Metal material defect detecting sensor based on pulsed eddy current and electromagnetic ultrasonic

A metal material and defect detection technology, which is used in the analysis of materials, material magnetic variables, and the use of sonic/ultrasonic/infrasonic waves to analyze solids, etc. Achieve the effect of reducing the volume and weight, and solving the poor detection effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

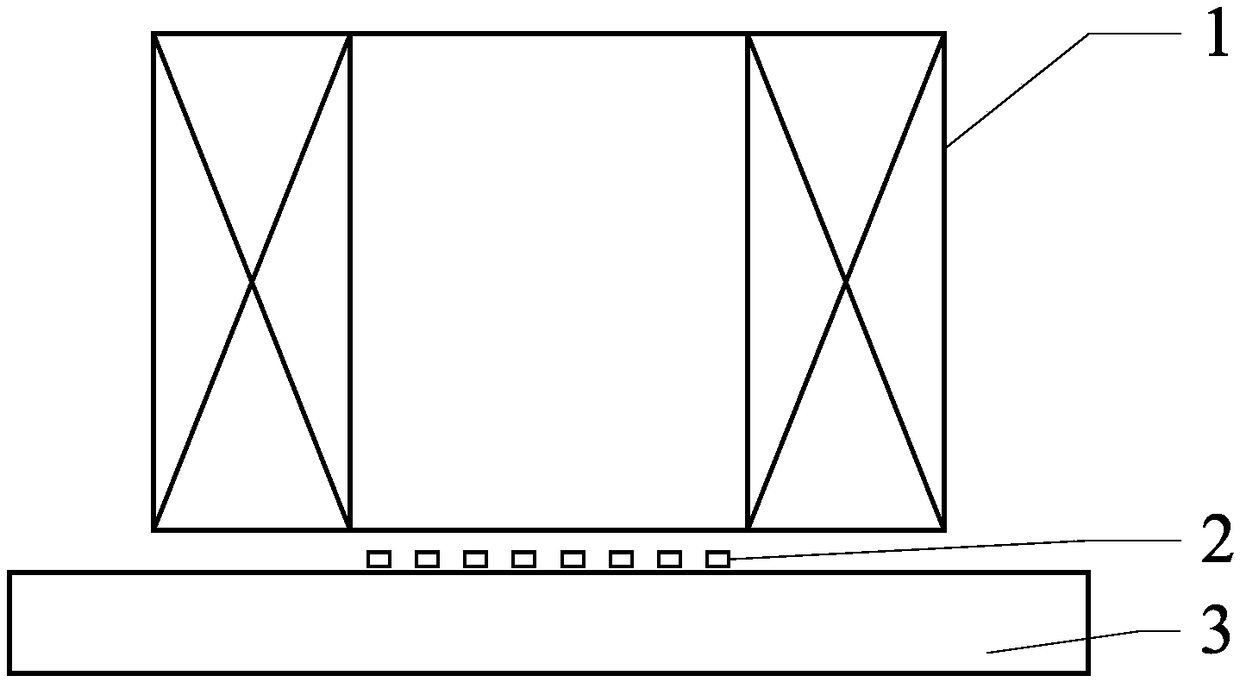

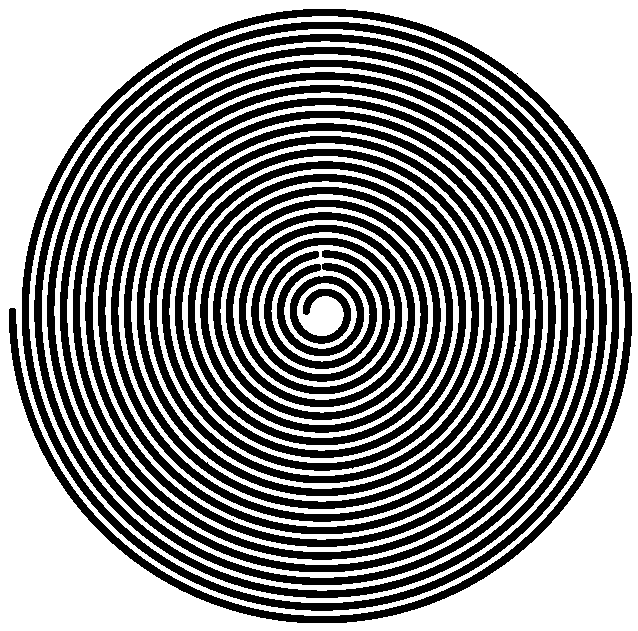

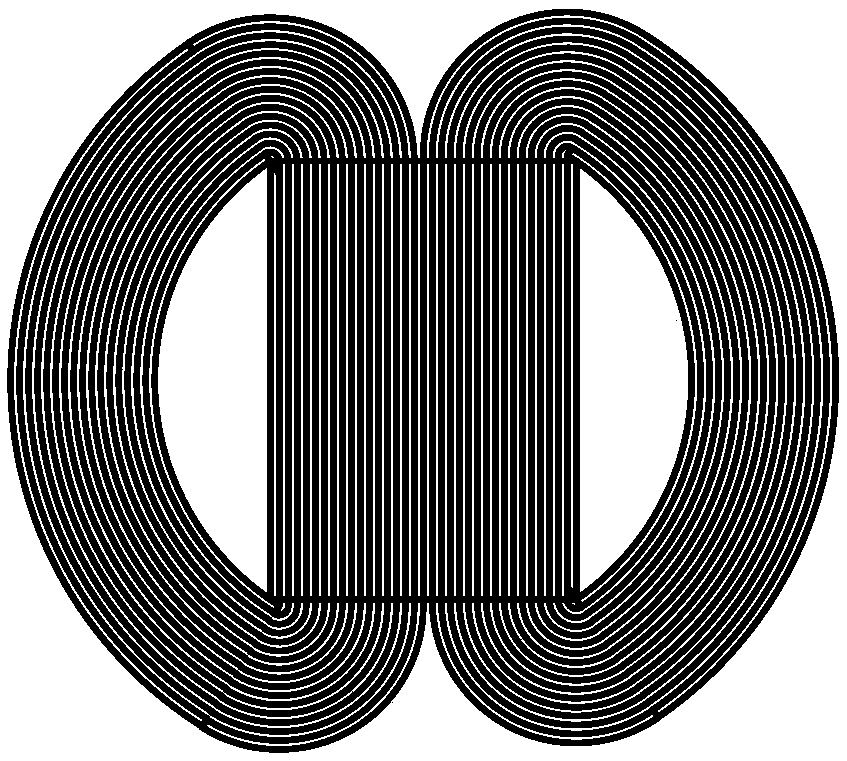

[0032] Embodiment: combine below Figure 1 to Figure 6 This embodiment will be described in detail.

[0033] refer to figure 1 , the metal material defect detection sensor based on pulsed eddy current and electromagnetic ultrasound described in this embodiment includes a hollow solenoid 1 and a flat coil 2;

[0034] The hollow solenoid 1 is connected with a pulse signal, and the flat coil 2 is connected with a Tone-burst signal;

[0035] The hollow solenoid 1 is used to cause the eddy current effect to occur on the metal material 3 to be tested. After the eddy current effect occurs, the self-induced voltage signal between the two ends of the hollow solenoid 1 is the first sensing signal of the metal material defect detection sensor ;

[0036] The hollow solenoid 1, the flat coil 2 and the metal material 3 to be tested constitute an electromagnetic ultrasonic transducer. Ultrasonic waves are emitted, and the echo signal of the ultrasonic waves entering the metal material 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com