Patents

Literature

48results about How to "High quality and efficient processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

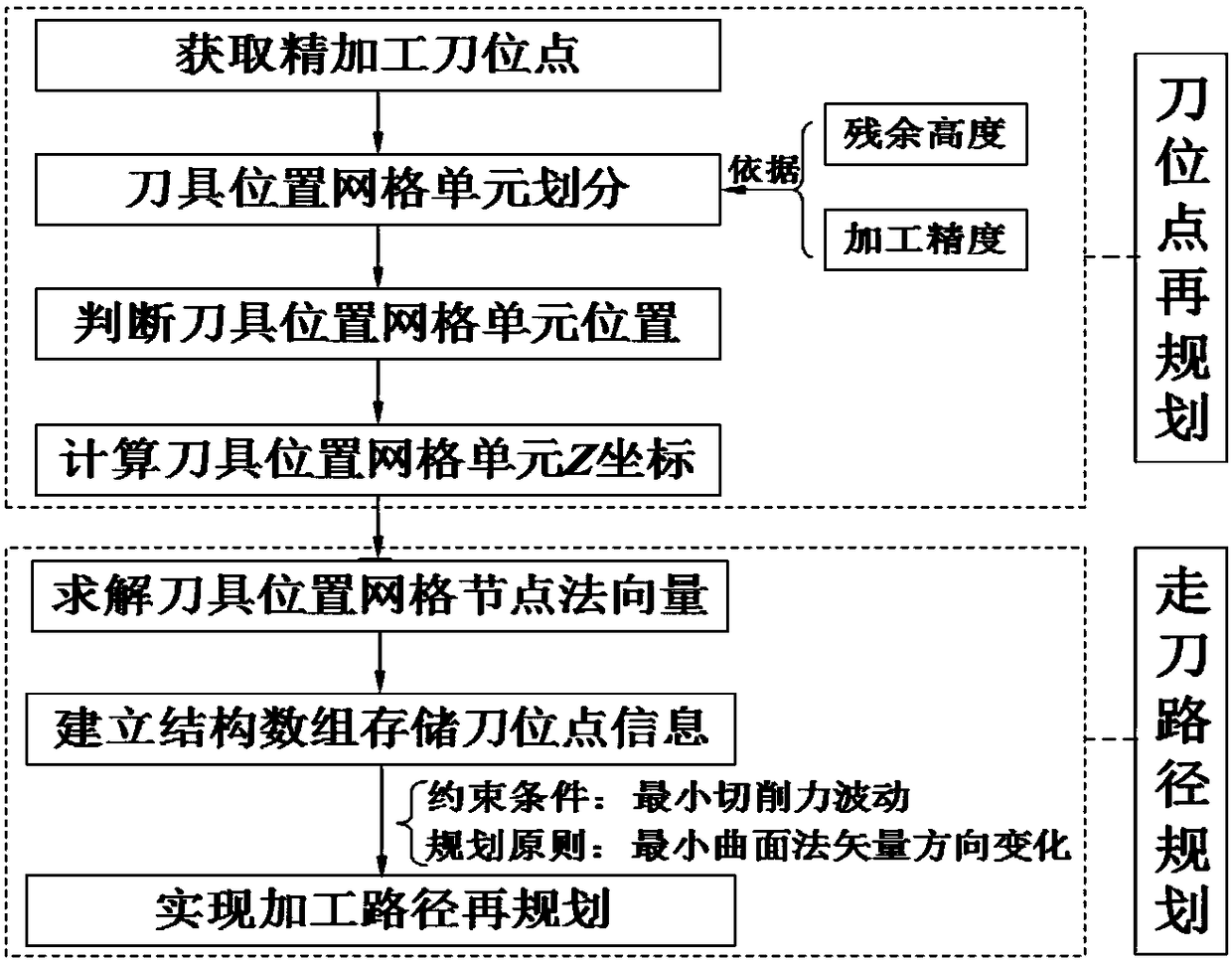

Curved-surface machining cutter track planning method using cutting force fluctuation as constraint

ActiveCN106125666AExcellent line spacingExcellent step sizeNumerical controlCutter locationEngineering

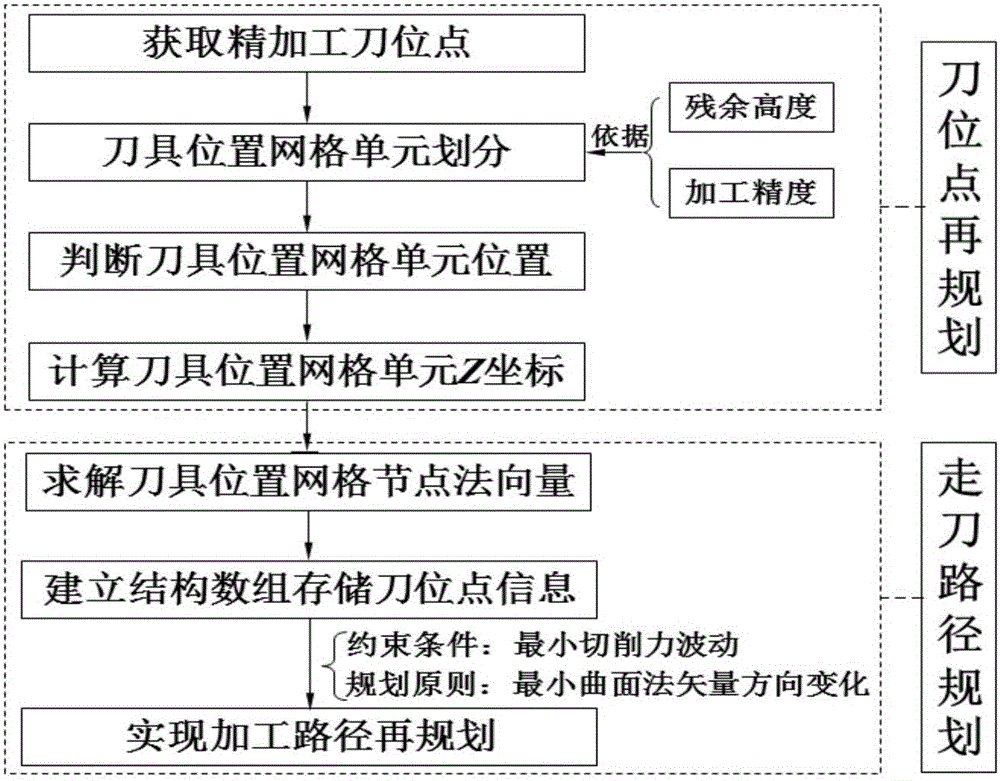

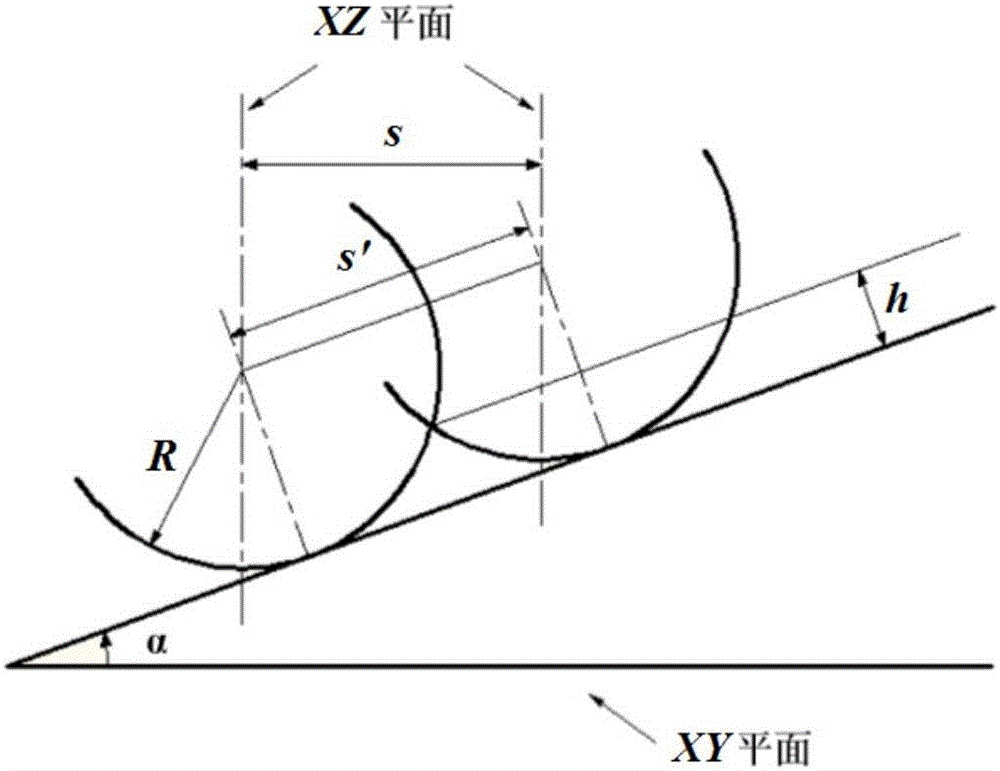

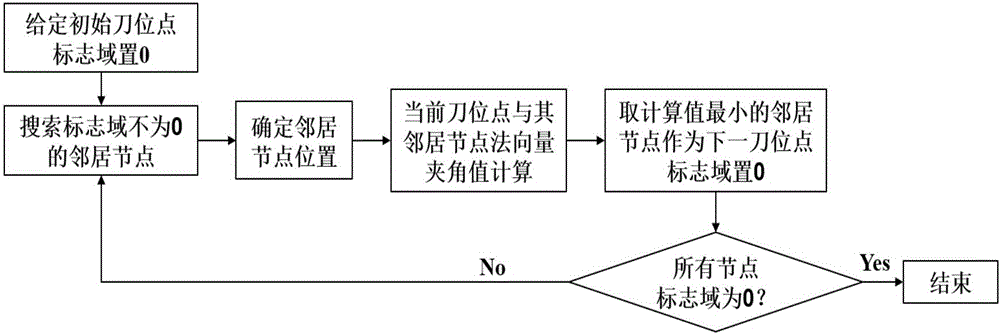

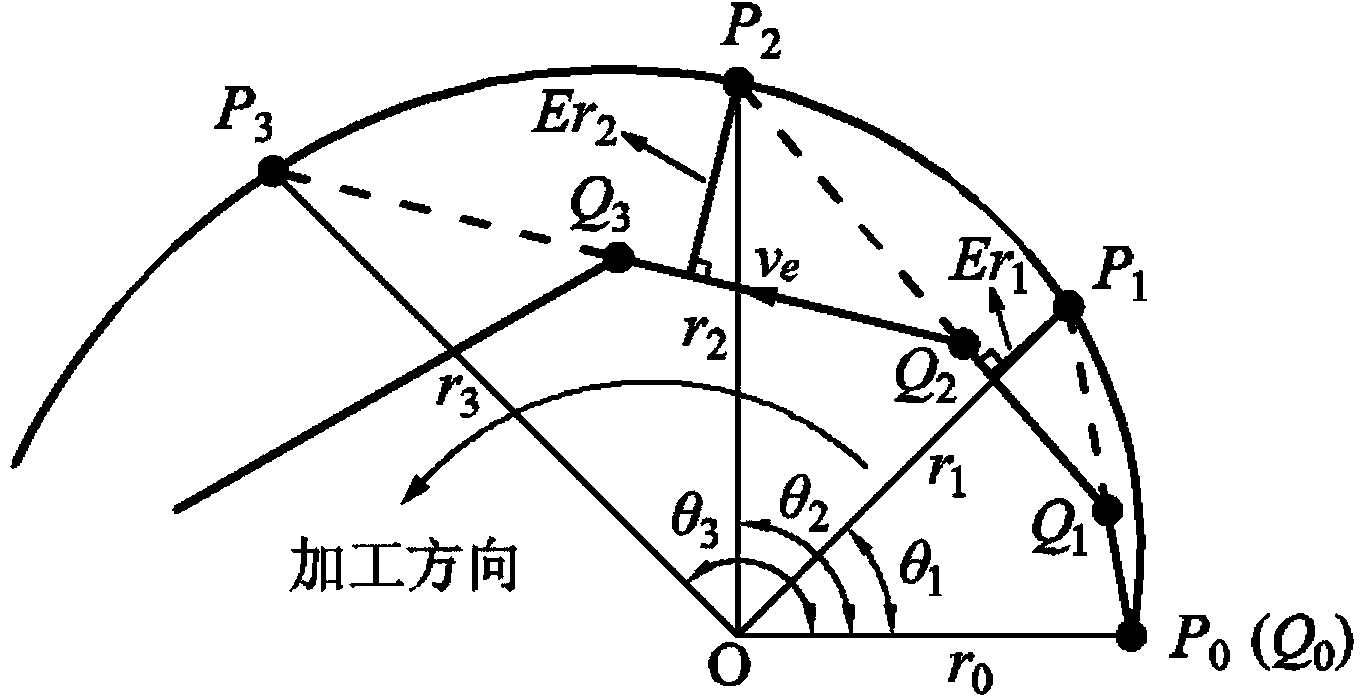

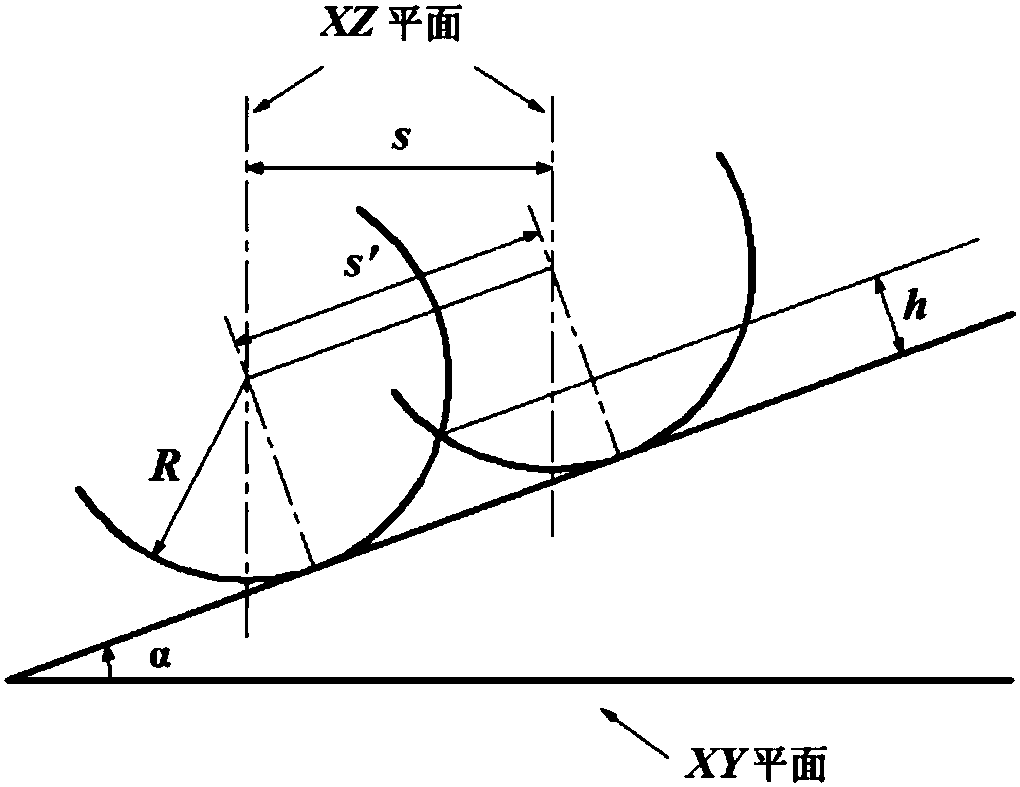

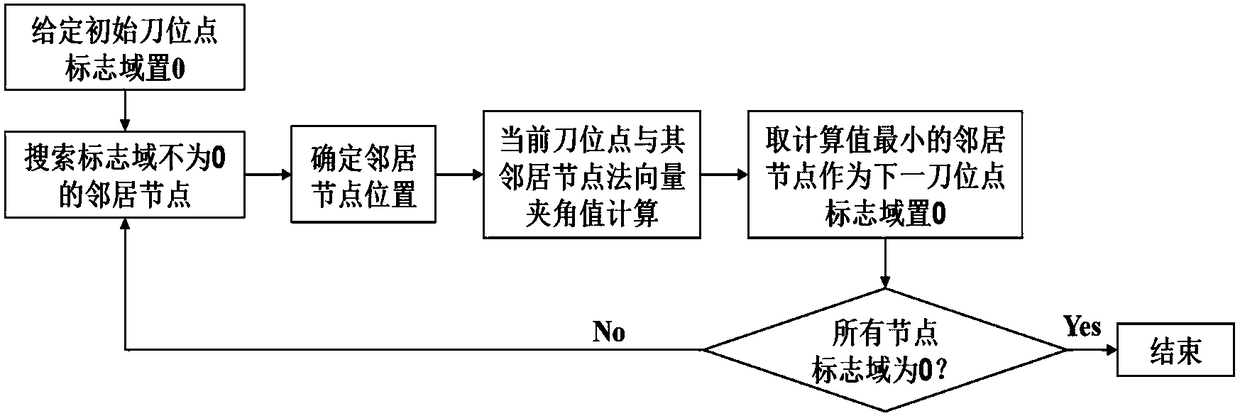

The invention relates to a curved-surface machining cutter track planning method using cutting force fluctuation as a constraint, which belongs to the technical field of the high-efficiency milling processing for complicated curved-surface parts. According to the method, on the basis of cutter location point data obtained by an equal-residual-height method, an optimal feeding ling spacing value and an optimal feeding step length are determined, thereby realizing a cutter location grid unit division based on a cutter location grid node. With fitting of a cutter location grid unit plane, a cutter location grid node Z coordinate is determined by combining an adjacent associated cutter location grid unit. And then a cutter location grid node normal vector is calculated; and with the cutting force fluctuation during the processing process as a constraint, a curved-surface processing cutter track is planned by using the cutter location grid node as a cutter location point according to a fundamental principle of normal vector included angle minimization between adjacent cutter location points, so that the high-quality and high-efficiency curved surface processing is realized. The method has the high adaptability to the local complicated geometrical features; and high-quality and high-efficiency curved surface processing is realized.

Owner:DALIAN UNIV OF TECH

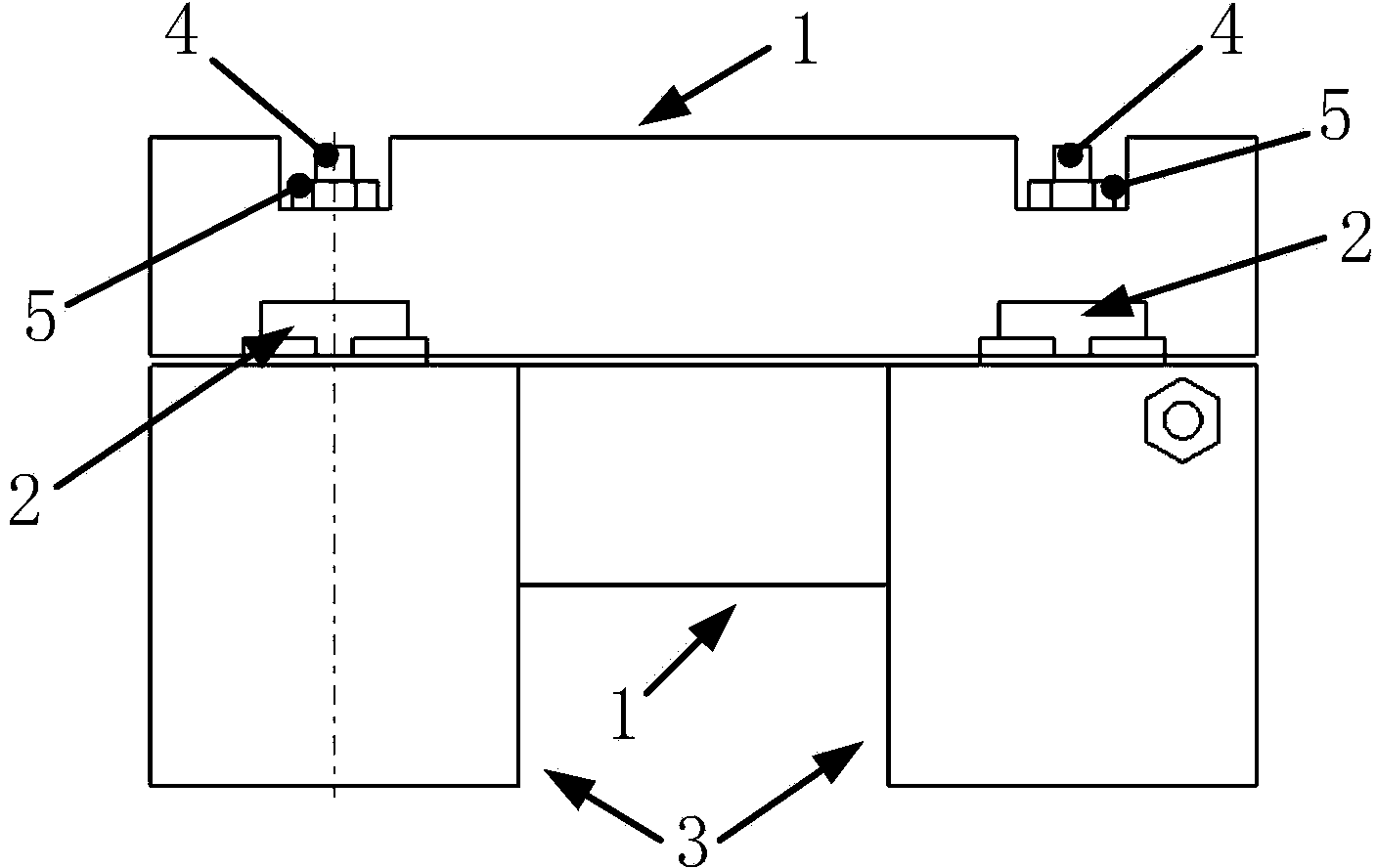

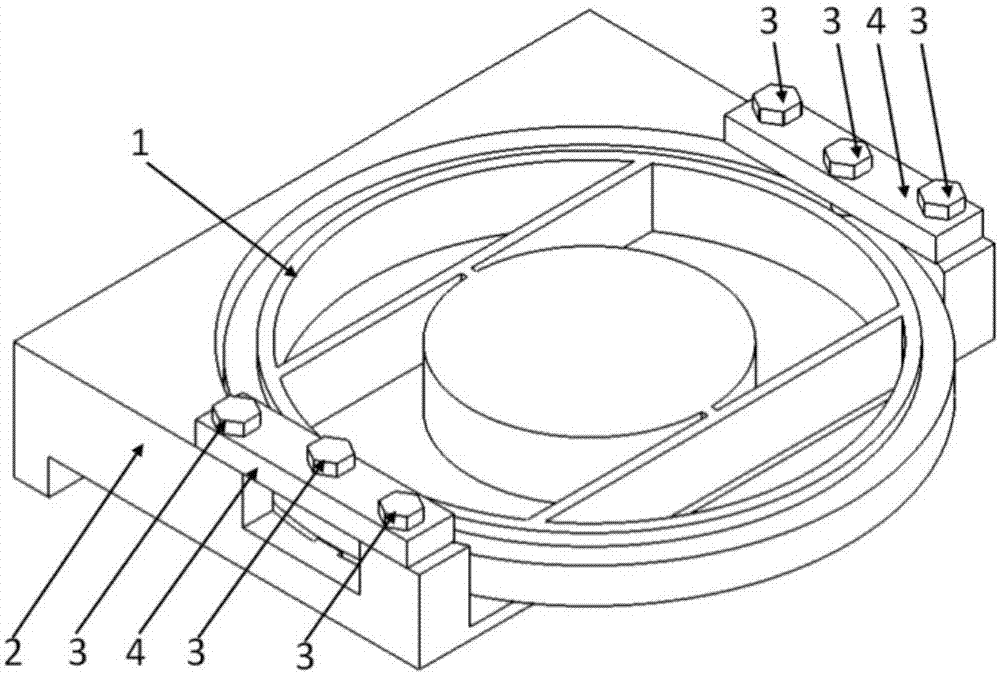

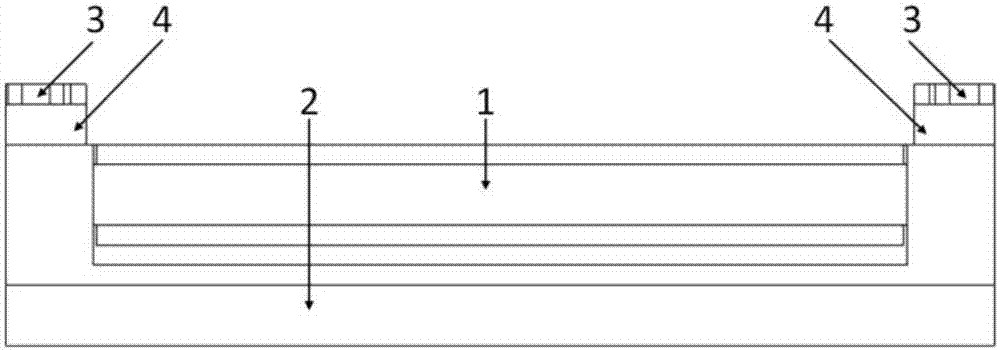

Tuned passive damper with two degrees of freedom

InactiveCN103867636AHigh quality and efficient processingInhibition first orderNon-rotating vibration suppressionMaintainance and safety accessoriesAngular degreesDamping ratio

The invention discloses a tuned passive damper with two degrees of freedom. The tuned passive damper with the two degrees of freedom comprises mass blocks, sliding blocks, elastic-damping units and rigidity adjusting bolts; grooves are formed in the two ends of each mass block, every two sliding blocks are arranged in one groove and are tightly attached to a thin plate in the corresponding elastic-damping unit, and each thin plate is provided with a sliding groove corresponding to the groove in the corresponding mass block. Each sliding block is located by the corresponding rigidity adjusting bolt penetrating through the corresponding groove and the corresponding sliding groove, so that the distance between the two sliding blocks on the same side of each mass block is adjusted through the corresponding bolts, and rigidity adjustment of the damper is achieved. Besides, a friction plate with the adjustable angle is arranged between the corresponding sliding blocks and the side wall of a base of the corresponding elastic-damping unit, the contact area between each friction plate and the corresponding mass block is changed by adjusting the angle of the corresponding friction plate, and therefore the damping ratio of the damper is adjusted. The tuned passive damper with the two degrees of freedom has the advantages of being simple in structure, convenient to implement and low in cost, having no pollution to the environment, being capable of effectively lowering vibration in a cutting process, and achieving high-efficiency and high-quality machining of parts.

Owner:BEIHANG UNIV

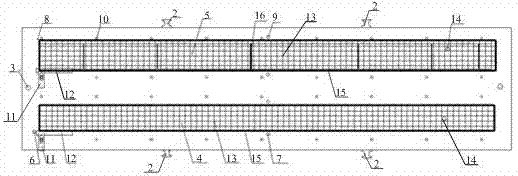

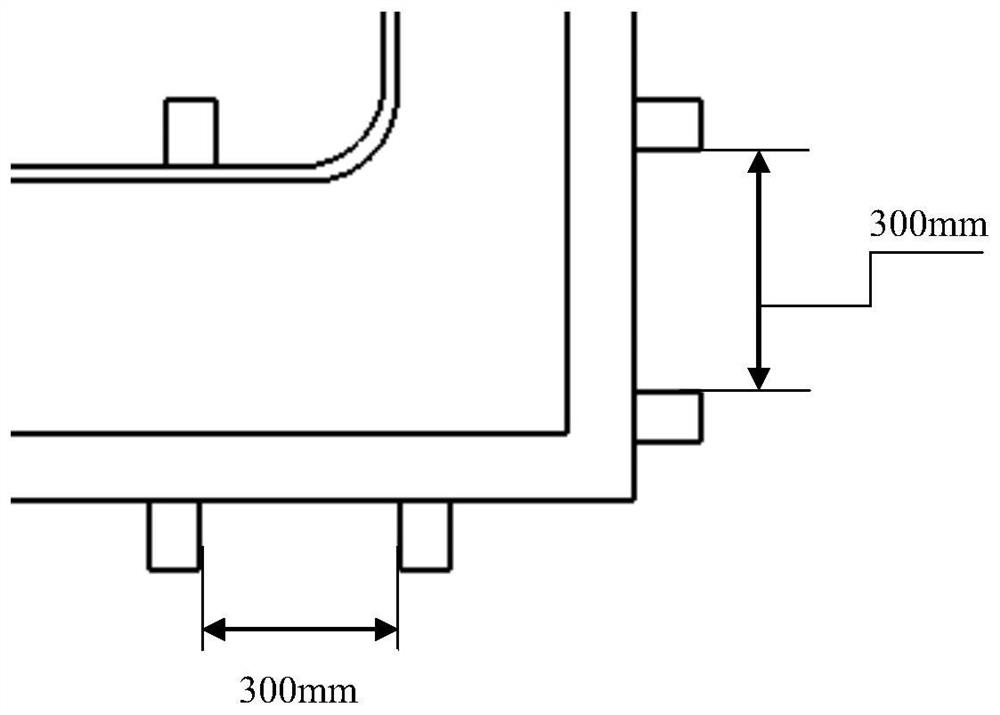

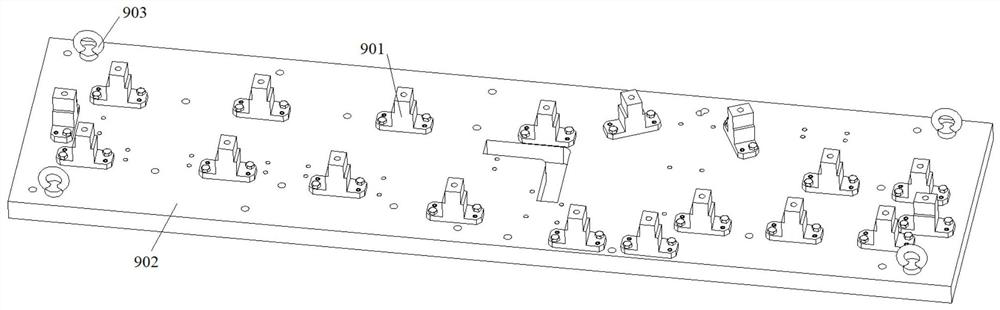

Tool and technique for machining long and narrow skin part

ActiveCN107309658AHigh quality and efficient processingFast locationFuselage bulkheadsOther manufacturing equipments/toolsPosition toleranceVirtual machining

The invention provides a technique for machining a long and narrow skin part. The machining scheme of a long and narrow skin is optimized on the aspects such as the clamping and cutting parameters and the technical scheme by adopting the technical method that roll bending and pit machining are conducted successively, the purposes of clamping of the dual-side-concave long and narrow skin and butt joint of the front side and the back side are achieved, the machining thickness tolerance and the position tolerance of the narrow and long skin are ensured, and the situation that concave areas crack as pit machining is conducted before roll bending is avoided. According to the technique for machining the long and narrow skin part, by adoption of the technical machining method that roll bending formation and vacuum adsorption unfolding are conducted successively, the adsorption stability in the machining process of the dual-side long and narrow skin is ensured; by designing the length and width standards of the front side and the back side, the location degrees of the part outline and the pit during machining of the front side and the back side can be quickly met, and high-quality and high-efficiency machining of the long and narrow skin is achieved.

Owner:JIANGXI HONGDU AVIATION IND GRP

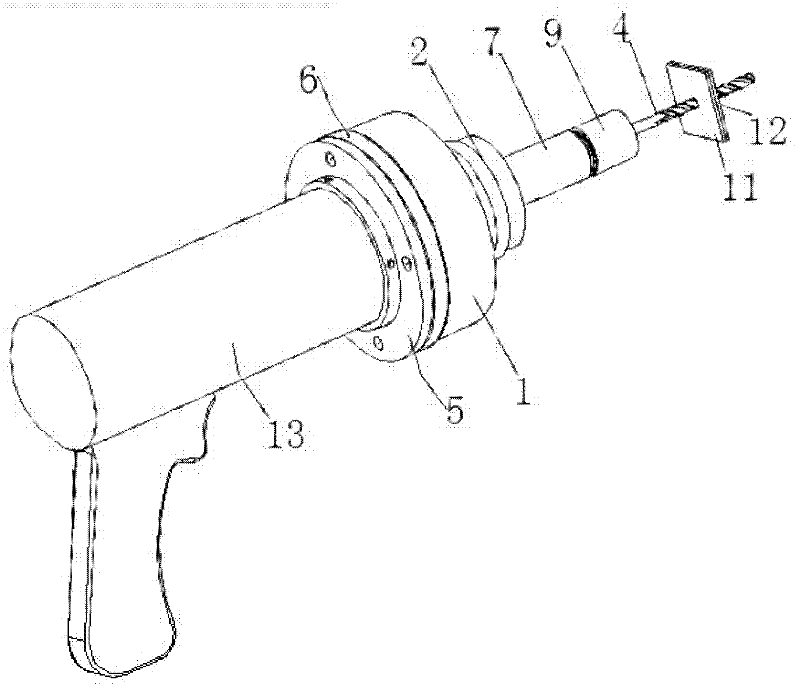

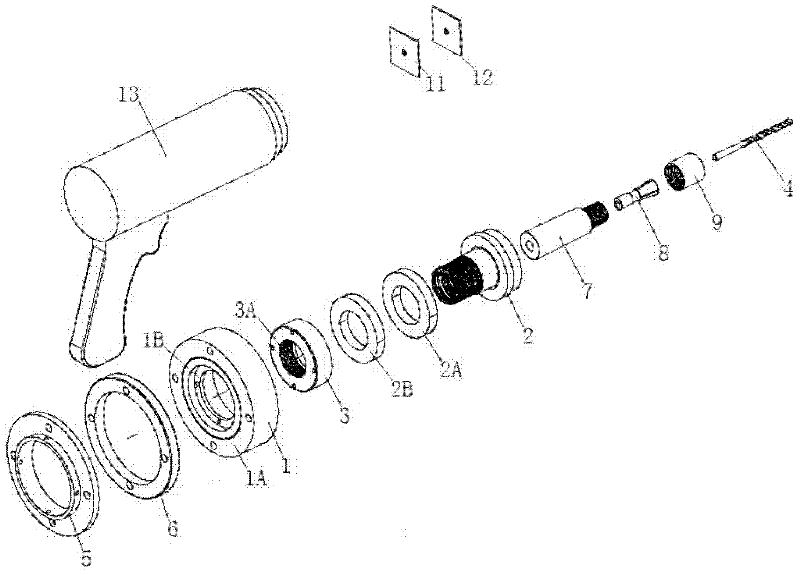

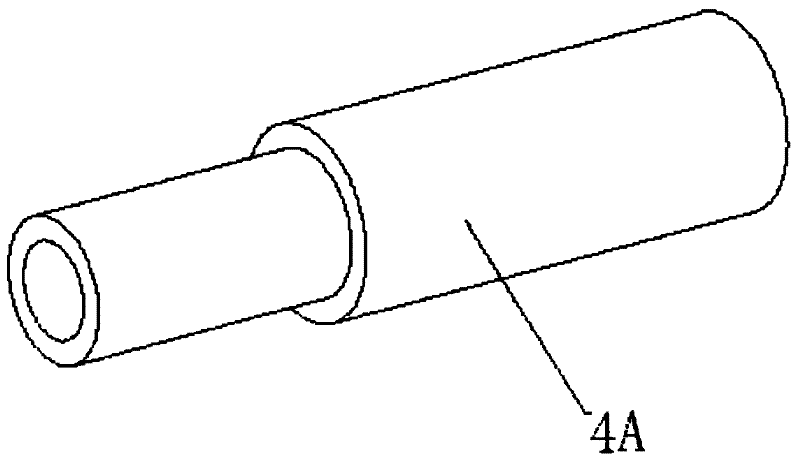

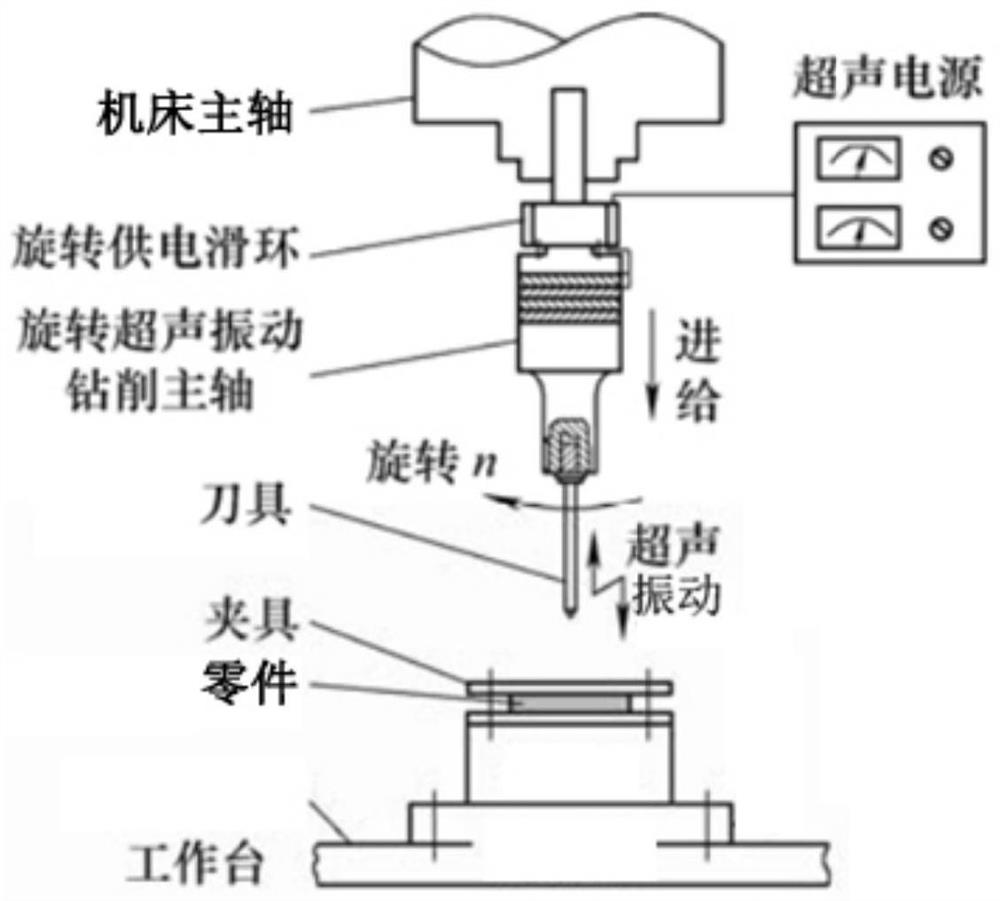

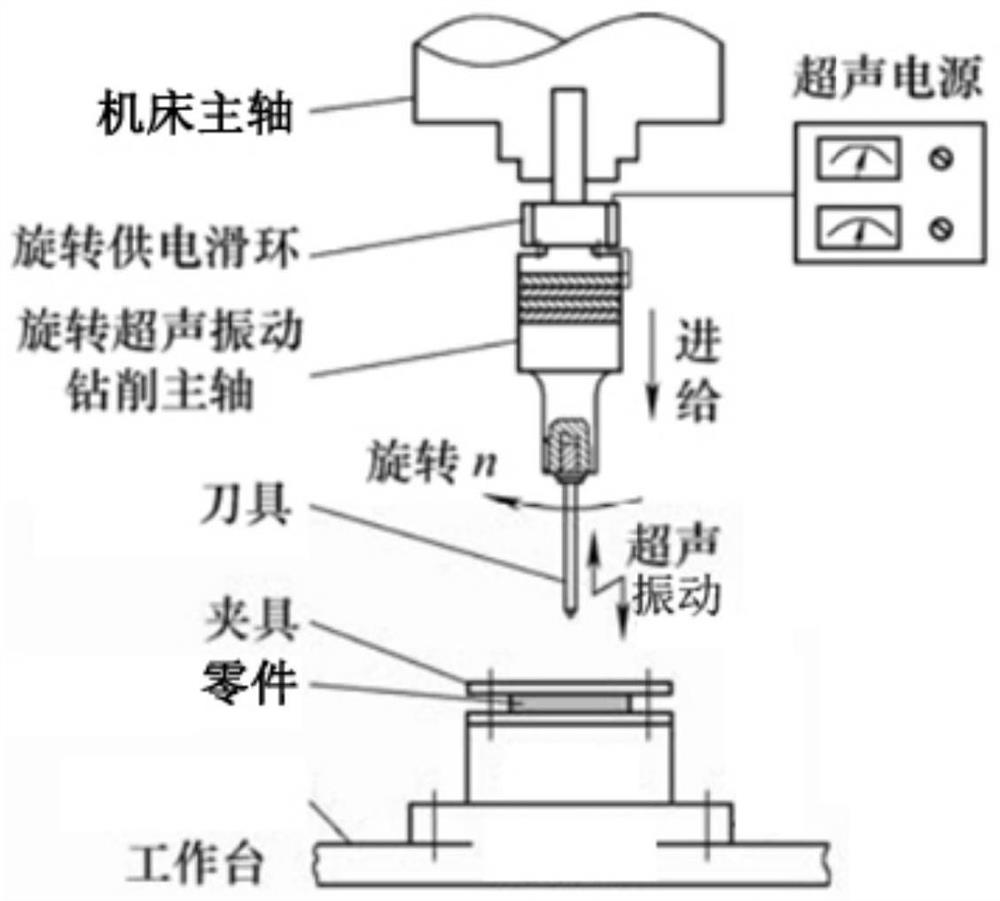

Ultrasonic vibration sleeve reaming machining device applied to air drill

ActiveCN102229001ASimple structural designRealize rotating power supplyReaming devicesTransducerUltrasonic vibration

The invention discloses an ultrasonic vibration sleeve reaming machining device applied to an air drill. The device comprises a slip ring, a front cover plate, a ceramic plate A, a ceramic plate B, a rear cover plate, a flange plate, a retainer ring, a manual air drill, a drill shaft sleeve, a spring chuck and a fastening cap; the main shaft of the manual air drill is connected into an internal thread hole of the front cover plate; after the ceramic plate A and the ceramic plate B are sequentially sleeved at the external thread section of the front cover plate, the front cover plate is in threaded connection into an internal thread hole of the rear cover plate; an inner ring of the slip ring is arranged on the rear cover plate, and an outer ring of the slip ring is connected with the retainer ring and the flange plate through bolts; and the inner conical section of one end of the drill shaft sleeve is connected with the outer cylindrical section of the spring chuck, the outer cylindrical section of the other end of the drill shaft sleeve is thermally fed into the inner cylindrical section of the front cover plate, and the chuck section of the spring chuck chucks a reamer or a coredrill and is finally locked through the fastening cap. By assembly design of the spring chuck, the clamped tool bit form is varied, a transducer, the main shaft of a common air drill and a cutter aredetached conveniently, and the rotary precision of the whole air drill tool is ensured.

Owner:BEIHANG UNIV

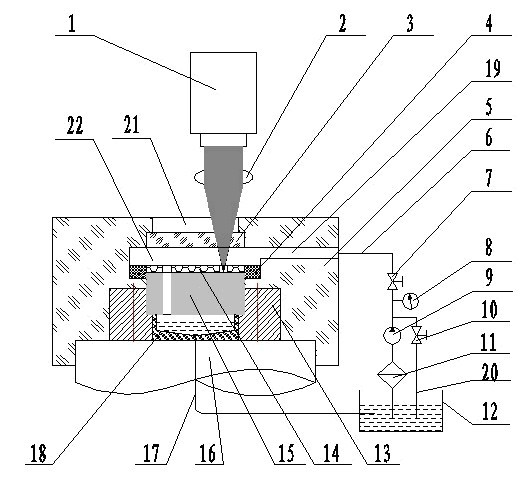

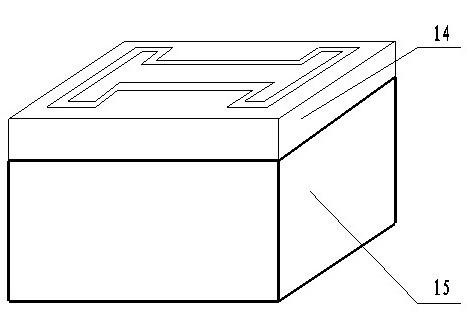

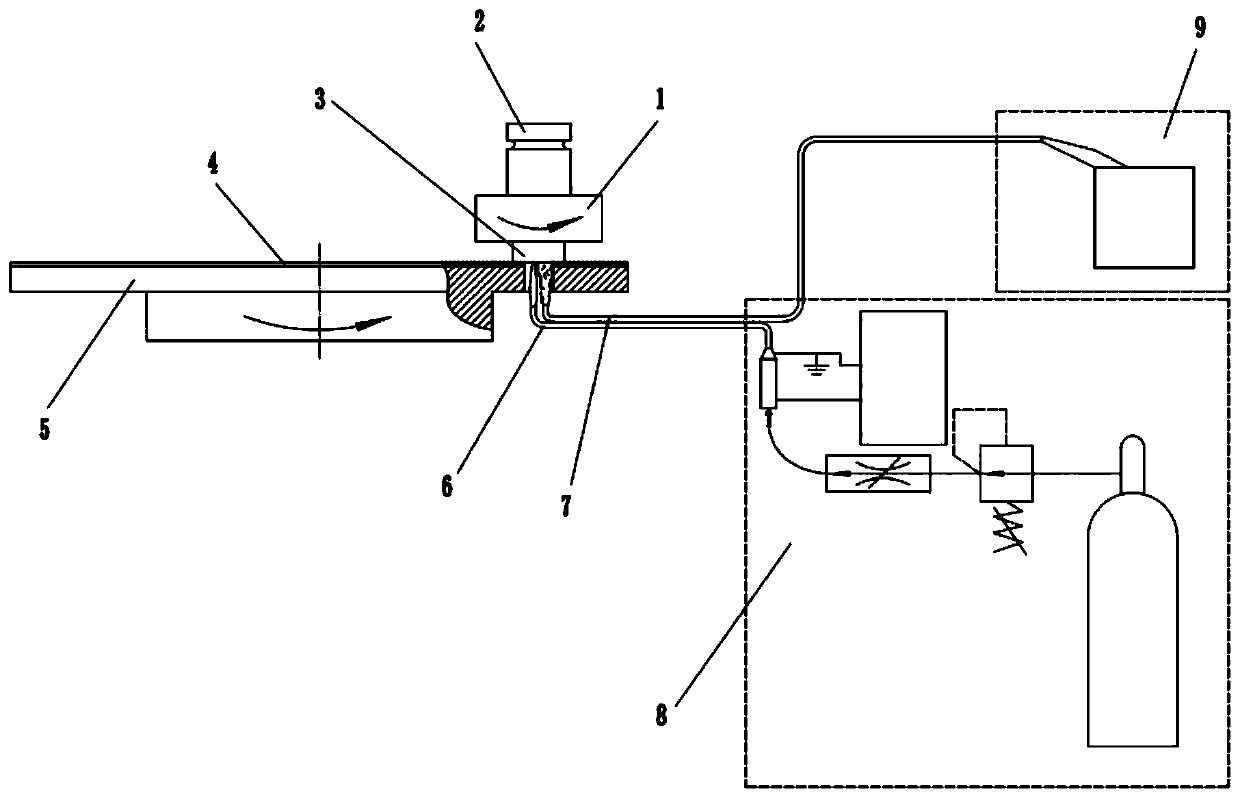

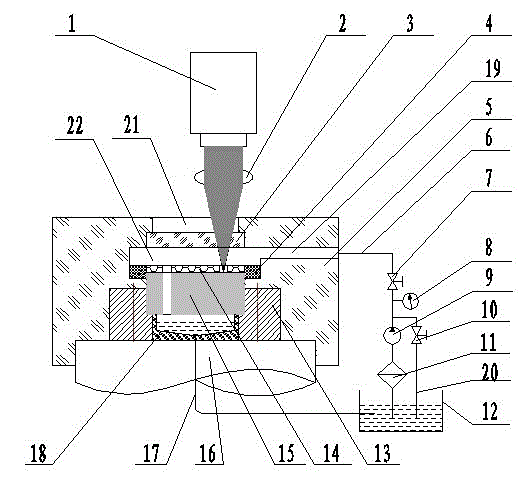

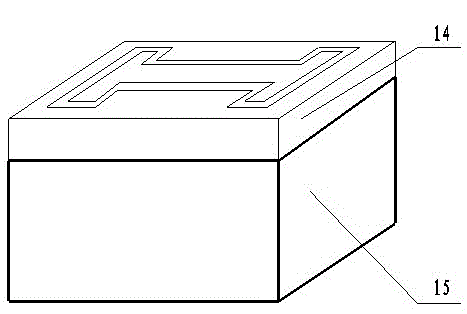

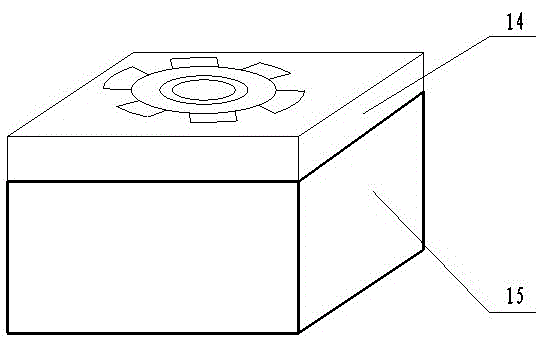

Method and device for preparing silicon-based three-dimensional (3D) microstructure

InactiveCN102381682AHigh quality and efficient processingEffective protectionDecorative surface effectsChemical vapor deposition coatingChemical solutionMachined surface

The invention relates to a method and a device for preparing a silicon-based three-dimensional (3D) microstructure. The method comprises the following steps: carrying out laser machining, chemical corrosion and combined machining on a silicon wafer covered with a picture mask; performing laser scanning and cutting along a preset track of the picture mask; simultaneously chemically etching a laser machining surface by utilizing a chemical solution; and finishing the machining surface. The device for implementing the method mainly consists of a laser, the picture mask, a focusing lens, a work box, a worktable, a liquid collecting tank and a chemical solution circulating and filtering system, wherein the work box is connected on the worktable, a cavity is arranged inside the work box, and a window is arranged on one end of the work box; the picture mask is adhered to the upper end face of the silicon wafer and is placed in the cavity; the liquid collecting tank is placed below the silicon wafer; the chemical solution circulating and filtering system is communicated with the cavity and the liquid collecting tank; the focusing lens and the laser are placed at one side of the window; and lasers are focused on the silicon wafer through the focusing lens and the window. The silicon-based 3D microstructure obtained by the method has the advantages of large height-width ratio, good perpendicularity and good surface quality.

Owner:NANTONG UNIVERSITY

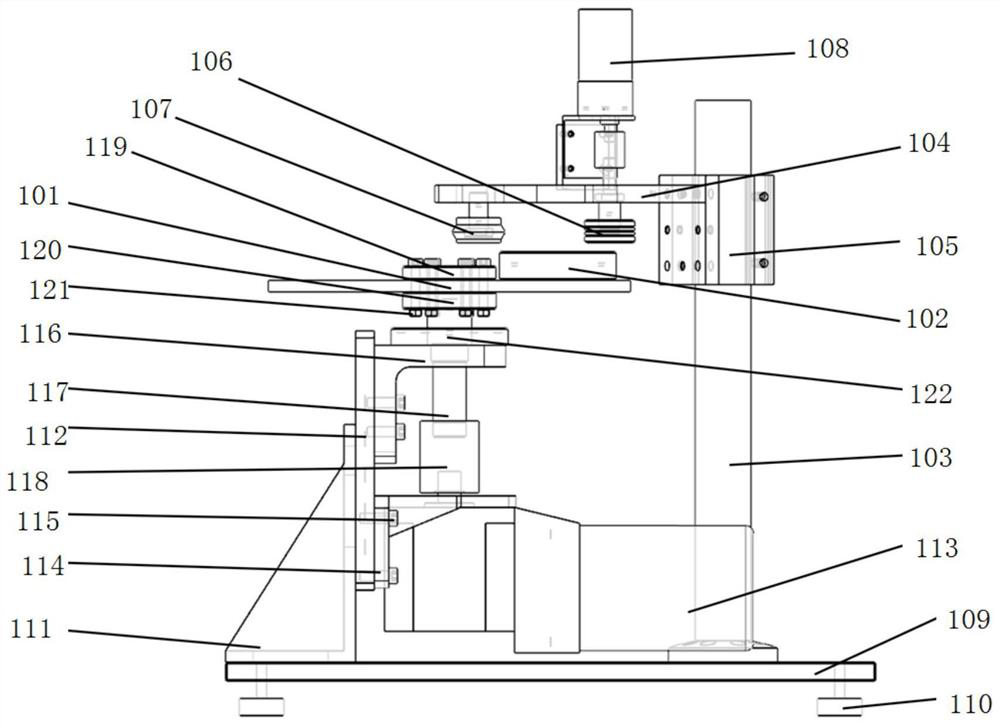

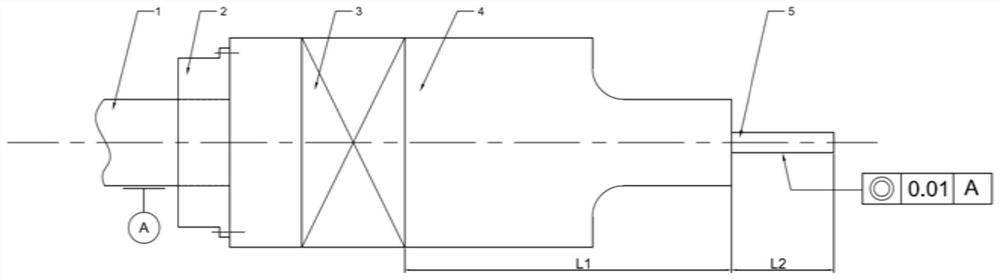

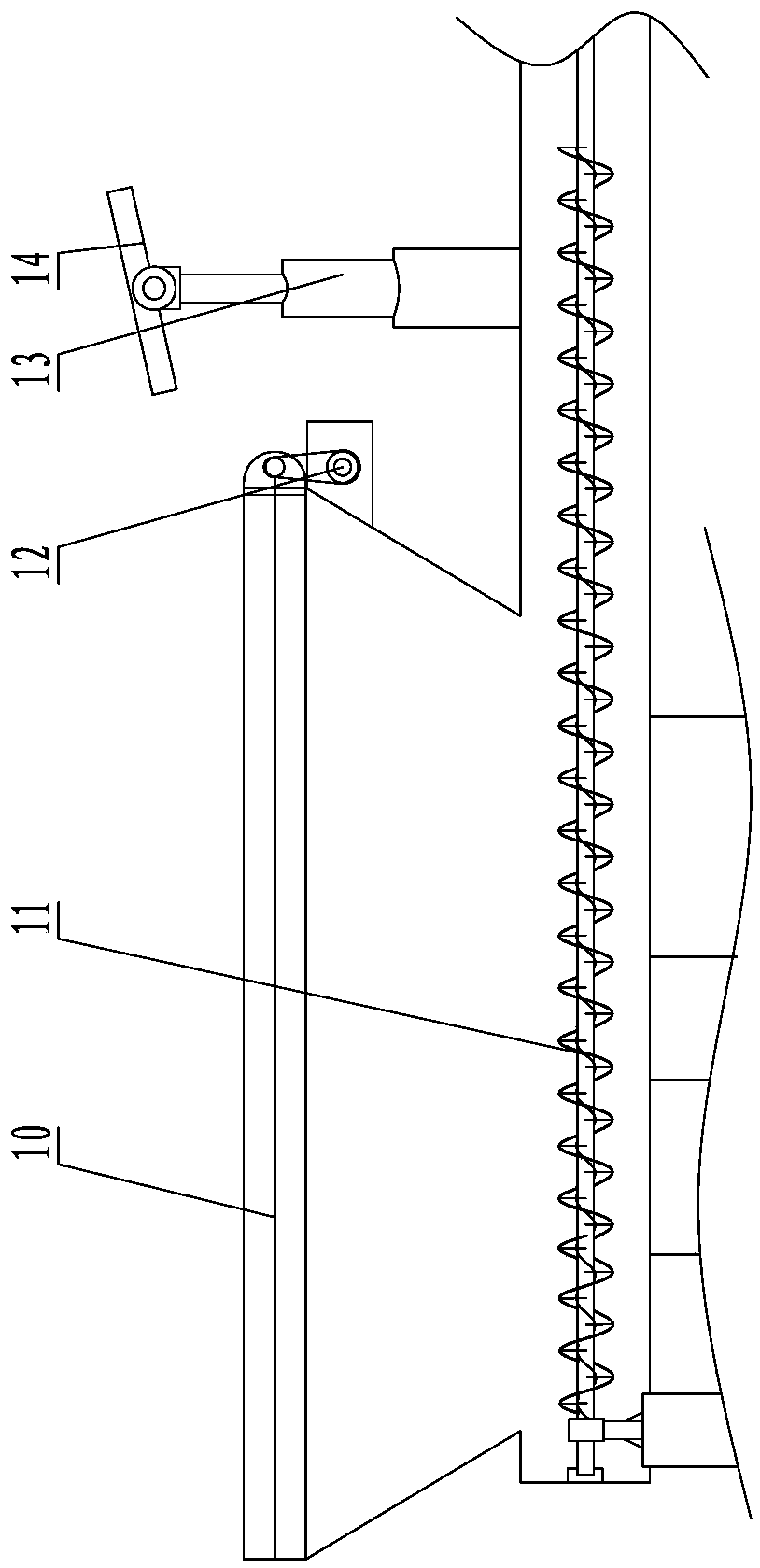

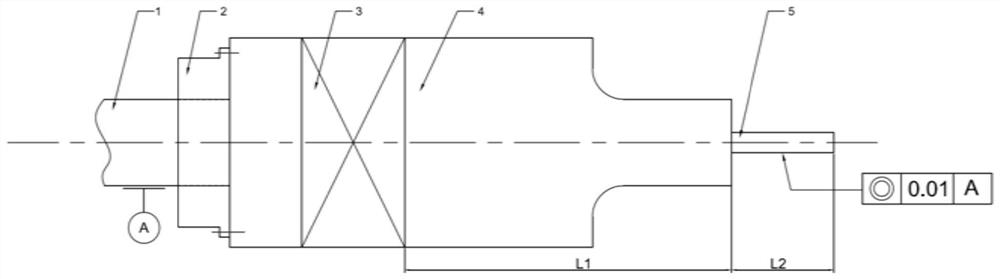

Numerical control and reducing ultrasonic vibration device for machining complicated inner cavity of deep hole

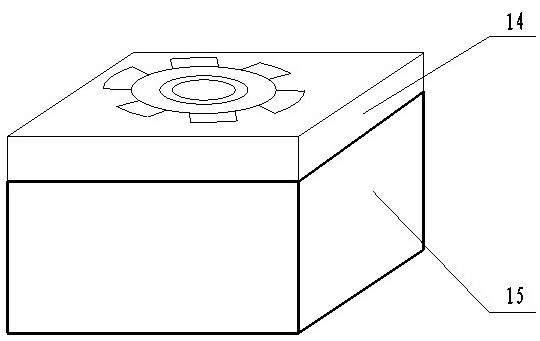

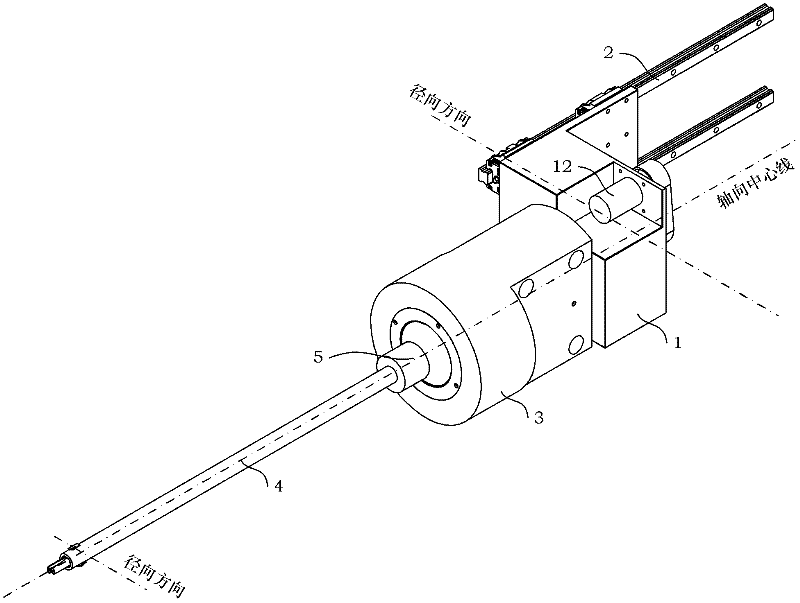

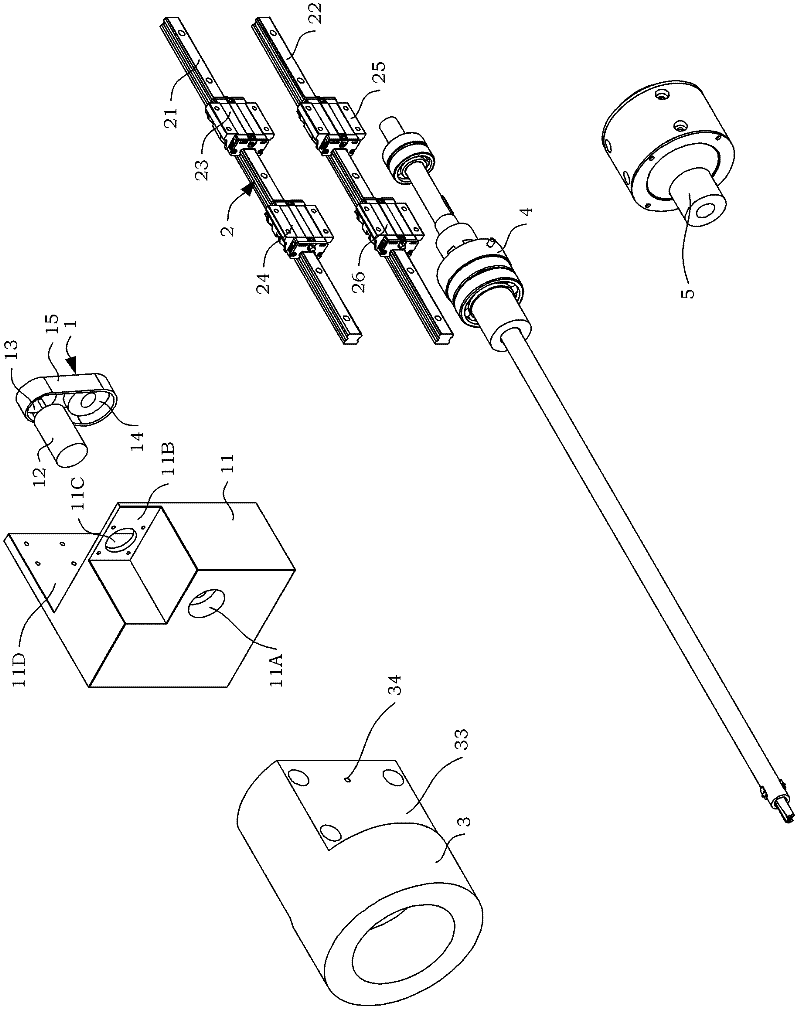

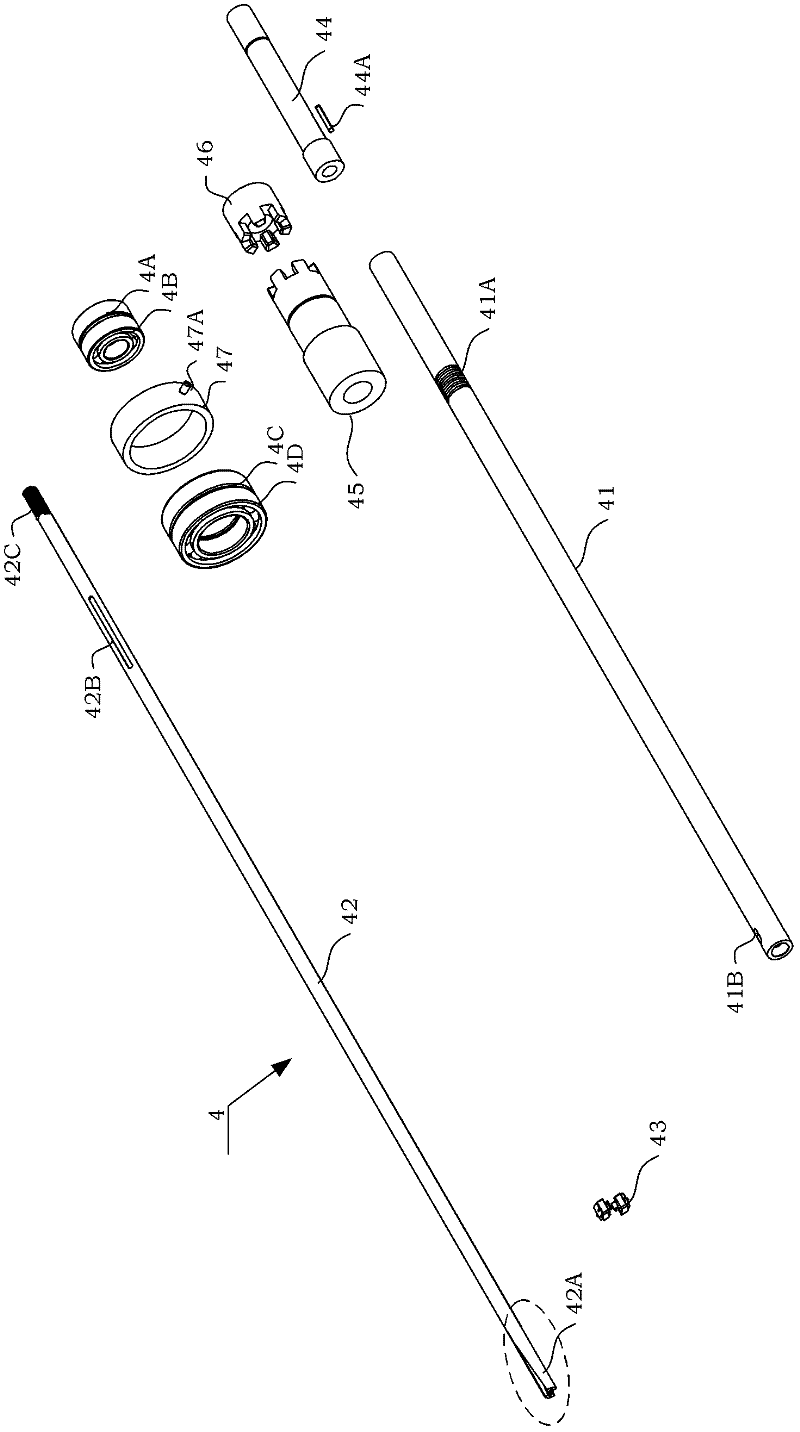

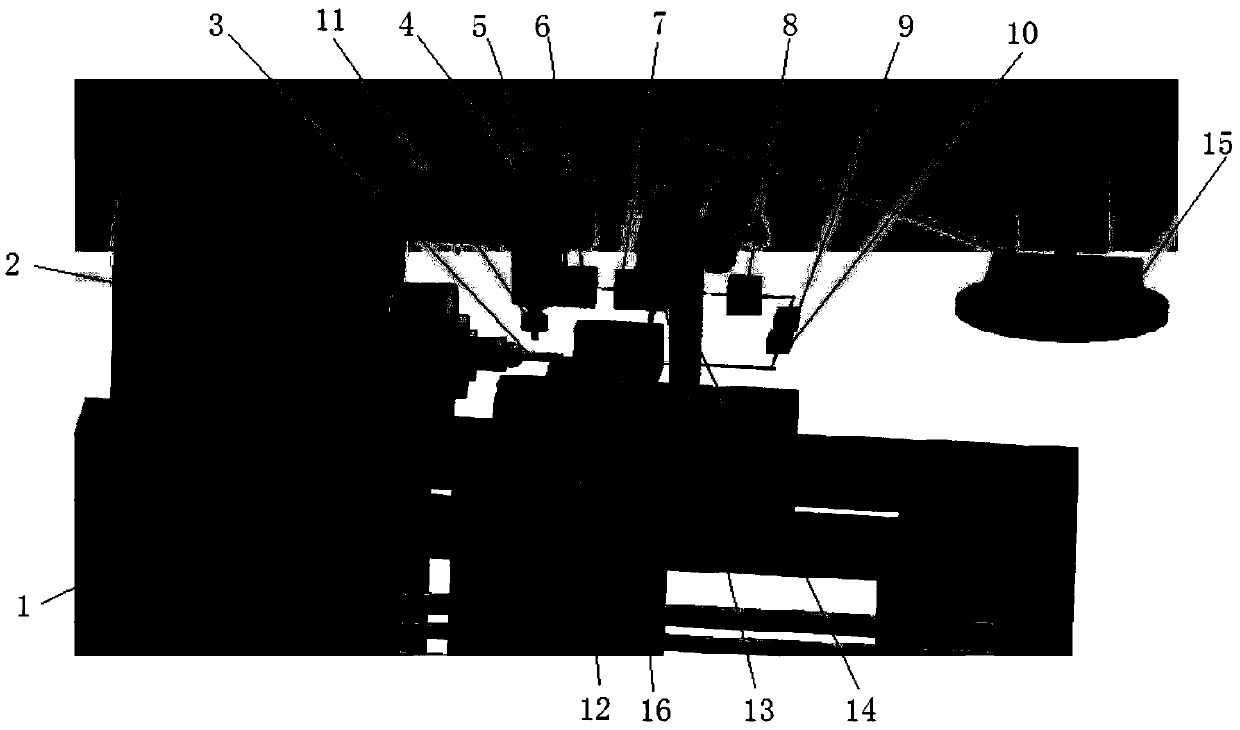

InactiveCN102500775AImprove rigidityImprove machining accuracyTurning toolsMechanical vibrations separationNumerical controlEngineering

The invention discloses a numerical control and reducing ultrasonic vibration device for machining a complicated inner cavity of a deep hole. The device comprises a driving subassembly, a sliding subassembly, a knife sheath, a reducing boring rod subassembly and an ultrasonic transduction subassembly, wherein the ultrasonic transduction subassembly is mounted in the knife sheath and the knife sheath is mounted on a knife tower; a sliding block of the sliding subassembly is mounted on a base of the driving subassembly and a guide rail of the sliding subassembly is mounted on a box of a machinetool; and the reducing boring rod subassembly is connected with the sliding subassembly. According to the numerical control and reducing ultrasonic vibration device provided by the invention, the machining efficiency and the machining precision of the complicated inner cavity of the deep hole are improved by utilizing a numerical control and reducing way. The application range of ultrasonic vibration boring is enlarged.

Owner:BEIHANG UNIV

Composite energy field heating assisted turning and milling integrated device and application method thereof

ActiveCN109571020AHeating up fastEasy to controlOther manufacturing equipments/toolsMetal working apparatusNumerical controlMilling cutter

The invention discloses a composite energy field heating assisted turning and milling integrated device and an application method thereof. The device comprises a numerical control lathe worktable, anelectric hating assisting device and an industrial personal computer; a three-jaw chuck is arranged on the left side of the numerical control lathe worktable; a workpiece is transversely and fixedly mounted in the center of the three-jaw chuck; a milling machine frame is fixedly mounted on the right side of the numerical control lathe worktable, and is longitudinally and rotationally assembled with a milling machine main shaft; and a milling cutter is longitudinally and fixedly mounted at the bottom end of the milling machine main shaft, and is positioned on the upper side of the workpieces. The device solves the machining problems of difficult-machined materials, such as complicated structural parts of particle reinforced composite materials, ceramic, high-temperature alloys and quenchedsteel, so that the technology of heating turning and milling is widely applied; and the device also can realize coupling of laser heating and electric heating composite energy fields to provide theoretical support for further research of deformation mechanisms of materials under composite energy fields.

Owner:SHENYANG AEROSPACE UNIVERSITY

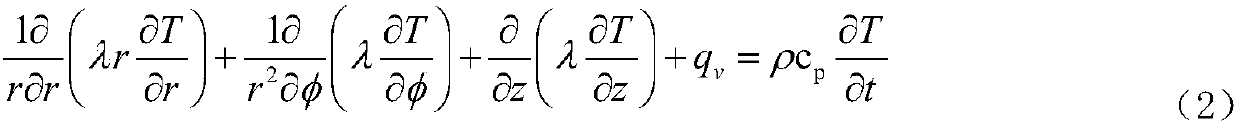

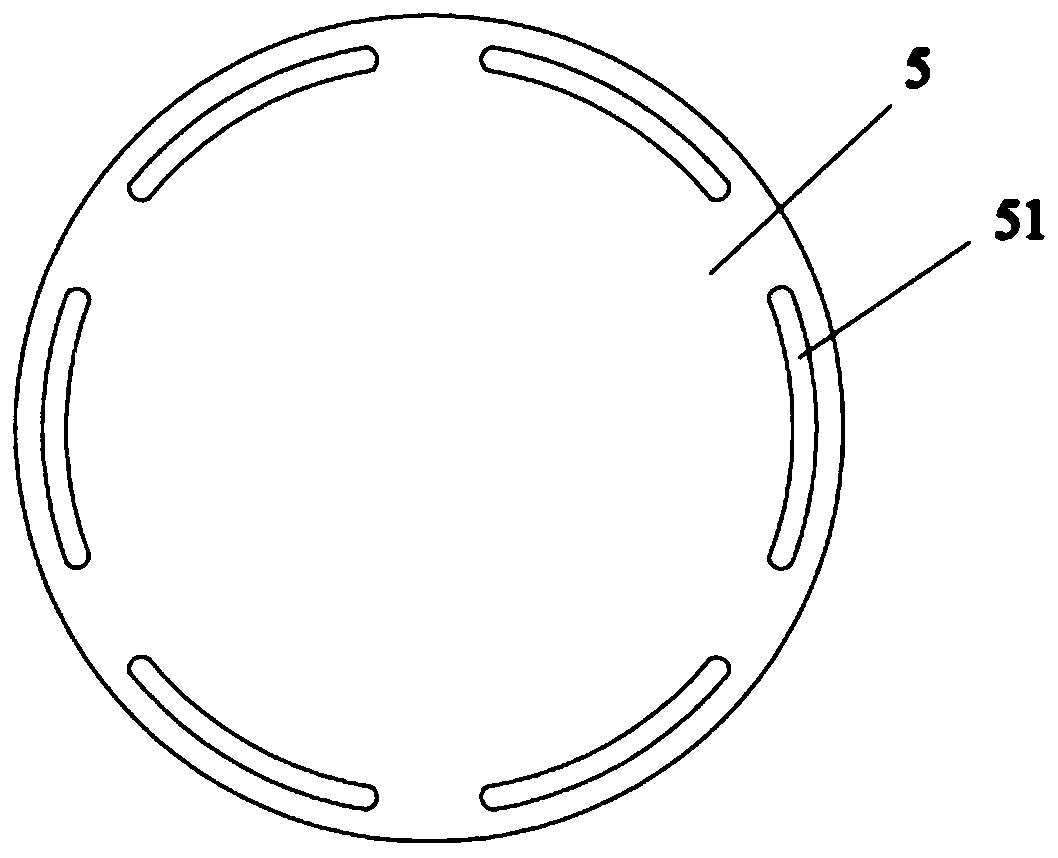

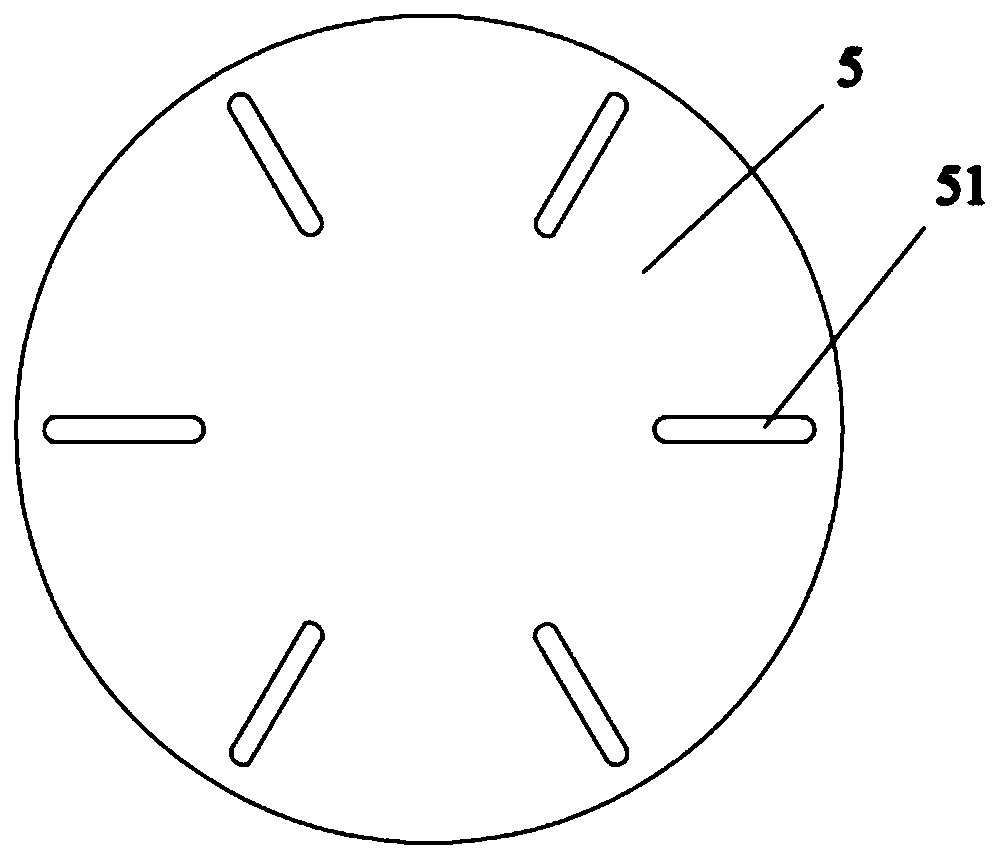

Processing device and process for ultraviolet-assisted chemical mechanical polishing of diamond wafer

ActiveCN113334242AHigh quality and efficient processingEfficient oxidationLapping machinesLapping toolsUltraviolet lightsSingle crystal

The invention provides a processing device and process for ultraviolet-assisted chemical mechanical polishing of a diamond wafer. The device comprises a polishing device, a polishing solution supply device and an ultraviolet irradiation device, wherein a polishing disc is made of JGS1 quartz glass; the polishing solution supply device is positioned above the polishing disc; and the ultraviolet irradiation device is positioned below the polishing disc. According to the processing device and process, ultraviolet light is directly irradiated to the surface of the single crystal diamond wafer, and a proper oxidizing agent is combined, so that the wafer is efficiently oxidized and modified; an oxidation modification layer is mechanically removed through the polishing disc and abrasive particles; in a processing process, the wafer and the polishing disc rotate separately to generate relative motion; and meanwhile, ultraviolet irradiation and polishing solution feeding enable a photochemical modification effect and a mechanical polishing effect to be alternatively performed, so that photochemical mechanical processing can be performed on the wafer, and high-quality and high-efficiency processing of single crystal diamond can be realized under the action of multi-energy field coupling.

Owner:DALIAN UNIV OF TECH

Contact deliquescene polishing device and polishing method for plasma modified liquid film

The invention provides a contact deliquescene polishing device for a plasma modified liquid film. The device comprises an object carrying block, a heavy object, a polishing pad, a polishing disc, a first hose, a second hose, a plasma generating device and a micro-mist generating device, wherein the polishing pad is mounted on the upper surface of the polishing disc, and the object carrying block is arranged above the polishing disc; and the heavy object is arranged on the object carrying block, wherein the object carrying block and the heavy object are used for applying pressure to a deliquescent crystal, through holes are formed in the positions, corresponding to the deliquescent crystal, of the polishing disc and the polishing pad, and the plasma generating device and the micro-mist generating device correspondingly communicate with the through holes through the first hose and the second hose. The invention further provides a polishing method for the plasma modified liquid film. Thecontact deliquescene polishing device and polishing method for the plasma modified liquid film has the beneficial effects that the problems that micro-pits and residual organic matters are difficult to clean caused by residing of liquid drops and the like in an existing deliquescence polishing method can be solved.

Owner:HUNAN UNIV

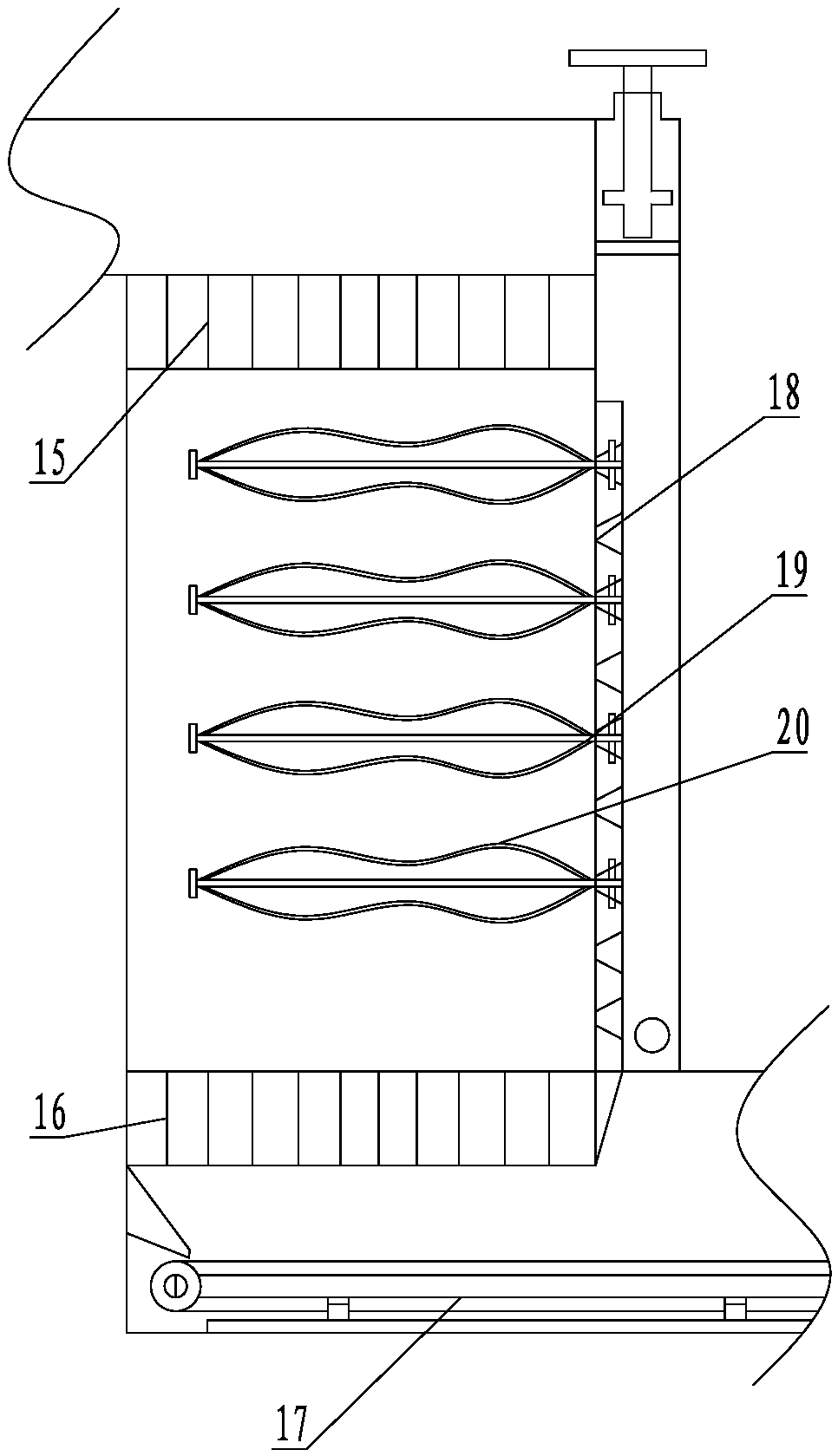

Freezing fixation flexible clamp used for numerical control cutting machining of thin-walled part

InactiveCN103100907BGood effectHigh quality and efficient processingPositioning apparatusMetal-working holdersNumerical controlProcess systems

The invention discloses a freezing fixation flexible clamp used for numerical control cutting machining of a thin-walled part. The freezing fixation flexible clamp used for the numerical control cutting machining of the thin-walled part comprises a clamping mechanism and a longitudinal positioning mechanism, wherein after the clamping mechanism clamps the thin-walled part, the thin-walled part is positioned on a lathe. The longitudinal positioning mechanism is arranged below the thin-walled part on the lathe and is wholly a container containing phase change material, a vertical support is arranged on the upper surface of the phase change material in a floating mode, and a cooling passage is designed between two opposite lateral walls in the container. Therefore, after the clamping mechanism clamps the thin-walled part, the bottom surface of the thin-walled part contacts the support and applies pressure on the support in the process of contacting, and the support is sunk. At present, cooling gas is injected into the cooling passage through a vortex tube to enable the phase change material to be converted into a solid state, the support is frozen and fixed, and longitudinal positioning of the thin-walled part is achieved. The freezing fixation flexible clamp used for the numerical control cutting machining of the thin-walled part has the advantages of being obvious in effect, convenient to achieve, low in cost, and free of pollution to the environment, and effectively improving efficiency and machining quality in the process of numerical control cutting machining of a weak-rigidity process system.

Owner:BEIHANG UNIV

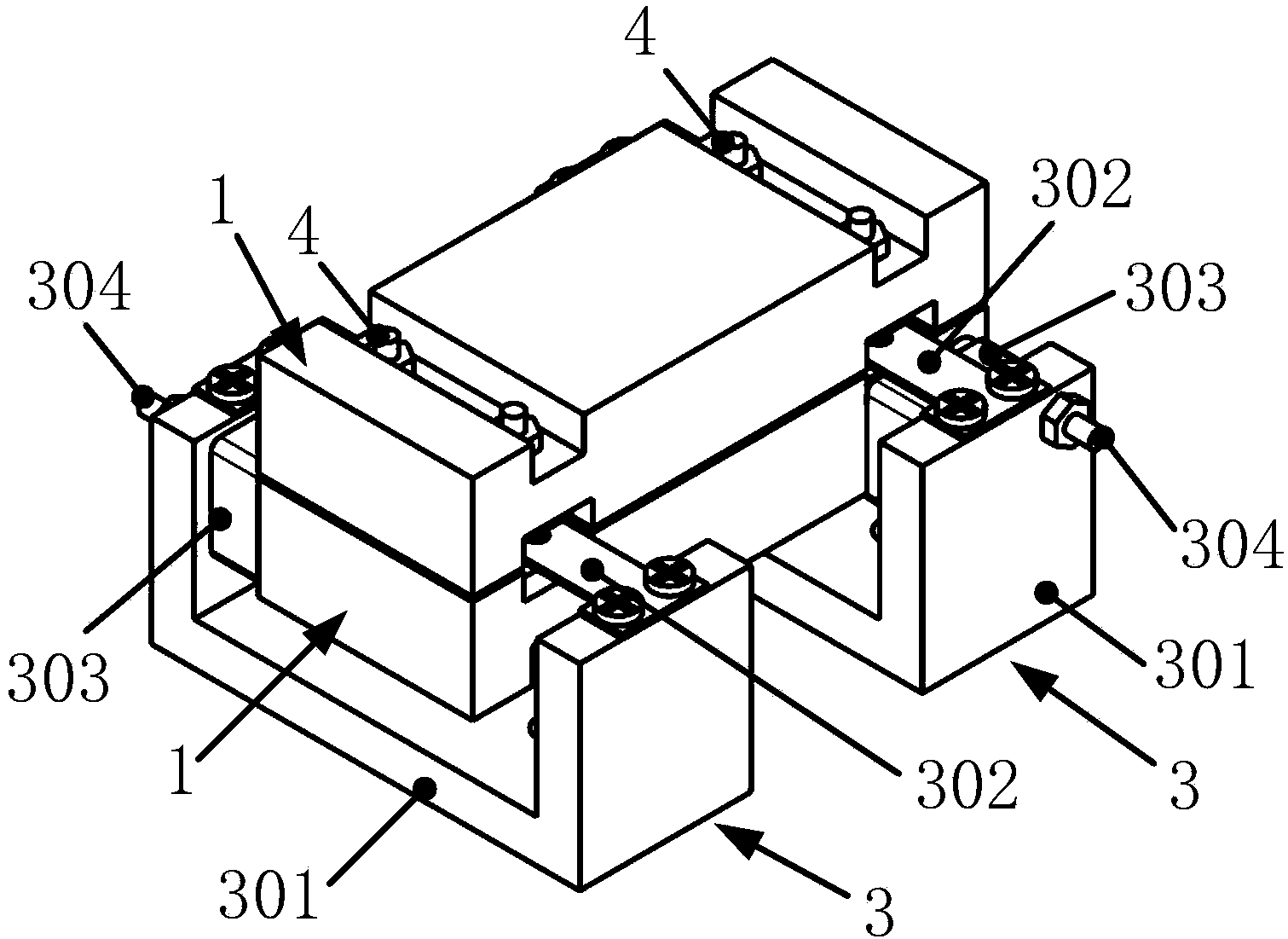

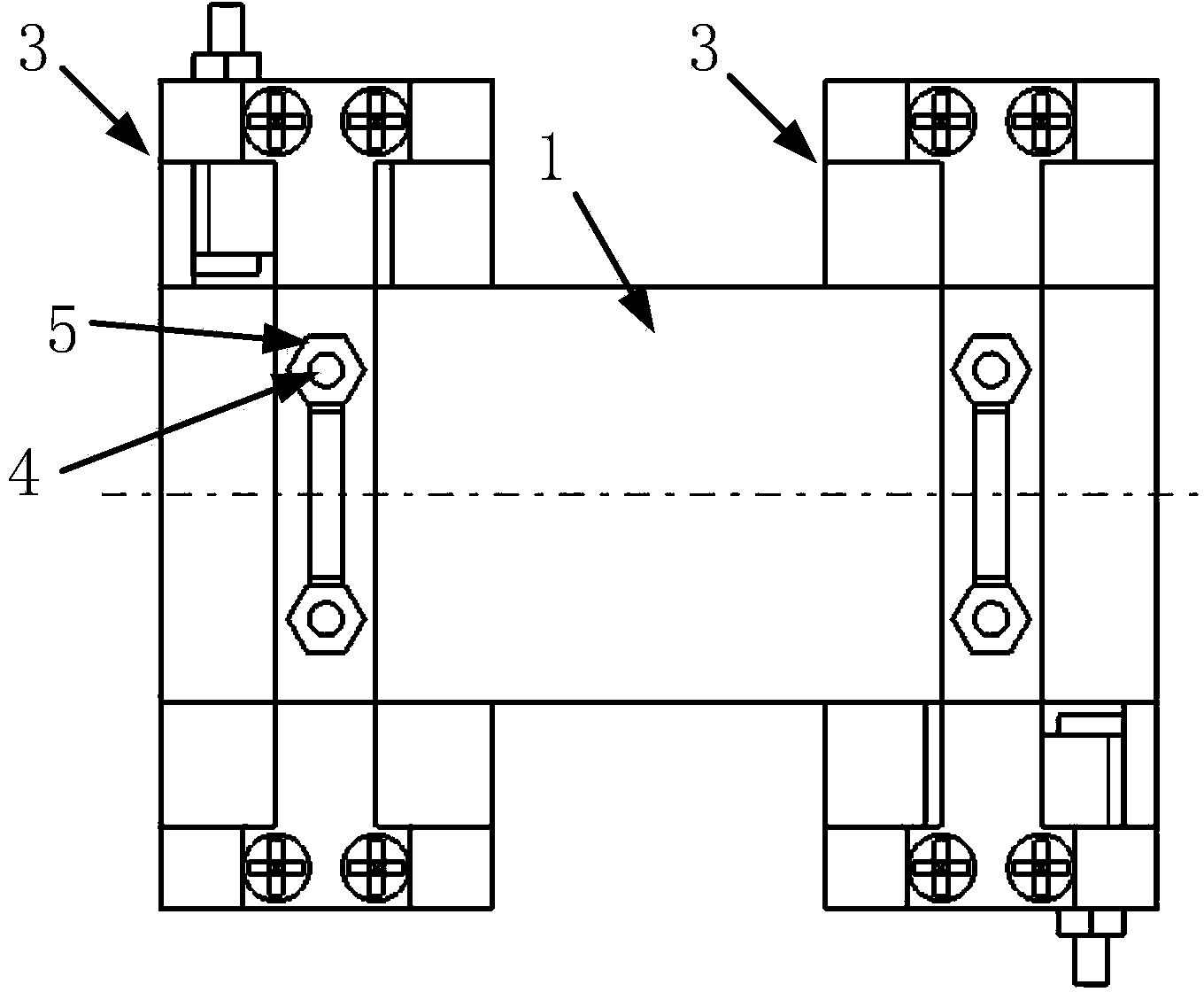

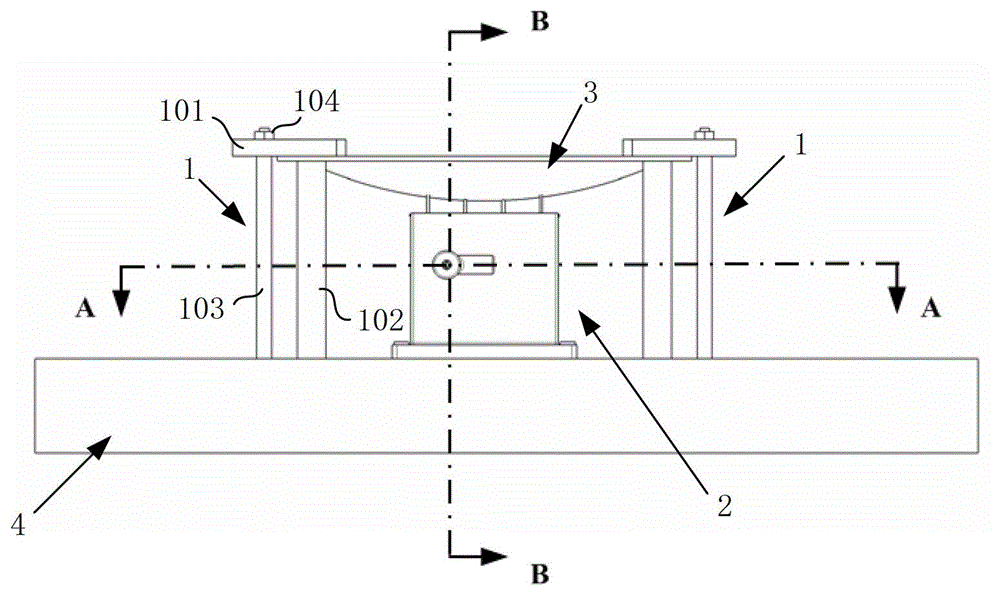

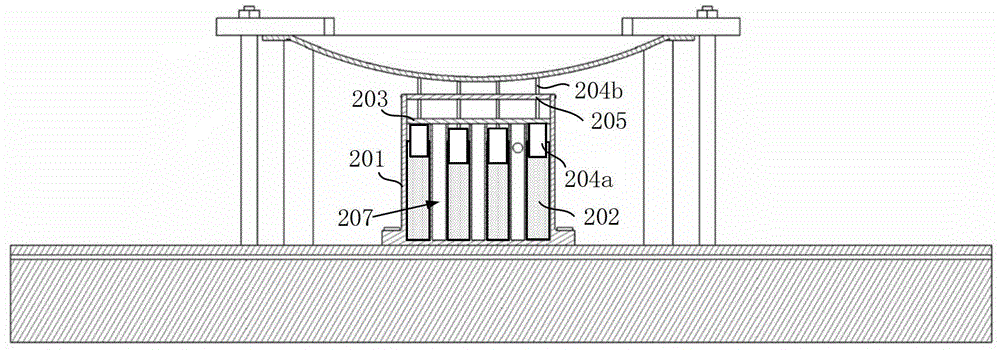

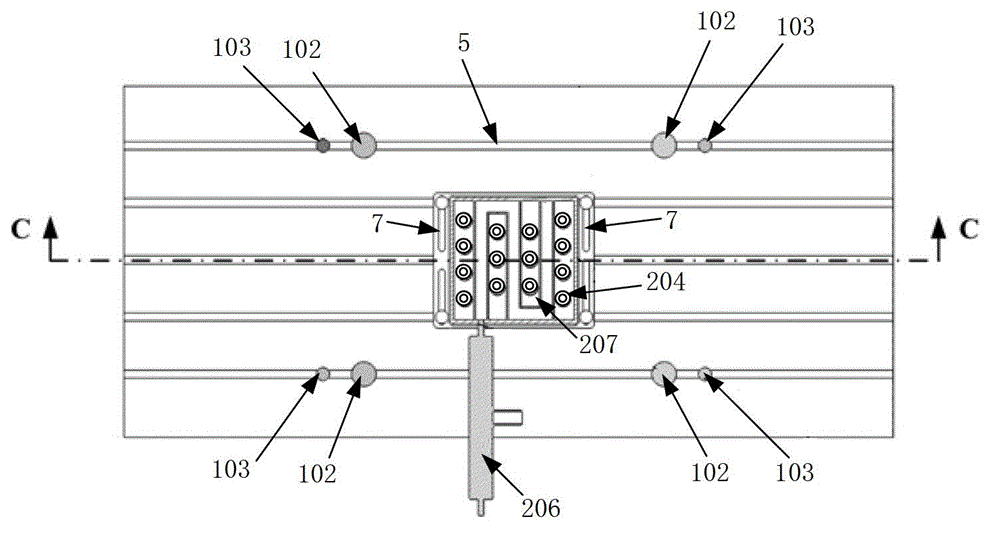

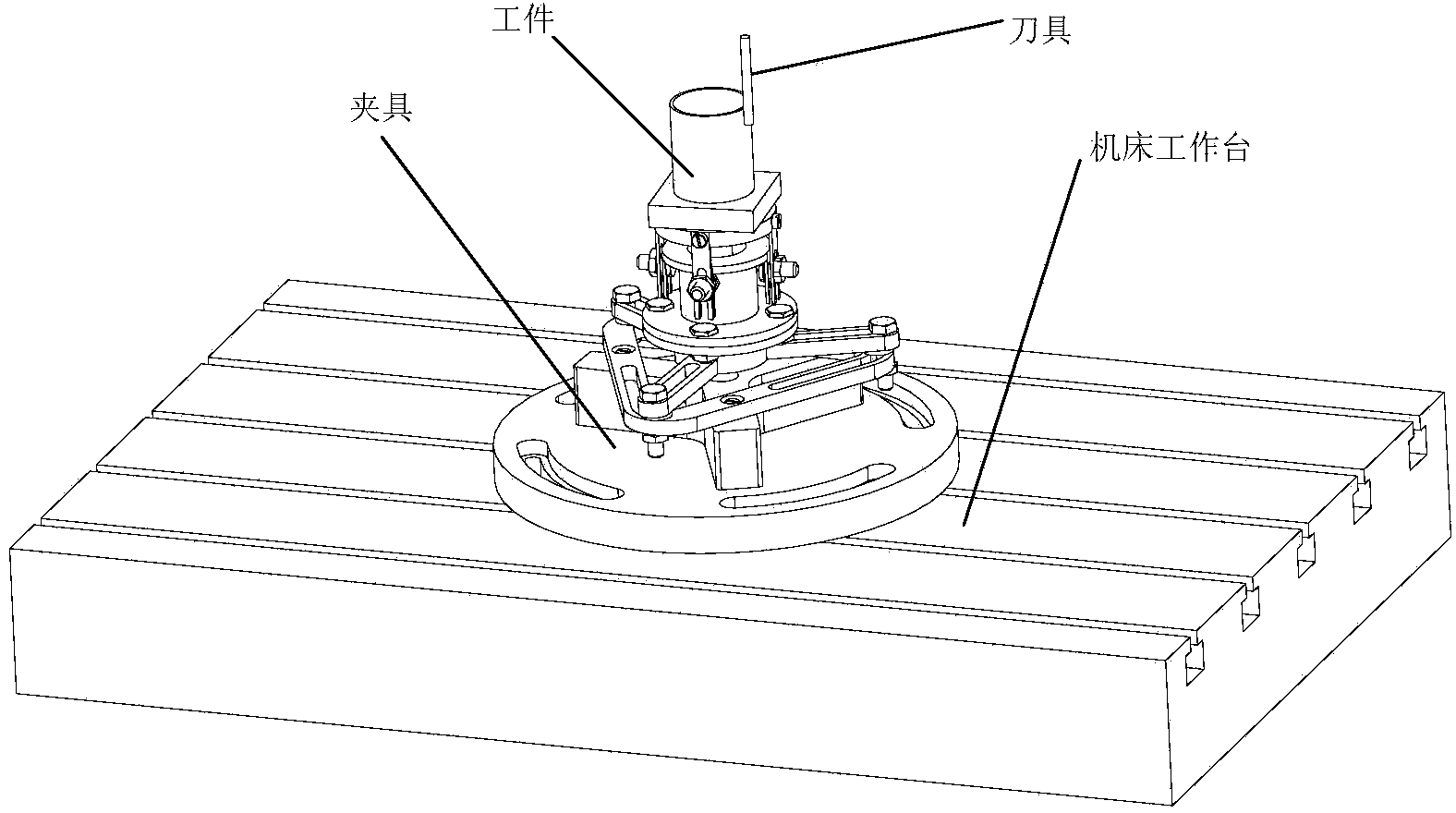

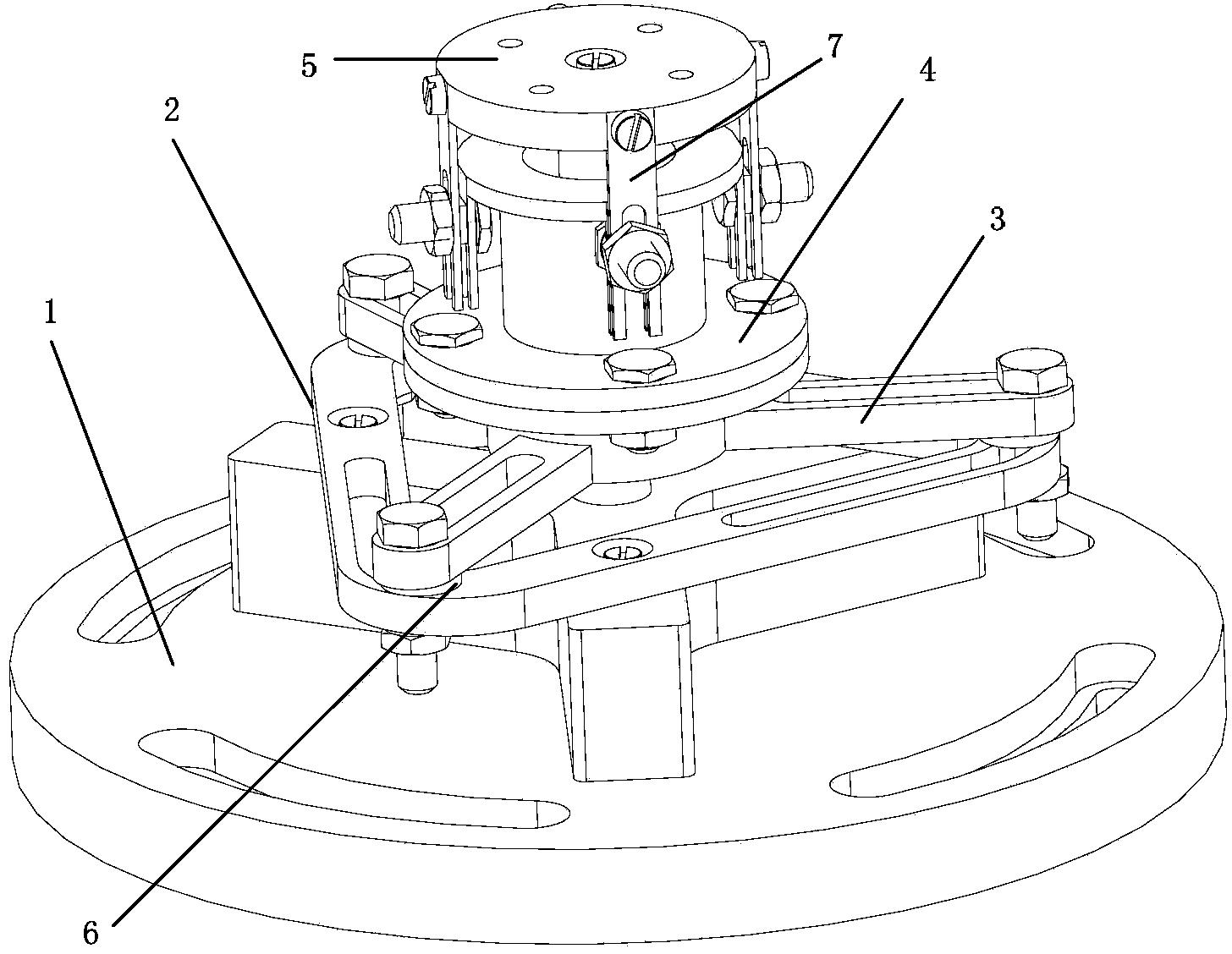

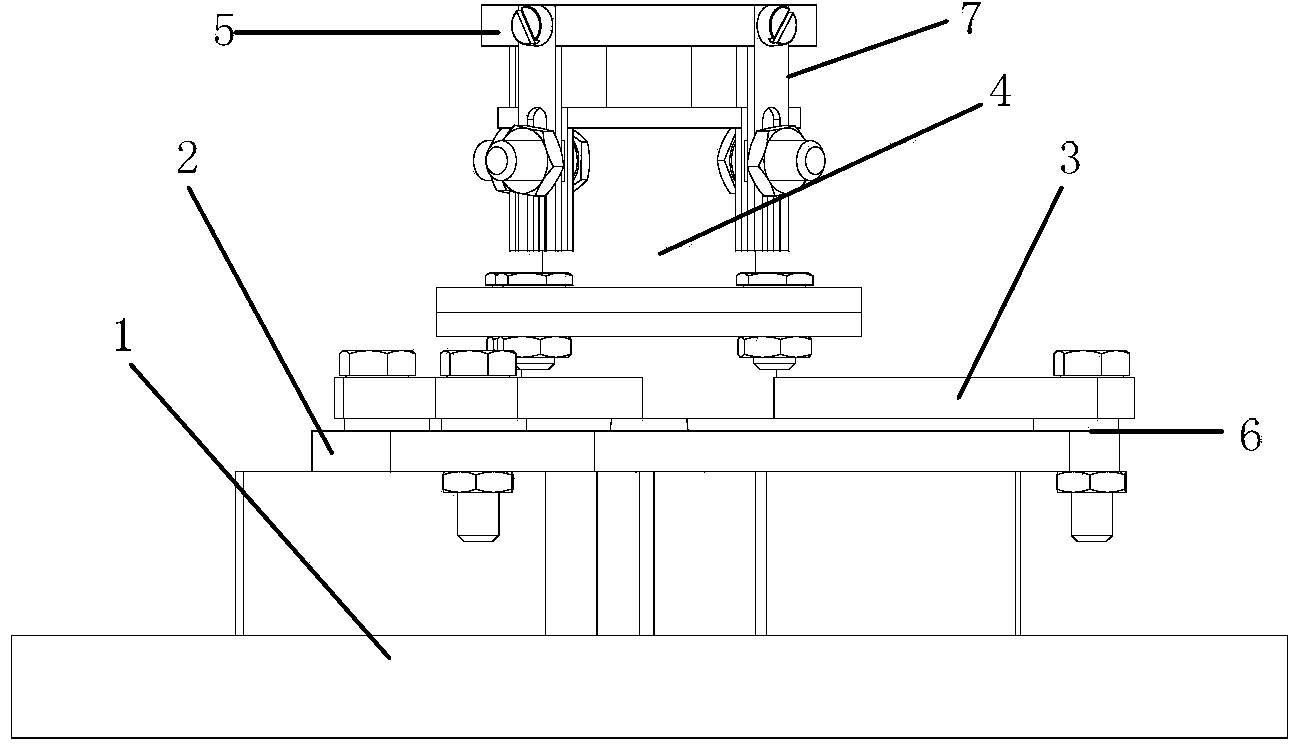

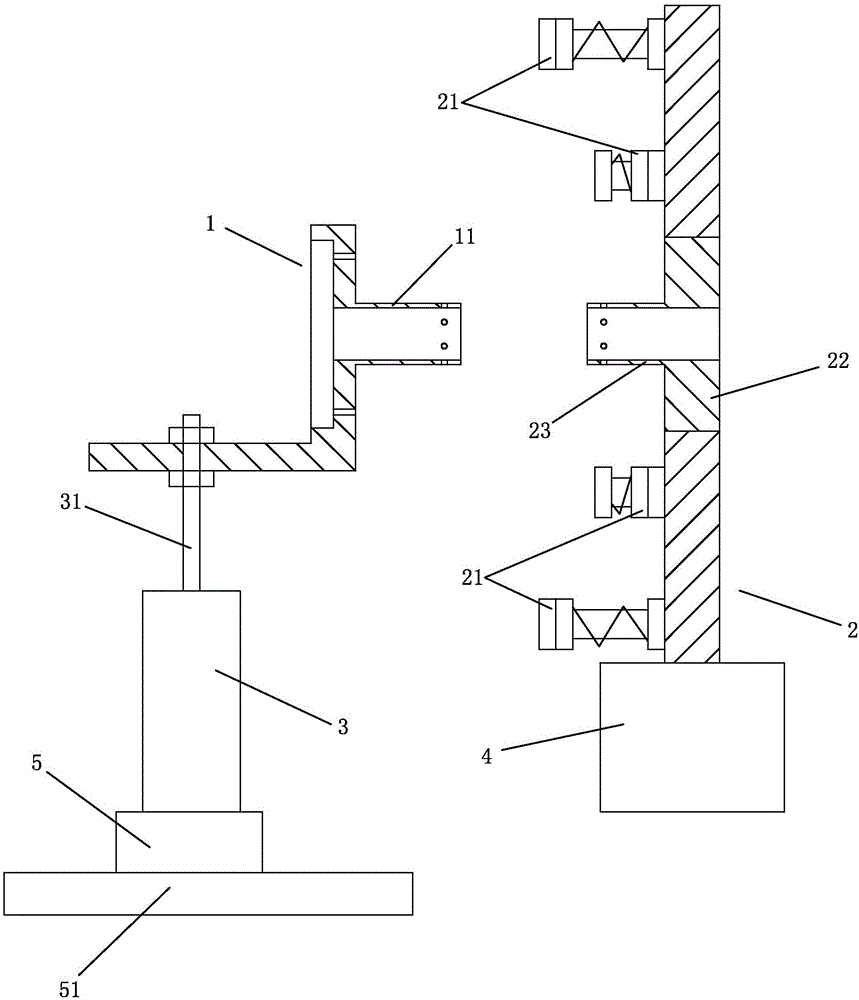

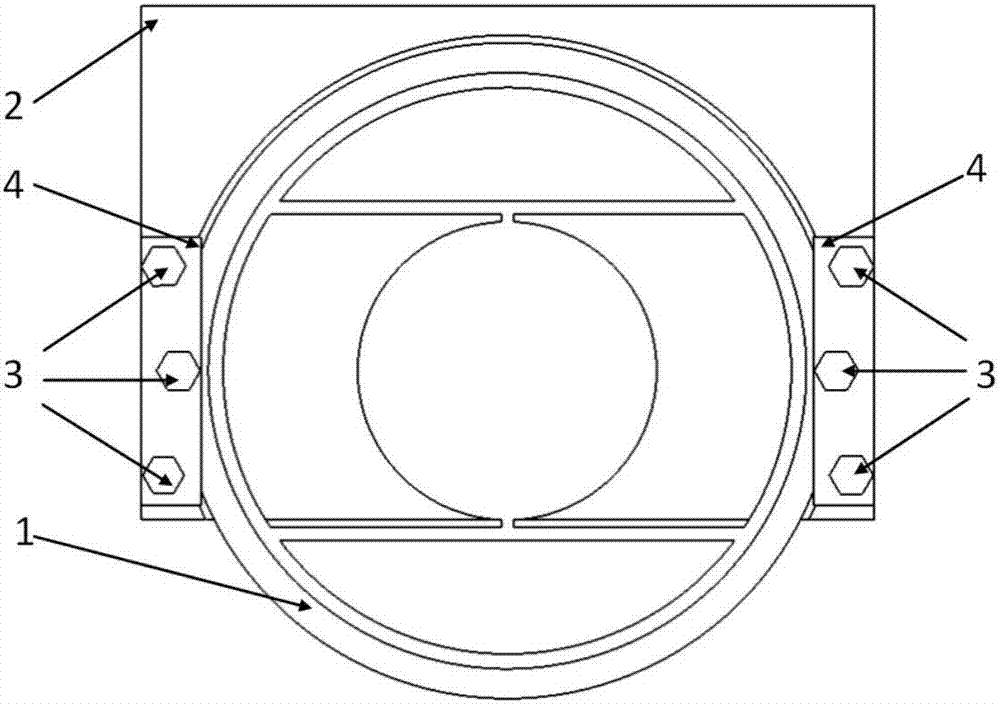

Milling passive vibration reduction clamp

InactiveCN103831646AChange the stiffnessHigh quality and efficient processingLarge fixed membersPositioning apparatusNumerical controlCantilever

A milling passive vibration reduction clamp is composed of a base, a supporting piece, a rotating piece, a supporting adjusting piece, a working table, supporting blocks, an adjusting plate, corresponding screws and corresponding nuts. The base is fixed to the machine table, the supporting piece is connected with the base through the screws, the supporting block is located on the supporting piece, three cantilever beam type supports are evenly distributed on the rotating piece in a horizontal plane and arranged on the three supporting blocks respectively, and the bolts sequentially penetrate through the rotating piece, the supporting blocks and the supporting piece for fixing. The milling passive vibration reduction clamp is characterized in that based on the passive control principle, rigidity adjustment in three orthogonal directions is achieved in a mechanical adjustment mode, vibration of rigid parts in the numerical control milling process is reduced, and efficient and high-precision machining is achieved. Rigidity adjustment in any direction can be independently conducted without affecting rigidity adjustment in other directions, the adjustable parameter range is large, and machining requirements of various parts can be met. The milling passive vibration reduction clamp is easy to implement and maintain and free of environmental pollution.

Owner:BEIHANG UNIV

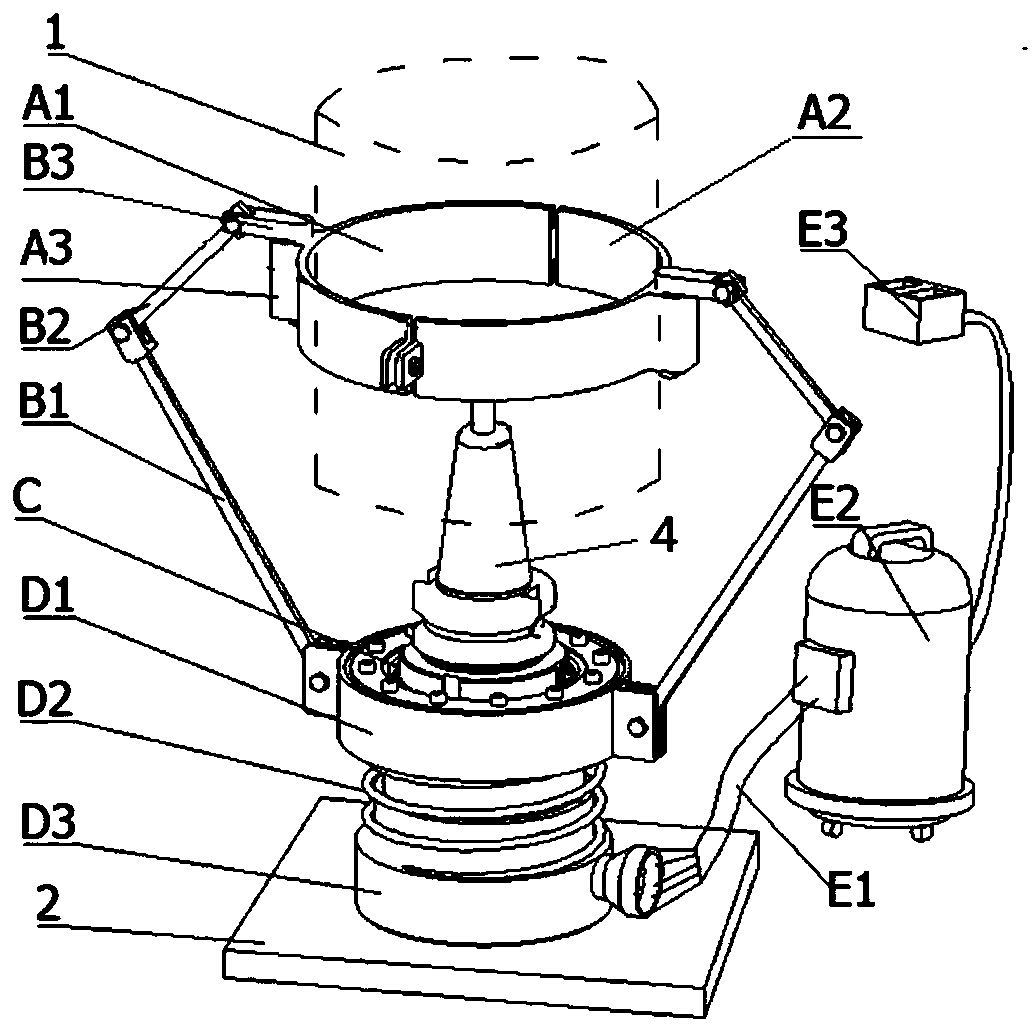

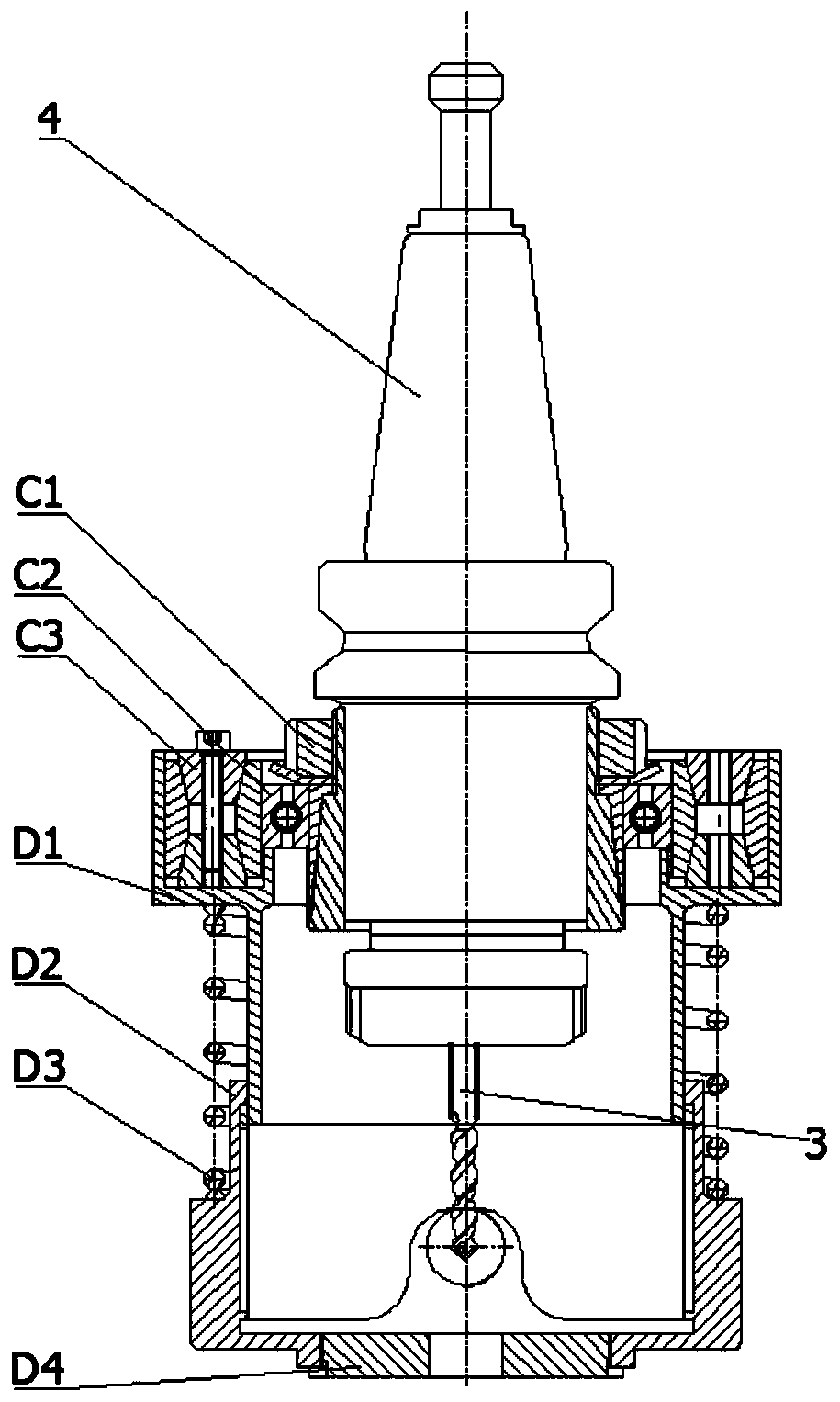

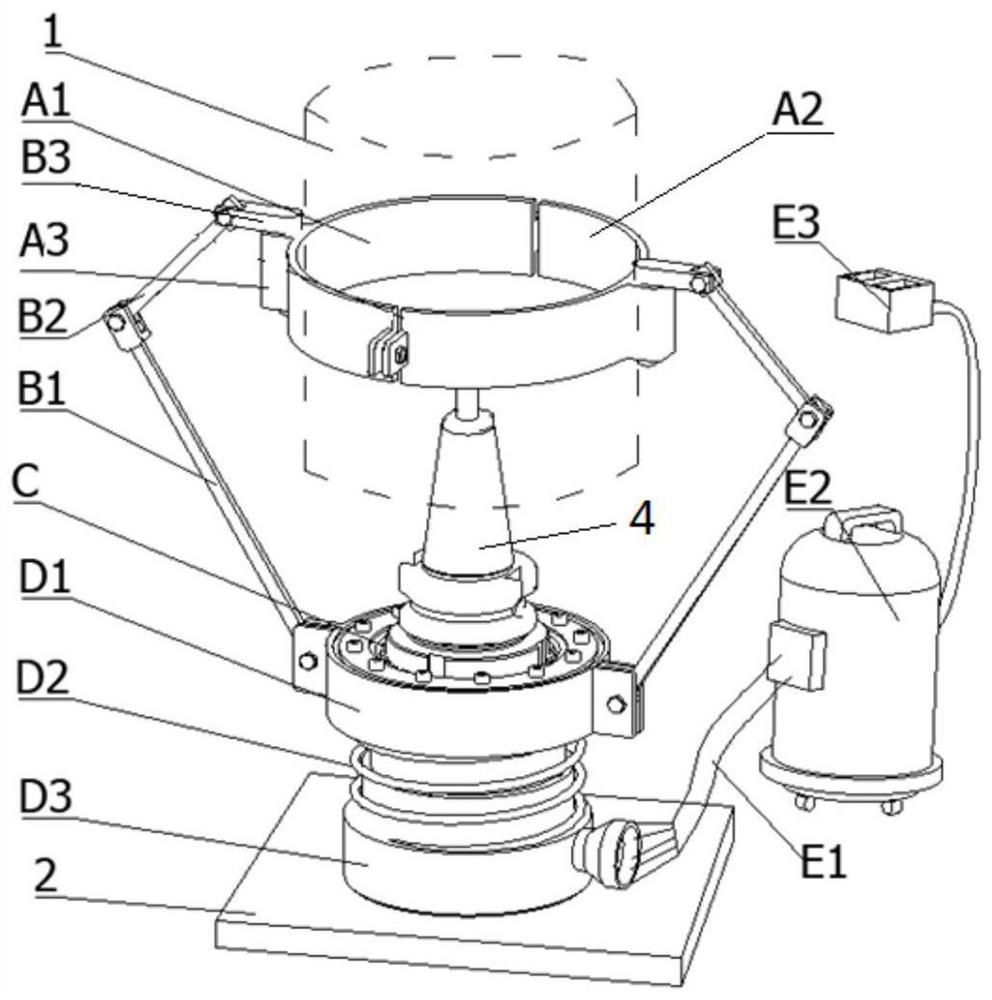

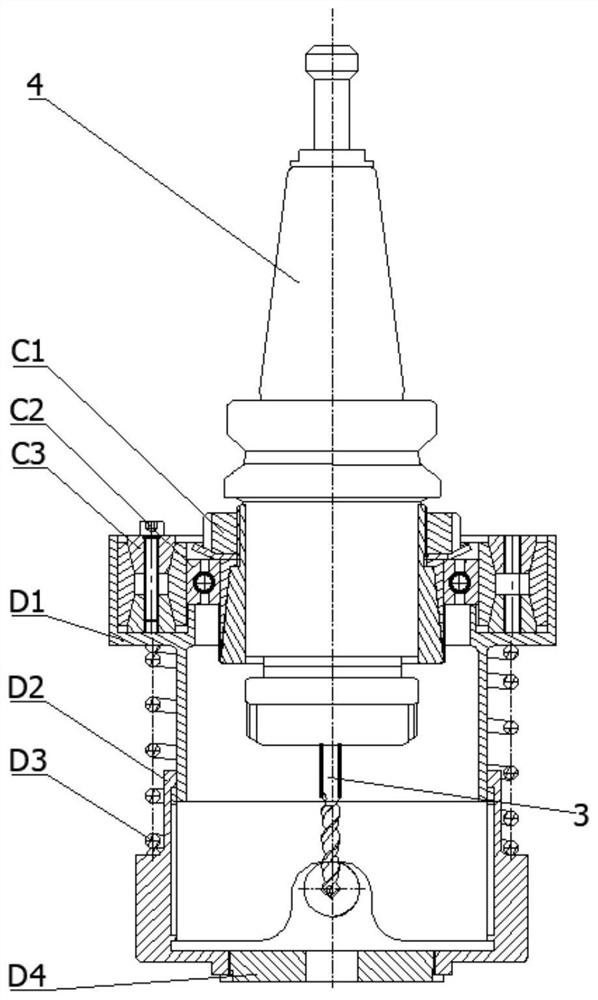

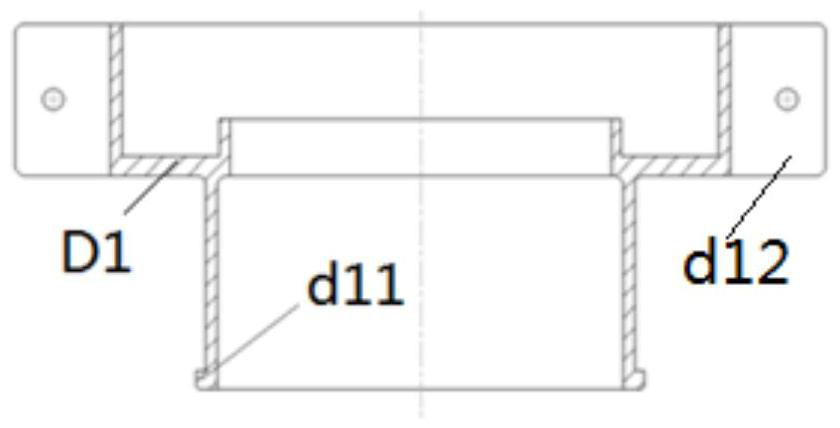

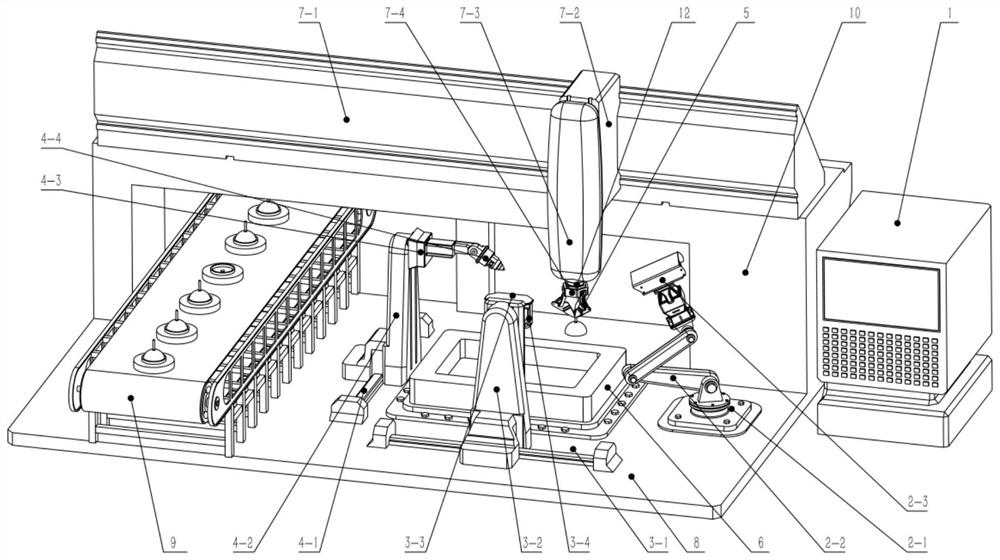

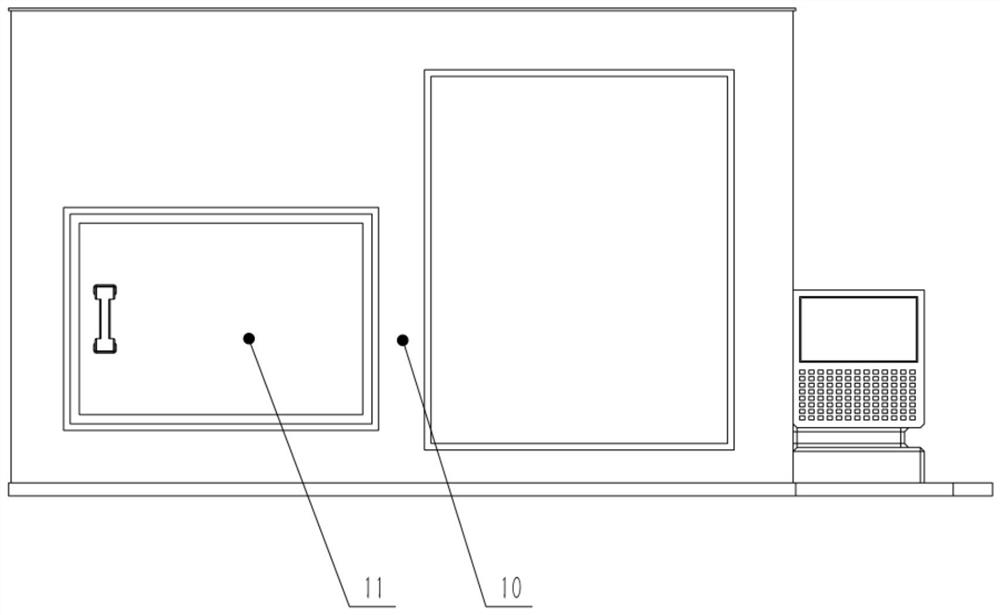

Multi-adaptive quick mounting type attached air cooling dedusting device

ActiveCN110919749AExtend your lifeTimely recyclingMetal working apparatusMachined surfaceDust control

The invention provides a multi-adaptive quick mounting type attached air cooling dedusting device, belongs to the field of cutting processing, and relates to the multi-adaptive quick mounting type attached air-cooled dust removing device for drilling and milling processing. The multi-adaptive quick mounting type attached air cooling dedusting device comprises five parts: a main shaft clamping mechanism, a link mechanism, a bearing connecting mechanism, an axial telescopic mechanism and a dust treatment mechanism. The multi-adaptive quick mounting type attached air cooling dedusting device is connected with a tool holder through an axial connecting mechanism, and is mounted on a machine tool. A cavity is defined by the axial telescopic mechanism and a machined surface, a negative pressure is formed in the cavity by using air flow generated by a negative pressure dedusting device, and the axial telescopic mechanism is fixed to a housing of a main shaft of the machine tool through the combination with the link mechanism, so that the condition that the main shaft rotates to drive the device to rotate to interfere with a workpiece is avoided, and quick collection and treatment of cuttings are finally realized. The multi-adaptive quick mounting type attached air cooling dedusting device is applied to drilling and milling processing, can effectively reduce the harm to human body and the damage to machine tool equipment, meanwhile, improves the processing quality, and has high practicability. For multiple kinds of machine tools, as long as the specification of tool holders is the same, the generality can be realized.

Owner:DALIAN UNIV OF TECH

Ultrasonic vibrating trepanning reamer machining device applied to pneumatic drill

InactiveCN102059365ASimple structural designRealize rotating power supplyReaming devicesEngineeringReamer

The invention discloses an ultrasonic vibrating trepanning reamer machining device applied to a pneumatic drill, which comprises a slide ring, a front cover plate, an A ceramic piece, a B ceramic piece, a back cover plate, a flange plate, a baffle ring, a reamer or a trepanning drill. The main shaft of the pneumatic drill is connected in an internal threaded hole of the front cover plate, an external threaded section of the front cover plate is sequentially sheathed with the A ceramic piece and the B ceramic piece, the external threaded section is arranged in a threaded hole of the back coverplate, and the other end of the front cover plate is connected with the reamer or a trepanning cutter; and an inner ring of the slide ring is arranged on the outer edge of the back cover plate, the baffle ring is arranged between an outer ring of the slide ring and the flange plate, and the shell of the pneumatic drill is connected with the flange plate. The device can be used for machining a large-pore, high-quality, high-efficiency and low-cost fastening piece hole of a composite titanium alloy laminated material.

Owner:BEIHANG UNIV +1

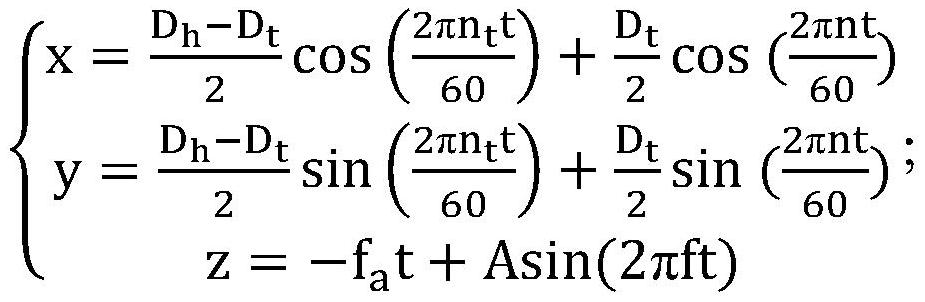

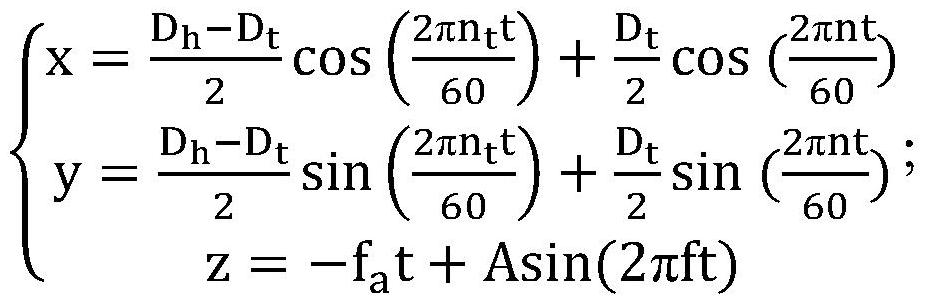

Aluminum-based silicon carbide thread precision machining method

ActiveCN112059535AHigh quality and efficient processingReduce wearCarbide siliconLongitudinal vibration

The invention discloses an aluminum-based silicon carbide thread precision machining method. The method comprises the following steps that an ultrasonic longitudinal vibration machining cutter handleis installed on a machine tool, an ultrasonic power source is connected with the ultrasonic longitudinal vibration machining cutter handle, and a workpiece is clamped on a machine tool workbench; a 2mm-10 mm drill bit is installed at the tail end of the ultrasonic longitudinal vibration machining cutter handle, and threaded bottom hole machining of the workpiece is completed; the 2 mm-10 mm drillbit is replaced with a diamond coating hard alloy cutter for thread machining, and an ultrasonic power source is started; the frequency of the ultrasonic power source and the amplitude of the diamondcoating hard alloy cutter carried at the tail end of the ultrasonic longitudinal vibration machining cutter handle are adjusted to meet the separation condition of the ultrasonic technology; a milling machine tool is started, and the diamond coating hard alloy cutter spirally mills a threaded hole of the workpiece according to a set spiral track; and the ultrasonic power source is shut off, and thread inlet and outlet chamfers of the workpiece are milled. By means of the aluminum-based silicon carbide thread precision machining method, threaded hole surface and hole inlet and outlet quality is improved, the machining efficiency is improved, and meanwhile cutter abrasion is reduced.

Owner:BEIJING SATELLITE MFG FACTORY

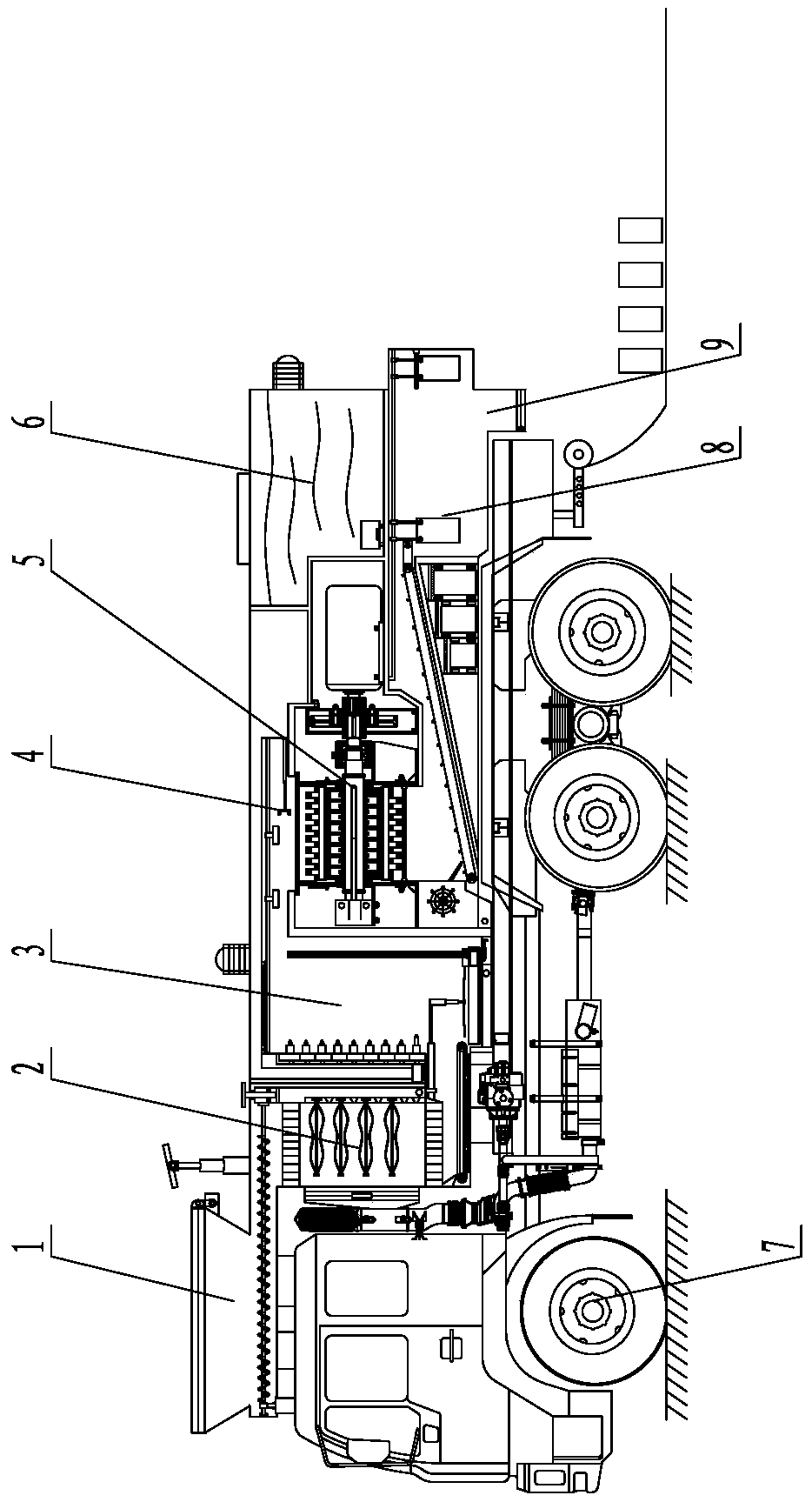

Vehicle agricultural grain packaging apparatus

InactiveCN109110209AReasonable process layoutHigh-quality and efficient processingWrapper twisting/gatheringItem transportation vehiclesWater coolingGrinding teeth

The invention discloses a vehicle agricultural grain packaging apparatus, and belongs to the field of farming machinery and equipment. The vehicle agricultural grain packaging apparatus is characterized in that the apparatus includes a grinding and crushing device and a track travelling packaging device. The grinding and crushing device includes a material grinding inlet, a grinding motor, a grinding rotating shaft, a grinding tooth saw, a grinding chamber, a powder outlet and a water cooling chamber. The material grinding inlet is arranged above the grinding chamber. The powder outlet is arranged under the grinding chamber. The track travelling packaging device includes a power conveyer belt, a packaging hung slide rail, a lifted bag changing device, telescopic lifting arms and a finishedbag discharging device. The power conveyer belt is arranged below a power outlet. A barrier plate is arranged on the power conveyor belt. The other end of the packaging hung slide rail is arranged above the finished bag discharging device. The telescopic lifting arms are arranged on the packaging hung slide rail. A nail plate is arranged on each telescopic lifting arm. The nail plates fix a lifted bag. The vehicle agricultural grain packaging apparatus can crushing, grinding and packaging threshed grain, is intensively designed in structure and reasonable in process layout, and can carry outprocessing with high quality and efficiency.

Owner:ZIBO DACHUANG AUTOMATIC TECH CO LTD

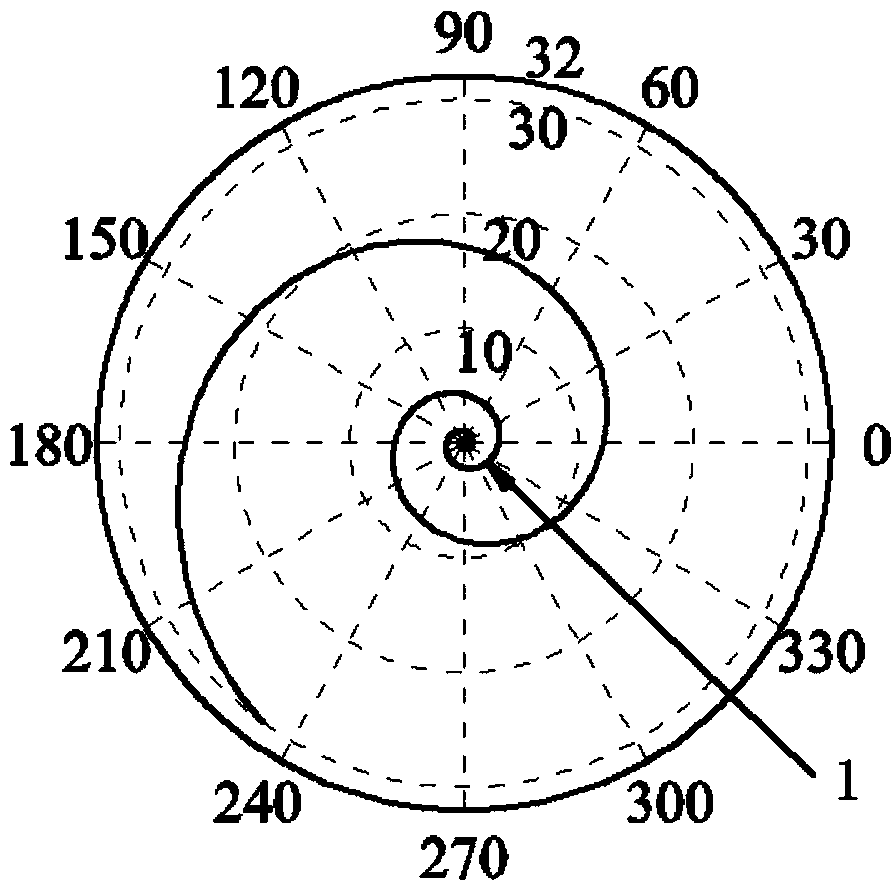

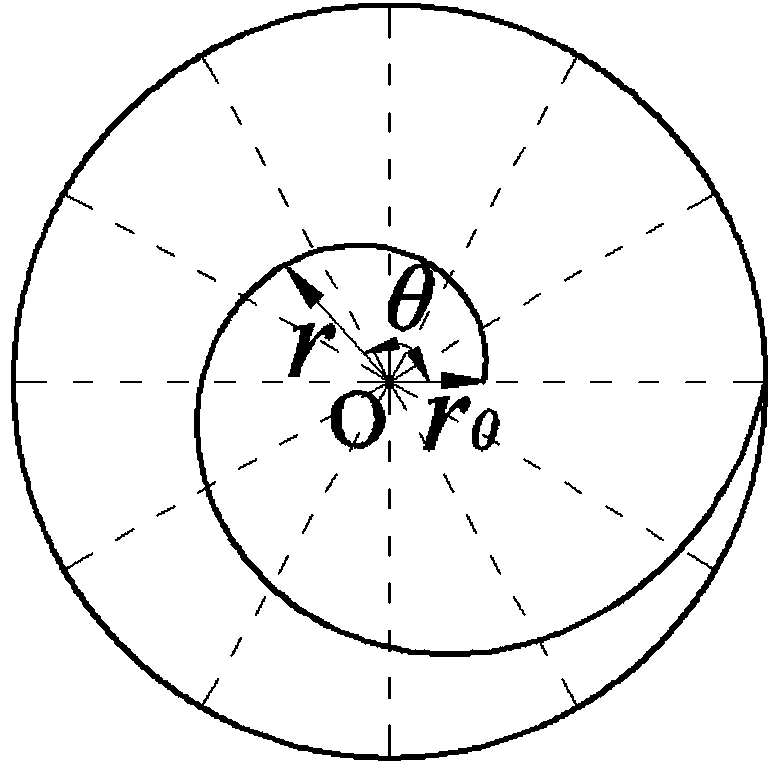

Equiangular spiral line partition variable parameter control precision machining method

ActiveCN103934727AMeet the process requirementsHigh quality and efficient processingAutomatic control devicesFeeding apparatusNumerical controlMathematical model

The invention discloses an equiangular spiral line partition variable parameter control precision machining method, and belongs to the field of numerical control precision machining. The method comprises the steps of analyzing an equiangular spiral line geometric model, determining the relation between the actual machining speed and machining time of an equiangular spiral line under constant technological parameters, on the basis of the equiangular spiral line machining error generating mechanism, building a mathematical model of the machining error, determining the rule of influences of equiangular spiral line geometrical characteristics and the NC program-set machining feed speed on the machining error, building the relation between the machining feed speed and the equiangular spiral line geometrical characteristics, conducting reasonable dividing on the equiangular spiral line machining area, and distributing corresponding machining feed speed to divided areas for machining. According to the partition variable parameter machining method of geometrical characteristic partition set machining feed speed, high-precision, high-quality and high-efficiency machining of the equiangular spiral line can be achieved.

Owner:DALIAN UNIV OF TECH

Real-time adjustable coil winding structure

The invention discloses a real-time adjustable coil winding structure. The structure comprises a front guiding rack and a wire guiding rack, the front guiding rack is provided with a guiding tube for guiding a tube to pass through, the front guiding rack is arranged on a lifting mechanism, the lifting mechanism is fastened to a translation mechanism, the guiding tube protrudes toward the wire guiding rack, the wire guiding rack is provided with a wire clamp for stabilizing a coil and an inner rack positioned in the center of the wire guiding rack, a coaxial winding tube protruding toward the guiding tube is arranged at the center of the inner rack, the tube wall of the winding tube is provided with a through hole corresponding to the wire clamp, and the wire guiding rack is connected with a rotating motor. The structure allows a plurality of coils to be wound simultaneously and the positions of the fed tube corresponding to the coils to be adjusted in real time, and realizes high-quality and high-efficiency tube screen tube layer processing.

Owner:广东亿洋管业科技有限公司

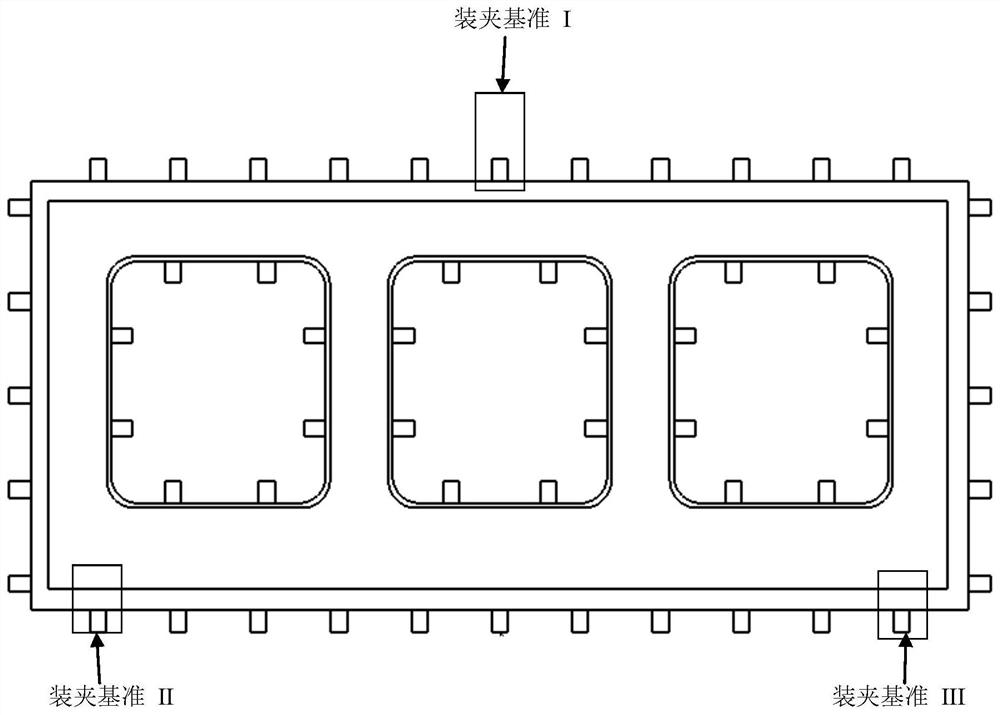

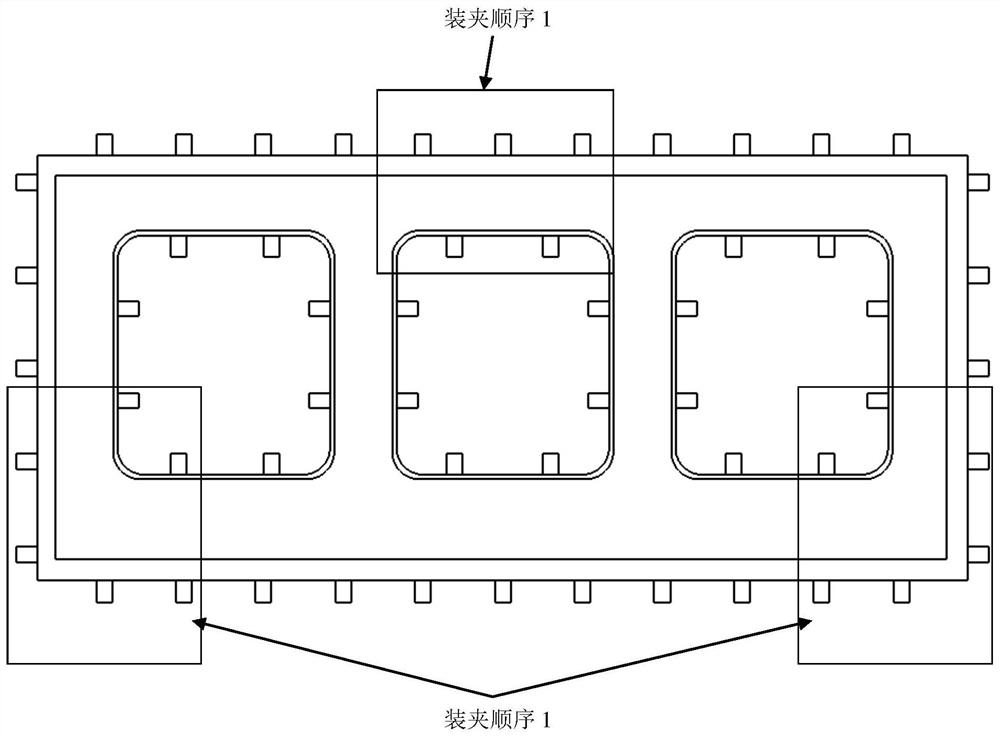

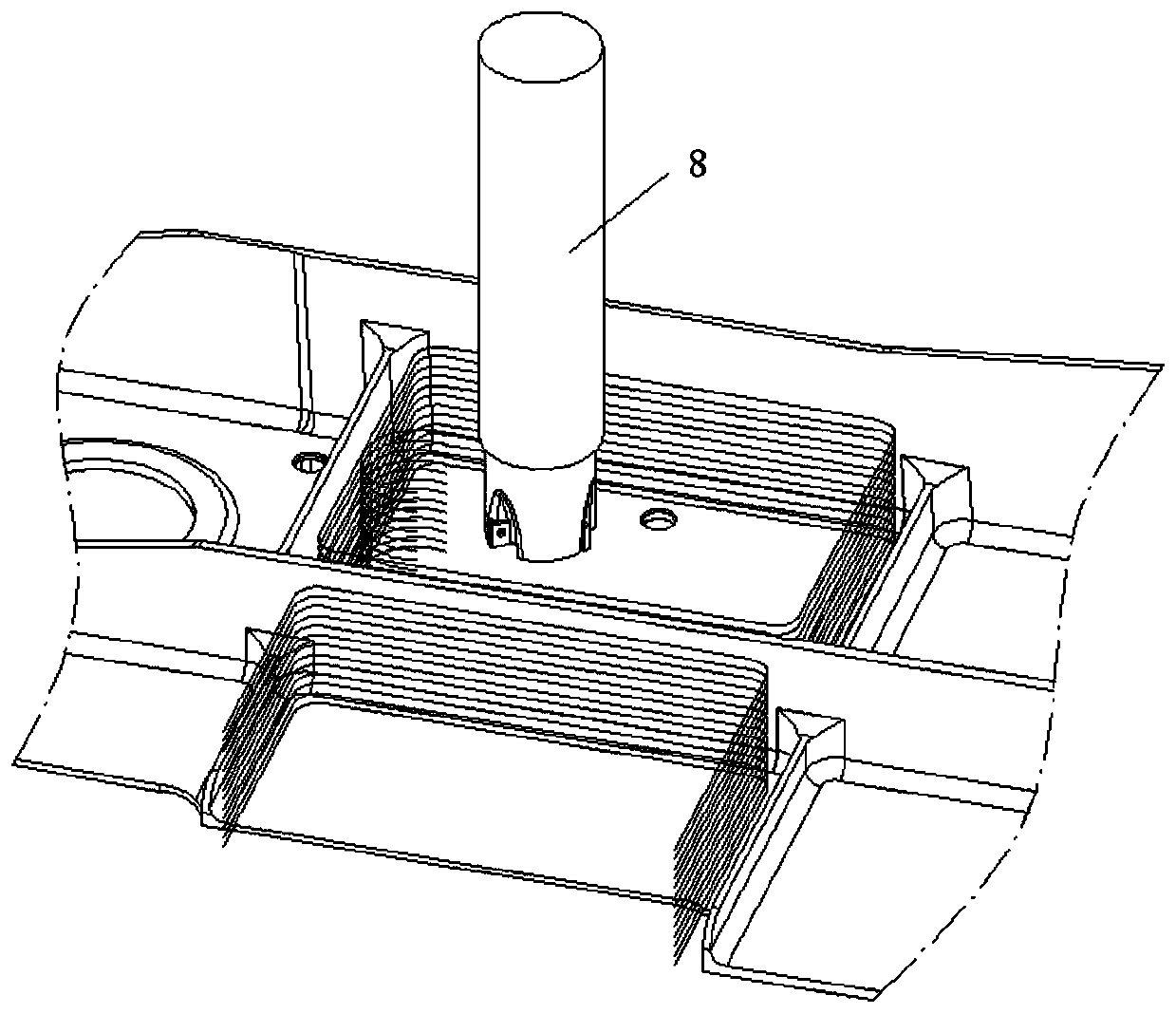

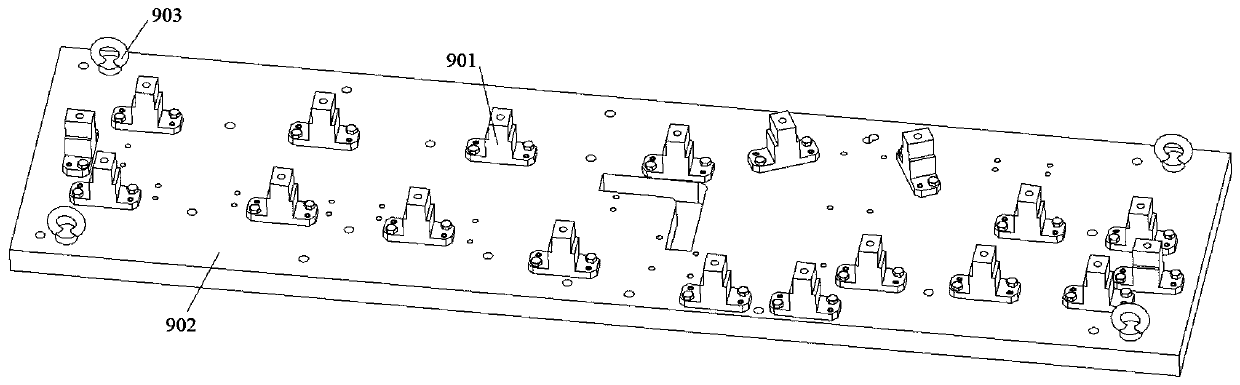

A numerical control machining method for super-large complex thin-walled parts of titanium alloy

ActiveCN110385466BHigh quality and efficient processingControl deformationMilling equipment detailsPositioning apparatusNumerical controlEngineering

Owner:SHENYANG AIRCRAFT CORP

Processing method of fully ripe xinhui citrus peel filled with Liupao tea

InactiveCN109393073AImprove qualityQuality improvementPre-extraction tea treatmentSteamingFermentation

The invention provides a processing method of fully ripe xinhui citrus peel filled with Liupao tea, and belongs to the technical field of processing of tea leaves. The processing method comprises thefollowing steps of preparing semi-finished Liupao tea and preparing the fully ripe xinhui citrus peel filled with Liupao tea. The semi-finished Liupao tea is prepared through the following steps of performing fixation on fresh leaves, performing primary twisting, performing heaping for fermentation, performing secondary twisting, and performing drying. The fully ripe xinhui citrus peel filled withLiupao tea is prepared through the following steps of treating fully ripe xinhui citruses, loading tea, performing primary steaming, performing cold fermentation, performing secondary steaming and performing ageing. The processing method is simple in technology, easy to operate, and high in production practicality. According to the method disclosed by the invention, high quality and high efficiency of processing of the fully ripe xinhui citrus peel filled with Liupao tea can be guaranteed, particularly the color, fragrance, taste, and shape and the quality of tea grounds of the fully ripe xinhui citrus peel filled with Liupao tea can be improved, the yield for making tea can be increased, and the quality of the fully ripe xinhui citrus peel filled with Liupao tea can be improved.

Owner:广西梧州六堡茶股份有限公司

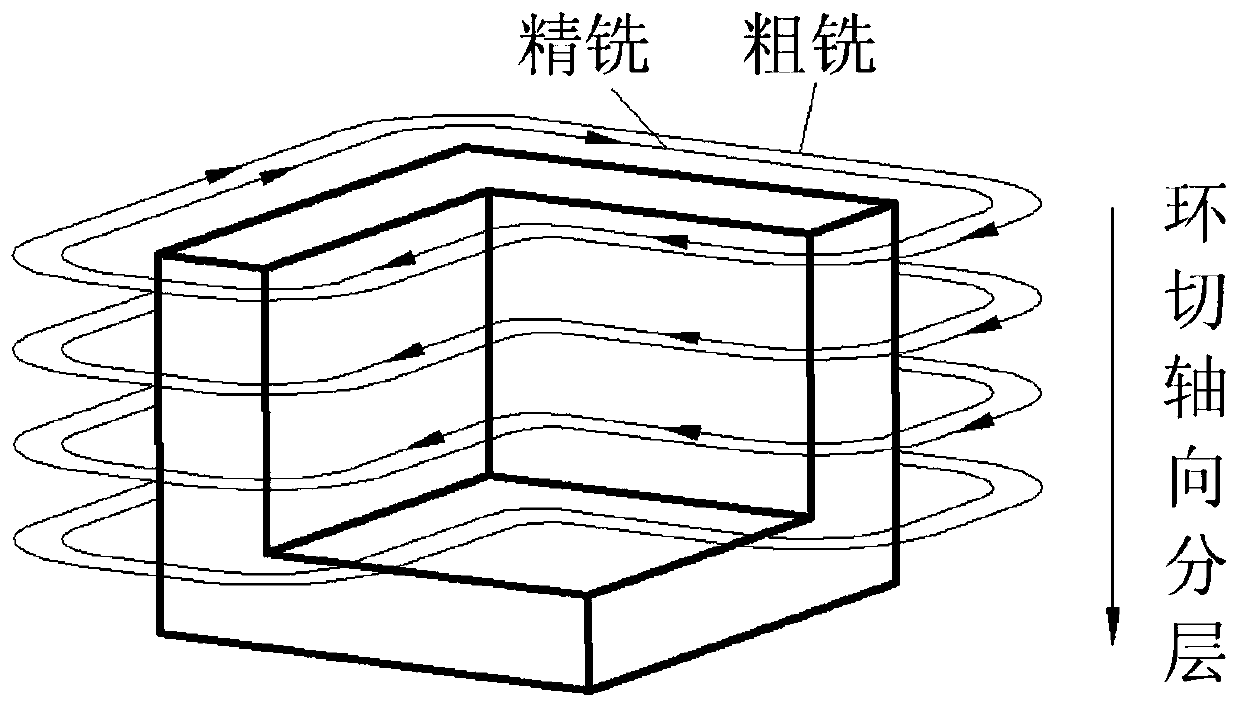

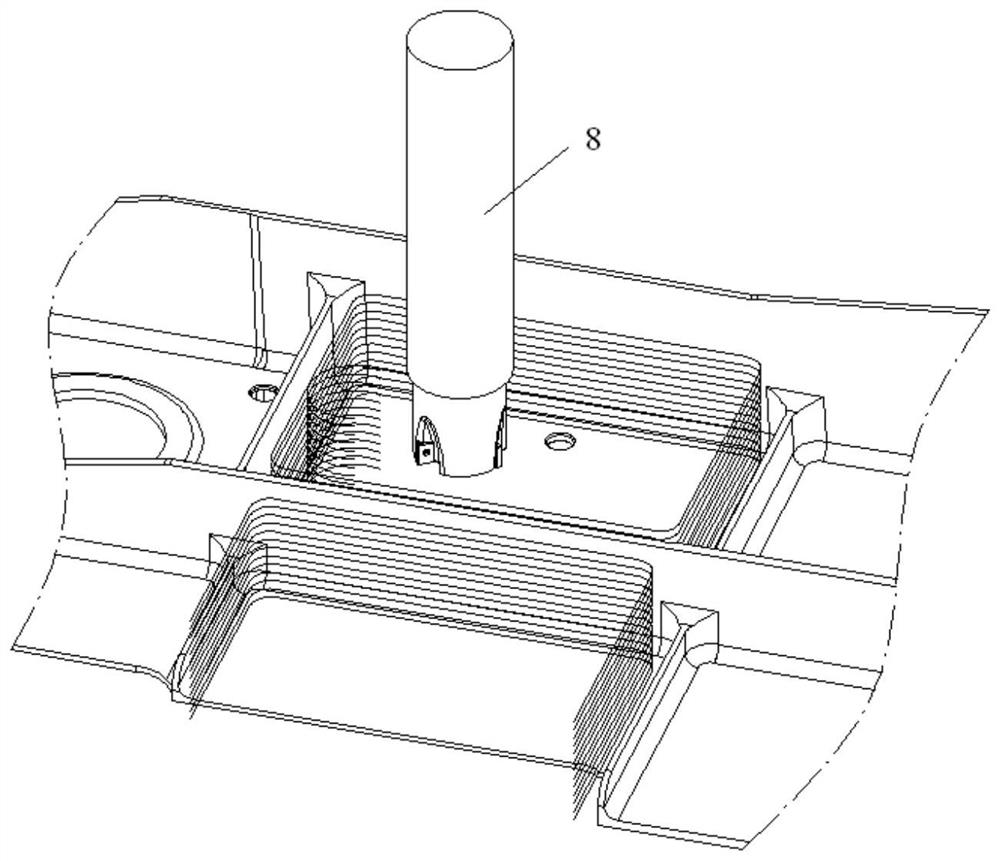

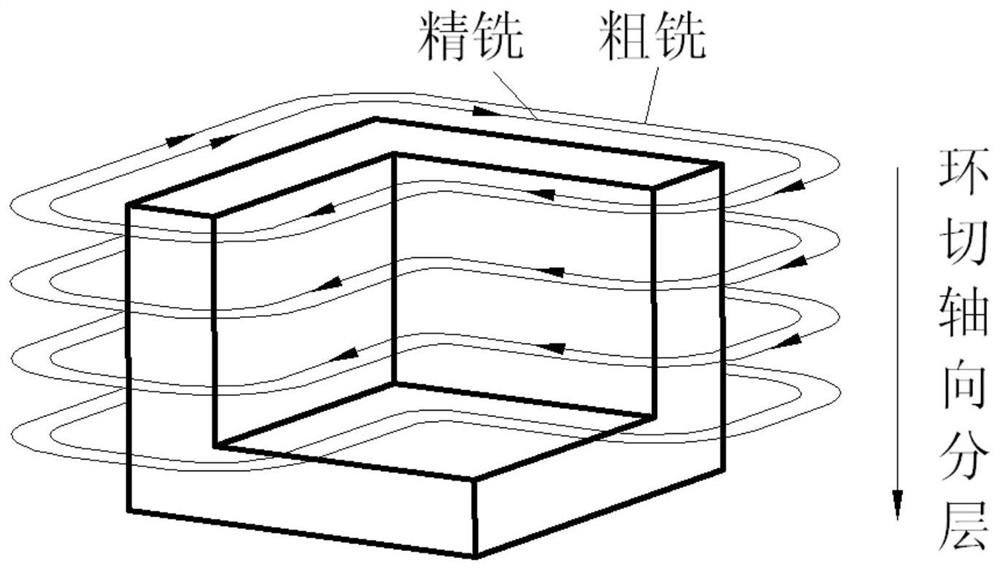

Method for machining AF1410 steel part before quenching

ActiveCN111203579AExtend your lifeHigh quality and efficient processingMilling equipment detailsChatter markCutting tool

The invention belongs to the technical field of machining and specifically relates to a method for machining an AF1410 steel part before quenching. According to the method, high-quality and high-efficiency machining is carried out on the AF1410 steel part before quenching strengthening through a shallow cutting-quick feeding equal-height layer reduction cutting process; when a deep cavity structure exists in the part, a ring cutting and axial layered rough milling-finish milling machining method is adopted so as to solve the problems of vibration of a cutting tool and chatter marks on the surface of the part. Through the method for machining the AF1410 steel part before quenching, the machining efficiency is improved by 3-4 times, the cutting temperature is effectively reduced, the servicelife of the cutting tool is prolonged, the quality of the part is improved, the problems that excess cutting temperature, serious work hardening, poor part quality and the like are solved, and high-quality and high-efficiency machining of the AF1410 steel part is realized.

Owner:SHENYANG AIRCRAFT CORP

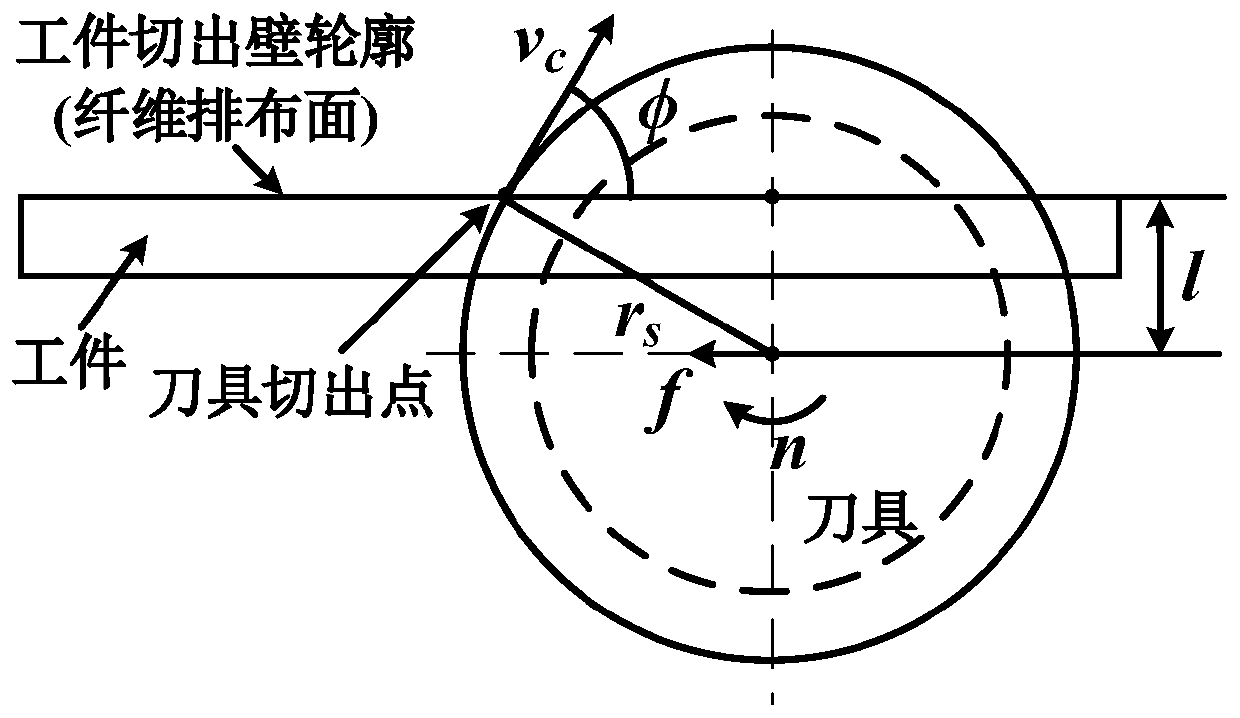

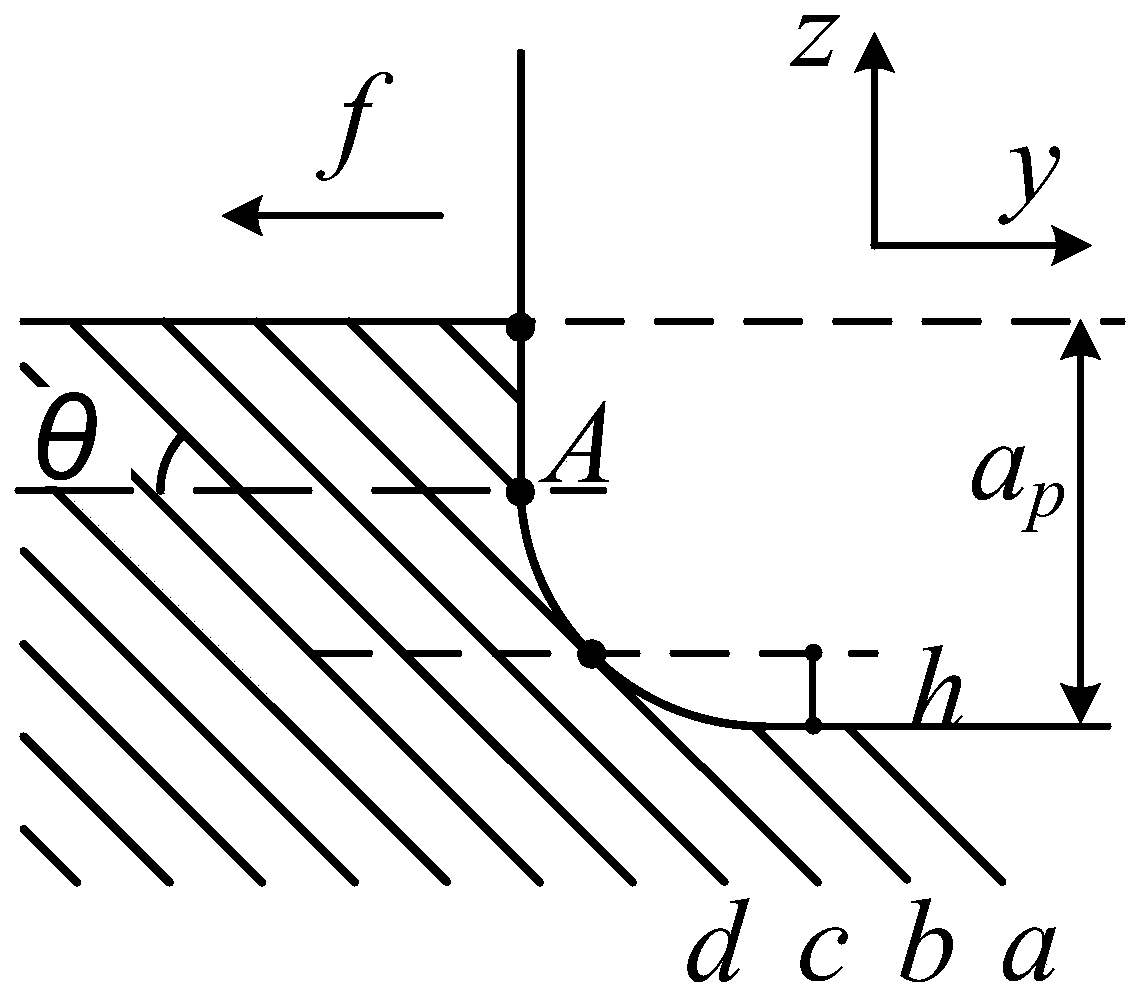

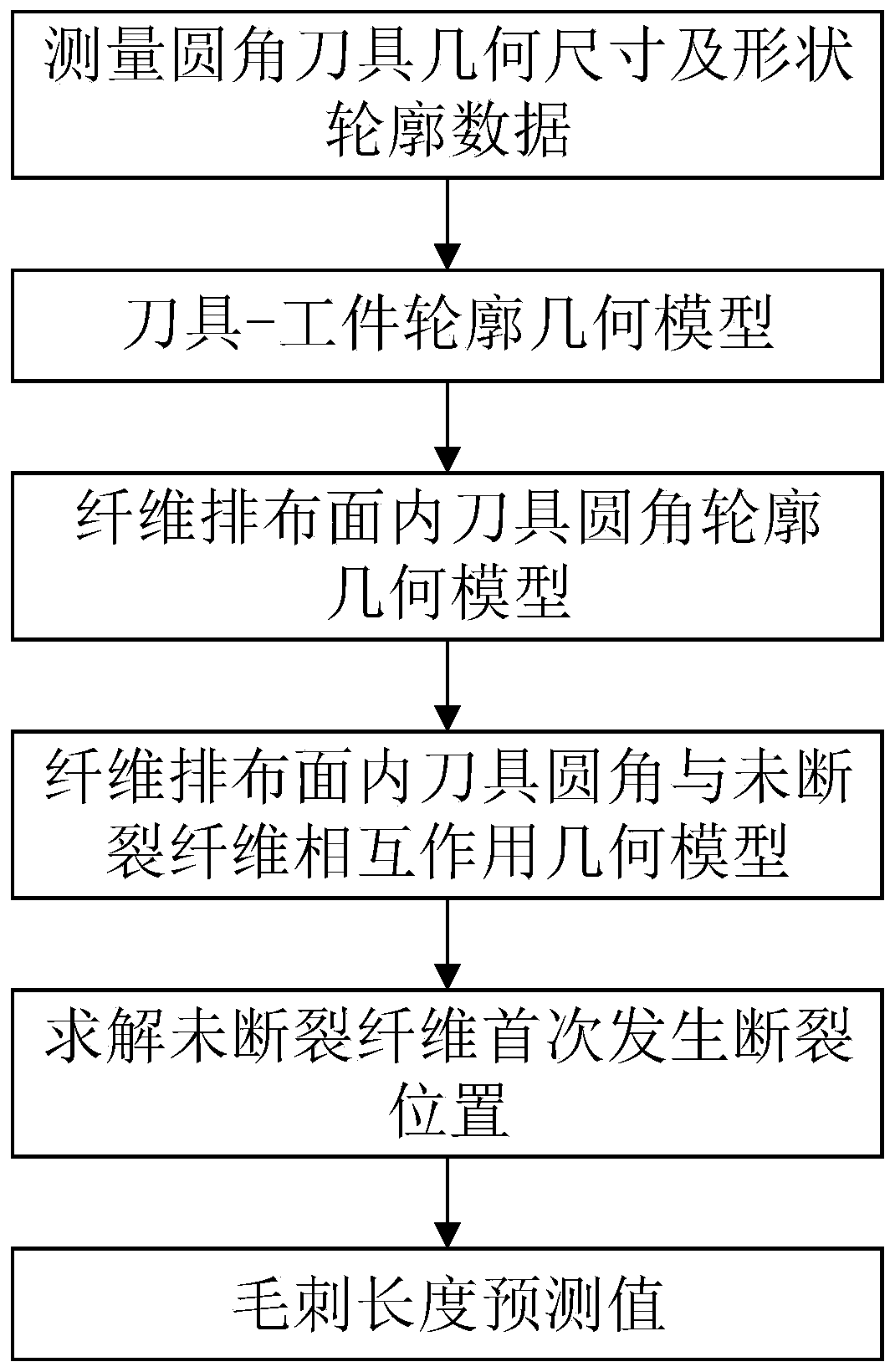

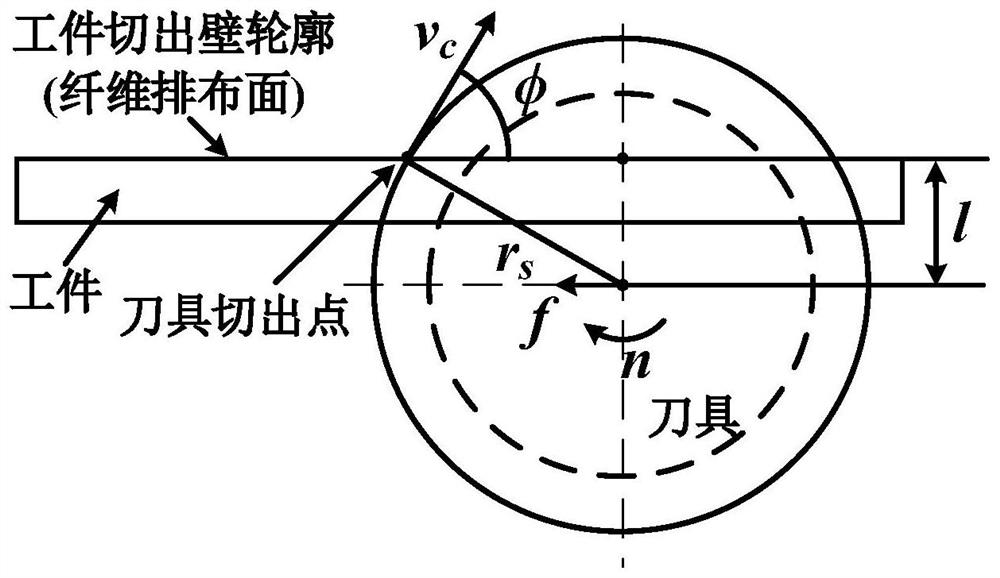

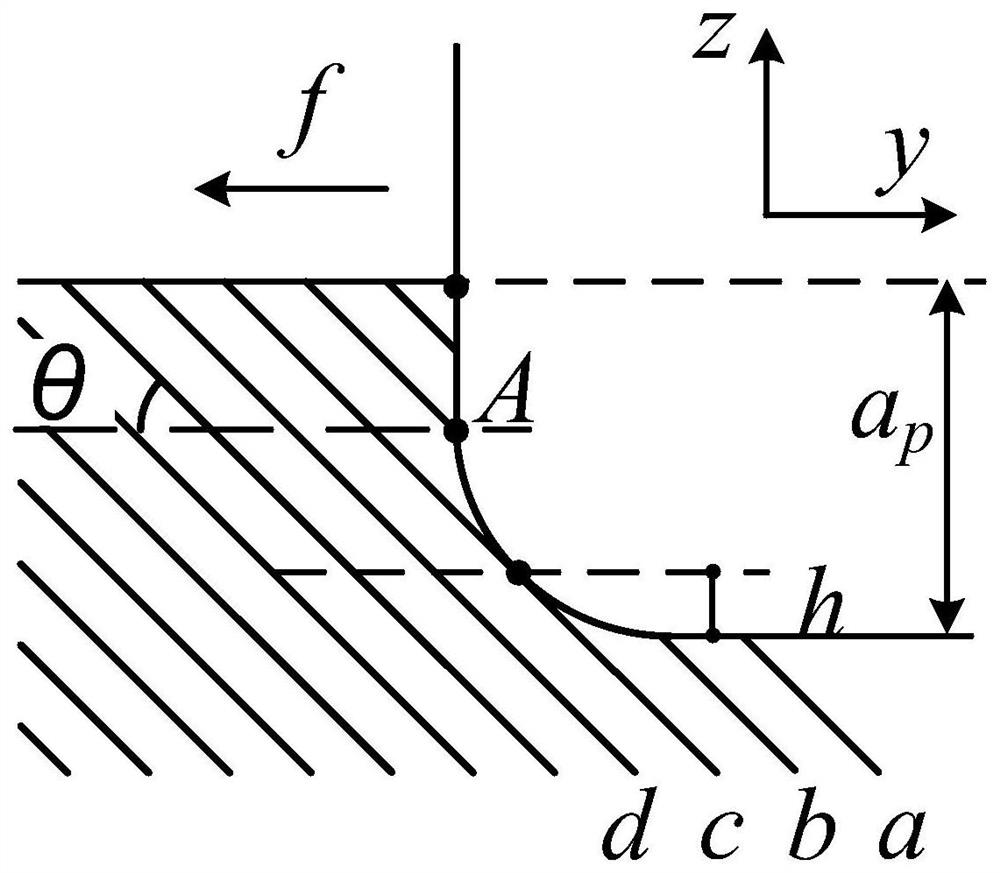

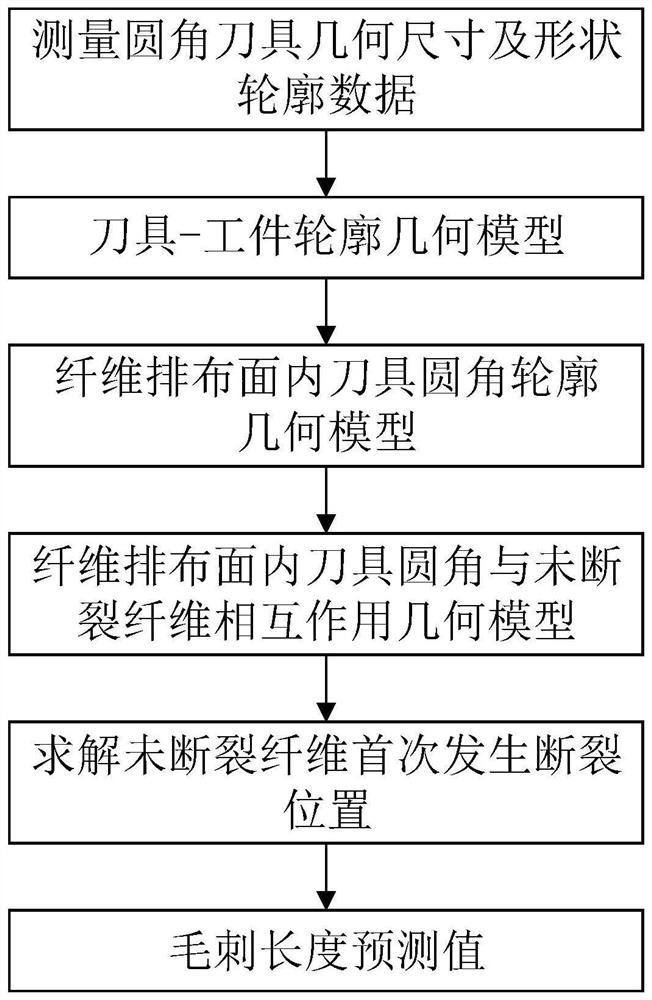

Method for predicting burr length of fiber reinforced composite material processed by fillet cutter

ActiveCN110889149ASave tooling and material costsFacilitates quality control of machined surfacesComputer aided designSpecial data processing applicationsStructural engineeringFiber-reinforced composite

The invention discloses a method for predicting the burr length of a fiber reinforced composite material machined by a fillet cutter, and belongs to the technical field of composite material machining. In the implementation process of the method, the method comprises the following steps of: firstly, measuring the geometric dimension and shape contour data of the fillet cutter, and establishing a cutter-workpiece contour geometric model; establishing a cutter fillet contour geometric model in a fiber arrangement surface on the basis, then considering a cut-out side fiber direction angle theta,establishing an interaction geometric model of a cutter fillet in the fiber arrangement surface and an unbroken fiber, solving the first breaking position of the unbroken fiber on the basis, and calculating the maximum theoretical burr length. According to the method, the burr length prediction model in the fiber reinforced composite material processing process is established according to the burrgeneration mechanism of the fiber reinforced composite material, and the method is comprehensive and complete in related content and easy to operate.

Owner:DALIAN UNIV OF TECH

Tool Path Planning Method for Surface Machining Constrained by Cutting Force Fluctuation

ActiveCN106125666BHigh quality and efficient processingImprove adaptabilityNumerical controlCutter locationEngineering

The invention relates to a curved-surface machining cutter track planning method using cutting force fluctuation as a constraint, which belongs to the technical field of the high-efficiency milling processing for complicated curved-surface parts. According to the method, on the basis of cutter location point data obtained by an equal-residual-height method, an optimal feeding ling spacing value and an optimal feeding step length are determined, thereby realizing a cutter location grid unit division based on a cutter location grid node. With fitting of a cutter location grid unit plane, a cutter location grid node Z coordinate is determined by combining an adjacent associated cutter location grid unit. And then a cutter location grid node normal vector is calculated; and with the cutting force fluctuation during the processing process as a constraint, a curved-surface processing cutter track is planned by using the cutter location grid node as a cutter location point according to a fundamental principle of normal vector included angle minimization between adjacent cutter location points, so that the high-quality and high-efficiency curved surface processing is realized. The method has the high adaptability to the local complicated geometrical features; and high-quality and high-efficiency curved surface processing is realized.

Owner:DALIAN UNIV OF TECH

An Eddy Current Rotary Variable Stiffness Damper

ActiveCN105889380BSuppress cutting chatterWeaken natural modesMagnetic springsVariable stiffnessElectricity

The invention discloses an electric-eddy-current rotation-transformation rigidity damper which comprises a mass block, a supporting frame, bolts, cover plates and a permanent magnet, wherein the mass block is mounted in a cylindrical groove of the supporting frame; the cover plates are fixedly arranged on the upper surface of the supporting frame through the bolts; meanwhile, the positions of the mass block in the supporting frame are fixed by the bolts through the cover plates; the permanent magnet is mounted in a cylindrical groove of the mass block. The electric-eddy-current rotation-transformation rigidity damper serves as a vibration reduction device in the field of machining, can effectively inhibit the cutting chatter of a thin-wall part, and guarantees a high-quality and high-efficiency machining process of the thin-wall part; when the mass block and the supporting frame generates relative motion, the electric-eddy-current rotation-transformation rigidity damper generates an electric eddy current effect, so as to obstruct the vibration of the supporting frame, and further inhibit the vibration of the thin-wall part; the electric-eddy-current damping is non-contact damping, and can inhibit multi-stage vibration modes; the electric-eddy-current rotation-transformation rigidity damper can accurately regulate the rigidity of the damper, so as to more conveniently and quickly match the rigidity of the thin-wall part, and more effectively inhibit the vibration of the thin-wall part; the electric-eddy-current rotation-transformation rigidity damper is simple in structure, convenient to mount and low in cost, has no pollution to an environment, and is wide in scope of application.

Owner:BEIHANG UNIV

A method for precision machining of aluminum-based silicon carbide threads

The invention discloses a method for precise machining of aluminum-based silicon carbide threads. The method comprises the following steps: installing an ultrasonic longitudinal vibration machining tool handle on a machine tool, connecting an ultrasonic power supply to the ultrasonic longitudinal vibration machining tool handle, and The workpiece is clamped on the machine table; a 2-10mm drill bit is installed at the end of the ultrasonic longitudinal vibration machining tool holder to complete the thread bottom hole processing of the workpiece; the 2-10mm drill bit is replaced with a diamond-coated carbide tool for thread processing, Turn on the ultrasonic power supply; adjust the frequency of the ultrasonic power supply and the amplitude of the diamond-coated carbide tool mounted on the end of the ultrasonic longitudinal vibration processing handle to meet the separation conditions of the ultrasonic process; start the milling machine, and the diamond-coated carbide tool will press the set spiral The threaded hole of the workpiece is helically milled by the trajectory; the ultrasonic power is turned off, and the chamfering of the thread entrance and exit of the workpiece is milled out. The invention improves the quality of the surface of the threaded hole and the entrance and exit of the hole, improves the processing efficiency and reduces tool wear at the same time.

Owner:BEIJING SATELLITE MFG FACTORY

Processing method of af1410 steel parts before quenching

ActiveCN111203579BExtend your lifeHigh quality and efficient processingMilling equipment detailsChatter markWorkmanship

The invention belongs to the technical field of machining and specifically relates to a method for machining an AF1410 steel part before quenching. According to the method, high-quality and high-efficiency machining is carried out on the AF1410 steel part before quenching strengthening through a shallow cutting-quick feeding equal-height layer reduction cutting process; when a deep cavity structure exists in the part, a ring cutting and axial layered rough milling-finish milling machining method is adopted so as to solve the problems of vibration of a cutting tool and chatter marks on the surface of the part. Through the method for machining the AF1410 steel part before quenching, the machining efficiency is improved by 3-4 times, the cutting temperature is effectively reduced, the servicelife of the cutting tool is prolonged, the quality of the part is improved, the problems that excess cutting temperature, serious work hardening, poor part quality and the like are solved, and high-quality and high-efficiency machining of the AF1410 steel part is realized.

Owner:SHENYANG AIRCRAFT CORP

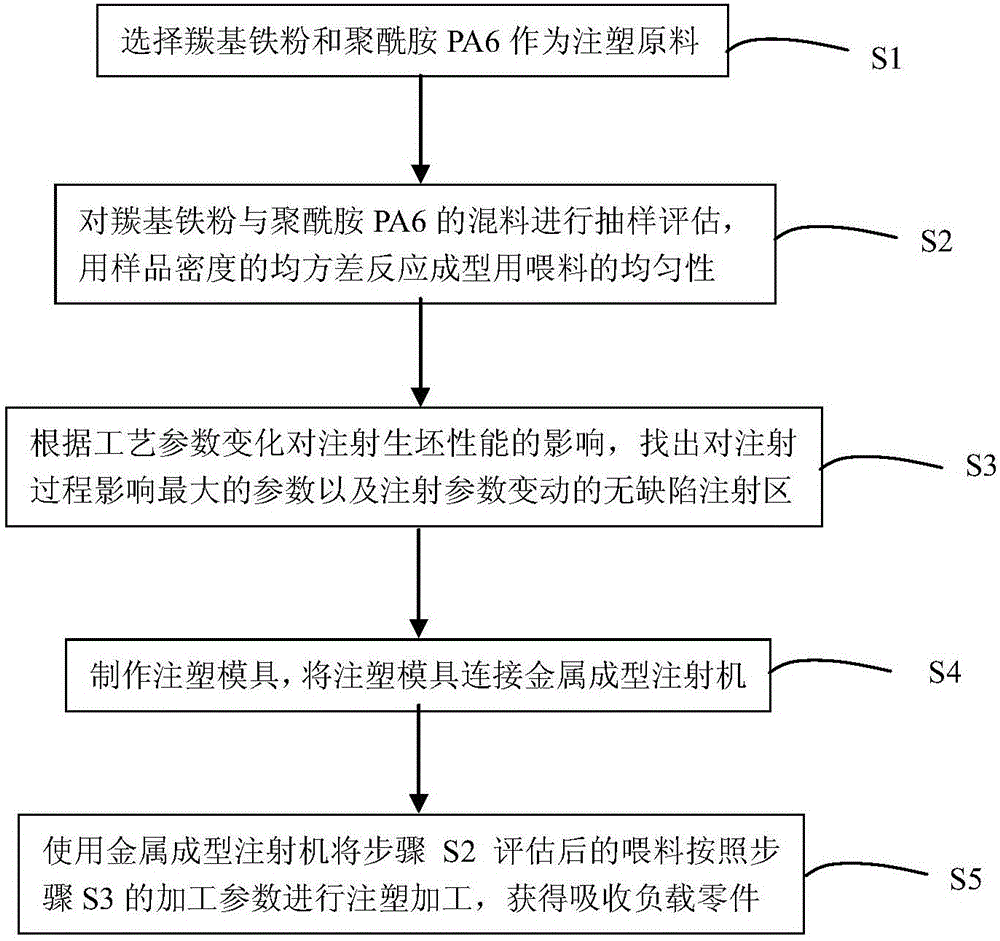

Manufacturing method of antenna absorption load

InactiveCN106626218AIncrease profitHigh quality and efficient processingDomestic articlesMetal formingPolyamide

The invention discloses a manufacturing method of an antenna absorption load. A thread bottom hole is formed in the bottom surface of the absorption load; and the manufacturing method comprises the following steps: (S1) carbonyl iron powder and polyamide PA6 are selected as injection raw materials; (S2) the mixture of carbonyl iron powder and polyamide PA6 is sampled and estimated; and the mean square error of the sample density is used for reflecting the uniformity of a feed for molding; (S3) according to influence on the injection blank performance by the process parameter change, parameters with maximum influence on the injection process and a no-defect injection area with changed injection parameters are found out; (S4) an injection mold is manufactured, and is connected with a metal molding injector; and (S5) the metal molding injector is used for injection molding of the feed estimated in the step (S2) according to the machining parameters in the step (S3) to obtain the absorption load part. The manufacturing method has the following advantages: the direct injection molding method for mixing high-grade engineering plastic with carbonyl iron powder according to a traditional design set ratio realizes once net molding of the absorption load, and largely increases the material utilization rate and the machining rejection rate.

Owner:SHANGHAI RADIO EQUIP RES INST

Method and device for preparing silicon-based three-dimensional (3D) microstructure

InactiveCN102381682BHigh quality and efficient processingEffective protectionDecorative surface effectsChemical vapor deposition coatingChemical solutionLaser scanning

The invention relates to a method and a device for preparing a silicon-based three-dimensional (3D) microstructure. The method comprises the following steps: carrying out laser machining, chemical corrosion and combined machining on a silicon wafer covered with a picture mask; performing laser scanning and cutting along a preset track of the picture mask; simultaneously chemically etching a laser machining surface by utilizing a chemical solution; and finishing the machining surface. The device for implementing the method mainly consists of a laser, the picture mask, a focusing lens, a work box, a worktable, a liquid collecting tank and a chemical solution circulating and filtering system, wherein the work box is connected on the worktable, a cavity is arranged inside the work box, and a window is arranged on one end of the work box; the picture mask is adhered to the upper end face of the silicon wafer and is placed in the cavity; the liquid collecting tank is placed below the silicon wafer; the chemical solution circulating and filtering system is communicated with the cavity and the liquid collecting tank; the focusing lens and the laser are placed at one side of the window; and lasers are focused on the silicon wafer through the focusing lens and the window. The silicon-based 3D microstructure obtained by the method has the advantages of large height-width ratio, good perpendicularity and good surface quality.

Owner:NANTONG UNIVERSITY

A multi-adaptive quick-installed air-cooled dust removal equipment

ActiveCN110919749BExtend your lifeTimely recyclingMetal working apparatusMachined surfaceDust control

The invention relates to a multi-adaptive quick-installation air-cooled dedusting equipment with accompanying air-cooling and dust removal equipment, which belongs to the field of cutting processing and relates to a multi-adaptive quick-installation air-cooled dedusting equipment for drilling and milling processing. The equipment consists of five parts: spindle clamping mechanism, connecting rod mechanism, bearing connection mechanism, axial expansion mechanism and dust treatment mechanism. The equipment is connected with the tool handle through the axial connection mechanism and installed on the machine tool. The axial telescopic mechanism and the processing surface form a cavity, and the gas flow generated by the negative pressure vacuum cleaner is used to form a negative pressure in the cavity, and the telescopic mechanism is fixed with the machine tool spindle shell with the linkage mechanism, so as to avoid the rotation of the spindle and the rotation of the equipment. Workpiece interference, ultimately enabling fast collection and disposal of swarf. This equipment is suitable for drilling and milling, which can effectively reduce the harm of chips to human body and machine tool equipment, and improve the processing quality at the same time, which is practical. For multiple types of machine tools, versatility can be achieved as long as the toolholders are of the same specification.

Owner:DALIAN UNIV OF TECH

A method for predicting the length of burrs in fiber-reinforced composites with fillet tools

ActiveCN110889149BFacilitates quality control of machined surfacesLow costComputer aided designSpecial data processing applicationsGeometric modelingEngineering

The invention discloses a method for predicting the burr length of a fiber-reinforced composite material processed by a fillet cutter, and belongs to the technical field of composite material processing. In the implementation process of this method, the geometric dimension and shape profile data of the fillet tool are firstly measured and the tool-workpiece profile geometric model is established. The fiber direction angle θ is used to establish the geometric model of the interaction between the tool fillet and the unbroken fiber in the fiber arrangement plane, and on this basis, the first fracture position of the unbroken fiber is solved and the maximum theoretical burr length is calculated. According to the burr generation mechanism of the fiber reinforced composite material, the method establishes a burr length prediction model during the processing of the fiber reinforced composite material, and the method involves comprehensive and complete content and is easy to operate.

Owner:DALIAN UNIV OF TECH

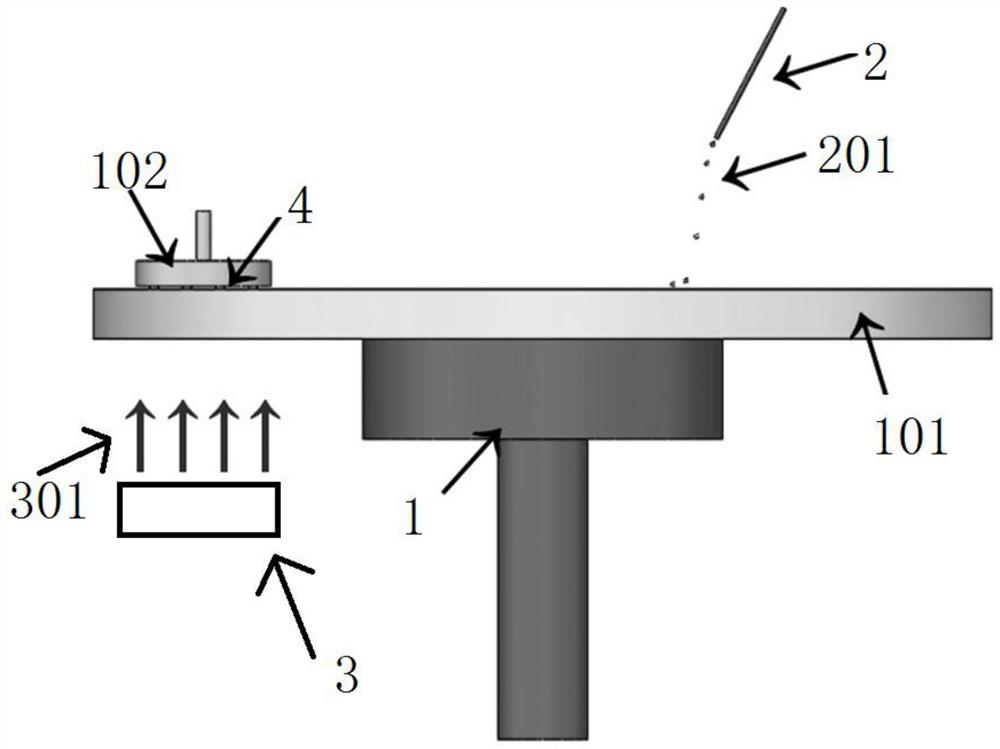

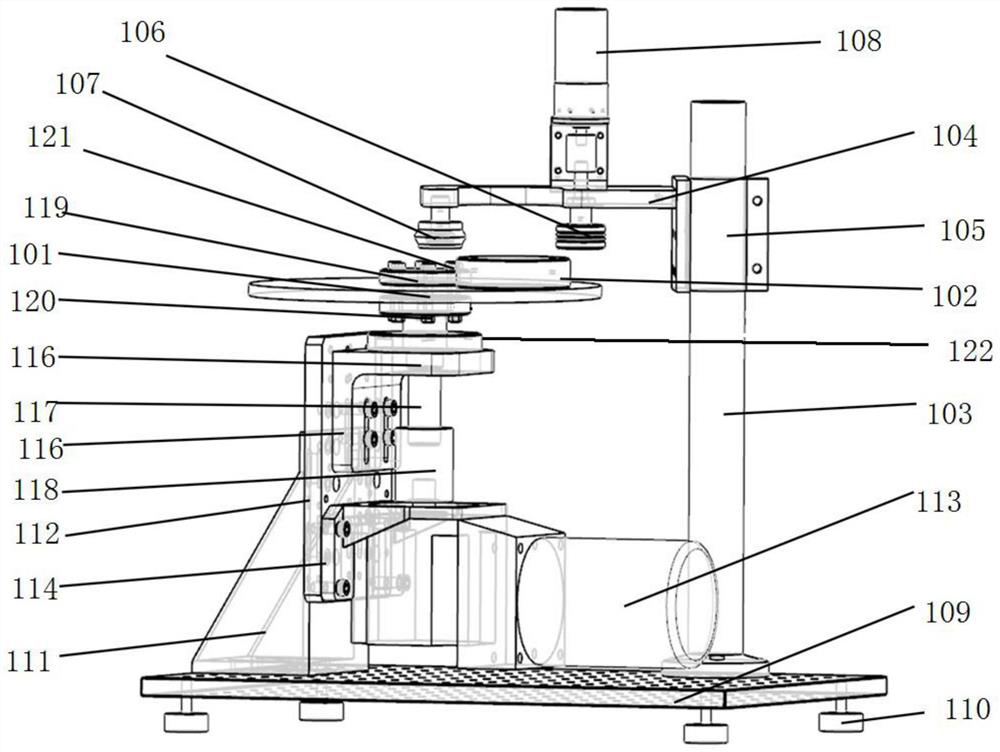

Quartz hemispherical resonator in-situ shape detection ion beam polishing atom manufacturing equipment and method

ActiveCN113600995BReduce one processNo wear and tearUsing optical meansTurn-sensitive devicesIon beam processingEngineering

The invention provides a quartz hemispherical resonator in-situ shape detection ion beam polishing atom manufacturing equipment and method, the equipment includes a numerical control system, a micro-scale mobile platform device installed on a machine tool, and an in-situ shape detection installed on a machine tool base device, frequency difference detection device, ion beam processing device, transmission device and worktable, the numerical control system receives the shape accuracy and profile of the quartz hemispherical resonator measured by the in-situ shape detection device and the quartz The frequency difference of the hemispherical resonator is accurately calculated, and the generated instructions are sent back to the micro-scale mobile platform device, which drives the fixture to move, and at the same time controls the ion beam processing device to perform precise machining on the quartz hemispherical resonator. The invention can significantly reduce the reject rate, and can precisely process the quartz hemispherical resonator with high quality and high efficiency.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com