Totally-closed rigidity adjustable type vibration isolator

An adjustable vibration isolator technology, applied in the field of buffer devices and airborne equipment vibration isolation, can solve the problems of high cost, long time period, inability to meet the use requirements, etc., to expand the scope of use, improve energy consumption, improve Vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

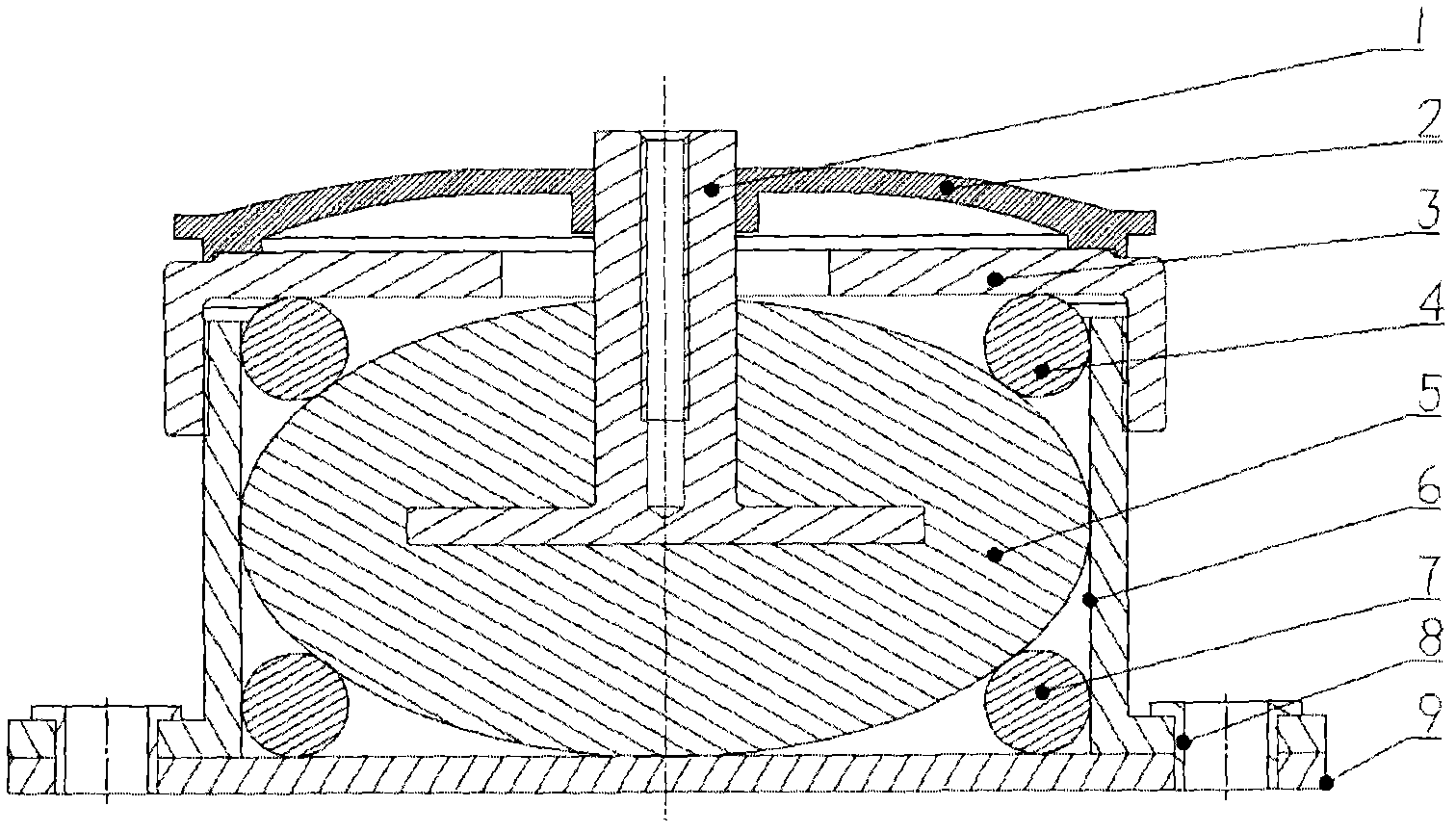

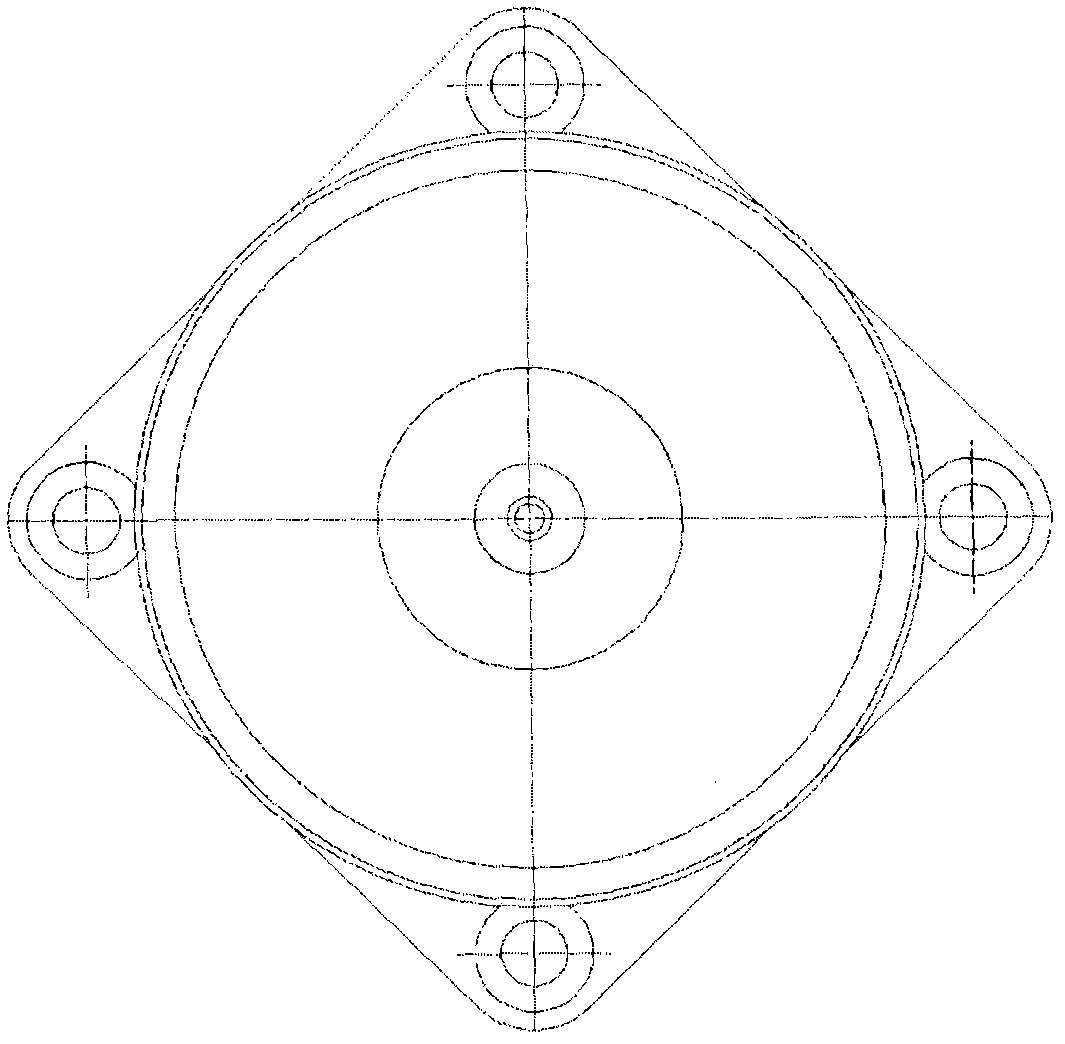

[0022] Please also see figure 1 and figure 2 ,in, figure 1 It is a structural schematic diagram of the fully enclosed stiffness-adjustable vibration isolator of the present invention, figure 2 yes figure 1 top view. The fully enclosed vibration isolator with adjustable stiffness includes a mounting mandrel 1, a protective rubber cover 2, an upper cover 3, an upper rubber ring 4, a damping rubber ball 5, a shell 6, a lower rubber ring 7, a hollow rivet 8, and a bottom plate 9. The upper cover 3 is arranged on the casing 6 and is threadedly connected with the casing, and the top has a mounting hole for placing the installation mandrel 1, and the bottom edge of the casing 6 is connected with the bottom plate 9 through a hollow rivet 8 to form an integral sealed casing. The bottom of the installation mandrel 1 is deep inside the housing and has a transverse boss struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com