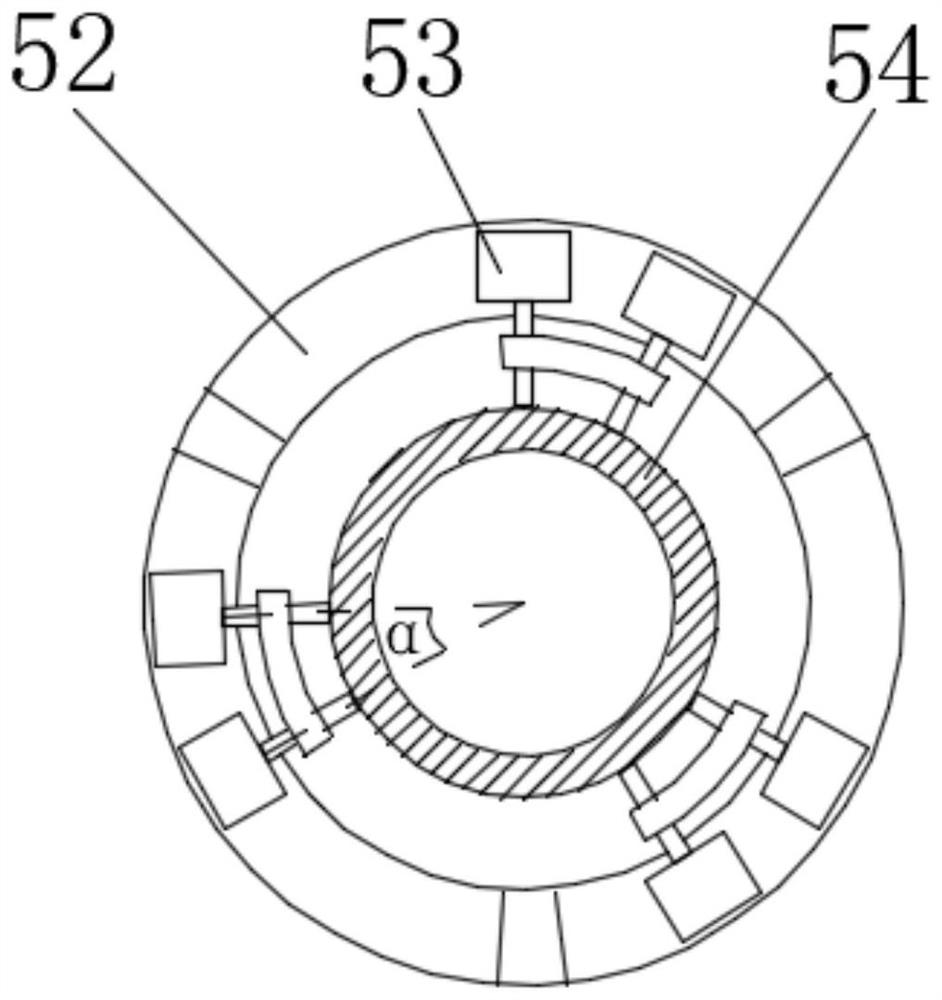

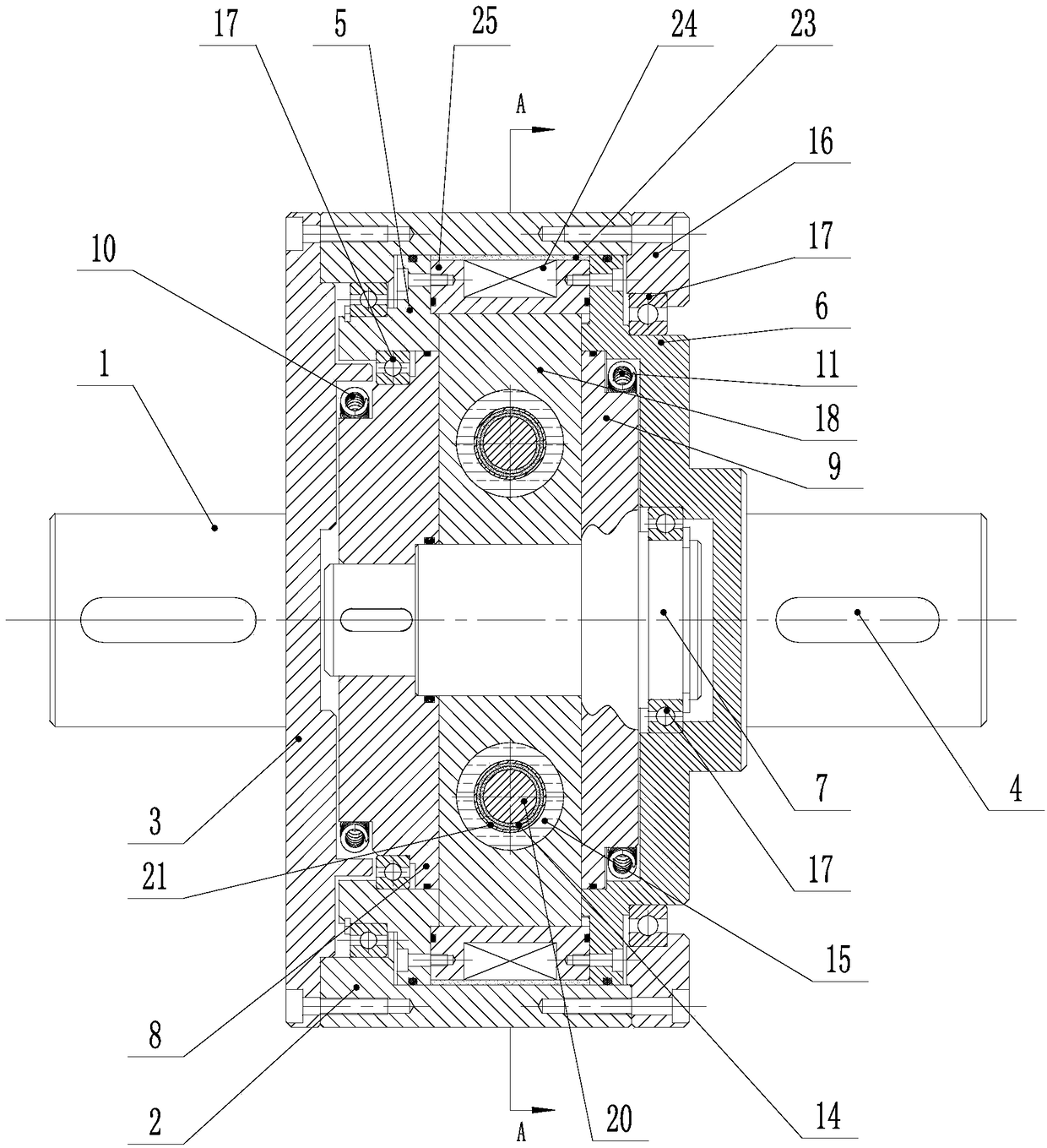

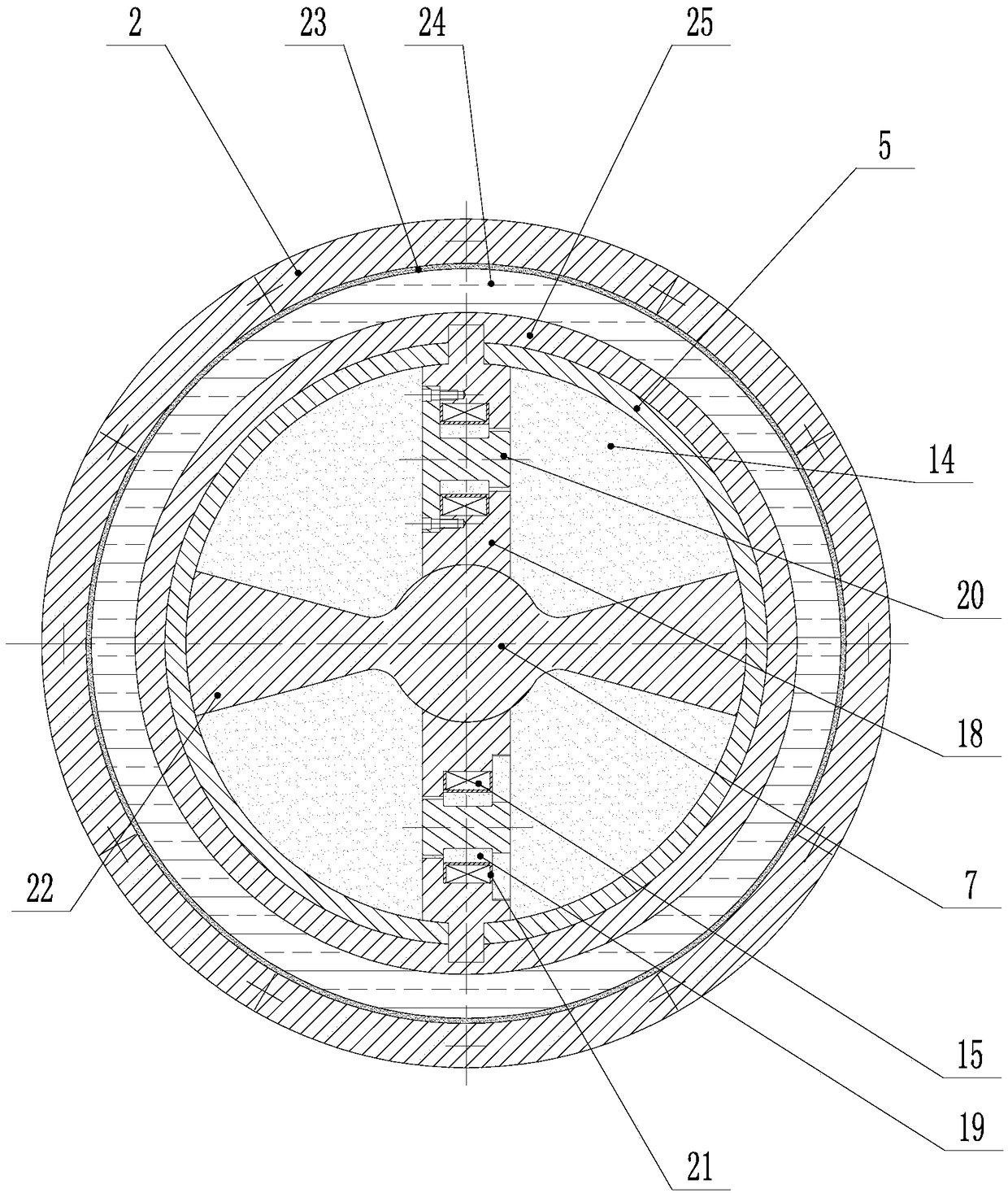

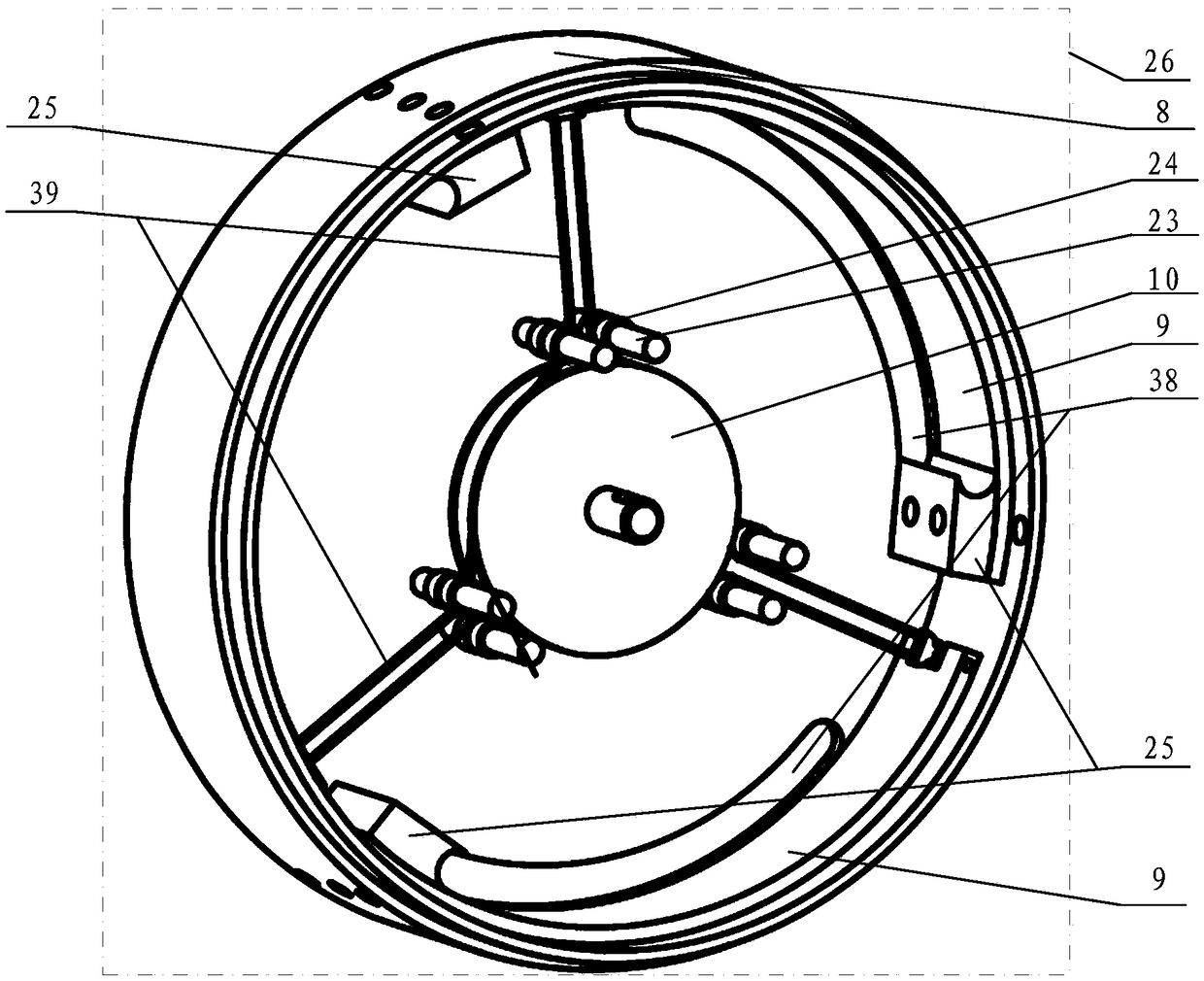

Series-stiffness, broadband and magnetorheological intelligent vibration absorbing device

InactiveCN105909721AWide overall stiffness adjustment rangeReduce energy input consumptionSpringsNon-rotating vibration suppressionBroadbandNegative stiffness

The invention discloses a series-stiffness, broadband and magnetorheological intelligent vibration absorbing device. The device comprises a bottom self-lubricating magnetic guide rail plate, a bottom magnetic yoke outer annular column, arc section circular ring sleeve keys, a bottom magnetic yoke anisotropic bar, disc-shaped springs, bottom inner column magnet exciting coils, bottom outer column magnet exciting coils, a bottom working clearance, a soft magnetic metal sealing plate, overlapped magnetorheological elastomers (MREs), overlapped magnetic conductive steel plates, an I-shaped iron connecting plate, bearing frame columns, an II-shaped iron connecting plate, a mass array, upper inner column magnet exciting coils, upper outer column magnet exciting coils and an upper working clearance; a negative stiffness system and a positive stiffness system form a basic power outputting unit of the series-stiffness, broadband and magnetorheological intelligent vibration absorbing device. With the adoption of the series-stiffness, broadband and magnetorheological intelligent vibration absorbing device, the shortages of narrow controllable broadband of a traditional passive vibration absorber, unadjustable performance, and complex active vibration absorbing assisting system. Compared with an existing intelligent vibration absorbing device, the series-stiffness, broadband and magnetorheological intelligent vibration absorbing device can reduce the low-frequency interference of flexible demands and high frequency vibration of rigid demand, applies a plurality of working conditions, and has a good economic advantage.

Owner:HOHAI UNIV

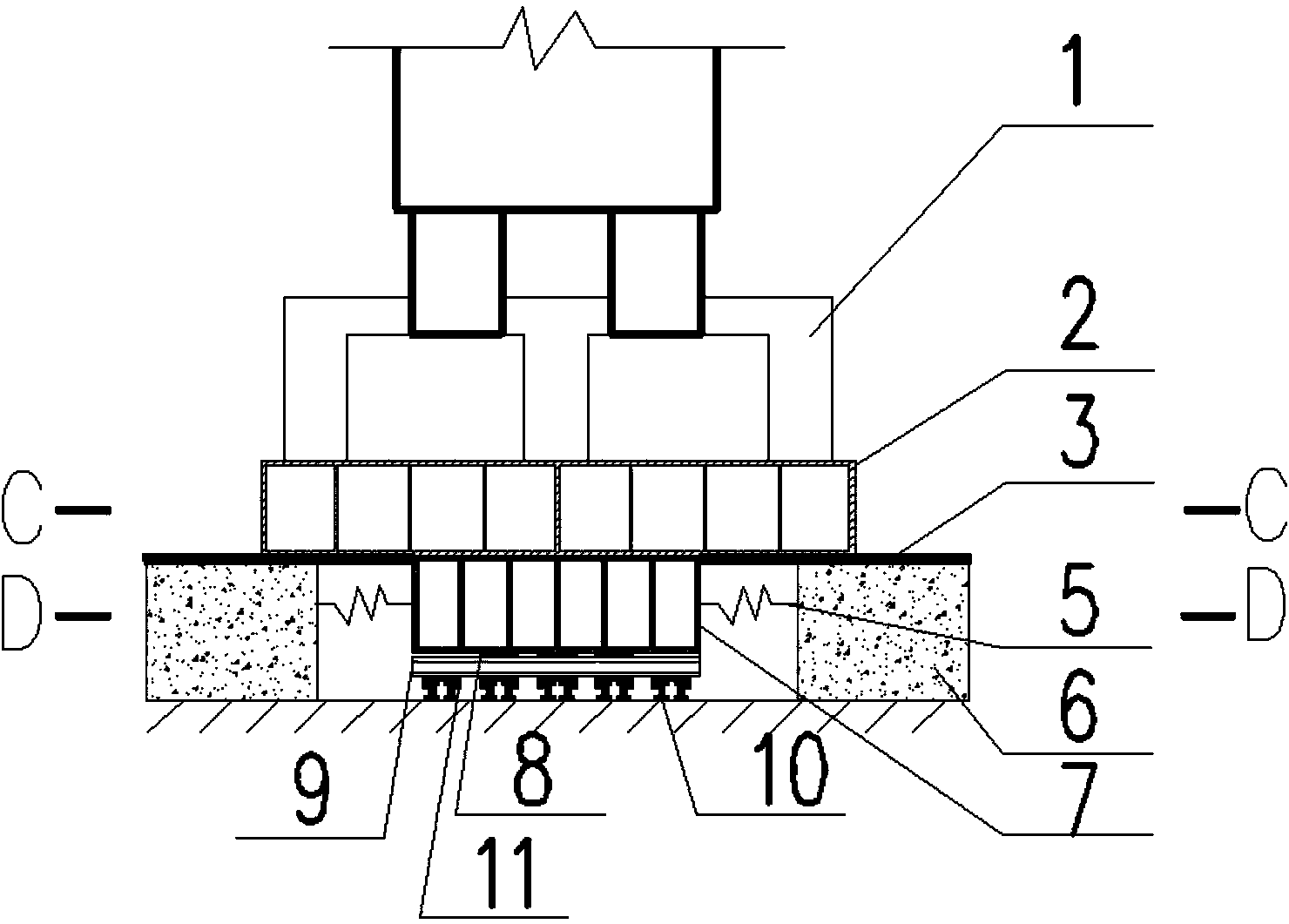

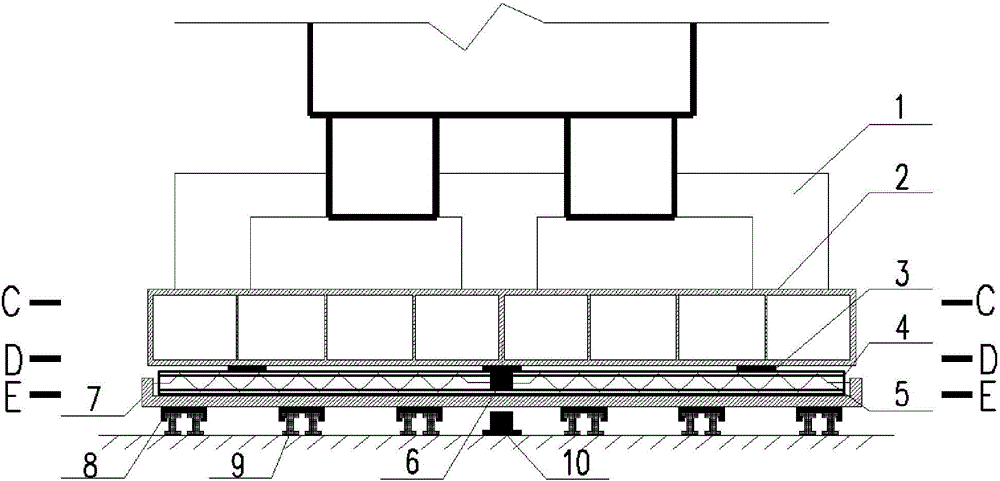

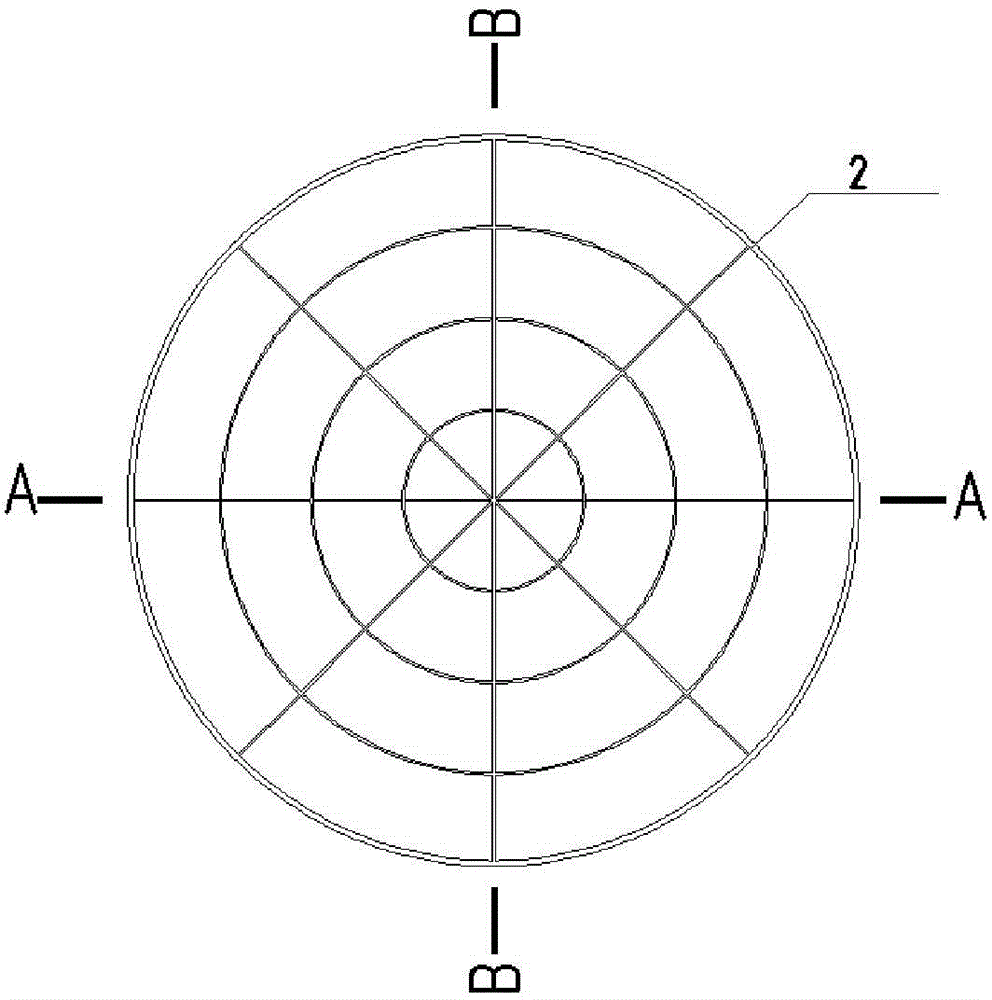

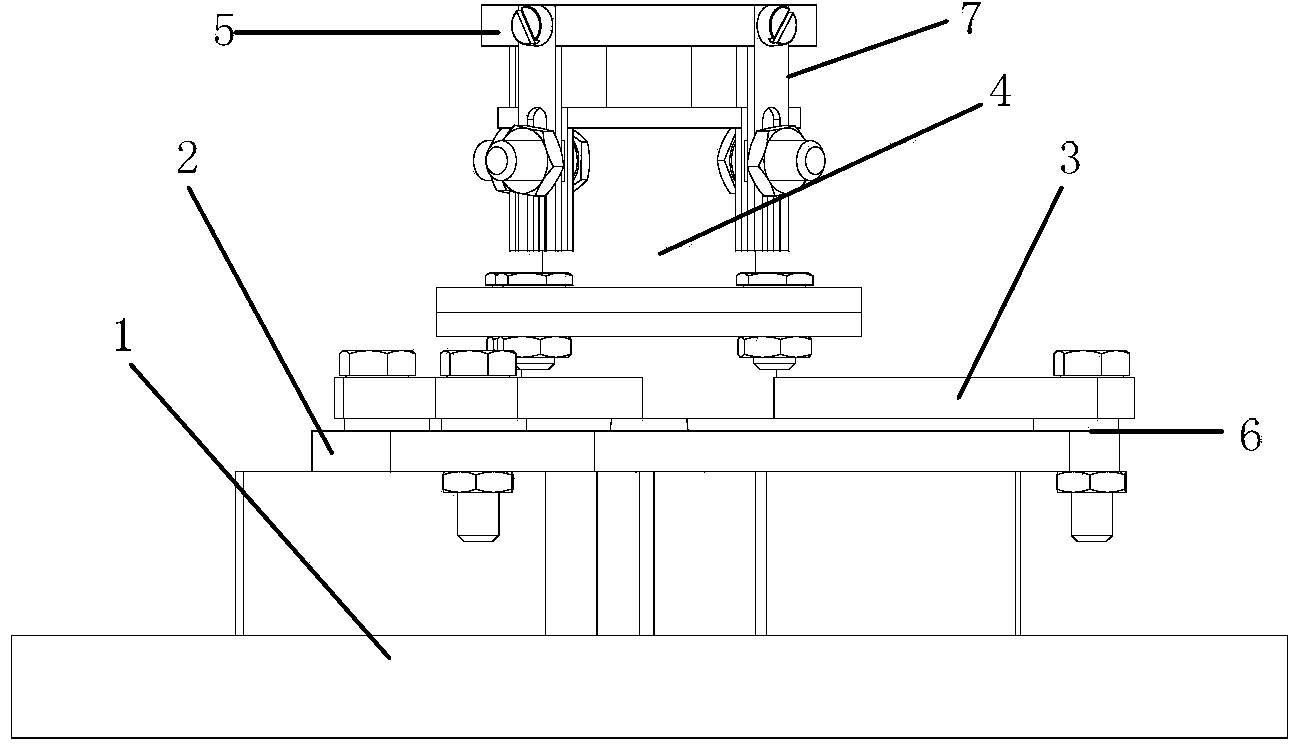

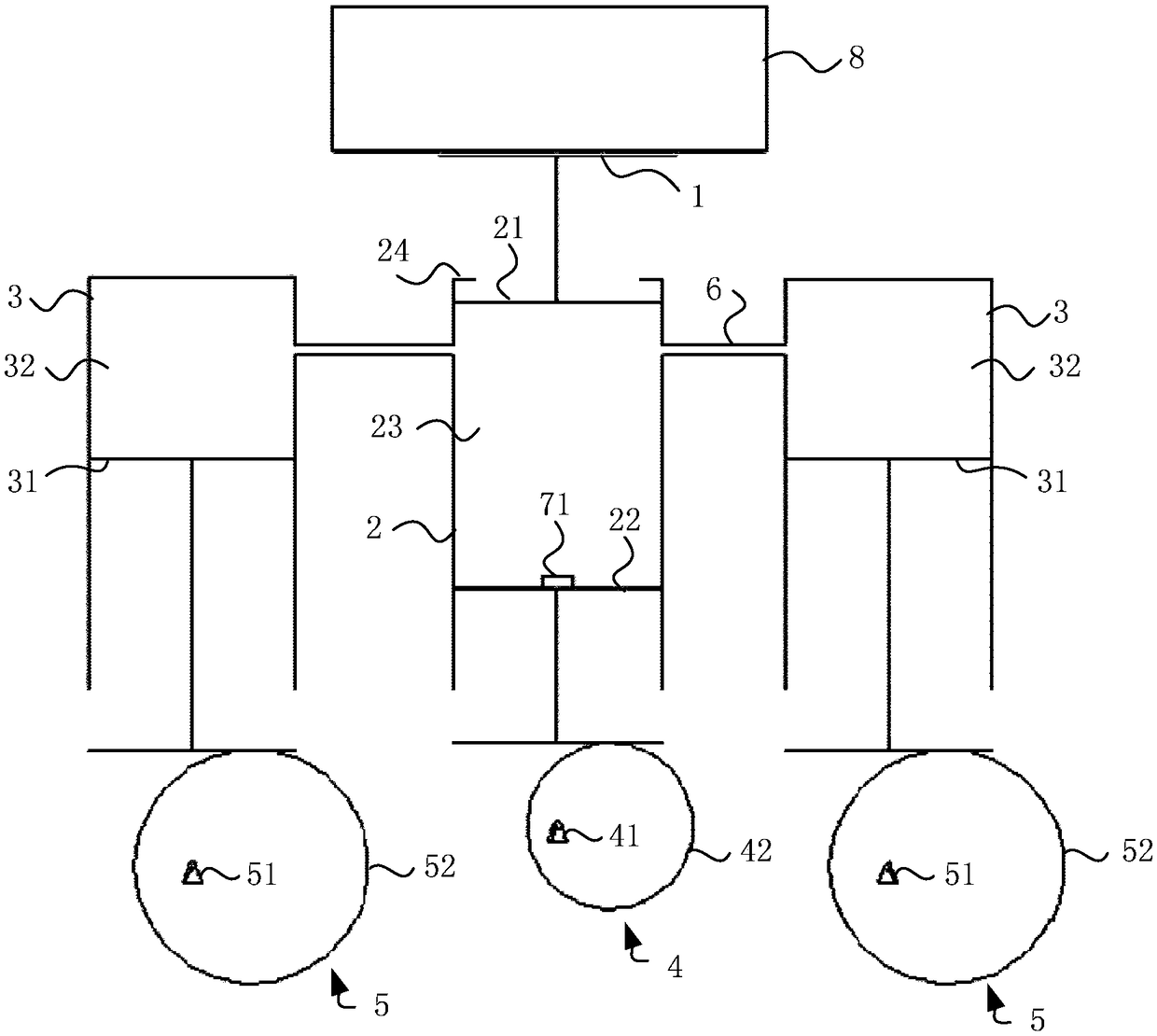

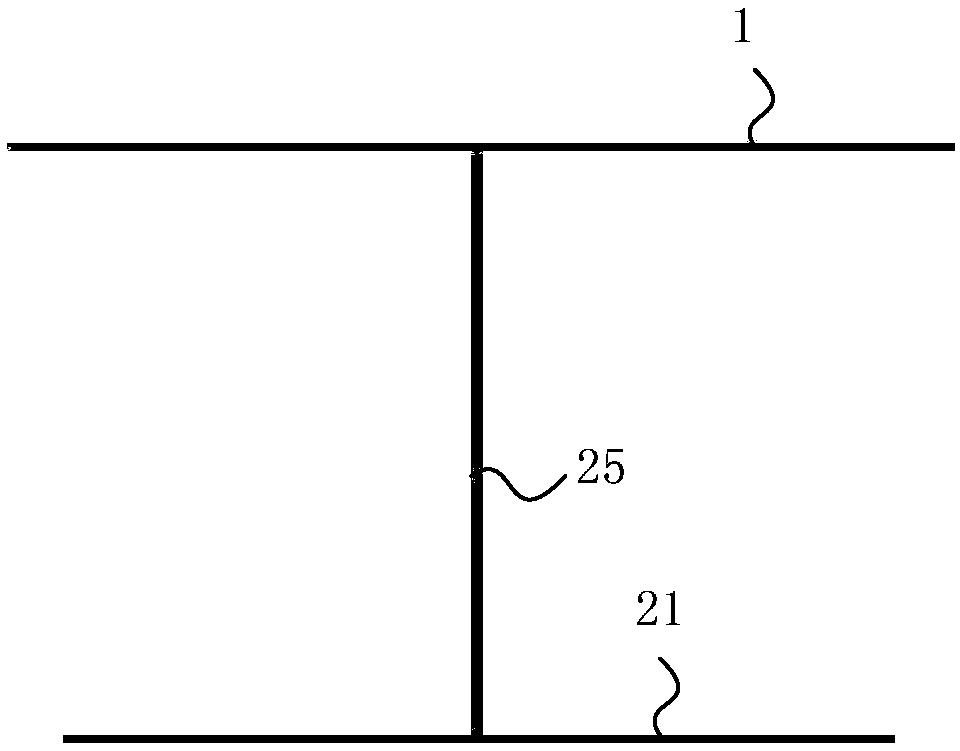

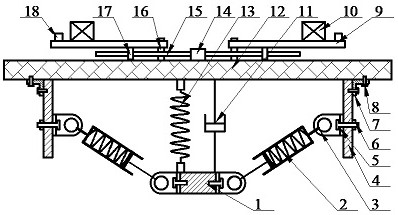

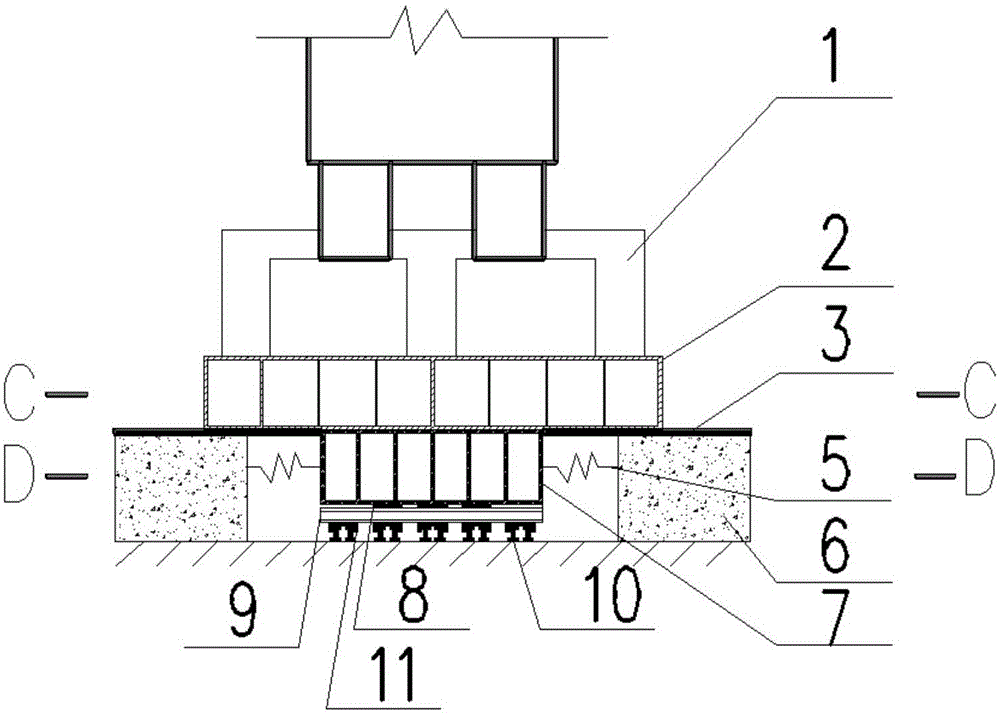

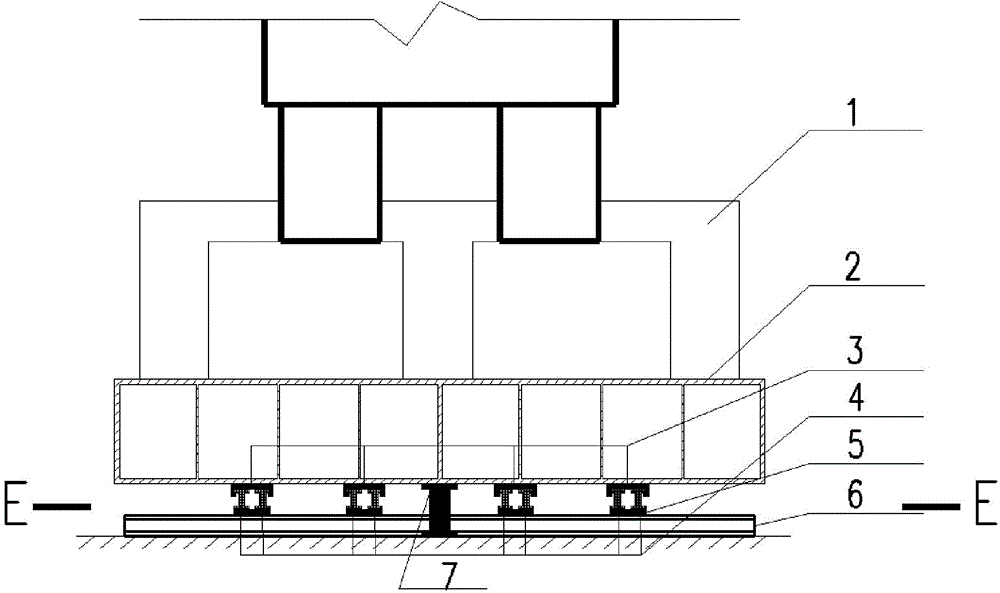

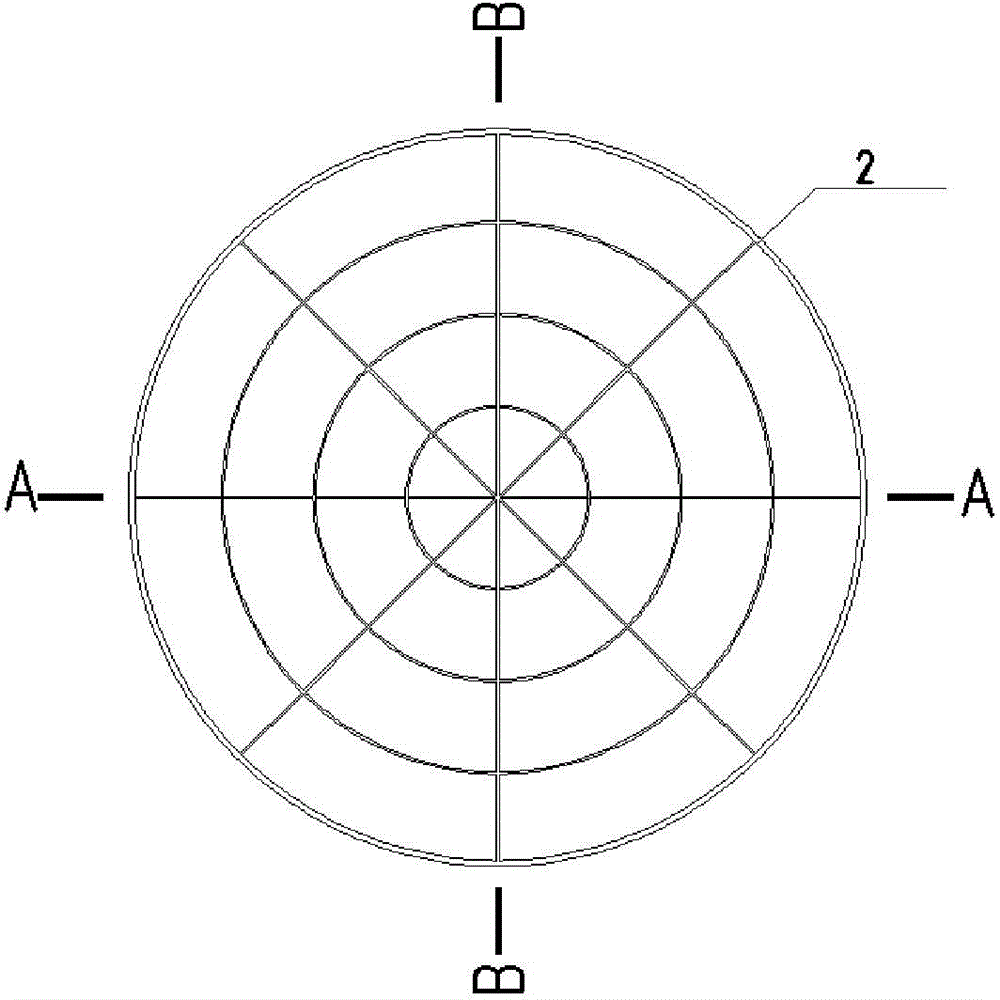

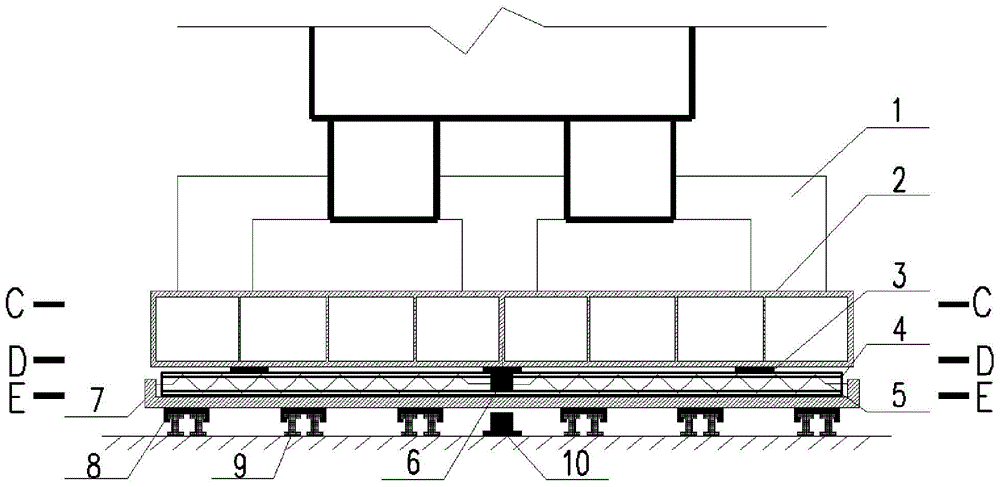

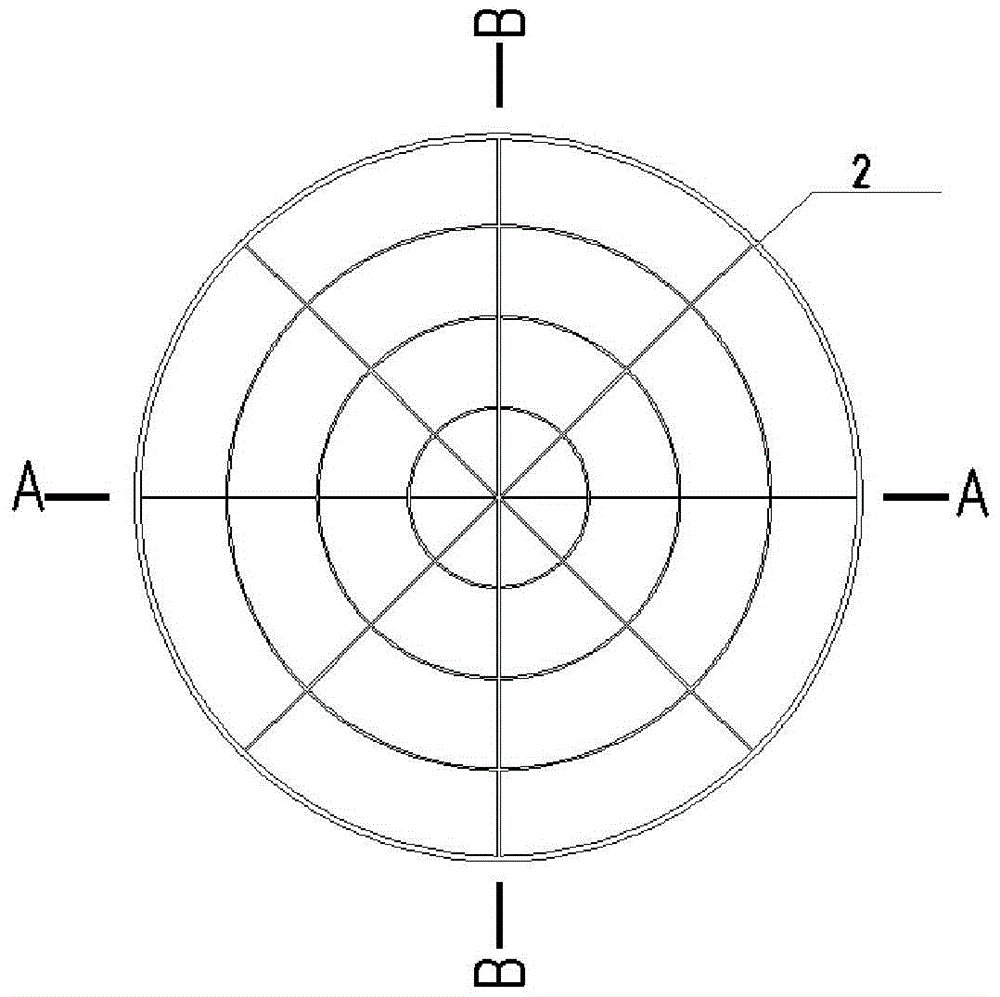

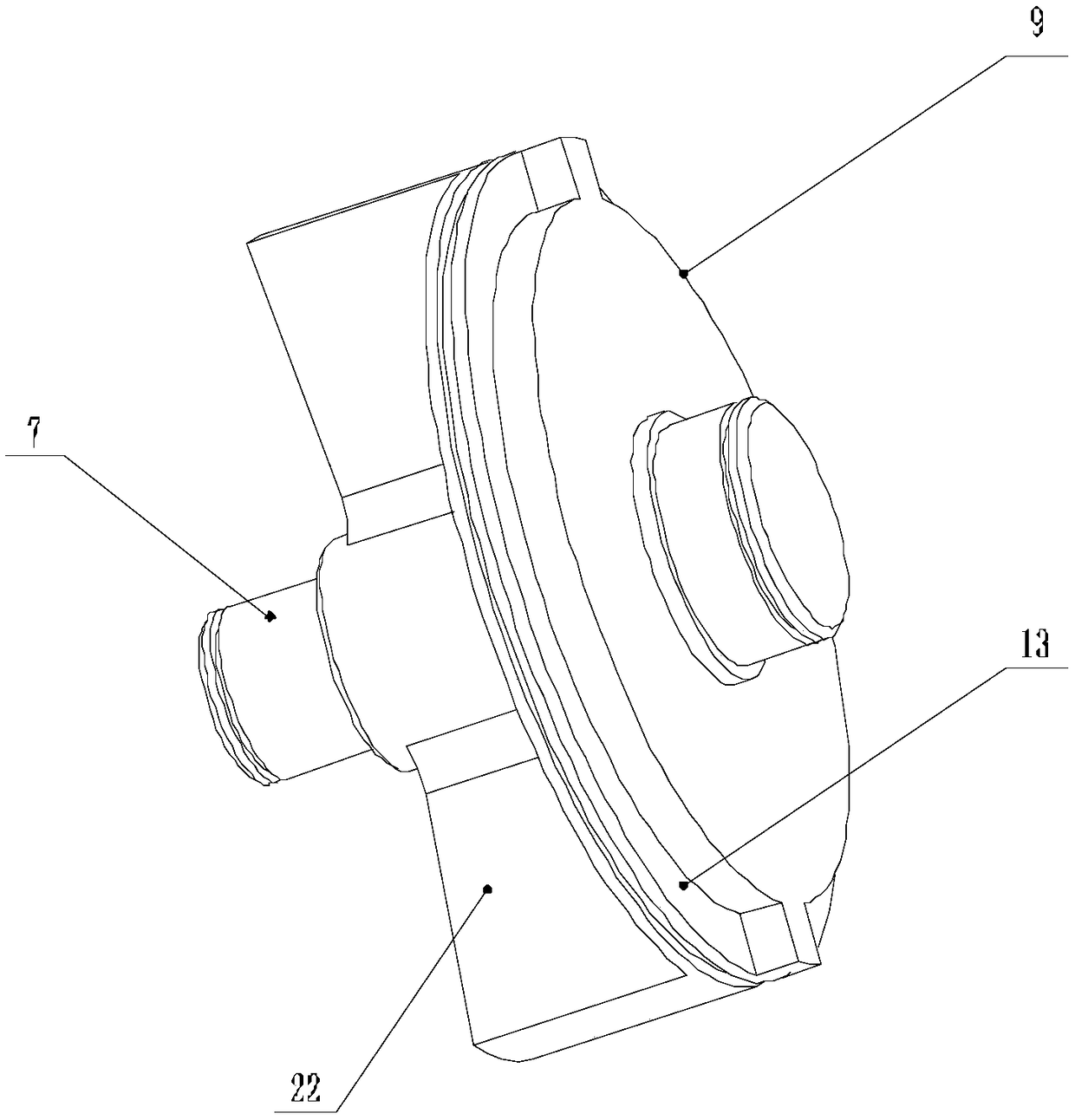

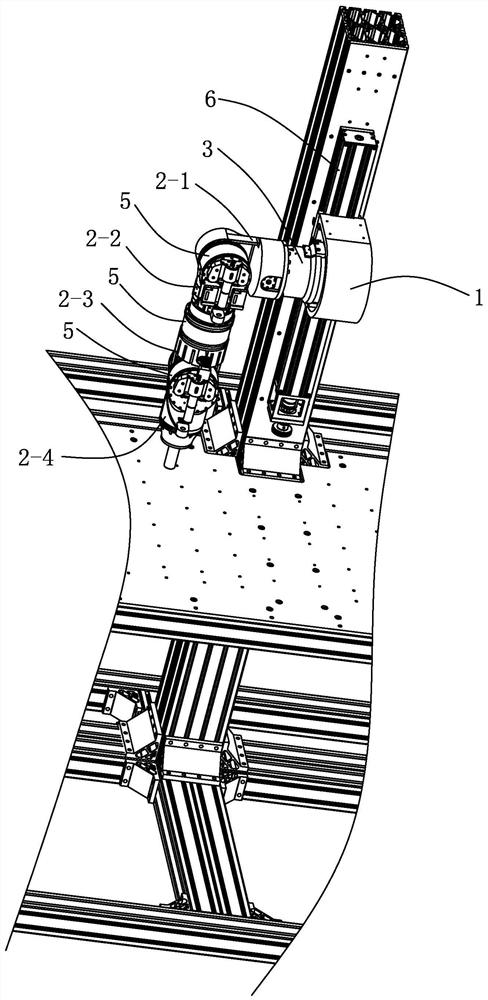

Shock insulating device resistant to pulling and twisting

InactiveCN103669633AWide range of stiffness adjustmentSignificantly prolonged periodShock proofingShock resistanceHigh rise

The invention discloses a shock insulating device resistant to pulling and twisting and belongs to the technical field of building shock resistance. The shock insulating device is mainly composed of a high-rise structure (1), an upper-portion rigid pedestal (2) with high rigidity and bearing capability, a base heat-insulating layer (3), viscous dampers (4), damping springs (5), springs, a damper supports (6), a lower-portion rigid pedestal (7) with high rigidity and bearing capability, horizontal limiting sliders (8), bottom horizontal shock-insulating linear guide rails (9), bottom longitudinal shock-insulating linear guide rails (10) and longitudinal limiting sliders (11). The shock insulating device is low in cost, simple in structure, convenient to construct, high in pulling resistance and twisting resistance and obvious in shock-insulating effect.

Owner:BEIJING UNIV OF TECH

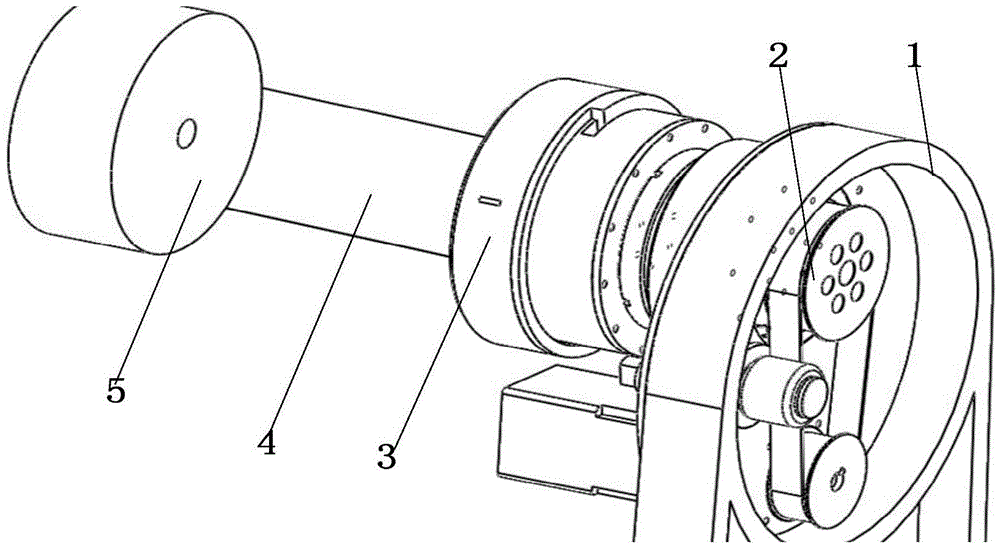

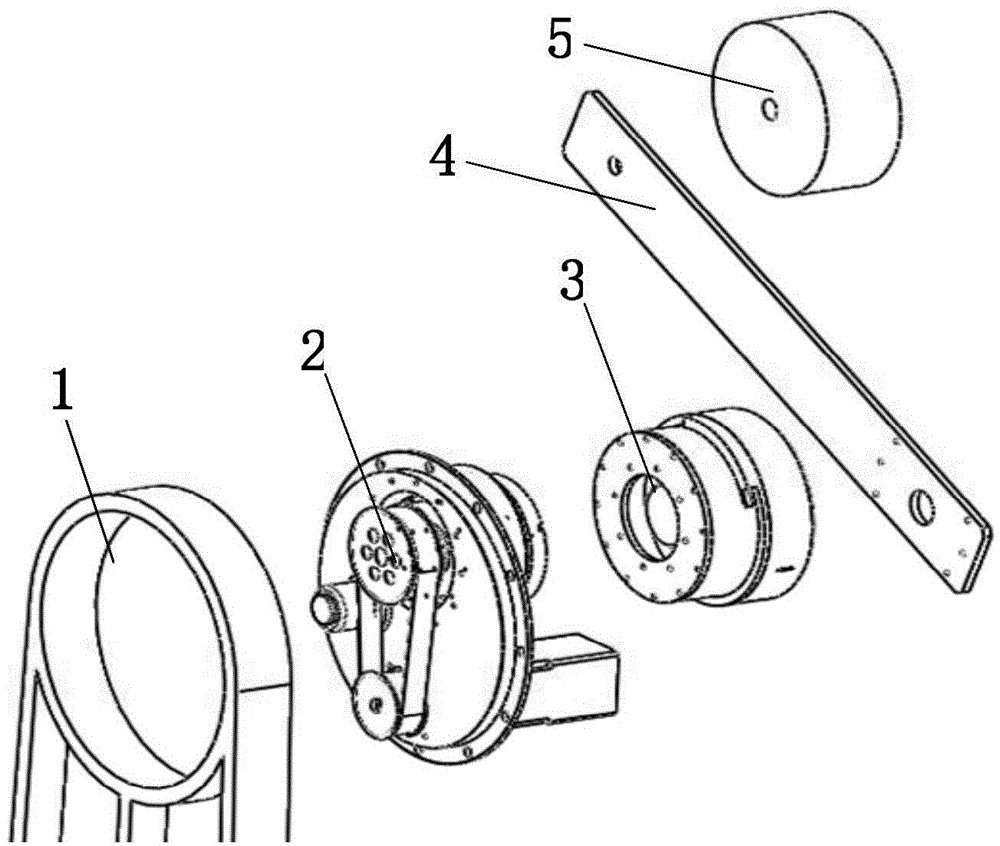

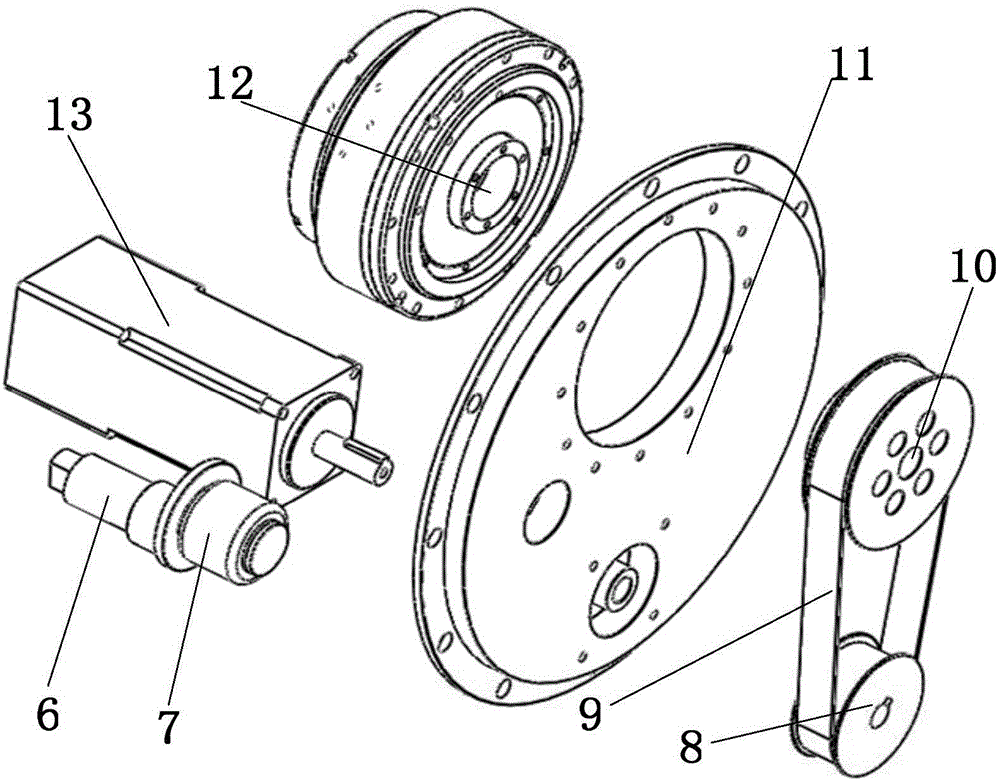

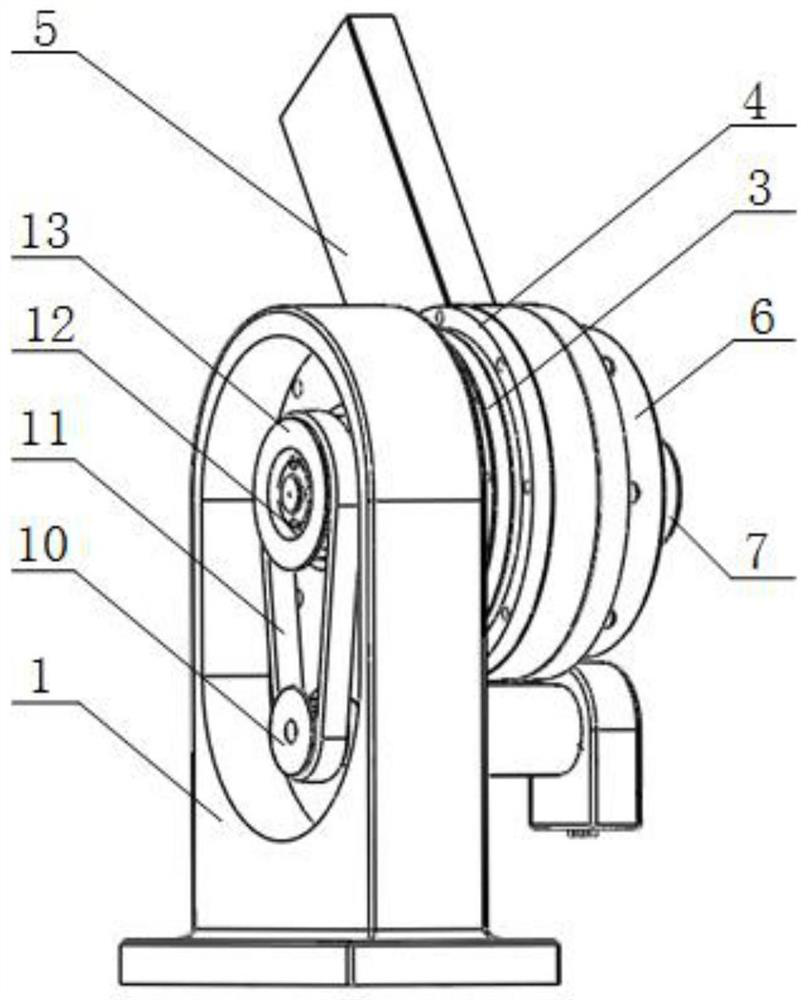

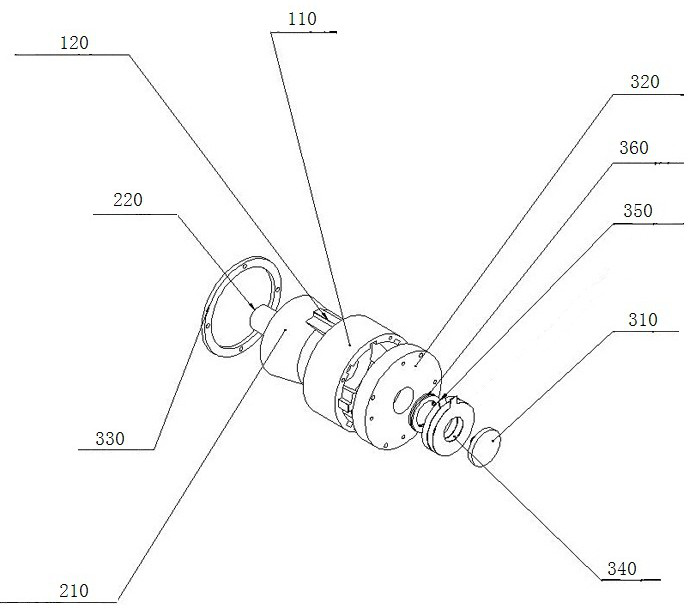

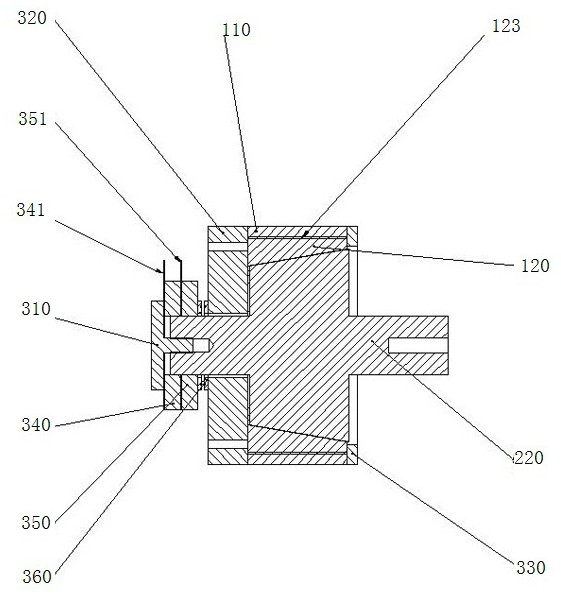

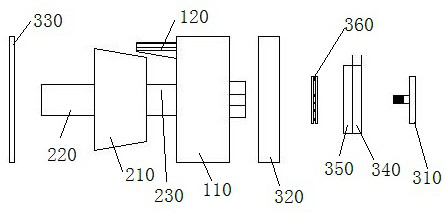

Permanent magnetic rigidity variable drive module for flexible robot

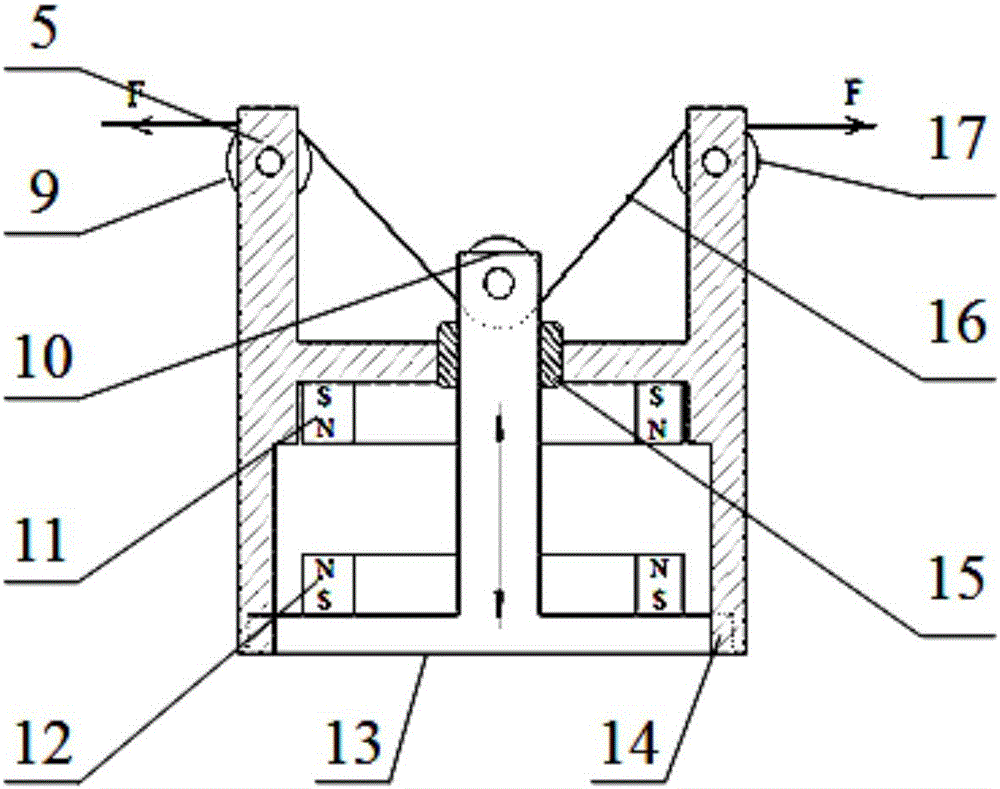

InactiveCN107175657AWide range of stiffnessWide range of stiffness adjustmentProgramme-controlled manipulatorJointsPull forceWinch

A permanent magnetic rigidity variable drive module for a flexible robot is suitable for establishing an antagonistic type flexible rigidity variable robot, especially a multi-freedom-degree flexible parallel rigidity variable robot. Compared with the prior art, the permanent magnetic rigidity variable drive module has the beneficial effect that under the situation that no motor torque is increased, the rigidity adjusting range is enlarged. When the multi-freedom-degree flexible robot is established, a drive unit and a rigidity variable module can be arranged on the rear part, the mass and the inertia of an operation arm are greatly reduced, and therefore the problem that in a traditional series manner, the rigidity change capacity is insufficient as the mass and the inertia are gradually increased is solved. According to the permanent magnetic rigidity variable drive module, one end of a rope is fixed to a rope winch, the rope sequentially penetrates through fixed pulleys, a movable pulley and a rope winch, the rope winch and the fixed pulleys are externally tangent to the same straight line, and the movable pulley is clamped to a symmetrical axis of the two fixed pulleys. The air gap interval between annular permanent magnets is reduced as the distance between a movable sliding base and a fixed base is reduced, and the rope tensile force and the rigidity are improved. The permanent magnetic rigidity variable drive module for the flexible robot is concise in movement type, easy and convenient to manufacture and easy to operate.

Owner:NORTHEASTERN UNIV

Flexible variable-stiffness joint mechanism

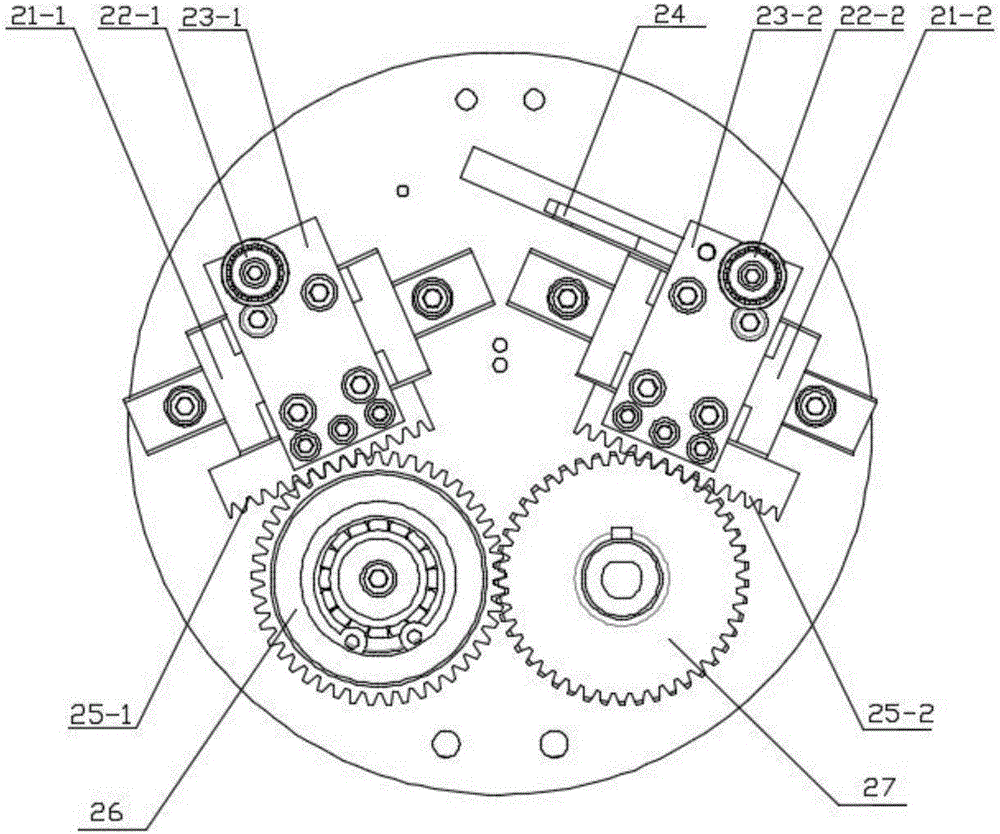

ActiveCN106695870AEnhanced load capacityWide range of stiffness adjustmentJointsLinear displacementSacroiliac joint

The invention provides a flexible variable-stiffness joint mechanism. The flexible variable-stiffness joint mechanism comprises an input structure and an output structure. The input structure and the output structure are connected and vertically corresponding. The input structure comprises a pair of guide rod shafts, a pair of guide rods, a pair of compression springs, a pair of spring installation seats and an input plate. The output structure comprises a pair of linear guide rail assemblies, a pair of roller sets, a pair of roller installation frames, a linear displacement sensor push rod, a pair of racks, a driven gear, a drive gear, a linear displacement sensor, an output plate, multiple bearings, multiple clamp springs and multiple bolts. The flexible variable-stiffness joint mechanism solves the problems that in the prior art, the loading capacity is poor, the stiffness adjustment range is narrow, the energy consumption of stiffness adjustment is large, the coupling performance is high, the passive stiffness performance is poor, and external connection with an air cylinder is needed.

Owner:泉州通维科技有限责任公司

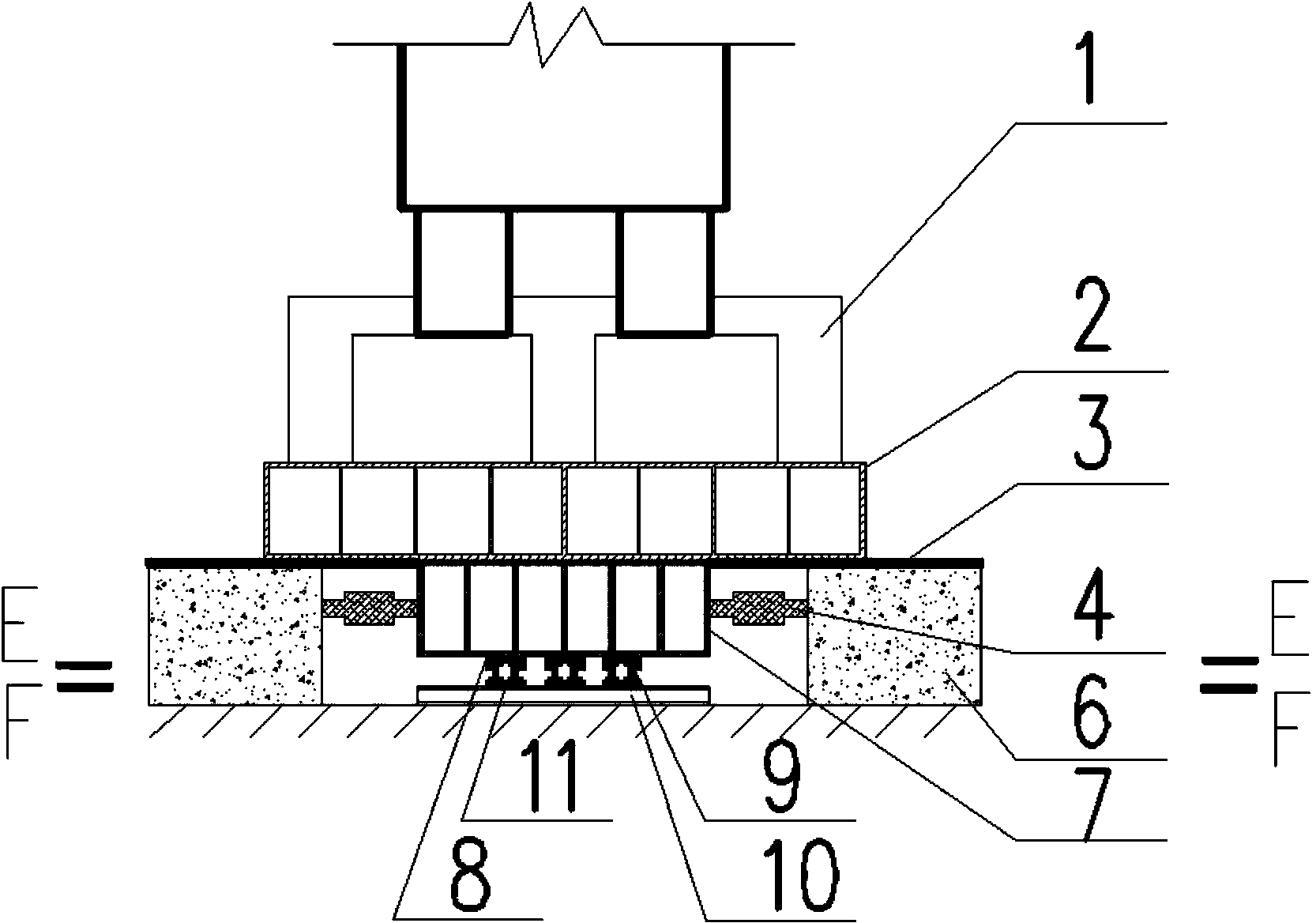

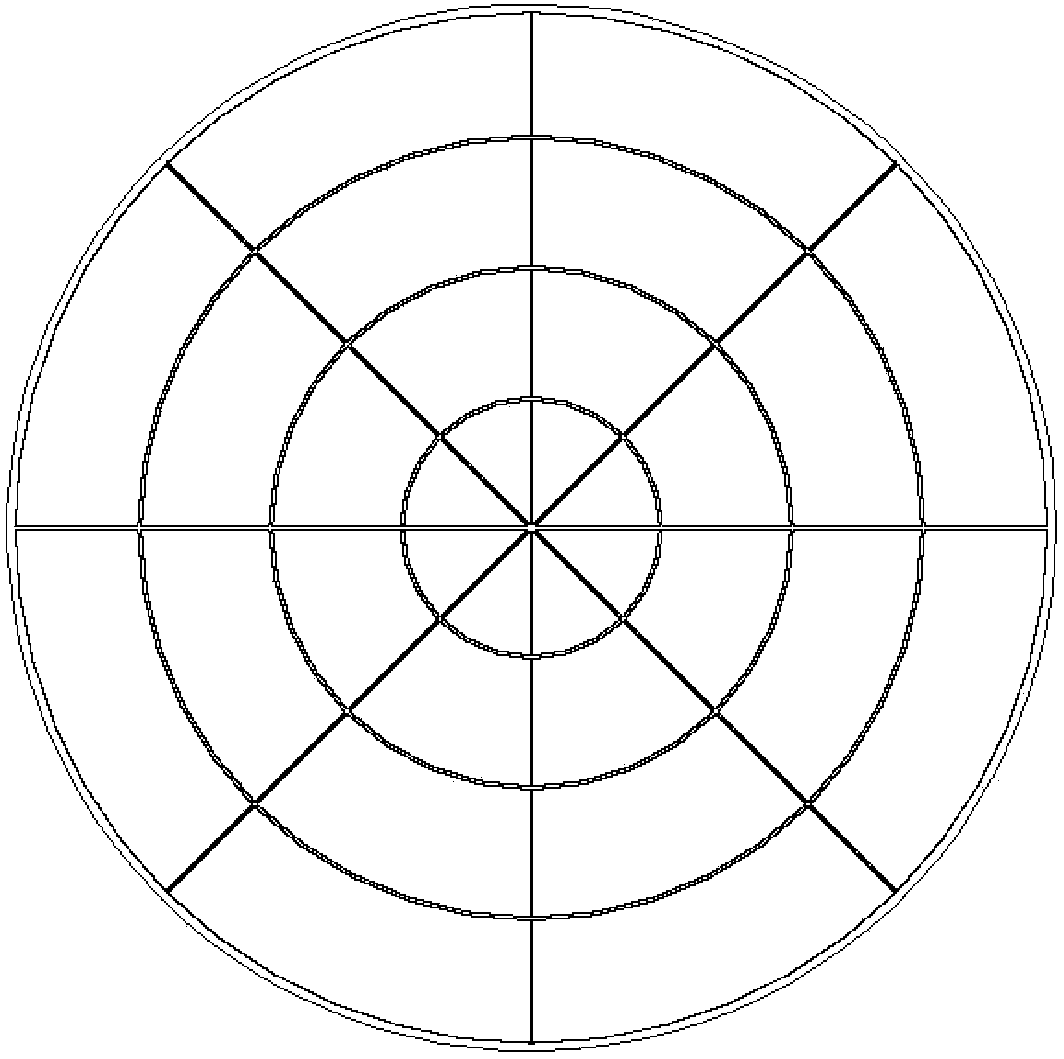

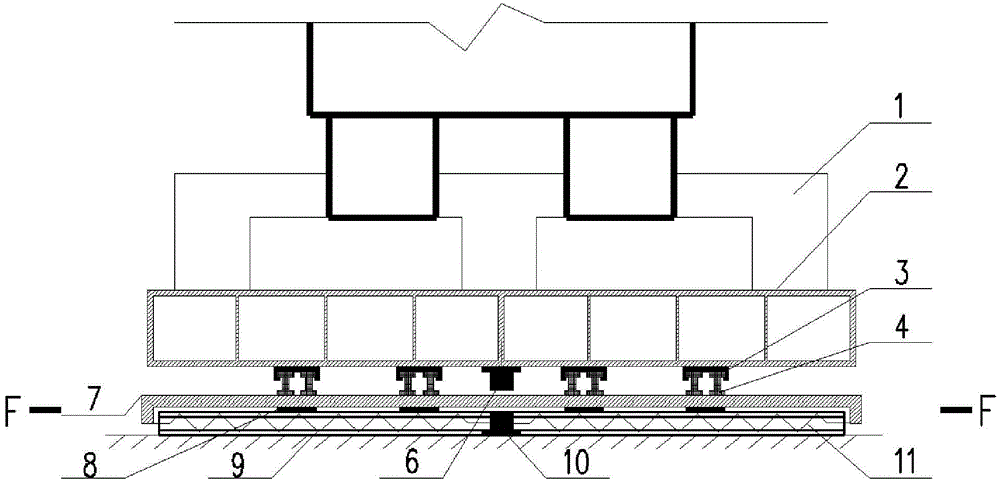

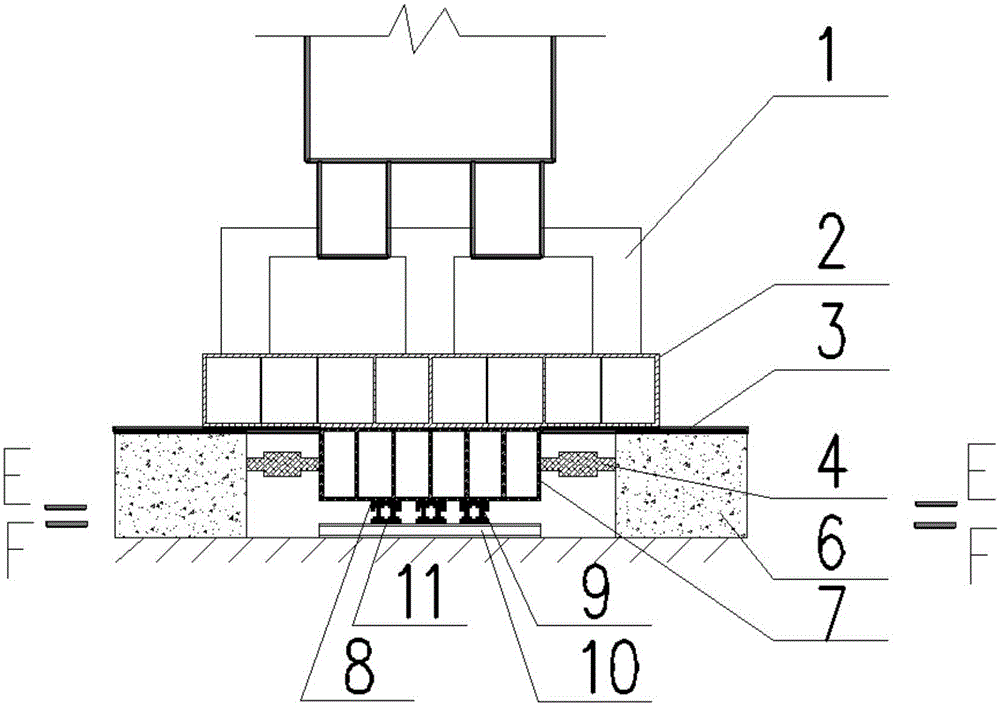

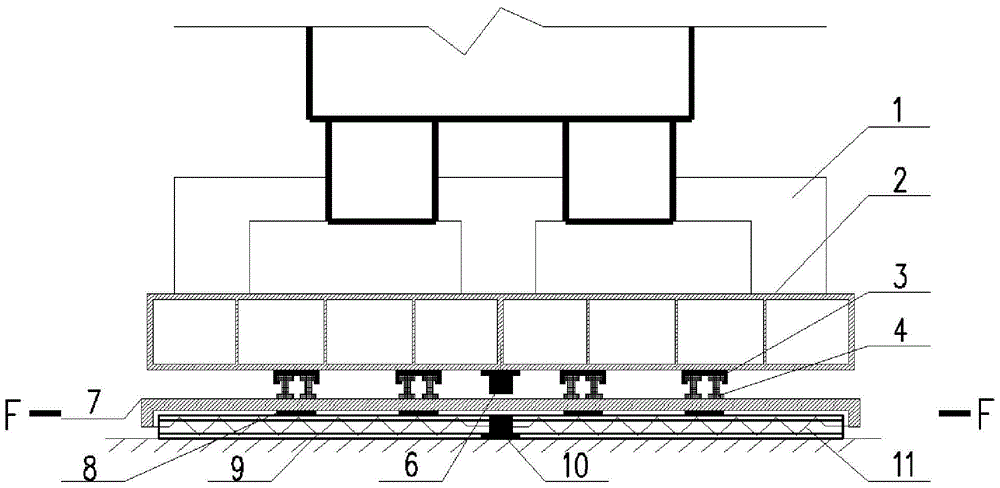

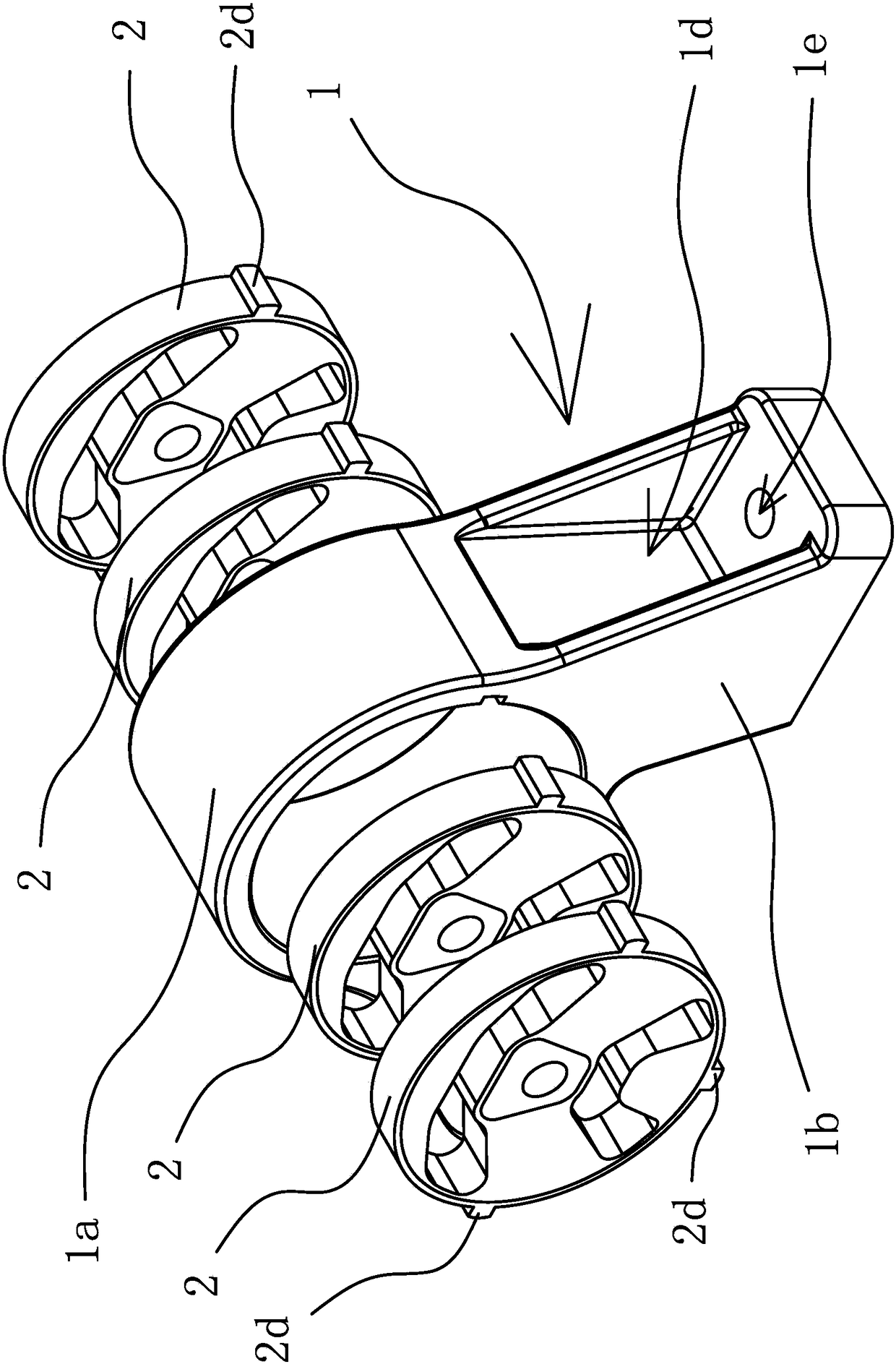

Tension resisting and twisting resisting combined shock isolation device with self-restoring function

InactiveCN104032846AImprove tensile propertiesImprove torsion resistanceBridge structural detailsShock proofingEngineeringMechanical engineering

The invention provides a tension resisting and twisting resisting combined shock isolation device with the self-restoring function, and belongs to the technical field of shock absorbing and isolating technique of structural engineering. The device mainly comprises a high-flexibility device (1), a rigid supporting pedestal (2), a transverse limiting sliding block (3), a transverse shock isolation linear guide rail (4), a transverse shock absorbing tension spring (5), a transverse shock absorbing tension spring support (6), a layering separating plate (7), a longitudinal limiting sliding block (8), a longitudinal shock isolation linear guide rail (9), a longitudinal shock absorbing tension spring support (10) and a longitudinal shock absorbing tension spring (11). The combined shock isolation device has the advantages that the material performance of each part can be fully utilized; in addition, the shortcoming of poor tension resisting capacity and vertical bearing capacity of a rubber support seat is overcome; the advantages of high tension resisting capacity and twisting resisting capacity, and outstanding effect on shock isolation for bases of the high-flexibility device and a high-flexibility structure are brought.

Owner:BEIJING UNIV OF TECH

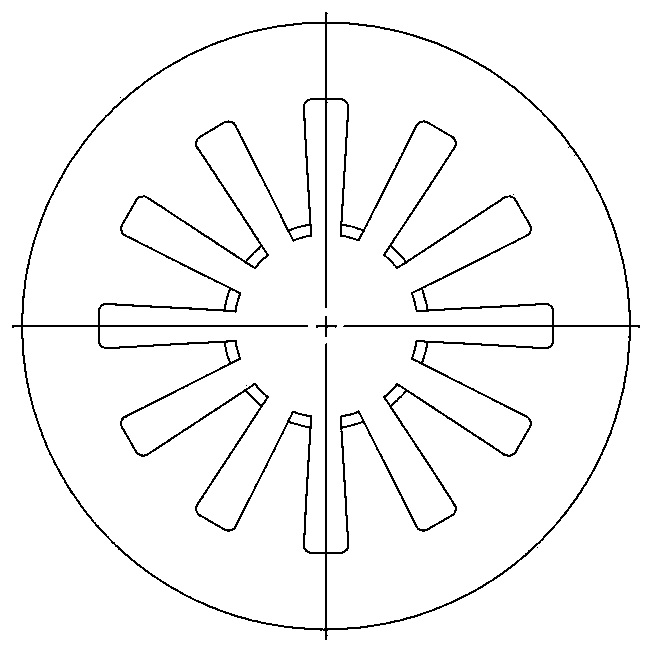

Cascadable variable-stiffness robot joint

The invention relates to a cascadable variable-stiffness robot joint. High-precision adjustment of the stiffness of the joint is conducted by using flexible shaft disc mechanisms composed of sheaves, steel wires and bent leaf springs for providing variable torque and using a rotary supporting mechanism composed of a supporting frame, a gear worm and a servo motor for uniquely determining the positions of working end points of the arc-shaped bent leaf springs which are symmetrically distributed on the shaft disc mechanisms; the energy storage capacity of the joint can be adjusted by changing the cascade number of the flexible shaft disc mechanisms; and a differential gear set mechanism is used for achieving coupled motions including rotation of the robot joint, rotation of the joint motor and rotation of an elastic mechanism, so that the balance position and stiffness of the joint are changed at the same time, and forward-rotation stiffness and reversed-rotation stiffness are made adjustable.

Owner:BEIJING INST OF CONTROL ENG

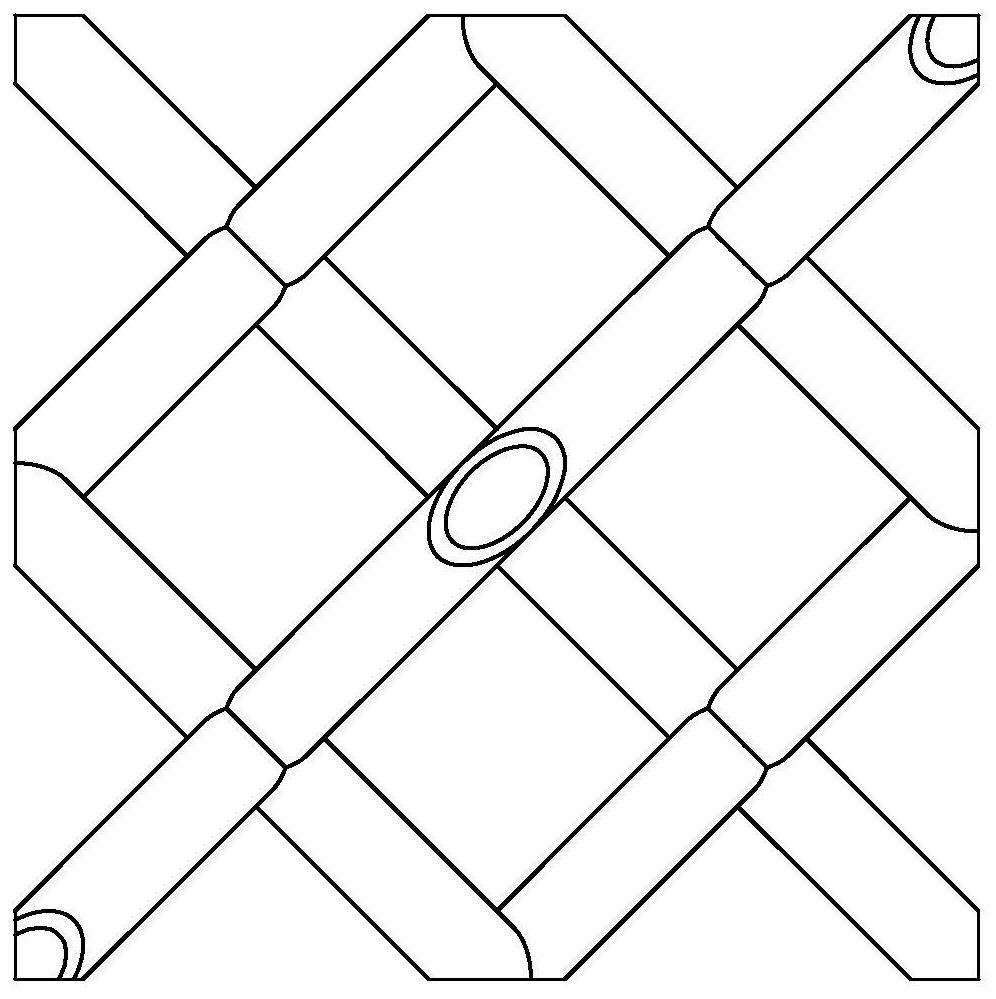

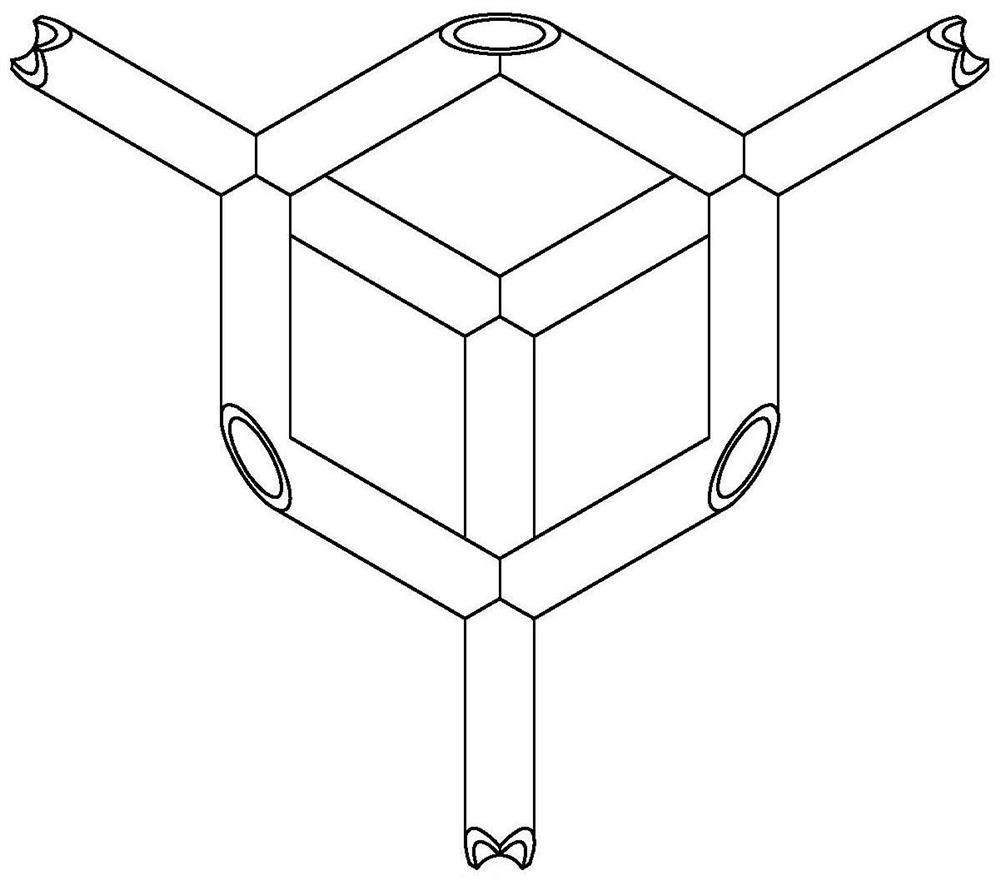

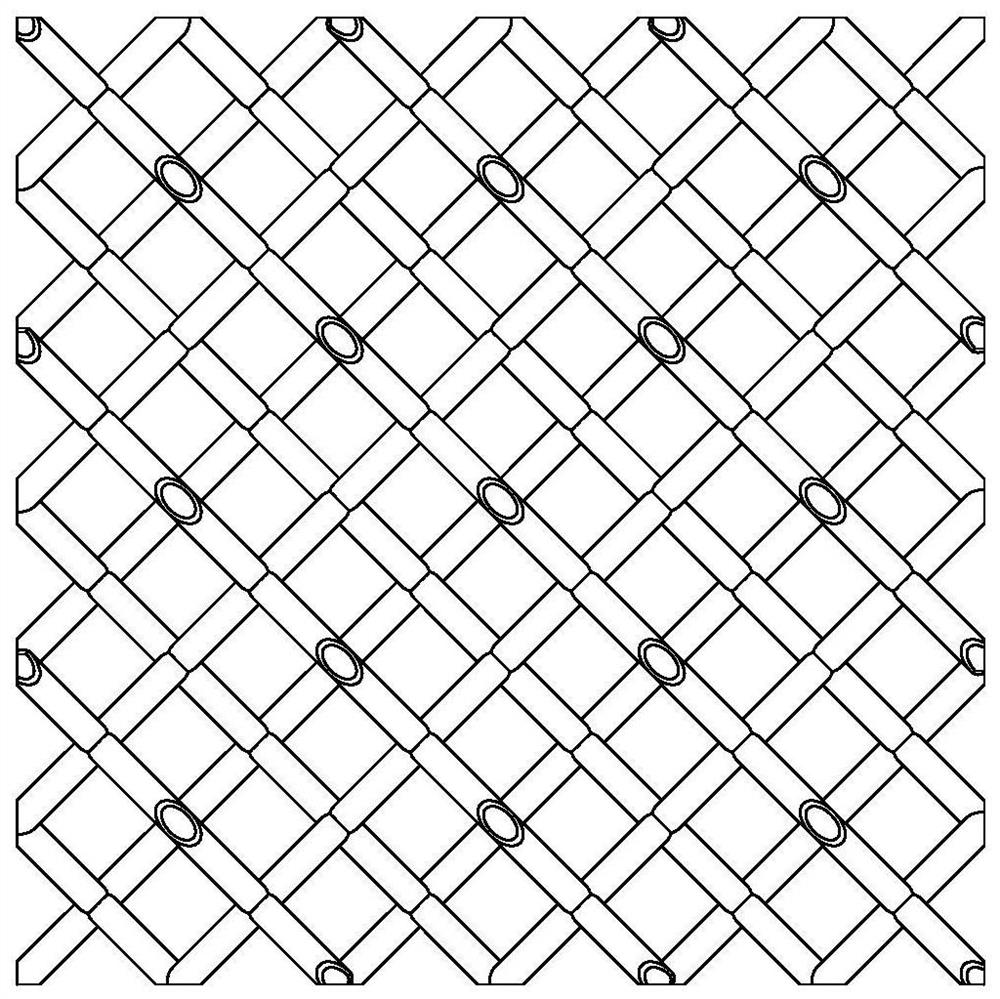

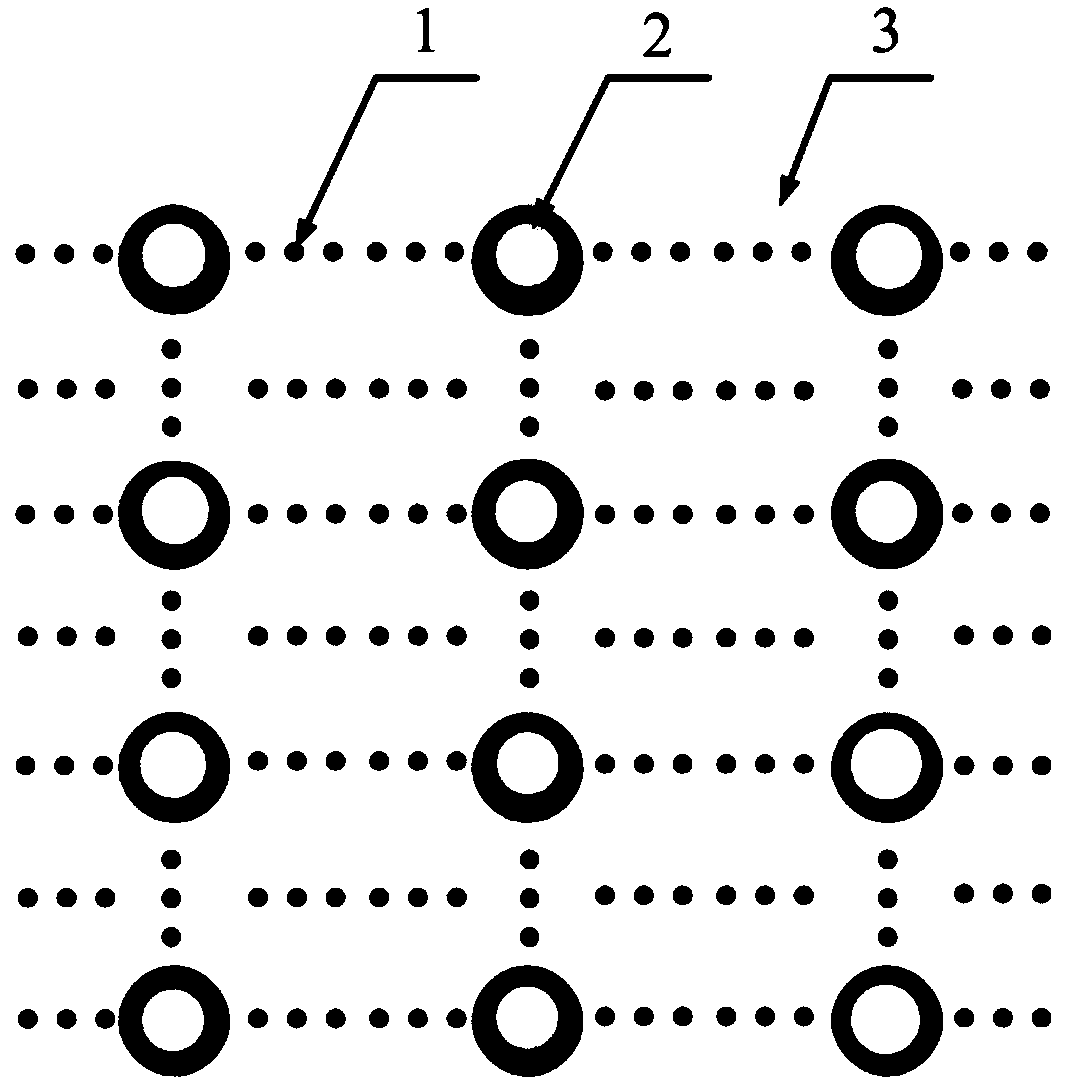

Lattice magneto-rheological intelligent vibration reduction structure, magneto-rheological vibration isolating device and manufacturing method of lattice magneto-rheological intelligent vibration reduction structure

PendingCN112555327APollution abilityWide range of stiffness adjustmentGeometric CADSpringsPhysicsMagneto

The invention discloses a lattice magneto-rheological intelligent vibration reduction structure, a magneto-rheological vibration isolating device and a manufacturing method of the lattice magneto-rheological intelligent vibration reduction structure. The lattice magneto-rheological intelligent vibration reduction structure comprises a plurality of lattice unit cells which are periodically and orderly arranged in a three-dimensional space and connected with one another; each lattice unit cell comprises spatially distributed joints and hollow rods connected between the joints; and the hollow rods are filled with magnetorheological fluid. The preparation method of the structure comprises the following steps that a three-dimensional model is constructed through computer modeling software, andcombining a high-precision stereolithography (SLA) technology, a lattice structure with a proper structure size is prepared; and meanwhile, the magneto-rheological vibration isolating body of the intelligent structure is prepared in combination with extrusion type magneto-rheological vibration isolating device product parameters, and the magneto-rheological vibration isolating body is applied to vibration isolating device products.

Owner:CHONGQING UNIV

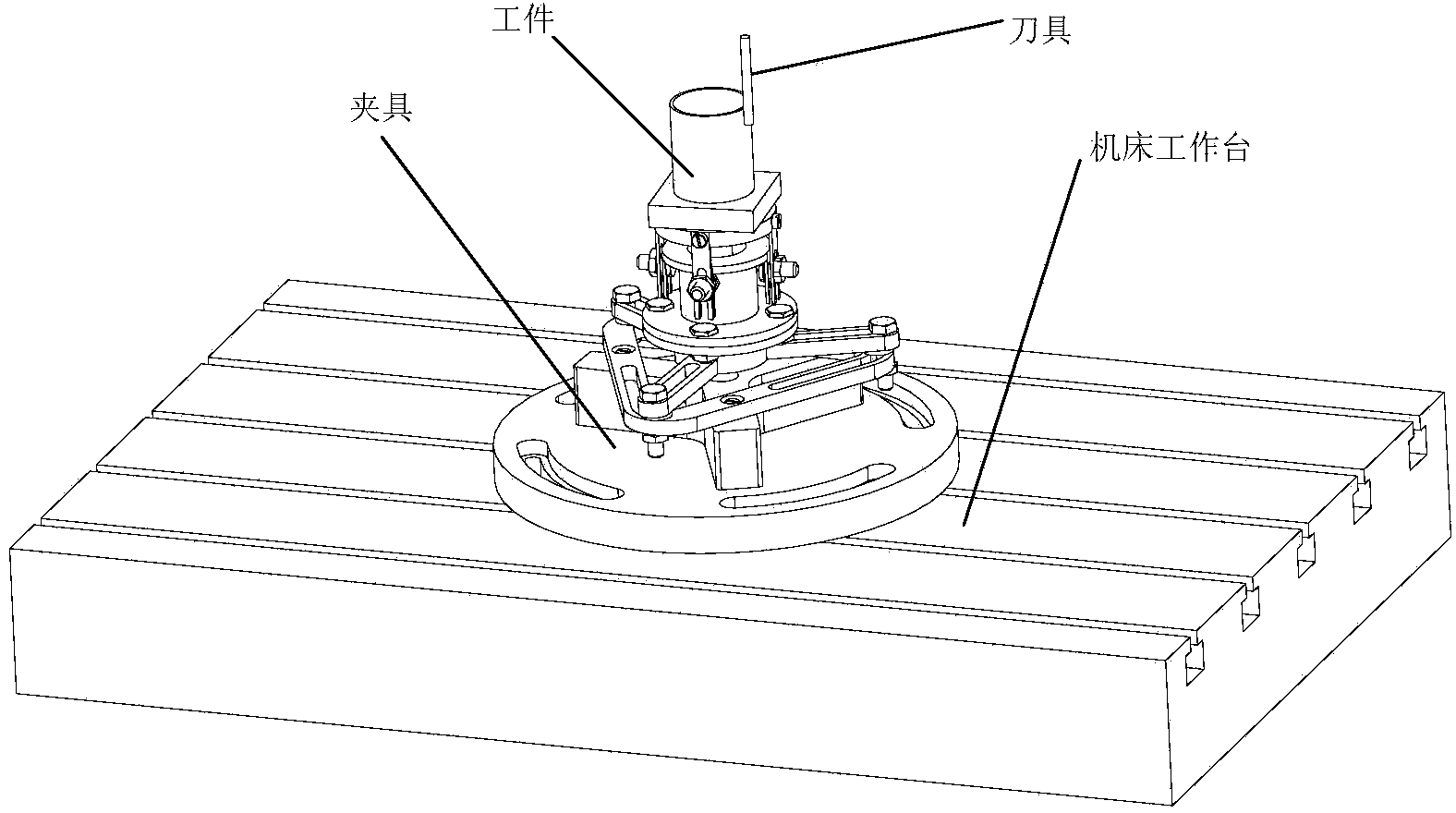

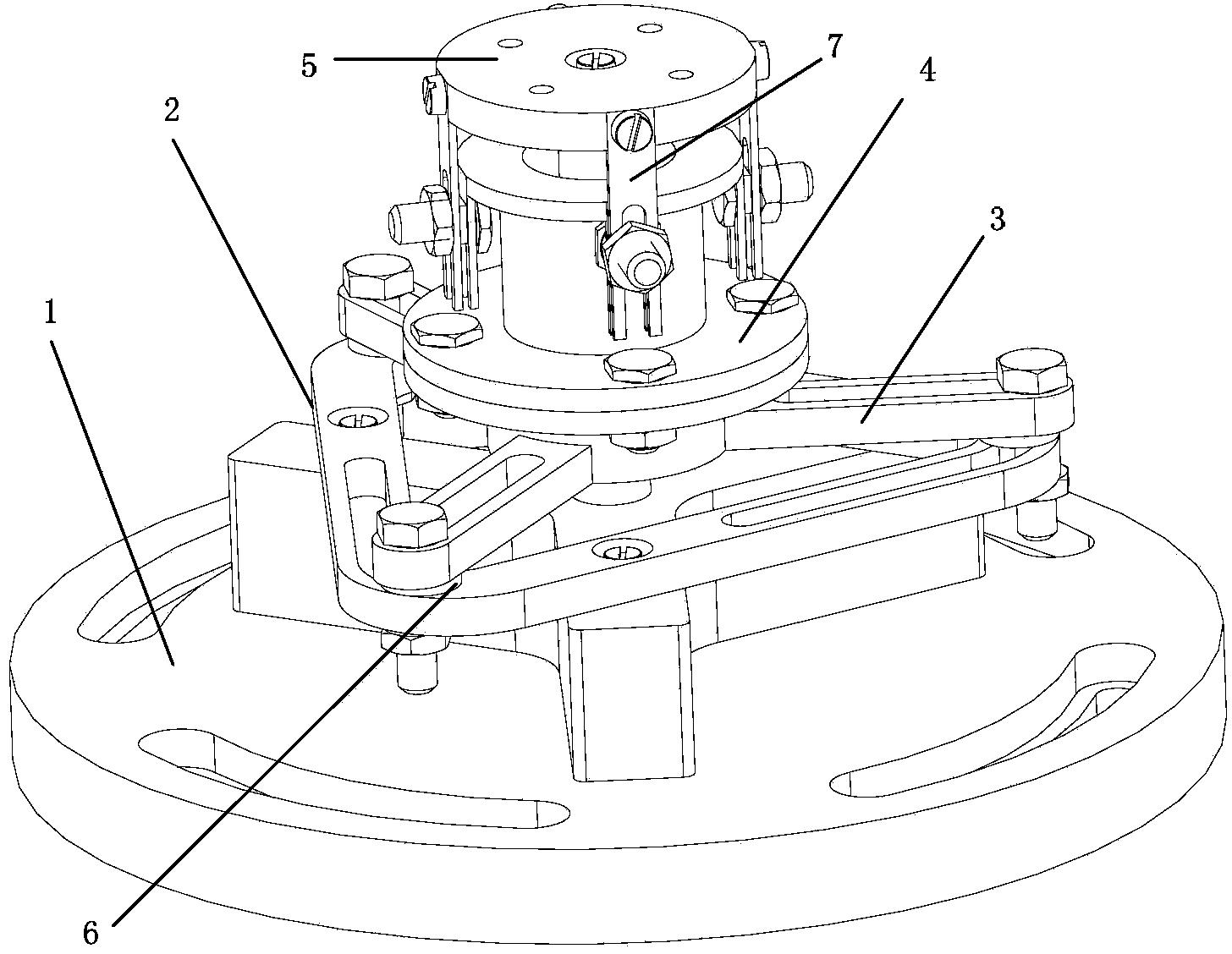

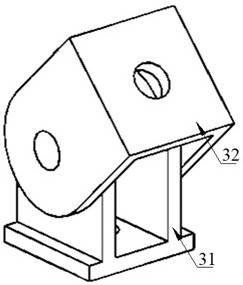

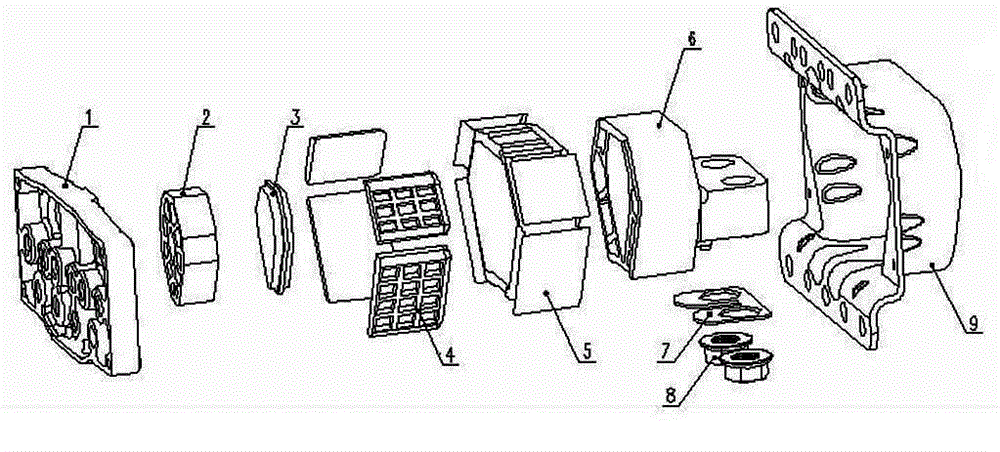

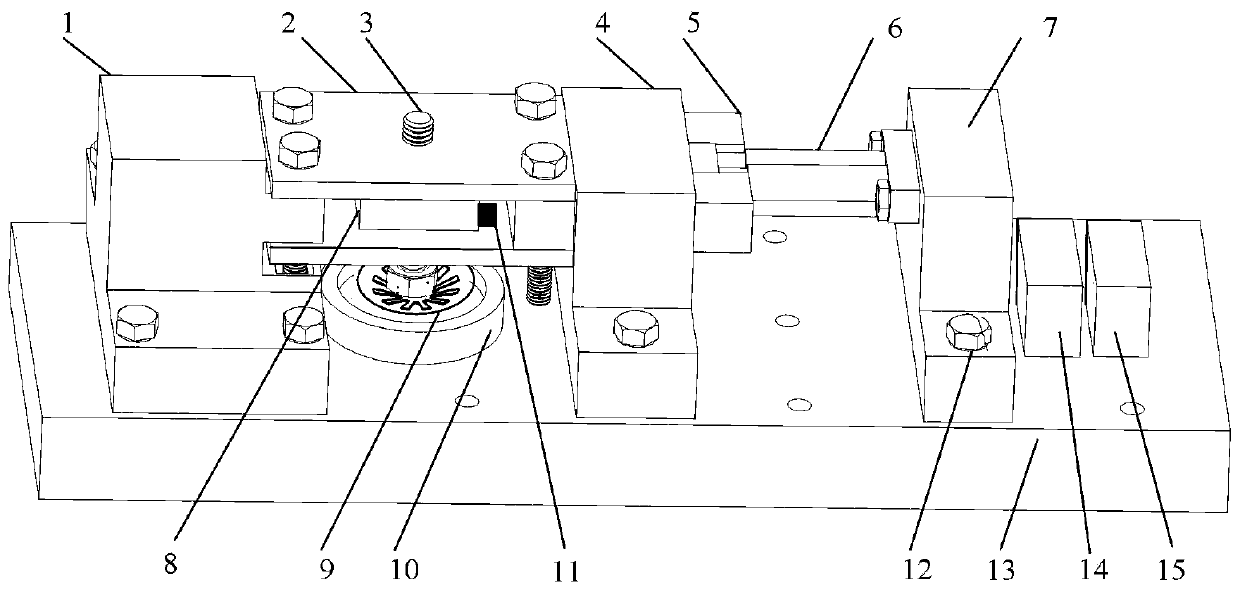

Milling passive vibration reduction clamp

InactiveCN103831646AChange the stiffnessHigh quality and efficient processingLarge fixed membersPositioning apparatusNumerical controlCantilever

A milling passive vibration reduction clamp is composed of a base, a supporting piece, a rotating piece, a supporting adjusting piece, a working table, supporting blocks, an adjusting plate, corresponding screws and corresponding nuts. The base is fixed to the machine table, the supporting piece is connected with the base through the screws, the supporting block is located on the supporting piece, three cantilever beam type supports are evenly distributed on the rotating piece in a horizontal plane and arranged on the three supporting blocks respectively, and the bolts sequentially penetrate through the rotating piece, the supporting blocks and the supporting piece for fixing. The milling passive vibration reduction clamp is characterized in that based on the passive control principle, rigidity adjustment in three orthogonal directions is achieved in a mechanical adjustment mode, vibration of rigid parts in the numerical control milling process is reduced, and efficient and high-precision machining is achieved. Rigidity adjustment in any direction can be independently conducted without affecting rigidity adjustment in other directions, the adjustable parameter range is large, and machining requirements of various parts can be met. The milling passive vibration reduction clamp is easy to implement and maintain and free of environmental pollution.

Owner:BEIHANG UNIV

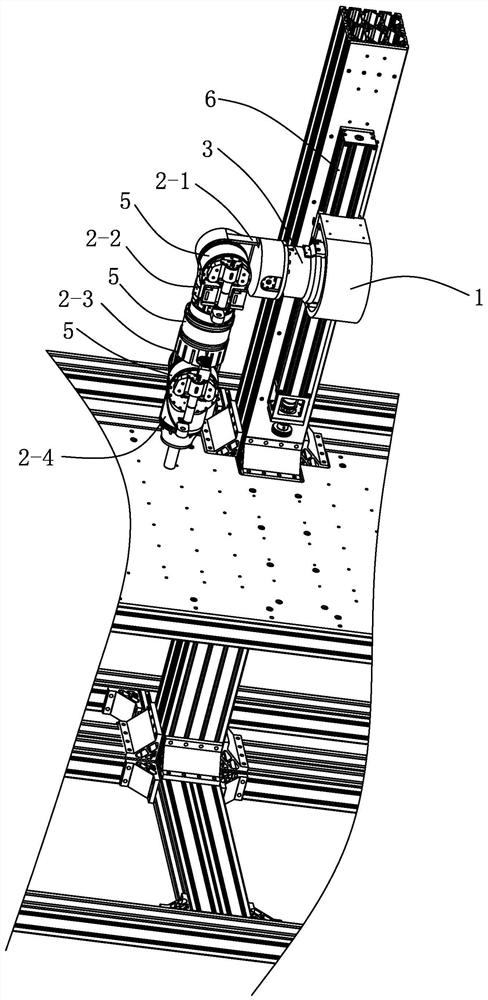

Multi-degree-of-freedom variable-rigidity joint mechanical arm

ActiveCN112092009AMajor rangeImprove carrying capacityProgramme-controlled manipulatorJointsStructural engineeringMechanical engineering

The invention discloses a multi-degree-of-freedom variable-rigidity joint mechanical arm. The multi-degree-of-freedom variable-rigidity joint mechanical arm comprises a mounting base, a base joint, three tail end joints and four connecting rods; an input end of the base joint is connected with the mounting base, and an output end of the base joint is connected with the first connecting rod; the first connecting rod is connected with an input end of the first tail end joint; an output end of the first tail end joint is connected with the second connecting rod; the third connecting rod is connected with an input end of the fourth tail end joint; an output end of the fourth tail end joint is connected with the fourth connecting rod; the base joint comprises a first joint shell, a main drivingmodule, an elastic module and a rigidity adjusting module; the first joint shell is connected with the first connecting rod; each tail end joint comprises a second joint shell, a main driving mechanism, an elastic mechanism and a rigidity adjusting mechanism; and the second connecting rod, the third connecting rod and the fourth connecting rod are separately connected with the second joint shellsof the corresponding tail end joints. The mechanical arm is wide in rigidity adjusting range, and can meet the safety interaction demands of cooperative mechanical arms.

Owner:HARBIN INST OF TECH

Pneumatic artificial muscles with self-sensing and actuating functions

InactiveCN105856219BImprove shrinkageWide range of stiffness adjustmentProgramme-controlled manipulatorFiberVoltmeter

The invention belongs to the pneumatic artificial technical field and in particular relates to a pneumatic artificial muscle with self-sensing and driving functions. The pneumatic artificial muscle comprises fibers, an elastic hose, a cylindrical sleeve pipe, a fiber collecting hoop, a fiber collecting hole, a piezoelectric body, an electrode, a sensing circuit, a drive circuit, a hoop and an air pipe joint. The pneumatic artificial muscle has the beneficial effects that via the direct piezoelectric effects of the piezoelectric body, the contractility of the fibers can be measured to obtain the external load driving force of the pneumatic muscle; meanwhile, collision of the pneumatic muscle can be self-sensed according to the real-time reading of a voltmeter; via the inverse piezoelectric effects of the piezoelectric body, the amount of contraction of the pneumatic muscle can be increased and the rigidity of the pneumatic muscle can be changed; compared with the same model of pneumatic muscle on the market, the pneumatic muscle provided by the invention can achieve the effects of detecting the external load driving force, self-sensing collision, increasing the amount of contraction of the pneumatic muscle and changing the rigidity of the pneumatic muscle; the properties of the pneumatic muscle are improved and enriched; and the pneumatic muscle has function innovation and extension and is worthy to be applied.

Owner:CHINA JILIANG UNIV

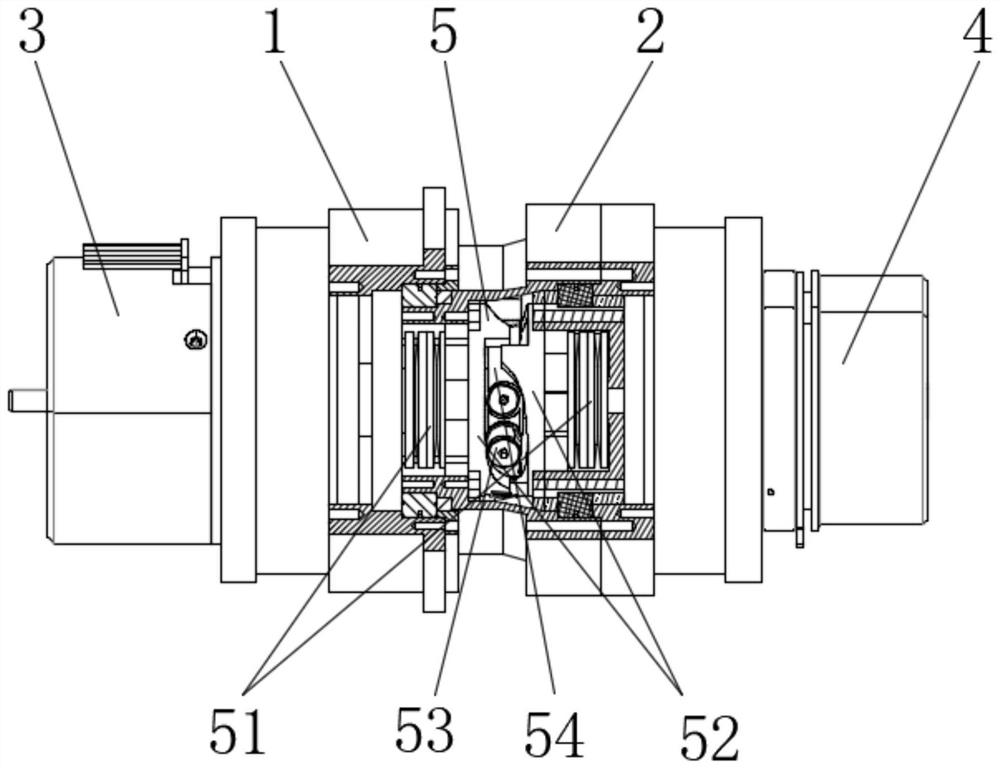

Vibration reduction suspension, adjusting method, compressor assembly and air conditioning system

PendingCN108799060AChange support heightWide range of stiffness adjustmentPositive displacement pump componentsPositive-displacement liquid enginesEngineeringAir conditioning

The invention relates to a vibration reduction suspension, an adjusting method, a compressor assembly and an air conditioning system. The vibration reduction suspension comprises a bearing rack used for supporting to-be-borne equipment, a main cylinder and an auxiliary cylinder. A main air cavity is formed in the main cylinder, and the air pressure in the main air cavity is used for supporting thebearing rack and can be adjusted. An auxiliary air cavity is formed in the auxiliary cylinder and communicates with the main air cavity, and the air pressure in the auxiliary air cavity can be adjusted so as to adjust the air pressure in the main air cavity. According to the vibration reduction suspension, the adjusting method, the compressor assembly and the air conditioning system, the supporting height of the vibration reduction suspension can be adjusted, the rigidity adjustment range of the vibration reduction suspension is wide, and effective compensation can be carried out on the mounting height of the to-be-borne equipment.

Owner:GREE ELECTRIC APPLIANCES INC

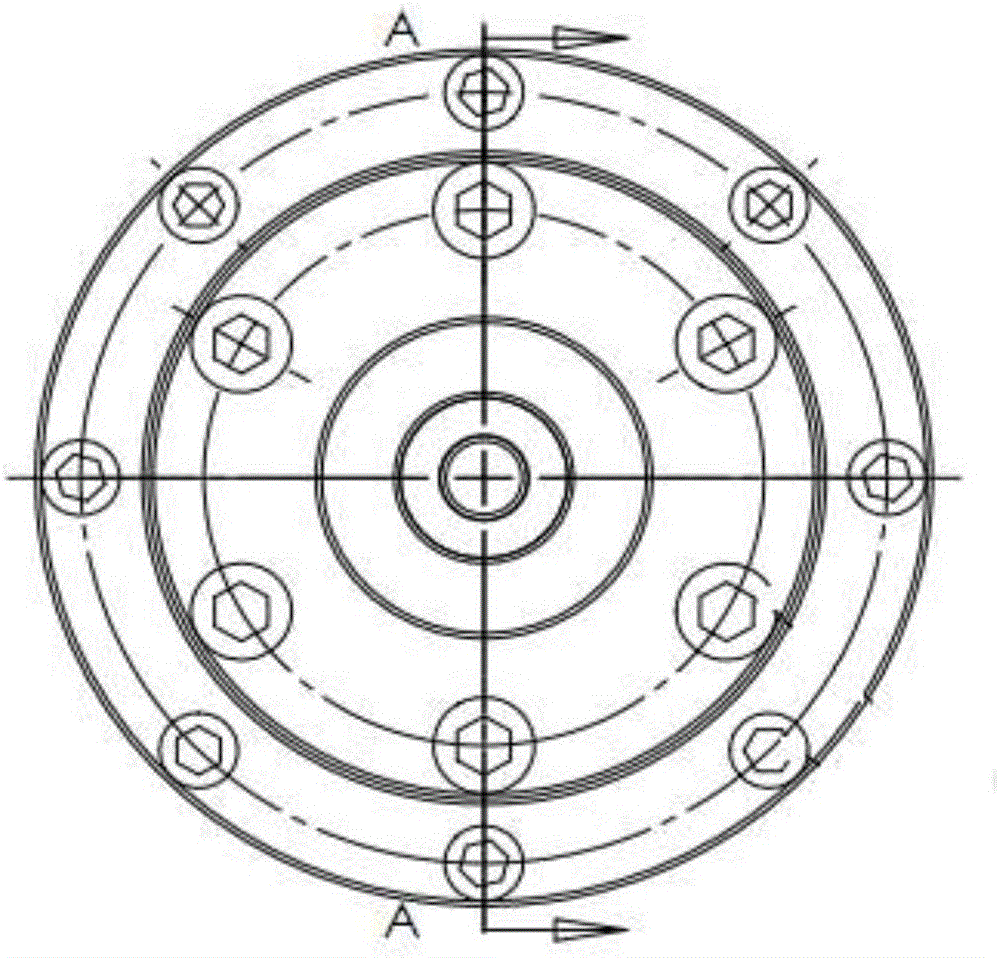

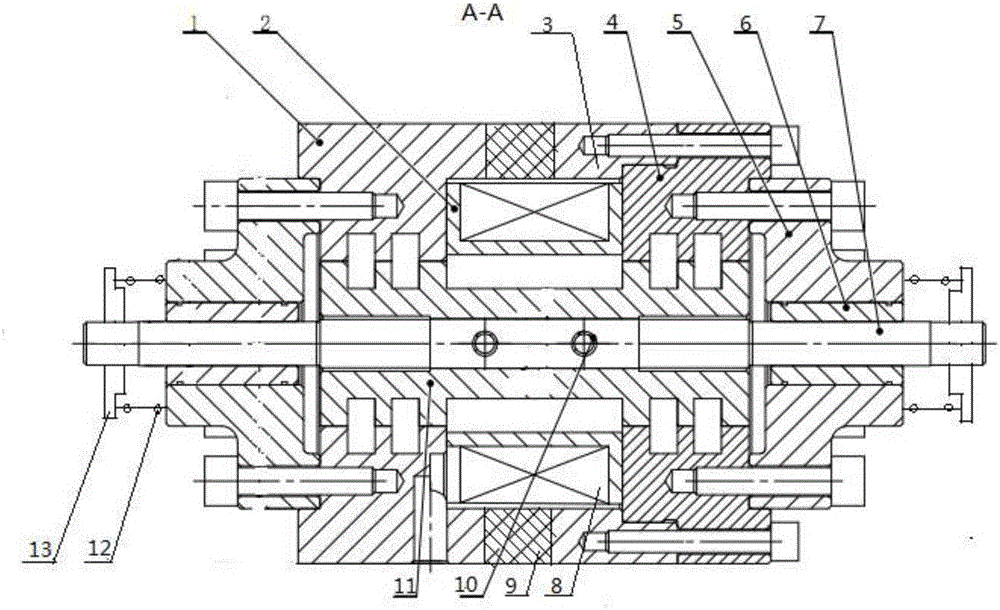

Permanent electromagnetic compounding semi-active vibration isolation actuator

ActiveCN105782306AReduce complexityReduce system stiffnessVibration dampersSprings/dampers functional characteristicsMagnetEngineering

The invention aims at providing a permanent electromagnetic compounding semi-active vibration isolation actuator. A permanent magnet is arranged between a first shell and a second shell. A hollow shell structure is jointly formed by the first shell, the permanent magnet and the second shell. A spindle is mounted in an armature, the armature is mounted in the shell structure, and the first end of the armature stretches out of the second shell. A flange and the end of the second shell are fixed. A first bearing end cover is fixed to the end of the first shell. A second bearing end cover is fixed to the end of the flange. The first bearing end cover and the second bearing end cover are arranged outside the two ends of the spindle correspondingly. The outer sides of the two ends of the spindle are each provided with a nut. Springs are mounted between one nut and the first bearing end cover and between the other nut and the second bearing end cover correspondingly. The permanent electromagnetic compounding semi-active vibration isolation actuator combines the functions of a passive vibration isolator and a controllable rigidity actuator in a traditional semi-active vibration isolation system, and meanwhile the problem that the passive vibration isolator in the traditional semi-active vibration isolation system is instable is solved.

Owner:HARBIN ENG UNIV

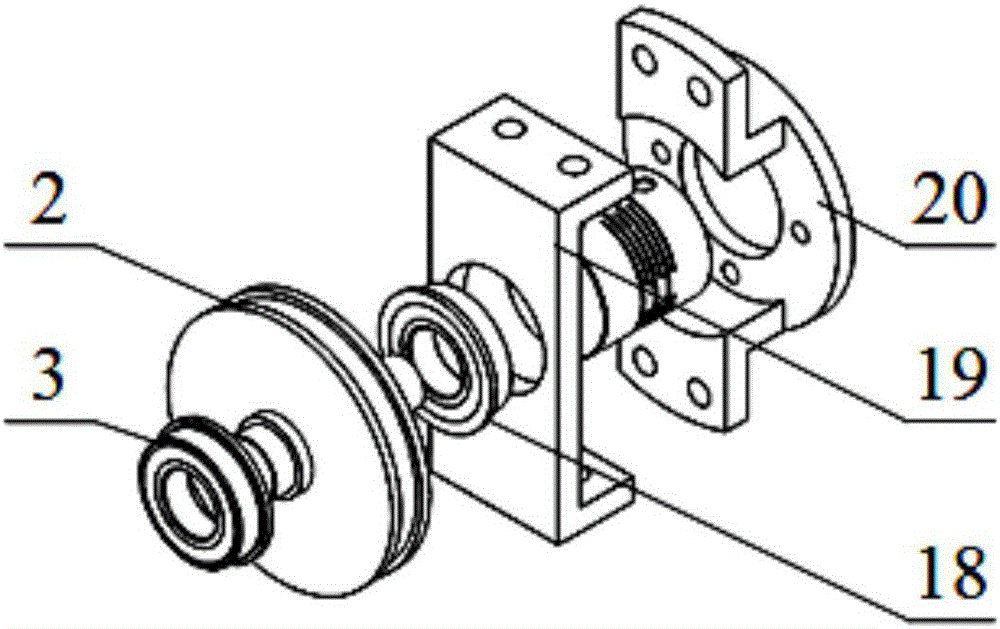

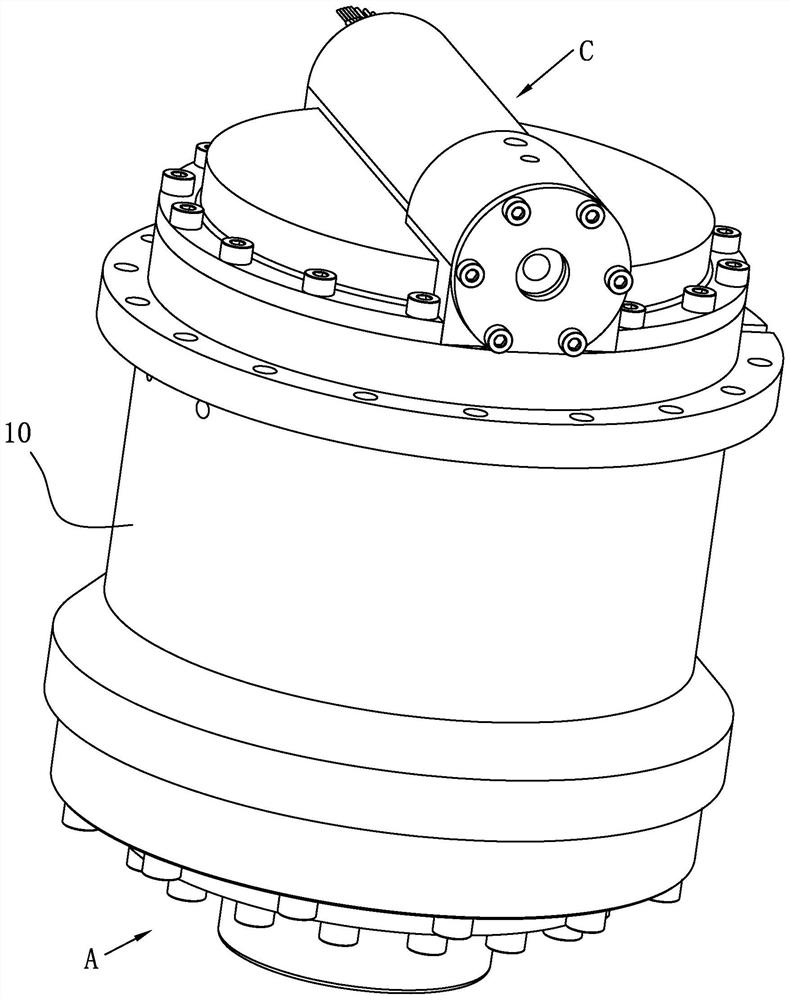

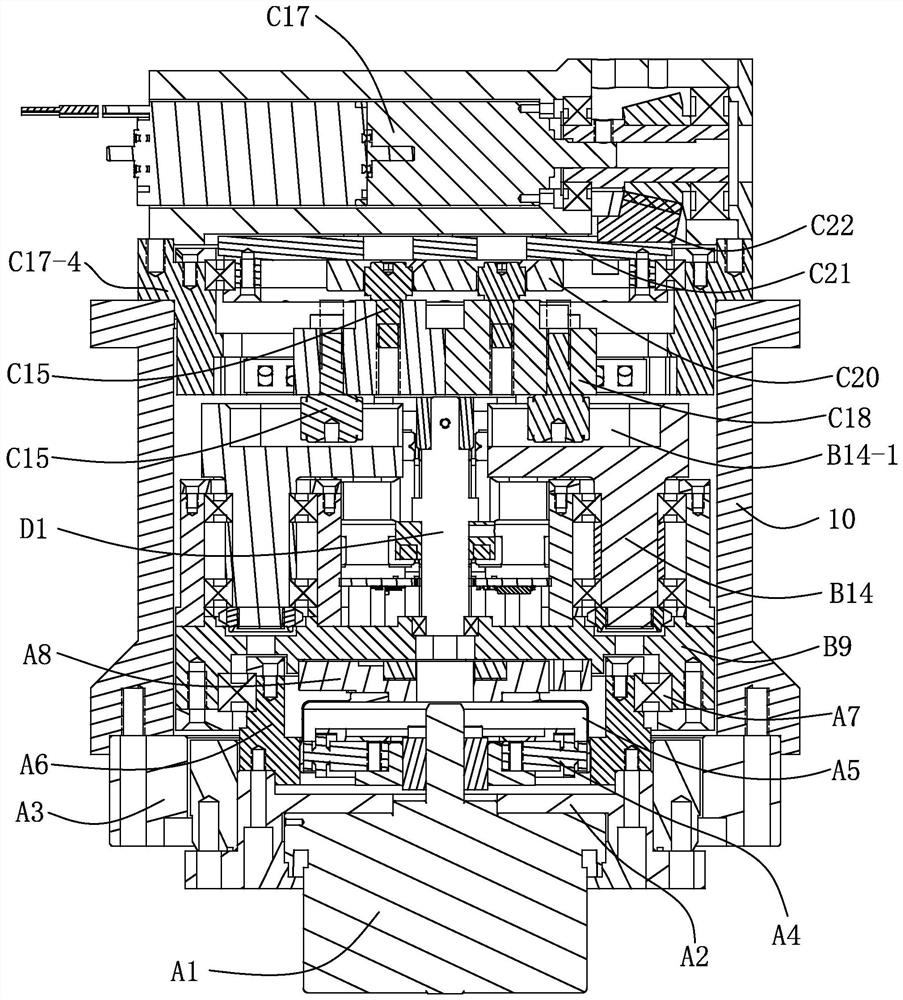

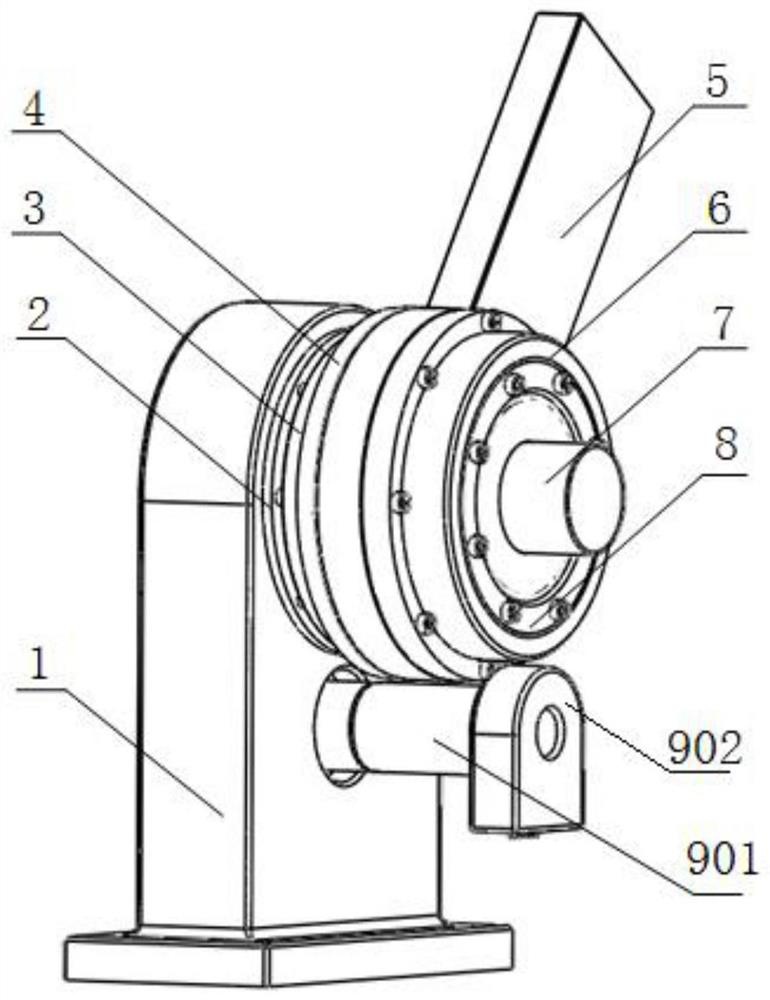

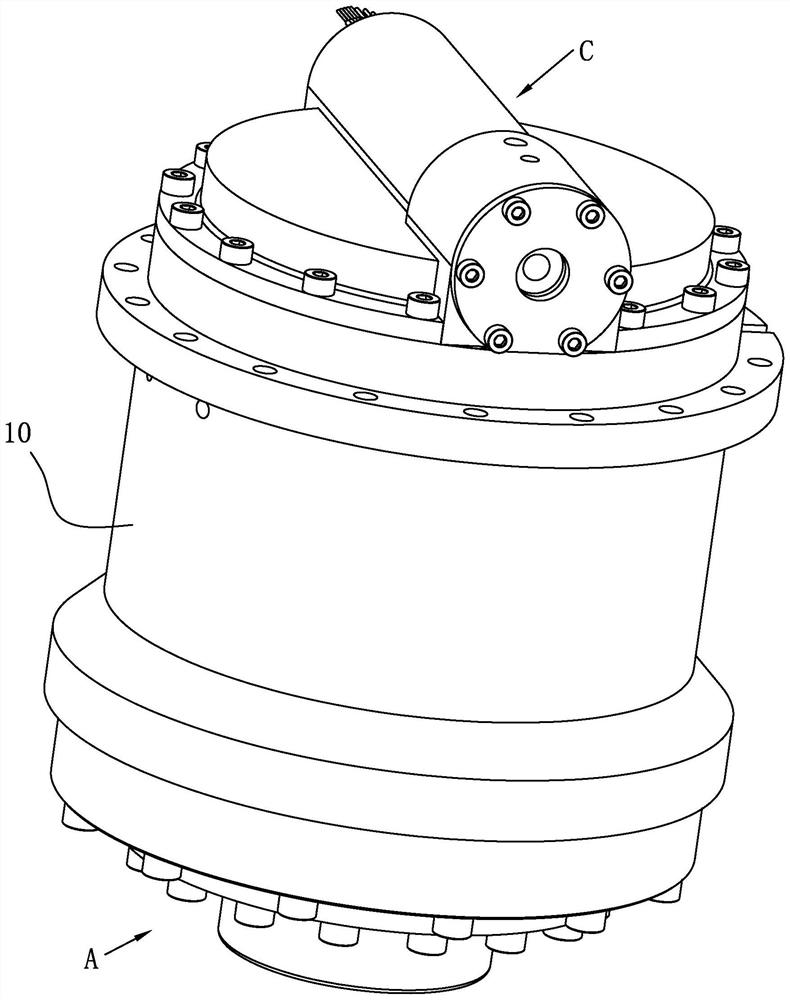

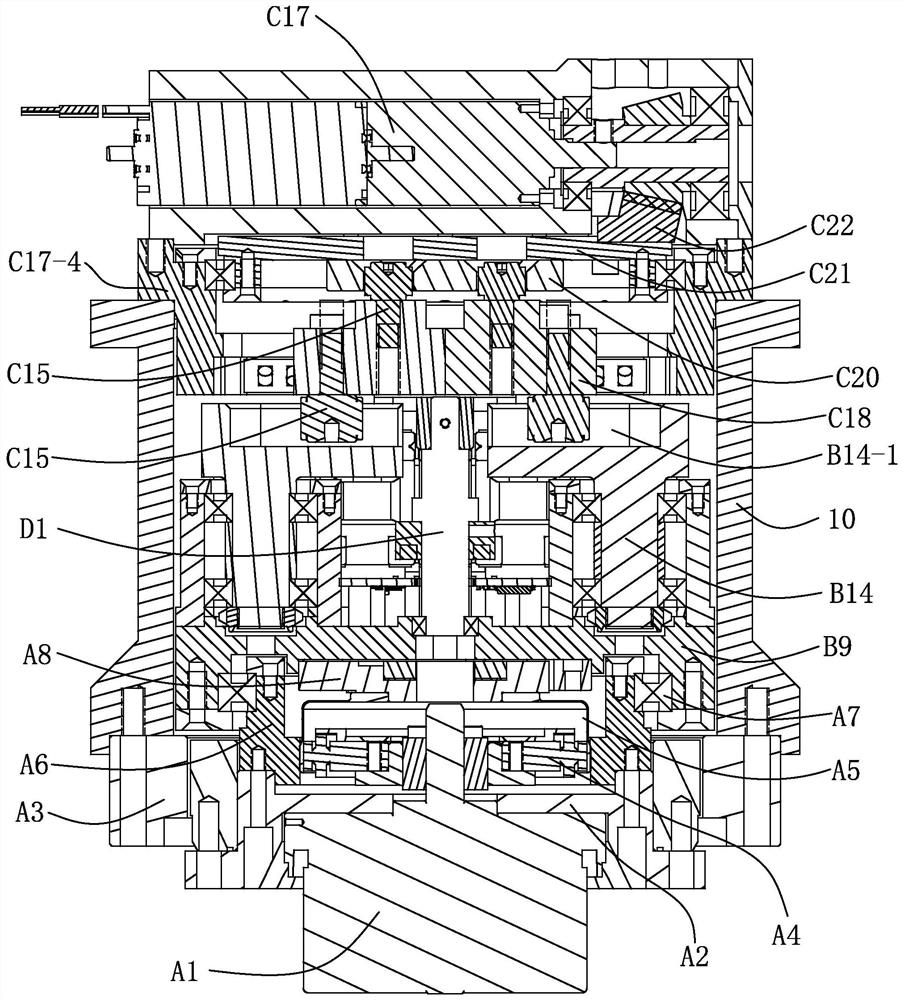

Series reconfigurable variable-stiffness robot joint structure based on permanent magnet spring

ActiveCN113084861AImprove interaction securityWide range of stiffness adjustmentProgramme-controlled manipulatorJointsCircular discReduction drive

A series reconfigurable variable-stiffness robot joint structure based on a permanent magnet spring comprises a base, a rope and a variable-stiffness motor. A kidney-shaped blind hole is machined in one end of a vertical base body of the base, an upper through hole and a lower through hole which are communicated with the kidney-shaped blind hole are machined in the other end of the vertical base body, a rotating shaft I is installed in the lower through hole through a bearing, one end of the rotating shaft I is sequentially connected with a speed reducer and a position servo motor, and a small belt wheel is installed on the portion, located in the kidney-shaped blind hole, of the other end of the rotating shaft I. A shaft body of an output disc is rotationally installed in the upper through hole through a crossed roller bearing I, the end face of the crossed roller bearing I is fixedly connected with one end of a disc of the output disc, a large belt wheel is installed on the portion, located in the kidney-shaped blind hole, of the shaft body of the output disc, a synchronous belt is installed between the large belt wheel and the small belt wheel, and the disc of the output disc is sequentially connected with a connecting rod disc and a variable-stiffness device through a crossed roller bearing II. The variable-stiffness device changes the stiffness adjusting range by rapidly adjusting the arrangement mode of the permanent magnet spring and the rope, and the application range is wider.

Owner:SHENYANG LIGONG UNIV

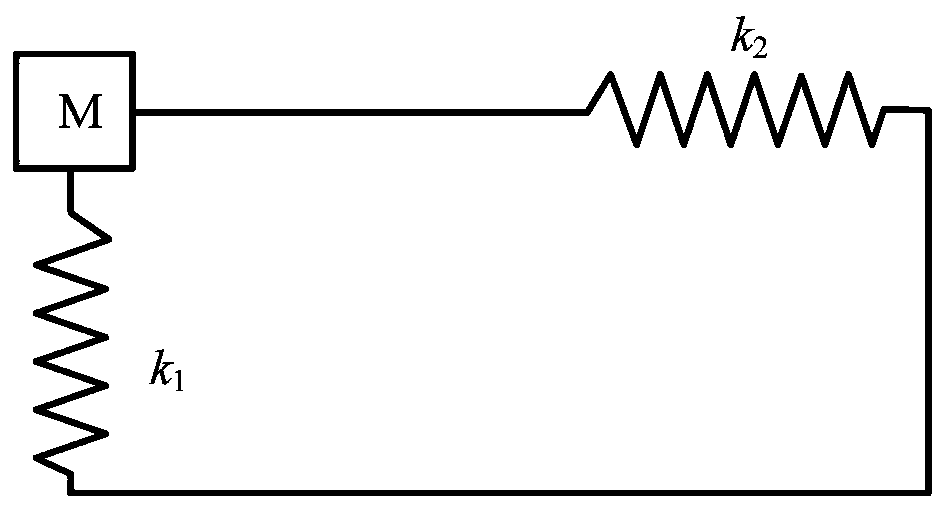

Quasi-zero stiffness vibration isolation device with mechanical frequency modulation type dynamic vibration absorber

PendingCN112984036AWide range of stiffness adjustmentIncrease falloff areaSpringsNon-rotating vibration suppressionPhysicsEngineering

The invention discloses a quasi-zero stiffness vibration isolation device with a mechanical frequency modulation type dynamic vibration absorber. The vibration isolation device is formed by combining a quasi-zero stiffness vibration isolation main system and a dynamic vibration absorber subsystem; and a bearing platform, a negative stiffness mechanism and a dynamic vibration absorber are mainly comprised. On the basis of a traditional "spring-mass block" vibration absorber, a frequency-adjustable dynamic vibration absorber of a "spring plate-sliding mass block" structure is provided, four negative stiffness mechanisms are additionally arranged on the basis of a traditional linear main system, positive stiffness and negative stiffness are connected in parallel to form the quasi-zero stiffness vibration isolation main system, and the quasi-zero stiffness vibration isolation device with the mechanical frequency modulation type dynamic vibration absorber is designed. According to the vibration isolation device, the inherent frequency of the dynamic vibration absorber can be adjusted by changing the effective length of a spring plate, the limitation that a traditional dynamic vibration absorption device is only suitable for single excitation frequency is broken through, the excitation frequency application range can be widened, excitation frequency self-adaptability is achieved, the amplitude of the quasi-zero stiffness vibration isolation main system is reduced, and self-adaptive ultralow-frequency vibration isolation effect is achieved.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +1

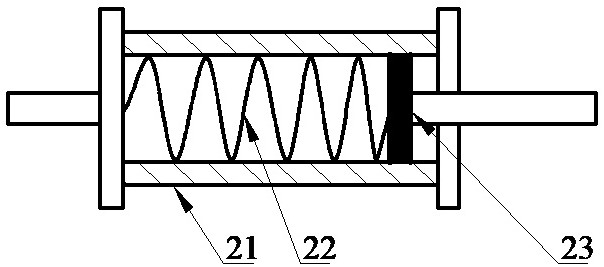

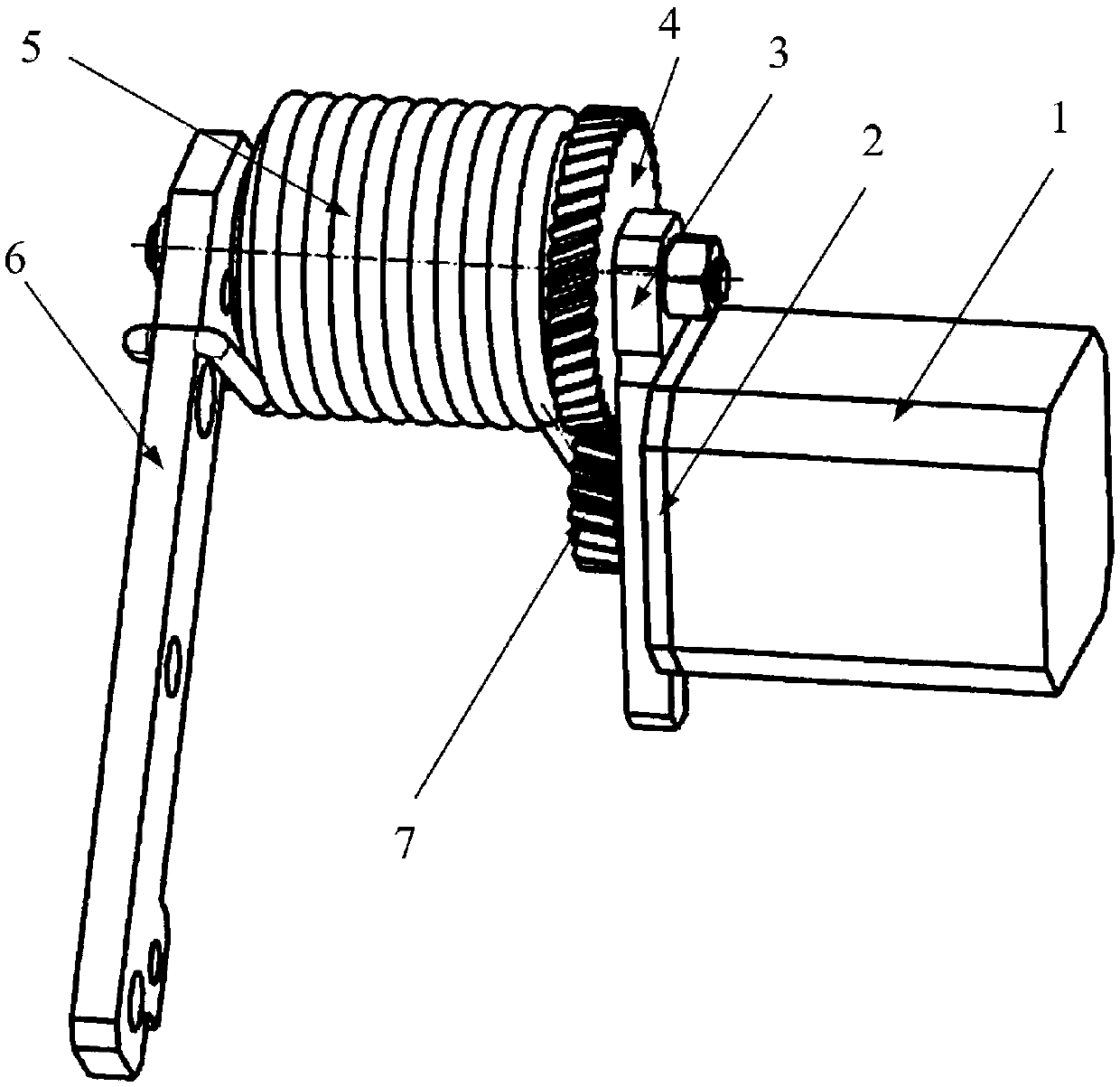

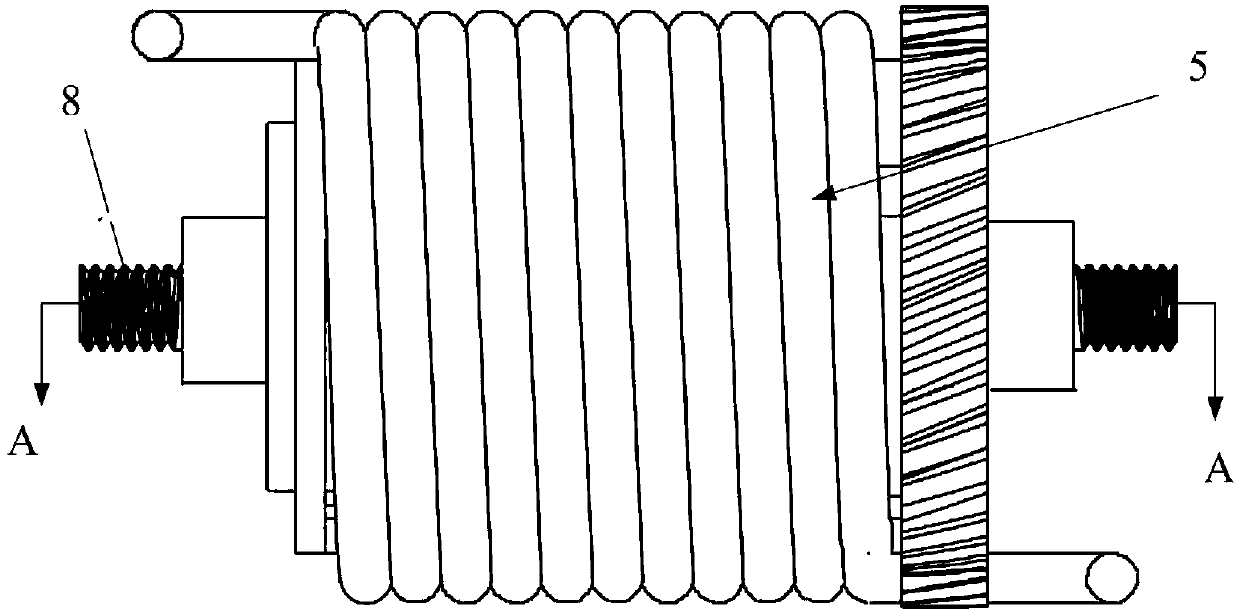

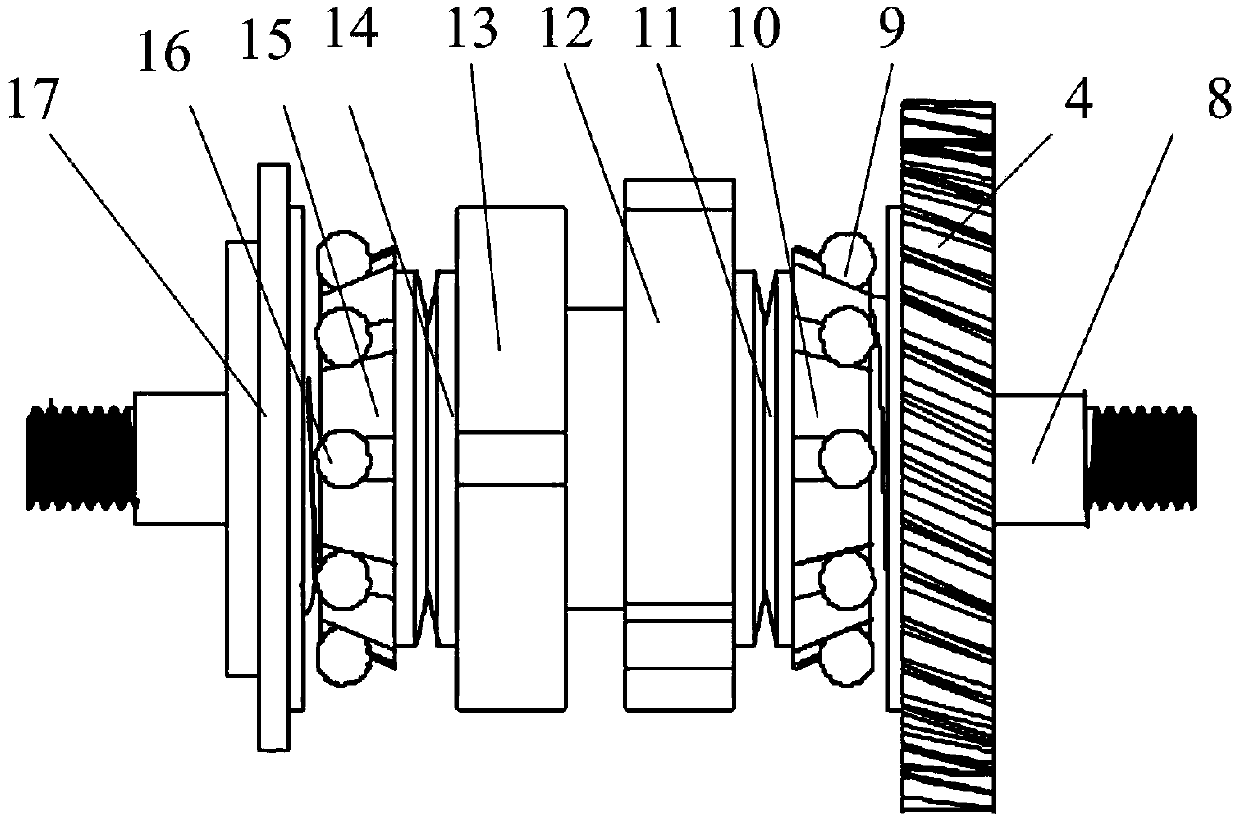

Active-passive variable stiffness joint and stiffness adjustment method thereof

ActiveCN109623871ARealize active-passive variable stiffness functionCompact structureJointsVariable stiffnessAxial displacement

The invention relates to an active-passive variable stiffness joint and a stiffness adjustment method thereof. The active-passive variable stiffness joint comprises a joint output rod, a joint drive rod, a central shaft, a stepping motor, a motor mounting base, a helical rack wheel, a torsion spring, a helical pinion, a first set of steel balls, a first cone disk, a first disc spring, a first slider, a second slider, a second disc spring, a second cone disk, a second set of steel balls, a left end cover, a first compression spring, a right-handed Nut, a left-handed nut, a sleeve, a second compression spring, a first shaft sleeve and a second shaft sleeve. By adjusting the compression of the two disc springs, the joint stiffness is changed to achieve the active variable stiffness function of the joint; when joints are relatively turned, the torsion spring is twisted and the sleeve is squeezed and deformed, so that the first set of steel balls and the first cone disk cooperate with eachother, and the second set of steel balls and the second cone disk cooperate with each other to convert the radial displacement into axial displacement, the first disc spring and the second disc springare compressed to hinder the relative rotation of the joint drive rod and the joint output rod, and therefore flexible output of the joint is achieved.

Owner:HEBEI UNIV OF TECH

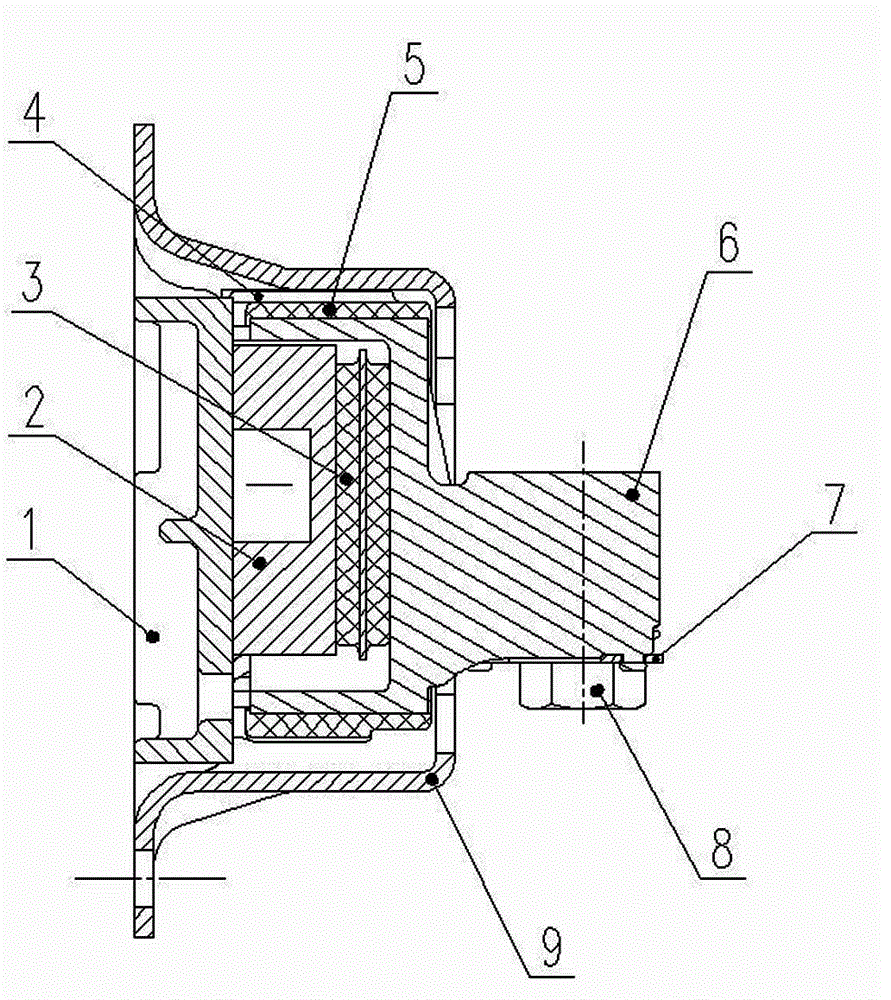

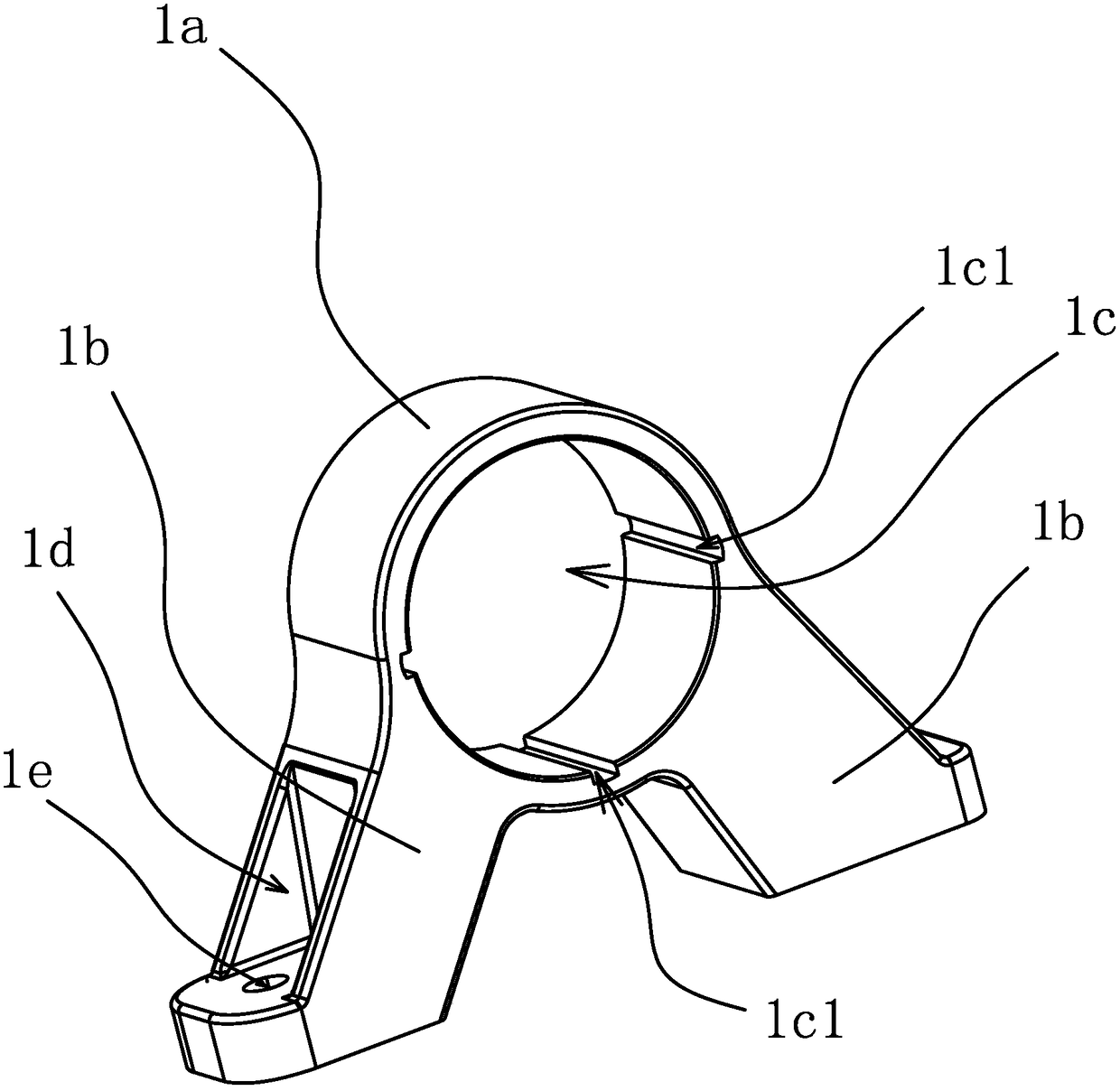

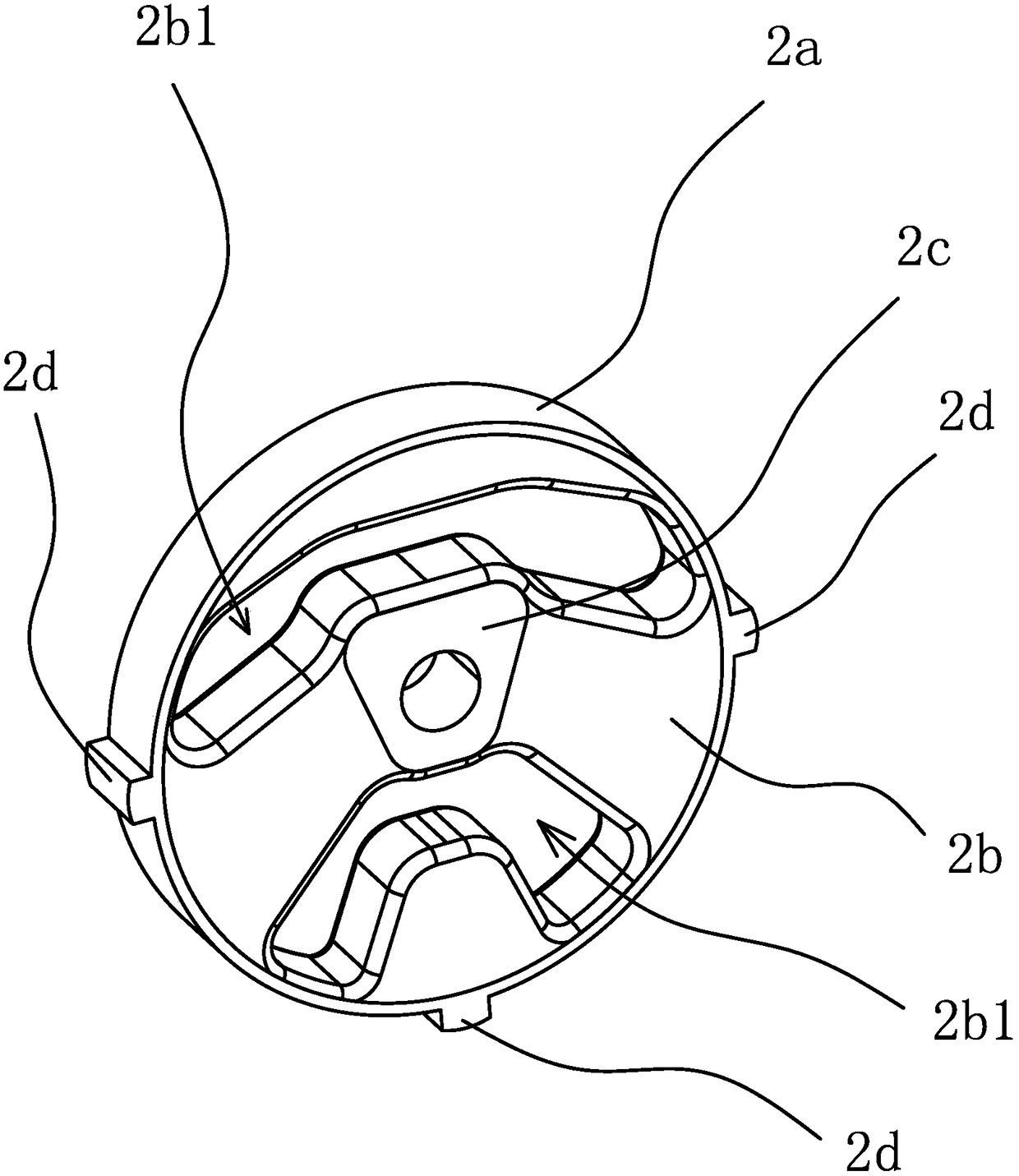

Heavy car engine rear suspension cushion assembly

InactiveCN104648110AWide range of stiffness adjustmentGood vibration reduction effectJet propulsion mountingInternal combustion mountingCar manufacturingEngineering

The invention discloses a heavy car engine rear suspension cushion assembly, and relates to the technical field of car manufacturing. The heavy car engine rear suspension cushion assembly comprises a hollow cone-shaped outer shell with holes in two ends and an inner frame arranged in a cavity of the outer shell, wherein the bigger end of the outer shell is flanged outwards, the smaller end of the outer shell is flanged inwards, and the shape of one end of the inner frame is a hexahedral hollow cavity; the shape of the other end of the inner frame is cuboid, the cuboid of the inner frame stretches out from the hole of the smaller end of the outer shell, a main rubber block and a plastic plate are radially and successively arranged between the hollow cavity of the inner frame and an inner cavity of the outer shell; the hollow cavity of the inner frame is internally and successively provided with a vibration block and a limiting block, and the limiting block props against a baffle plate, the baffle plate is fixedly arranged on the bigger end of the outer shell. The heavy car engine rear suspension cushion assembly is used for solving the problem that the existing heavy car engine damper device is time-consuming and labor-consuming in installation and poor in damping effect.

Owner:DONGFENG LIUZHOU MOTOR

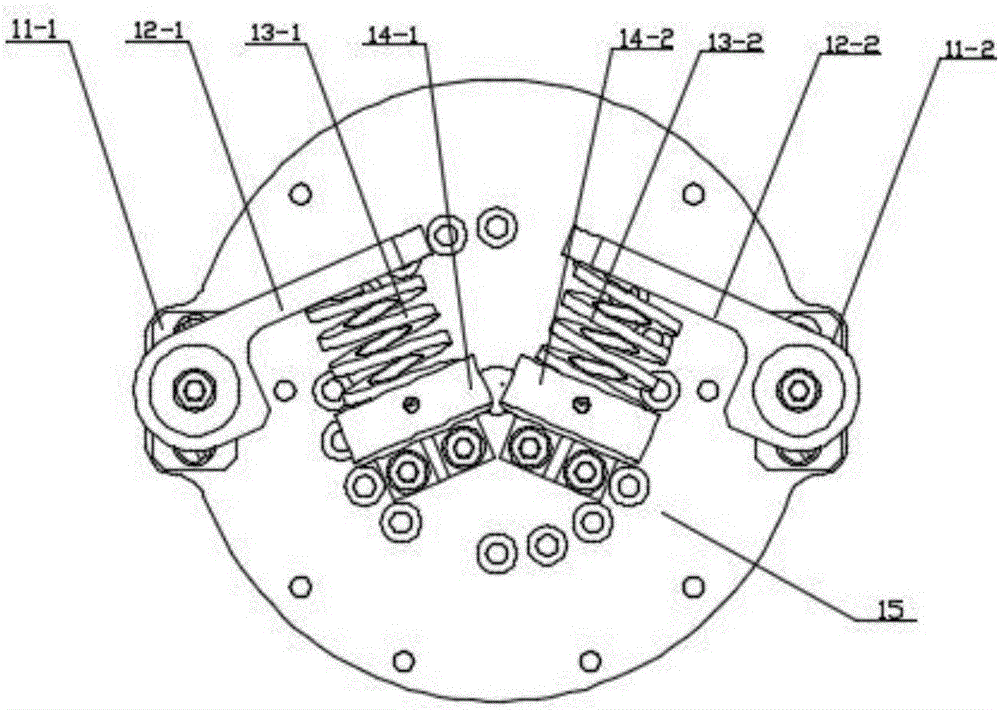

Variable-stiffness joint with symmetrical compression springs

The invention provides a variable-stiffness joint with symmetrical compression springs, and belongs to the field of bionic robots. The variable-stiffness joint comprises a base, a joint connecting rod, a position motor, a stiffness motor and a stiffness adjusting module, the stiffness adjusting module is composed of rollers and symmetrical structures comprising cam discs and the springs, the rollers are connected onto a roller retainer, the position motor is fixed on the base, the output end of the position motor is connected with the roller retainer, the stiffness adjusting module is arrangedon the base, the joint connecting rod is fixedly connected with one cam disc, the stiffness motor is fixedly connected with the joint connecting rod, and the output end of the stiffness motor is connected with the other cam disc. The variable-stiffness joint structure composed of the rollers, and the cam discs and the springs which are symmetrically arranged on the two sides is adopted, the structure is simple and reliable, the size is small, the same flexible effect can be achieved through forward driving and reverse driving, the advantages of being large in output torque and wide in rigidity adjusting range are achieved, and the variable-stiffness joint can be applied to various different occasions as a modular design.

Owner:JIANGSU UNIV

Quasi-zero stiffness vibration isolator based on magnetorheological elastomer

ActiveCN111219443AImprove static stiffnessReduce dynamic stiffnessNon-rotating vibration suppressionLeaf springsElastomerDynamic stiffness

The invention discloses a quasi-zero stiffness vibration isolator based on a magnetorheological elastomer. The vibration isolator is composed of a magnetorheological elastomer assembly, a belleville spring, a current source, an acceleration sensor, a controller and a vibration isolator base; the magnetorheological elastomer assembly is composed of magnet exciting coils, the magnetorheological elastomer, a magnetorheological elastomer base, cylindrical magnet exciting carriers and an outer cylinder body, the left end of the assembly is connected with a vibration-isolated mechanism through flexible plates, and the right end of the assembly is connected with a third fixing table through a fixing bolt to provide horizontal force; and the upper end of the belleville spring is connected with thevibration-isolated mechanism in the vertical direction through a connecting bolt, and the lower end of the belleville spring is connected with the vibration isolator base through a belleville springsupporting table to provide vertical supporting force. According to the vibration isolator, the high static stiffness and low dynamic stiffness near the balance position of the vibration-isolated mechanism can be achieved, the response speed is high, and the change range is wide.

Owner:奇瑞新能源汽车股份有限公司

A tensile and torsion-resistant shock-isolation device

InactiveCN103669633BImprove tensile propertiesImprove torsion resistanceShock proofingShock resistanceHigh rise

Owner:BEIJING UNIV OF TECH

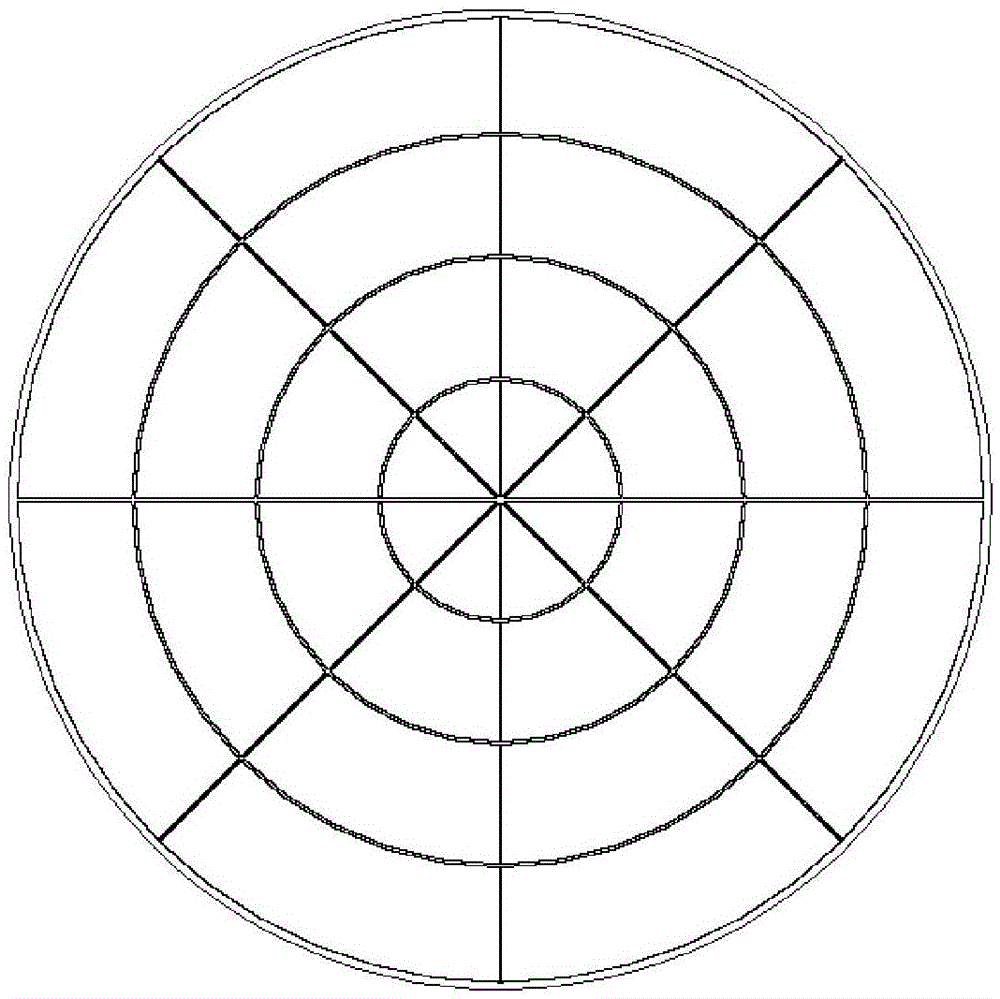

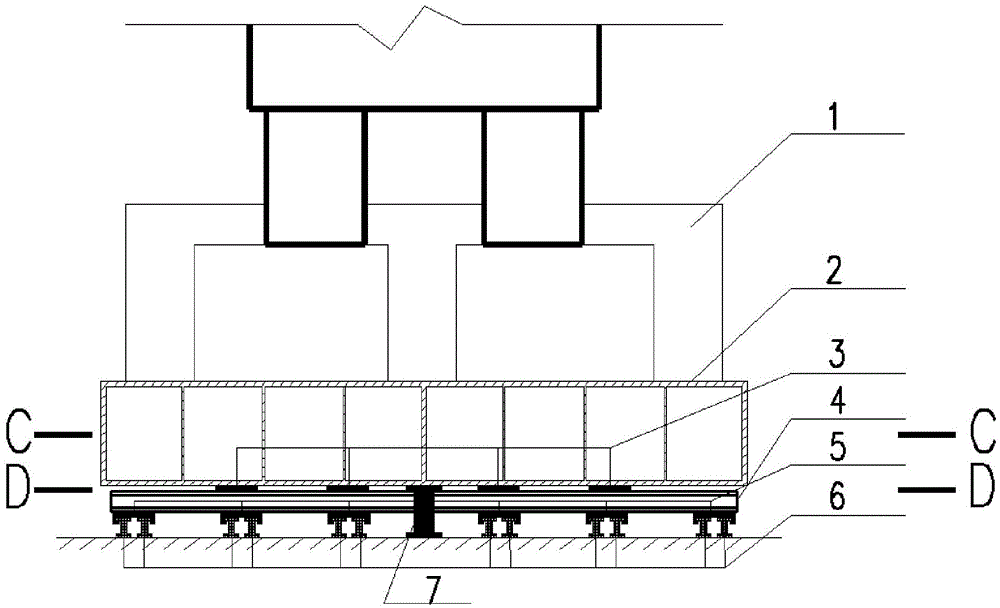

Tension resisting and twisting resisting combined shock isolation device based on linear guide rail

InactiveCN104033520AImprove tensile capacityLarge stiffness adjustment rangeShock absorbersMechanical engineeringVertical load

The invention provides a tension resisting and twisting resisting combined shock isolation device based on a linear guide rail, and belongs to the technical field of shock absorbing and isolating technique of structural engineering. The device mainly comprises a high-flexibility device (1), a rigid shock isolation pedestal (2) with relatively high rigidity and bearing capacity, a transverse limiting sliding block (3), a transverse shock isolation linear guide rail (4), a longitudinal limiting sliding block (5), a longitudinal shock isolation linear guide rail (6) and a rubber support seat (7). The tension resisting and twisting resisting combined shock isolation device based on the linear guide rail is low in cost, simple in structure, and convenient to construct; each part is clearly divided to bear force; the linear guide rails bear only the vertical load of an upper structure and bring tension resisting capacity, twisting resisting capacity and tumbling resisting capacity; the rubber support seat provides only the horizontal rigidity for the high-flexibility device; with the adoption of such combined shock isolation device, the material performance of each part can be fully utilized; in addition, the shortcoming of poor tension resisting capacity and vertical bearing capacity of the rubber support seat is overcome; the advantages of high tension resisting capacity and twisting resisting capacity, and outstanding effect on shock isolation for bases of the high-flexibility device and a high-flexibility structure are brought.

Owner:BEIJING UNIV OF TECH

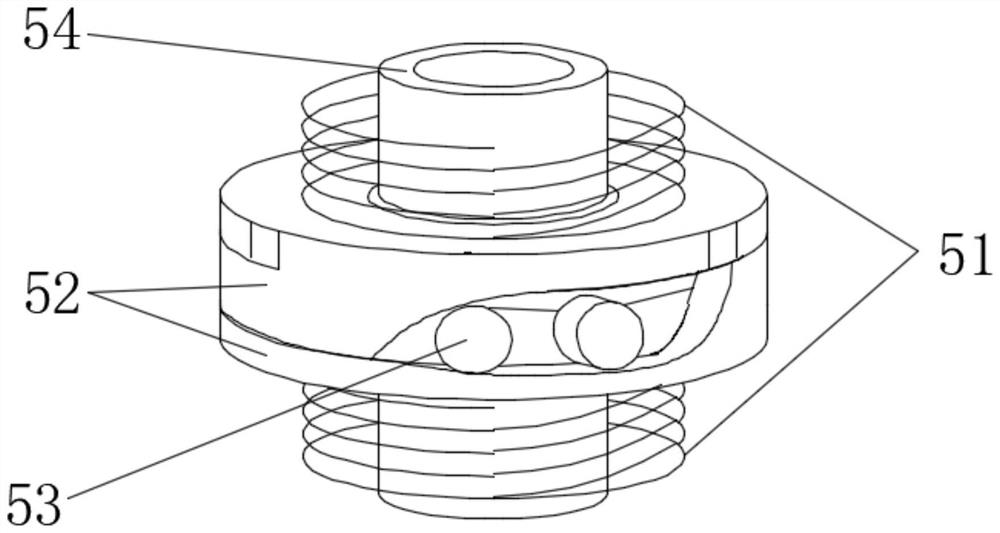

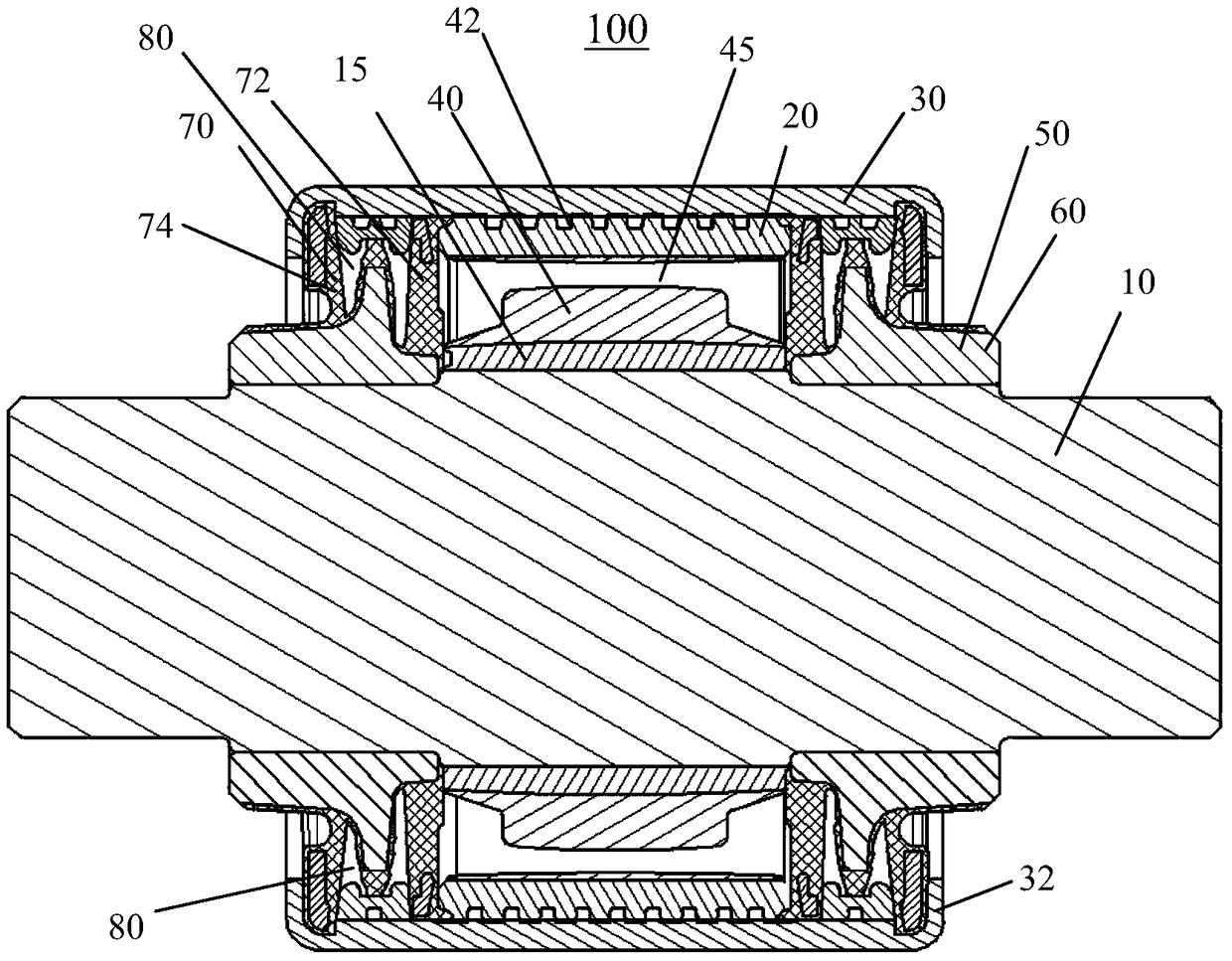

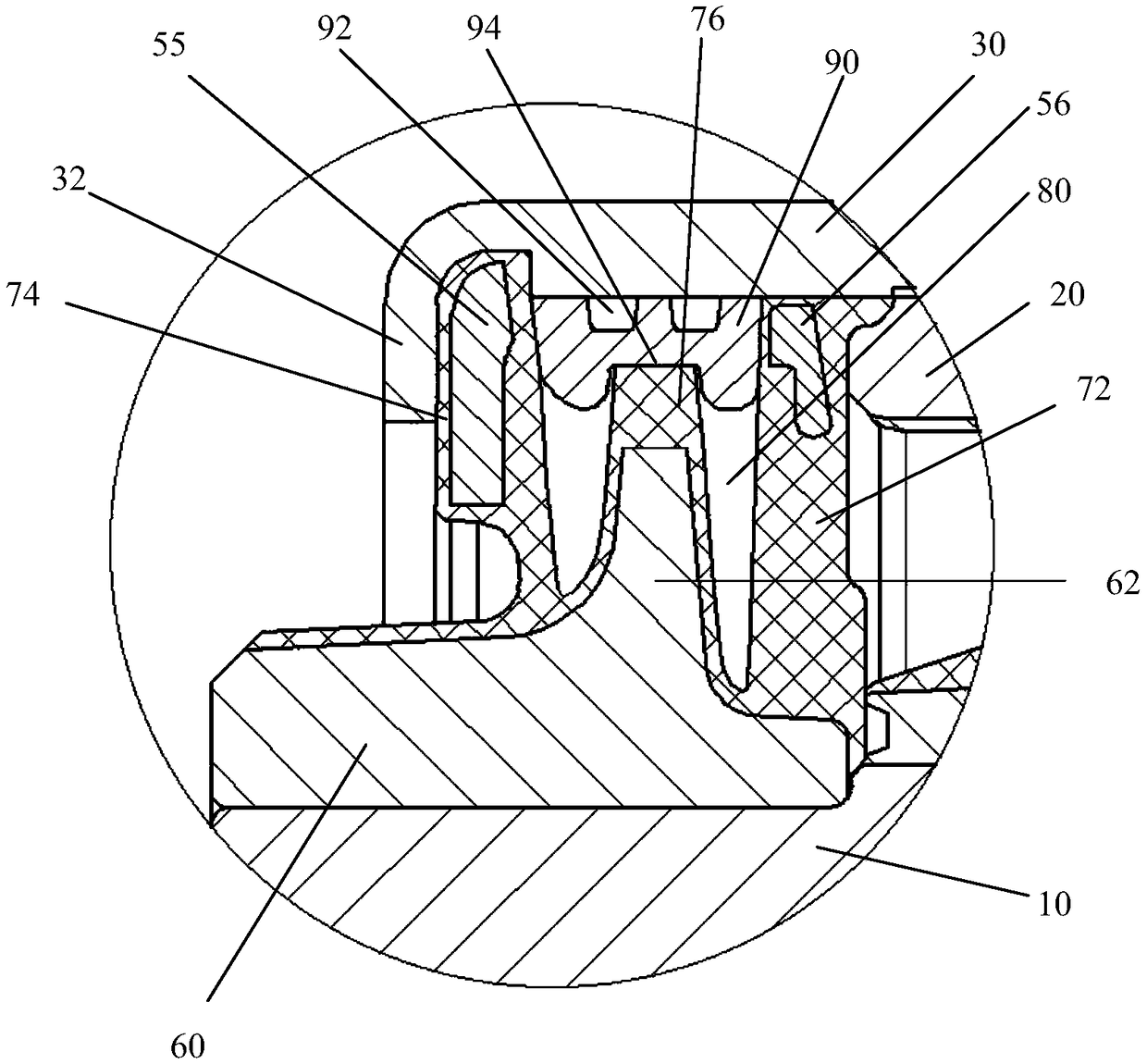

Hydraulic bushing

PendingCN109268441AWide range of stiffness adjustmentImproved variable stiffness characteristics and damping effectsSpringsSprings/dampers functional characteristicsEngineeringMechanical engineering

The invention provides a hydraulic bushing, comprising: a mandrel; a first runner member sleeving the mandrel and in sleeve shape, wherein a gap between the mandrel and the first runner member is filled with first rubber, the outer surface of the first runner member is provided with a first runner for a hydraulic fluid; and an outer sleeve that sleeves the first runner member radially in compressing manner. The first rubber is radially oppositely provided with two main fluid cavities to hold the hydraulic fluid, and the two main fluid cavities are communicated with each other via the first runner. A sealing component is arranged on the at least one axial outer side of the first runner member; the sealing component and the outer sleeve jointly define two auxiliary fluid cavities. A second runner member is arranged in each auxiliary fluid cavity; the outer surface of each second runner member is provided with a second runner for the hydraulic fluid; the two auxiliary fluid cavities are communicated with each other via the second runners.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Smart material consisting of thin-walled hollow spheres and magnetosensitive elastomers

ActiveCN109021573ASolve the mechanical propertiesOvercome the disadvantage of easy settlementMagnetic materialsElastomerPolymer science

The invention provides a smart material consisting of thin-walled hollow spheres and magnetosensitive elastomers. The material comprises magnetic particles, the thin-walled hollow spheres and a polymer matrix; the magnetic particles and thin-walled hollow spheres are evenly arranged inside the polymer matrix, and the magnetic particles encircle the thin-walled hollow spheres; the thin-walled hollow spheres are placed in a mold with a positioning circular hole or a positioning groove according to a certain arrangement form, a mixture containing magnetizable magnetic particles and a polymer matrix material is casted into the mold, or a mixed melt composed of magnetic particles and the polymer matrix material is extruded into the mold, and the mold is solidified in strong magnetic field environment to ensure that the magnetic particles therein are also arranged in a chain shape according to the direction of a magnetic field; The novel smart material with light weight, good mechanical property, controllable rigidity and damping, and large energy absorption has a very broad application prospect.

Owner:北京航数车辆数据研究所有限公司

A combined anti-tension and anti-torsion shock-isolation device with self-resetting function

InactiveCN104032846BImprove tensile propertiesImprove torsion resistanceBridge structural detailsShock proofingEngineeringMechanical engineering

The invention provides a tension resisting and twisting resisting combined shock isolation device with the self-restoring function, and belongs to the technical field of shock absorbing and isolating technique of structural engineering. The device mainly comprises a high-flexibility device (1), a rigid supporting pedestal (2), a transverse limiting sliding block (3), a transverse shock isolation linear guide rail (4), a transverse shock absorbing tension spring (5), a transverse shock absorbing tension spring support (6), a layering separating plate (7), a longitudinal limiting sliding block (8), a longitudinal shock isolation linear guide rail (9), a longitudinal shock absorbing tension spring support (10) and a longitudinal shock absorbing tension spring (11). The combined shock isolation device has the advantages that the material performance of each part can be fully utilized; in addition, the shortcoming of poor tension resisting capacity and vertical bearing capacity of a rubber support seat is overcome; the advantages of high tension resisting capacity and twisting resisting capacity, and outstanding effect on shock isolation for bases of the high-flexibility device and a high-flexibility structure are brought.

Owner:BEIJING UNIV OF TECH

Flexible manipulator joint device with controllable damping and stiffness

ActiveCN106763589BMeet needsChange rheological propertiesSpringsJointsMedial axisMagnetorheological fluid

Owner:CHONGQING UNIV

A rigidity-adjustable engine mount

ActiveCN105818666BReduce in quantityReduce wasteJet propulsion mountingInternal combustion mountingEngineeringMaterial resources

The invention provides an engine suspension with the adjustable rigidity and belongs to the technical field of machines. The engine suspension solves the problems that an existing engine suspension is limited in adjusting range, high in cost and poor in adaptability. The engine suspension with the adjustable rigidity comprises a connecting support and main suspension springs. The connecting support is provided with an installation cavity penetrating the two end faces of the connecting support. The two end faces of each main suspension spring are smooth planes. The main suspension springs can be arranged in the installation cavity and connected with the inner wall of the installation cavity in a tight fit manner. The axial depth of the installation cavity is larger than the thickness of the main suspension springs. By the adoption of the engine suspension, the rigidity of the suspension can be directly changed directly through the increase and reduction of the number of the main suspension springs, the rigidity is adjusted conveniently and rapidly, the rigidity adjusting range is wide, the rigidity adjusting accuracy is high, the adaptability to different vehicle models and different engines is good, manpower and material resources can be saved to a great extent, waste and cost are reduced, and a development period is shortened.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

A Cascadable Expandable Variable Stiffness Robot Joint

The invention relates to a cascadable variable-stiffness robot joint. High-precision adjustment of the stiffness of the joint is conducted by using flexible shaft disc mechanisms composed of sheaves, steel wires and bent leaf springs for providing variable torque and using a rotary supporting mechanism composed of a supporting frame, a gear worm and a servo motor for uniquely determining the positions of working end points of the arc-shaped bent leaf springs which are symmetrically distributed on the shaft disc mechanisms; the energy storage capacity of the joint can be adjusted by changing the cascade number of the flexible shaft disc mechanisms; and a differential gear set mechanism is used for achieving coupled motions including rotation of the robot joint, rotation of the joint motor and rotation of an elastic mechanism, so that the balance position and stiffness of the joint are changed at the same time, and forward-rotation stiffness and reversed-rotation stiffness are made adjustable.

Owner:BEIJING INST OF CONTROL ENG

A multi-degree-of-freedom variable-stiffness joint manipulator

ActiveCN112092009BMajor rangeImprove carrying capacityProgramme-controlled manipulatorJointsRobotic armControl engineering

A multi-degree-of-freedom variable-stiffness articulated manipulator, which includes a mounting base, a base joint, three end joints and four connecting rods; the input end of the base joint is connected to the mounting base, and the output end of the base joint is connected to the first Link connection, the first link is connected to the input end of the first end joint, the output end of the first end joint is connected to the second link, the third link is connected to the input end of the fourth end joint, and the third link is connected to the input end of the fourth end joint. The output ends of the four end joints are connected to the fourth connecting rod; the base joint includes the first joint housing, the main drive module, the elastic module and the stiffness adjustment module; the first joint housing is connected to the first connecting rod, and each end joint includes The second joint casing, the main driving mechanism, the elastic mechanism and the stiffness adjustment mechanism; the second connecting rod, the third connecting rod and the fourth connecting rod are respectively connected with the second joint casing corresponding to the end joint, and the rigidity adjustment range of the mechanical arm of the present invention is large , which can meet the requirements of safe interaction of collaborative manipulators.

Owner:HARBIN INST OF TECH

Variable stiffness device controlled by piezoelectric ceramics and its control method

ActiveCN110509264BChange frictionWide range of stiffness adjustmentProgramme-controlled manipulatorBall bearingEngineering

The present invention proposes a variable stiffness device controlled by piezoelectric ceramics and its control method, including: a torque speed input part and a torque speed output part; the torque speed input part includes a cylindrical ring with multiple spline grooves on the inner wall and a plurality of fine adjustment block; the top of the flat key of the fine-tuning block is pasted with a piezoelectric ceramic sheet, and has an arc surface with a slope; the torque and speed output part includes a circular frustum and a screw hole on the side of the small bottom of the circular frustum. Connect the shaft and the output shaft on the side of the large bottom of the conical frustum; the inclination of the inclination of the conical frustum is the same as that of the bottom surface of the contact part; the fine-tuning block and the conical frustum pass through the positioning bolts and the mounting plate on the side of the connecting shaft, and the input shaft The cover plate on one side maintains limited contact; the first stacked piezoelectric ceramic group, the second stacked piezoelectric ceramic group and thrust ball bearings are arranged sequentially between the positioning bolts and the mounting plate. Compared with conventional methods, it has a larger stiffness adjustment range, and the stiffness is precisely controllable.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com