Patents

Literature

370 results about "Eddy current effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

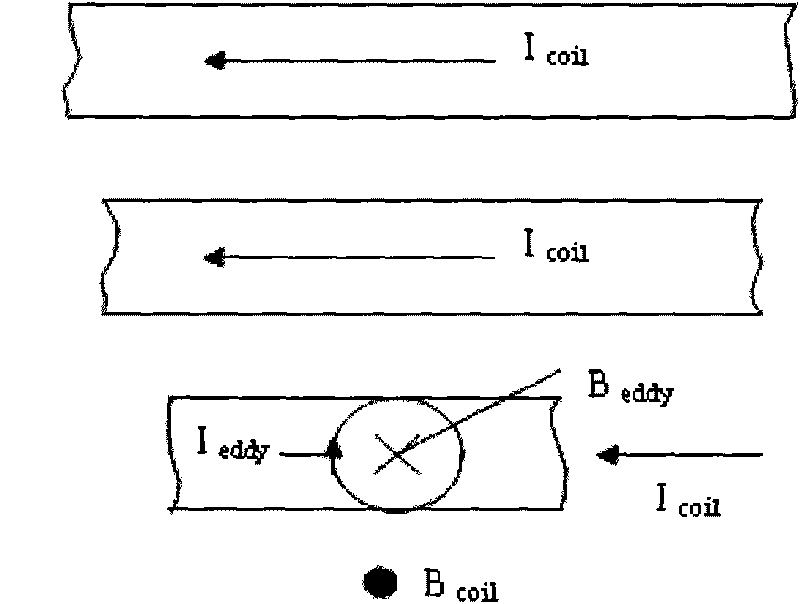

The effect of eddy current is also used in electrical instruments like in induction type energy meters for providing braking torque. For providing damping torque in permanent magnet moving coil instruments. Eddy current instruments are used for detecting cracks in metal parts.

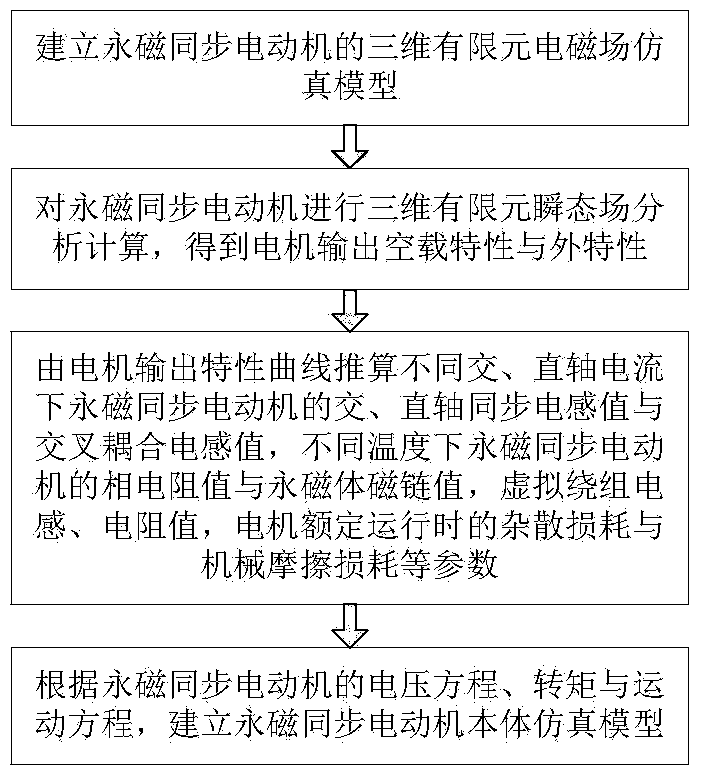

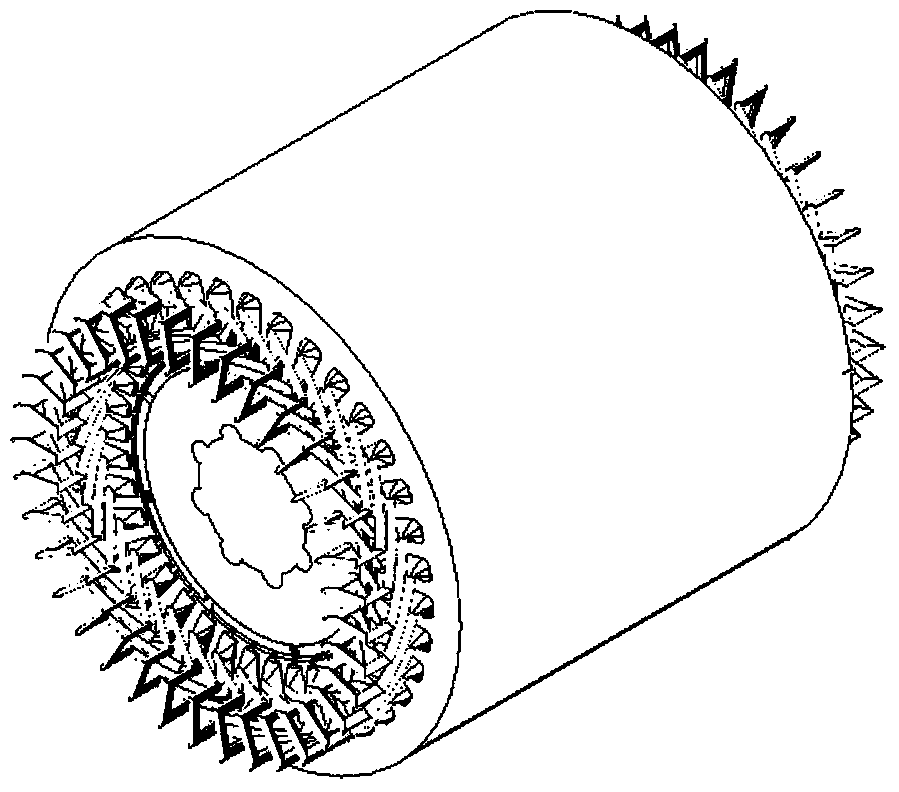

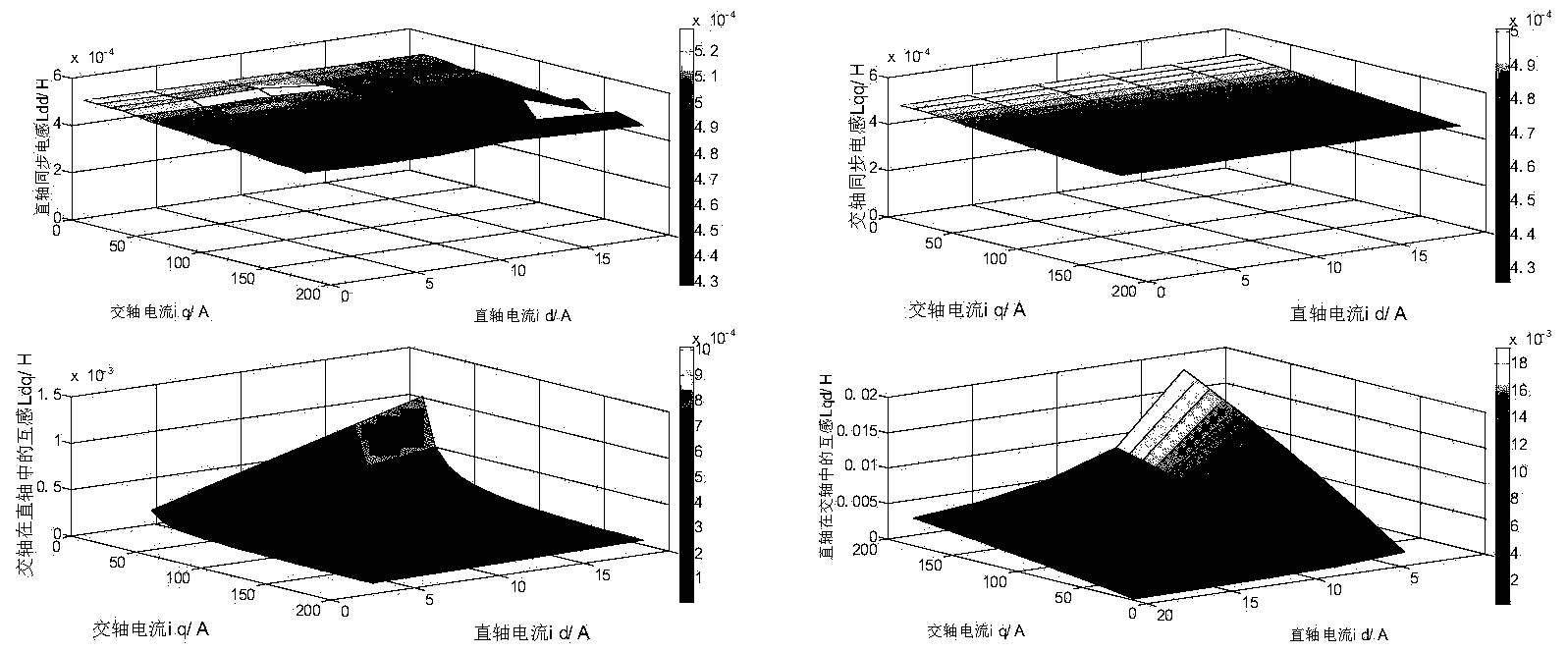

Finite element analysis-based variable-element permanent magnet synchronous motor modeling method

ActiveCN103853891AAchieve real-time controlImprove accuracySpecial data processing applicationsHysteresisElement analysis

The invention relates to a finite element analysis-based variable-element permanent magnet synchronous motor modeling method which comprises the following steps of constructing a three-dimensional finite element electromagnetic field simulation model of a permanent magnet synchronous motor, and performing transient field road coupling analysis on the three-dimensional finite element electromagnetic field simulation model to obtain a large quantity of characteristic parameters; creating an improved permanent magnet synchronous motor voltage equation and a torque equation; constructing a simulation model of the permanent magnet synchronous motor according to an improved permanent magnet synchronous motor math model; leading all the obtained characteristic parameters into corresponding ports of the simulation model to construct a finite element analysis-based variable-element permanent magnet synchronous motor dynamic simulation model. The permanent magnet synchronous motor model modeled by the method disclosed by the invention comprehensively considers the magnetic field saturation effect, the d-q axis cross coupling effect, the eddy current effect, the hysteresis effect and the like; the instantaneity is considered, and the accuracy of the permanent magnet synchronous motor model is improved; the permanent magnet synchronous motor model is particularly suitable for the research on the dynamic processes such as power failure-bepelt and three-phase sudden short circuit of the permanent magnet synchronous motor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and apparatus for testing material integrity

InactiveUS20050285588A1Base element modificationsElectrical testingElectrical conductorEddy current effect

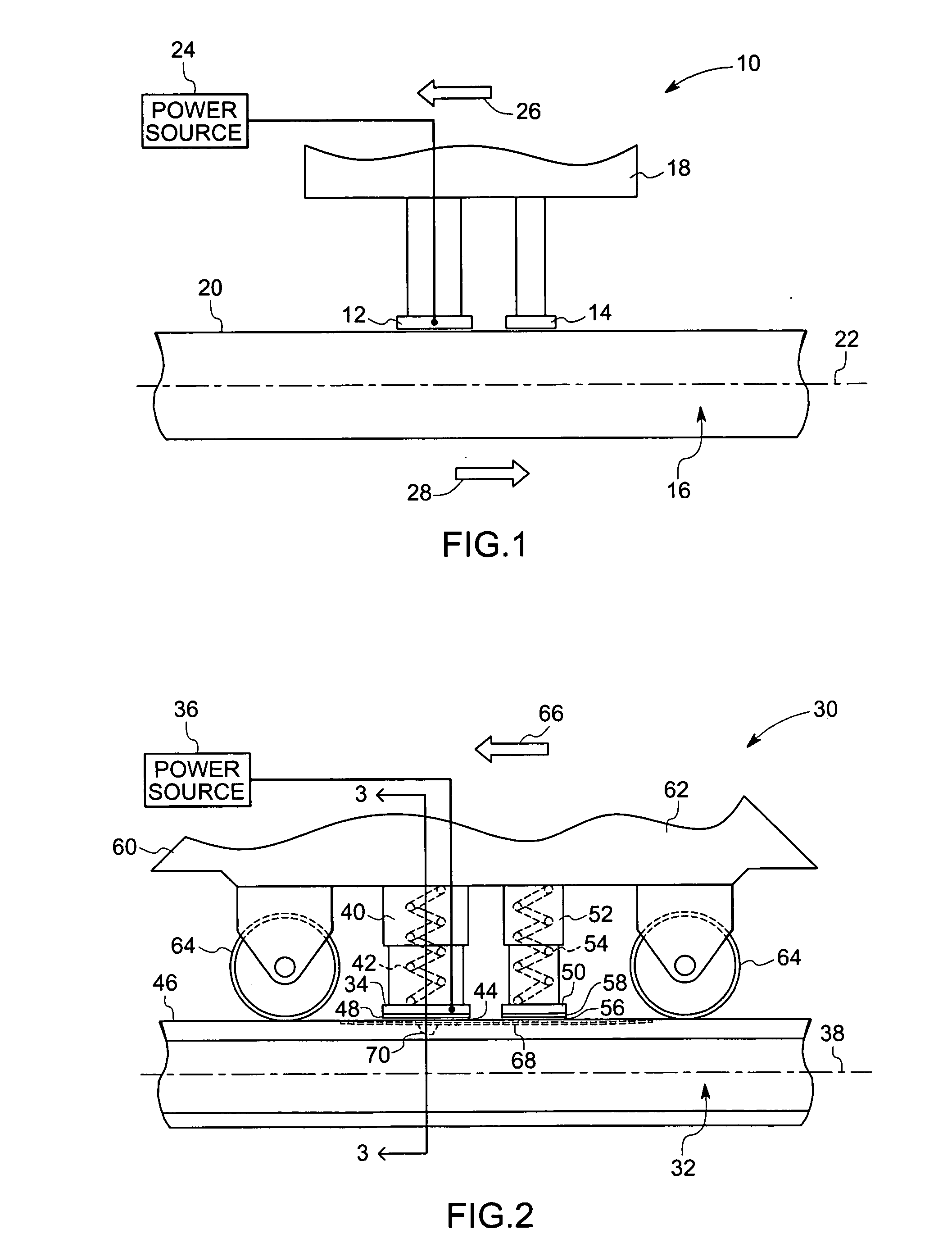

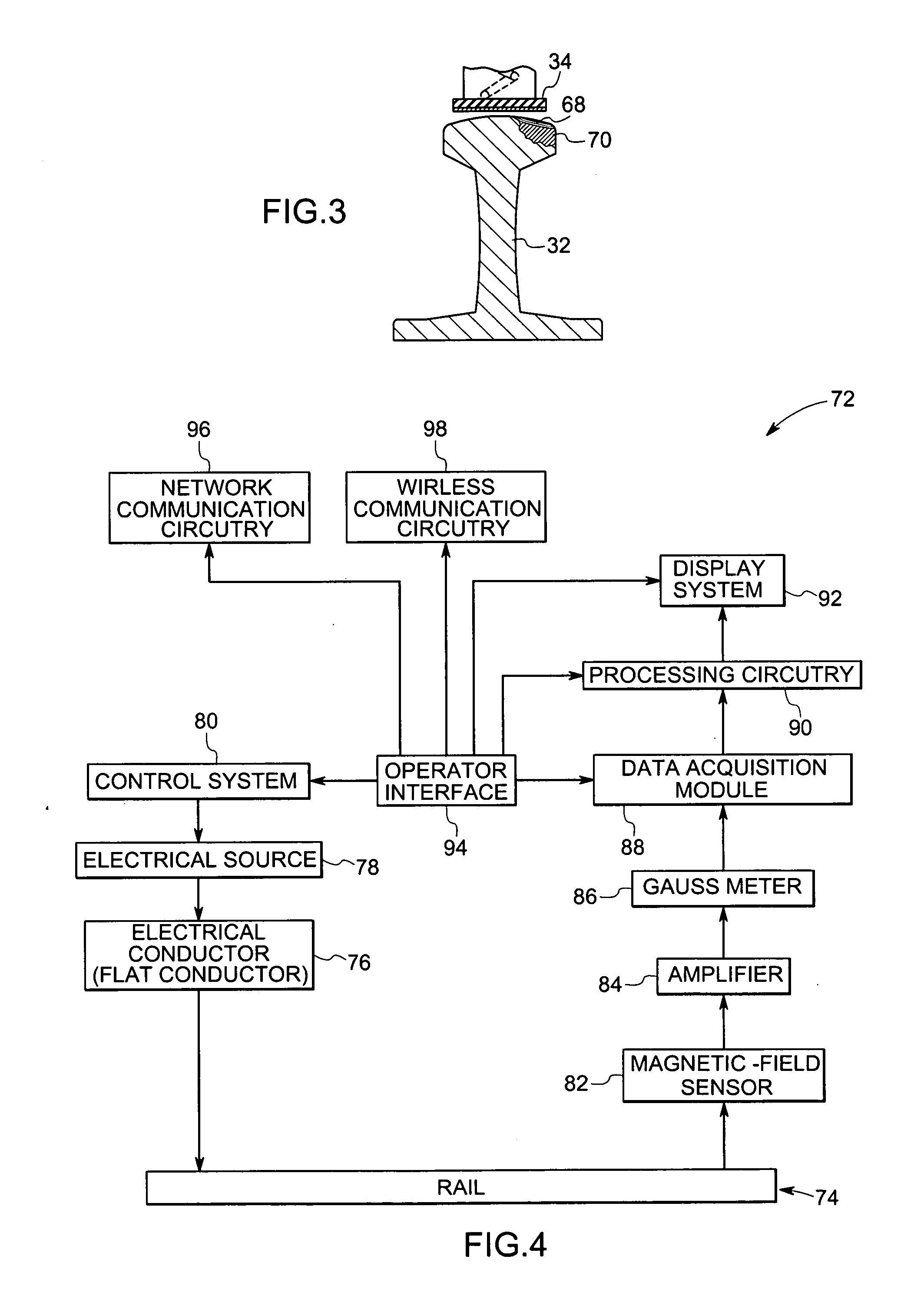

In accordance with one embodiment, the present technique provides a testing apparatus for testing material integrity in an object. The testing apparatus includes an electrical conductor and a sensing device. In the exemplary testing device, the electrical conductor extends in a generally linear direction and is configured to route current in a direction generally transverse to a longitudinal axis of the object being tested. Routing of current through the electrical conductor creates remote field eddy current effect, which, in turn, affects a magnetic field around the test object. The testing apparatus also includes a sensing device located at a distance from the electrical conductor and configured to detect magnetic fields generated in response to current routed through the electrical conductor.

Owner:GE GLOBAL SOURCING LLC

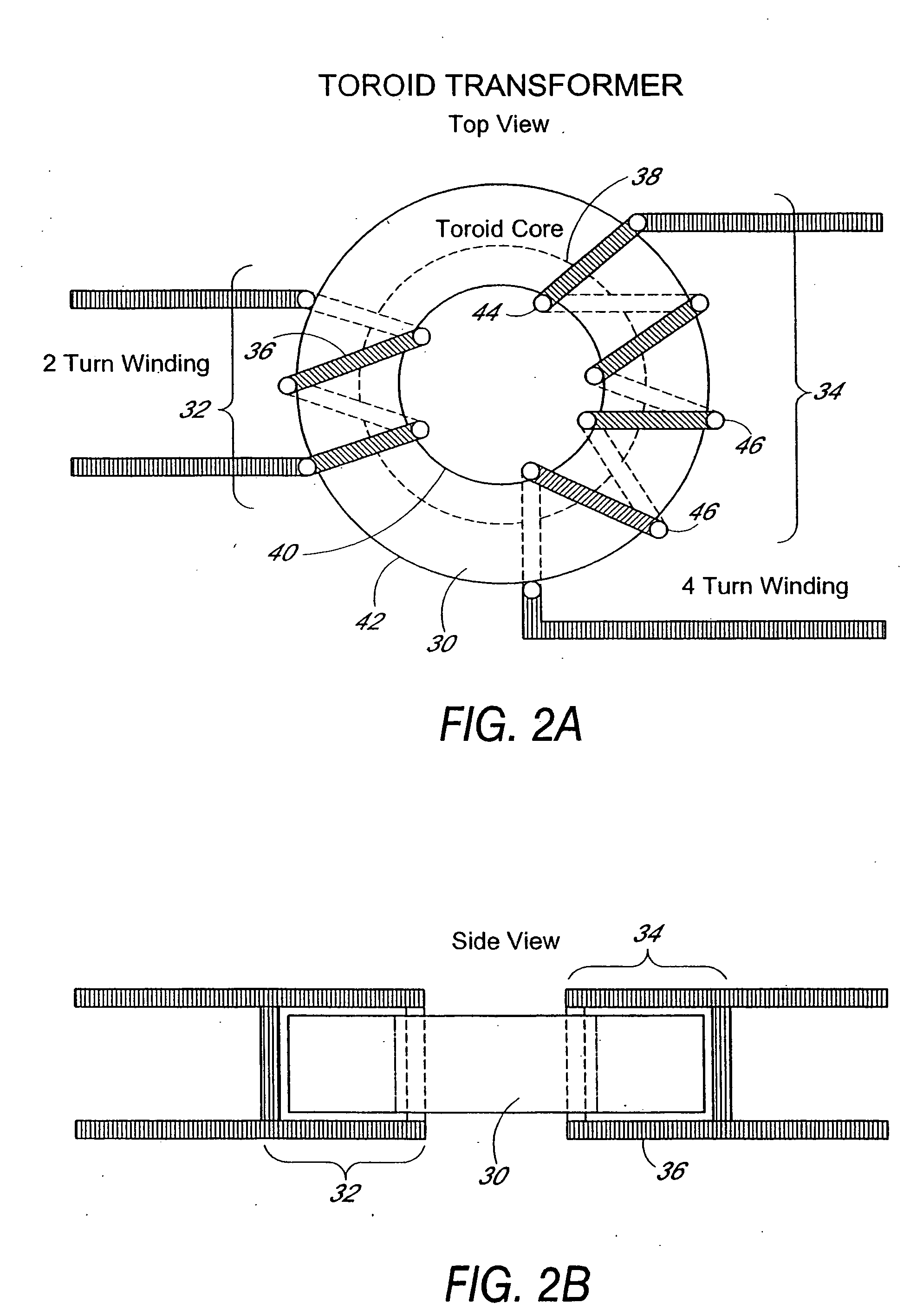

Electronic transformer/inductor devices and methods for making same

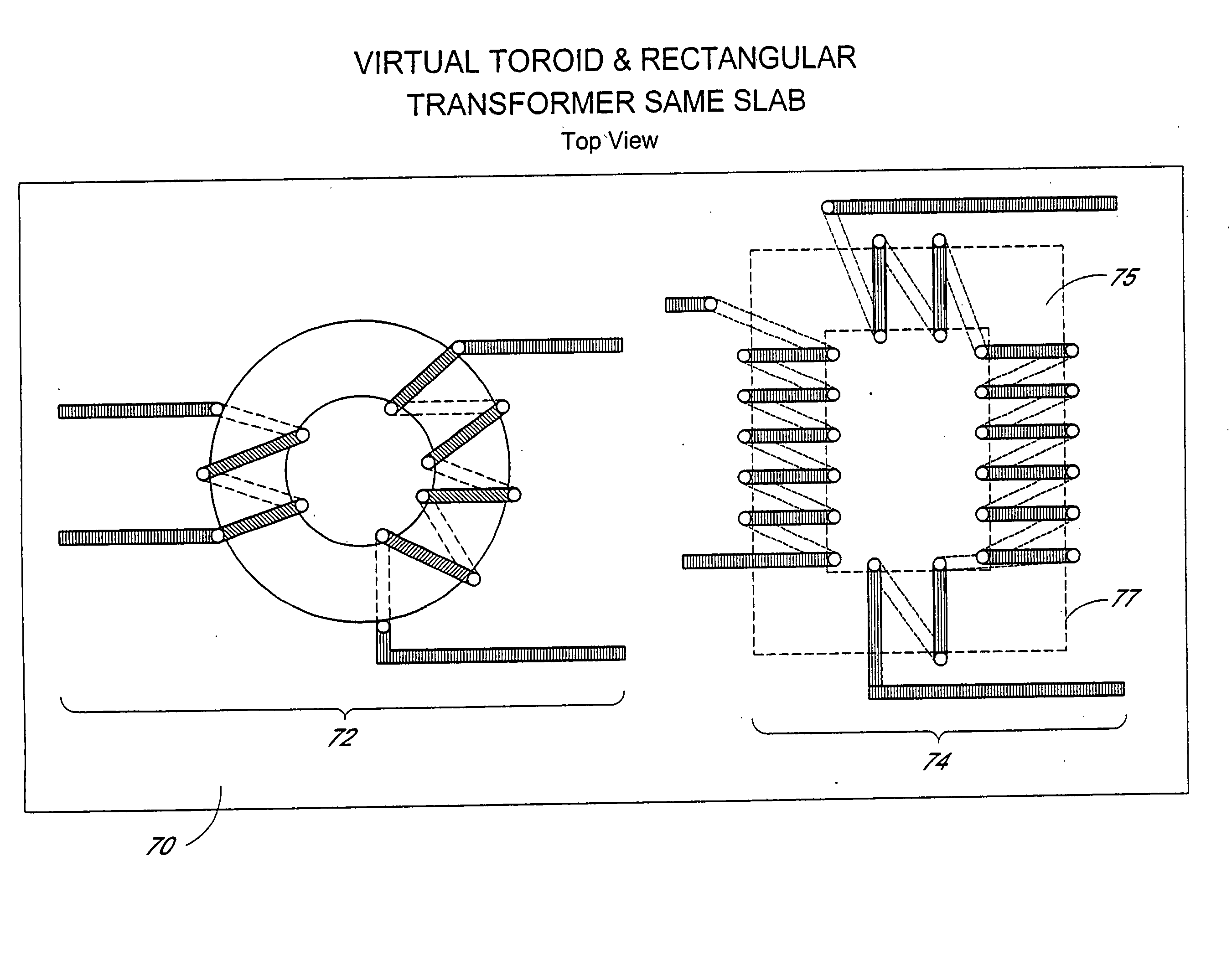

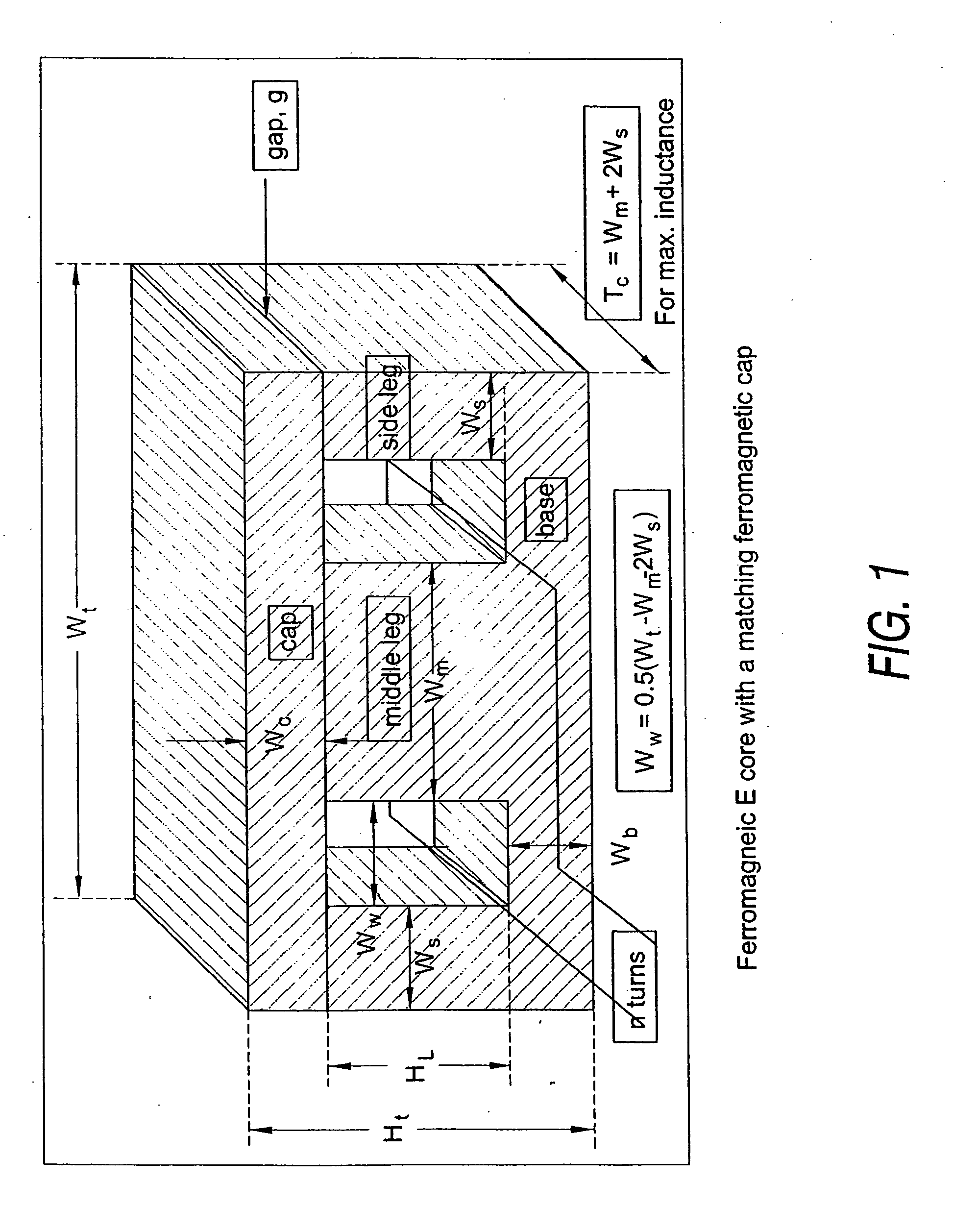

InactiveUS20050093672A1Improve cooling effectSimplifies electrical connectionsTransformers/inductances coils/windings/connectionsPrinted circuit aspectsModem deviceTransformer

The present invention relates to the methods of construction for inductive components of, preferably, ferromagnetic materials such as inductors, chokes, and transformers when used as an integral part of the fabrication of PCB's or FLEX's. In one preferred embodiment, holes are formed through a ferromagnetic substrate and plated with conductive material. The arrangement of these holes, and the subsequent design that ensues, will form the inductive components within the plane of the media in which the device is formed; using the substrate for a magnetic core. By using this approach, the inductive components can be miniaturized to physical sizes compatible with the requirements of modem surface mount technology (SMT) for integrated circuitry (IC). This process also allows these components to be fabricated using mass production techniques, thereby avoiding the need to handle discrete devices during the manufacturing process. In another preferred embodiment, a series of thin, concentric high permeability rings are etched on a substrate to provide high permeability transformers and inductors having minimal eddy current effects.

Owner:HARDING PHILIP A

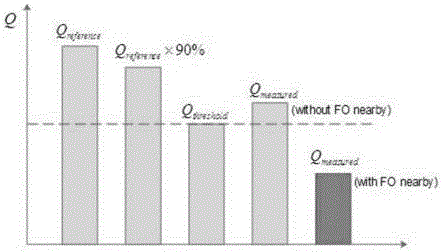

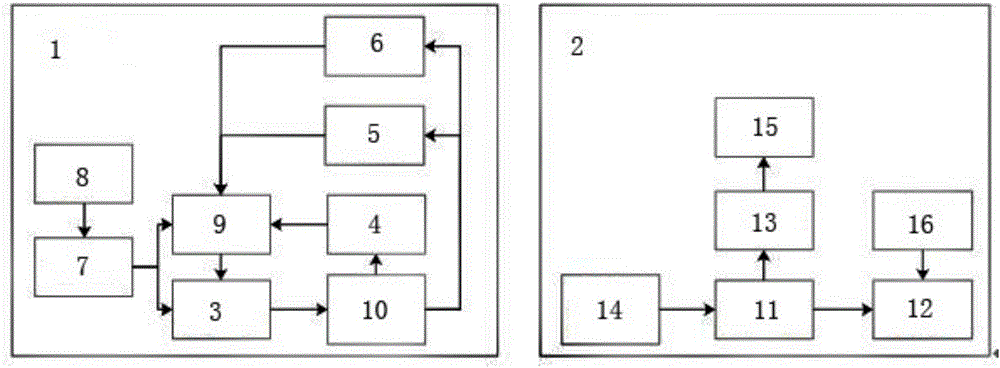

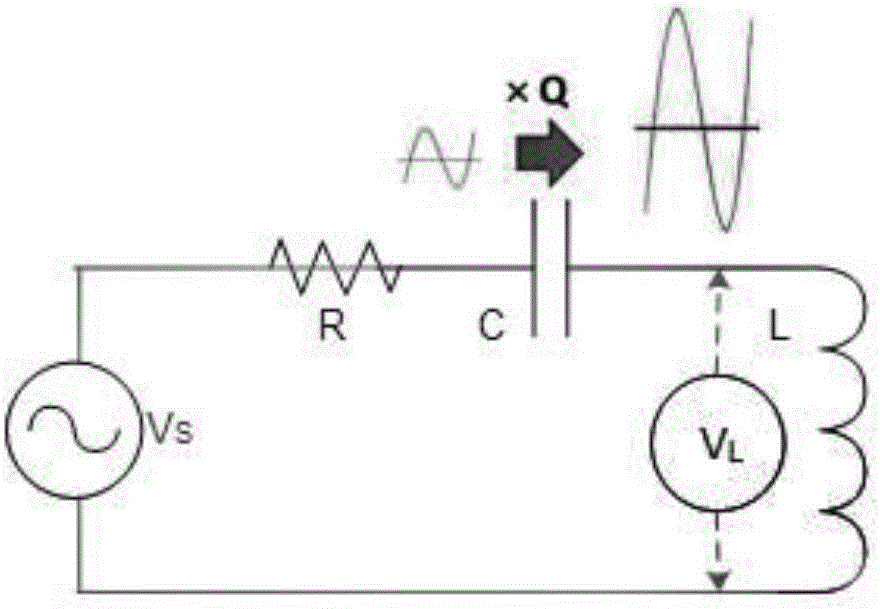

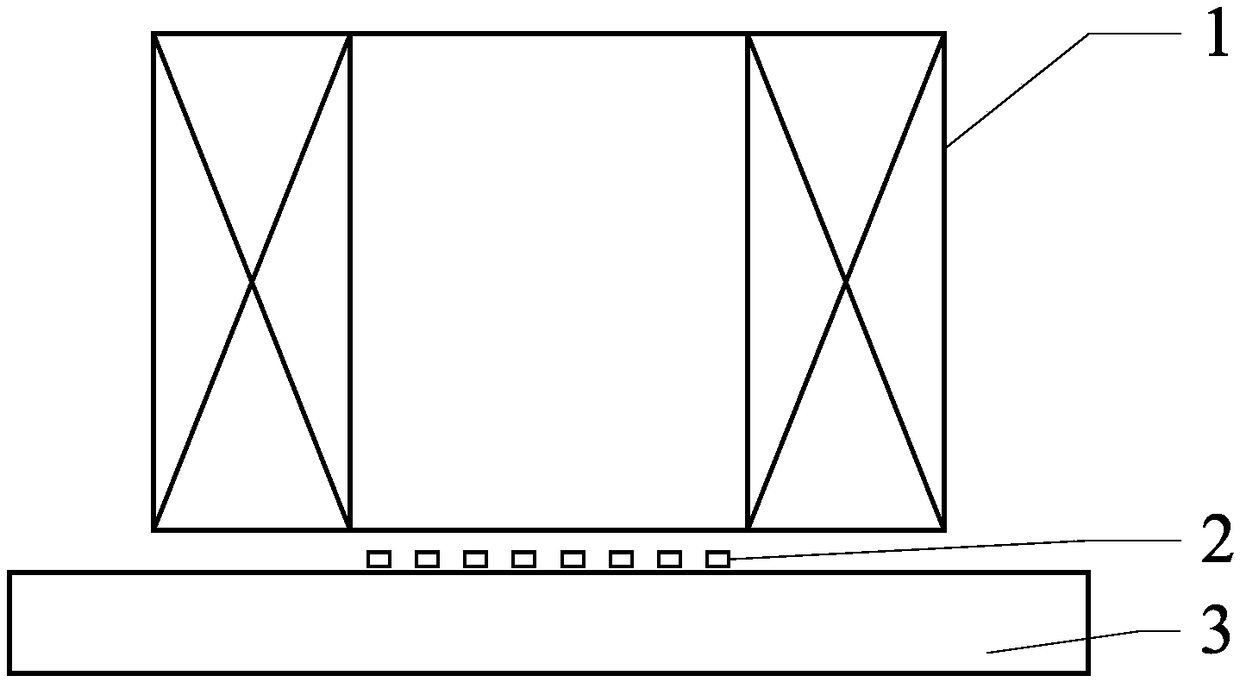

Wireless charging device and metal foreign substance detection method thereof

InactiveCN106685029AAccurate detectionImprove securityBatteries circuit arrangementsElectric powerForeign matterEddy current effect

The invention proposes a metal foreign substance detection method based on a quality factor. The method is applicable to a wireless charging device of a magnetic induction technology. The device comprises an emission end and a receiving end. When a metal foreign substance exists between a primary coil of the emission end and a secondary coil of the receiving end, the metal foreign substance will be heated by an eddy current effect to cause a serious safety potential. The detection method proposed by the invention is used for detecting the metal foreign substance, and power transmission can be automatically ended. The core content lies that the quality factor of the primary coil of the emission end is detected, whether the metal foreign substance exists is judged by comparing a detection value and a setting threshold value, the fact that the metal foreign substance exists is judged if the detection value is smaller than the setting threshold value, the emission end prompts warning, and the power transmission is ended.

Owner:TIANDI CHANGZHOU AUTOMATION +1

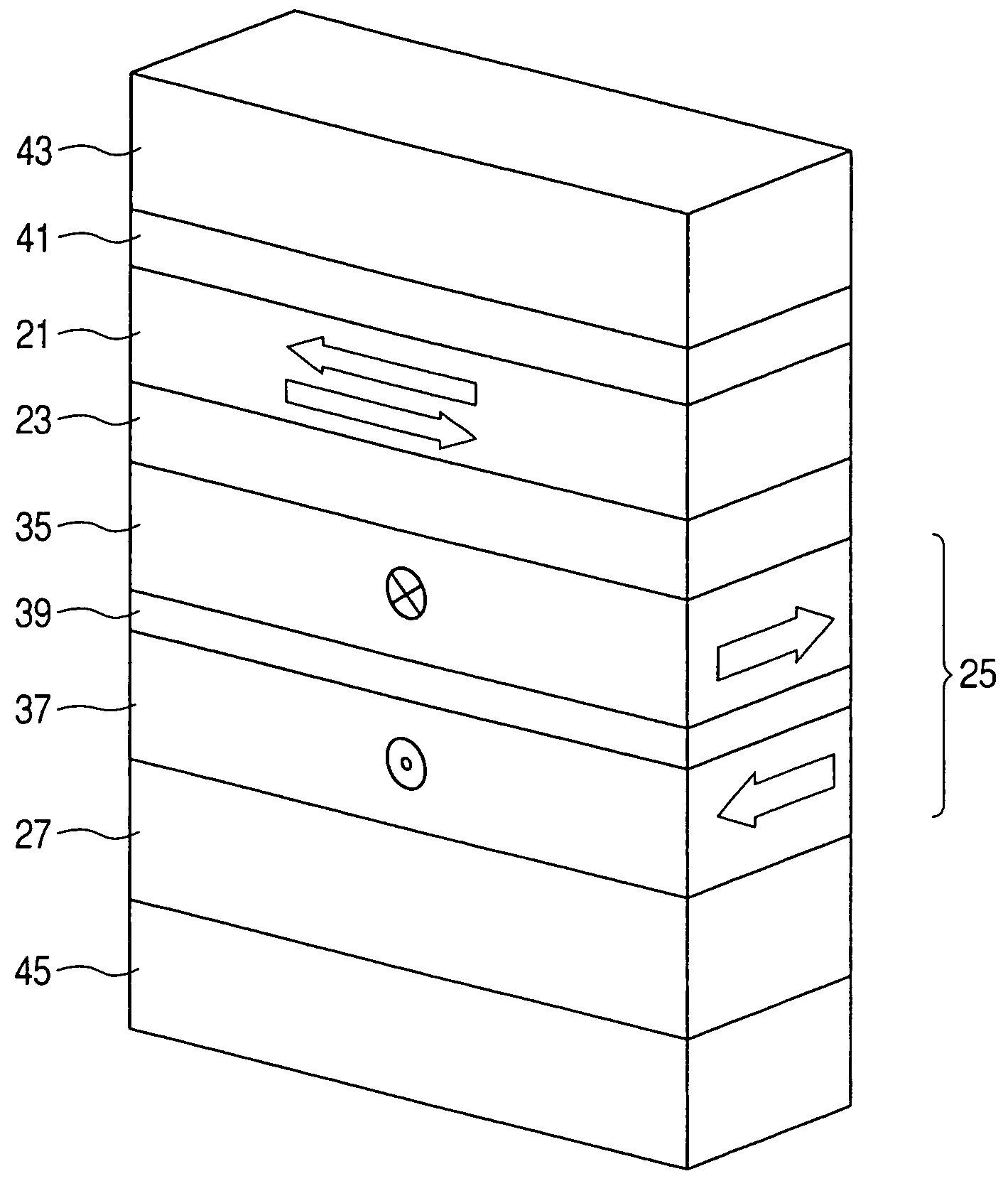

Stabilizer for magnetoresistive head and method of manufacture

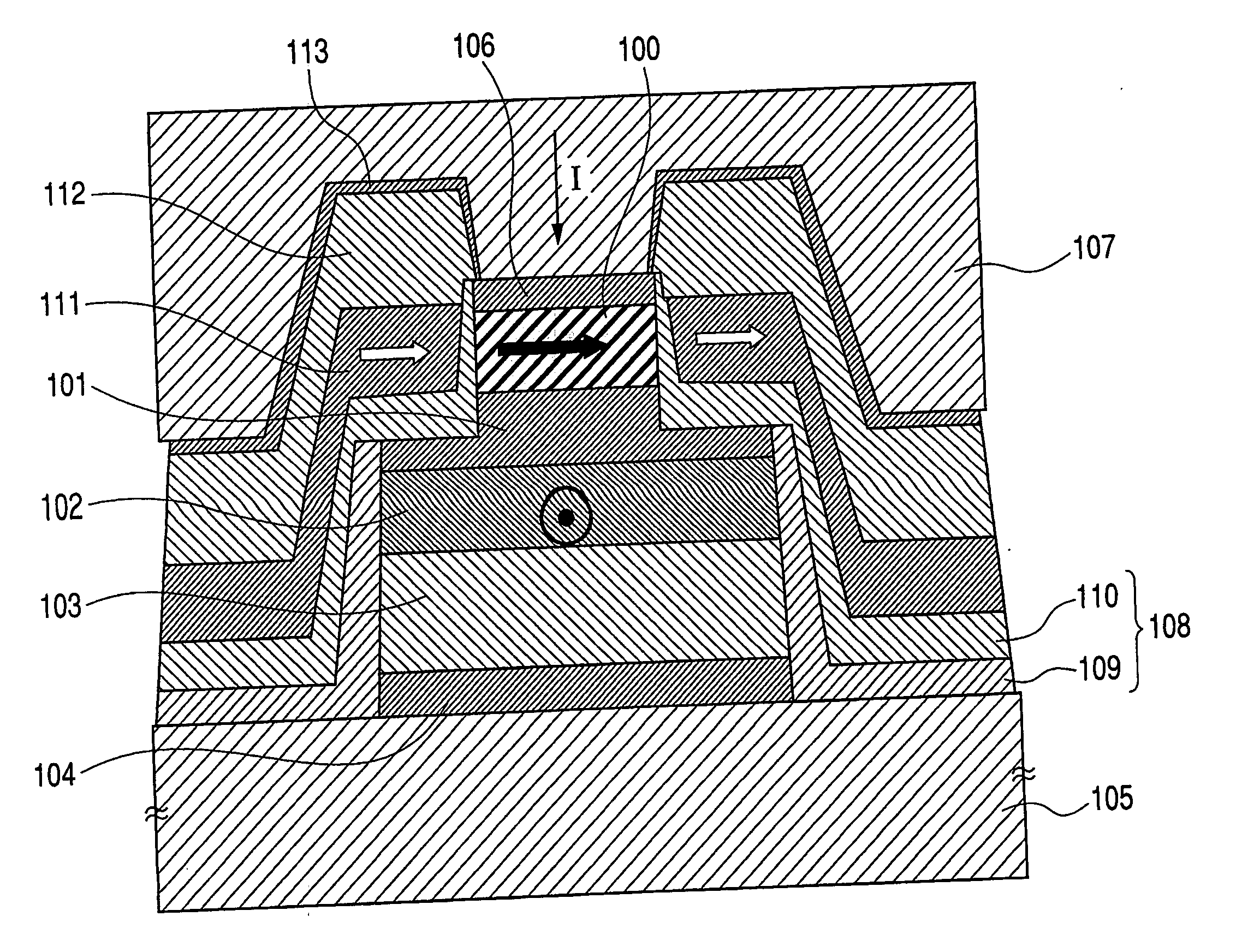

A reader of a current-perpendicular-to-plane magnetoresistive head includes a spin valve with sensor having a stabilizer adjacent thereto, to substantially avoid magnetization distribution at the edge of the sensor due to vortex effect and charge accumulation. At least one free layer is spaced apart from at least one pinned layer by a spacer. Above the free layer, a capping layer is provided. The stabilizer includes a pinned ferromagnetic layer adjacent to the free layer, and an antiferromagnetic layer positioned thereon. It becomes easy to provide an effective biasing using a variety of materials having different magnetic moments and thickness. Also problems related to sensor edge for small size will be overcome. A method of manufacturing the reader is also provided.

Owner:TDK CORPARATION

Method and apparatus for diffusion magnetic resonance imaging with the effects of eddy currents compensated

ActiveUS20070052417A1High precisionEffect of eddy current can be minimizedMagnetic measurementsElectric/magnetic detectionDiffusionResonance

Owner:TOSHIBA AMERICA MRI

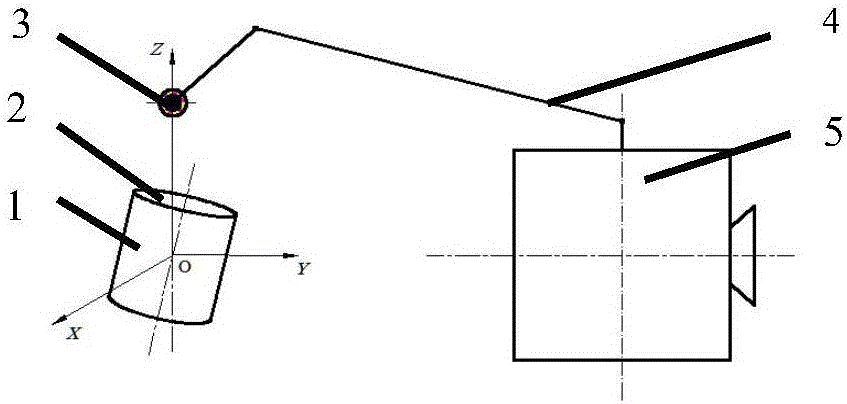

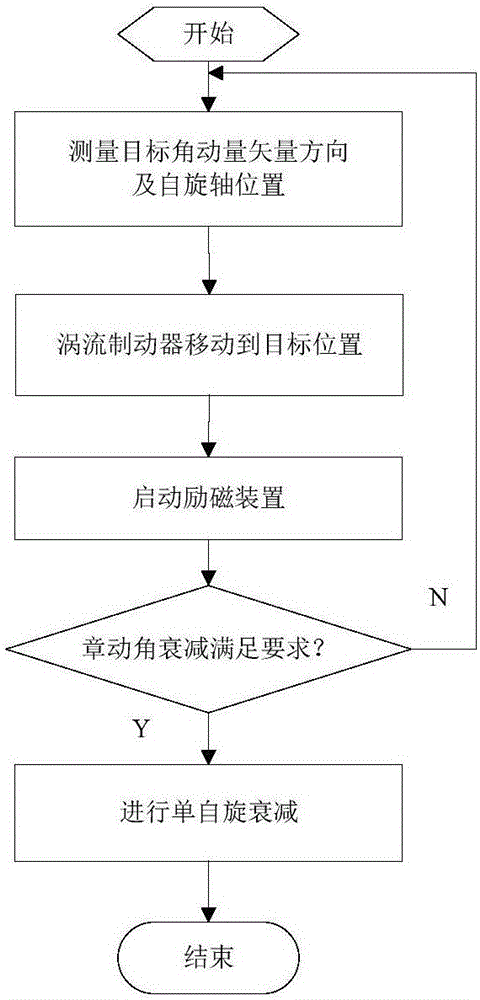

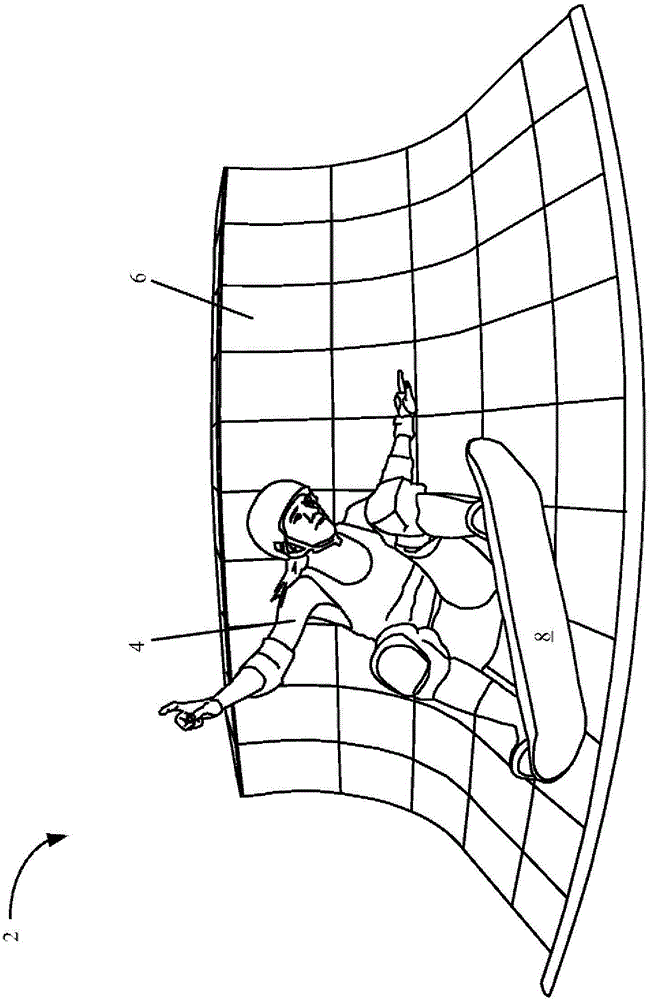

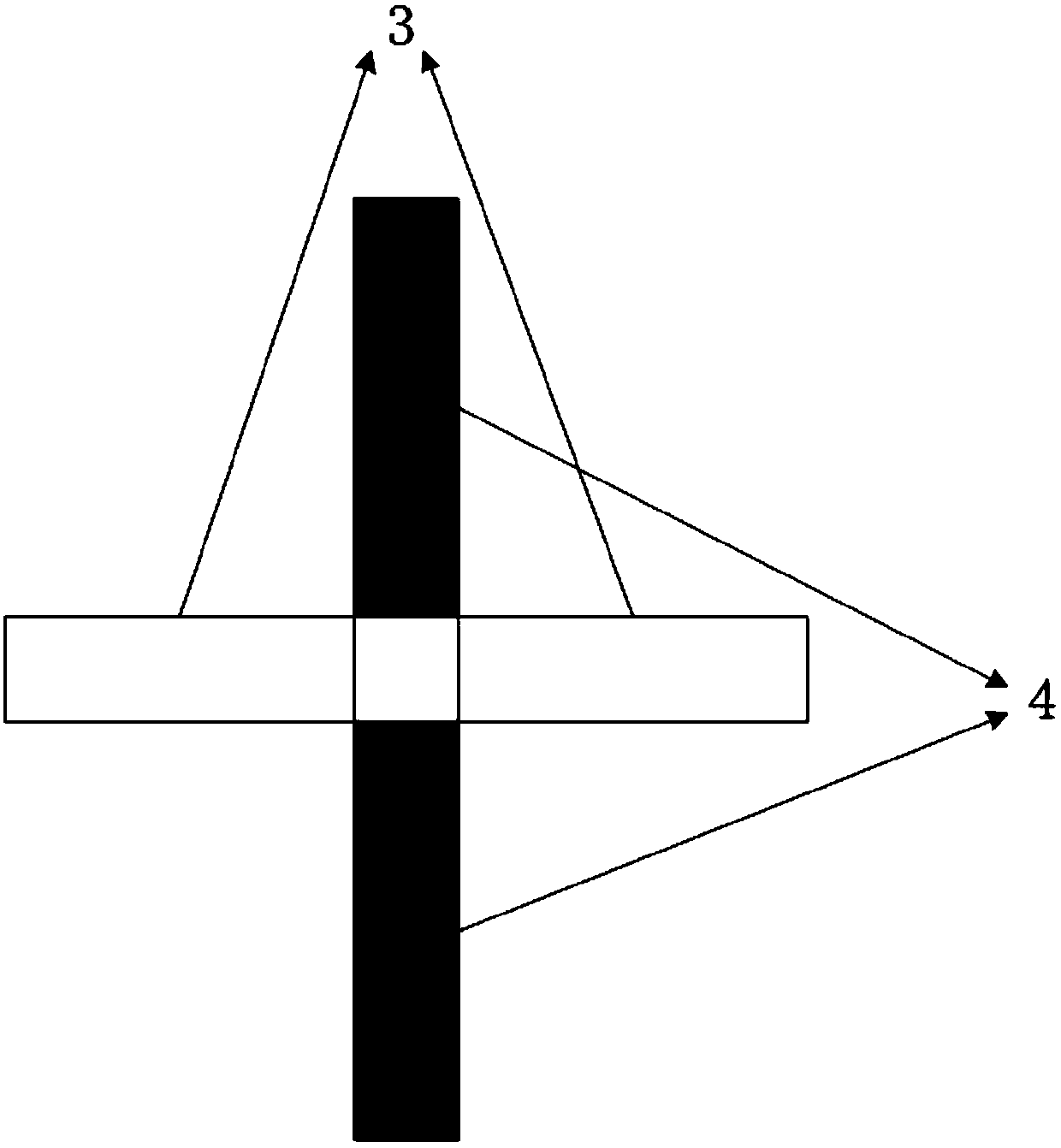

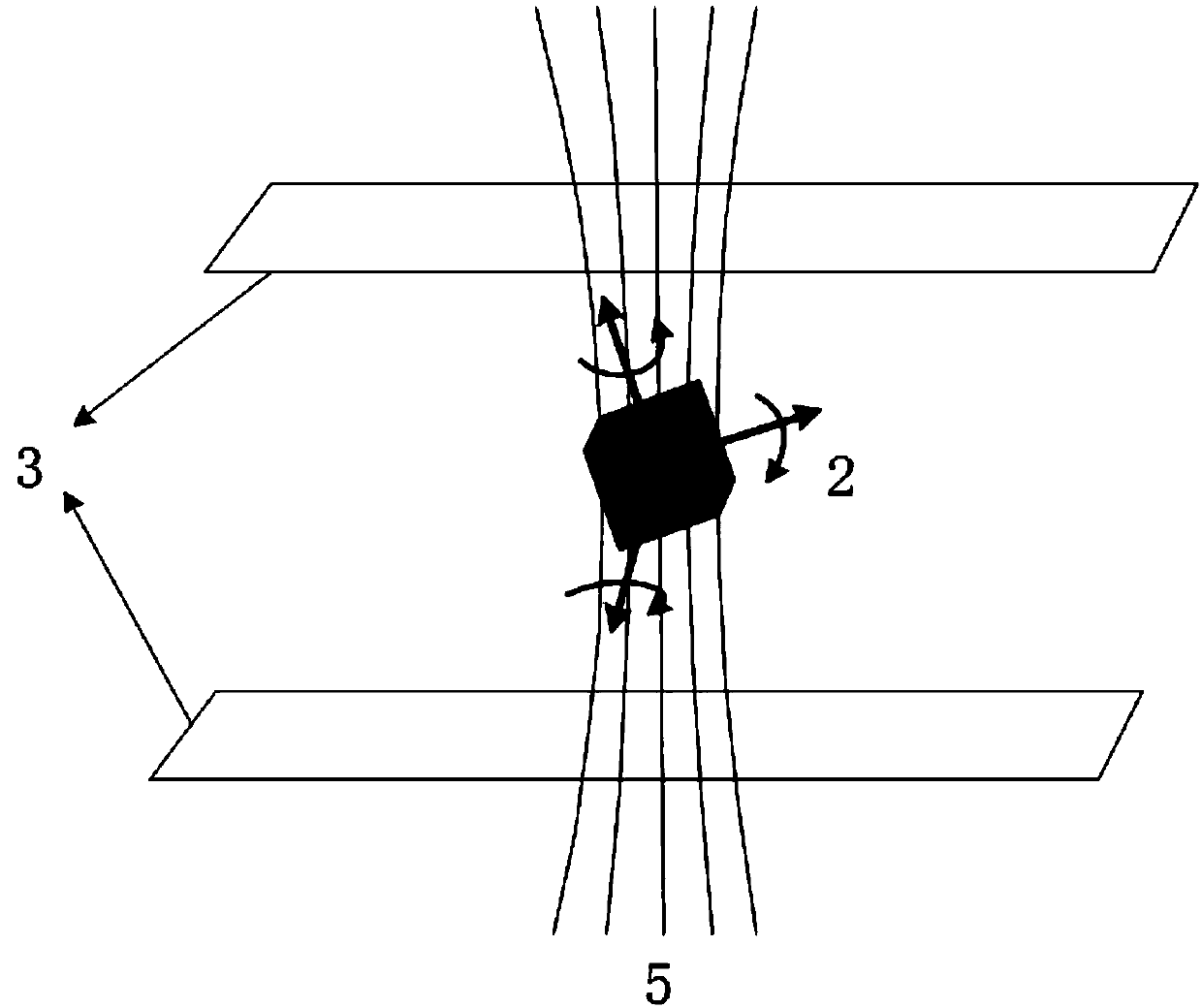

Space tumbling target de-spinning control method based on permanent magnet eddy current effect

ActiveCN106406329AMeet the attitude adjustment control requirementsIncrease the working distanceCosmonautic vehiclesCosmonautic partsNutationEngineering

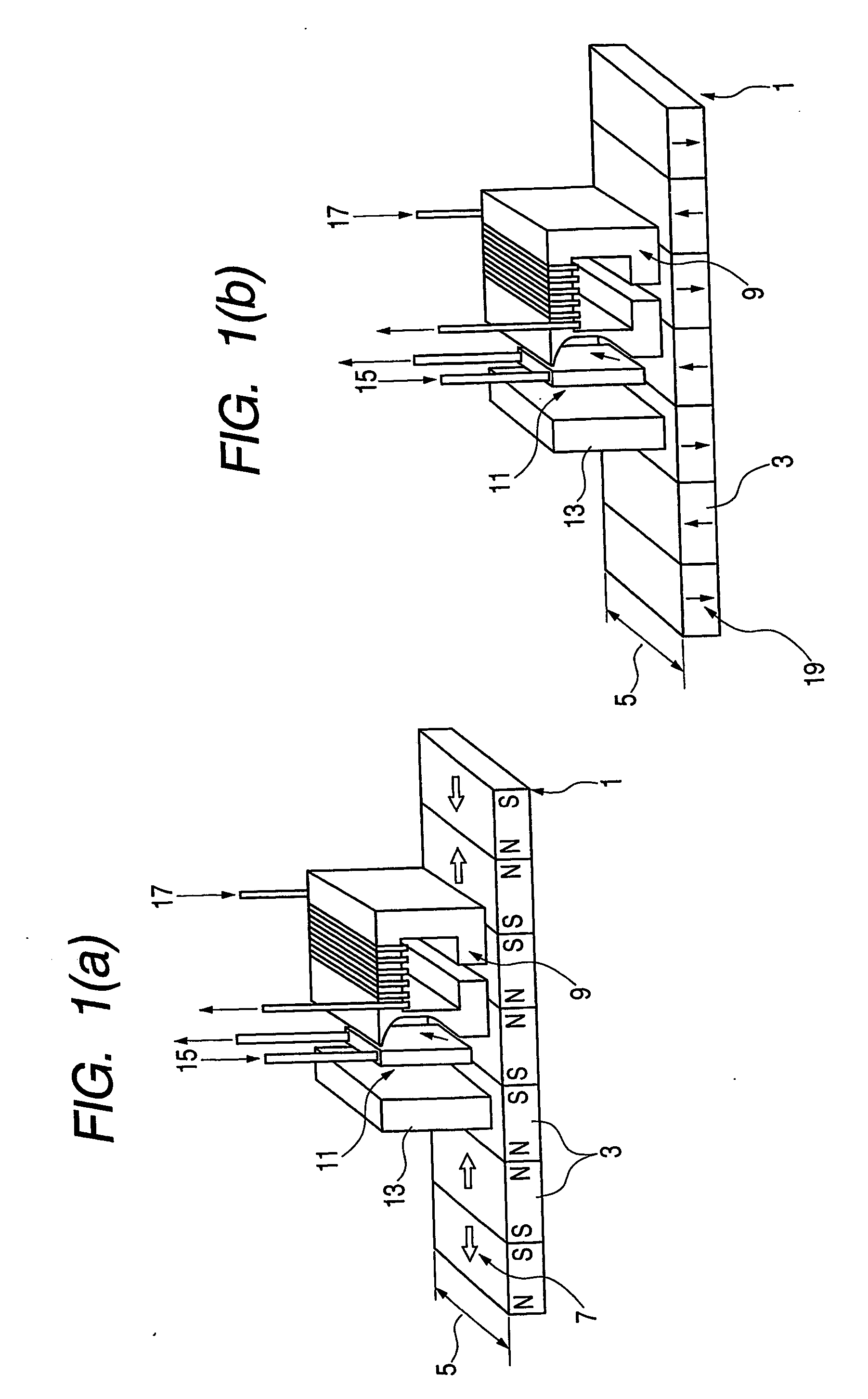

Disclosed is a space tumbling target de-spinning control method based on a permanent magnet eddy current effect. The method comprises the following steps: a service spacecraft docks in the working space of a mechanical arm, and is kept at a safety distance from a tumbling non-cooperative target; a visual inspection system carried by the service spacecraft measures the direction of a target angular momentum vector H and the direction of a spin axis position vector Zb, and the mechanical arm drives a permanent magnet eddy current braking device at the end to an initial de-spinning position, and the docking position is 100mm from the surface of the target in the direction of the target angular momentum vector; the permanent magnet eddy current braking device is started, the direction of a vector outputting an external torque T1 is corrected according to the real-time change of attitude angle in the tumbling process of the target until the angle of nutation attenuates completely, and the rotation state of the target is changed to a single spinning motion state; the position of the permanent magnet eddy current braking device is adjusted to the side of the tumbling non-cooperative target, the permanent magnet eddy current braking device is started to output a brake torque T2 until the single spinning motion state attenuates completely; after the target is completely de-spun, an end actuator is replaced with a grasping paw, and the target is captured directly by the mechanical arm.

Owner:黑龙江省工研院资产经营管理有限公司

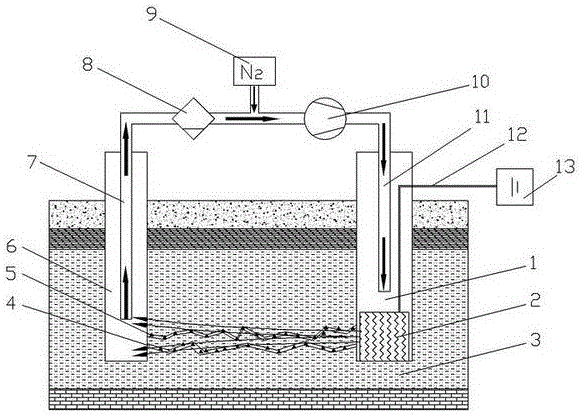

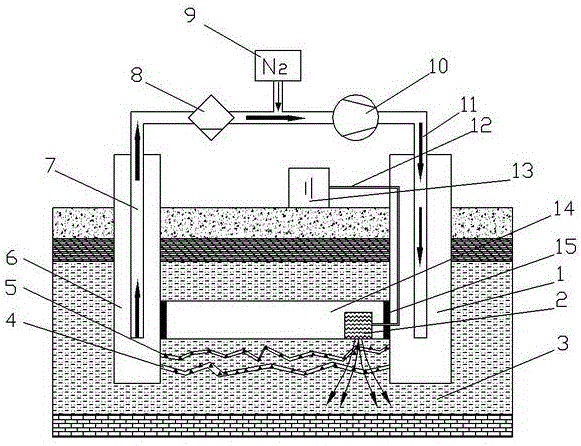

Eddy current heating oil shale underground in-situ mining method

ActiveCN106437667AHeating fastImprove energy utilizationFluid removalInduction current sourcesOil shale gasNitrogen gas

The invention discloses an eddy current heating oil shale underground in-situ mining method. The method comprises the steps that a mining well is drilled from the ground to a target oil shale layer, a propping agent containing ion particles is adopted during fracturing, and the iron particles are pressed into clearances of the oil shale layer; then a gas injection well is drilled again to the target oil shale layer within the fracturing range with the fracturing well as the center; an eddy current effect magnetic field generator is tripped in the well bottom of the gas injection well; nitrogen is introduced into the gas injection well for system internal circulation; the eddy current effect magnetic field generator is started to generate a high-frequency strong magnetic field, the iron particles in the oil shale layer are heated due to the eddy current effect at this moment, and then oil shale is heated to carry out in-situ fracturing on kerogen; nitrogen can carry shale oil and combustible gas and returns to the ground from the mining well, and after oil and the combustible gas are separated through a comprehensive separator, remaining gas is injected into the gas injection well again for circulating. The heating process of the oil shale can be effectively accelerated, the energy utilization rate can be increased, and the heating cost can be reduced.

Owner:JILIN UNIV

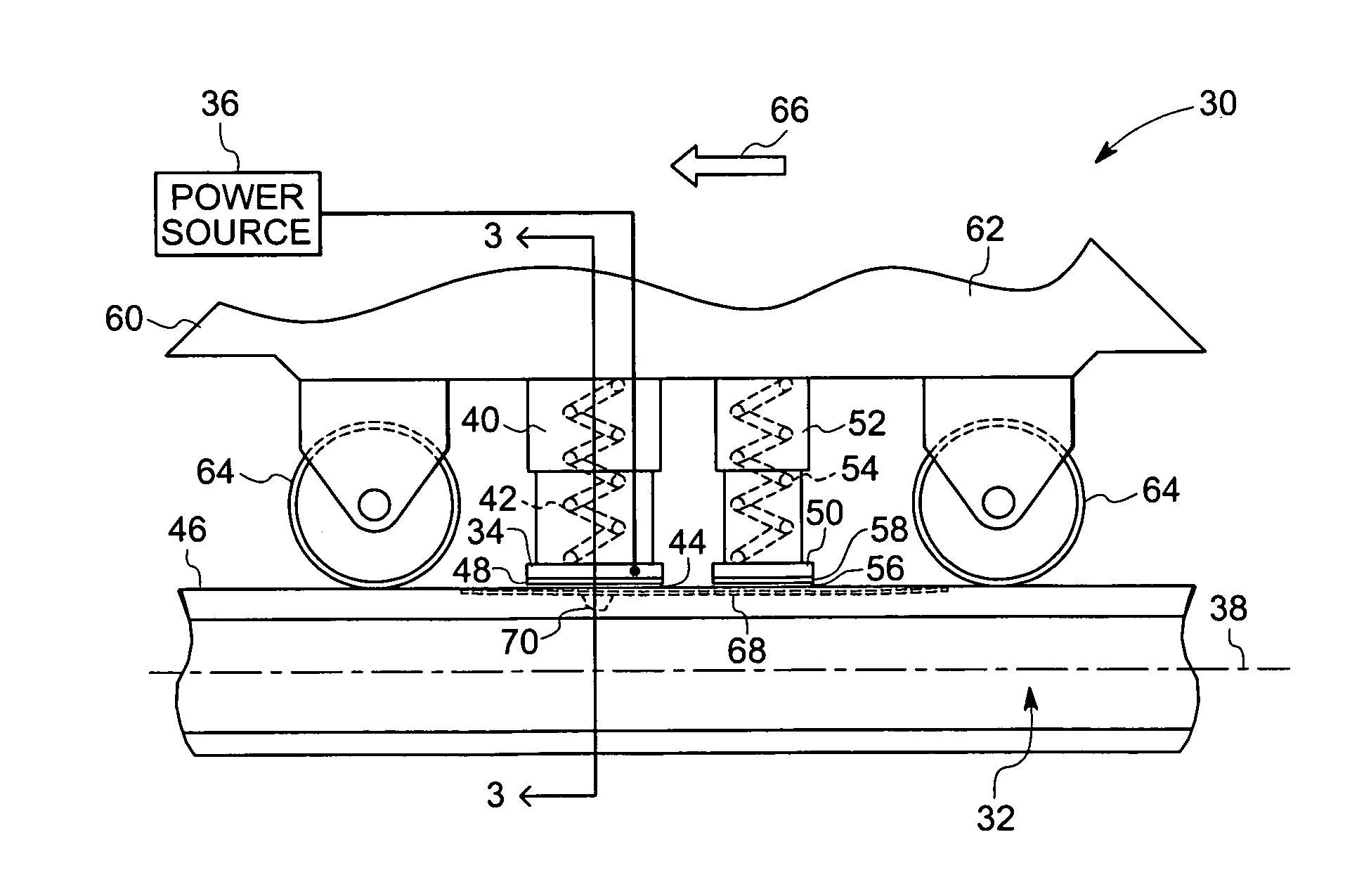

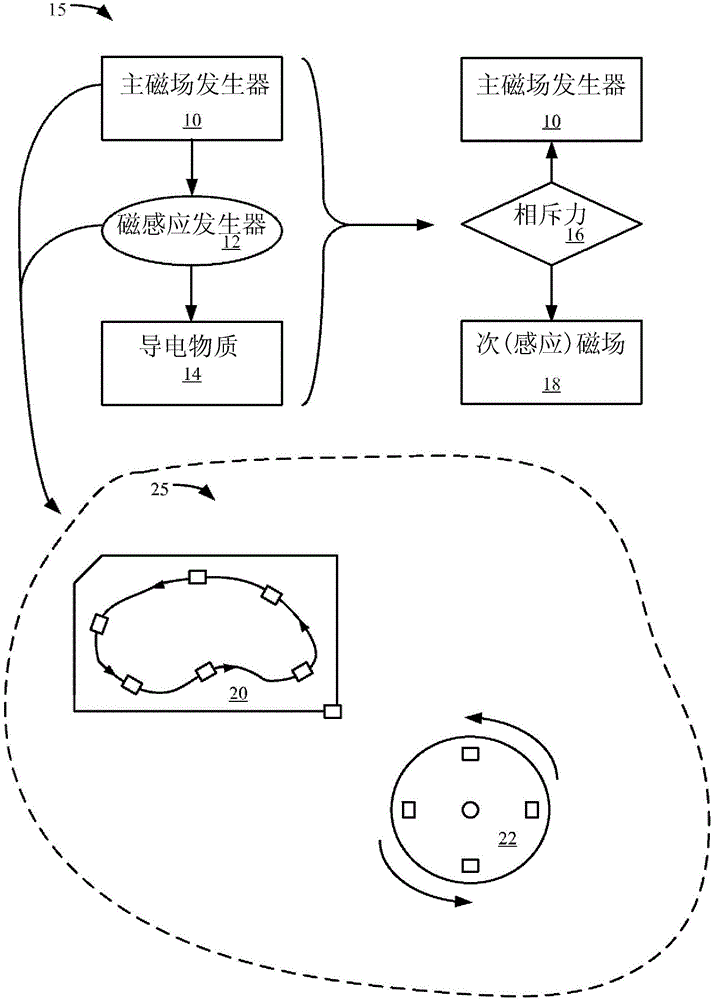

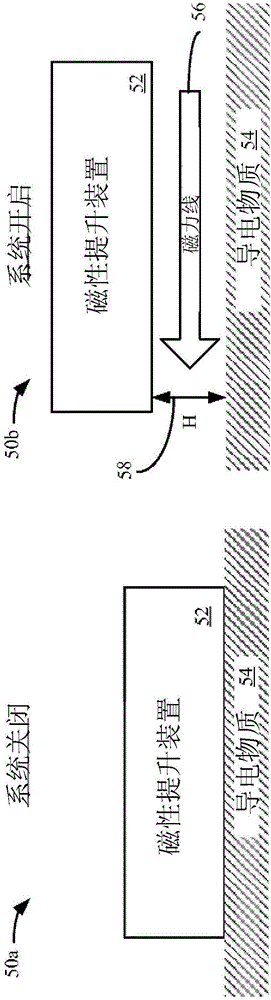

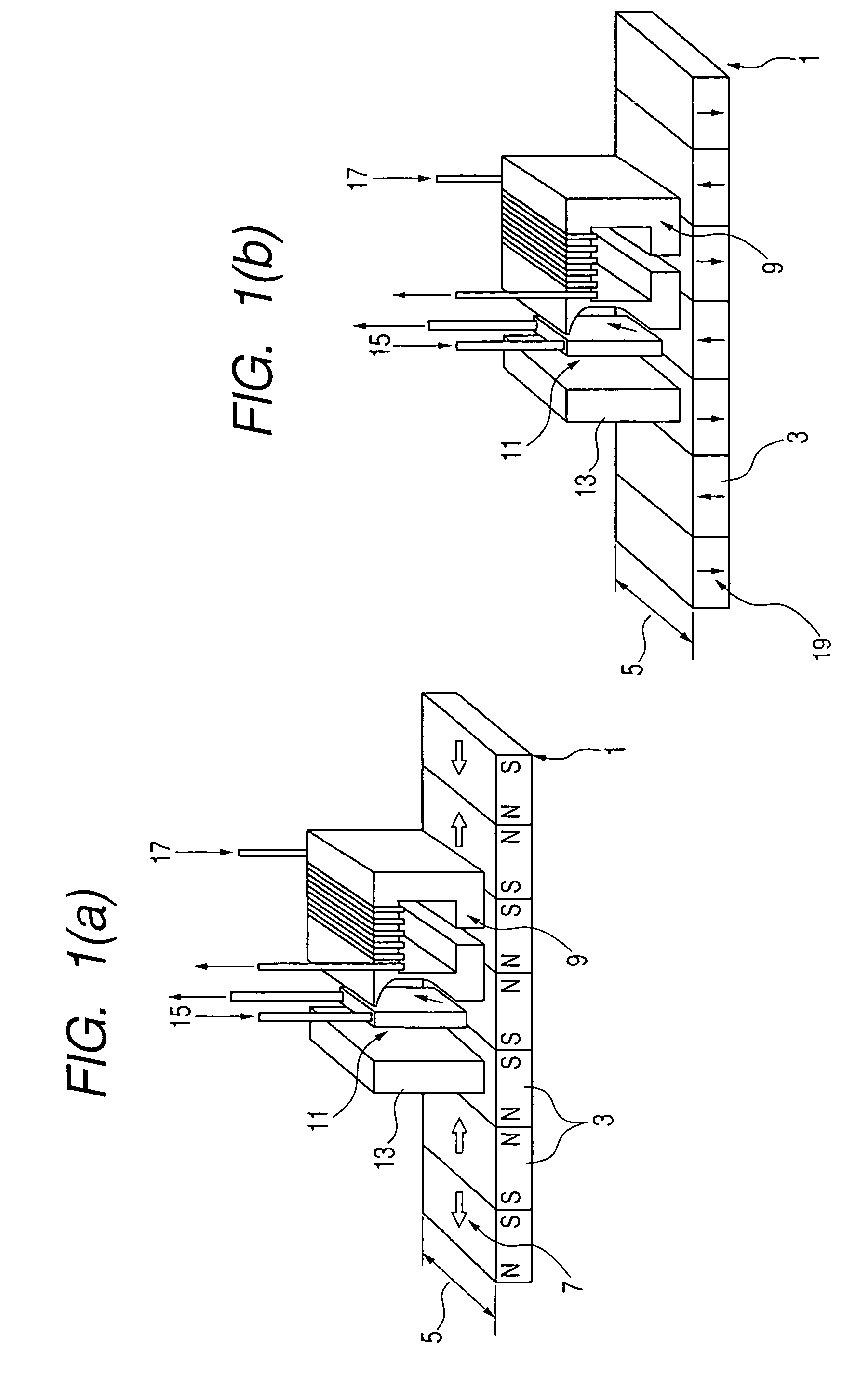

Magnetic levitation of a stationary or moving object

InactiveCN105142971ANon-mechanical conveyorsPropulsion by batteries/cellsEddy current effectThreshold velocity

A magnetic lifting device is described. The magnetic lifting device can be configured to generate magnetic lift using a moving magnetic field to generate an eddy current effect in conductive substrate beneath the device. In one embodiment, the moving magnetic field can be generated by a rotor with arrangement of permanent magnets which is driven by a motor. In operation, the rotor can be spun up from rest to above a threshold velocity, which causes the magnetic lifting device to rise up from the conductive substrate, hover in place in free flight and move from location to location. In free flight, the magnetic lifting device can be configured to carry a payload, such as a person.

Owner:阿克斯帕克斯莱柏公司

Flexible magnetostriction and eddy integrated sensor for detecting defects of high-voltage transmission line

ActiveCN102841132ARealize full structural defect detectionAchieve axial positioningOptically investigating flaws/contaminationMaterial magnetic variablesEngineeringHigh pressure

The invention relates to a flexible magnetostriction and eddy integrated sensor for detecting defects of a high-voltage transmission line and belongs to the technical field of an electromagnetic acoustic sensor. An outer-layer magnetostriction sensor is printed on a substrate through a flexible printing coil and an inner-layer eddy sensor is printed on the substrate through the flexible printing coil; the flexible printing coil can be coiled into a cylindrical shape and clung to the surface of the high-voltage transmission line so as to form a solenoid coil; after the solenoid coil is clamped and fixed by a connector, the solenoid coil is mounted on a detected transmission line so as to detect the defects; and after the clamped and fixed state is released, the solenoid coil can be detached from the surface of the transmission line. The integrated sensor can be used for stimulating a longitudinal modal ultrasonic guide wave from the transmission line and detecting the defects of the whole structure of the transmission line on the basis of a magnetostriction effect; the integrated sensor also can be used for detecting complex impedance change of a sensor detecting coil due to the defects of the transmission line by utilizing a multi-channel eddy sensor and realizing the peripheral positioning for the defects on the basis of an eddy effect; and meanwhile, the deep positions of the defects in the transmission line can be confirmed on the basis of a surface action of an eddy field.

Owner:BEIJING UNIV OF TECH

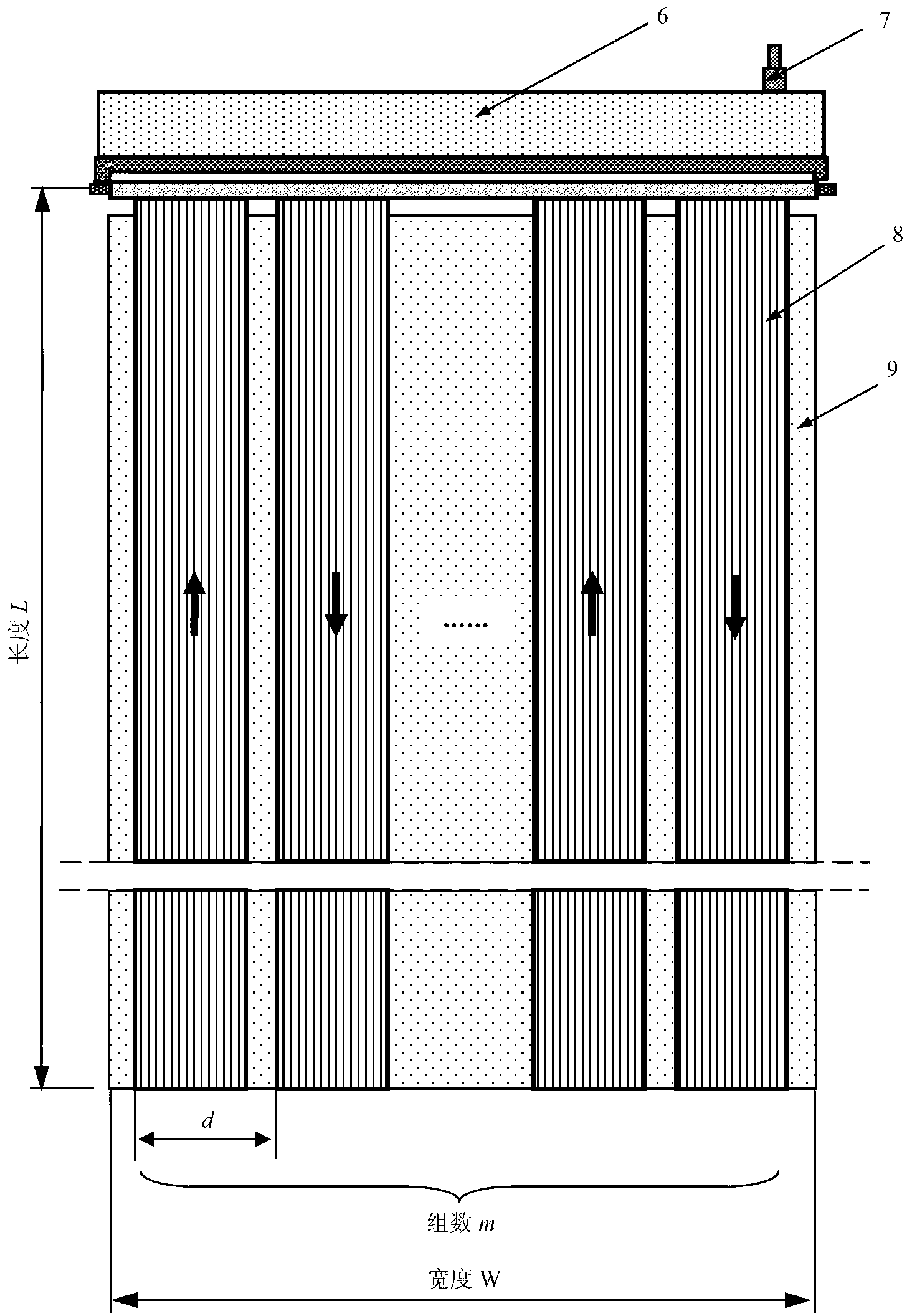

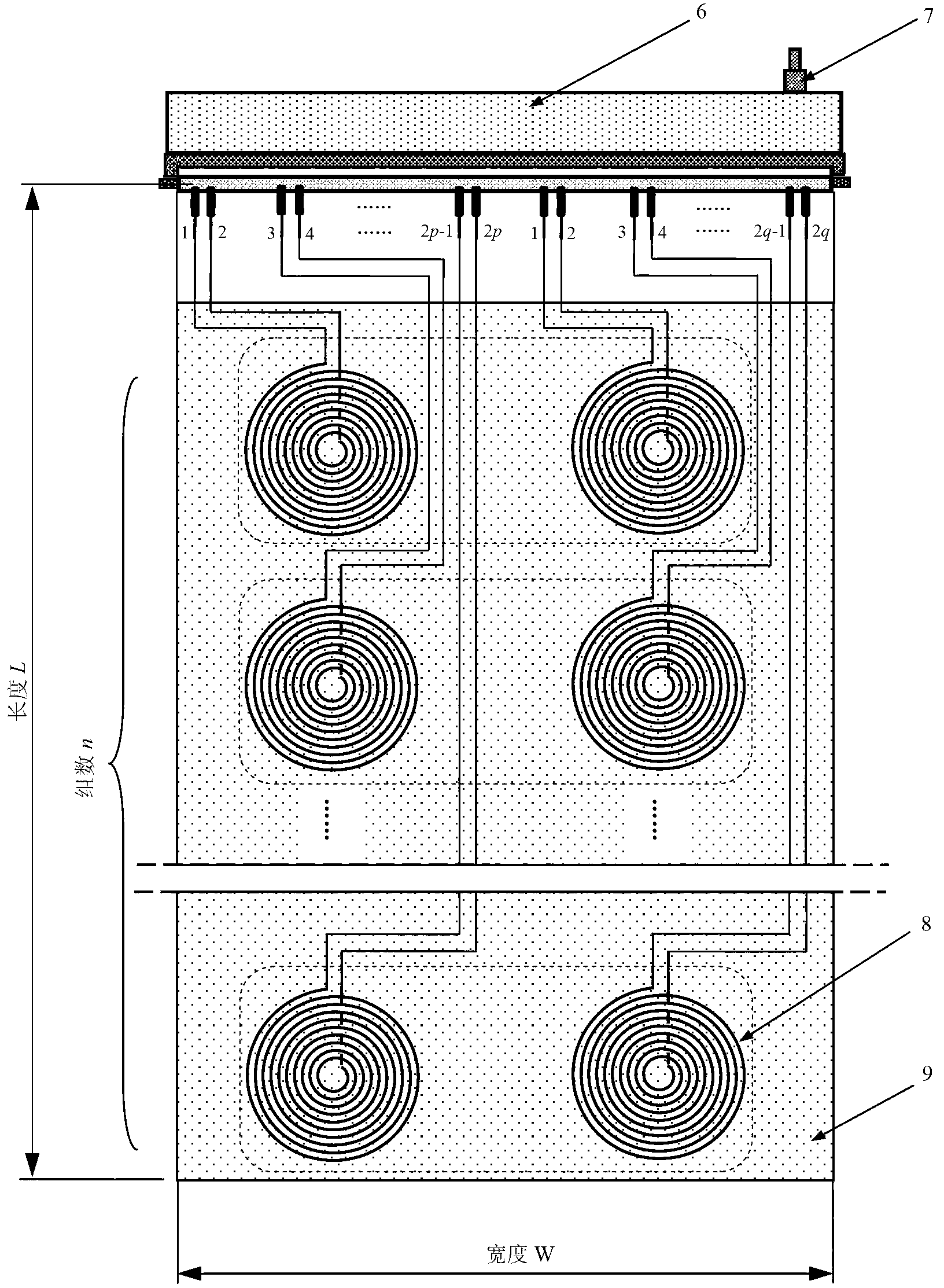

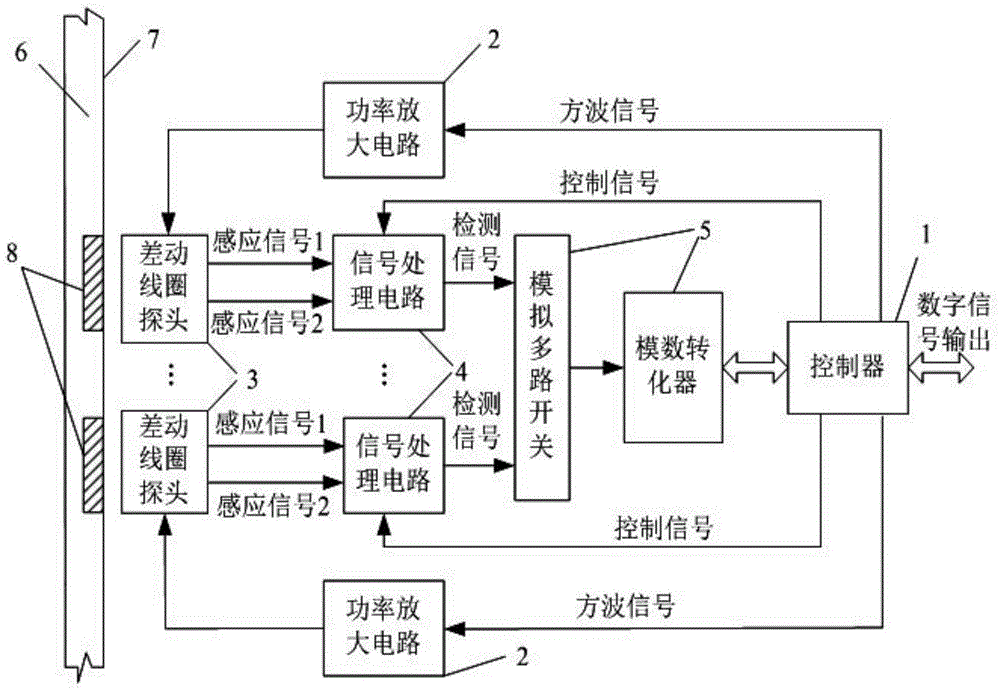

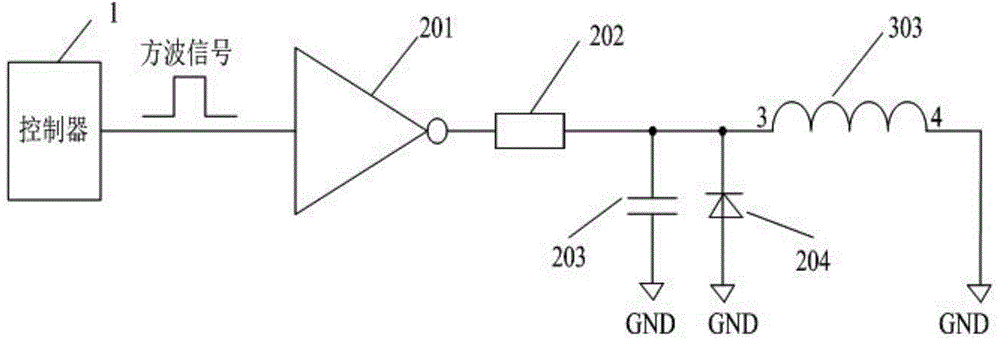

Detection system of metal surface defect and detection method thereof

ActiveCN104820015ALow sampling rateRealize the distinction between internal and external defects in magnetic flux leakage testingMaterial magnetic variablesSignal processing circuitsControl signal

The invention discloses a detection system of metal surface defects and a detection method thereof. In the method, a square signal and a control signal, which is sent to a signal treatment circuit, are generated through a controller. A power amplification circuit excites an exciting coil to generate an eddy current effect on a to-be-test metal surface. An inductive signal generated in a first detection coil and a second detection coil in a probe of a differential coil is subjected to treatments of difference forming, amplification, wave filtering and peak value maintenance through the signal treatment circuit, and then a DC voltage signal is outputted. The position of the probe of the differential coil is moved. The whole process is repeatedly performed for carrying out scanning detection to the to-be-test metal surface. By means of the detection system and the detection method, the metal surface defects can be detected at a low sampling speed with an intuitive detection result obtained, and meanwhile the detection method can be integrated with a magnetic flux leakage testing method to performing composite detection, thereby achieving difference of inner defects and outer defects of magnetic flux leakage testing of a pipeline.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

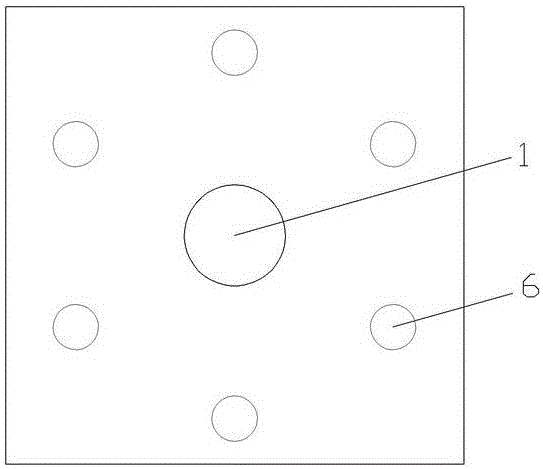

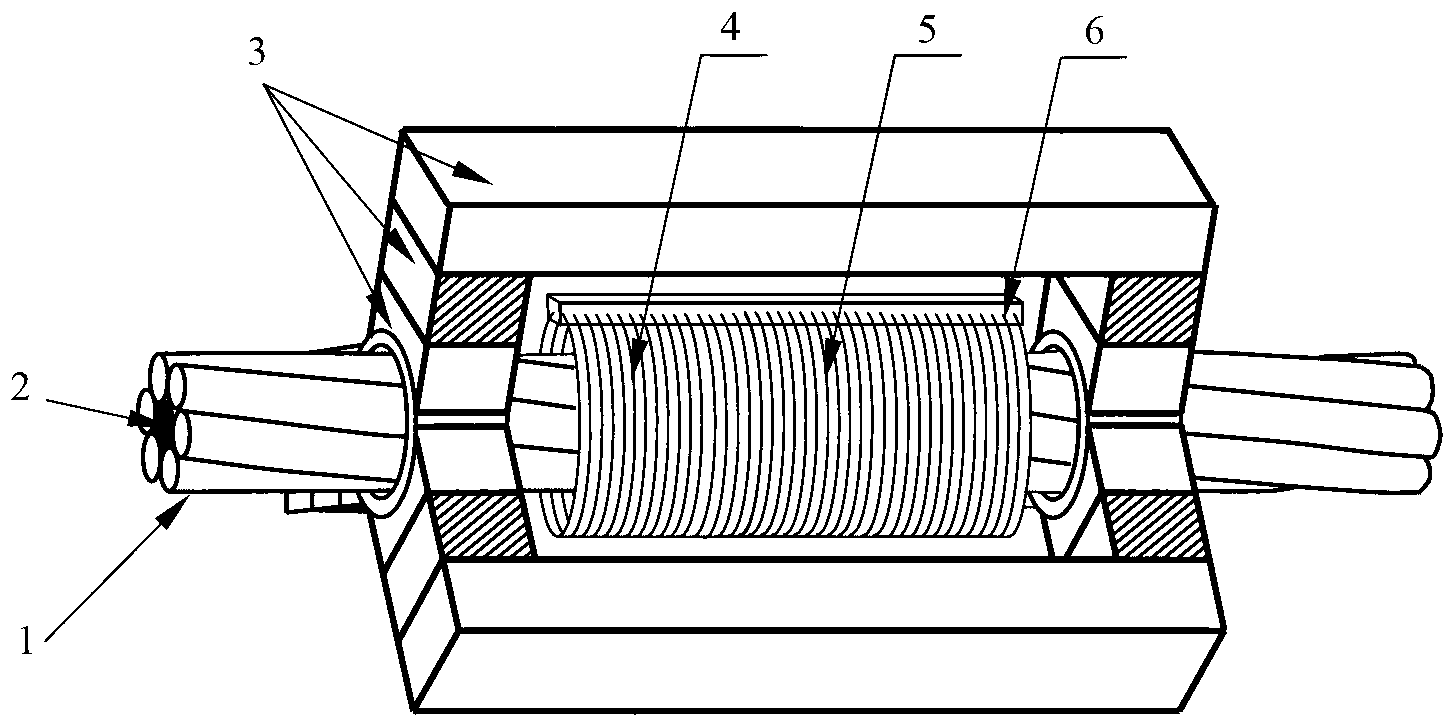

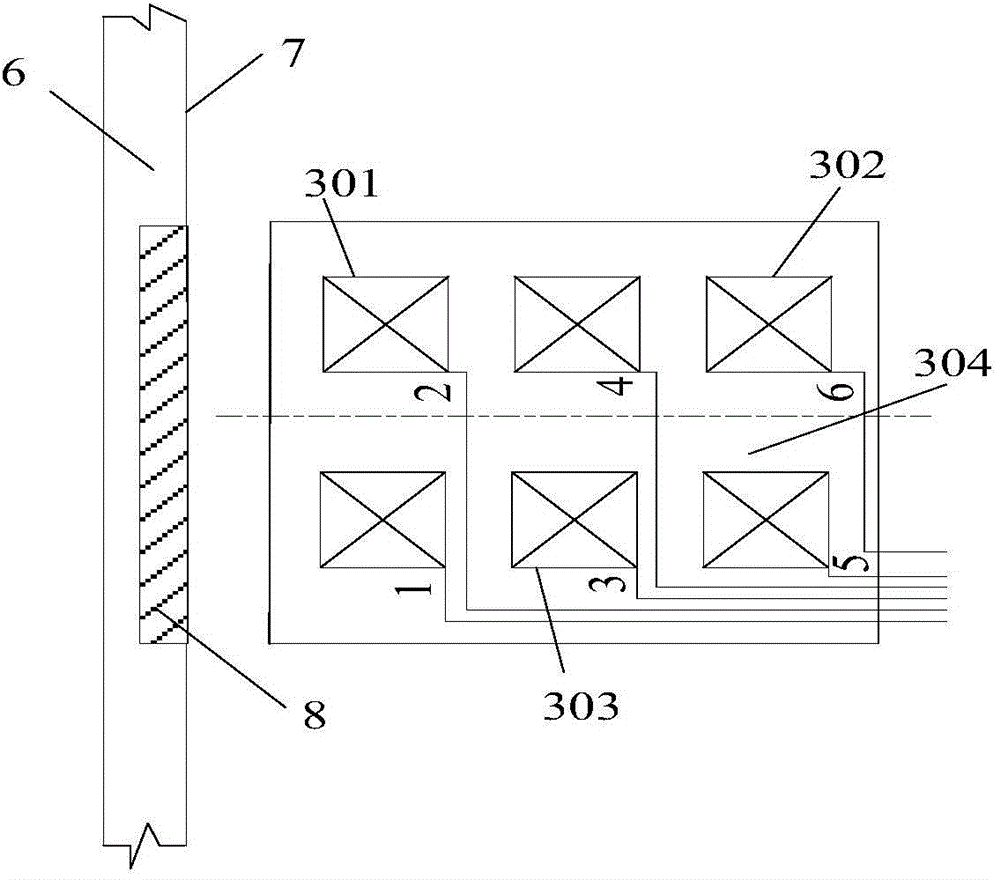

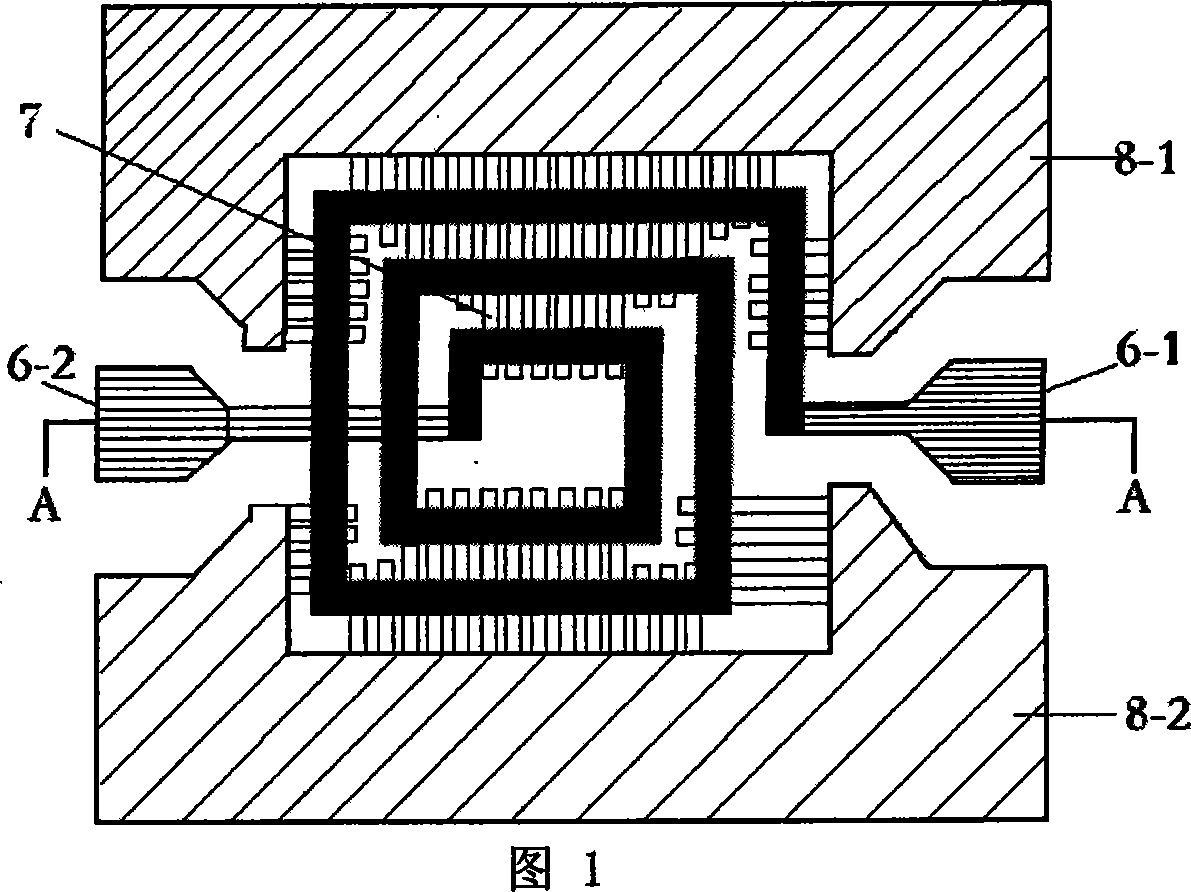

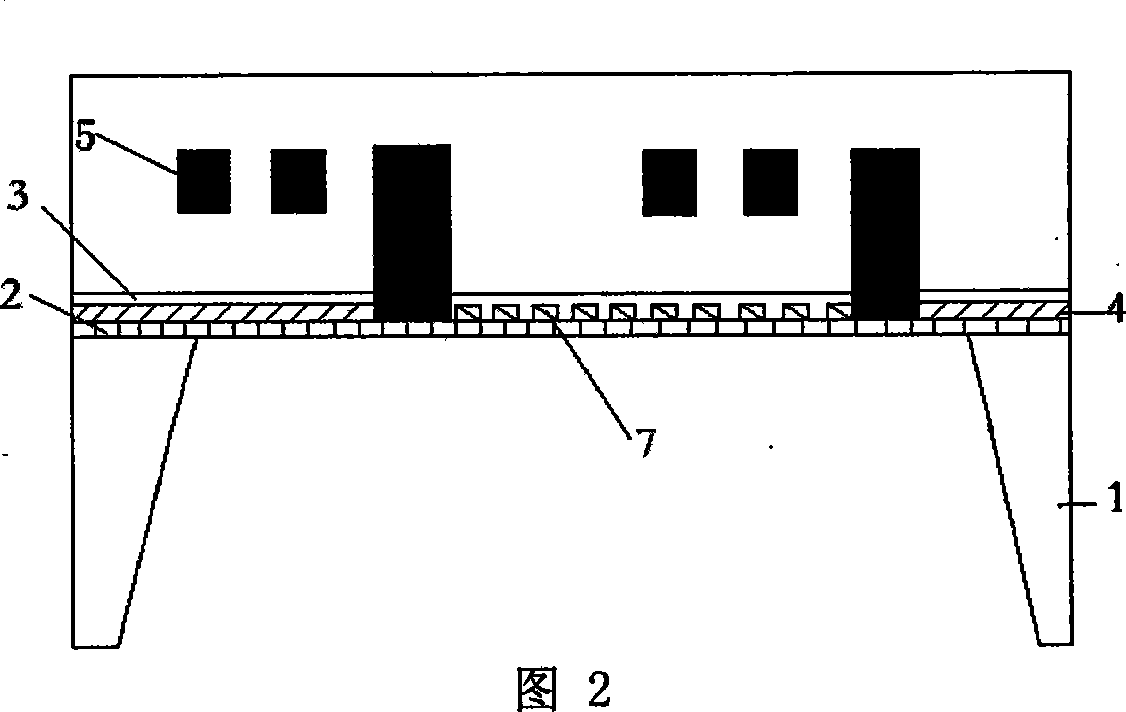

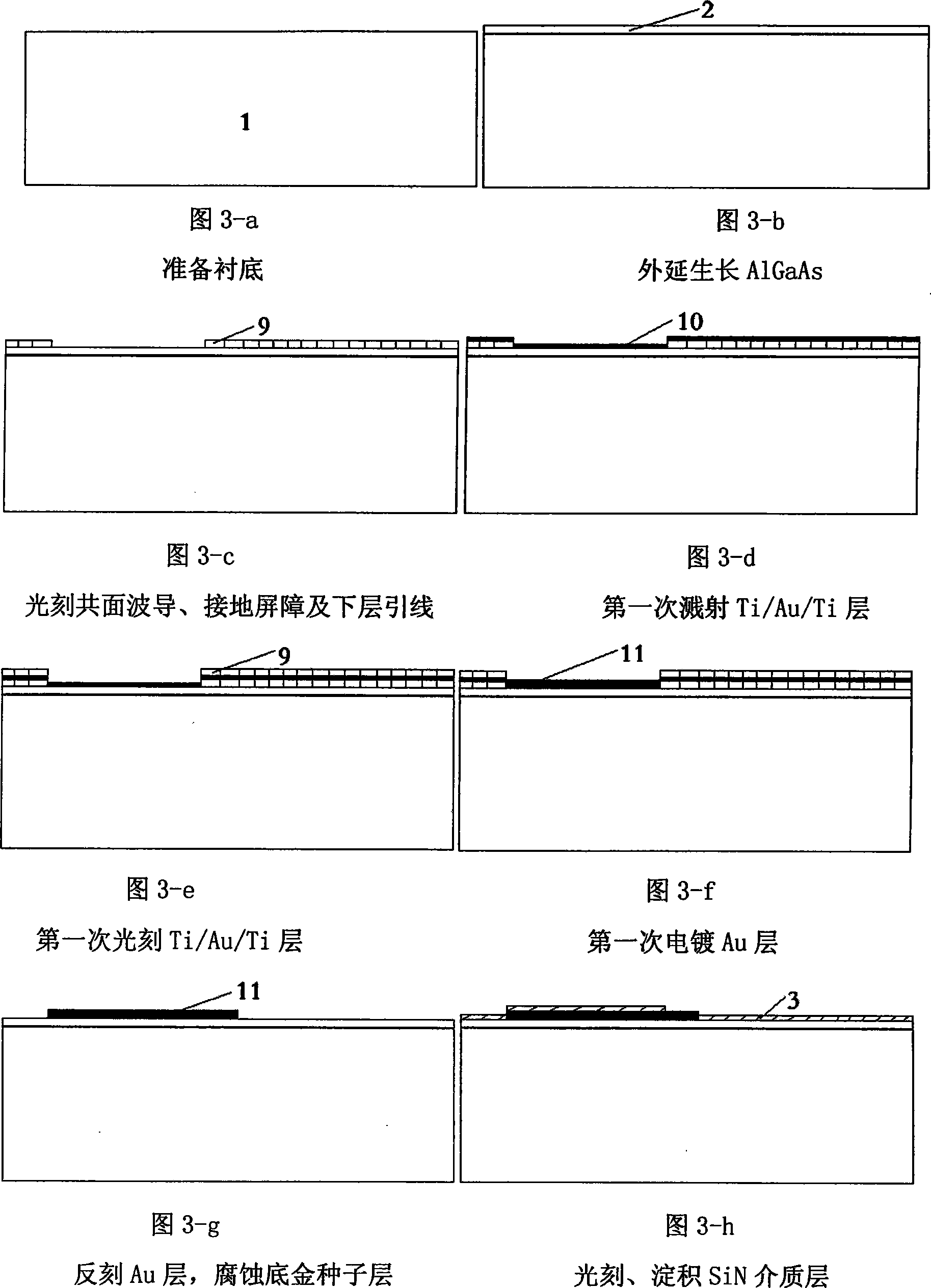

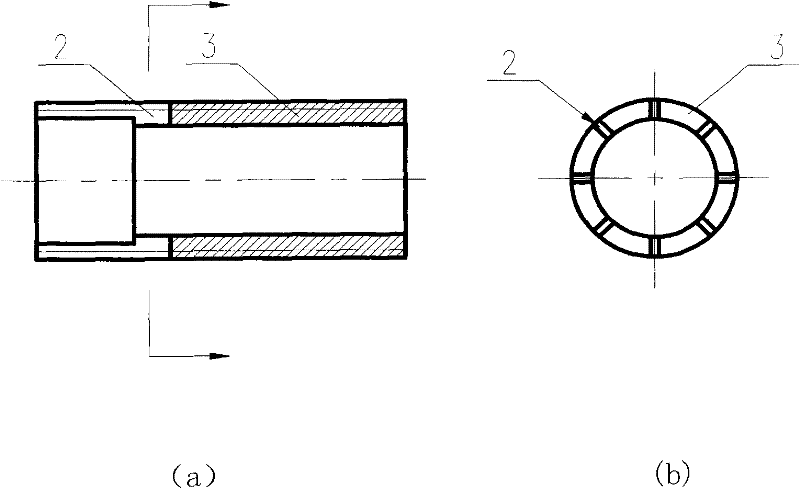

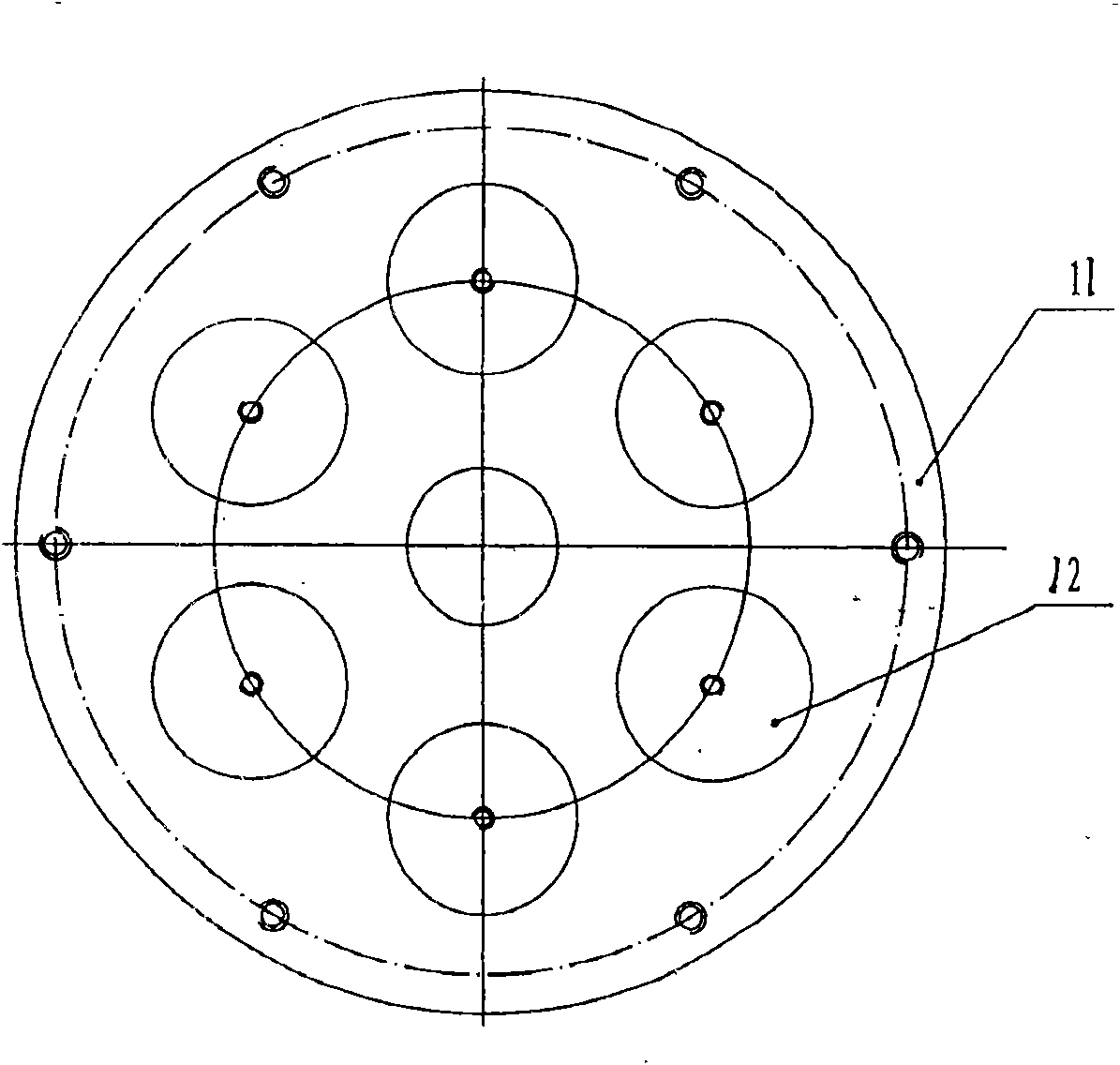

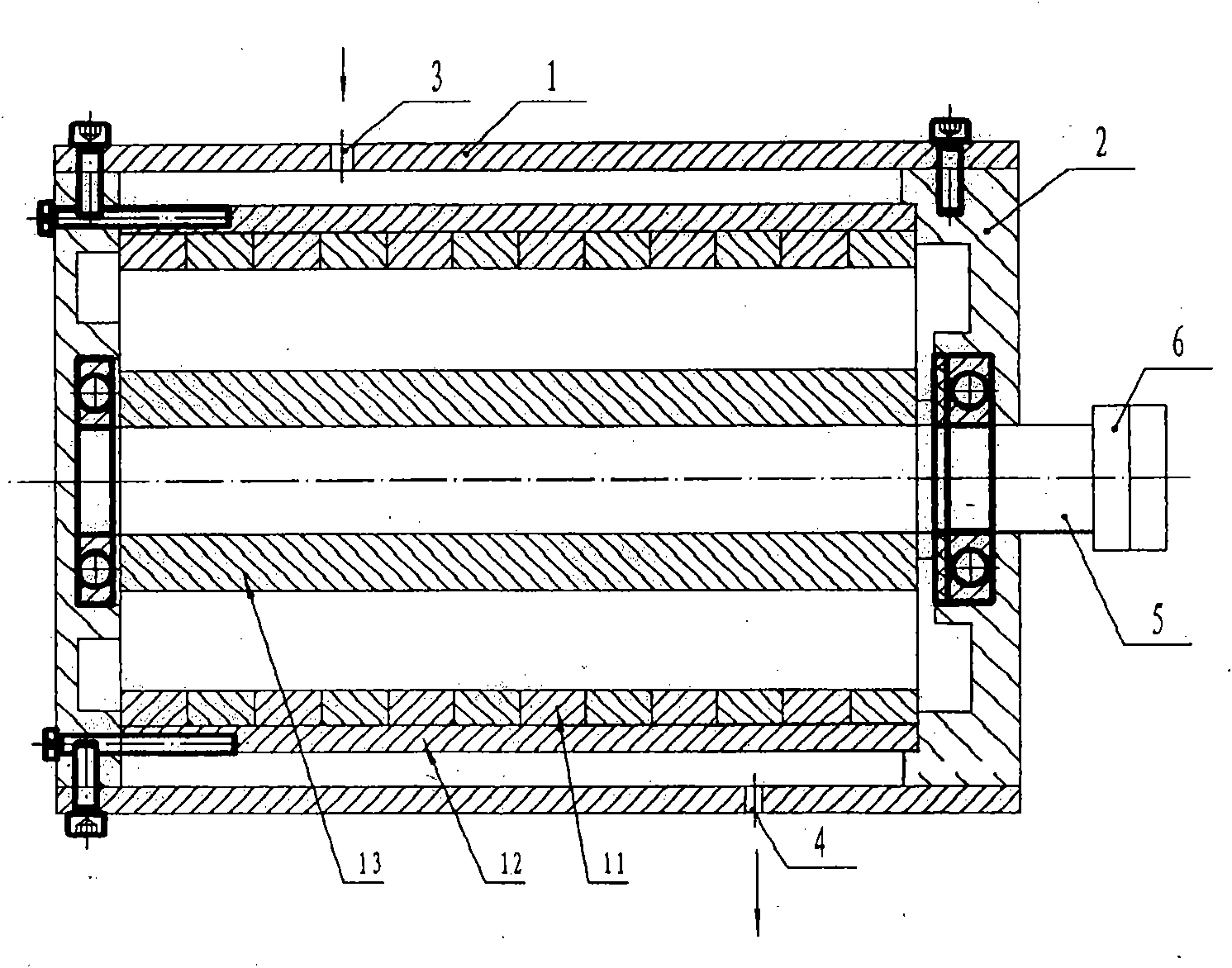

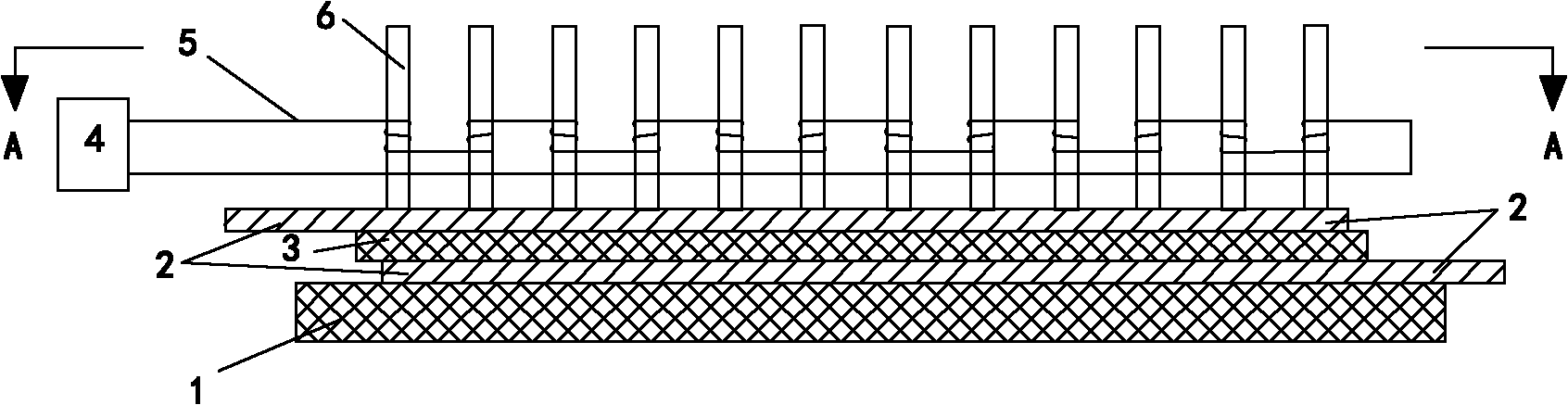

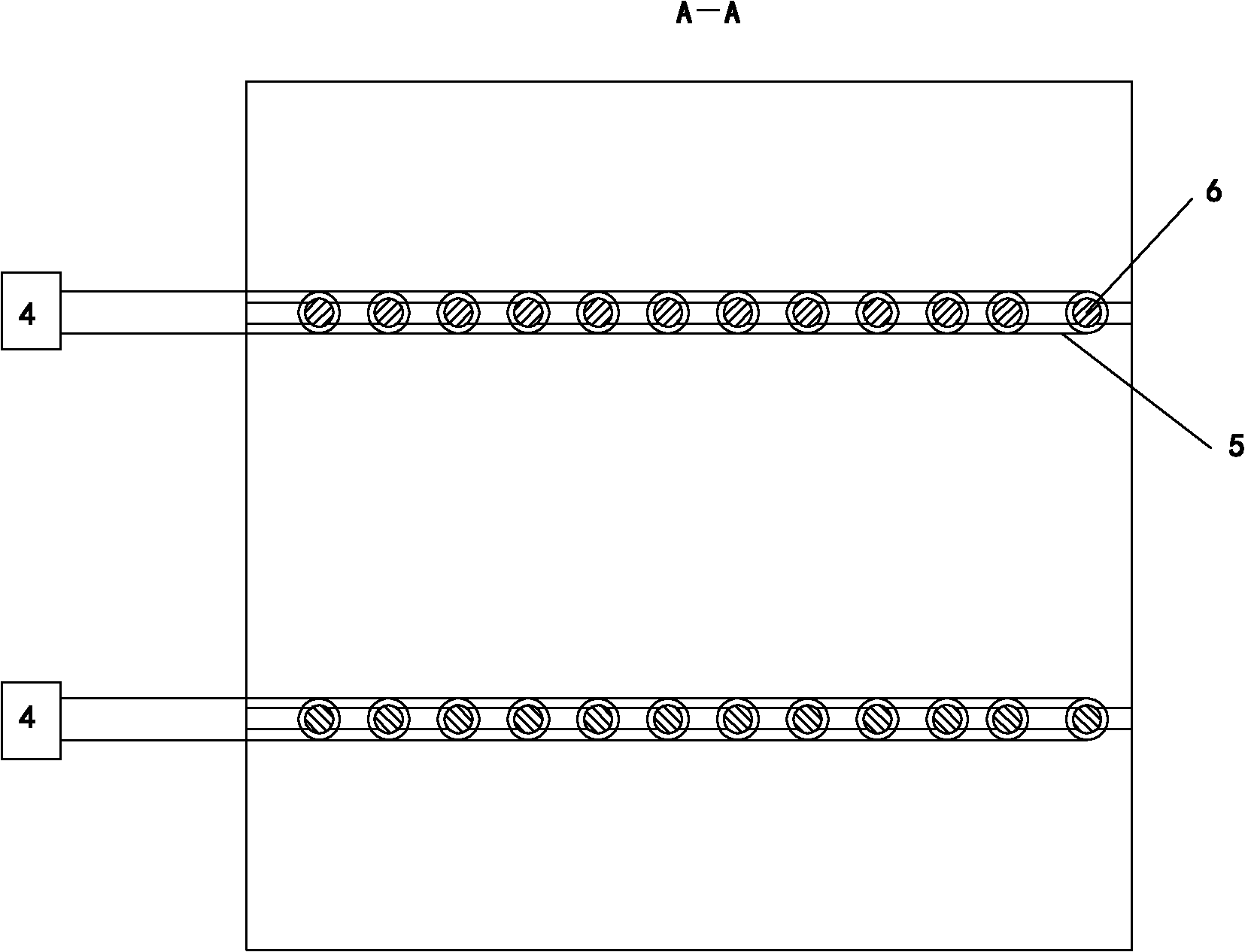

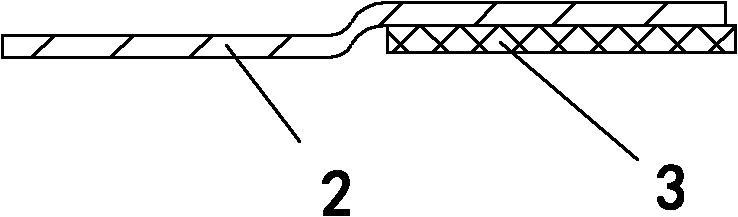

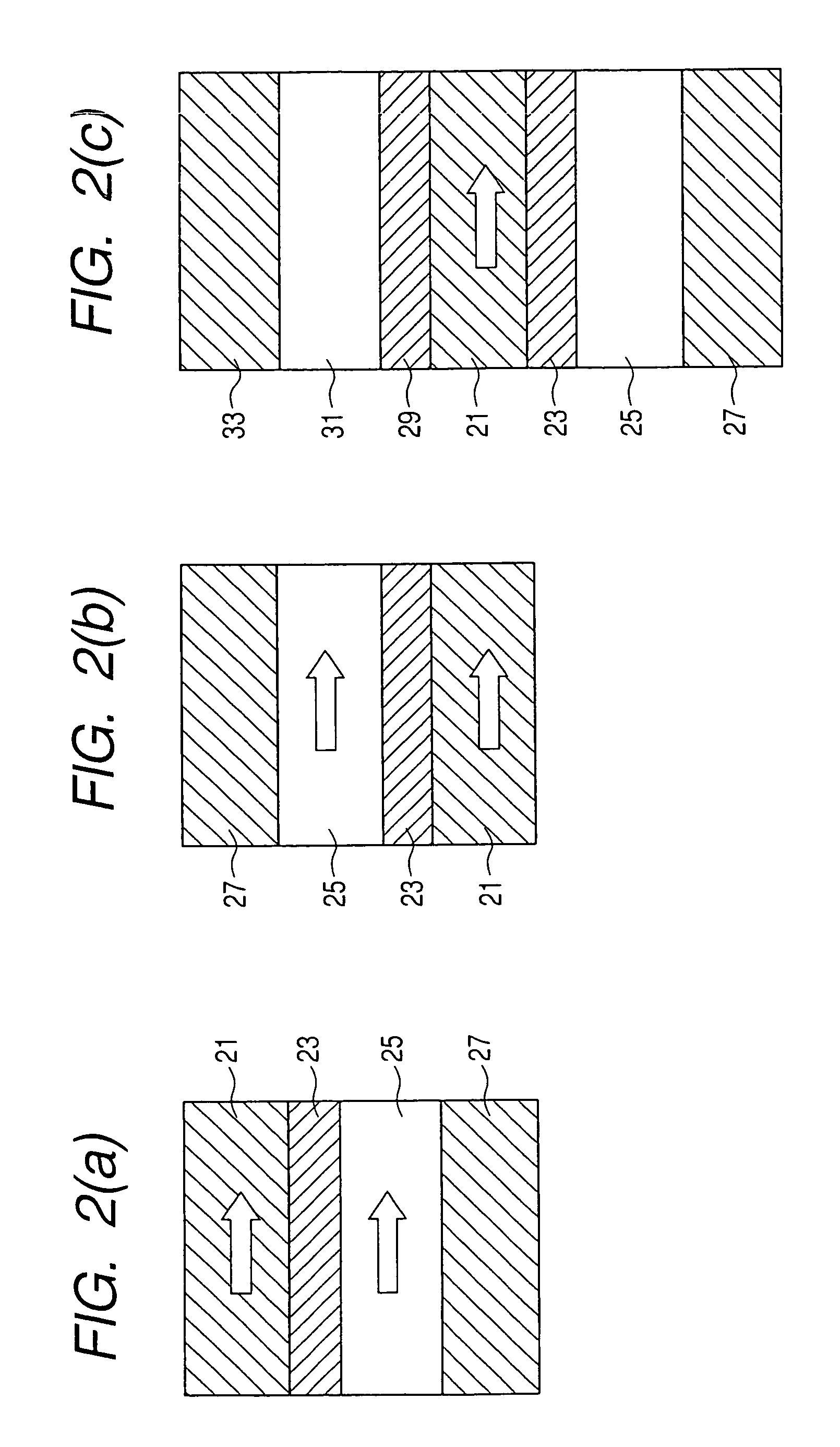

Micro-electromechanical inductor for suppressing the substrate eddy effect and its manufacture method

InactiveCN101060027AReduced eddy current effectAvoid it happening againSolid-state devicesSemiconductor/solid-state device manufacturingEddy current effectCoplanar waveguide

The MEMS-based inductance comprises: a GaAs (1) substrate, one layer of AlGaAs film (2) on top surface of (1), a SiN medium layer (3) on top surface of (2), a top ring (5) hanging above (3), the center of (5) connecting with the bottom wire (4) on (2), the outer insulation part of (5) connecting with the first coplanar waveguide signal wire (61), a grounding barrier (7) between (5) and (3) connecting with the inner side of coplanar waveguide grounding wire, and all of the coplanar waveguide signal lines (61, 62) and grounding lines (81, 82) together forming the coplanar waveguide transmission line. This invention can inhibit the vortex effect in substrate.

Owner:SOUTHEAST UNIV

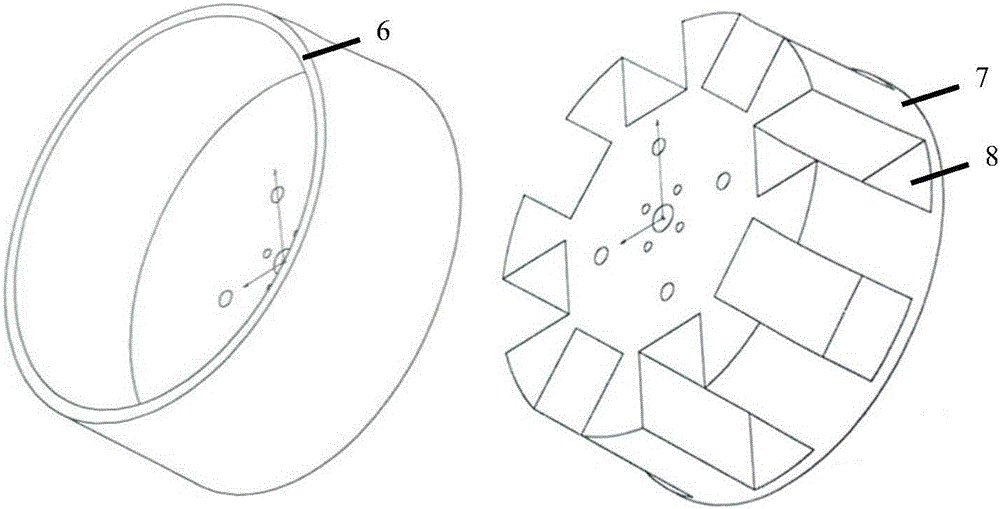

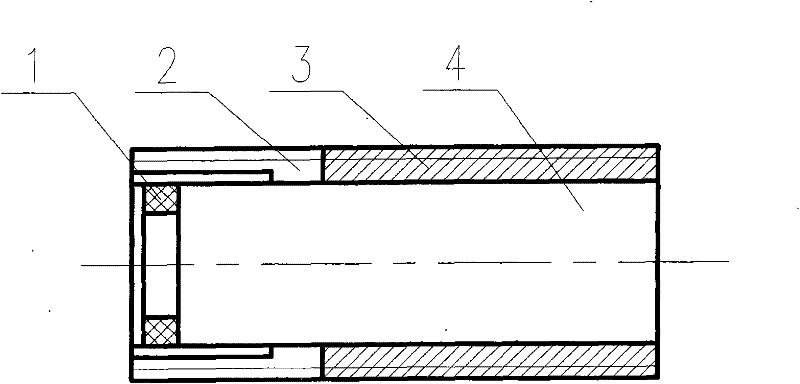

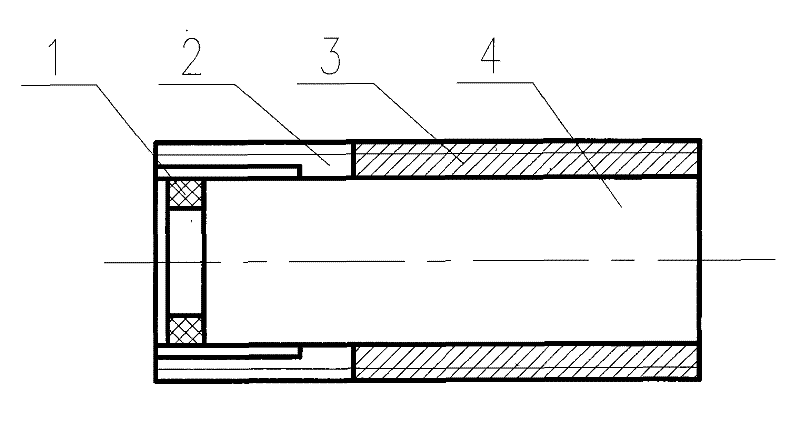

Magnetic-shielding eddy current sensor probe and method for reducing eddy current effect

InactiveCN101750009ASmall sizeReduce the influence of eddy currentUsing electrical meansMagnetic bearingEddy current effect

The invention discloses a magnetic-shielding eddy current sensor probe and a method for reducing eddy current effect, which relates to the technical field of eddy current sensors. The magnetic-shielding eddy current sensor probe comprises a measuring coil (1), a magnetic-shielding cover (3) and a winding framework (4), wherein the measuring coil (1) is wound on the winding framework (4); the measuring coil (1) and the winding framework (4) are placed in an inner hole of the magnetic-shielding cover (3) together; the magnetic-shielding cover (3) is at the other end of the measuring coil (1); the magnetic-shielding cover (3) is provided with 1 to 100 narrow slits (2) in the circumferential direction; the width of the narrow slits is 0.02 to 10 mm; and the depth of the narrow slits in the axial direction is 0.2 to 100 times the outer diameter of the measuring coil. By providing the end of the magnetic-shielding cover with the axial narrow slits (2) along the circumference, the pathway of eddy current is blocked, and the influence of the magnetic-shielding cover on the performance of eddy current sensors is reduced. The magnetic-shielding eddy current sensor probe can shield other AC magnetic fields around the sensor probe, and is small in size, thereby having great application prospects in the fields of magnetic bearings, motors, maglev trains and the like.

Owner:NANJING CIGU TECH CORP LTD +1

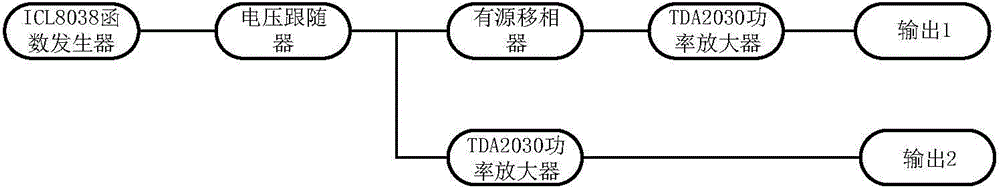

Magnetic induction heating method and special devices

ActiveCN102143621AReduce power consumptionEasy to useInduction heating apparatusMagnetic sensingElectric energy consumption

The invention discloses a magnetic induction heating method and special devices, which belong to the field of electromagnetic eddy current induction. A high-strength magnetic field is provided by a correspondingly arranged permanent magnet; a metal body rotates at a high speed in the magnetic field to cut a magnetic line of force so as to be heated through an eddy current effect; and the heated metal body outputs heat energy through a fluid medium. In a device, a rotating shaft in a barrel body is provided with a metal turbine with a spiral groove; the metal turbine is covered by metal clamping plates; and a barrel cover at the periphery of the rotating shaft is provided with the corresponding permanent magnet. In another device, the rotating shaft in the barrel body is provided with a metal barrel; and the inner wall of the barrel body is provided with the permanent magnet. High-temperature hot water or hot steam is produced through heat exchange to output heat energy. The invention can be widely applied to household heating or industrial heat supply and air supply, and has the advantages of low electric energy consumption, wide application range, convenience for use, economy andenvironmental protection.

Owner:张洪军 +1

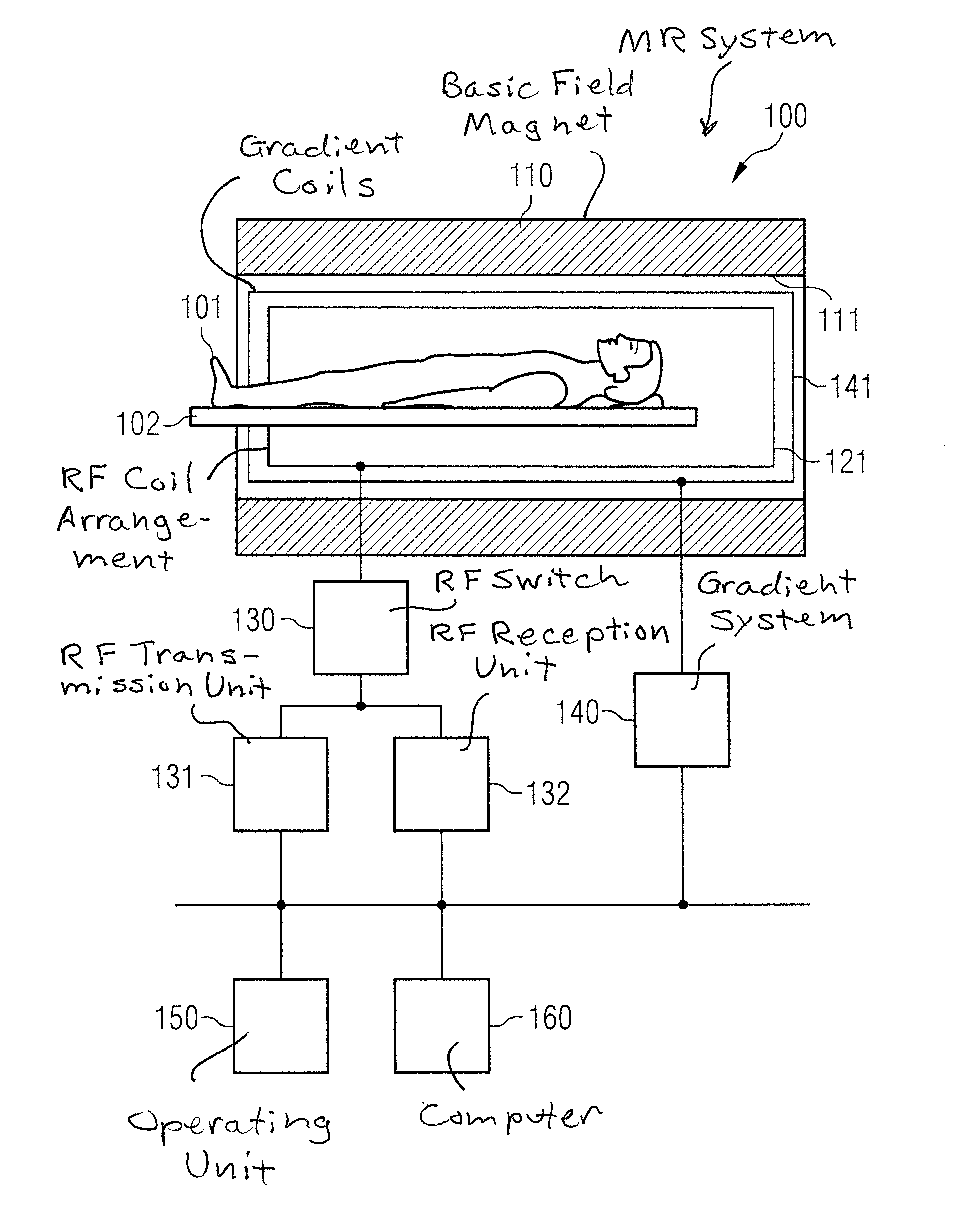

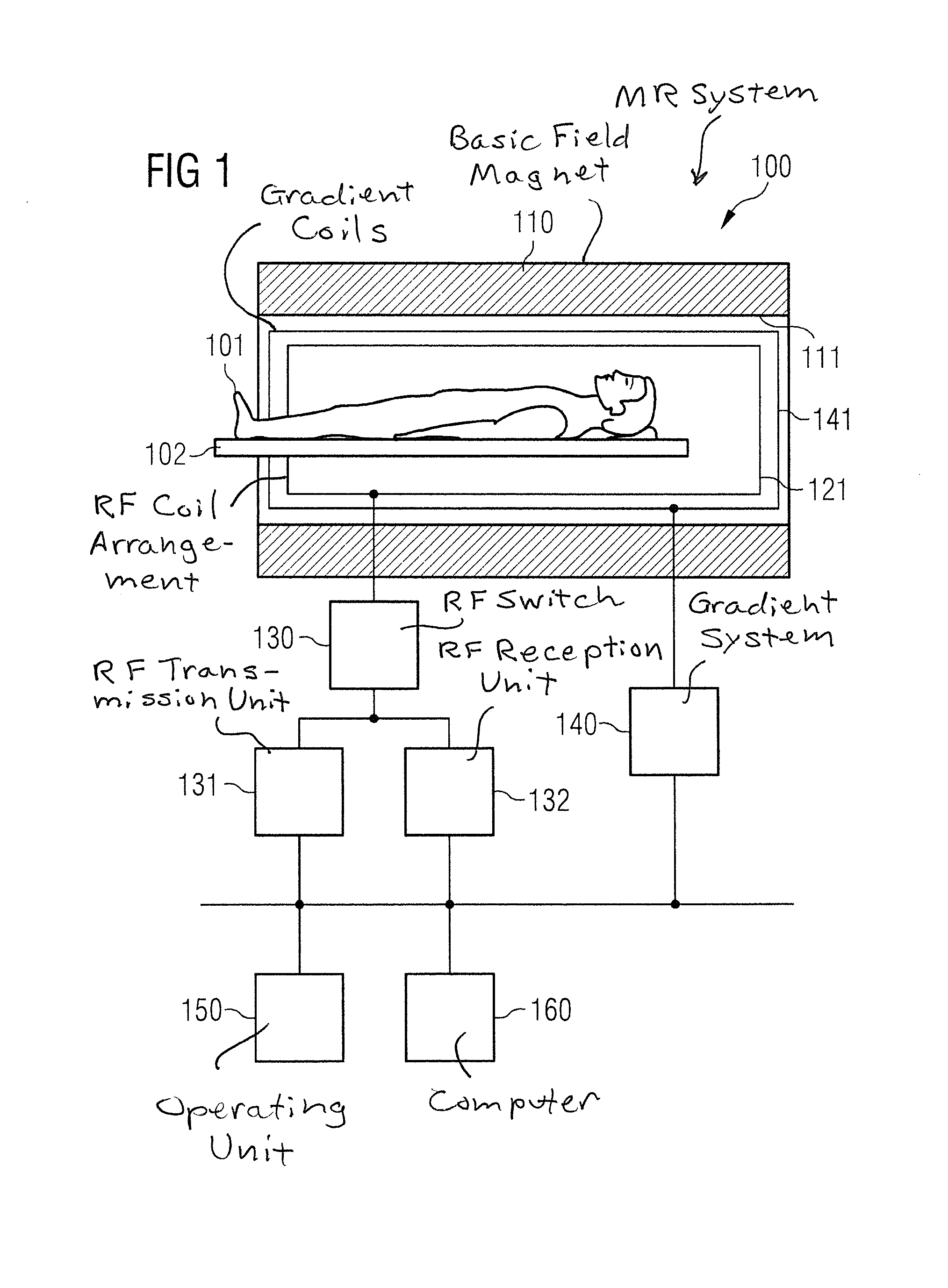

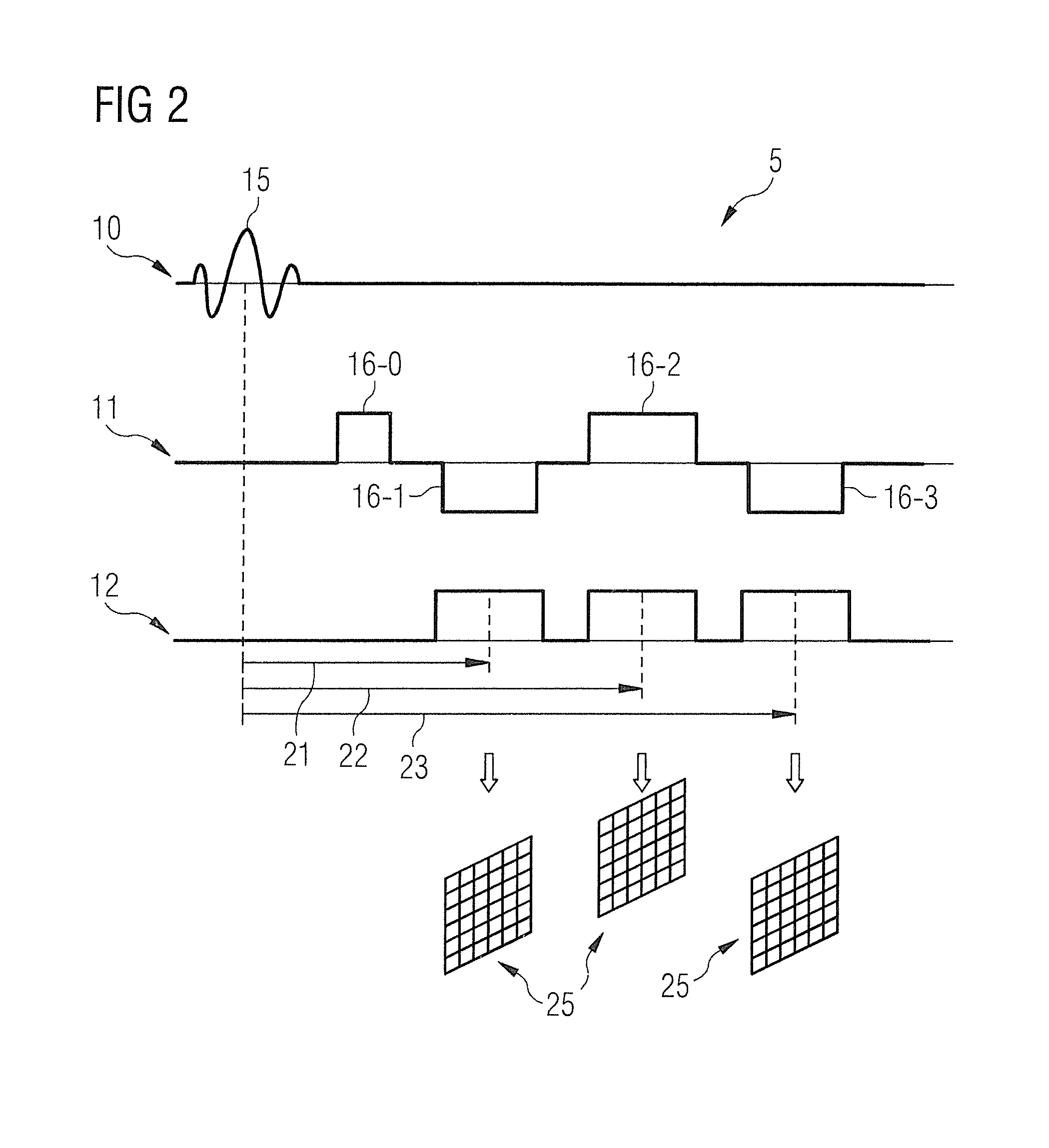

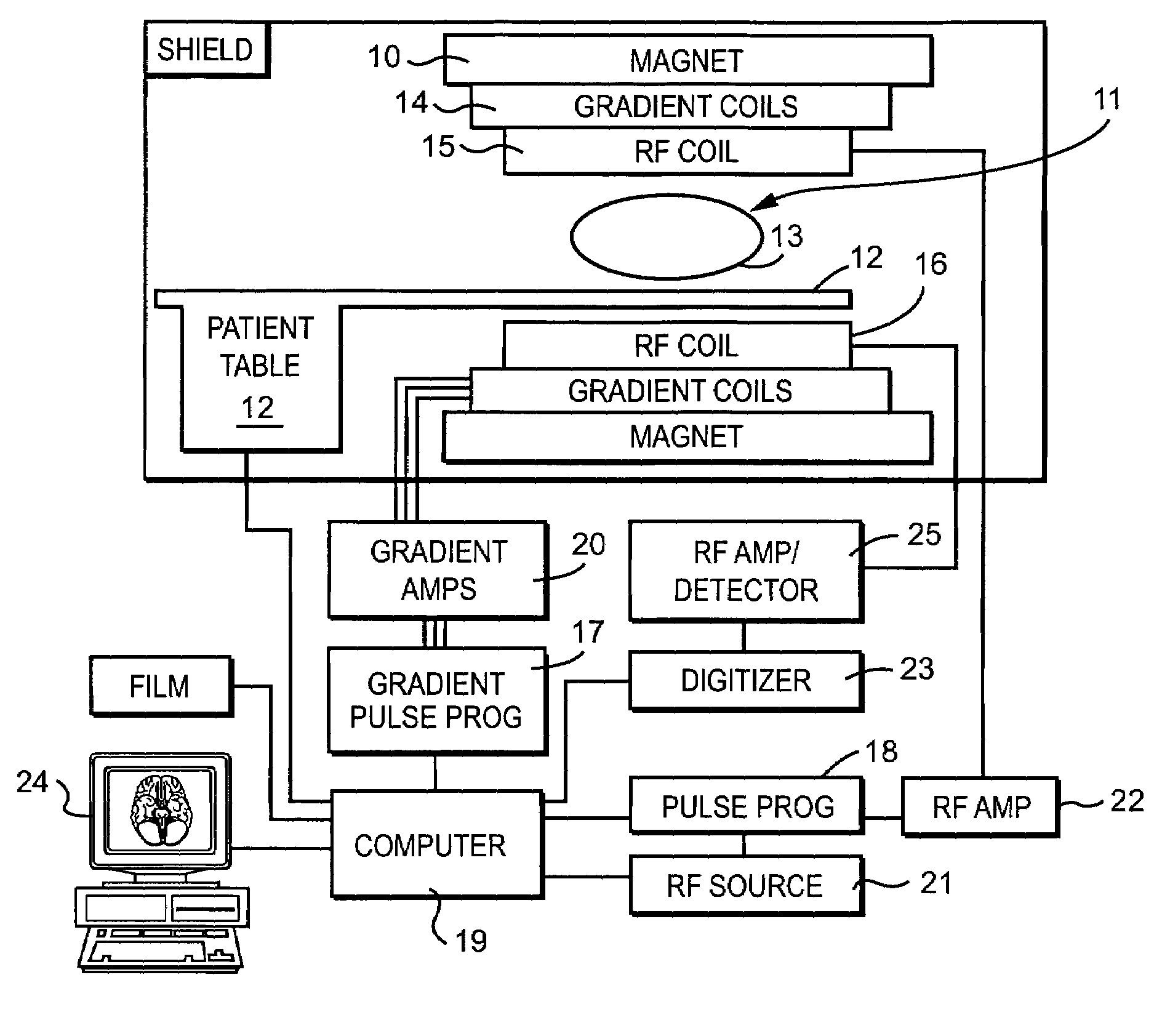

Method and apparatus for magnetic resonance data acquisition using a multipoint dixon technique

ActiveUS20150061672A1Short measurement durationPrecise determination of spectral componentsMeasurements using NMR spectroscopyDiagnostic recording/measuringResonanceData acquisition

In a method and magnetic resonance (MR) apparatus to acquire MR data from a subject, a predetermined spectral model of a multipoint Dixon technique is used that includes at least two spectral components with respective associated relaxation rates, a first phase due to field inhomogeneities; and a second phase due to eddy current effects. MR data are acquired using a bipolar multi-echo MR measurement sequence for multiple image points wherein, for each image point, the multi-echo MR measurement sequence alternately uses positive and negative readout gradient fields for the readout of MR signals of the MR data at at least three echo times. The at least two spectral components are determined based on the MR data.

Owner:SIEMENS HEATHCARE GMBH

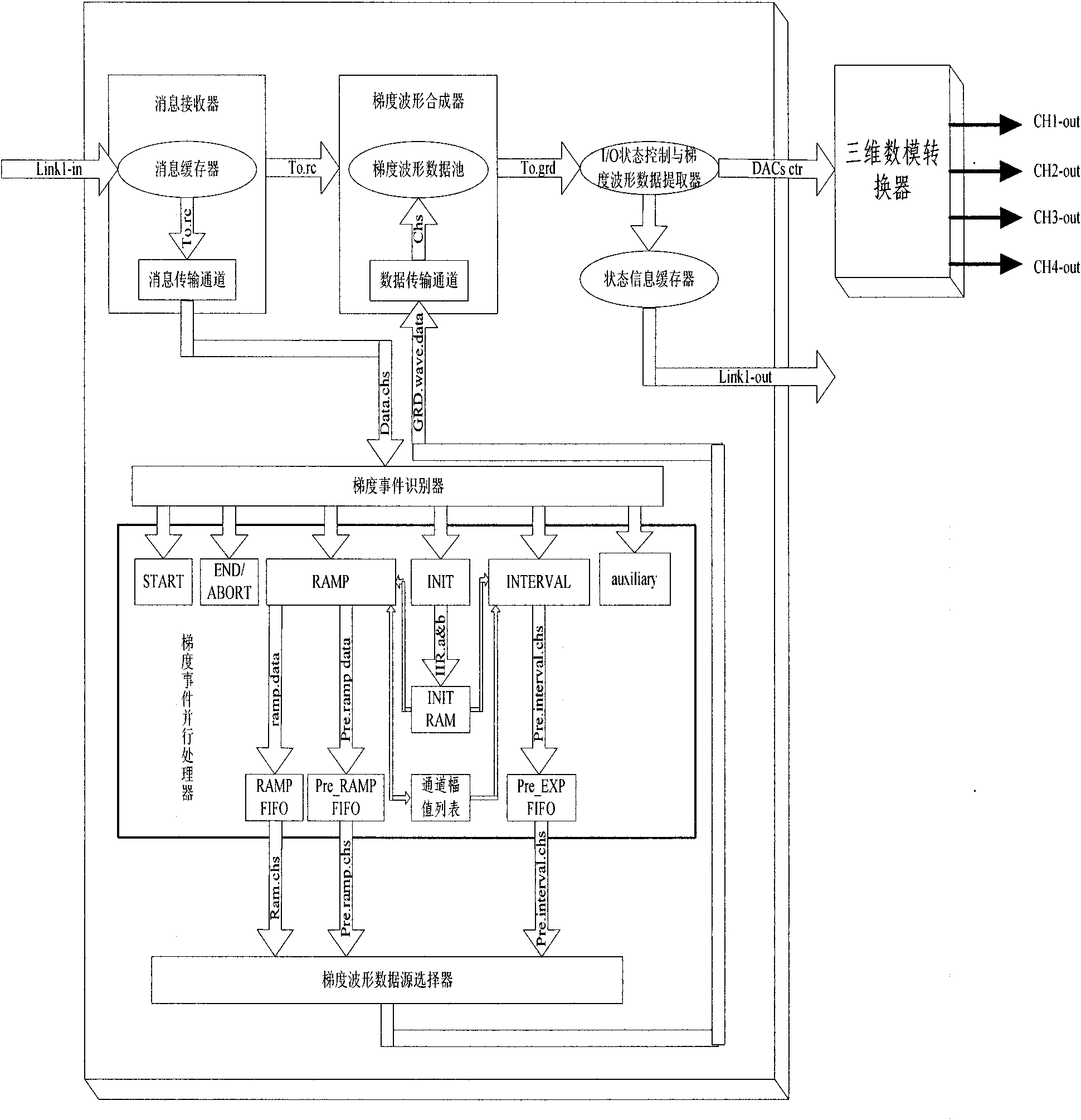

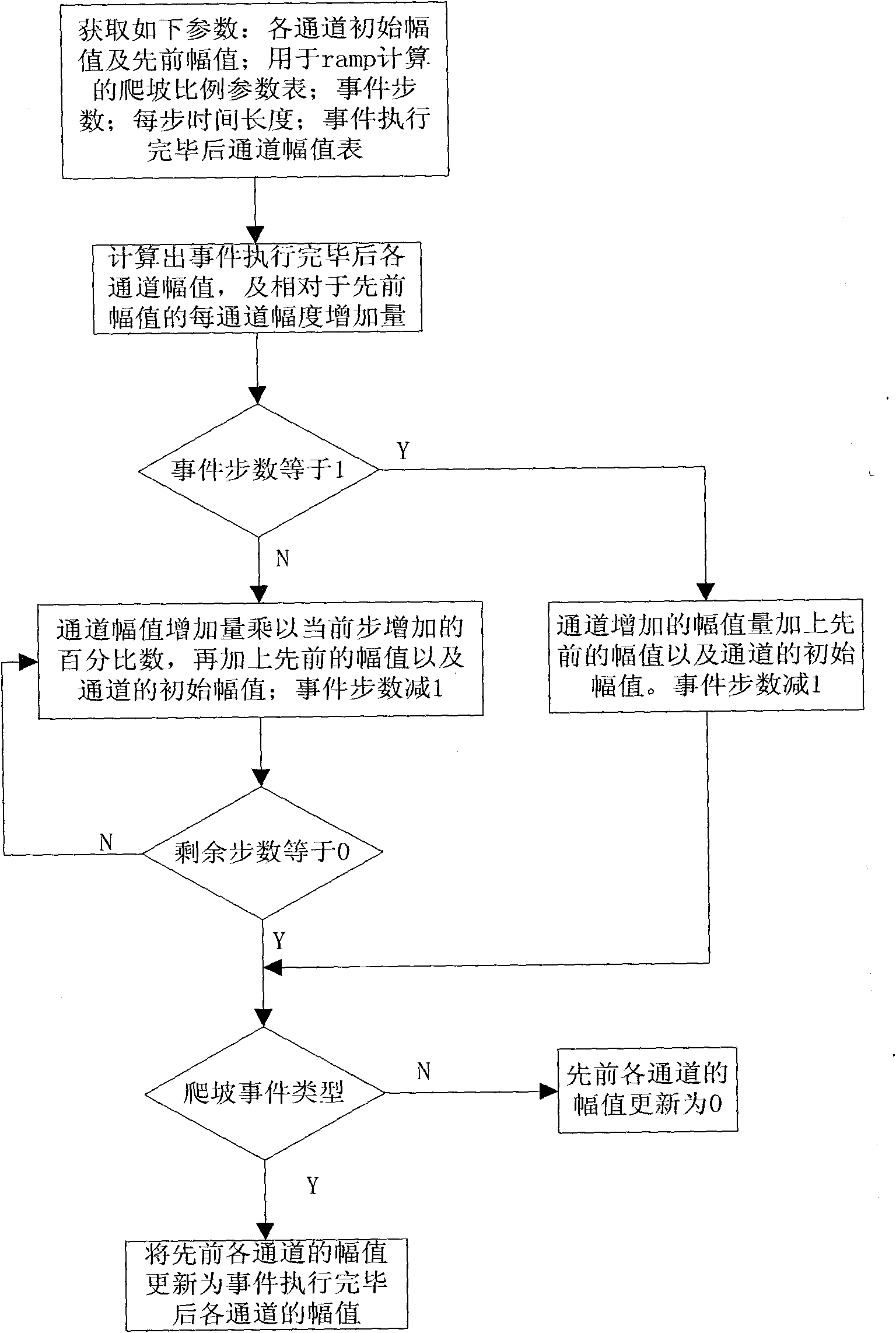

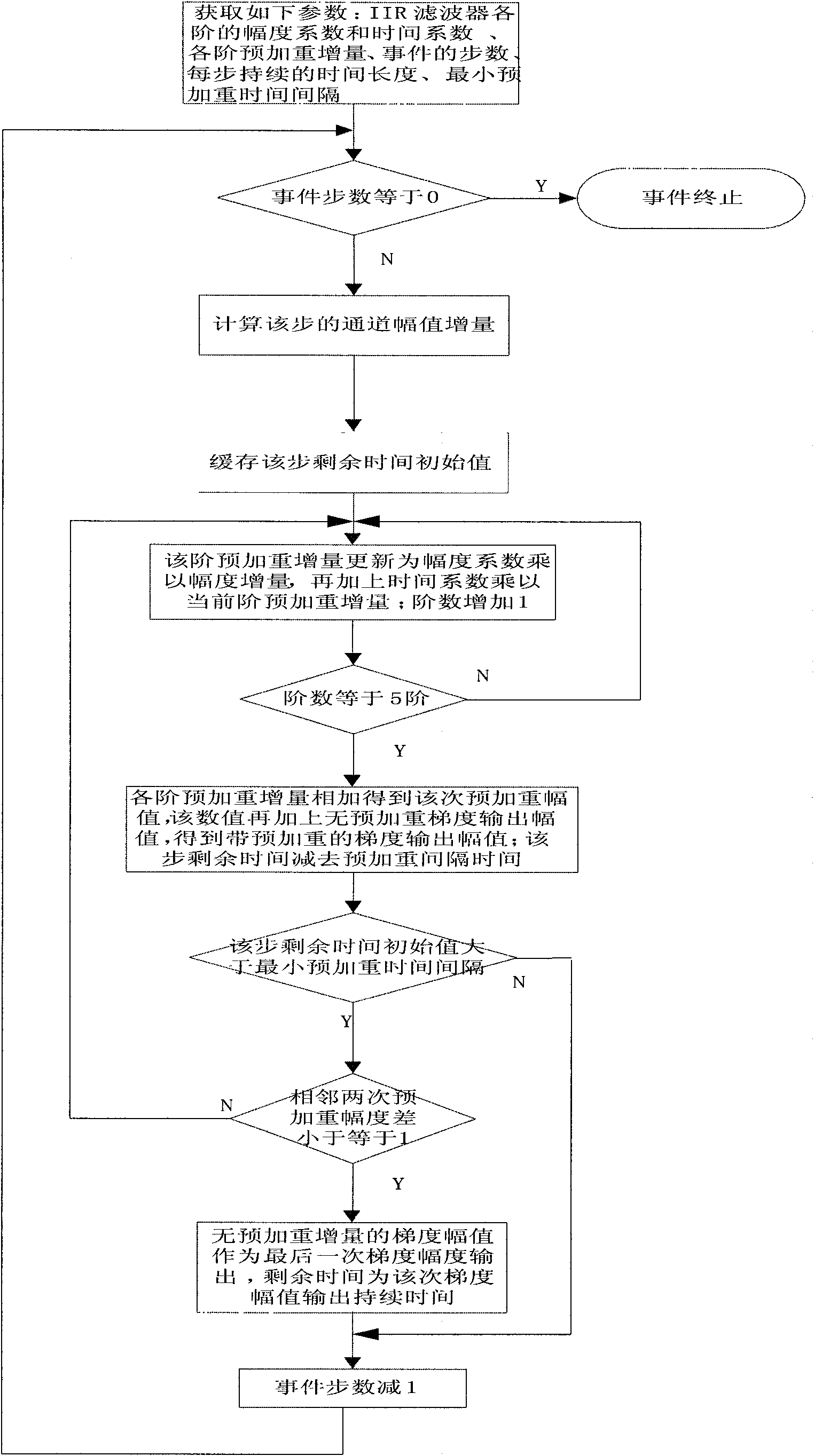

System and method for generating magnetic resonance gradient waveform with adjustable digital pre-emphasis

ActiveCN102103196AStrong real-timeAdjustable pre-emphasis parametersMagnetic measurementsMessage queueResonance

The invention relates to a system and method for generating a magnetic resonance gradient waveform with adjustable digital pre-emphasis. The system is provided with a FPGA (Field Programmable Gate Array) and a three-dimensional digital to analog converter, wherein the FPGA receives message queues, relevant to gradient, sent by a magnetic resonance scanning sequence compiler and processes the message queues to form three-dimensional gradient pulse digital waveform signals; the three-dimensional gradient pulse digital waveform signals can meet linear variation and can effectively compensate thegradient eddy-current effect, and number of slope steps can be randomly set; and the signals are processed through the three-dimensional digital to analog converter for generation of three-dimensional gradient pulse simulating waveform signals. The method comprises the following steps of: receiving the message queues of the magnetic resonance scanning sequence compiler; identifying the gradient event attributes of the message queues to obtain different gradient event attributes to carry out a corresponding processing operation, and obtaining gradient waveform data with adjustable digital pre-emphasis; and generating the gradient waveform according to the gradient waveform data. In the invention, the FPGA is used as a hardware carrier, so that the control of the gradient waveform signals has good instantaneity, and the gradient waveform with arbitrary gradient slope characteristics and gradient pre-emphasis characteristics can be obtained.

Owner:PHILIPS CHINA INVESTMENT +1

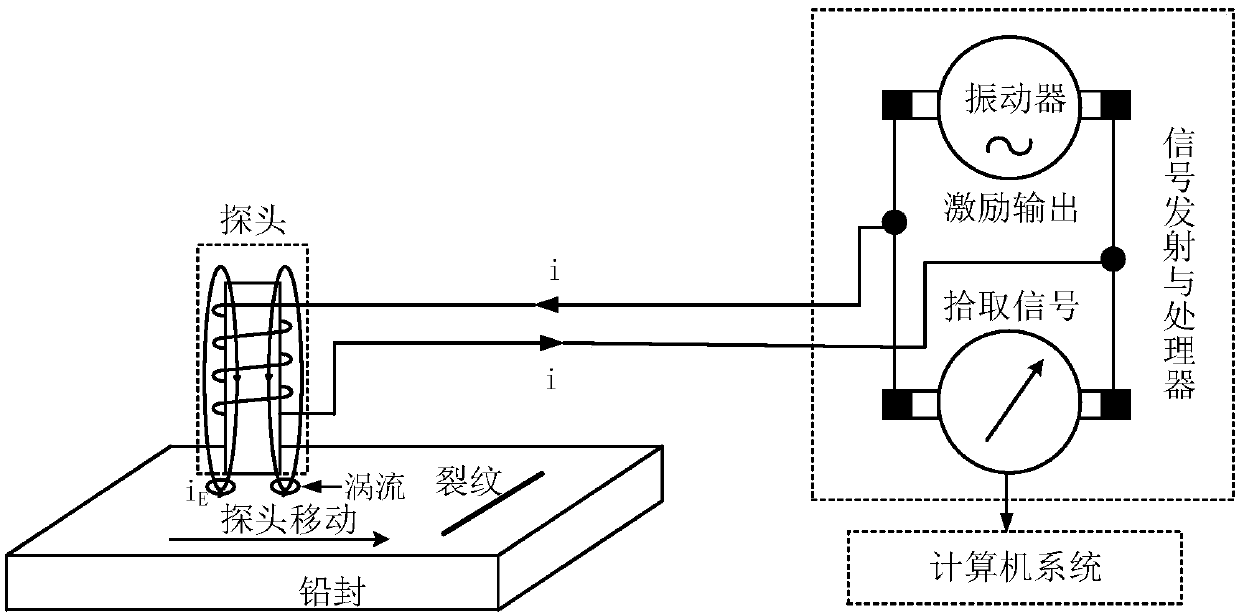

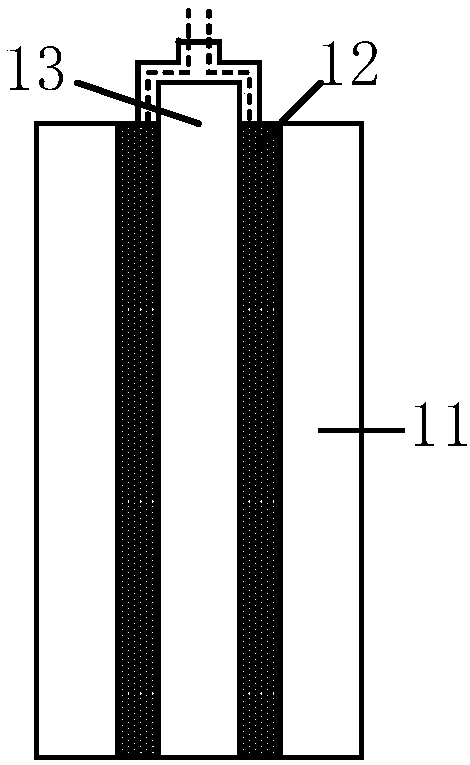

High-voltage cable lead seal eddy current flaw detection device and method

PendingCN108037181AEasy to distinguishEfficient detectionMaterial magnetic variablesEddy current effectComputerized system

The invention discloses a high-voltage cable lead seal eddy current flaw detection device and method. No effective detection method for a high-voltage cable lead seal defect is provided at the present. Only when the lead seal is broken completely, the breakage can be detected by mainly referring to live detection of grounding current and contact voltage of a sheath. The high-voltage cable lead seal eddy current flaw detection device disclosed by the invention comprises a probe, a signal emission and processor and a computer system. The signal emission and processor comprises a vibrator for providing alternating current and an eddy current meter for picking up a signal; the probe comprises a coil; the signal emission and processor provides the alternating current for the probe to enable thecoil of the probe to generate an alternating magnetic field and induce eddy current at the lead seal position; a fed back eddy current signal is picked up, analyzed and processed by the eddy currentmeter; the processed signal is displayed through the computer system. According to the high-voltage cable lead seal eddy current flaw detection device, the lead seal sheath is not required to be stripped off, so that the operation is convenient, and the detection is fast; the high-voltage cable lead seal eddy current flaw detection device is high in detection sensitivity.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +2

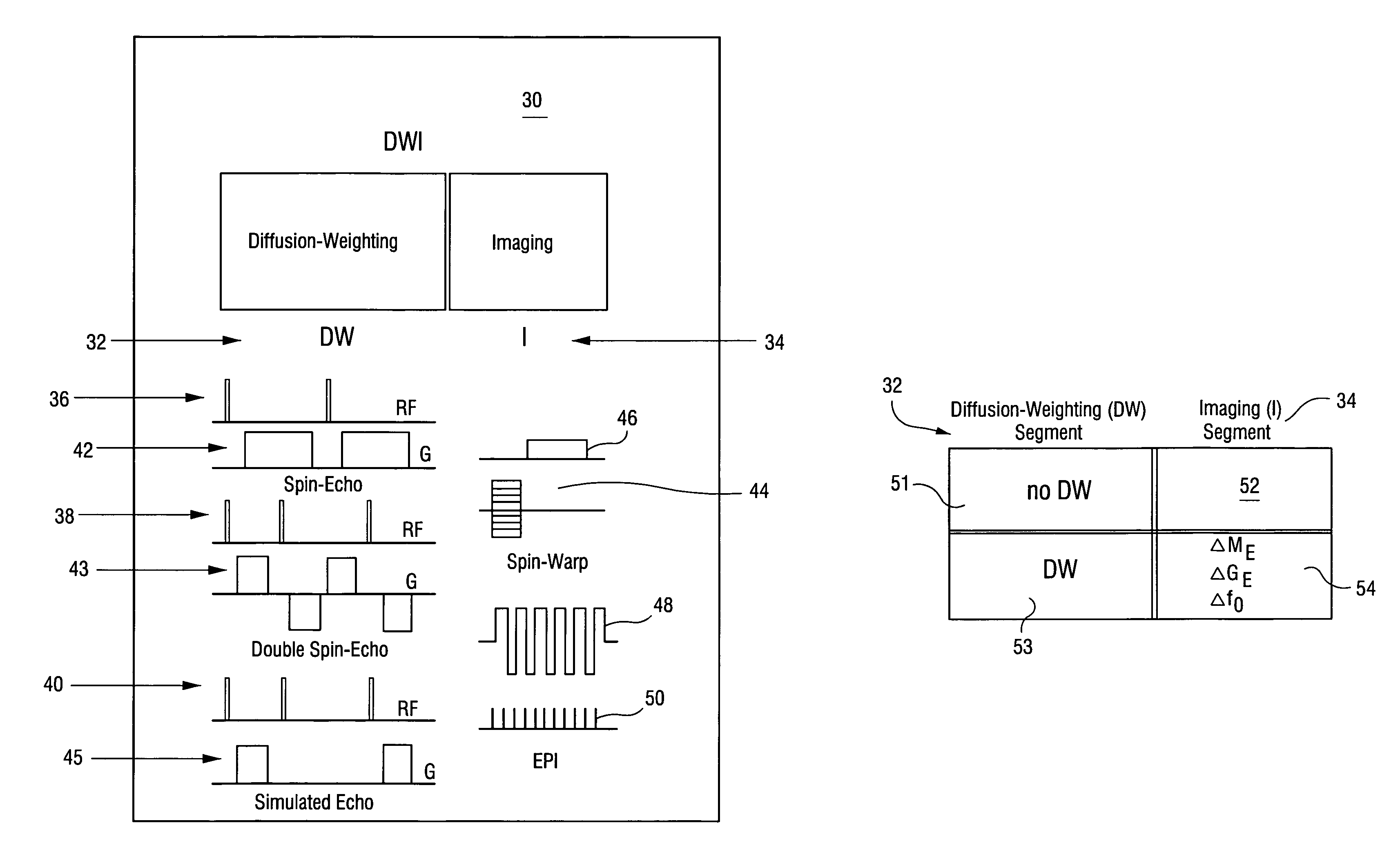

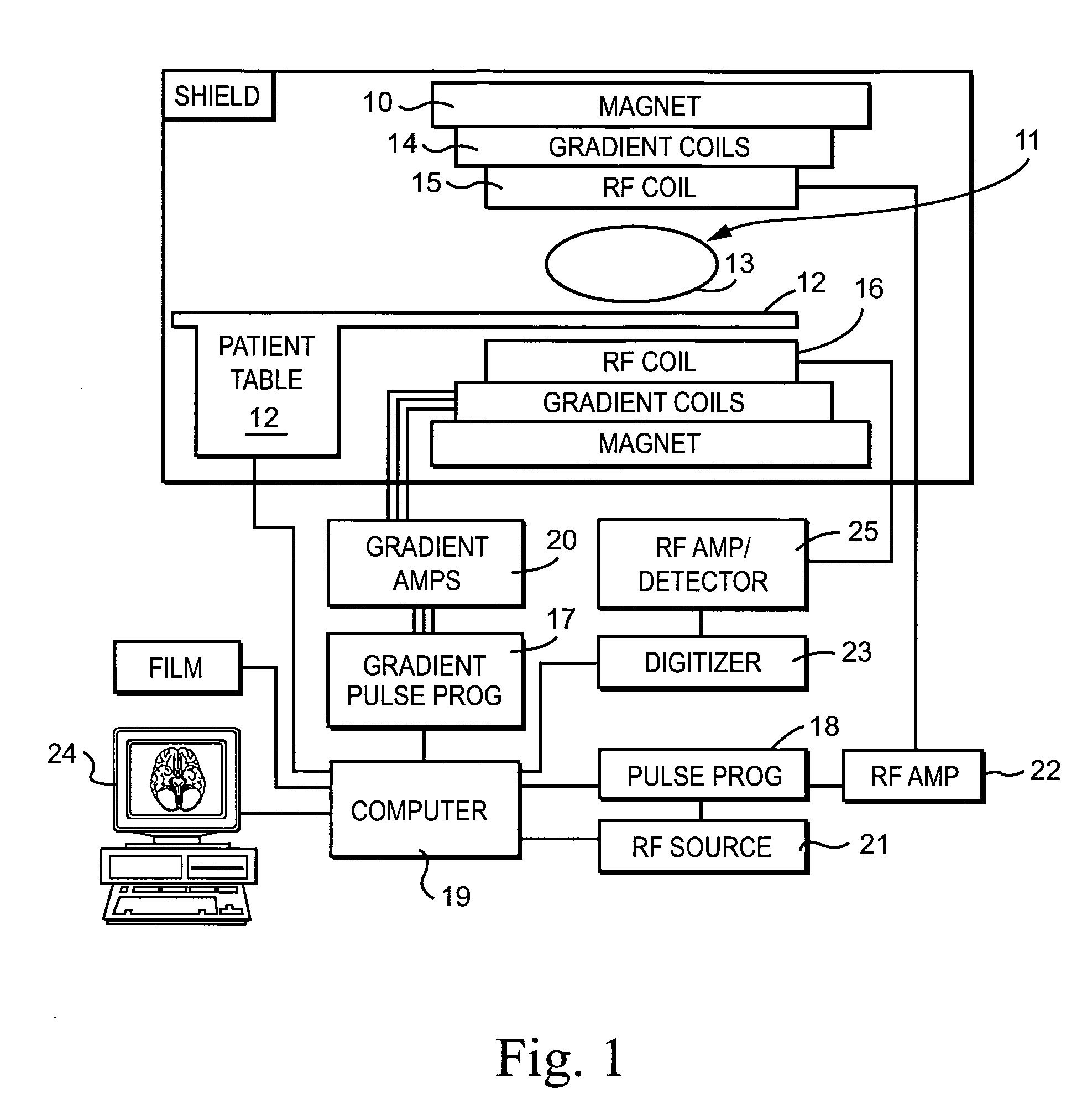

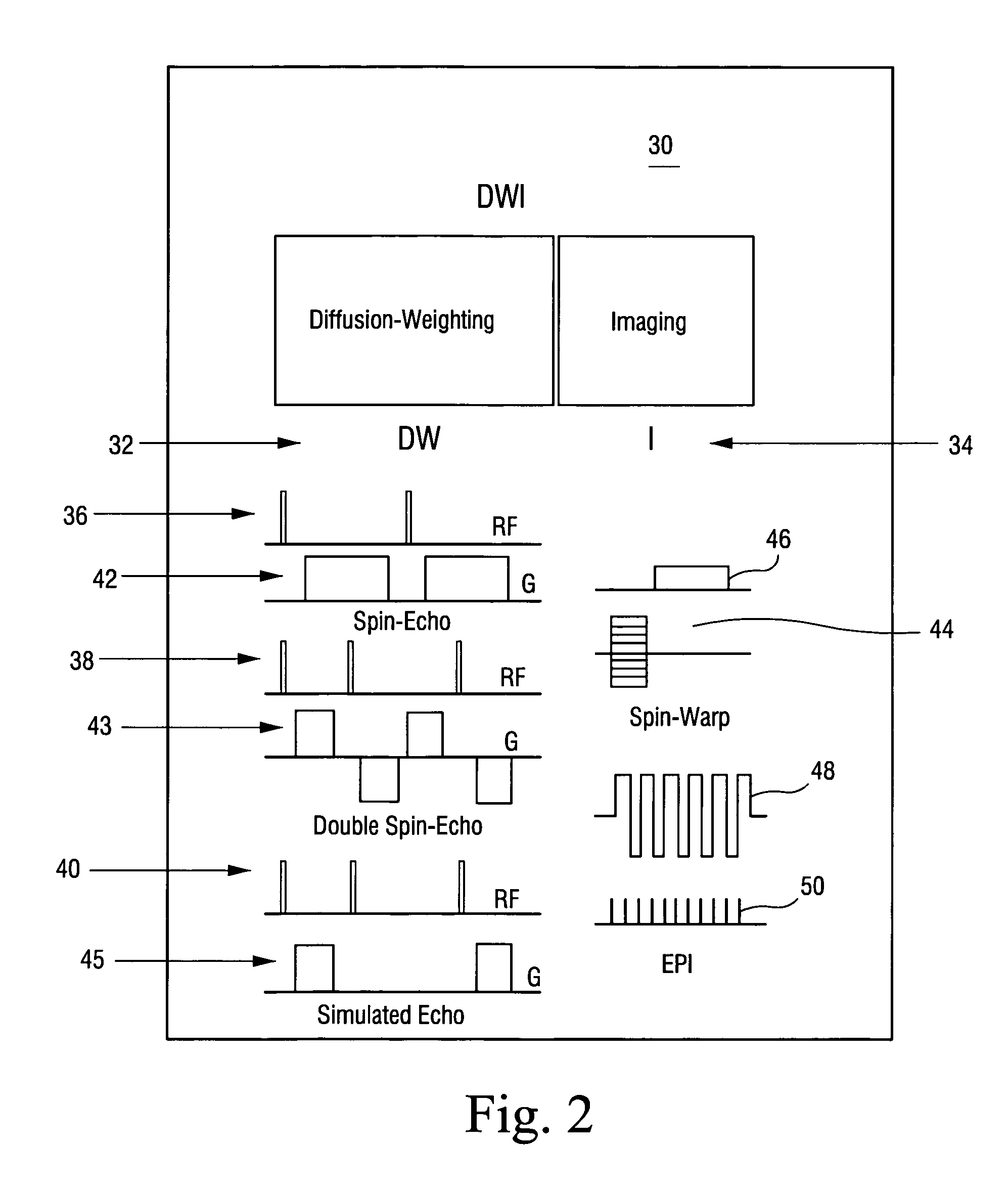

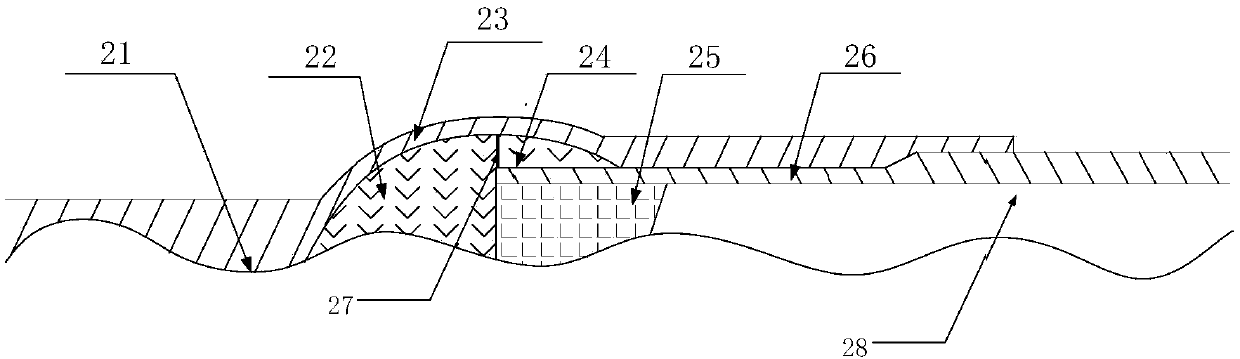

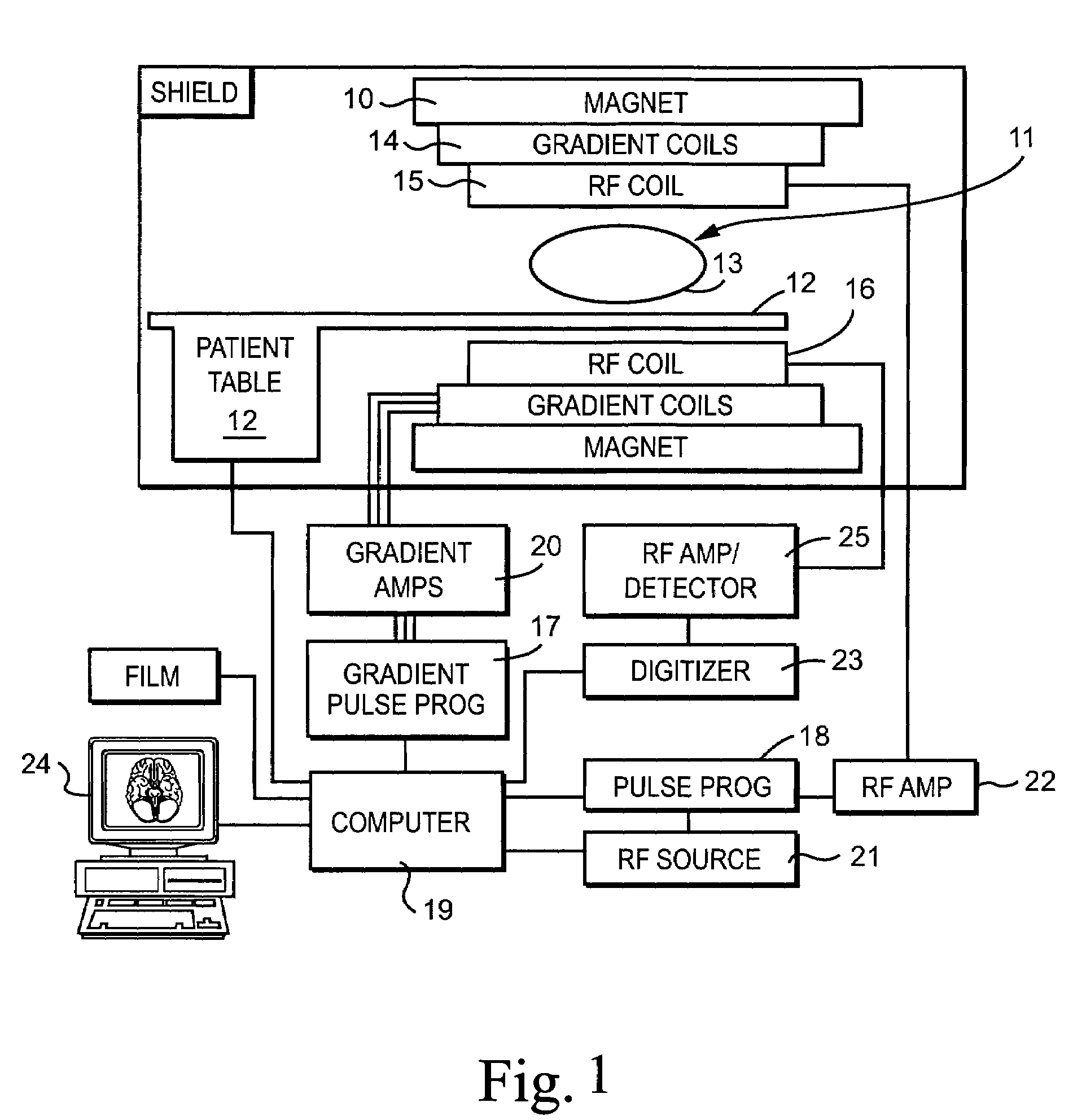

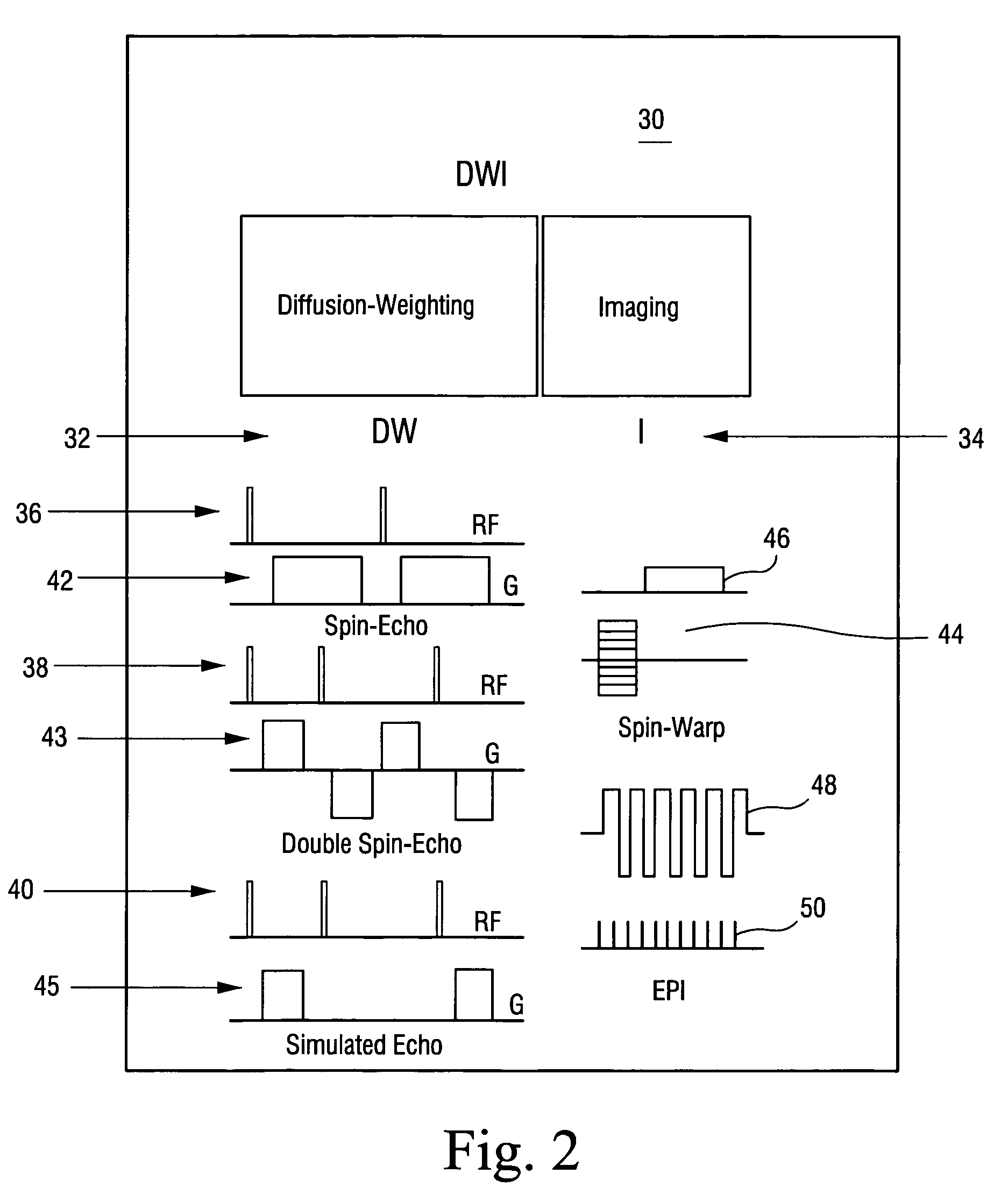

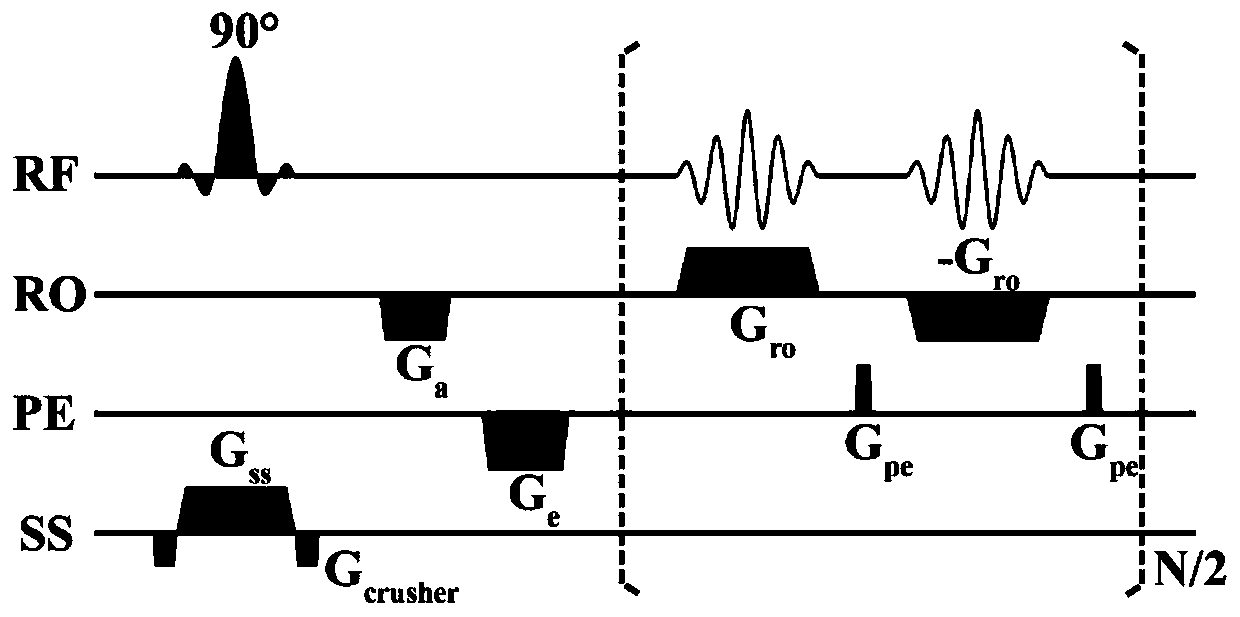

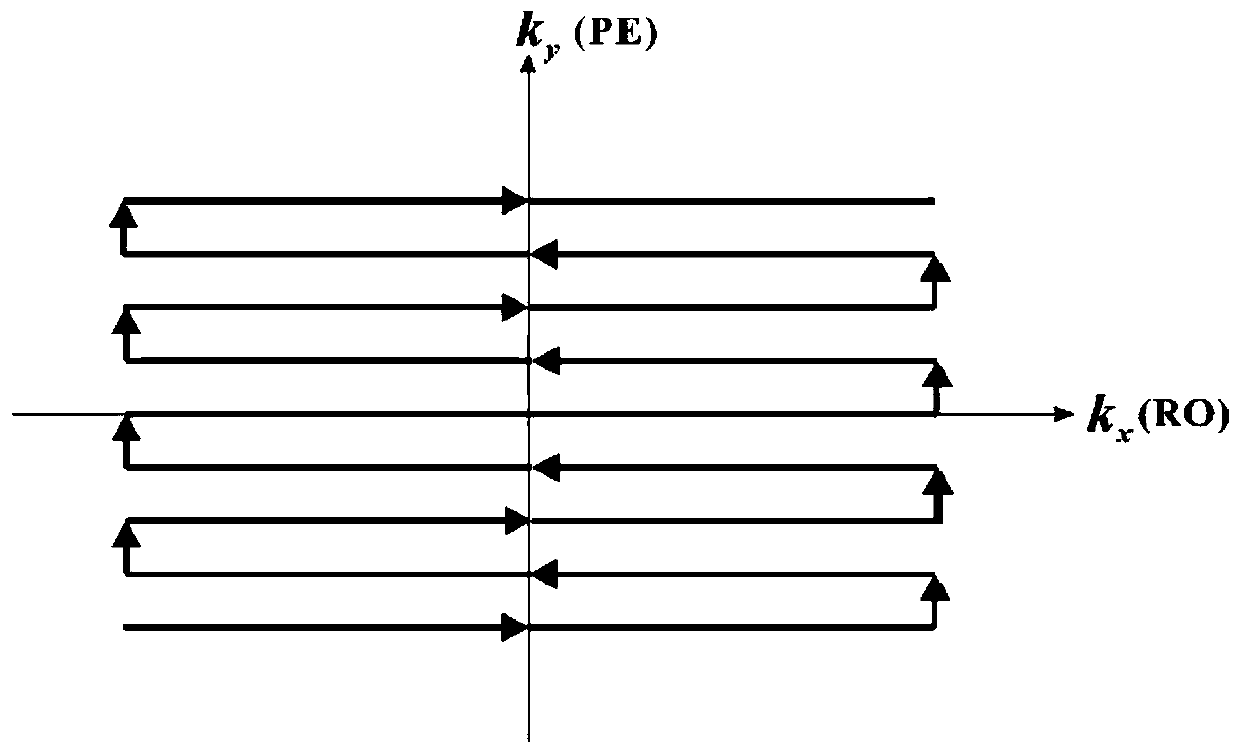

Method and apparatus for diffusion magnetic resonance imaging with the effects of eddy currents compensated

ActiveUS7218110B2High precisionEffect of eddy current can be minimizedMagnetic measurementsElectric/magnetic detectionDiffusionResonance

A method and a system for acquiring diffusion magnetic resonance images with compensation of the effects of eddy currents induced by the diffusion weighting (DW) gradient pulses. Prescan data are first acquired using the same DW sequence to be used for imaging. The prescan data are used to obtain eddy current parameters that model the effects of DW-induced eddy currents under the exact conditions under which DW images are to be acquired. The DW imaging sequence is then slightly modified according to the eddy current parameters and used to acquire DW image data with the effects of DW-induced eddy currents compensated.

Owner:TOSHIBA AMERICA MRI

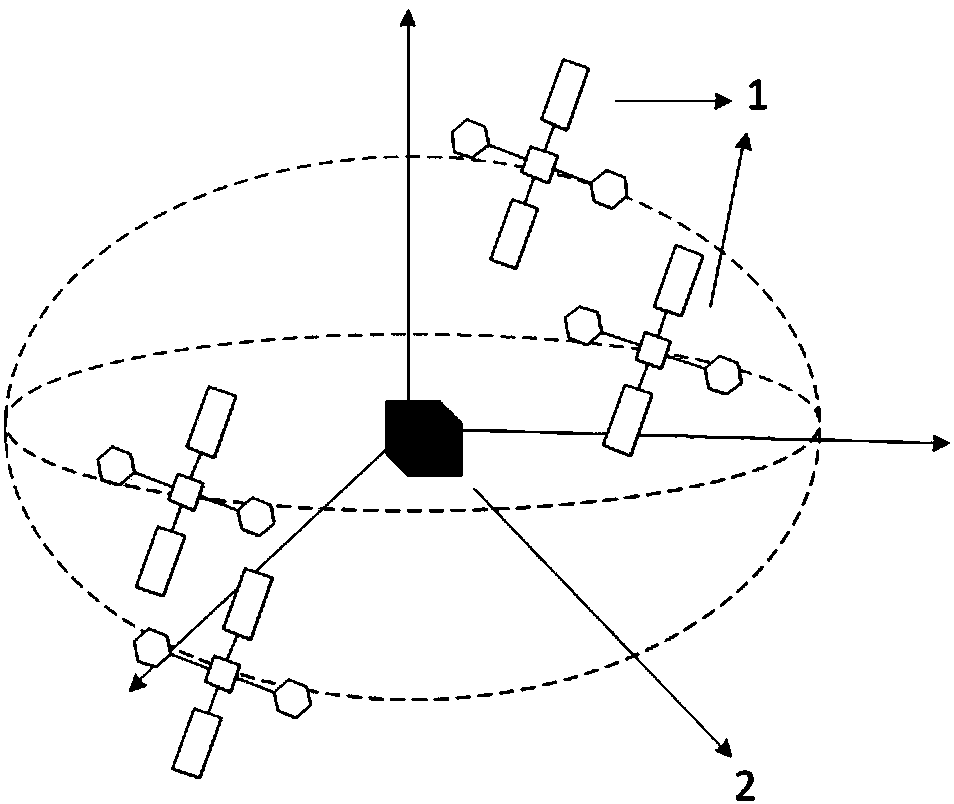

Small satellite formation design method for realizing space debris racemization by utilizing eddy current effect

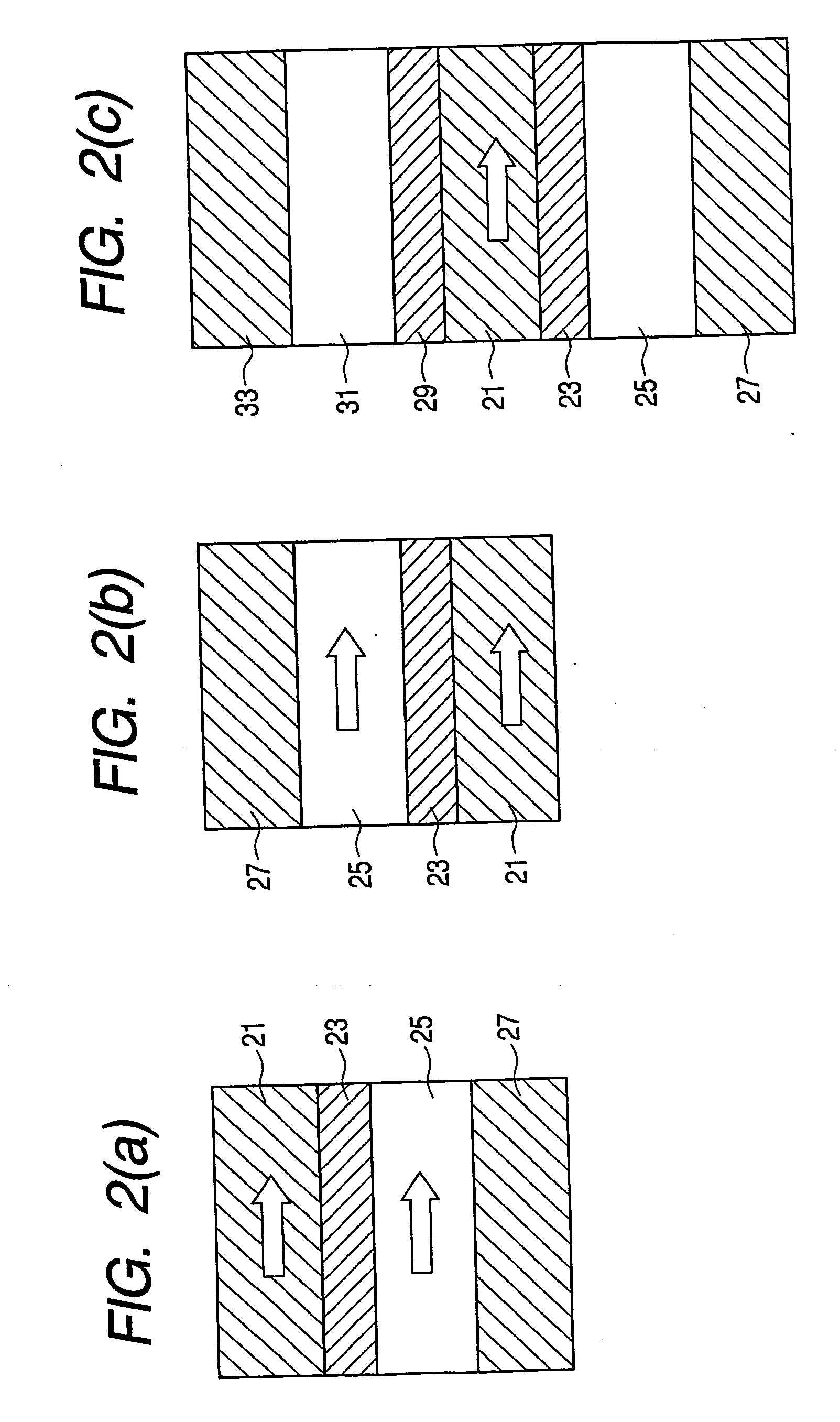

InactiveCN107357303ARapid racemizationAccelerate racemizationPosition/course control in three dimensionsNatural satelliteAttitude control

The invention discloses a small satellite formation design method for realizing space debris racemization by utilizing an eddy current effect. Small satellites launched by a spacecraft platform are formed into groups according to the position of debris with respect to the spacecraft platform and external dimensions of the debris. Four of the small satellites are released by the spacecraft platform to around the target debris, and the small satellites unwind energized solenoid coils and solar panels and form a natural circular or elliptical formation centered on the target debris by controlling positions and velocities of the small satellites during the release. Through the attitude control, the energized solenoid coils of the small satellites are facing right towards the target debris, a magnetic field is generated to the energized solenoid coils, the solar panels supply the required power to racemase the debris, the angular velocity of the rolling of the debris is reduced, and quick racemization of the high-speed rotating space debris is realized. By the method, as the multiple small satellites carry the energized solenoid coils, the strength of the magnetic field is increased, and the rotational angular velocity of the high-speed rotating debris can be rapidly reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

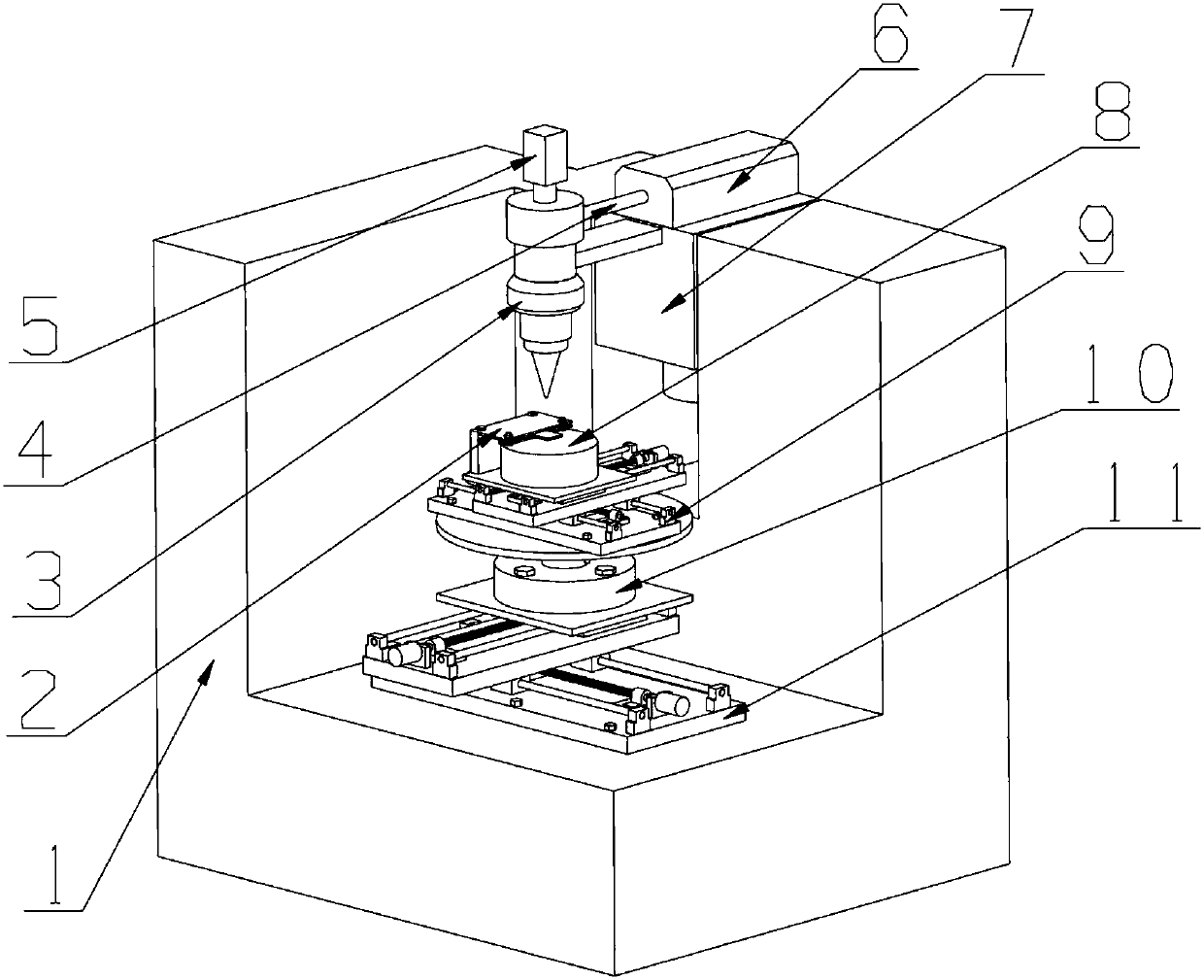

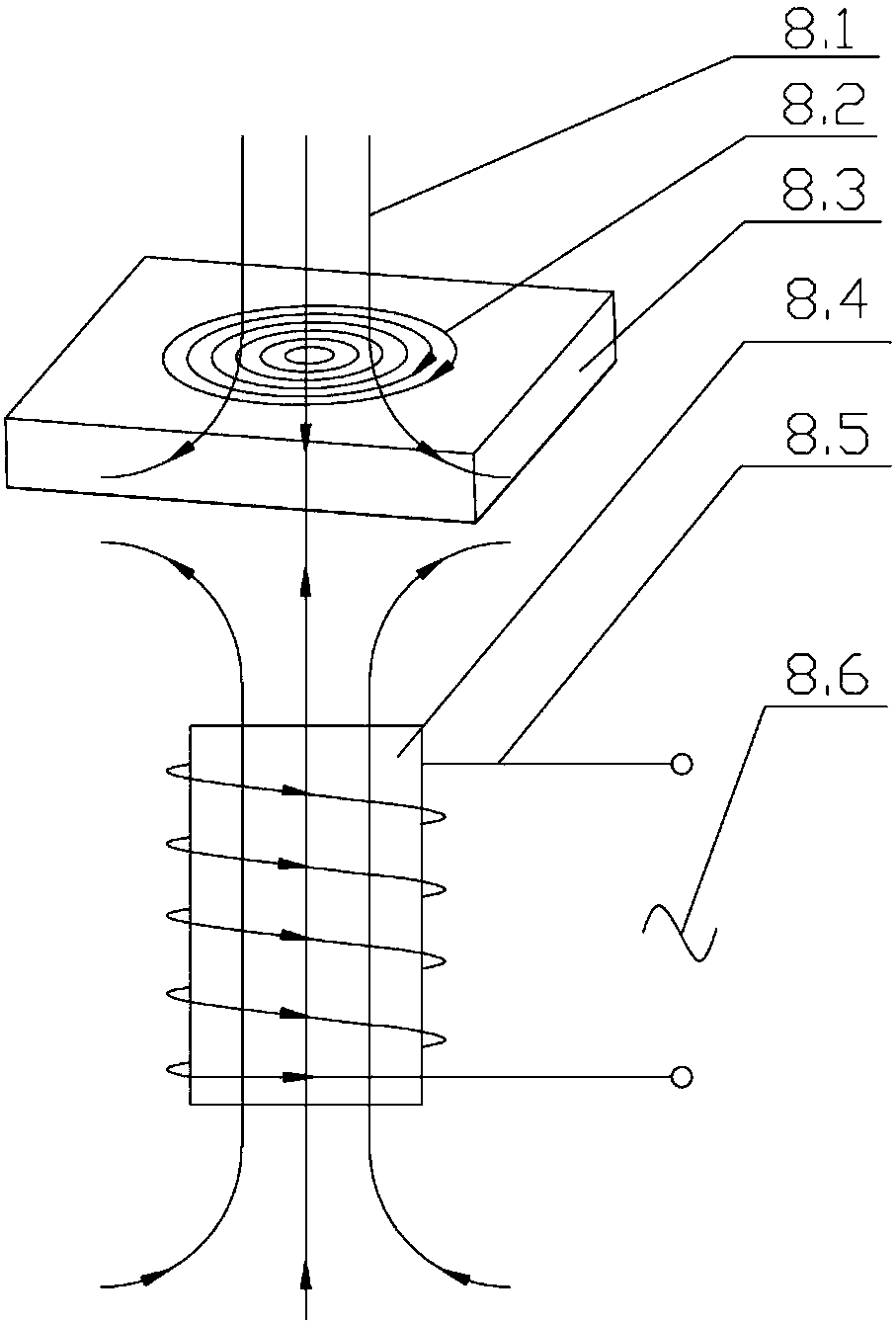

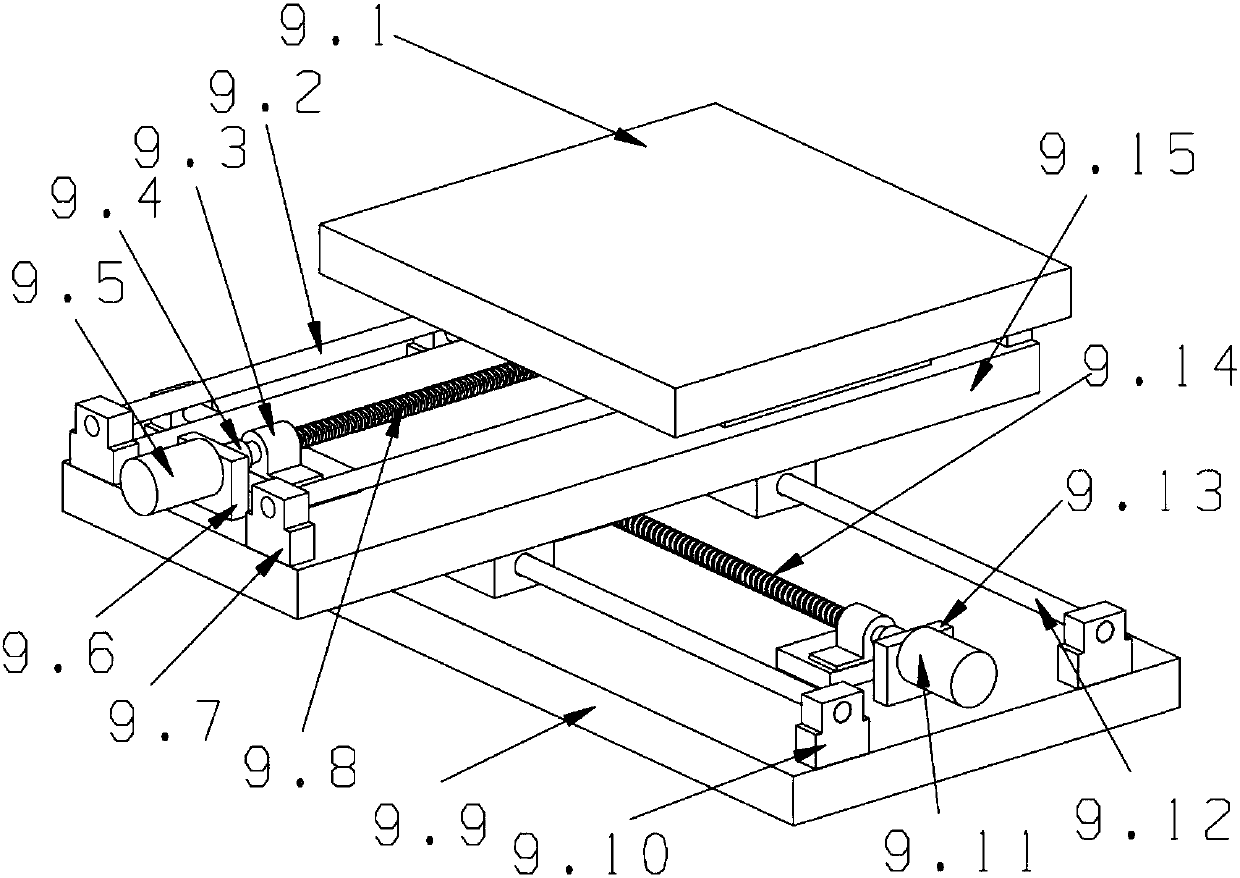

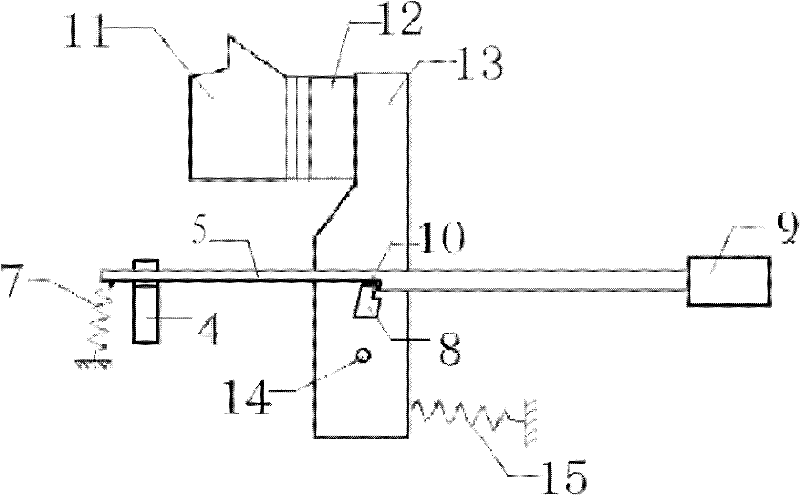

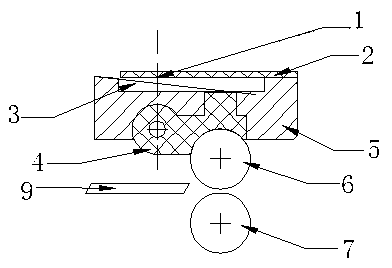

Laser spiral perforating device and device adopting eddying effect for assisting in heating

InactiveCN107695543AReduce temperature gradientReduce hardening tendencyLaser beam welding apparatusLow speedLight guide

The invention discloses a laser spiral perforating device and device adopting the eddying effect for assisting in heating. The method includes the steps that (1) a first x-y movable platform is used for enabling the center of the workpiece perforating position to be located on a rotating shaft of a rotating platform device, and a second x-y movable platform is used for enabling the center of the workpiece perforating position to departure from a laser beam by one rotary-cut radius; (2) an eddy generation device is started to enable workpieces to form eddy current; and (3) the rotating platformdevice is started, a pumping of a laser device is started, a z-direction movement mechanism conducts downward feeding, and when the focal point is located on the workpiece surfaces, the z-direction movement mechanism conducts feeding at a low speed. In addition, the laser spiral perforating device adopting the eddying effect for assisting in heating comprises the laser device, a power case, a laser head, a CCD camera, a light guide pipe, the x-y movable platforms, the rotating platform device, the eddy generation device, the z-direction movement mechanism and a workpiece clamp. By means of the device and method, the small hole roundness is improved, and the small hole taper and recasting layer are reduced.

Owner:JIANGSU UNIV

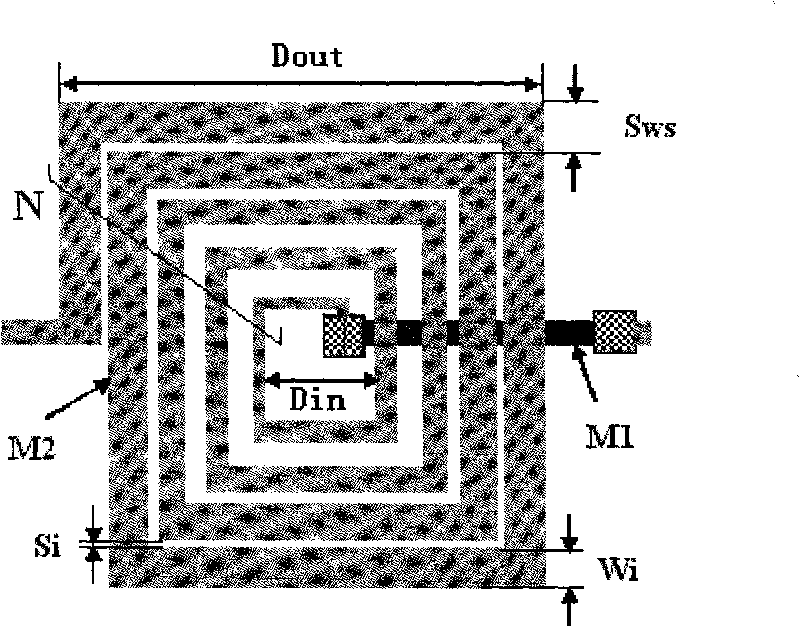

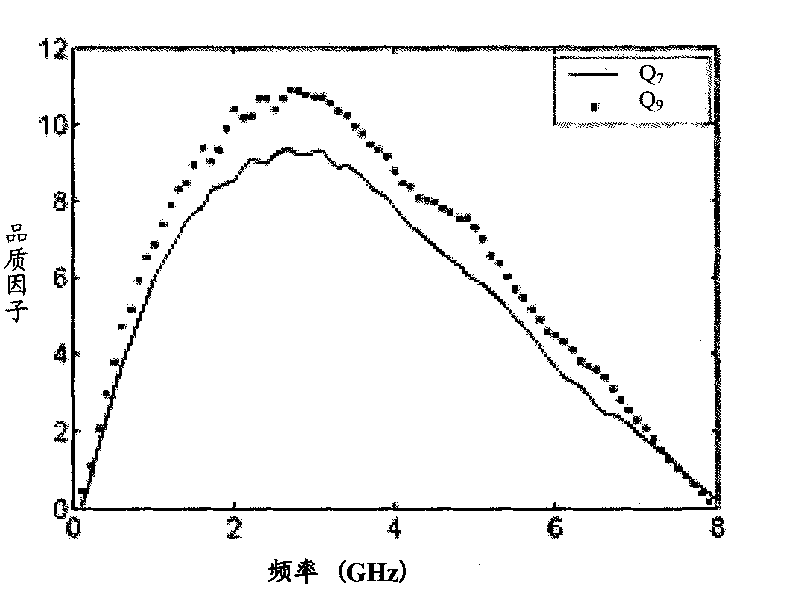

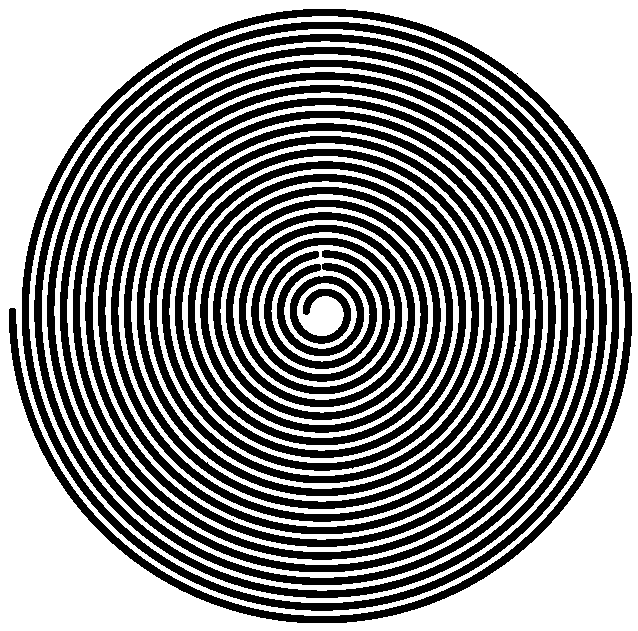

Plane spiral inductor

InactiveCN101719415AImprove quality factor Q valueReduced series resistanceSolid-state devicesSemiconductor devicesElectrical resistance and conductanceSpiral inductor

The invention discloses a plane spiral inductor; the width of a lead wire of the plane spiral inductor is gradually increased from interior to exterior, the distance between the lead wires is gradually reduced from an inner ring to an outer ring; compared with the inductor with the traditional structure, eddy effect and proximity effect of the plane spiral inductor are reduced at high frequency, the series resistance of inductor coil lead wires is reduced, so as to improve the quality factor Q value of the inductor on the premise of not changing the domain area and the size of inner diameter; a preparation process of the plane spiral inductor is compatible to the conventional CMOS process, and the performance of an important functional unit at the CMOS radio-frequency front end can be improved.

Owner:EAST CHINA NORMAL UNIV +1

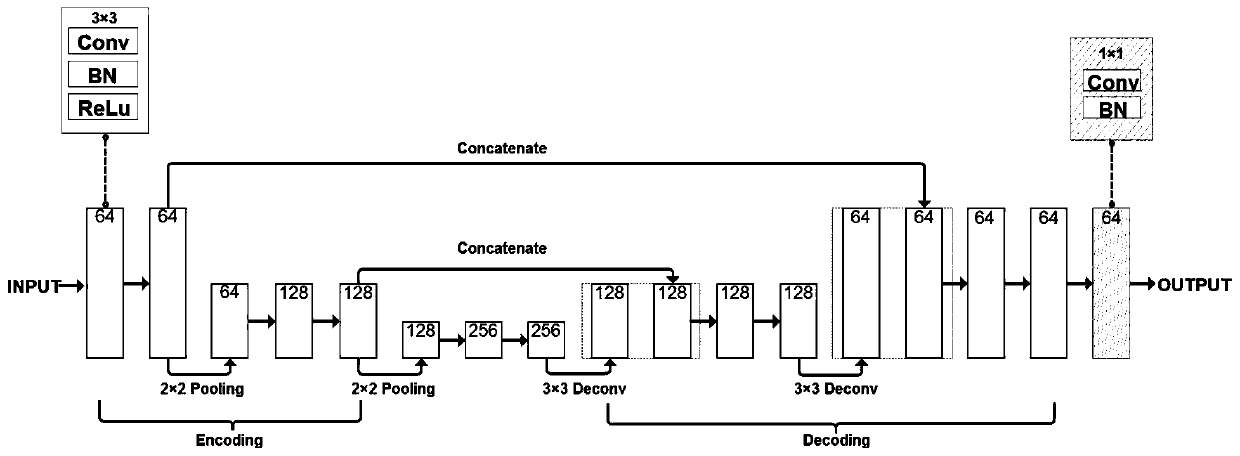

No-reference scanning correction method for echo plane imaging eddy current artifacts

InactiveCN109741409AQuality improvementImage enhancement2D-image generationData setEddy current effect

A no-reference scanning correction method for echo plane imaging eddy current artifacts comprises the following steps: firstly, training parameters of a neural network: randomly generating simulationsamples in batches by utilizing simulation software, and then introducing pre-compiled EPI sequences to sample the simulation samples to obtain K space data corresponding to each sample; and accordingto the phase characteristics of the eddy current effect, carrying out phase modification on the collected signal, and carrying out Fourier transform to obtain a simulated EPI image influenced by theeddy current effect, and storing the modified phase information as a label, and training the neural network model by taking the images as a training data set, and storing network parameters when the training error is reduced to be lower than a set threshold value, and after training of the neural network model is completed, inputting the truly acquired EPI image into the neural network model for reconstruction, thereby obtaining the EPI image without the eddy current artifact. According to the method, the EPI image eddy current artifacts are removed under the condition of no reference scanning, and assistance can be provided for clinical application of EPI.

Owner:XIAMEN UNIV

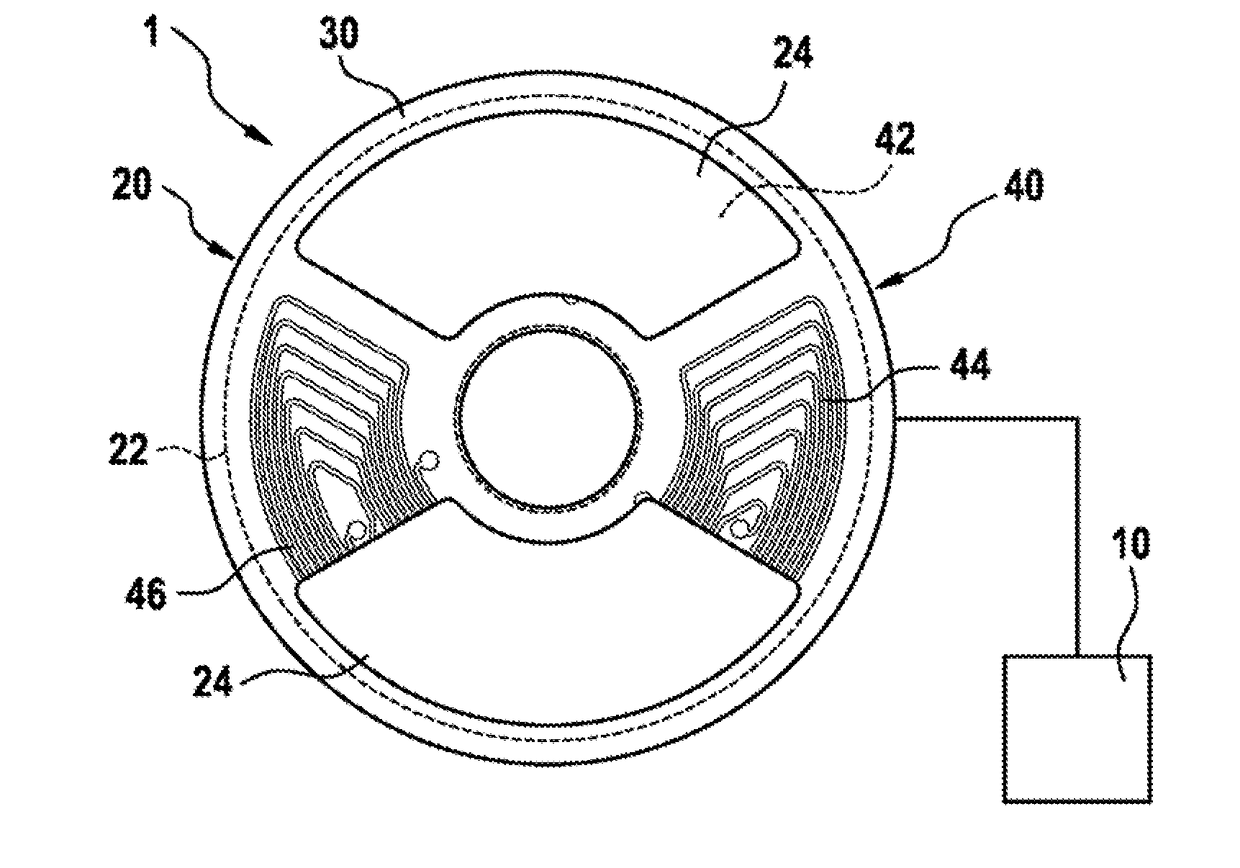

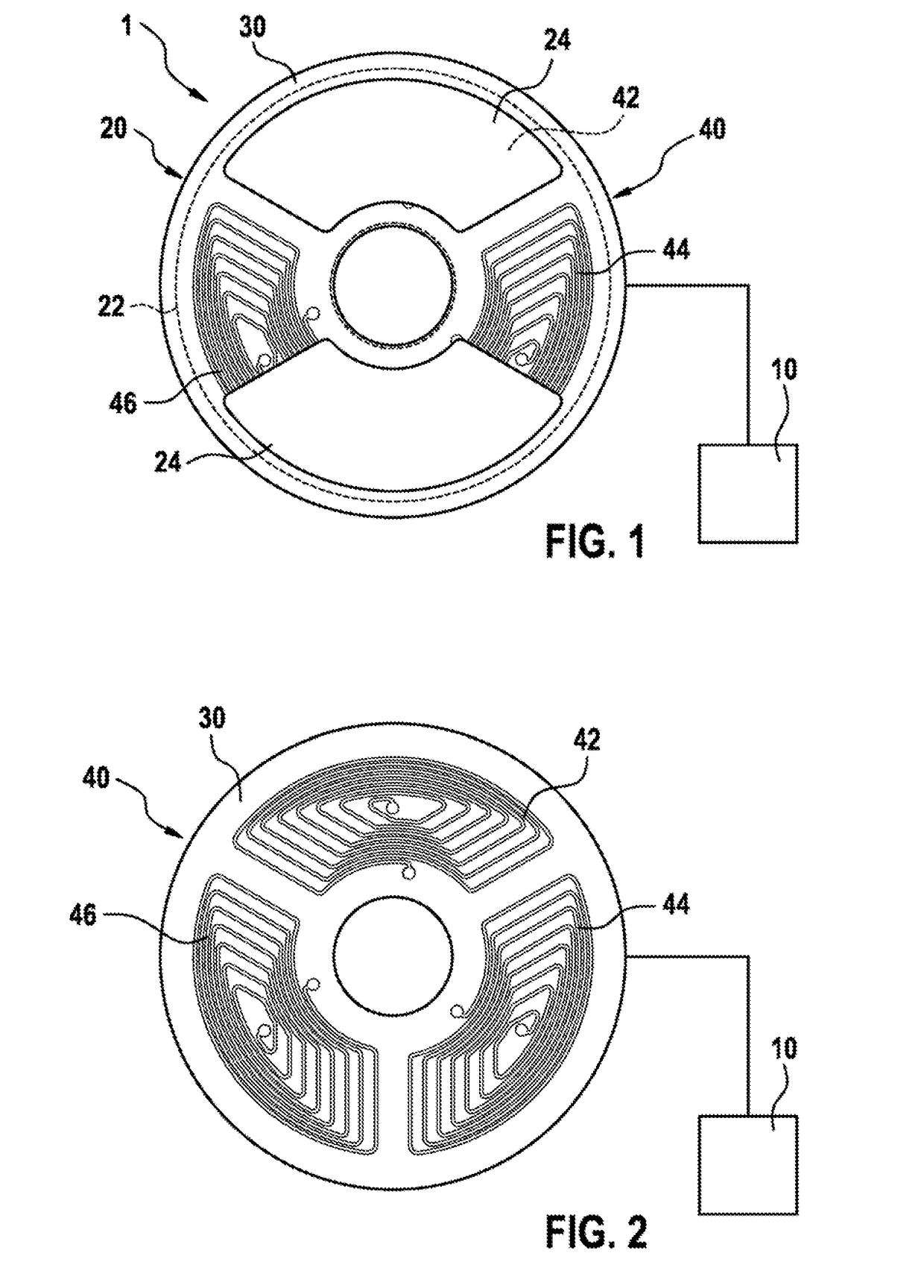

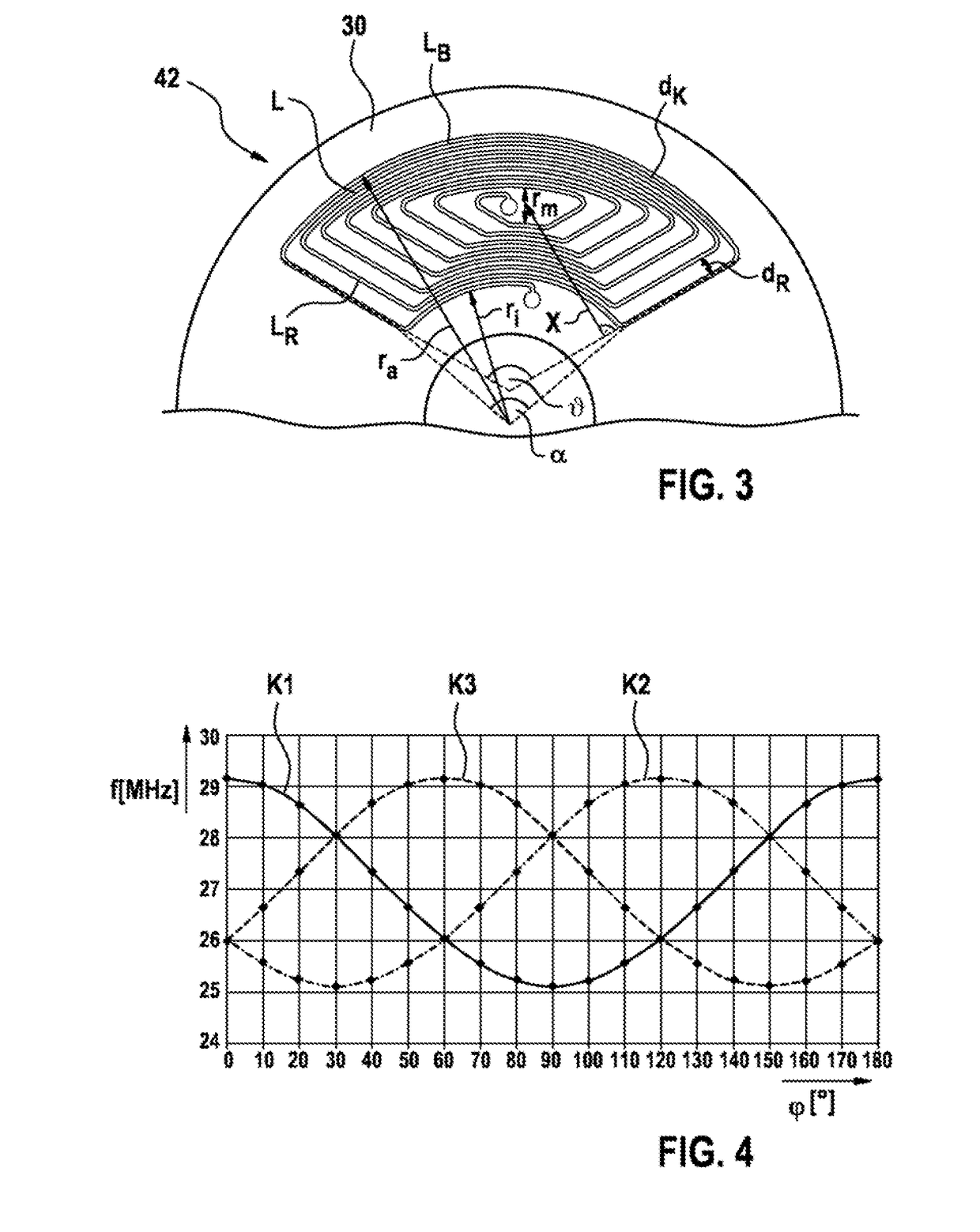

Sensor Arrangement for the Contactless Sensing of Angles of Rotation on a Rotating Part

InactiveUS20170292857A1Simple algorithmPossible to measureDielectric property measurementsInductance measurementsEddy current effectEngineering

In one embodiment, a sensor arrangement for the contactless sensing of angles of rotation on a rotating part includes a disk-shaped target, a coil arrangement, and an evaluation and control unit. The disc-shaped target is coupled to the rotating part and includes at least two metal surfaces that influence the inductances in the flat detection coils due to eddy current effects as a function of the degree of overlap. The disc-shaped target can generate at least one piece of information for ascertaining the instantaneous angle of rotation of the rotating part, in connection with the coil arrangement. The coil arrangement has has three flat detection coils uniformly distributed on the circumference of a circle. The evaluation and control unit can generate essentially sinusoidal evaluation signals which represent the changes in inductance of the detection coils and can evaluate them for calculating the angle of rotation.

Owner:ROBERT BOSCH GMBH

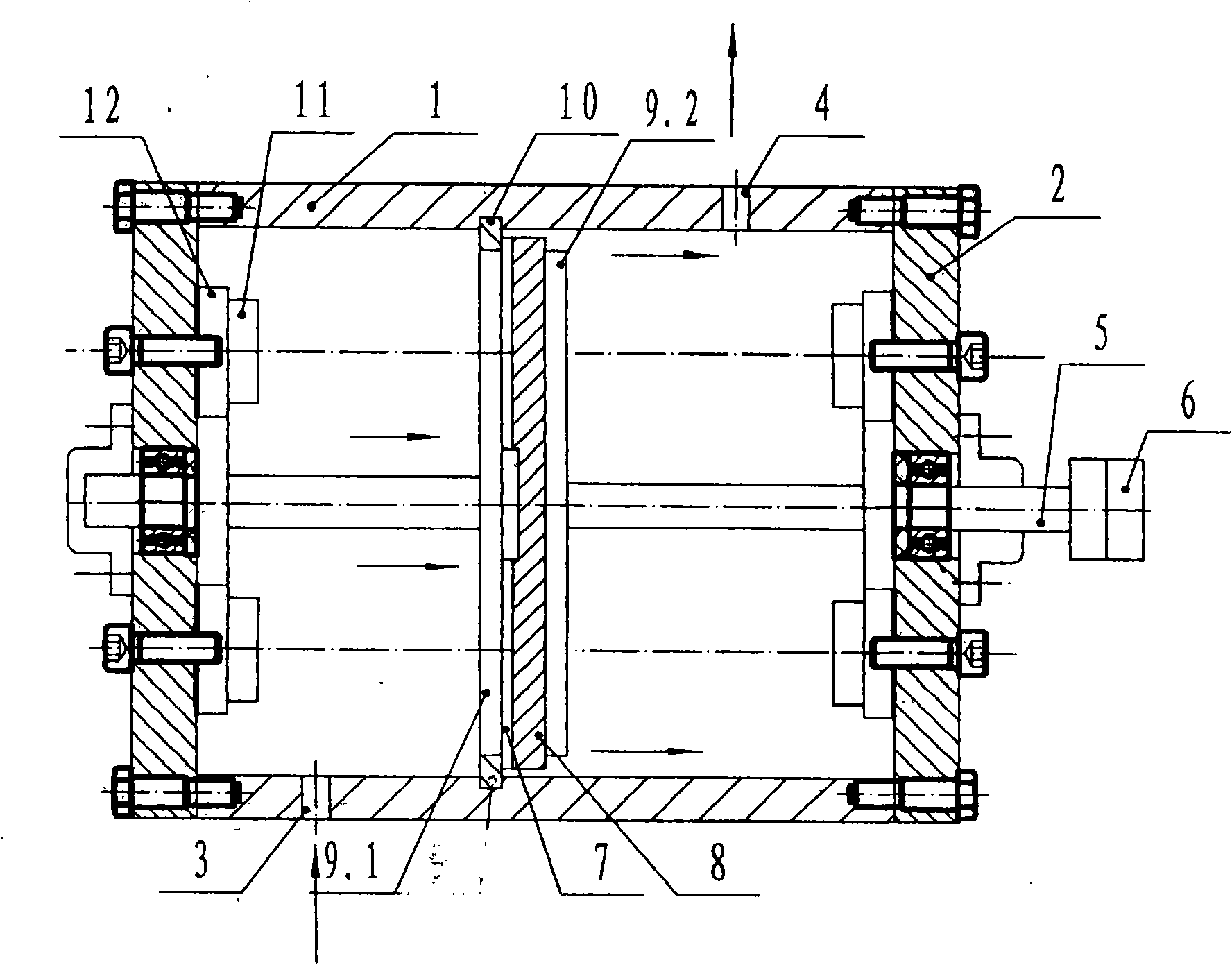

A quick repulsion tripping mechanism and tripping method for a DC circuit breaker

ActiveCN102270553ACompact structureFast tripping speedProtective switch operating/release mechanismsDc circuit breakerRepulsion force

The invention discloses a rapid repulsion tripping mechanism for a direct-current circuit breaker and a tripping method thereof. The repulsion-tray tripping mechanism has high response speed and small dispersivity and is not affected by the changes of external short-circuit current during the motion process. A tripping pusher is directly driven to rapidly trip by an electromagnetic repulsion force which is generated due to the eddy current effect of an alternating magnetic field in an electromagnetic repulsion tray. The instantaneous eddy-current electromagnetic force generated by the repulsion tray is large, and the direct-drive design significantly reduces intermediate mechanism links and reduces the qualities of moving components, so that the action speed of the direct-current circuit breaker is effectively increased and the inherent opening time of the circuit breaker is greatly shortened. Besides, the repulsion tray has a compact structure and a small size, the spatial distribution of the circuit breaker is fully utilized and optimized to reduce the size of the circuit breaker.

Owner:XI AN JIAOTONG UNIV

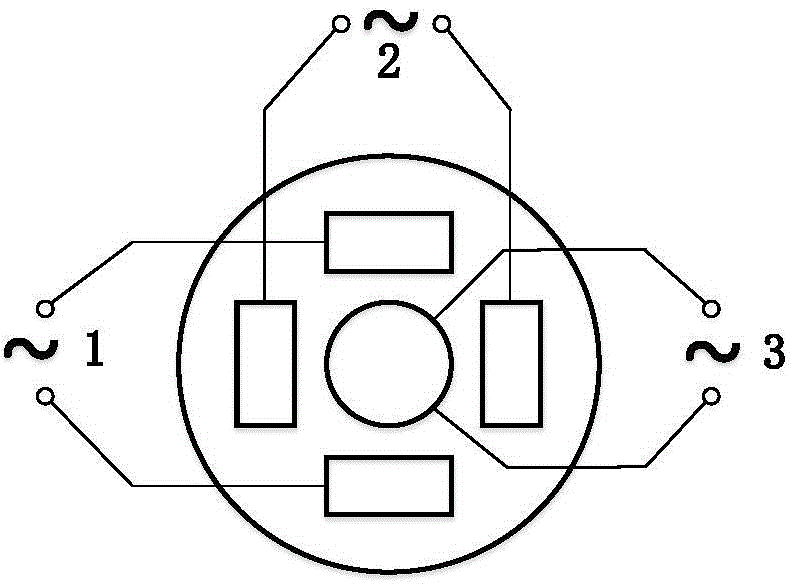

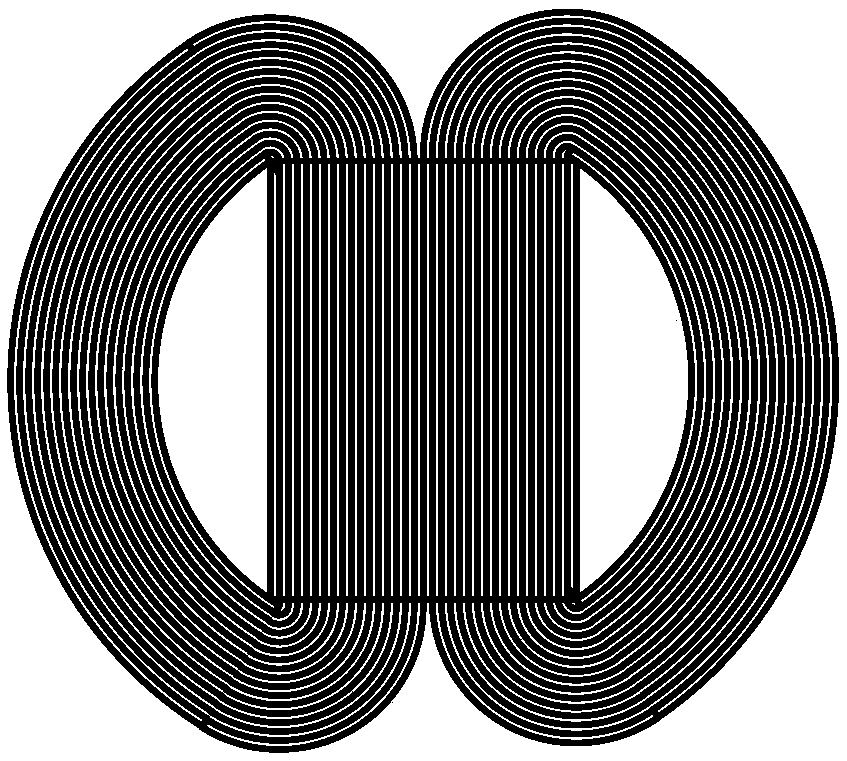

Orthogonal rotation exciting field eddy current transducer

InactiveCN104880508AHigh sensitivityOvercoming Orientation Sensitivity IssuesMaterial magnetic variablesElectricityAbsolute structure

The invention provides an orthogonal rotation exciting field eddy current transducer belonging to the technical scope of electric eddy current detection in the field of nondestructive testing. The eddy current transducer is mainly divided into an absolute structure and a differential motion type structure; the absolute type eddy current transducer cannot easily meet small defect detection requirements; and the differential motion type transducer can be used for effectively inhibiting common mode interference signals including temperature, lift-off effect and the like, and is relatively suitable for identifying small defects. A traditional differential motion transducer exciting coil is improved and a novel transducer exciting coil is composed of a sine winding and a cosine winding; in a working process, two harmonic currents are conducted into the two exciting coils by sine and cosine given frequencies; the two exciting currents are combined to form a rotary eddy current field so that the transducer is sensitive to eddy current distributed in each direction; when no crack exists, the two eddy current fields are balanced in a detection coil; and when a test piece has defects including the cracks and the like, the balance is broken through and an induction signal is generated in a measuring coil.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

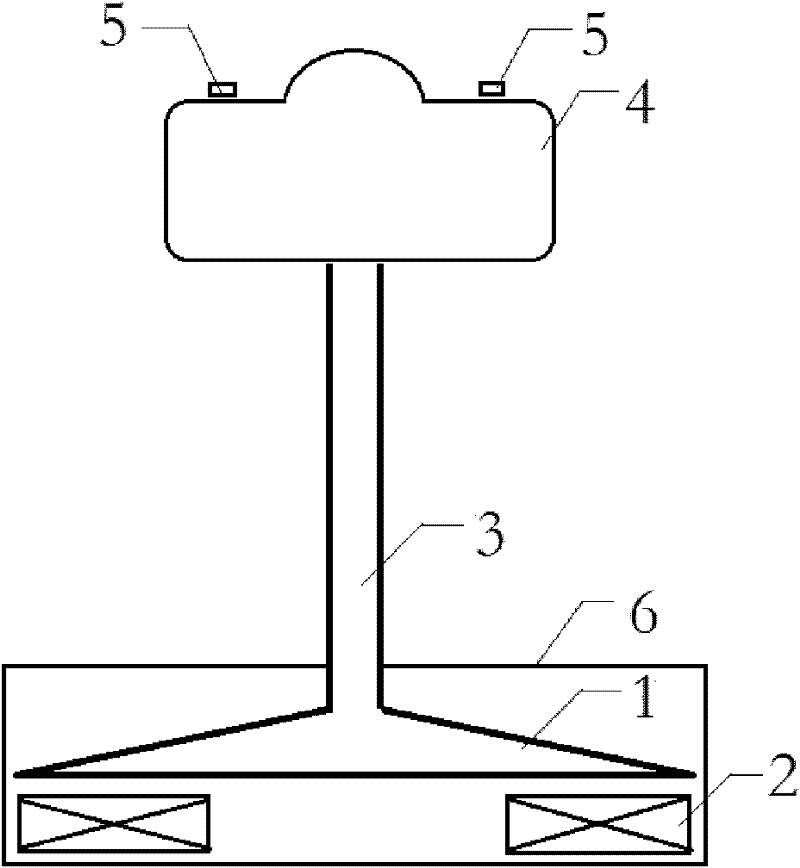

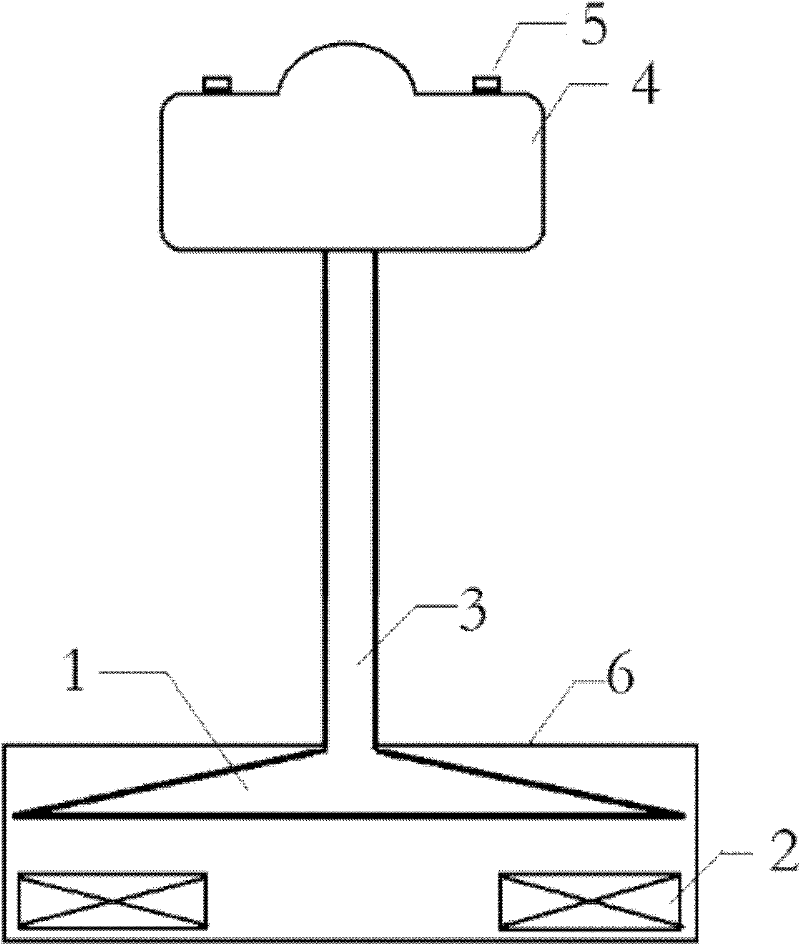

Note thickness measurement device in note sorter and measurement method thereof

InactiveCN103177502ASimple structureEasy to operateElectrical/magnetic thickness measurementsCoin/paper handlersDrive wheelMeasurement device

The invention discloses a note thickness measurement device in a note sorter. The note thickness measurement device comprises a base, a metal thickness sensing piece, a plurality of printed circuit board (PCB) planar coils, a sliding block, a driving wheel, a driven wheel, a transmission shaft and a signal processing circuit. According to the note thickness measurement device in the note sorter and a measurement method thereof, thicknesses of notes can be measured accurately through the electric eddy-current effect caused by thicknesses of notes, the structure is simple, the operation is convenient, the accuracy is high, a powerful tool is provided for differentiation of counterfeit money, and the practicability is high.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

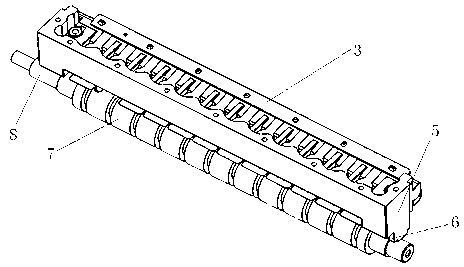

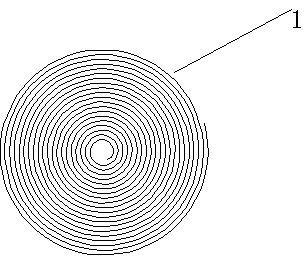

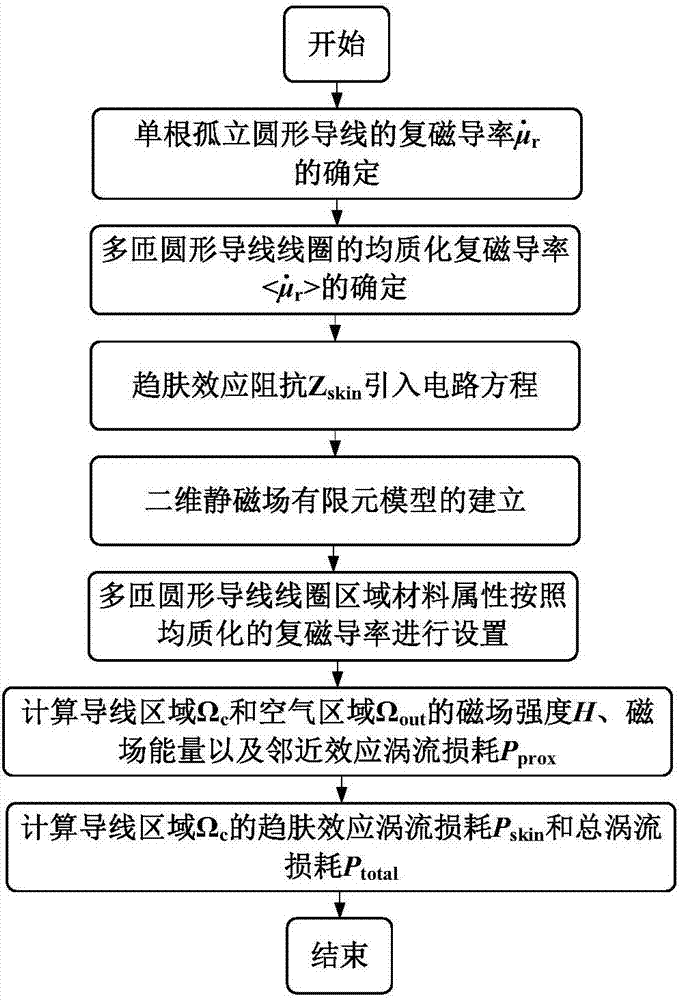

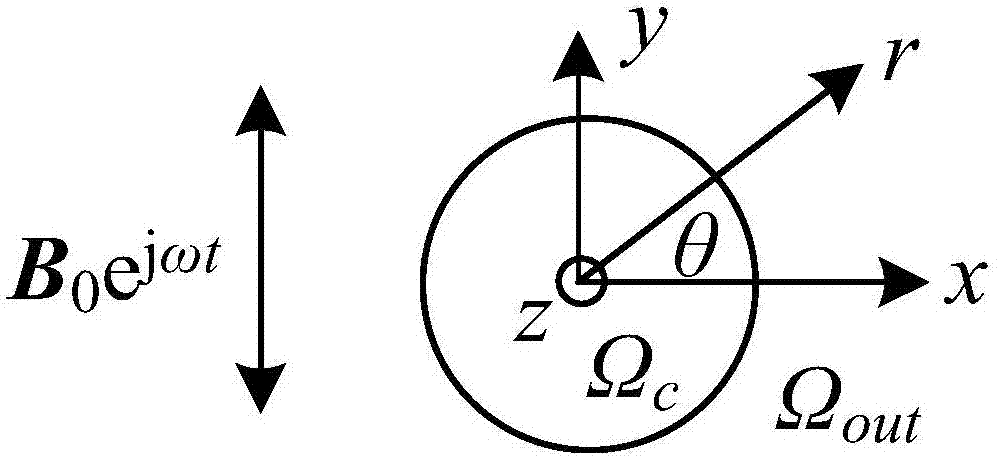

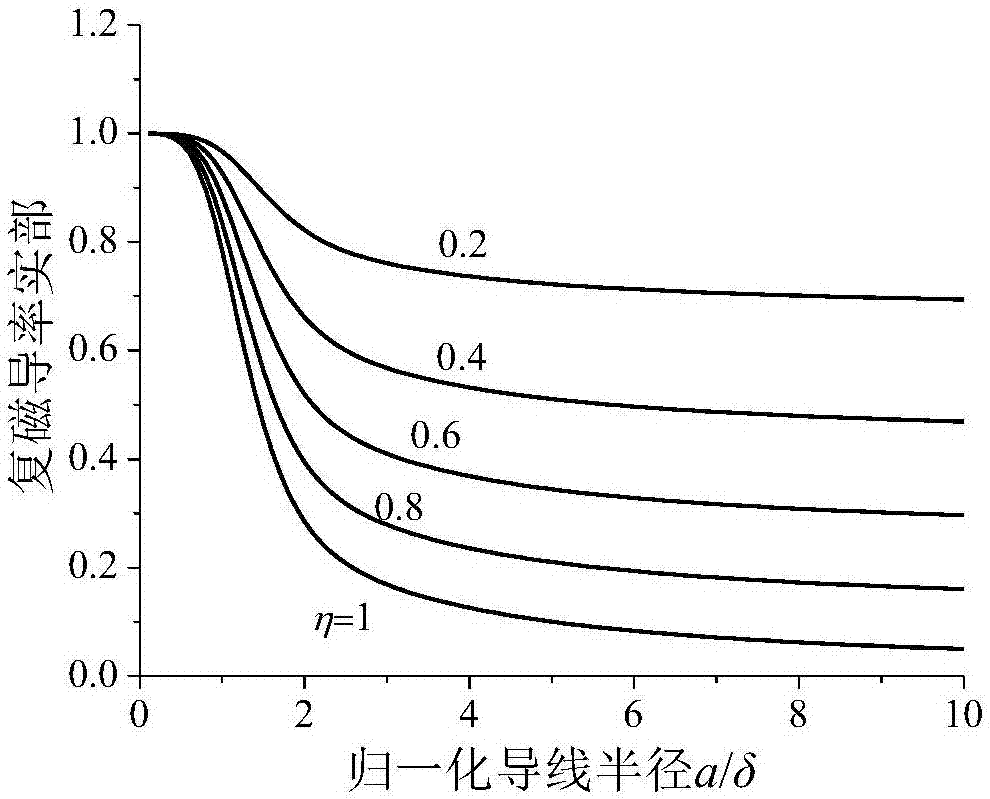

High-frequency eddy current effect-considered semi-analytical calculation method for winding loss

InactiveCN107977485ALoss gets quicklyReduce computational workloadDesign optimisation/simulationSpecial data processing applicationsElectrical conductorEngineering

The invention belongs to the field of inductor design, and particularly relates to a high-frequency eddy current effect-considered semi-analytical calculation method for winding loss. The method comprises the following steps of: obtaining a complex permeability expression of a single isolated circular conductor in a uniform time-harmonic magnetic field; calculating complex permeability of homogenization of a multi-turn circular conductor coil; metering influences which consider a skin effect through importing an impedance corresponding to the skin effect; establishing a two-dimensional finiteelement model, and calculating magnetic field intensity of a space region so as to obtain magnetic field intensity of a conductor region and an air region; calculating total magnetic field energy eddycurrent loss stored by the conductor region and the air region by combining the magnetic field intensity, obtained via static magnetic field finite element simulation, of the conductor region and theair region; and calculating eddy current loss of a multi-turn conductor region, and summating skin effect eddy current loss and proximity effect loss to obtain total loss of a winding region. The method can be used for determining winding loss of multi-turn conductor coils and effectively decreasing the calculation workload, and is beneficial for engineering application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Metal material defect detecting sensor based on pulsed eddy current and electromagnetic ultrasonic

ActiveCN108802185AReduce volumeReduce weightAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesMaterial defectMetallic materials

The invention discloses a metal material defect detecting sensor based on pulsed eddy current and electromagnetic ultrasonic and belongs to the field of nondestructive detection of metal material defects. The problem is solved that an existing metal material defect detecting mode based on pulsed eddy current and electromagnetic ultrasonic causes excessive size and weight of a corresponding sensor,is not suitable for high-temperature occasions and is poor in defect detecting effect. According to the sensor, an air core solenoid and a plate coil respectively transmit pulse signals and radio-frequency pulse signals. The air core solenoid makes a metal material to be detected produce eddy current effect, self-sensing voltage signals between two ends of the air core solenoid are the first sensing signals of the sensor after eddy current effect, the air core solenoid, the plate coil and the metal material to be detected form an electromagnetic ultrasonic transducer, the plate coil receivesultrasonic waves excited by the metal material to be detected and transmits ultrasonic waves to the metal material to be detected, and echo signals of the ultrasonic waves entering the metal materialto be detected are second sensing signals of the sensor.

Owner:HARBIN INST OF TECH

Welding method of solar energy battery plate

InactiveCN102151973AShorten the timeSave man hoursHigh frequency current welding apparatusEddy current effectEngineering

The invention relates to a welding method of a crystalline silicon solar energy battery plate, which is used for welding a battery plate and a welding strip in the manufacturing process of a crystalline silicon solar energy battery plate component and is suitable for manufacturing the crystalline silicon solar energy battery plate component. The welding method of the solar energy battery plate comprises the following steps: firstly placing the battery plate and the welding strip on a preheating board and welding the battery plate and the welding strip through the heating of a welding device; the welding device comprises a current generator, a metal bar and an induction loop connected between a high-frequency generator and the metal bar; and the induction loop is arranged on the periphery of the metal bar in a surrounding manner. The welding method can realize the automation welding by using eddy-current effect heating to replace the traditional manual welding and has the advantages of quick heating speed, good welding quality and high production efficiency.

Owner:常州博润达自动化科技有限公司

Stabilizer for magnetoresistive head and method of manufacture

A reader of a current-perpendicular-to-plane magnetoresistive head includes a spin valve with sensor having a stabilizer adjacent thereto, to substantially avoid magnetization distribution at the edge of the sensor due to vortex effect. At least one free layer is spaced apart from at least one pinned layer by a spacer. Above the free layer, a capping layer is provided. The stabilizer includes a pinned ferromagnetic layer adjacent to the free layer, and an antiferromagnetic layer positioned thereon. It becomes easy to provide an effective biasing using a variety of materials having different magnetic moments and thickness. Also problems related to sensor edge for small size will be overcome. A method of manufacturing the reader is also provided.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com