Motor magnet ring and magnet for reducing eddy-current effect

A technology of eddy current effect and magnet ring, applied in the direction of magnetic circuit shape/style/structure, can solve the problems of reduced efficiency, increased motor energy consumption, difficult and time-consuming processing, etc., to improve performance and life, reduce stress concentration, and reduce eddy current effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

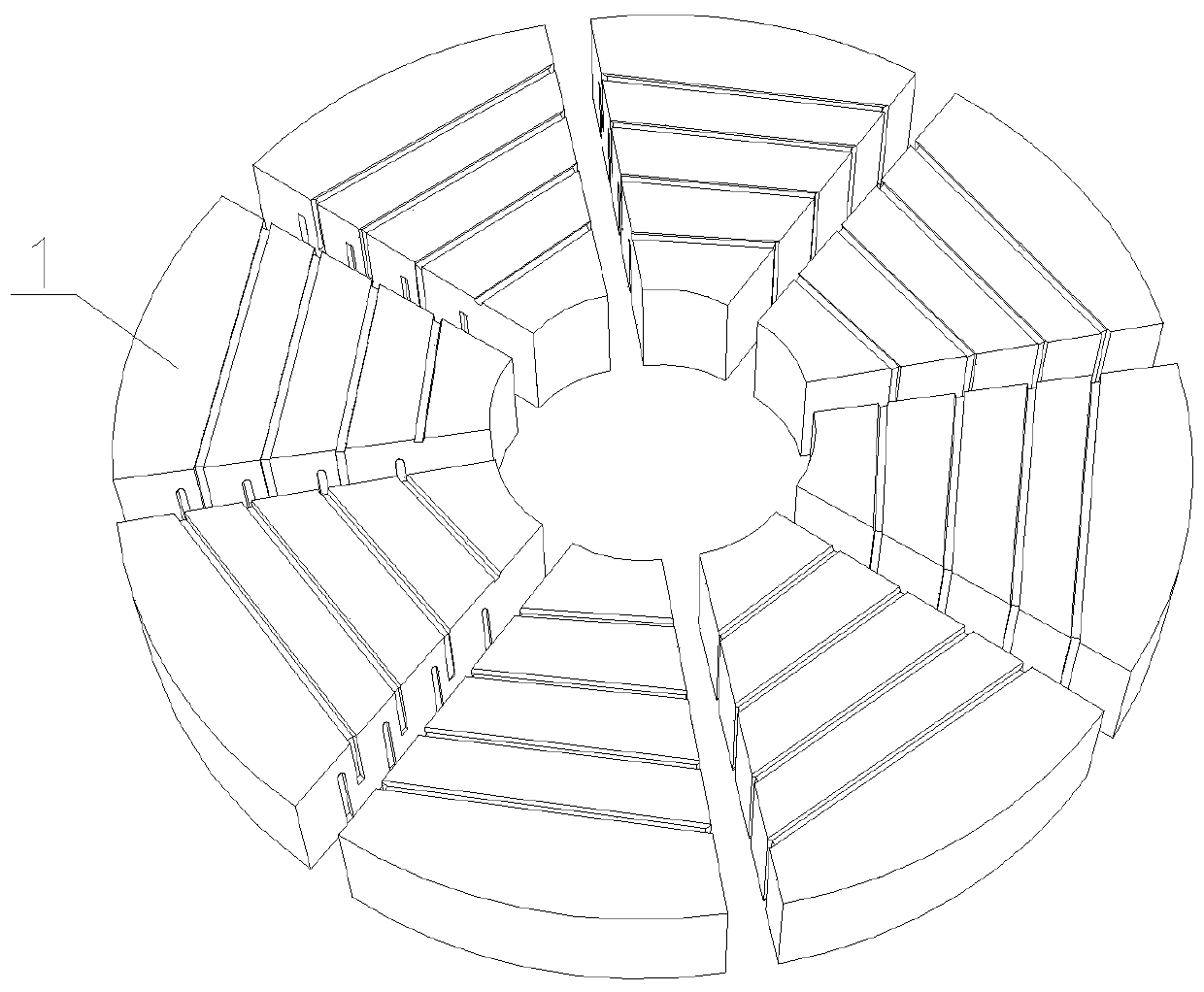

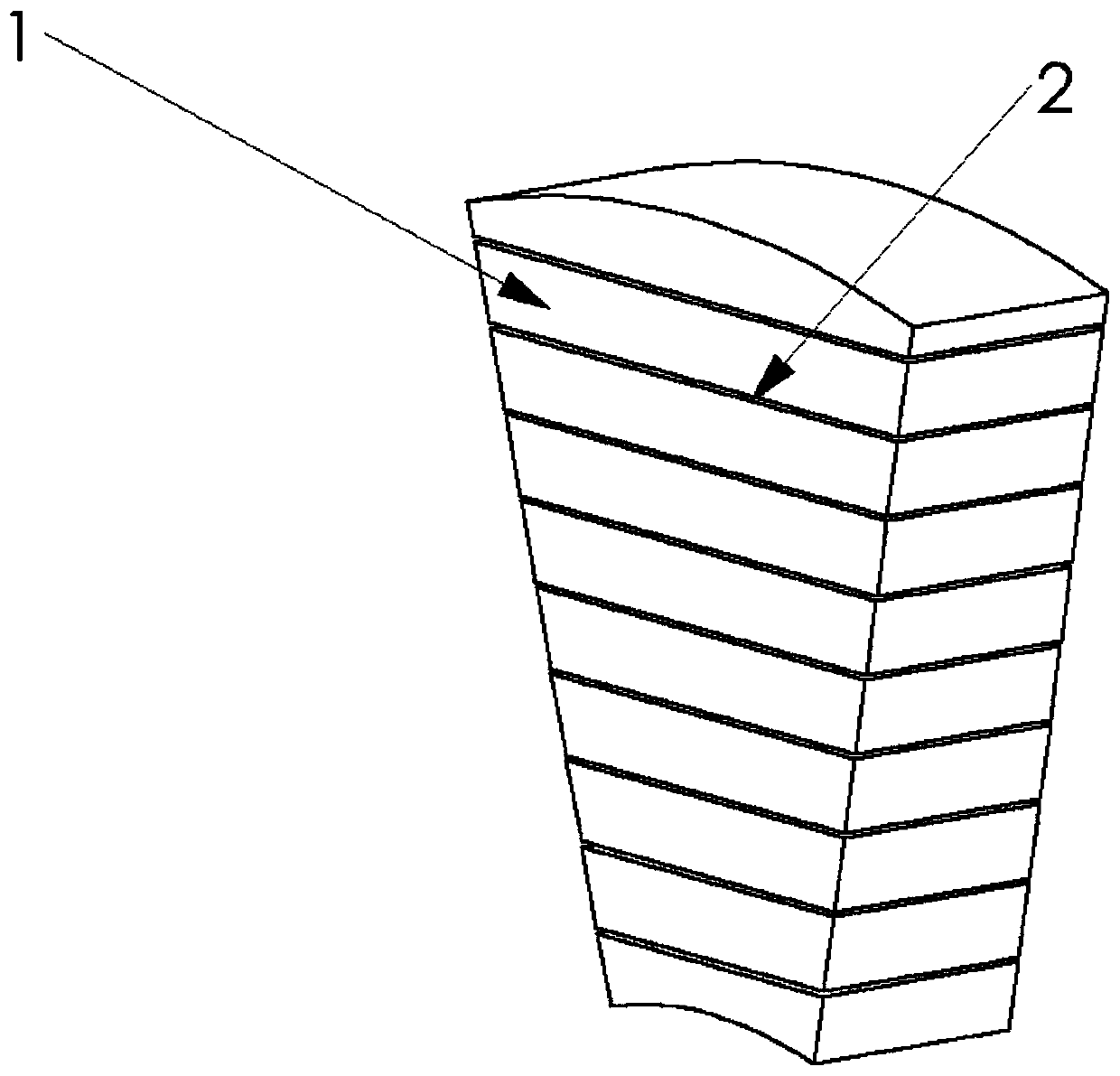

[0027] refer to figure 1 with figure 2 , a motor magnet ring that reduces eddy current effects according to the present invention, which includes magnets 1 arranged in a ring shape. Cutting grooves 2 are arranged on the magnets 1. The ends of the cutting grooves 2 do not intersect and overlap up and down. The end of the groove 2 is arc-shaped, and the magnet 1 is fan-shaped, and the end is arc-shaped. The cutting groove 2 is filled with epoxy glue, and it is characterized in that: the depth of the cutting groove 2 is 20% of the magnet 1 thickness.

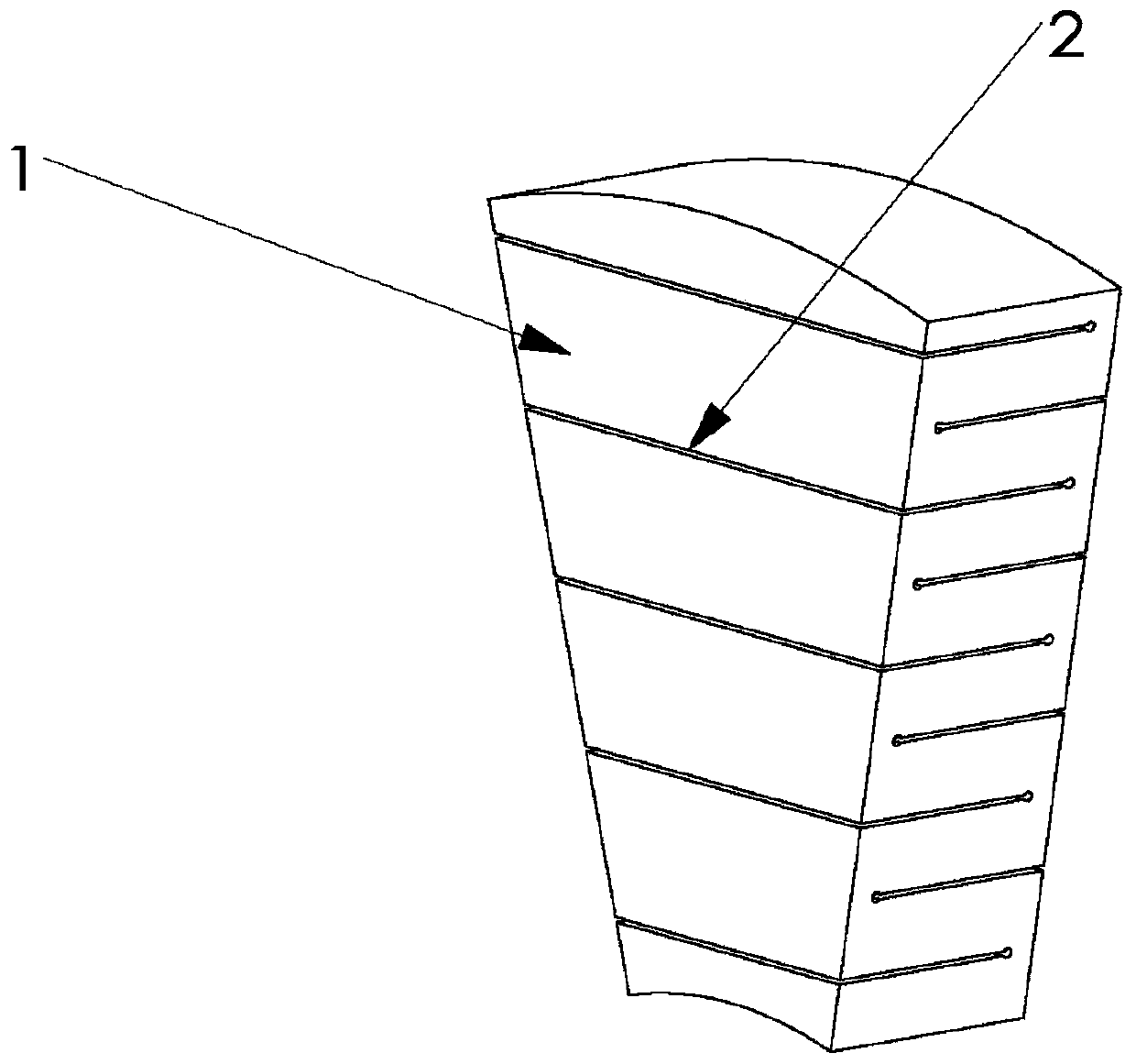

[0028] refer to image 3 , the present invention is a motor magnet for reducing eddy current effect. The magnet 1 is provided with at least one cutting groove 2 whose two ends do not intersect, the number of the cutting grooves 2 is four, and the ends of the cutting grooves 2 are Arc shape, the depth of the cutting groove 2 is 20% of the thickness of the magnet 1, the cutting groove 2 is filled with colloid, and the type of col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com