Seal type viscoelastic damper suitable for on-orbit application of spacecraft

A viscoelastic, spacecraft technology, applied in the field of sealed viscoelastic dampers, can solve the problems of shortened life, attenuation of damping performance, pollution of optical payloads, etc., to achieve long life, convenient damping performance, and avoid the effect of rapid decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

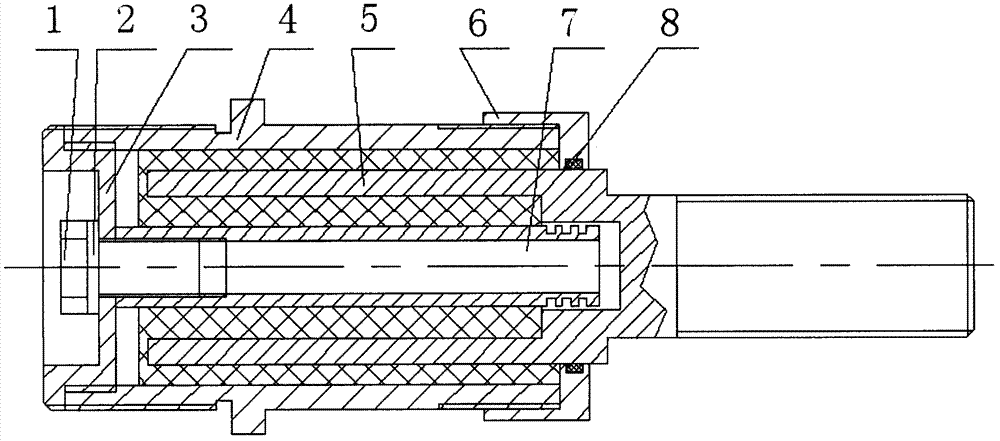

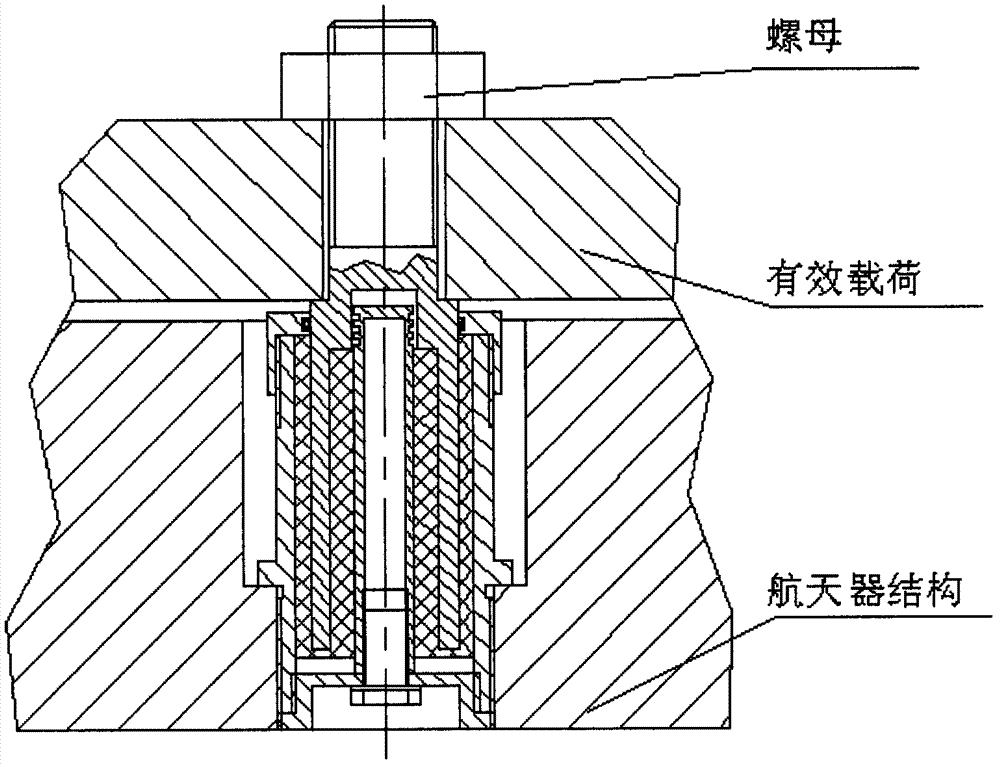

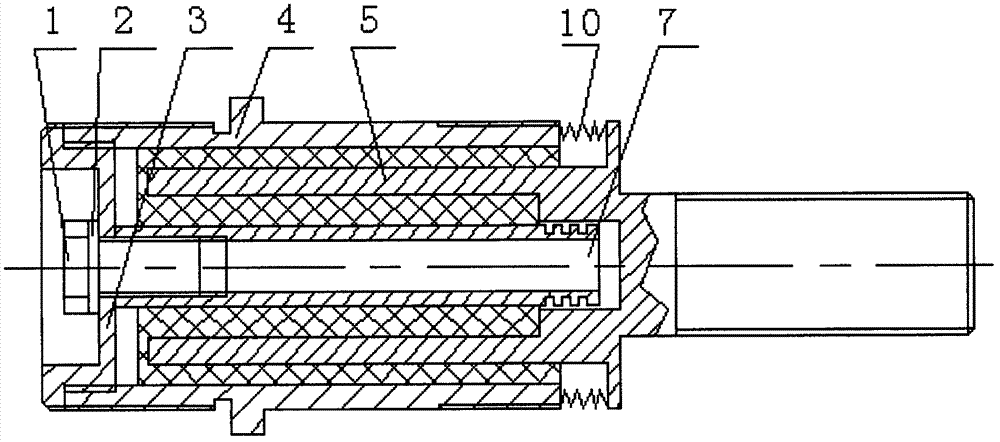

[0023] The invention provides a sealed viscoelastic damper suitable for spacecraft on-orbit applications, such as figure 1 As shown, it includes: connecting screw 1, end face sealing ring 2, pressing plate 3, housing 4, shaft sleeve 5, cover plate 6, hollow mandrel 7 and radial sealing ring 8;

[0024] The shell 4 is a hollow cylinder. The pressing plate 3 is screwed to one end of the shell 4, and the threaded connection is coated with sealant to achieve sealing. The center of the pressing plate 3 has a round hole through which the connecting screw 1 passes through the hole and the hollow core. The shaft 7 is threaded, and the connecting screw 1 and the pressure plate 3 are sealed by the end face seal ring 2; the shaft sleeve 5 is cylindrical and the shaft sleeve 5 is placed between the hollow shaft 7 and the housing 4, and the shaft sleeve 5 is connected to the hollow core There are gaps between the shaft 7 and between the sleeve 5 and the housing 4. The cover plate 6 is screwed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com