An Eddy Current Rotary Variable Stiffness Damper

A technology of variable stiffness and damper, applied in the direction of spring/shock absorber, spring, magnetic spring, etc., can solve the problems of damper damage and failure, narrow suppression frequency, limited vibration suppression effect, etc., to overcome narrow bandwidth, suppression mode The effect of state change and stiffness convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

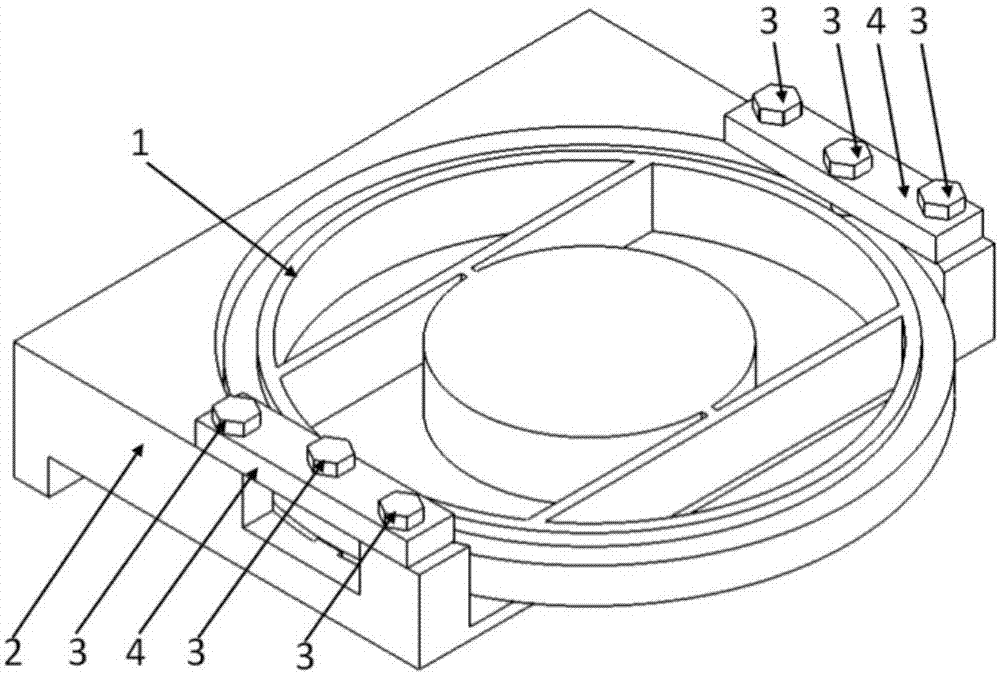

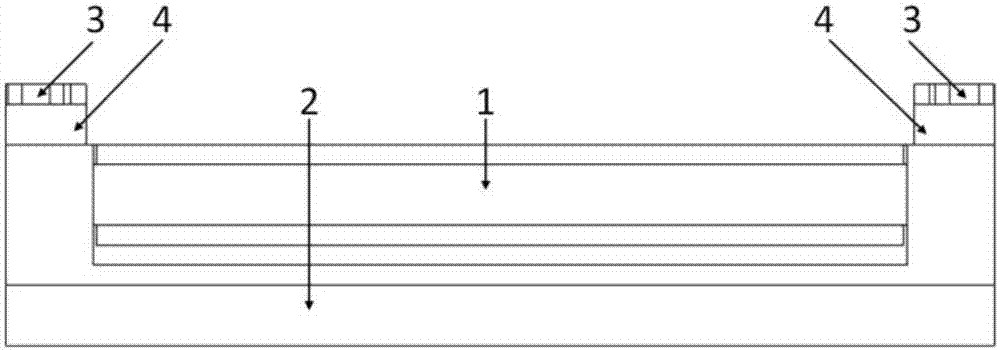

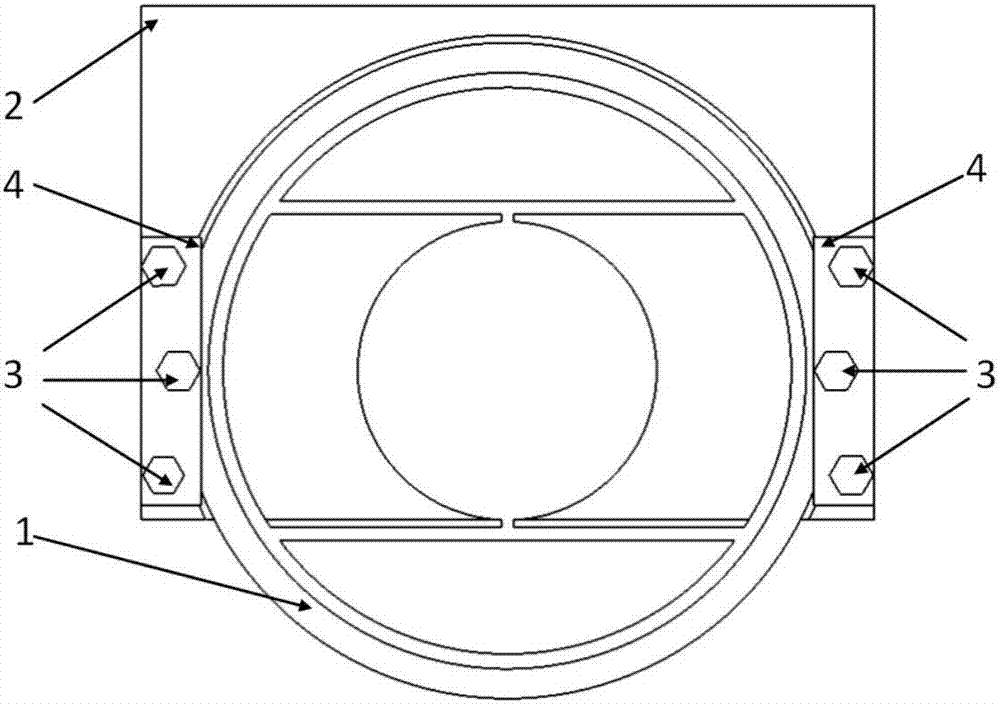

[0031] The present invention is an electric eddy current rotary variable stiffness damper, such as figure 1 , figure 2 , image 3 , Figure 5 As shown, it includes a mass block 1, a support frame 2, a bolt 3, a cover plate 4, and a permanent magnet 5.

[0032] The outer edge of the mass block 1 is a cylindrical step, and the center is a cylindrical frame with a bottom. There are a pair of vertical beams on the diameter of the cylindrical frame extending outward, and a pair of cross beams are connected to the vertical beams in the vertical direction. The main factor for changing the rigidity of mass block 1 is aluminum alloy. When installing, the bottom of the cylindrical frame faces upwards, and is buckled in the groove in the middle of the support frame. The cylindrical steps are supported on the square pillar plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com