Milling passive vibration reduction clamp

A milling and fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of complexity, high manufacturing cost, multi-control of components, etc., to achieve strong adaptability of parts, no pollution to the environment, easy to use maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

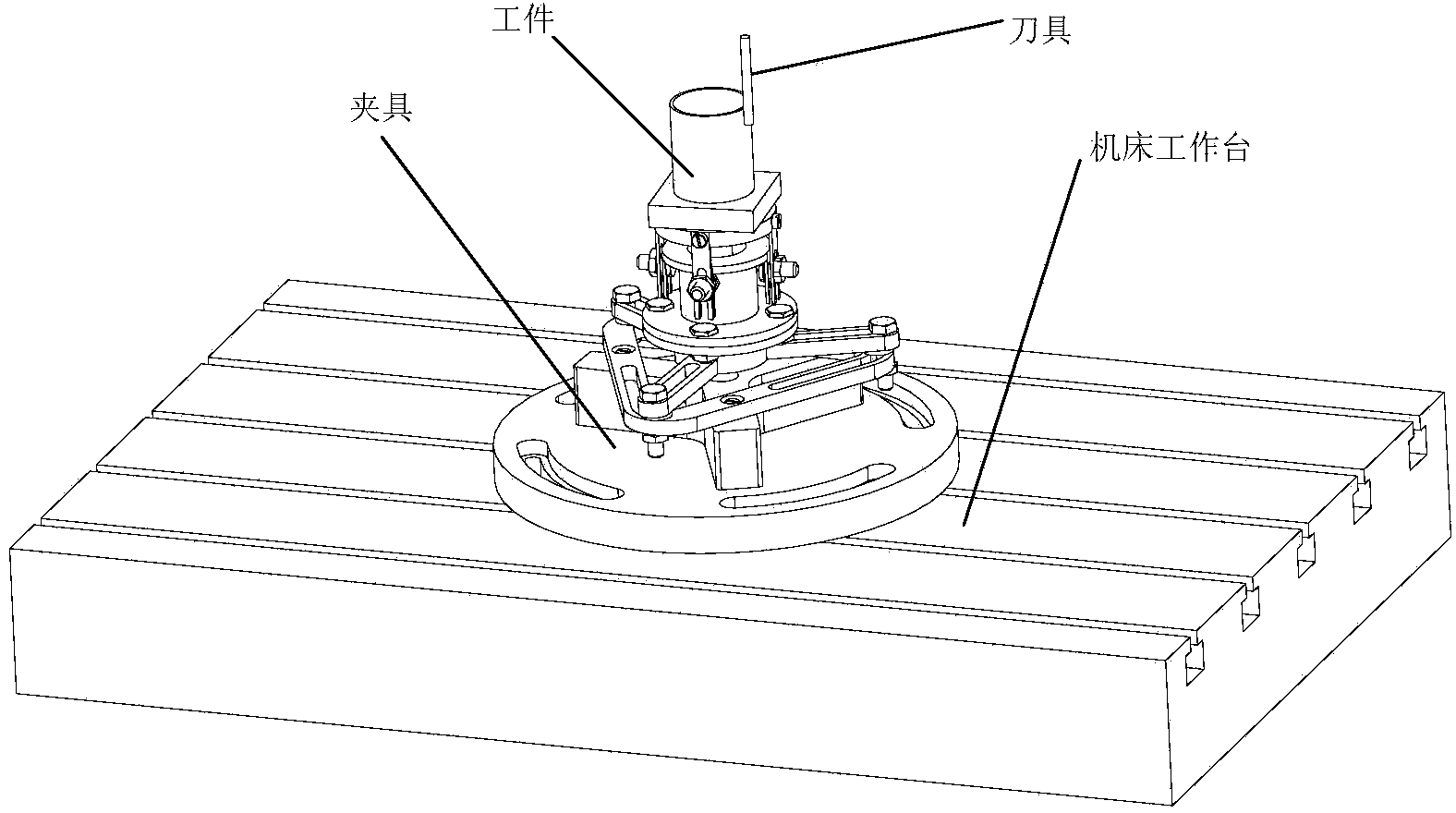

[0028] The present invention will be further described in detail below in conjunction with accompanying drawings and examples. A passive damping fixture for milling processing, the schematic diagram of its processing application is as follows figure 1 shown. The passive damping fixture for milling processing is fixed on the workbench of the machine tool, the weakly rigid part to be processed is fixed on the fixture, and then the tool cuts the part.

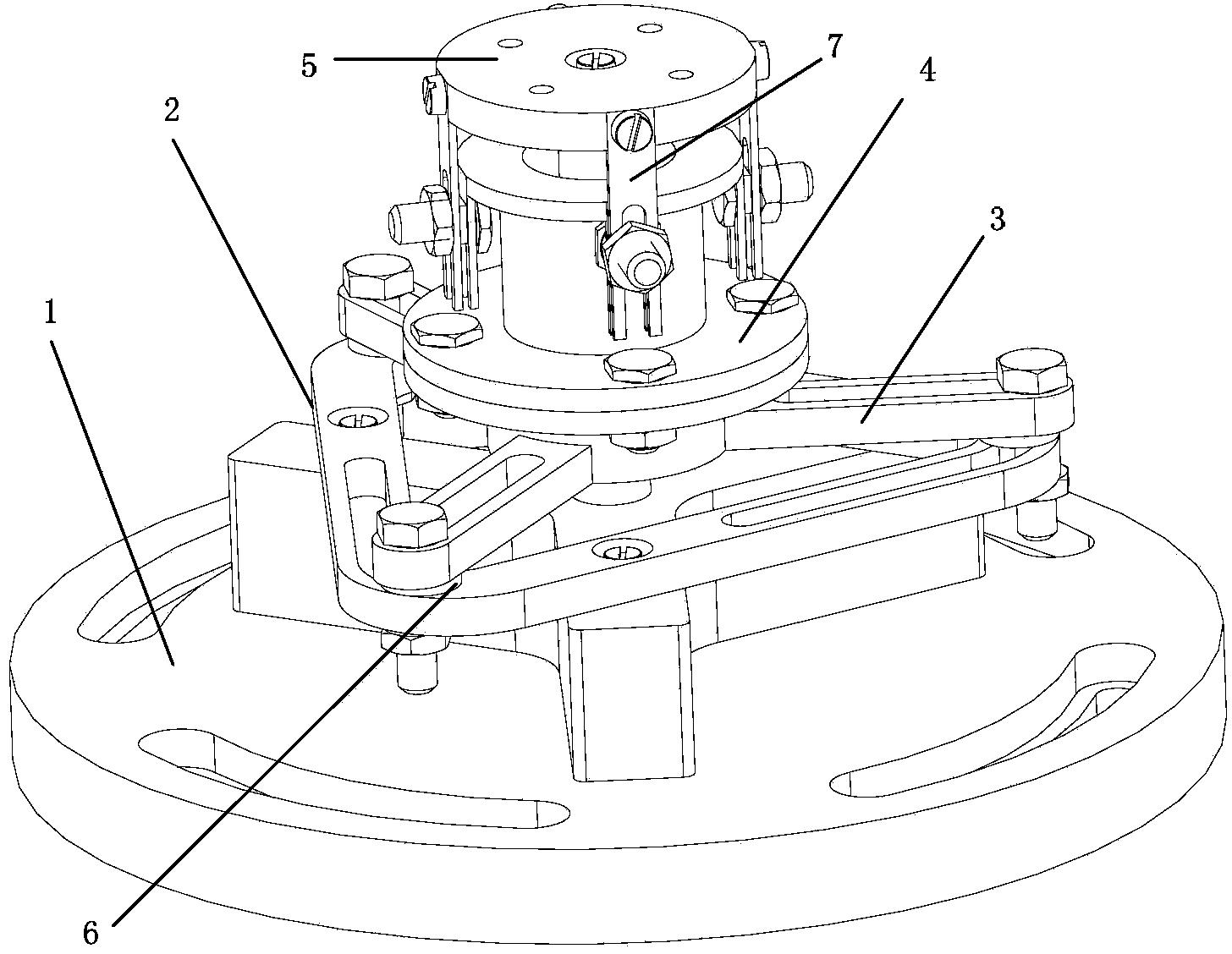

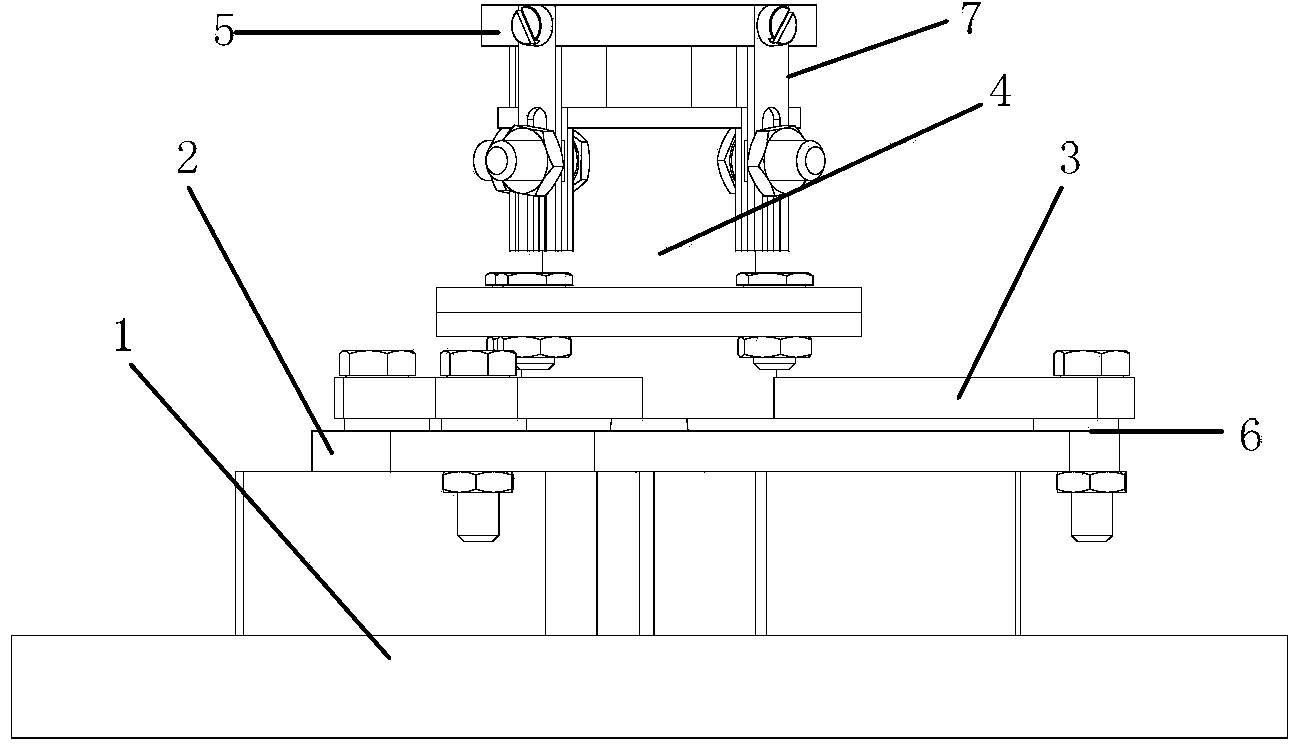

[0029] The invention relates to a passive damping fixture used for milling of weak rigid parts. like figure 2 As shown, the device is composed of a base 1, a support member 2, a rotating member 3, a support adjustment member 4, a workbench 5, a support block 6, an adjustment plate 7 and corresponding screws, bolts and nuts. When using the device, first fix the base 1 on the machine table, and then fix the support 2 with the base 1 with screws, as figure 2 and Figure 4 The positions of middle parts 1 and 2 are shown. Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com