Active control method and system for milling chattering time delay of motorized spindle

A technology of active control and milling chatter, applied in the direction of manufacturing tools, large fixed members, complex mathematical operations, etc., can solve the problems of increasing the difficulty of control algorithm design and complex milling dynamic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

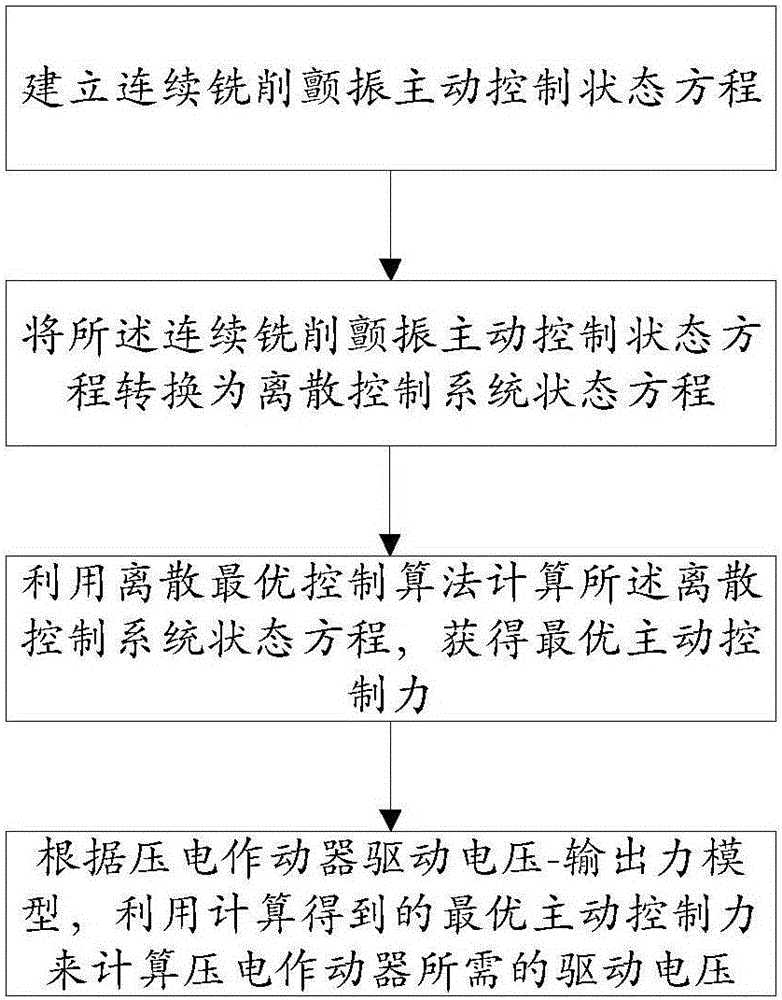

[0062] In order to suppress the vibration of the electric spindle during high-speed milling and improve the precision and efficiency of milling, in one embodiment, as figure 1 As shown, the present disclosure discloses a method for active control of chatter delay in electric spindle milling, and the method includes the following steps:

[0063] S100, establishing a continuous milling chatter active control state equation;

[0064] S200, converting the continuous milling chatter active control state equation into a discrete control system state equation;

[0065] S300. Using a discrete optimal control algorithm to calculate the state equation of the discrete control system to obtain an optimal active control force;

[0066] S400. According to the piezoelectric actuator driving voltage-output force model, use the calculated optimal active control force to calculate the driving voltage required by the piezoelectric actuator, and then drive the piezoelectric actuator to apply act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com