Damping device and method for restraining cutting chatter of machine tool spindle and machine tool spindle

A technology of machine tool spindle and damping device, applied in the direction of manufacturing tools, metal processing mechanical parts, large fixed members, etc., can solve the problems of large installation space, difficult to guarantee the damping effect, and can not meet the large-scale engineering application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described in detail below with reference to the accompanying drawings:

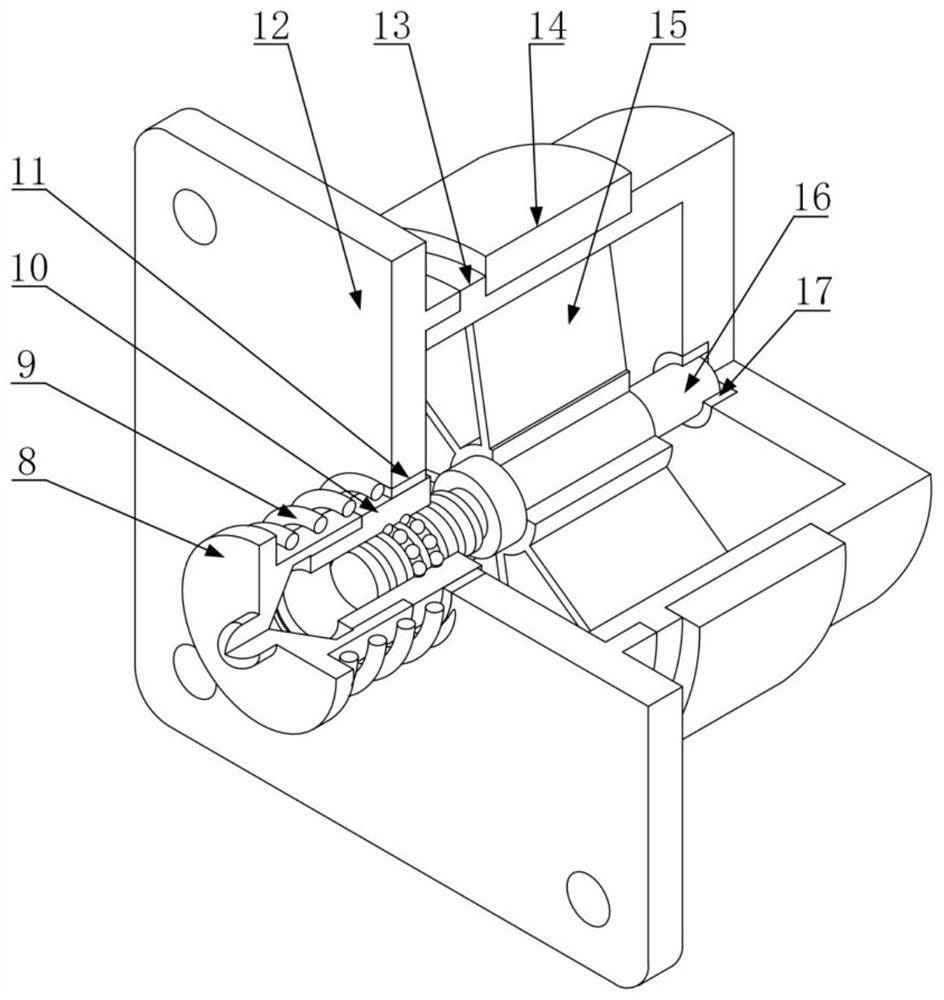

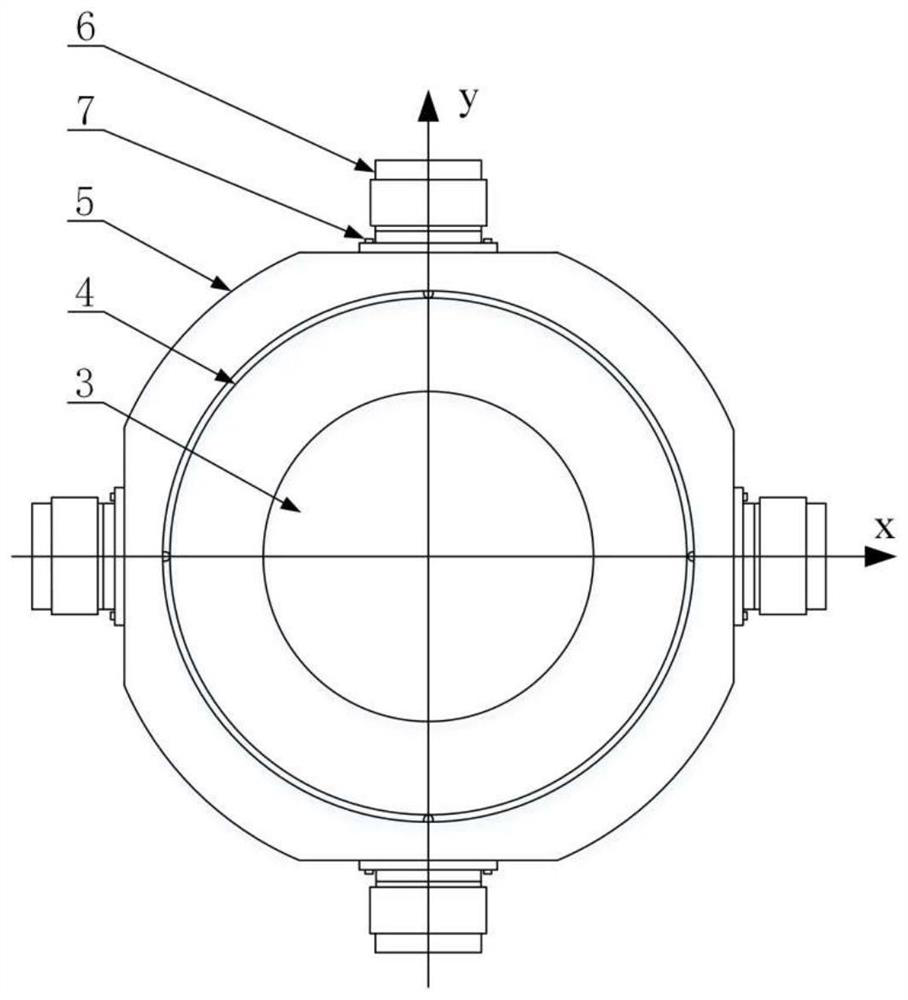

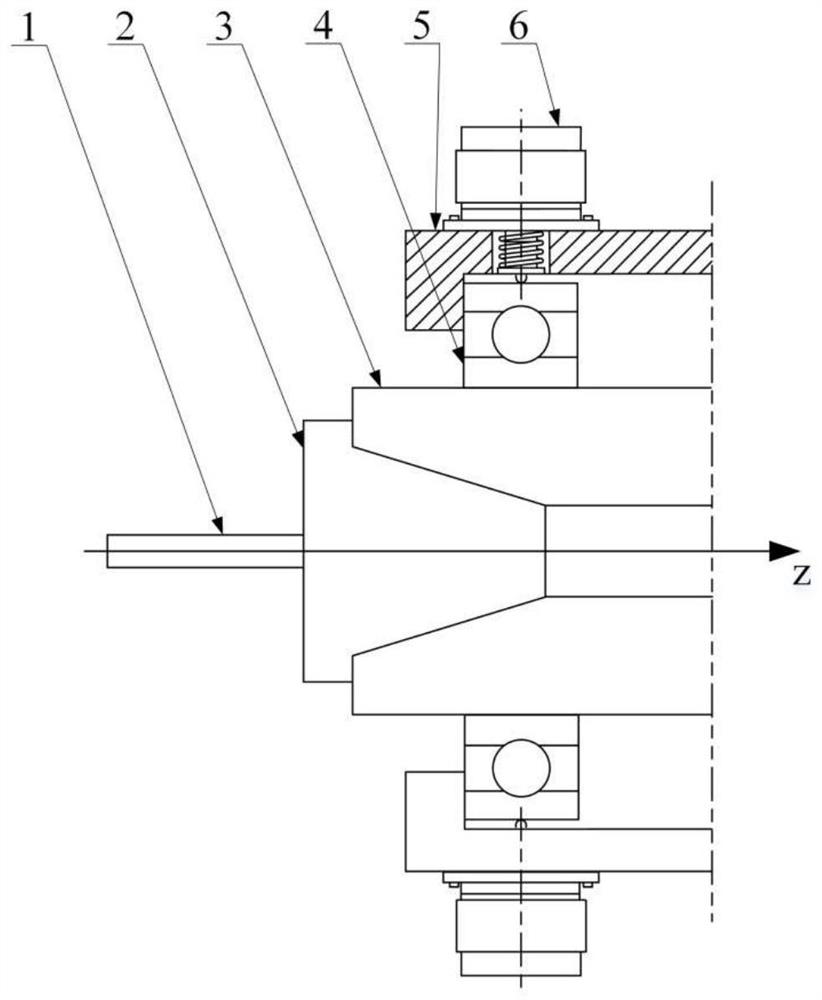

[0031] like figure 1 As shown, a damper device for suppressing the spindle cutting fibril of the machine tool, including the damper seat 13 of the ball screw 16 and the cylindrical structure, and the bottom of the damper seat 13 is provided with a rotating groove, and one end of the ball screw 16 is provided in rotation. In the groove, it is possible to rotate in the rotating groove, and the opening end of the damper seat 13 is provided with a ball screw nut 10, and the ball screw nut 10 is slidably connected. The other end of the ball screw 16 is coordinated with the ball screw nut 10. Connecting, the end portion of the ball screw nut 10 is fixedly connected to the across rod 8, and there is a caching spring 9 between the sidewall 8 and the damper 13, and the ball screw 16 is located in the damping seat 13 fixed to a fan blade 15, damping seat. 13 The internal charge is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com