Semi-active eddy current damping wall

An eddy current damping and semi-active technology, applied in the direction of building components, shockproof, building types, etc., can solve problems such as difficult adjustment, hydraulic viscous damper oil leakage, difficult maintenance, etc., to improve the shock absorption effect and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

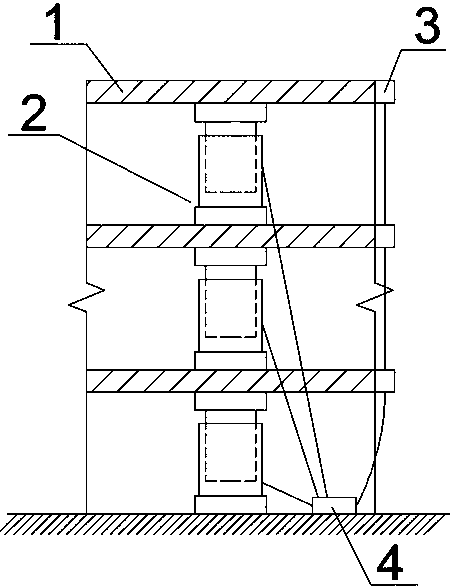

[0022] Embodiment 1: as Figure 1 to Figure 3 As shown, a kind of semi-active eddy current damping wall of the present invention is made up of eddy current damping wall 2, acceleration sensor 3 and controller 4, wherein:

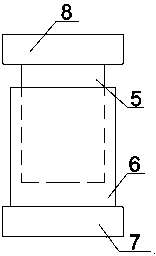

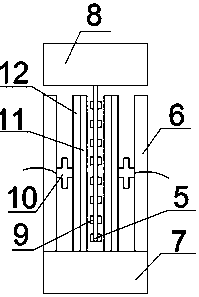

[0023] The eddy current damping wall 2 is composed of a steel plate 5 , a maintenance wall 6 , a lower pier 7 , an upper pier 8 , a permanent magnet 9 , an actuator 10 , a conductor plate 11 and a magnetically conductive plate 12 .

[0024] The acceleration sensor 3 is installed in the lateral direction of each floor of the main structure 1 .

[0025] When an earthquake occurs, the controller 4 can collect the lateral acceleration signals of each floor of the main structure 1 in real time, and control the movement of the actuator 4 .

[0026] The eddy current damping wall 2 is installed between adjacent floors of the main structure 1 .

[0027] The upper pier 8 is connected with the upper floor, and the lower pier 7 is connected with the lower floor. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com