Figure filler structure inserted about inductor

A filler and inductor technology, which is applied in the field of graphic filler structure, can solve the problems of reducing the quality factor of inductors, increasing the energy loss of inductors, and achieving the effects of meeting density requirements, increasing qualityfactor, and reducing eddy current effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

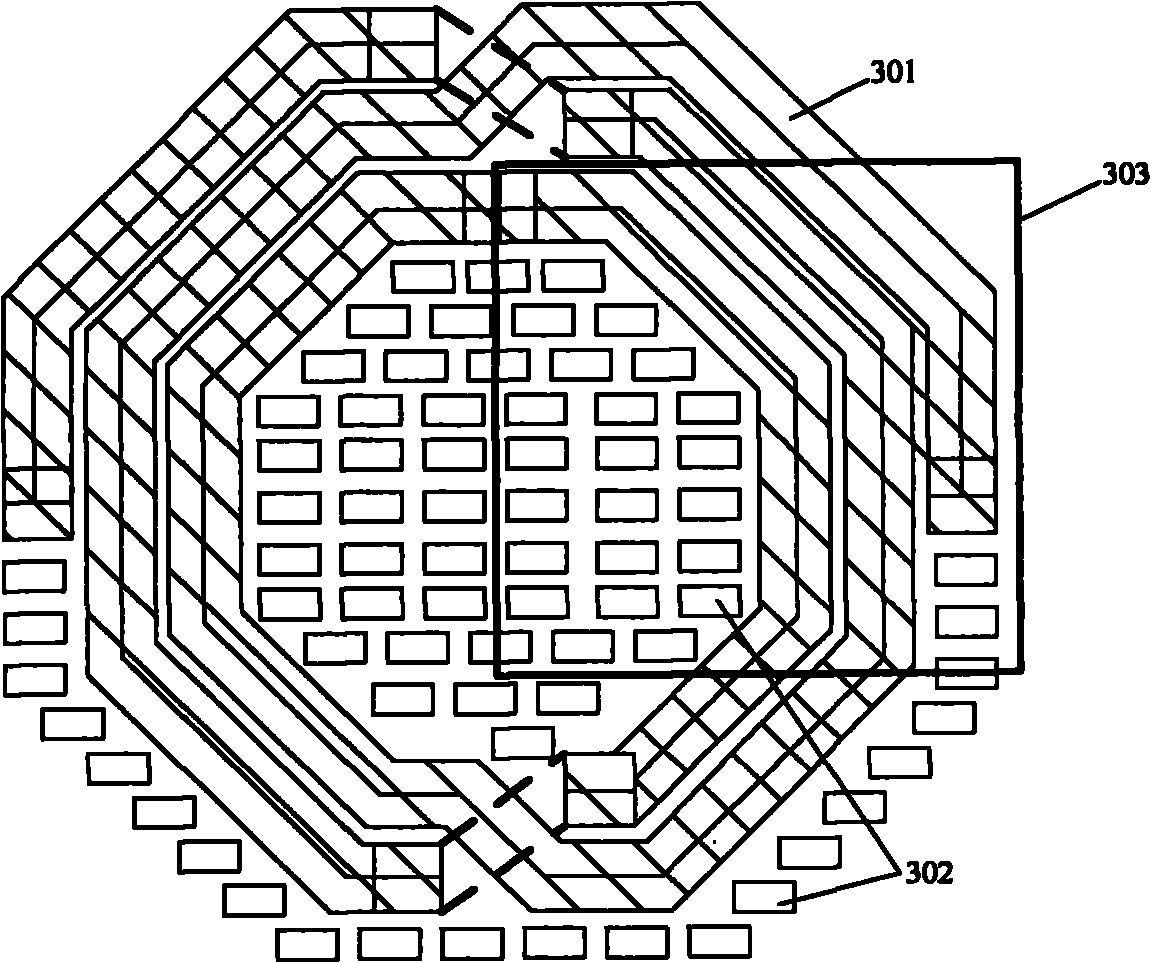

[0029] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0030] The core idea of the present invention is to reduce the eddy current effect of the pattern filling structure and increase the quality factor of the inductor by optimizing the shape, size and interval of the pattern filling structure.

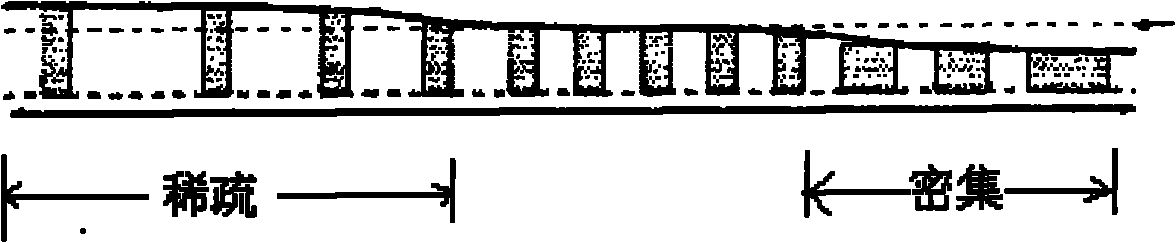

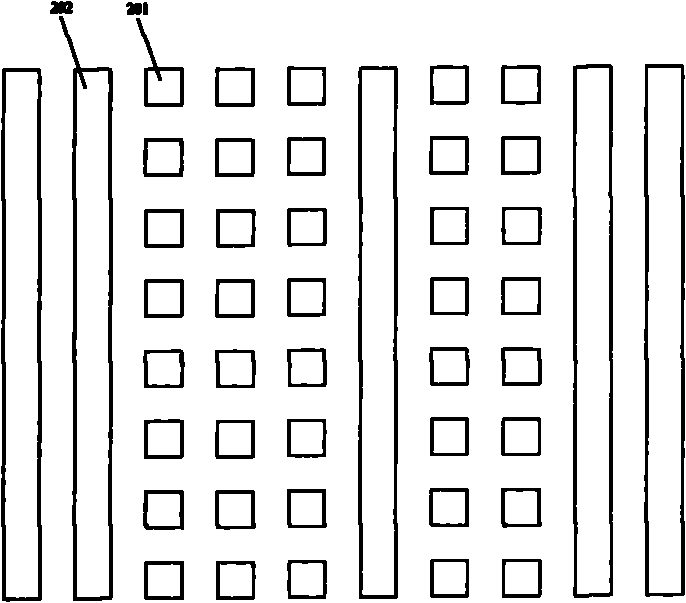

[0031] The main metal coil of the inductor is located on the top metal (Top Metal) layer to image 3 Taking a differential inductor with 3 terminals as an example, a pattern filler structure is inserted around the metal coil of the inductor, that is, the inner area and the outer area. The pattern filling structure is a square metal block, obviously the height of the metal block is equal to the height of the metal coil of the inductor. After research, it is found that when the side length of the square metal blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com