Designing method of high-speed ball bearing formed by sandwich integral damping outer circle

A design method and technology of high-speed balls, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., can solve the problems of changing system stiffness and damping, and achieve the goals of increasing system damping, wide application range, and improving high speed and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

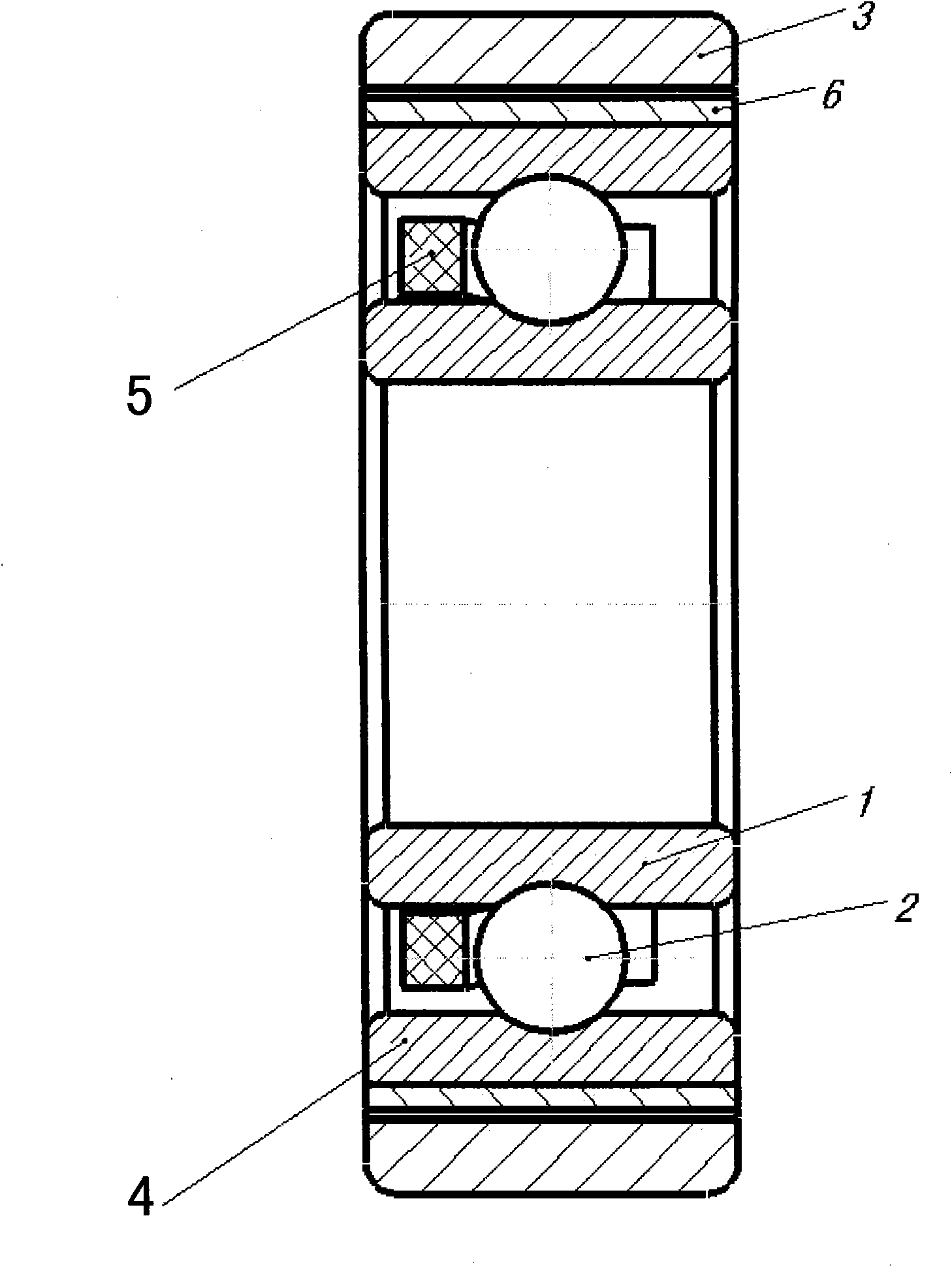

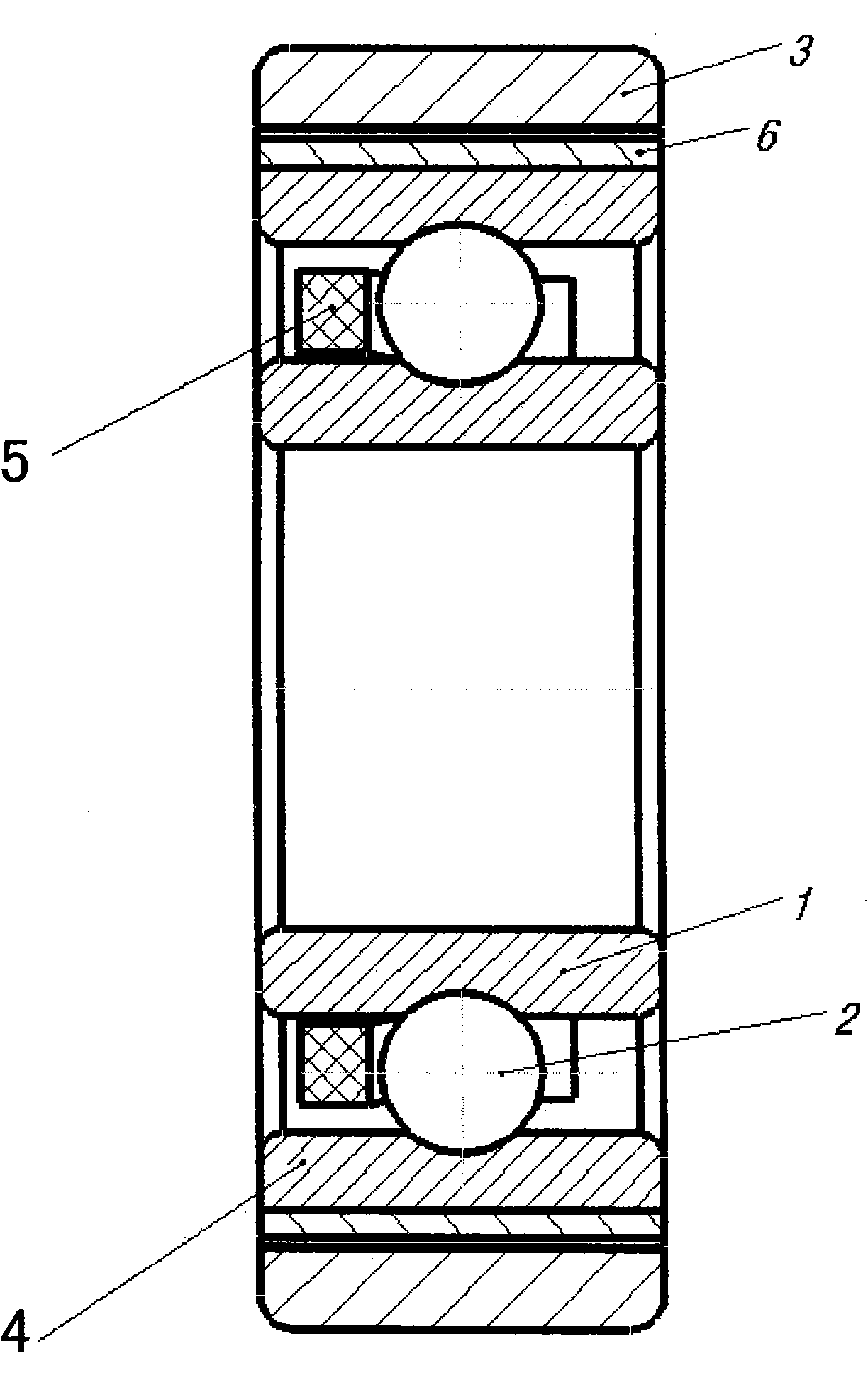

[0022] Combine figure 1 The design method of a high-speed ball bearing composed of a sandwich-type integral damping outer ring of the present invention is to reduce the design diameter of the steel ball 2 as much as possible on the premise of ensuring the strength of the high-speed ball bearing inner ring 1, and its purpose is to reduce the steel ball. 2 The centrifugal force generated during rotation improves the high-speed running stability of the high-speed ball bearing. On the other hand, it also reserves space for the improvement of the outer ring structure.

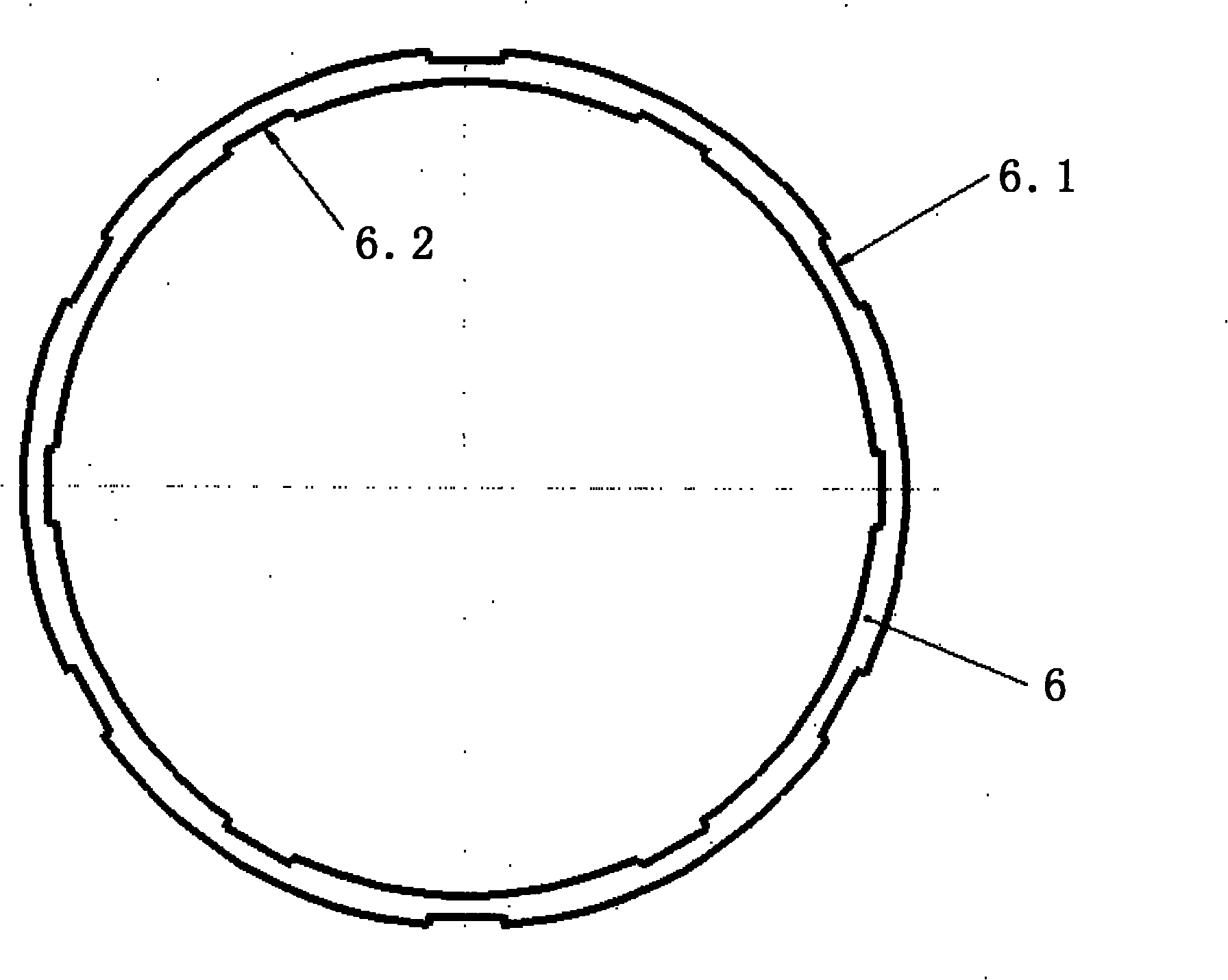

[0023] The structure of the outer ring is improved to a sandwich-type integral damping outer ring. The sandwich-type integral damping outer ring is composed of the outer ring inner ring 4, the damping ring 6 and the outer ring outer ring 3, that is, the outer ring 3 and the inner ring 4 A damping ring 6 is sandwiched in between, and the sandwich-type integral damping outer ring can increase the system damping of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com