A rigidity-adjustable engine mount

An engine mount and adjustable technology, which is applied in the mechanical field to achieve the effects of cost reduction, force buffering, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

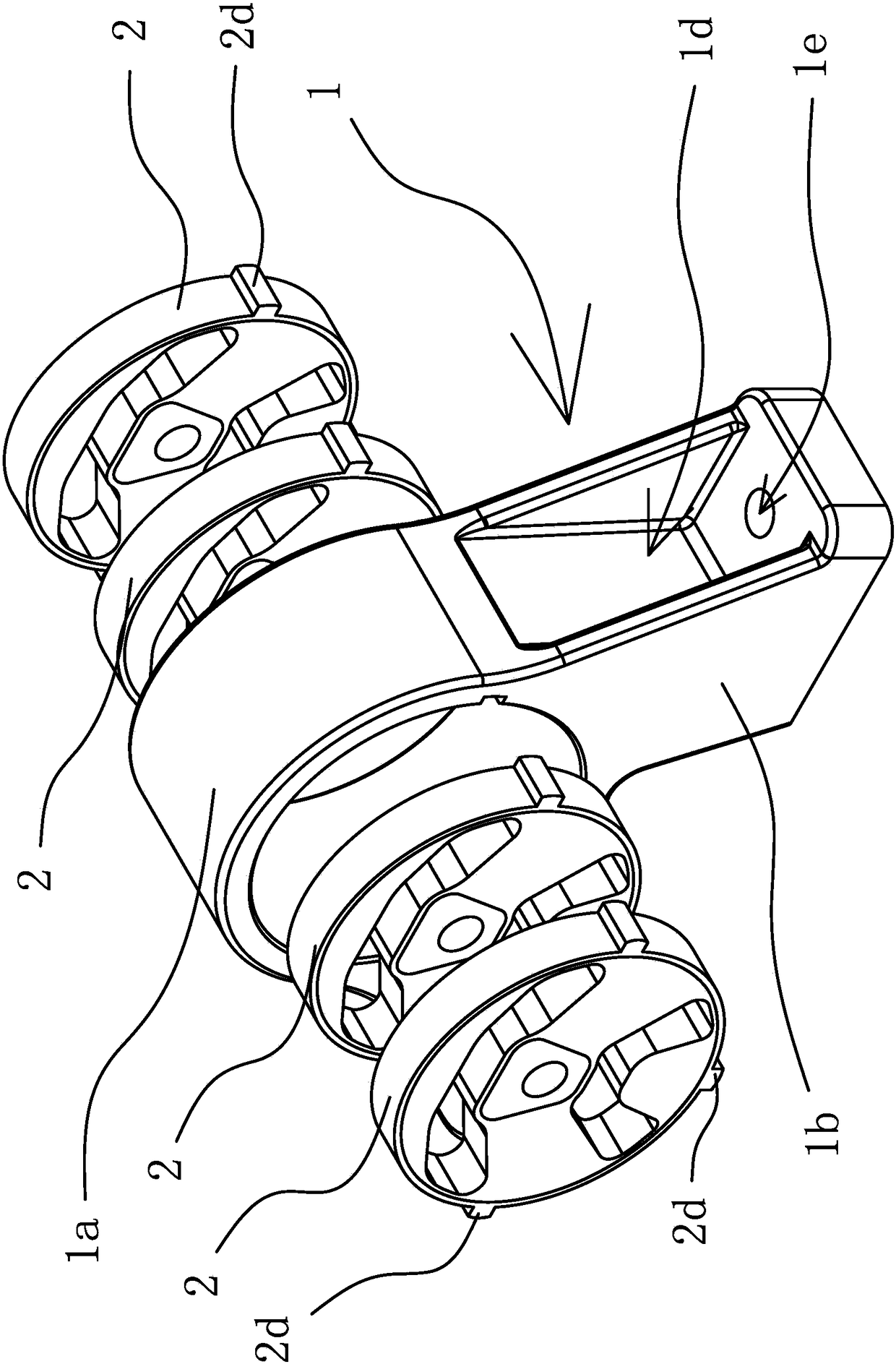

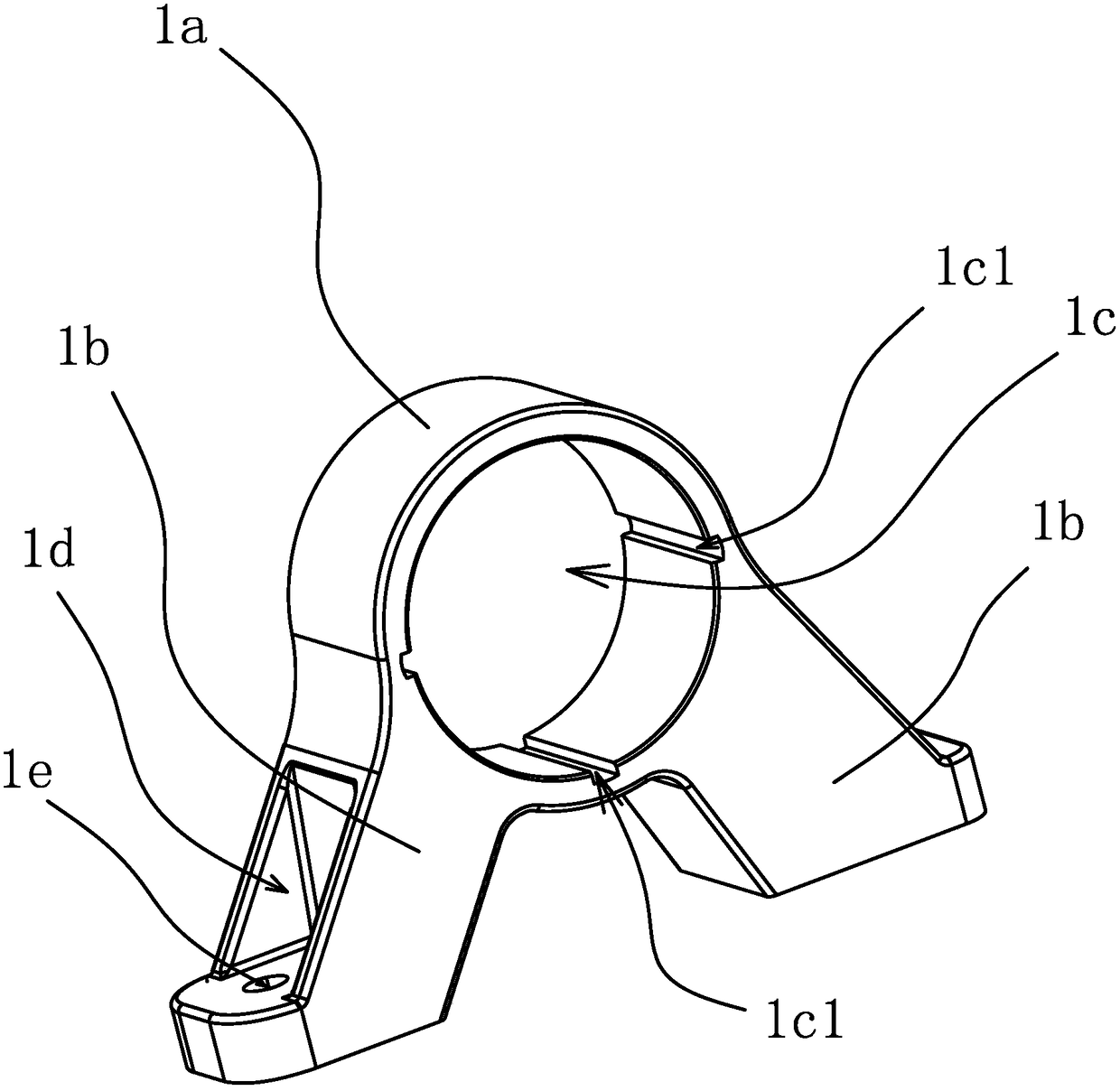

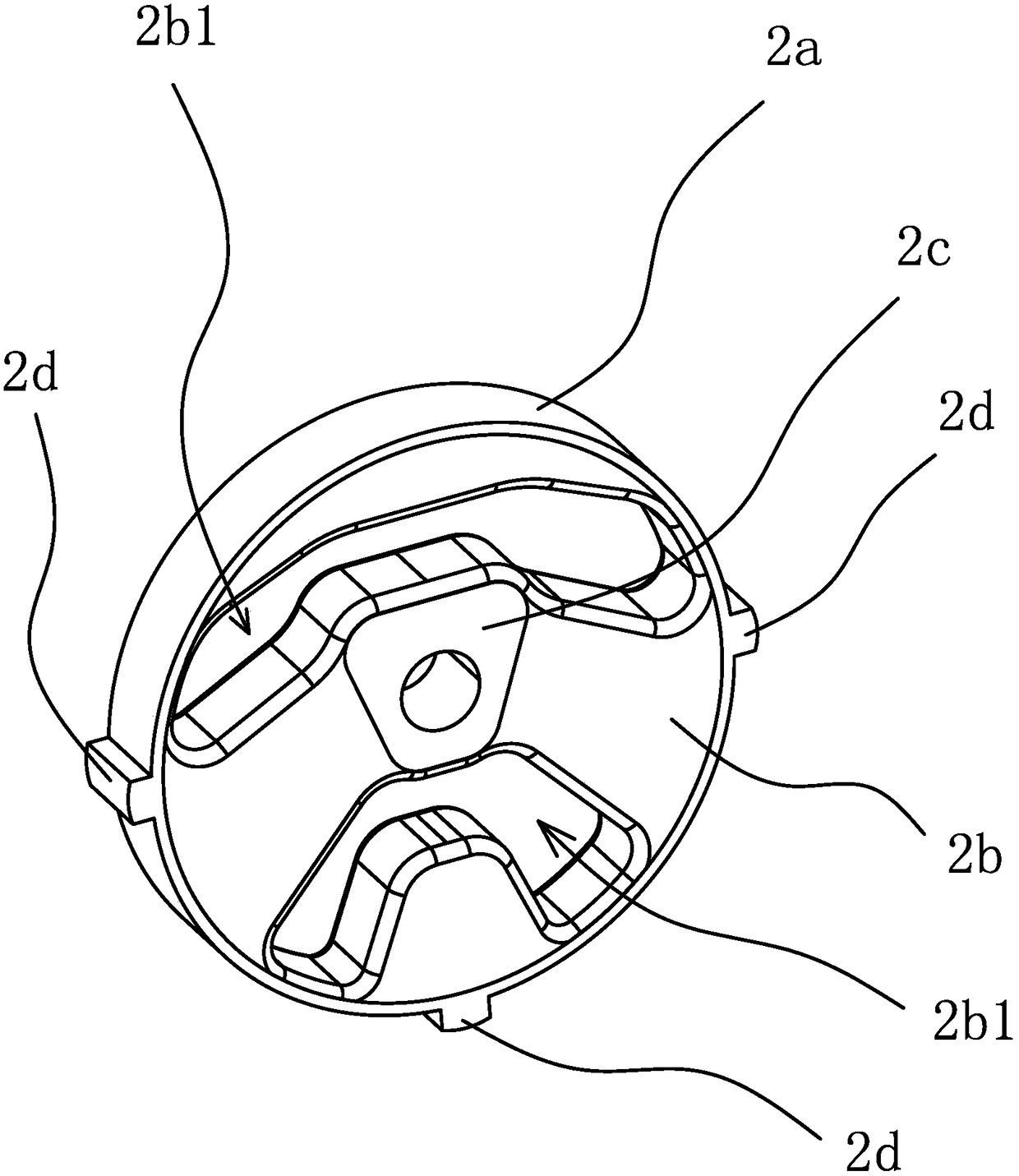

[0035] Such as Figure 1-4 As shown, the engine mount with adjustable stiffness includes a connection bracket 1 and a suspension main spring 2. The connection bracket 1 has an installation cavity 1c that runs through both ends of the connection bracket 1. The suspension main spring 2 and the installation cavity 1c are both in the shape of The columnar, suspended main spring 2 can be arranged in the installation cavity 1c and tightly fitted with the inner wall of the installation cavity 1c.

[0036] Specifically, as figure 2 As shown, the connecting bracket 1 includes a cylindrical mounting part 1a and two legs 1b, the mounting cavity 1c is the inner cavity of the cylindrical mounting part 1a, the two legs 1b are relatively inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com