Micro-electromechanical inductor for suppressing the substrate eddy effect and its manufacture method

A technology of micro-electronic machinery and eddy current effect, applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., can solve the problems of difficult to exceed the quality factor of inductors, increase the cost and design difficulty, and achieve the suppression of eddy currents in the substrate effect, reduce substrate loss, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

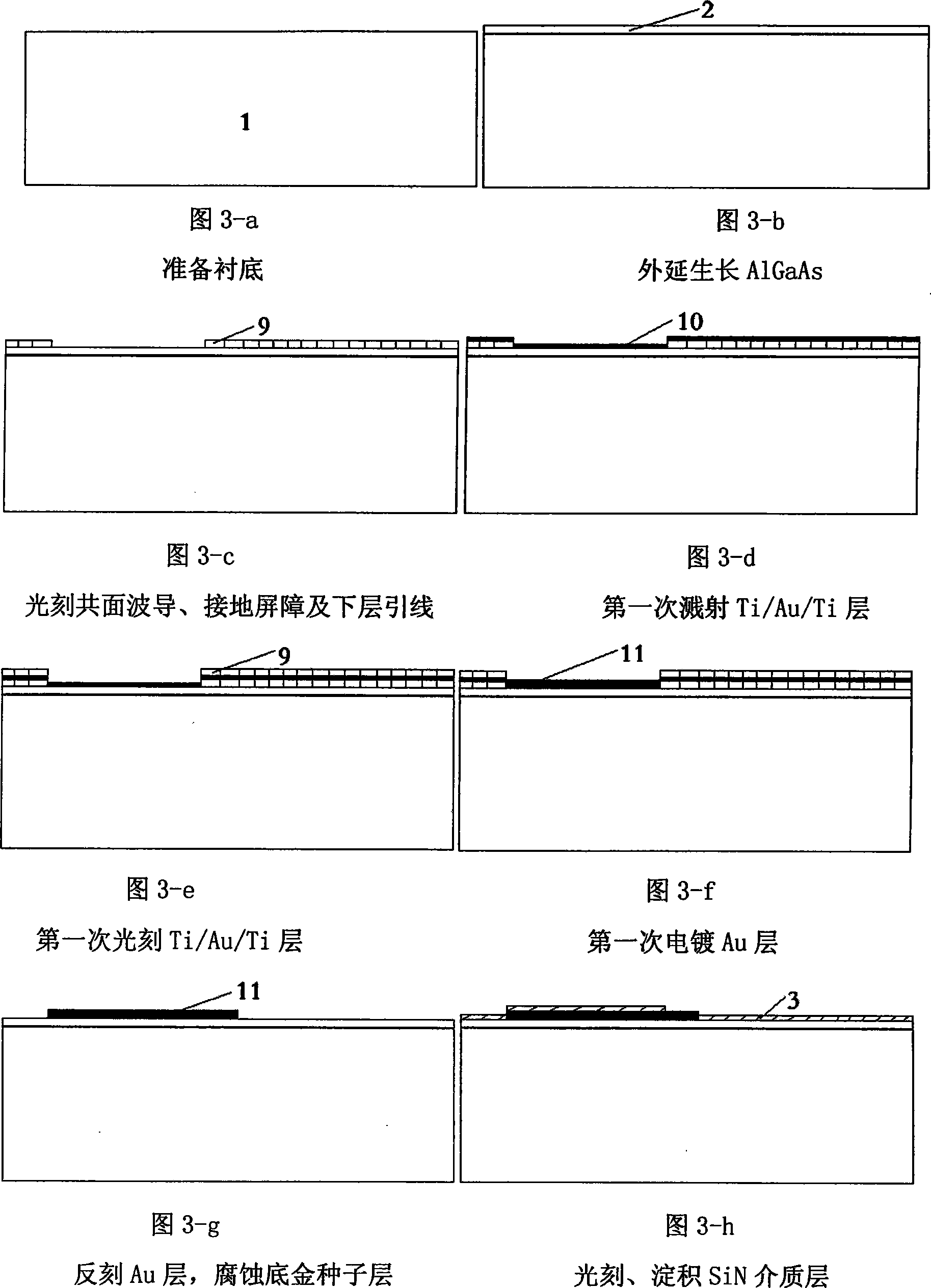

[0037] The practical application of the steps of the present invention will be described in detail below in conjunction with the accompanying drawings.

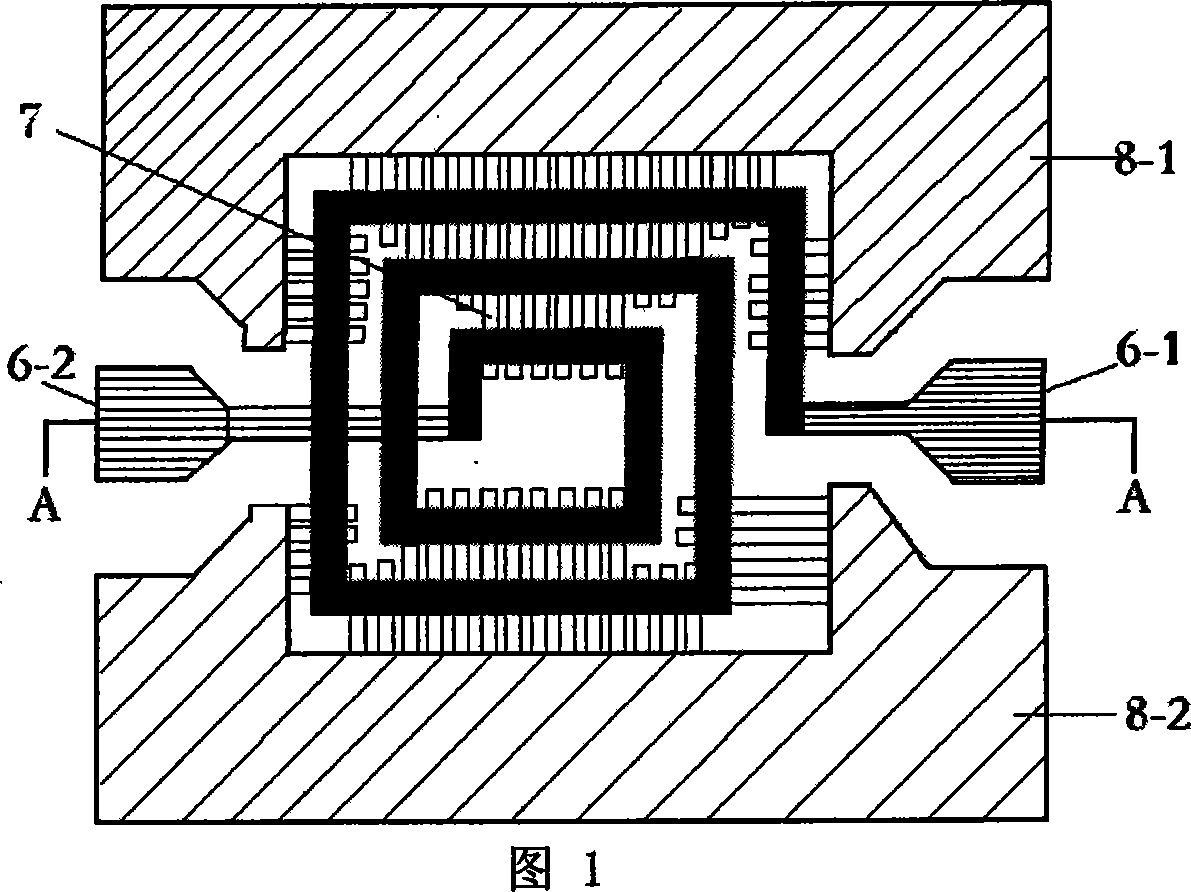

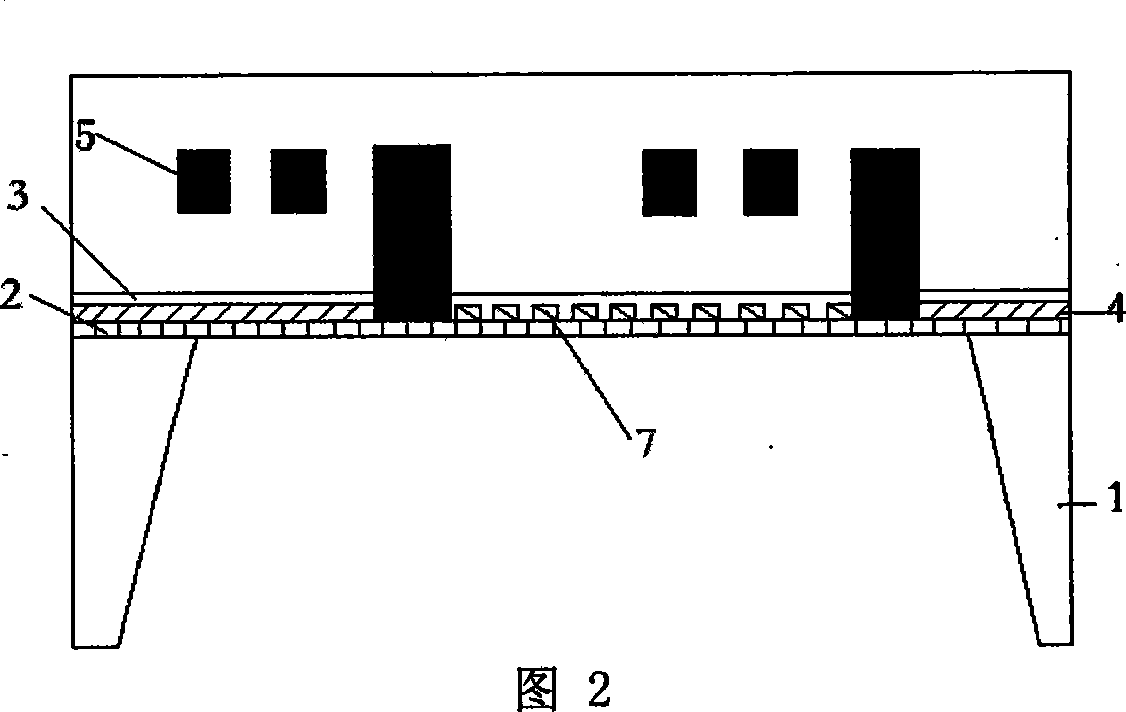

[0038] As shown in Fig. 1 and Fig. 2, it is the schematic diagram of the micromechanical inductor prepared by the method of the present invention, comprising gallium arsenide (GaAs) substrate 1, aluminum gallium arsenide (AlGaAs) thin film 2, silicon nitride (SiN) dielectric layer 3 , Inductor lower lead wire 4, inductor upper coil 5, first coplanar waveguide signal line 61, second coplanar waveguide signal line 62, ground barrier 7 and first coplanar waveguide ground wire 81, second coplanar waveguide ground wire 82 The inductance is based on a GaAs substrate 1, a layer of AlGaAs thin film 2 is arranged on the upper surface of the GaAs substrate 1, and a layer of SiN dielectric layer 3 is arranged on the upper surface of the AlGaAs thin film 2, and the upper layer coil 5 of the inductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com