Semi-active bump leveler with adjustable parameters based on magnetostriction materials

A magnetostrictive material and magnetostrictive technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as low stability, large size and static mass, and difficulty in practical application. Achieve the effect of increasing the ability of damping regulation, strong reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

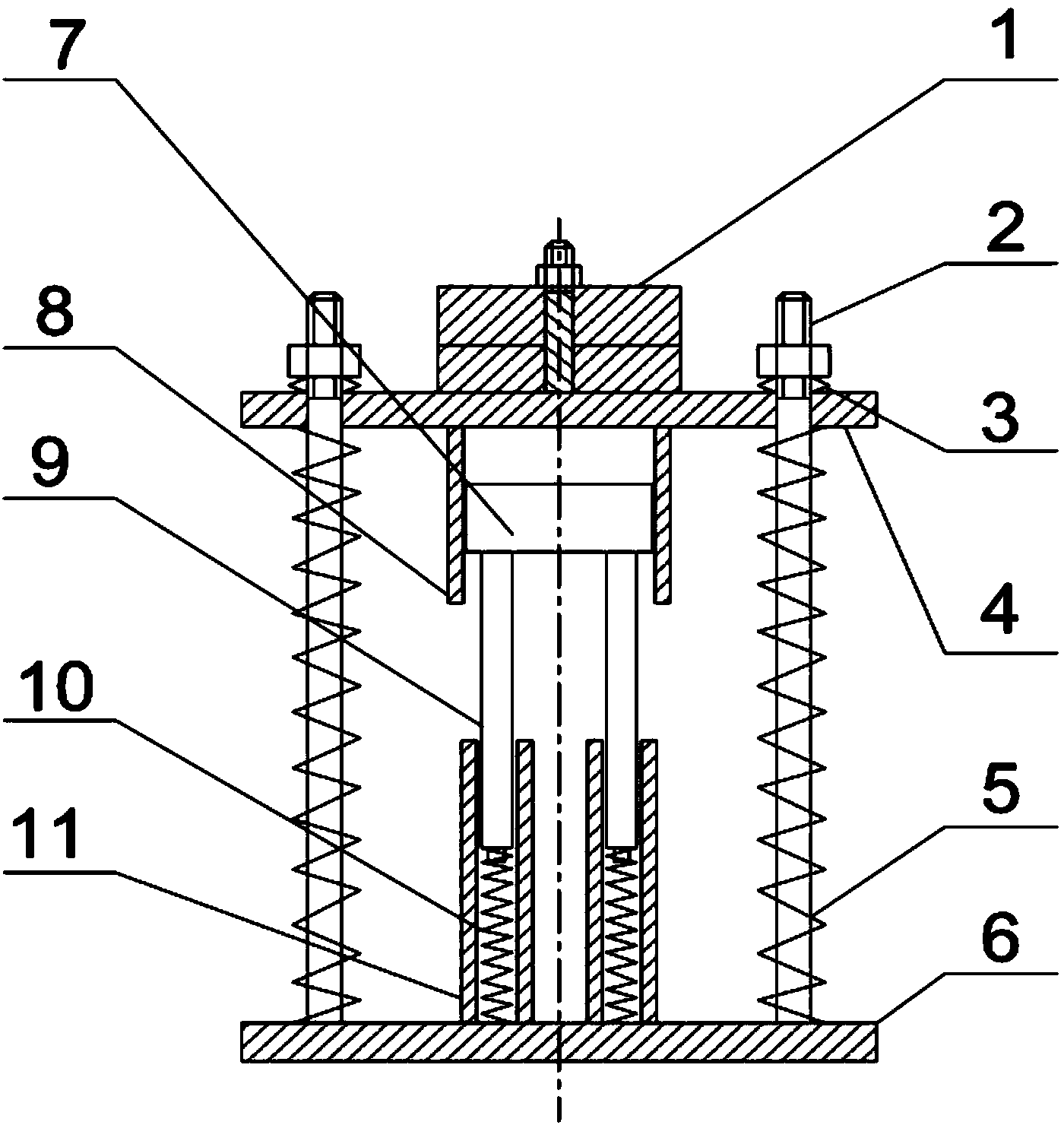

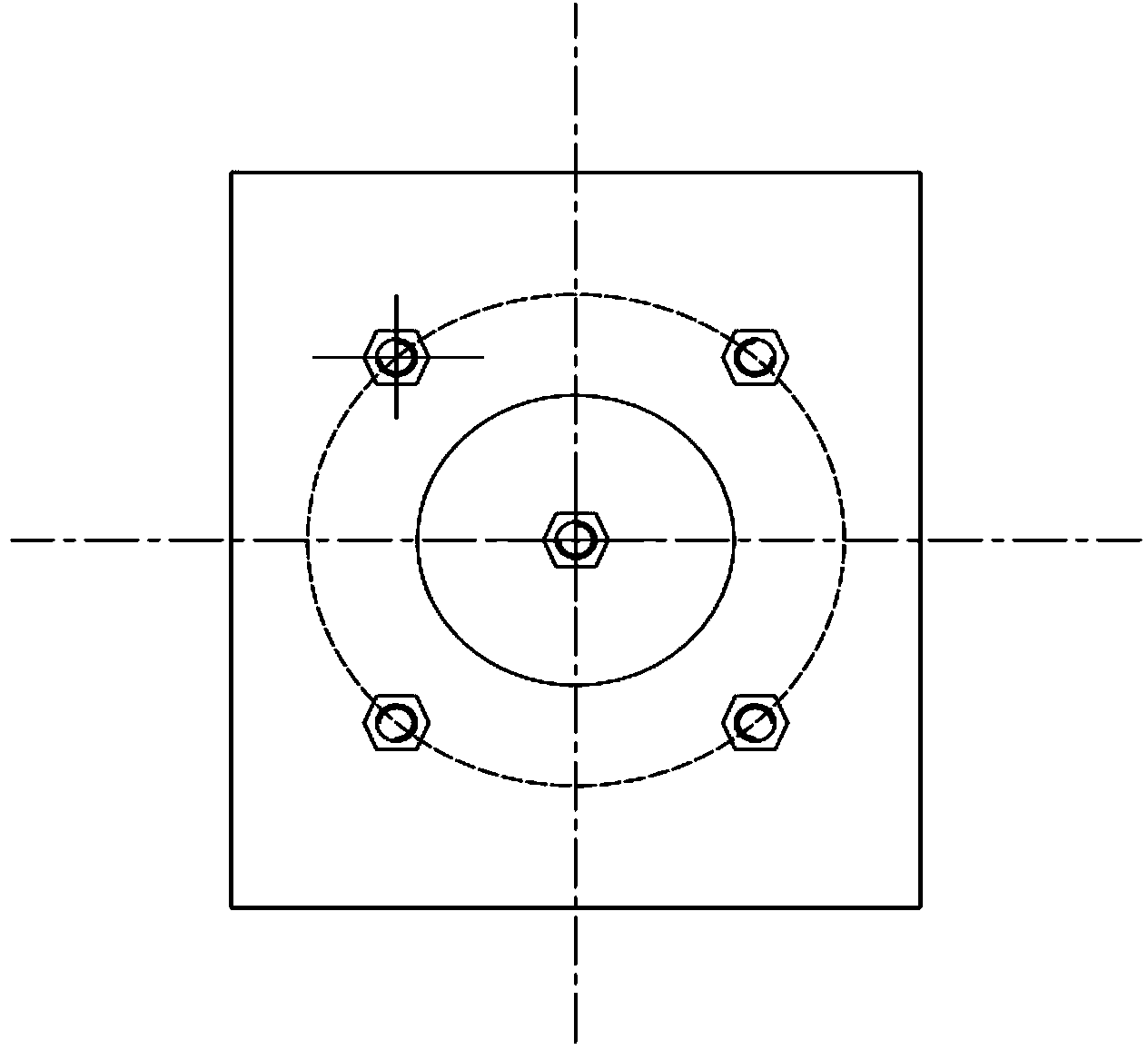

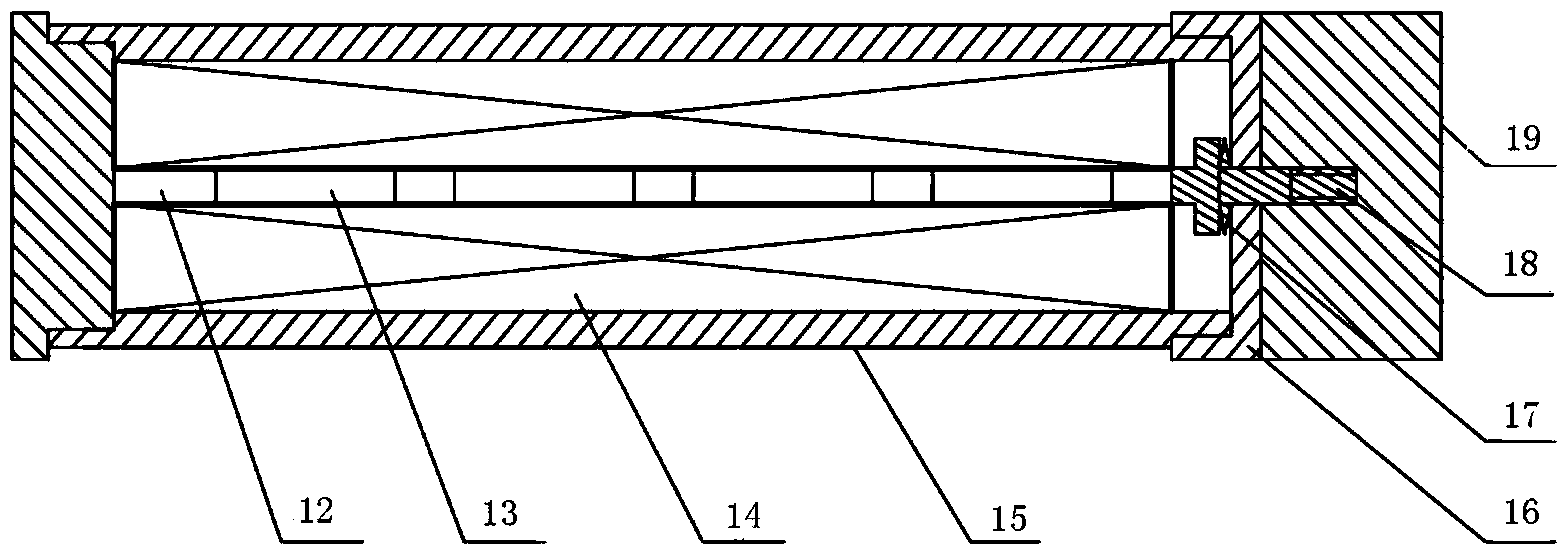

[0018] combine Figure 1~3 , the present invention comprises base 6, spring guide column 2, base spring sleeve 11, and these three parts constitute the fixed part of vibration absorber. The peripheral spring 5 is fixedly connected with the base 2 and the upper end cover 4. The upper end cover 4 can move up and down with the spring guide column 2. The upper end cover 4 is equipped with a disc spring 3 to avoid collision with the bolt when going up. The upper end cover 4 is fixed with a counterweight 1. A splint 8 is fixed below, which can move up and down with the upper end cover. A magnetostrictive unit 7 is installed in the middle of the splint, and the gap between the magnetostrictive unit and the splint is very small, about 1mm. The magnetostrictive unit 7 is supported by the magnetostrictive unit pillar 9 and the magnetostrictive unit base spring 10, the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com