Patents

Literature

51results about How to "Meet density requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing bamboo/wood composite recombined bamboo plate

InactiveCN101879731AHigh weight contentIncrease contentWood treatment detailsVolumetric Mass DensityEngineering

The invention discloses a method for manufacturing a bamboo / wood composite recombined bamboo plate. The production method comprises the following steps of: (1) processing bamboo filaments; (2) dyeing poplar veneers; (3) drying; (4) dipping gum; (5) performing air drying; (6) weighing, and assembling for molding; (7) performing high temperature curing; and (8) balancing and slicing. The plate manufactured by the method saves a large amount of wood; and the recombined bamboo plate comprises the following components in percentage by weight: 15 to 25 percent of phenolic resin, 2 to 10 percent of poplar and 65 to 83 percent of bamboo, and has the density of 1.05 to 1.15 g / cm<3>. Therefore, the manufactured plate has high bamboo content and less poplar. Meanwhile, the plate is made of small-diameter bamboo, branches and other poor bamboo and has low cost; and the manufactured plate also has colorful stripes or speckles.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

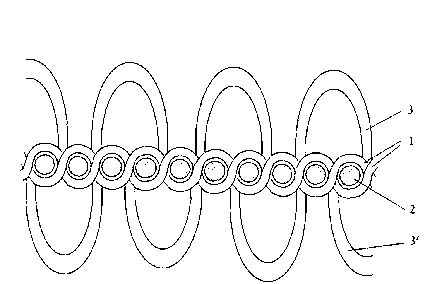

Ultrahigh-elasticity extensible towel and manufacturing method thereof

ActiveCN103015001AEasy to cleanIncrease elasticityCleaning apparatus for vehicle exteriorsWoven fabricsPolyesterEngineering

The invention provides an ultrahigh-elasticity extensible towel and a manufacturing method thereof. The ultrahigh-elasticity extensible towel comprises a ground warp, a ground weft and terry warps, wherein the ground warp is made of a polyester low stretch yarn / ultrahigh-elasticity coarse denier spandex filament wrap yarn to achieve the longitudinal extensible high elasticity of the towel. The polyester low stretch yarn / ultrahigh-elasticity coarse denier spandex filament wrap yarn takes a (140-210)D / (8-12)f ultrahigh-elasticity spandex filament as an inner core; and the polyester low stretch yarn warps the inner core through overfeeding networking. The ground weft is made of a polyester low stretch yarn; and the ground warp and the ground weft are interwoven in a plain weave manner to form a ground stitch. The terry warps are interwoven with the ground weft to form a terry stitch; and the terry stitch forms terry on the outer surface of the ground stitch after the terry stitch is removed from a loom. The terry warps are made of sea island composite superfine polyester yarns. The ultrahigh-elasticity extensible towel provided by the invention has ultrahigh elasticity, can be elastically deformed to different areas to adapt to cleanness and use of different area zones, and is especially suitable for cleaning vehicles.

Owner:ZHEJIANG GRACE

High-density iridium alloy billet and preparation method of the high-density iridium alloy billet

The invention discloses a high-density iridium alloy billet and a preparation method of the high-density iridium alloy billet. The high-density iridium alloy billet contains 0.1%-0.5% of tungsten by weight, 40ppm-80ppm of thorium, and the balance of iridium and unavoidable impurities. The preparation method includes the steps as follows: according to the requirement for the components of the final iridium alloy billet, conducting high energy activation on tungsten powder, tungsten-thorium alloy powder and iridium powder by adopting a high-energy ball mill, uniformly mixing the tungsten powder, the tungsten-thorium alloy powder and the iridium powder, then placing the mixed powder into a vacuum oven to dry so as to obtain a high-energy activated mixed powder, later pressing and moulding the high-energy activated mixed powder in a mould pressing or cold isostatic pressing way to botain a powder pressed billet, then placing the powder pressed billet in a high-temperature sintering furnace to sinter, and cooling along with the furnace to obtain the high-density iridium alloy billet. In the invention, high-energy ball milling activation and mixing in batches are adopted, thus achieving the uniform distribution of trace thorium in the alloy powder and reducing sintering activation energy; and the high-density iridium alloy billet which meets the requirements of an iridium alloy applying piece and follow-up hot working on the density of the billet is prepared, and the relative density achieves above 95%.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

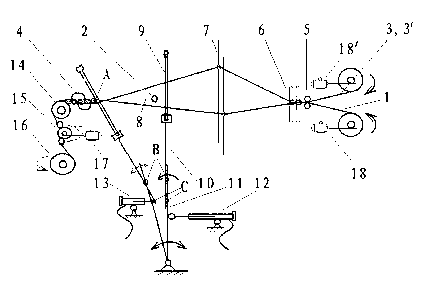

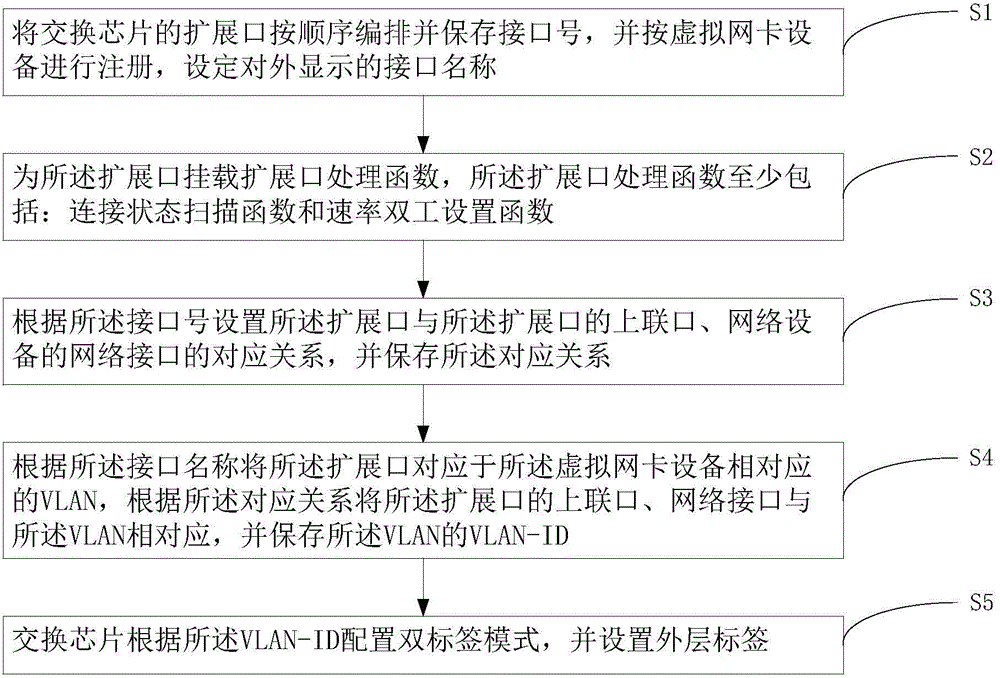

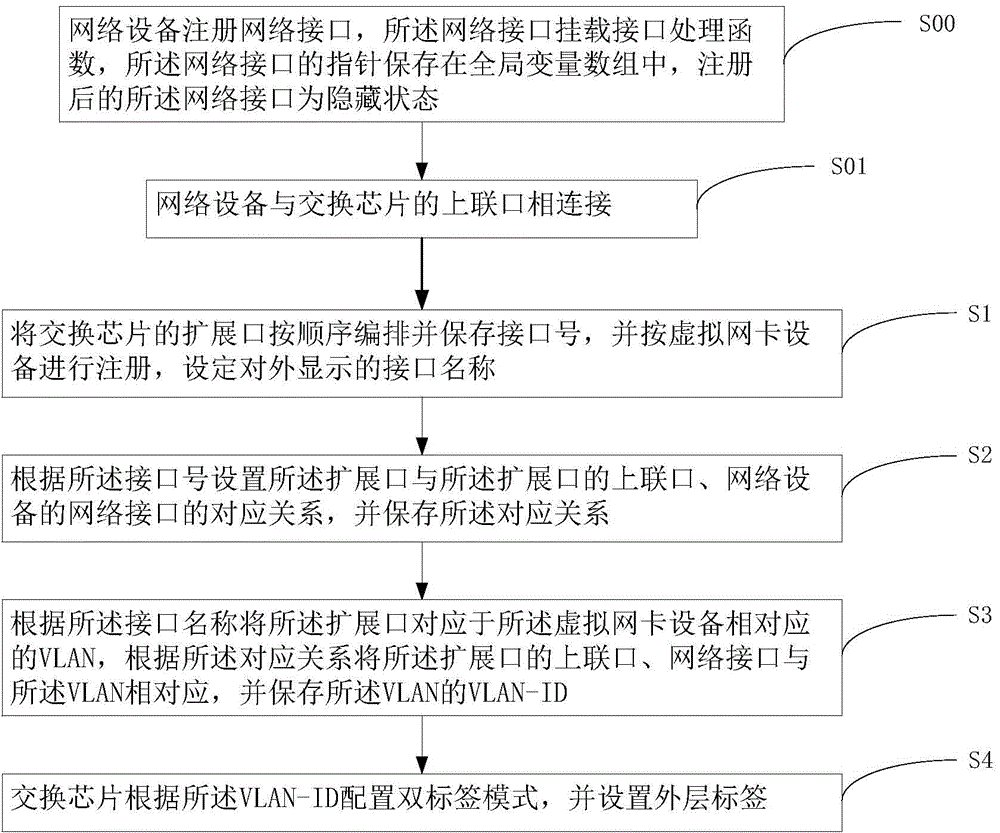

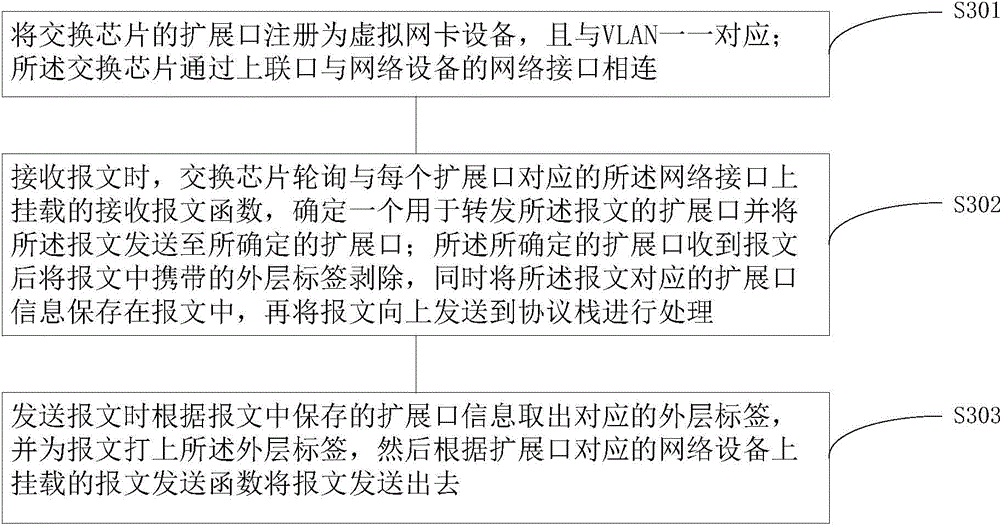

Method and system for extending network interfaces, and method for receiving and sending message

ActiveCN104158768AMeet density requirementsNetworks interconnectionNetwork interface deviceVolumetric Mass Density

The invention discloses a method and a system for extending network interfaces, and a method for receiving and sending a message. The method for extending the network interfaces comprises a step of arranging extension ports of switch chips in sequence and storing interface numbers, carrying out registration according to virtual network card equipment, and setting interface names displayed to the external; a step of setting corresponding relations between the extension ports and upper link ports of the extension ports and network interfaces of network equipment according to the interface numbers, and storing the corresponding relations; a step of mapping the extension ports with corresponding VLANs of the virtual network card equipment according to the interface names, mapping the upper link ports of the extension ports, the network interfaces and the VLANs according to the corresponding relations, and storing a VLAN-ID of each VLAN; and a step of each switch chip configuring a double-label mode according to the VLAN-ID and arranging an outer layer label. According to the invention, requirements for the density of network interfaces of different pieces of network equipment can be met, the extension port of each switch chip is an independent internet access, and independent configuration issuing and message receiving and sending can be achieved.

Owner:OPZOON TECH

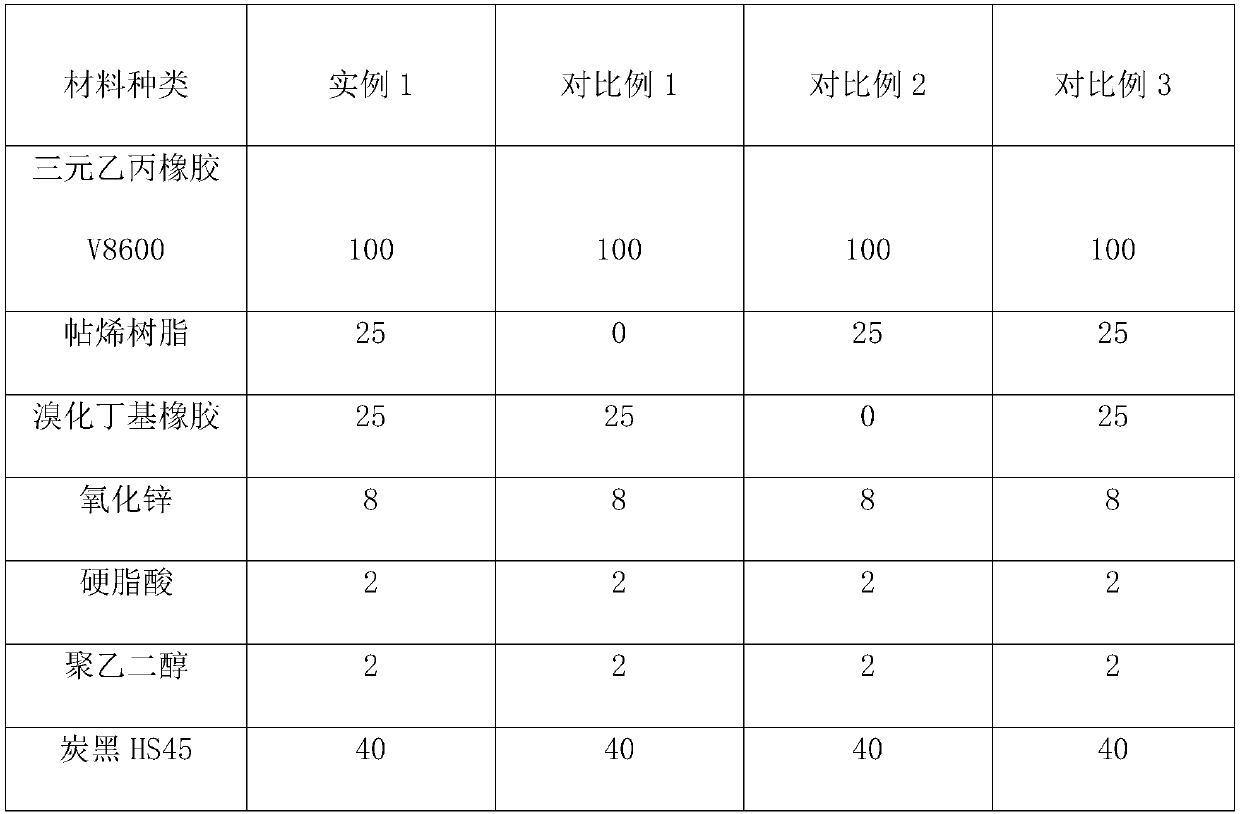

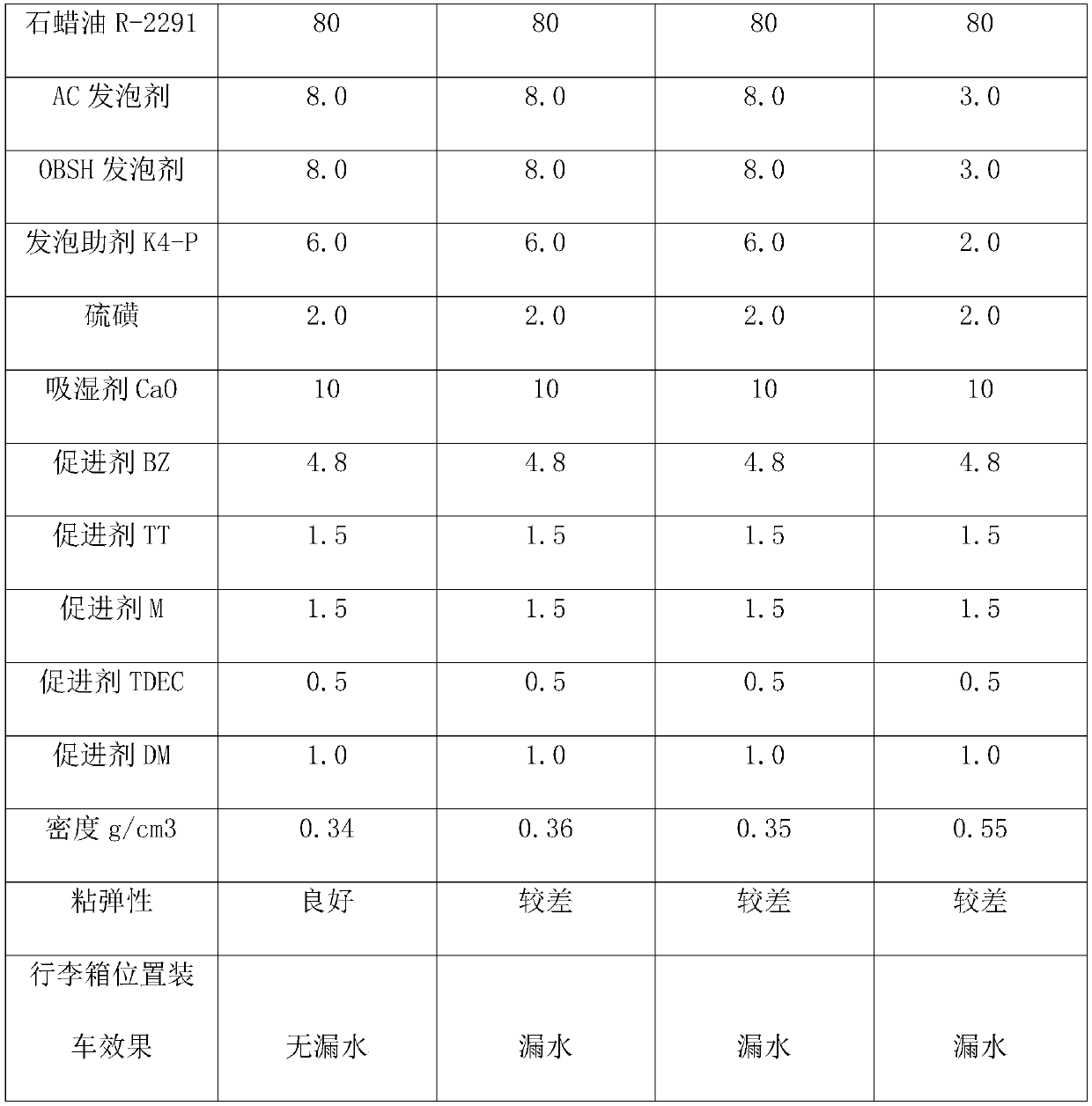

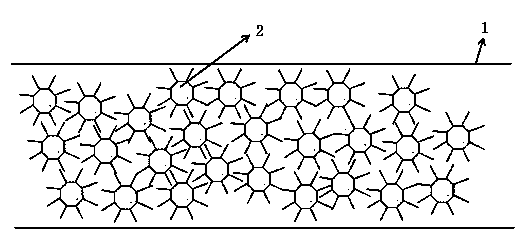

Water-stopping sponge rubber material and preparation method thereof, sealing strip and preparation method thereof, and automobile

ActiveCN109651642AEasy to processReduced durabilityEngine sealsVehicle sealing arrangementsRubber materialPolyethylene glycol

The invention provides a water-stopping sponge rubber material, a preparation method thereof, a sealing strip and a preparation method of the sealing strip and an automobile, the water-stopping spongerubber material is prepared from the following components in parts by weight: 100 parts of ethylene-propylene-diene monomer v8600, 20-30 parts of terpene resin, 20-30 parts of brominated butyl rubber, 6-10 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of polyethylene glycol, 30-50 parts of carbon black HS45, 70-90 parts of R-2291 paraffin oil, 6-10 parts of an OBSH foaming agent, 6-10parts of an AC foaming agent, 5-7 parts of foaming assistant K4-P, 1.5-2.5 parts of sulfur, 7-12 parts of hygroscopic agent CaO and 6-10 parts of an accelerant. The water-stopping sponge rubber material disclosed by the invention has the characteristics of low density, low damping and high viscosity, can be conveniently arranged in a sealing sleeve, has good water stopping performance, and has very good practicability.

Owner:NUOBO RUBBER PRODION

Preparation method of large high density tungsten alloy counterweight

A preparation method of a large high density tungsten alloy counterweight is characterized by comprising the steps that: dividing the large counterweight into a plurality of small counterweights with the weight below 50Kg; compounding, by mass, the following components: 91%-95% of tungsten powder, 3.50%-7.5% of nickel powder and 1.0%-3.0% of iron powder; weighing the three kinds of raw material powder, mixing evenly and pressing into a small counterweight blank, then performing liquid phase sintering; processing the connection surfaces of the sintered small counterweights into flat faces, putting one of the small counterweights in a sintering boat, wherein the connection surface maintains horizontal or is vertical to the sintering boat, then putting another small counterweight with the connection surfaces of the small counterweight and the before small counterweight being attached, putting other small counterweights in the same manner, and finally putting all the small counterweights together with the sintering boat into a fixed-point type hydrogen furnace for liquid phase sintering. The large tungsten alloy counterweight prepared by the method is high in density and uniform in structure, the average grain size of the sintered counterweight is 30-50 mum, and the cost is low.

Owner:北方材料科学与工程研究院有限公司 +1

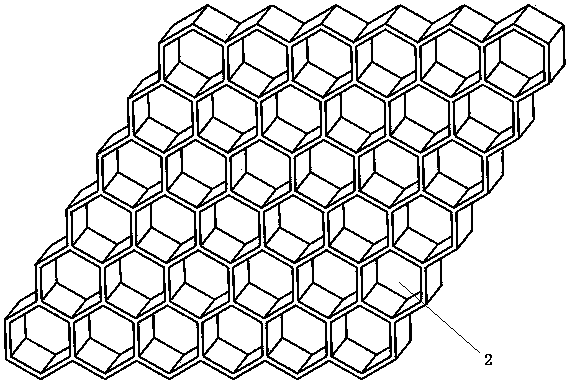

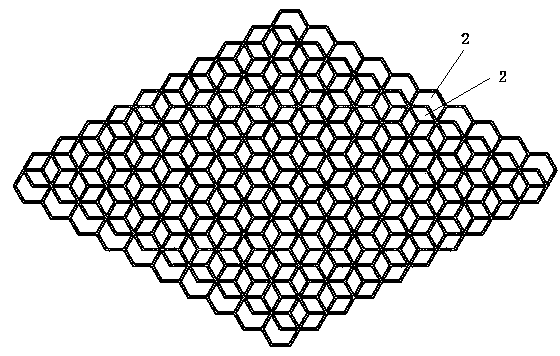

Artificial skeletal structure

ActiveCN103908357AImprove permeabilityImprove liquidityBone implantTitanium alloySkeletal structures

The invention provides an artificial skeletal structure which can lower elasticity modulus of an artificial skeleton made of biological titanium alloy to enable the artificial skeleton to be more similar to a natural skeleton. The artificial skeletal structure comprises an artificial skeleton body and is characterized in that the artificial skeleton body is internally provided with a plurality of cavities which penetrate through the artificial skeleton in the length direction, and accordingly a hollow structure in the artificial skeleton body is formed.

Owner:飞而康快速制造科技有限责任公司

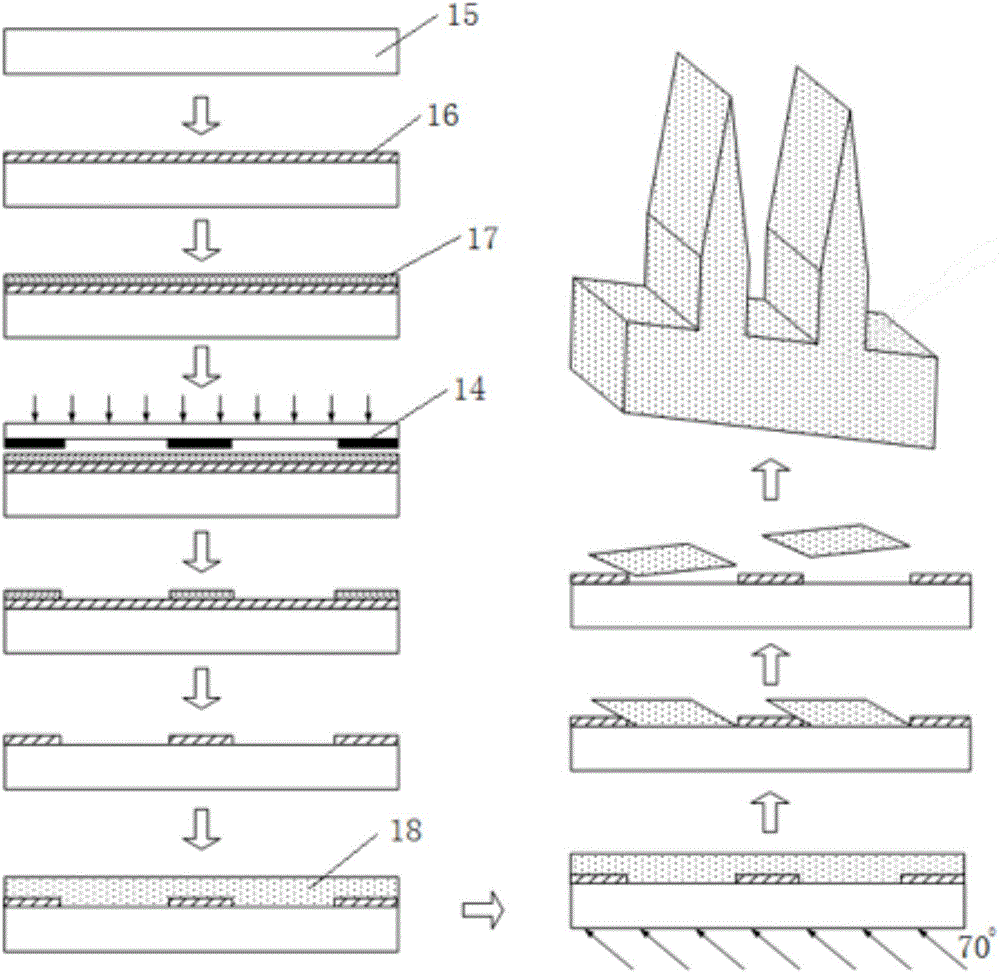

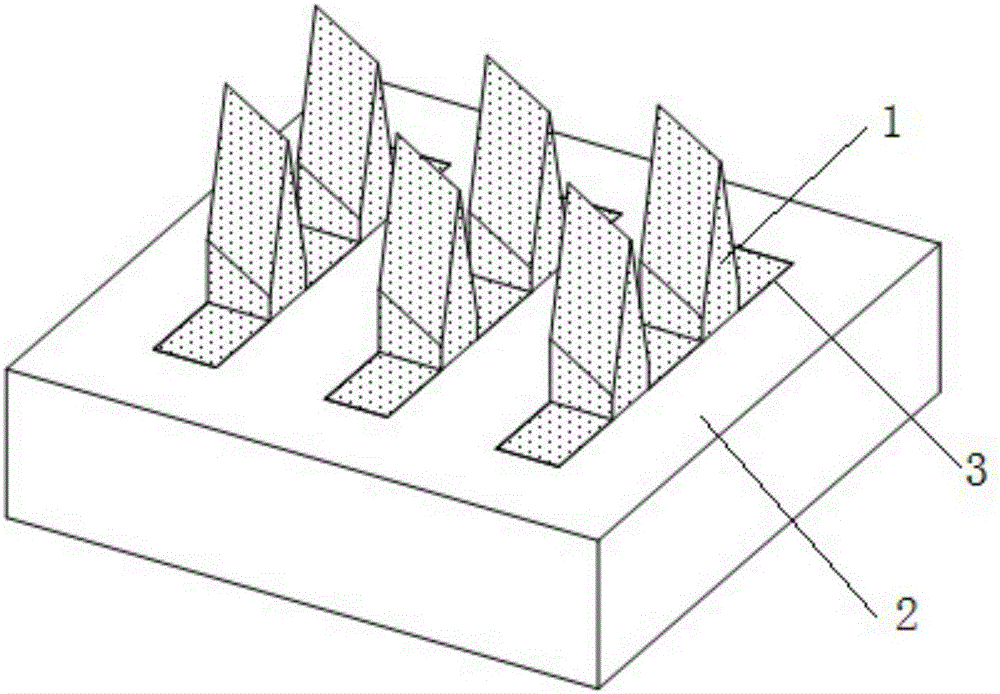

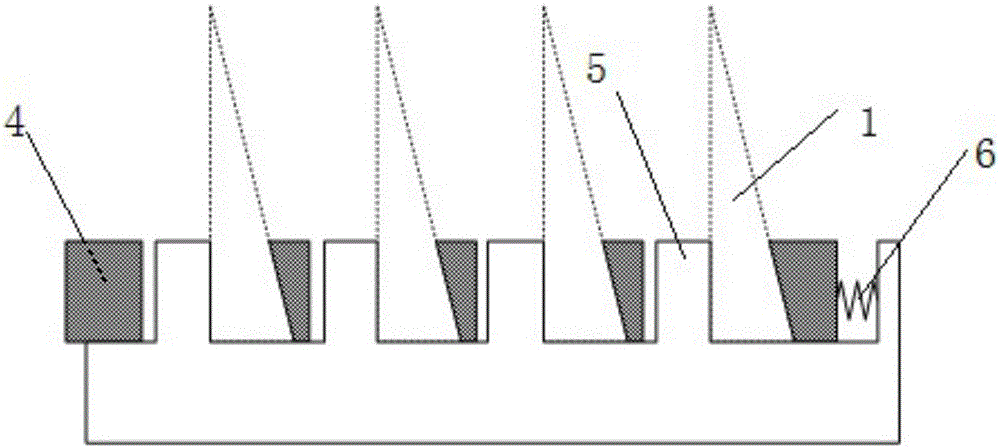

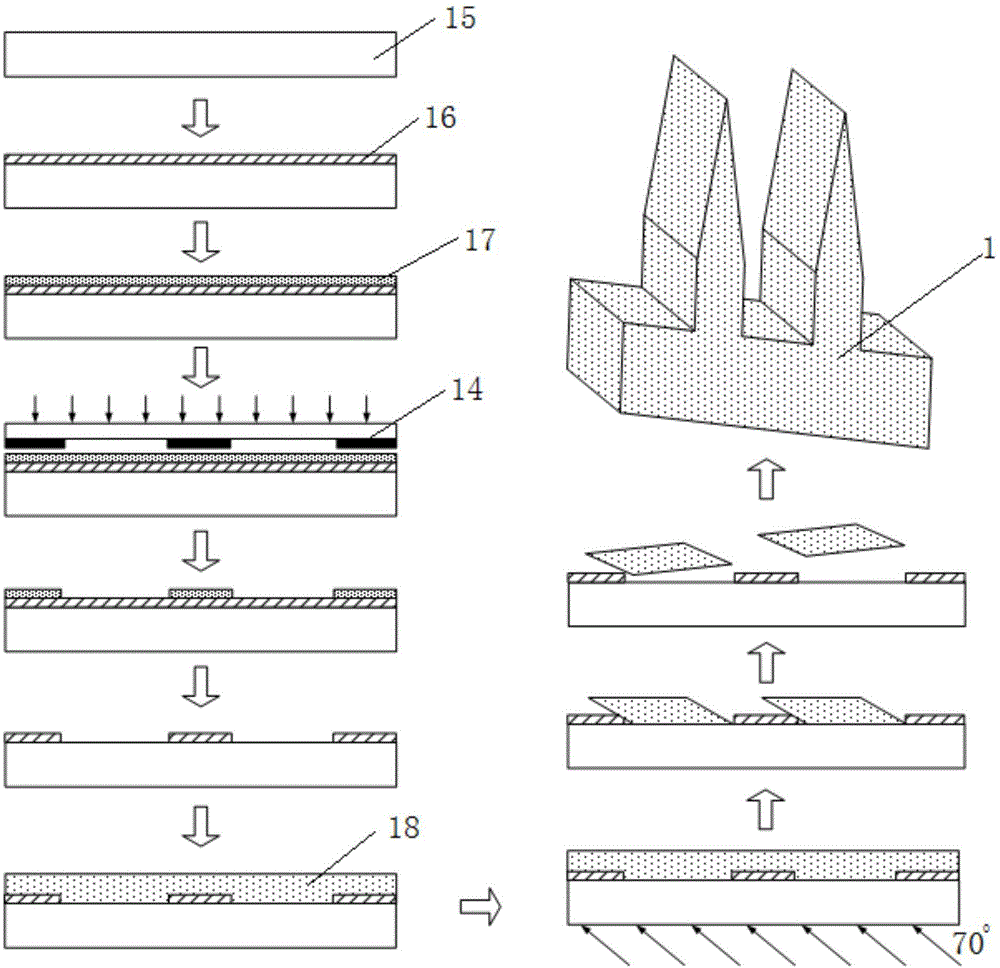

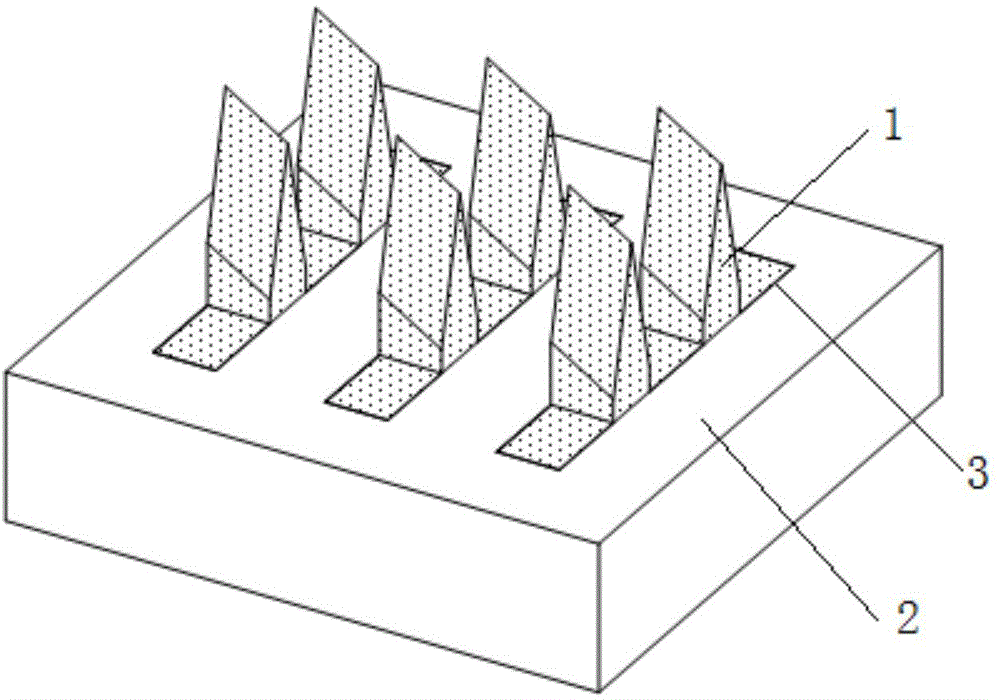

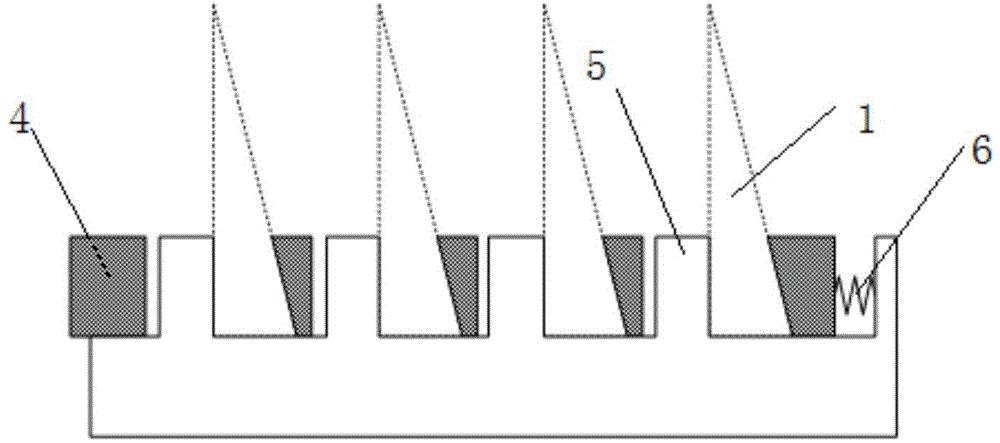

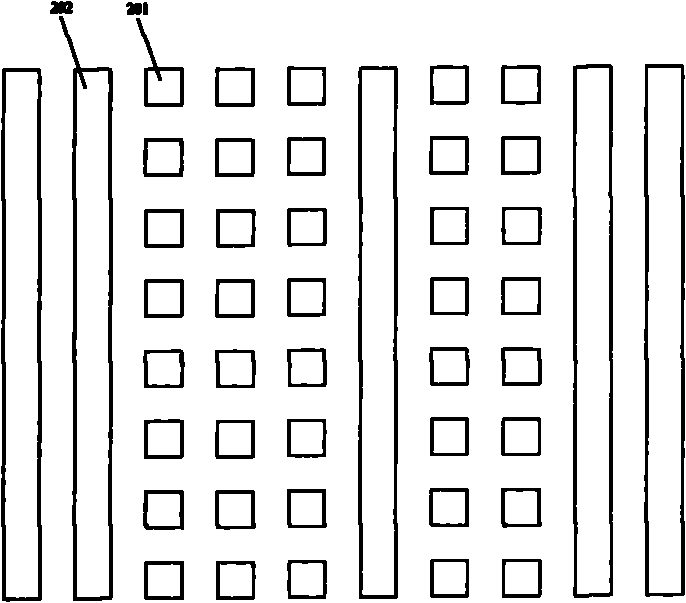

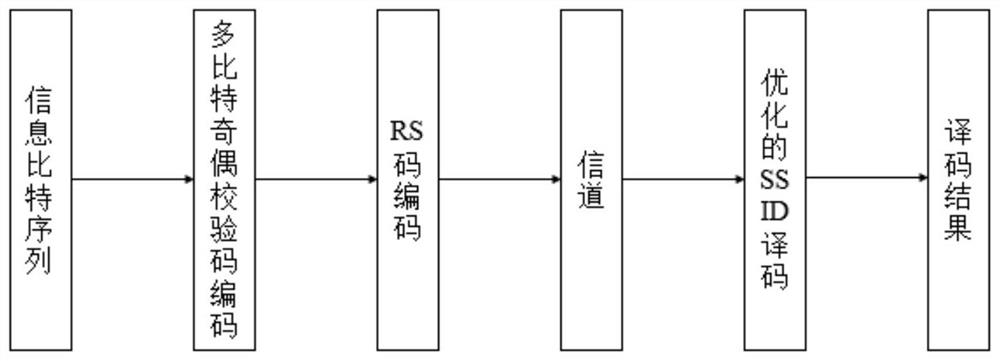

Nonplanar microneedle array and manufacturing method thereof

ActiveCN106512199AMeet density requirementsControllable shapeDecorative surface effectsMicroneedlesVolumetric Mass DensityBiomedical engineering

Owner:厦门薇针医药科技有限公司

Isoplanar microneedle array and manufacturing method thereof

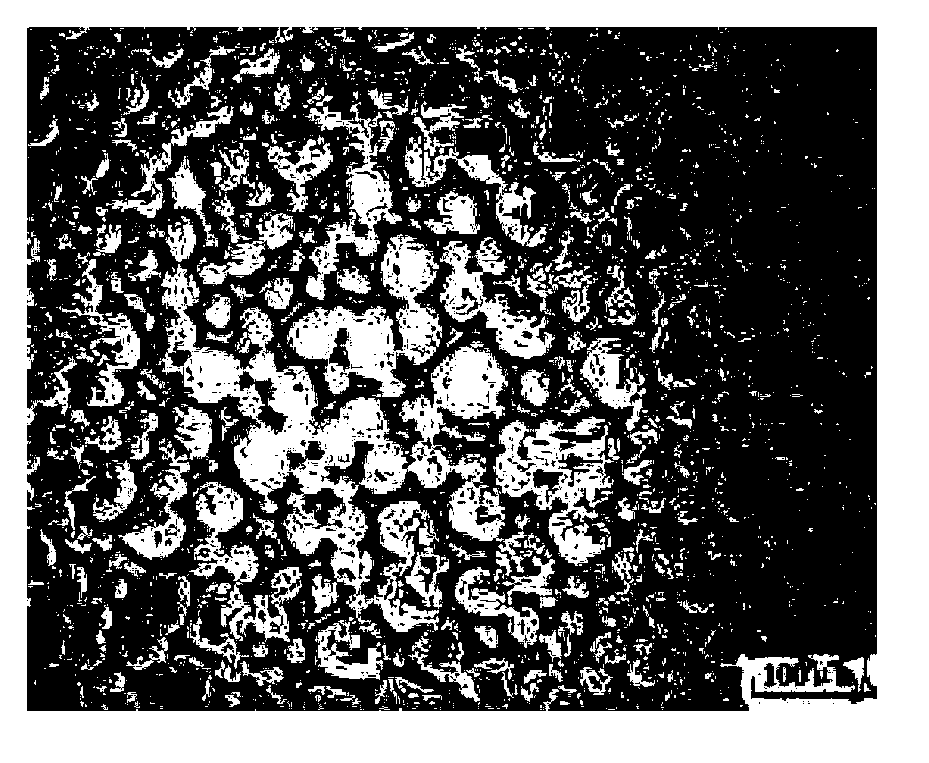

ActiveCN104056346AMeet density requirementsControllable shapeDecorative surface effectsMicroneedlesDie castingBiomedical engineering

The invention relates to an isoplanar microneedle array and a manufacturing method thereof. The isoplanar microneedle array comprises coplanar microneedles and a base plate, wherein each coplanar microneedle comprises one or more than one needle point and a base which is connected with the needle point, the needle point and the base are in a same plane, and more than two coplanar microneedles are assembled on the base plate. The manufacturing method of the isoplanar microneedle array comprises the steps of utilizing the isoplanar microneedle array as a main die, manufacturing a negative die which can be reused by utilizing a reverse die casting technology, and then manufacturing the isoplanar microneedle array by using the reverse die casting technology again. The isoplanar microneedle array and the manufacturing method which are disclosed by the invention have the beneficial effects that the shape of the needle points of the coplanar microneedles is easily controlled, the quality of the needle points is good, the needle points, the needle shape and the needle length can be ensured by utilizing the microneedle array assembled by multiple coplanar microneedles side by side, and the microneedle density requirement can be met; technologies which are used during a microneedle array manufacturing process are all more mature and are easily realized, the isoplanar microneedle array assembled side by side is just used for the main die which is used for manufacturing the negative die in a reverse die casting way if the technologies are used for batch production, the use times are few, the finished product rate of the coplanar microneedles can be ensured, and the manufacturing cost of the microneedle array is reduced.

Owner:厦门薇针医药科技有限公司

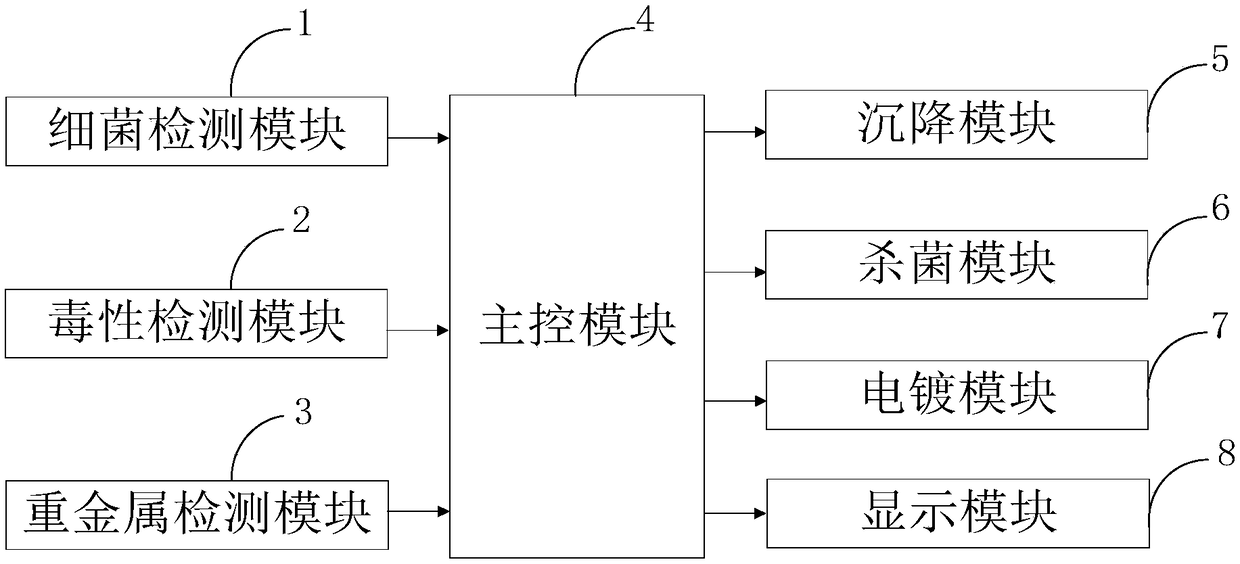

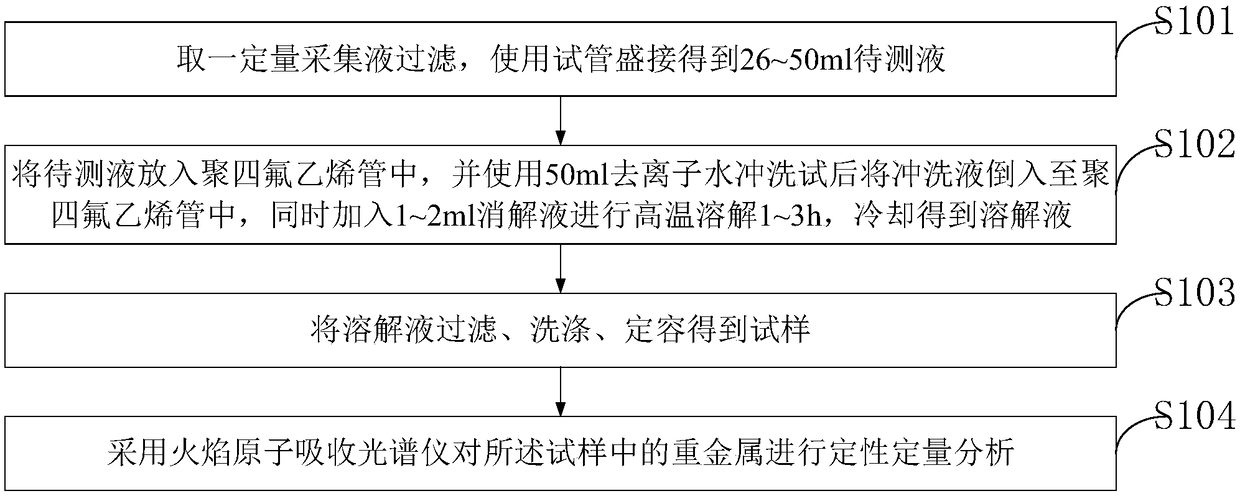

Intelligent equipment system for recycling mineral processing wastewater and detection method of intelligent equipment system

InactiveCN109081524AIn line with the actual concentrationImprove integrityWater/sewage treatment by centrifugal separationTreatment involving filtrationFresh waterMineral processing

The invention belongs to the technical field of wastewater treatment and discloses an intelligent equipment system for recycling mineral processing wastewater and a detection method of the intelligentequipment system. The intelligent equipment system comprises a bacterial detection module, a toxicity detection module, a heavy metal detection module, a main control module, a settlement module, a sterilization module, an electroplating module and a display module. After the heavy metal detection module is flushed by a certain amount of deionized water, flushing fluid is poured into a polytetrafluoroethylene tube, heavy metal ions remained on the inner wall of a test tube can be dissolved in the deionized water, ignoring of the amount of the heavy metal ions remaining on the inner wall of the test tube is avoided, generation of large accidental errors in data is reduced, and detection accuracy is improved; fresh water subjected to treatment of the electroplating module can be recycled directly after detection, and reuse of the wastewater is increased.

Owner:JIANGXI UNIV OF SCI & TECH

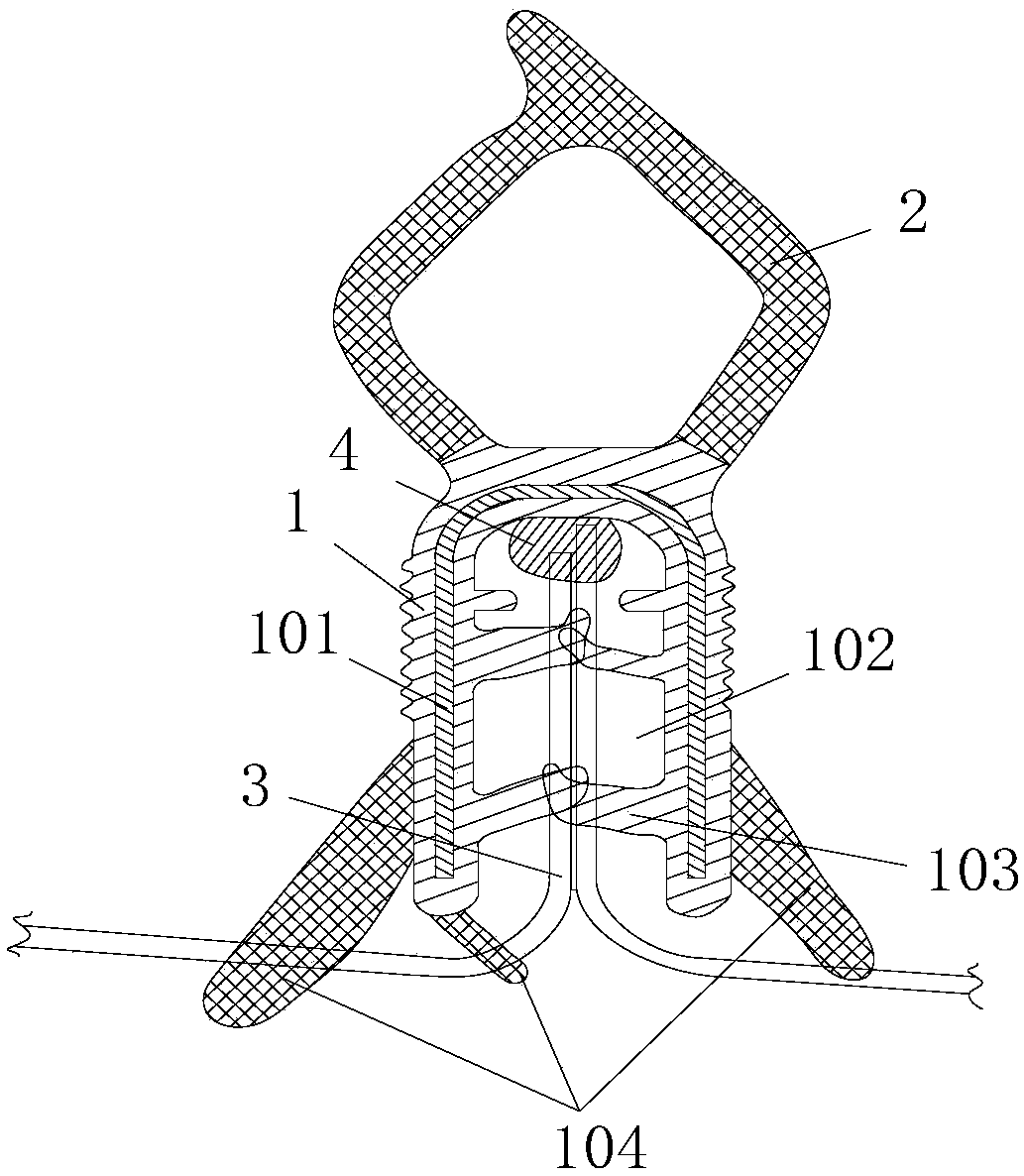

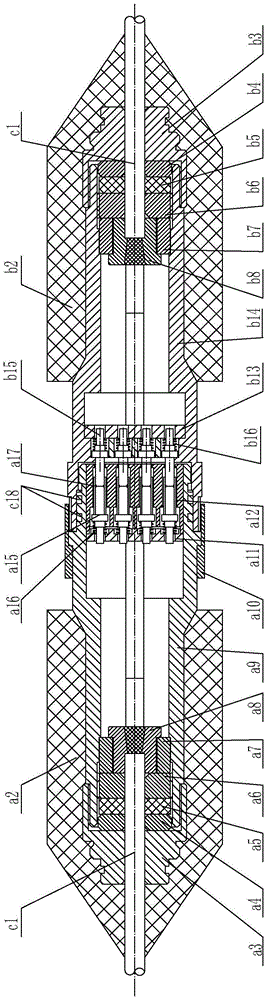

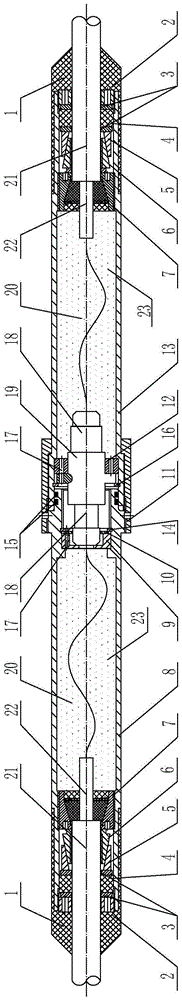

Zero-buoyancy optical cable watertight force bearing connector

ActiveCN105487180AGuaranteed Loss CouplingLow loss couplingCoupling light guidesEngineeringUnderwater noise

A zero-buoyancy optical cable watertight force bearing connector comprises a plug and a socket. The plug comprises a plug housing, a sealing tail sleeve, an O-shaped ring, a sealing assembly, a force bearing assembly and a plug butt-joint assembly. The socket comprises a socket housing, a locking nut, a sealing tail sleeve, a sealing assembly, a force bearing assembly and a socket butt-joint assembly. The plug butt-joint assembly comprises a baffle plate, an MPO optical fiber connector, a plug core and a plug retaining ring. The socket butt-joint assembly comprises an MPO optical fiber connector, an MPO optical fiber flange, a socket core and a socket retaining ring. When integral butt-joint between the plug and the socket is performed by means of a pair of MPO optical connectors through the MPO optical fiber flange, the plug housing is hermetically connected with the socket housing through the locking nut and the O-shaped ring. The zero-buoyancy optical cable watertight force bearing connector has advantages of high mechanical strength, high butt-joint coupling efficiency, high insertion loss consistency, low machining difficulty, low machining cost and long service life. The density of the zero-buoyancy optical cable watertight force bearing connector can approach the density of seawater. The zero-buoyancy optical cable watertight force bearing connector has advantages of greatly reducing resistance in towing and effectively reducing underwater noise of a system.

Owner:8TH RES INST OF CETC

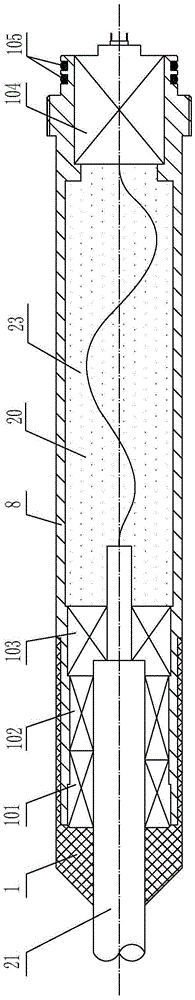

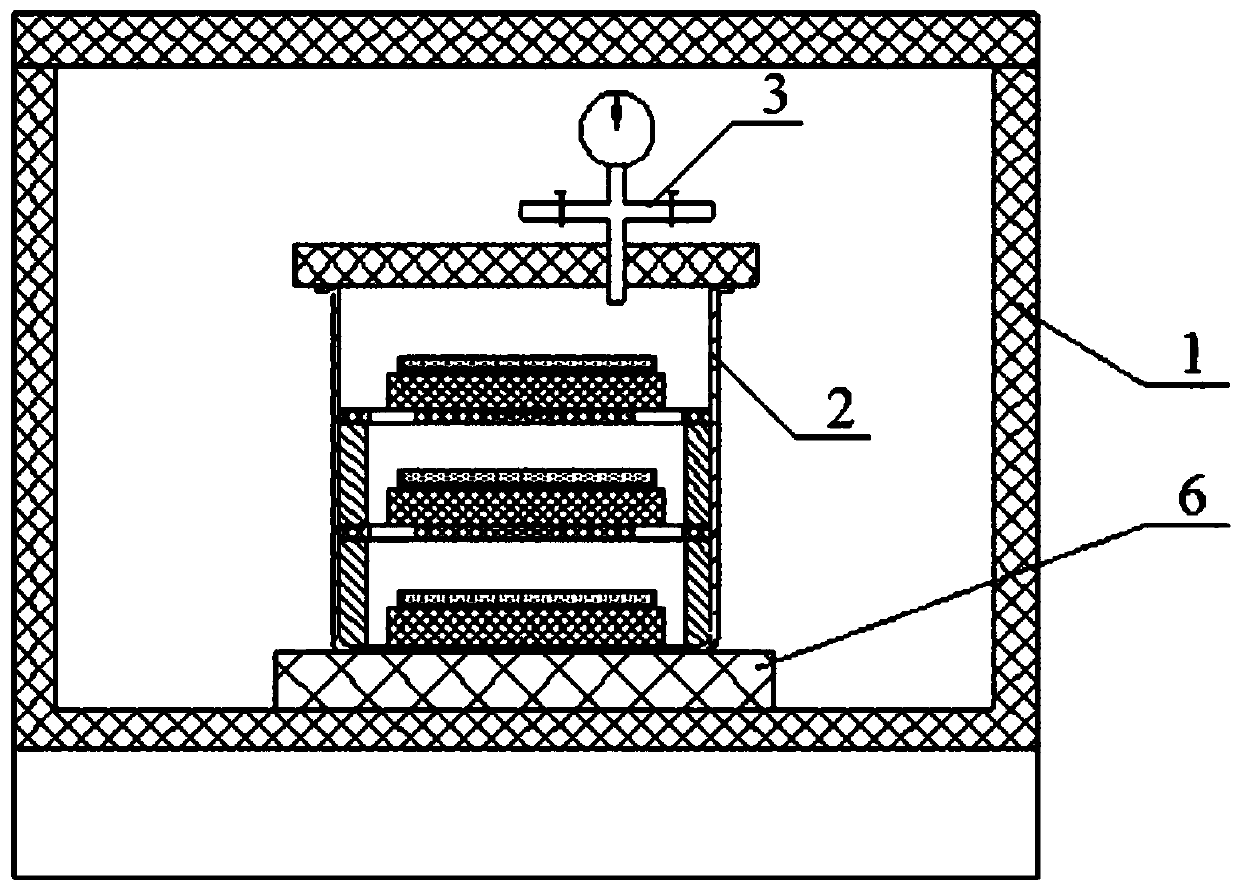

Preparation device and method of ice for complete machine ice swallowing test of aero-engine

ActiveCN111288699AReduce volume lossEasy to demouldLighting and heating apparatusIce productionTemperature controlSilicon mold

The invention belongs to the technical field of aero-engine tests, and particularly relates to a preparation device and method of ice for a complete machine ice swallowing test of an aero-engine. Thedevice comprises a temperature control freezer (1), a vacuum barrel (2) and a silica gel mold (5), wherein the vacuum barrel (2) is arranged in the temperature control freezer (1), the vacuum barrel (2) comprises a vacuum barrel body (21) and a vacuum barrel cover (22), a pressure control assembly (3) is installed on the vacuum barrel cover (22), and a partition plate assembly (4) is arranged in the vacuum barrel (2); and the silica gel mold (5) is arranged on the partition plate assembly (4). According to the preparation device of the ice for the complete machine ice swallowing test of the aero-engine, low-density ice can be prepared, the density requirement of ice for the complete machine ice swallowing test in the national military standard is met, the silica gel mold is easy to demoldand not prone to being broken, and the volume loss of the ice is reduced.

Owner:AECC SHENYANG ENGINE RES INST

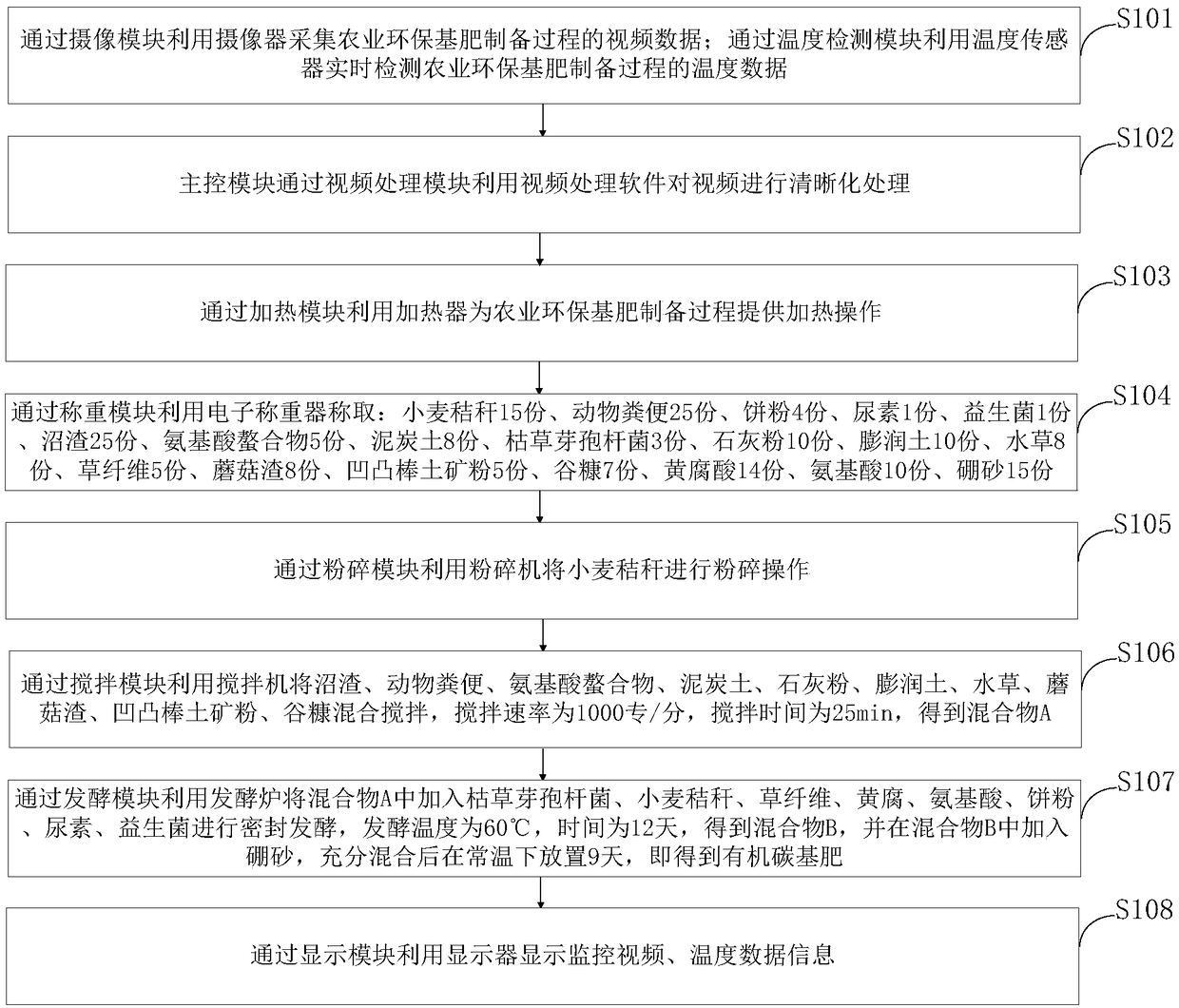

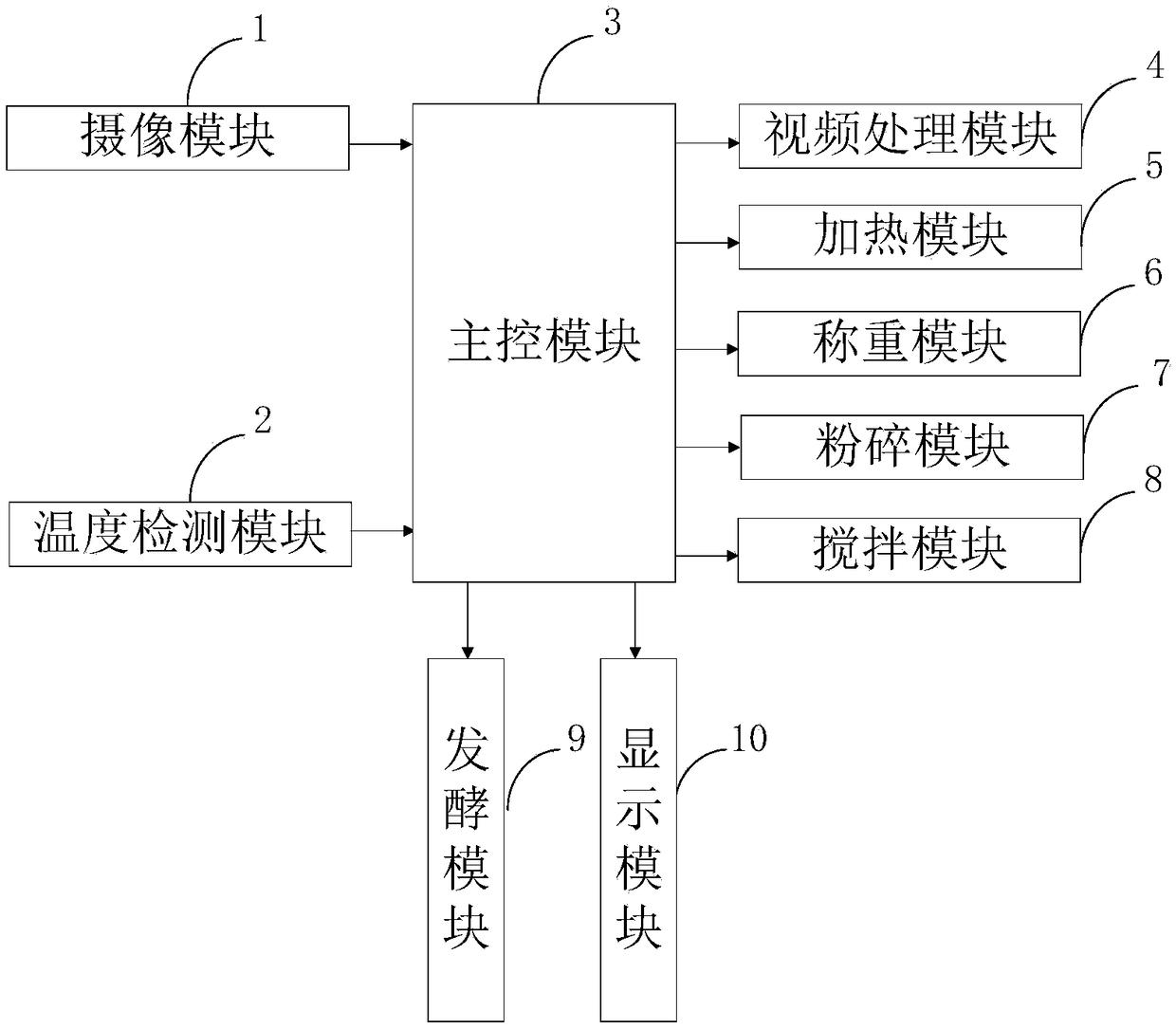

Agricultural environmentally-friendly base fertilizer and preparation method thereof

PendingCN109293434ANo pollutionImprove fertilizer efficiencyCalcareous fertilisersExcrement fertilisersVideo processingSoil fertility

The invention belongs to the technical field of preparation of base fertilizers, and discloses an agricultural environmentally-friendly base fertilizer and a preparation method thereof. The preparation method comprises that: a camera device collects video data in the preparation process of the agricultural environmentally-friendly base fertilizer through a camera; a temperature detection device real-timely detects temperature data in the preparation process of the agricultural environmentally-friendly base fertilizer through a temperature sensor; a main control device performs clearness processing on the video by using video processing software through a video processing device; a heating device supplies heating operation in the preparation process of the agricultural environmentally-friendly base fertilizer through a heater; and a weighing device weighs raw materials through an electronic weigher. The base fertilizer prepared by using the preparation method provided by the invention can improve soil and foster soil fertility, increases yield, improves quality, does not generate pollution to the environment, is pollution-free and harmless, improves the quality of a product, reducesharmful accumulation, effectively enhances the fertility of a cultivated land, and improves the nutrient supply environment of the soil.

Owner:关静

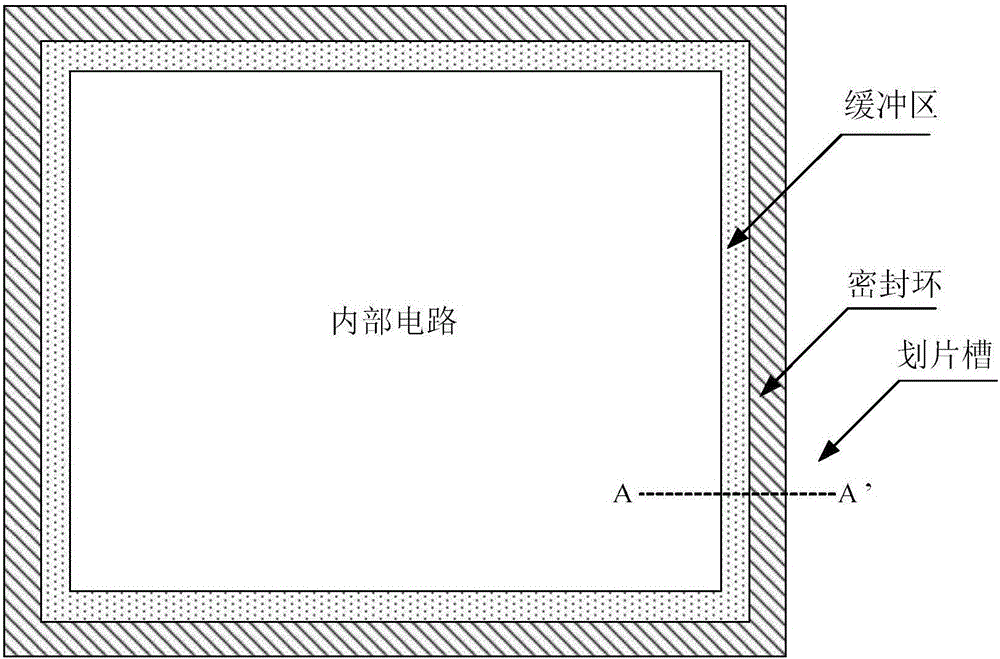

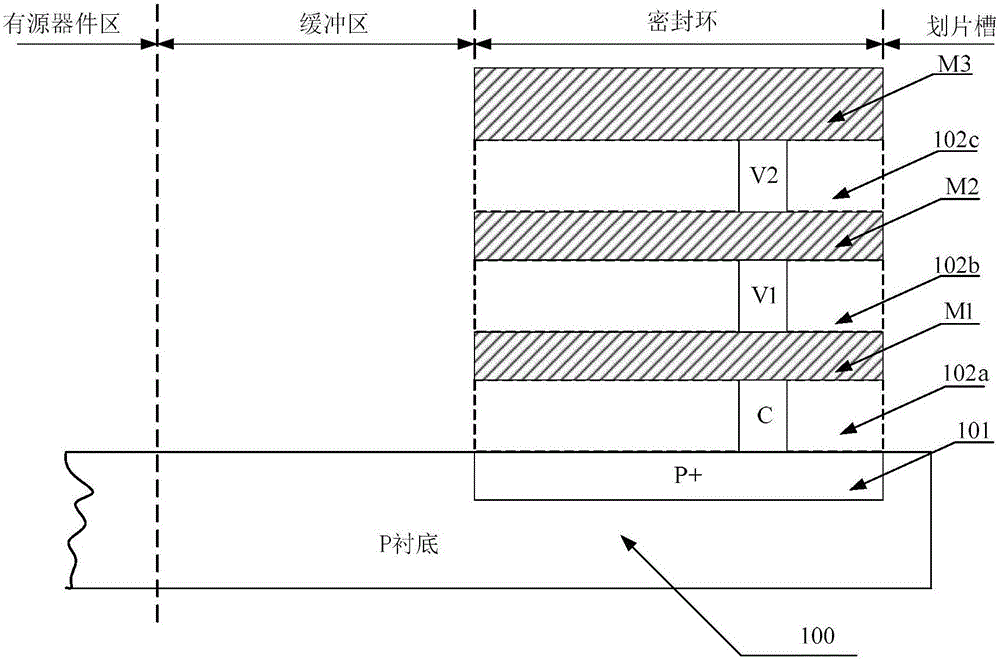

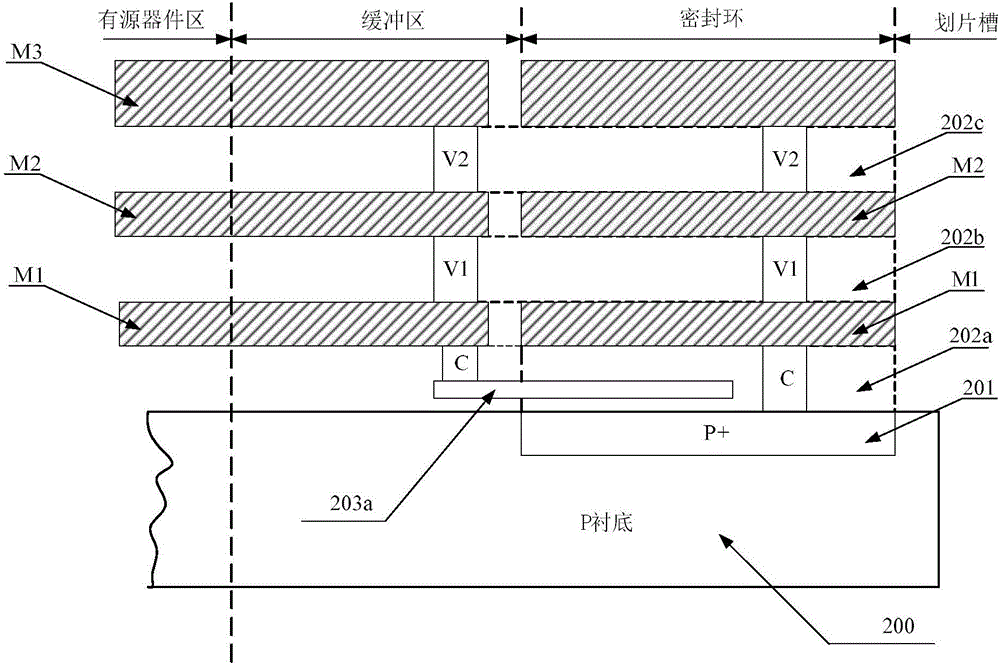

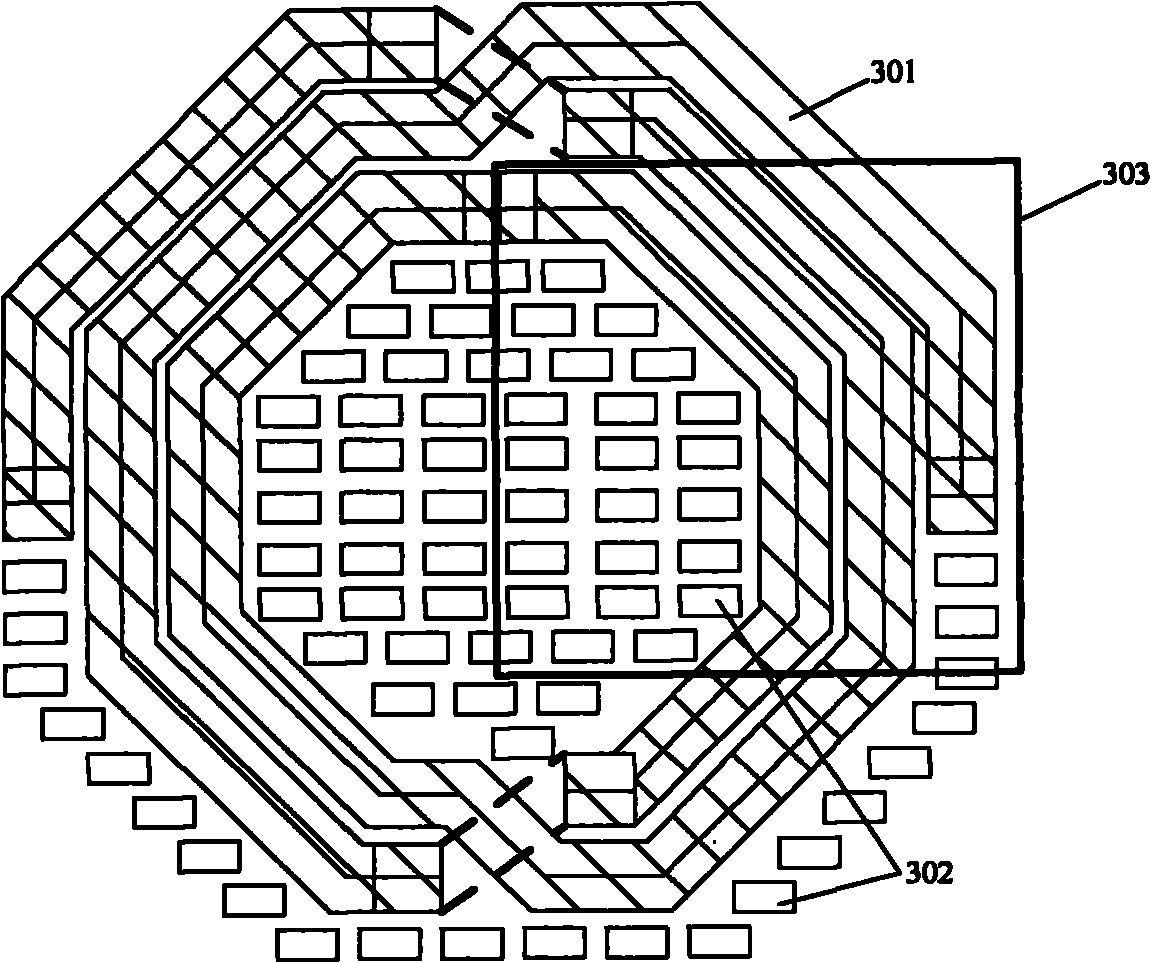

Sealing ring of integrated circuit

InactiveCN106449600AAvoid Uneven Surface WrappingIncrease capacitanceSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitElectrical connection

The invention provides a sealing ring of an integrated circuit. The sealing ring comprises a substrate layer, a doping region, a laminated structure of dielectric layers and metal layers, and a capacitor, wherein the doping region is formed in the substrate layer; the laminated structure of dielectric layer and metal layers is formed on the doping region, and the metal layers and the doping region realize electrical connection through connecting holes; the capacitor is formed in the laminated structure, and a first pole plate and a second pole plate of the capacitor are connected with a substrate and an internal circuit through the metal layers in the laminated structure and metal layers in a buffer region respectively. According to the sealing ring of the integrated circuit provided by the invention, under the condition of not influencing the area of the integrated circuit or changing the function and performance of the sealing ring, the structure of an existing sealing ring of the integrated circuit is improved, so that the integrated circuit meets the density requirement of polycrystalline silicon and adds a filtering performance at the same time.

Owner:SHANGHAI NATLINEAR ELECTRONICS CO LTD

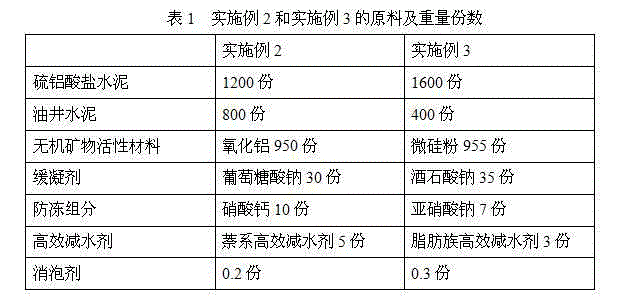

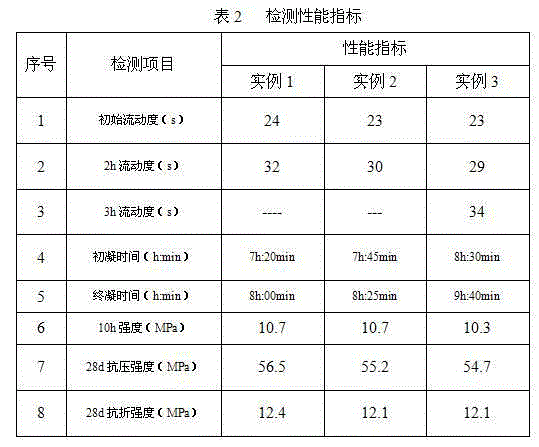

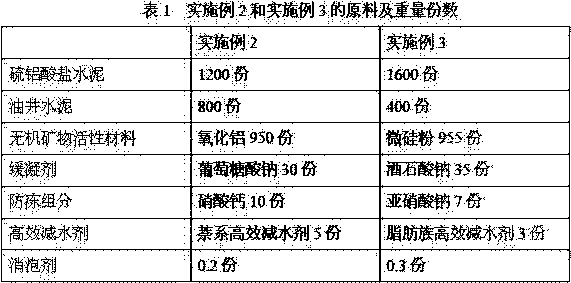

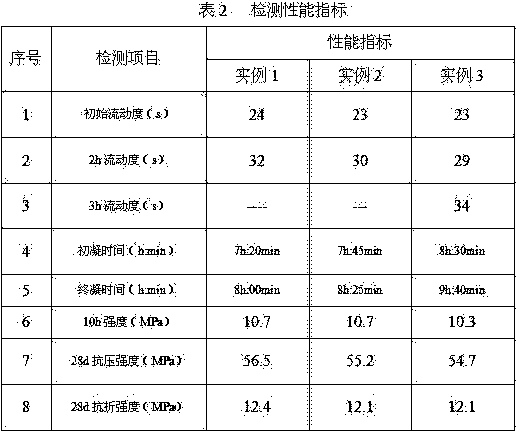

Low temperature rapid hardening grouting material for offshore oil well and preparation method thereof

The invention relates to a low temperature rapid hardening grouting material for an offshore oil well. The low temperature rapid hardening grouting material for the offshore oil well comprises the following raw materials in parts by weight: 2,000 parts of gel materials, 950-965 parts of inorganic mineral active materials, 25-35 parts of retarders, 5-10 parts of anti-freezing ingredients, 3-5 parts of high efficiency slushing agents, and 0.1-0.3 part of defoaming agents, wherein the gel materials are quick-hardening sulphate aluminium cement and oil well cement; the mass ratio of the quick-hardening sulphate aluminium cement and oil well cement is 5:5-8:2. The invention also provides a preparation method thereof. The grouting material is suitable for construction under a well cementation low-temperature environment, slurry can maintain better mobility and is high in early strength, the slurry is full without shrinkage, the long-term strength is high, and the well cementation construction time and the underground grouting environment parameter requirement are effectively ensured.

Owner:河北铁园科技发展有限公司

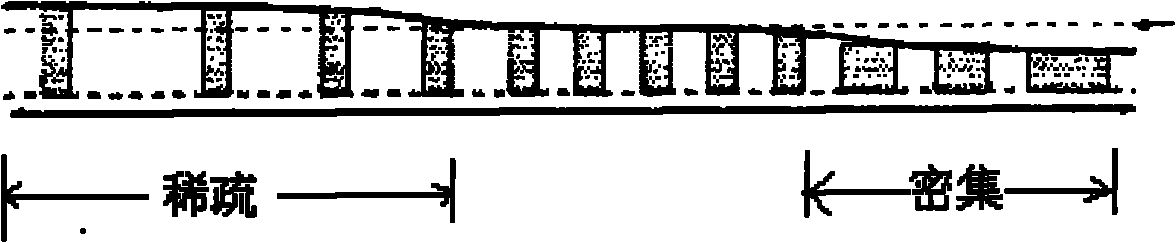

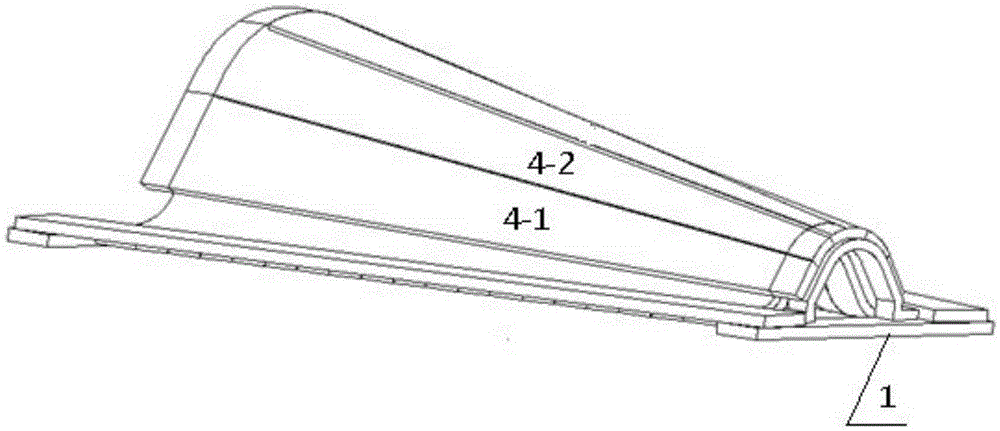

Figure filler structure inserted about inductor

InactiveCN102082143AReduced eddy current effectRaise the quality factorSemiconductor/solid-state device detailsSolid-state devicesInductorMaterials science

The invention discloses a figure filler structure inserted about an inductor. The figure filler structure are characterized by a plurality of square metal blocks with the same height as an inductor metal coil, the square metal blocks are inserted in an inside area and an outside area of the inductor metal coil which is positioned on a top metal layer; the side length of the square metal block is equal to a first minimum design rule which is the minimum measurement allowed by the technology; the density of the figure filler structure is not less than a second minimum design rule which is the minimum value for the density of the figure filler structure; the distance between the square metal blocks can be any measurement value in the scope from a third minimum design rule to the maximum distance value which is the distance between the square metal blocks when the density of the figure filler structure is equal to the second minimum design rule; and the third minimum design rule is the minimum distance between metals allowed by the technology. The invented structure effectively enhances the quality factor of inductor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

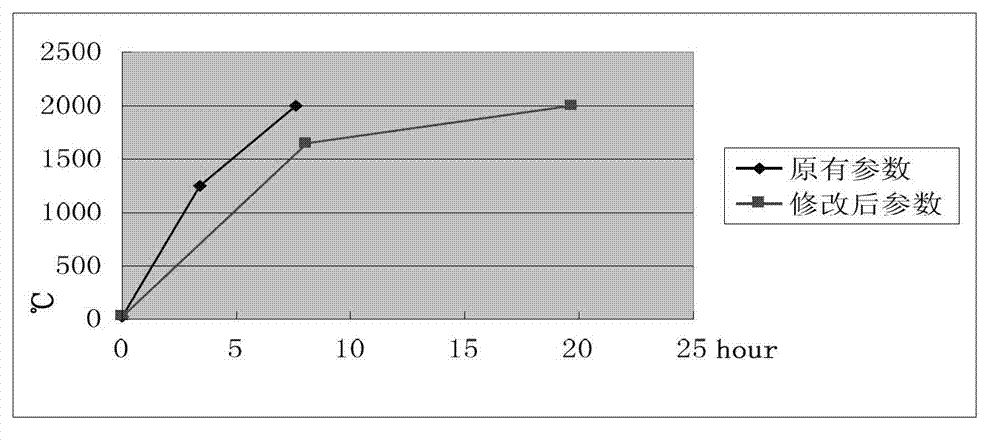

Method for heating and melting precast shaped filler in sapphire crystal growth

InactiveCN103243388AMeet density requirementsReduce air bubble contentAfter-treatment apparatusPolycrystalline material growthCrucibleLarge size

The invention discloses a method for heating and melting a precast shaped filler in sapphire crystal growth, which comprises the following steps: starting a heating system to heat from 25 DEG C to 1650 DEG C, wherein the heating gradient is 200 DEG C / h; and after the temperature reaches 1650 DEG C, changing the temperature increase gradient to 30 DEG C / h, and further heating to 2000 DEG C until a block material is completely molten. The precast shaped filler disclosed by the invention causes less bubble defects in comparison with a crystal block treated by a flame method; the packed density of the precast shaped filler can be up to 2.6-2.8 g / cm<3>; and more materials can be filled under the condition of not changing the size of a crucible, thereby meeting the requirements for the density of the raw material in large-size sapphire crystal growth in China at present.

Owner:苏州海铂晶体有限公司

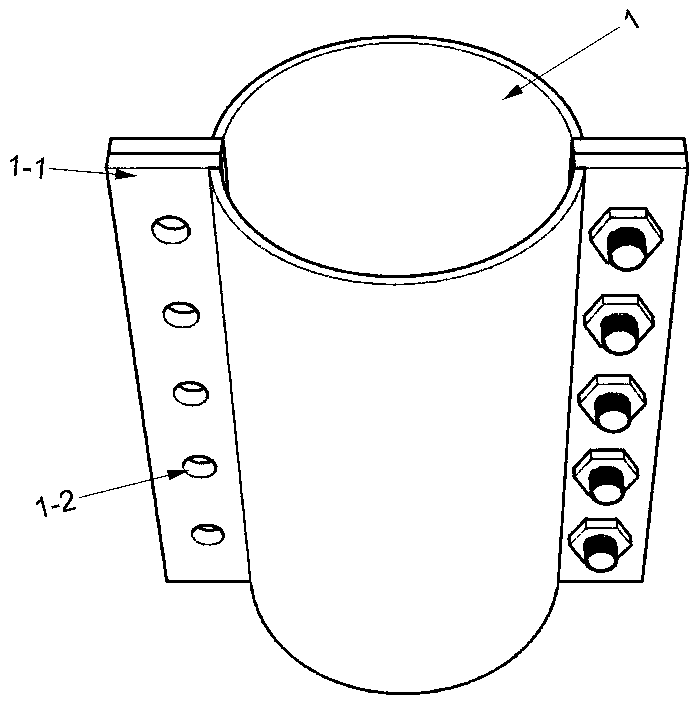

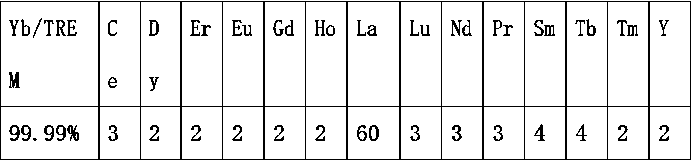

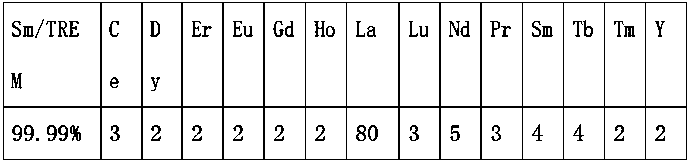

Manufacturing method and device used for preparing rare earth metal target material through lanthanum thermal reduction

InactiveCN109252141AHigh yieldNot easily oxidizedVacuum evaporation coatingSputtering coatingVacuum pumpingDistillation

The invention discloses a manufacturing method used for preparing a rare earth metal target material through lanthanum thermal reduction. The manufacturing method comprises following steps: a high purity rare earth oxide and high purity metal lanthanum chip prepared through calcium reduction method are mixed at a certain ratio, an obtained mixture is introduced into a stainless steel die for pressing so as to obtain blocks; the blocks are introduced into a vacuum reducing furnace crucible, vacuum-pumping heating distillation is carried out, top preset of a special target die is adopted for collecting so as to obtain a rare earth high purity metal blank; and the blank is subjected to surface processing so as to obtain the rare earth metal target material. The preparation process of the rareearth metal target material is short; the purity is high; and the cost is low.

Owner:包头市镧系新材料科技有限公司

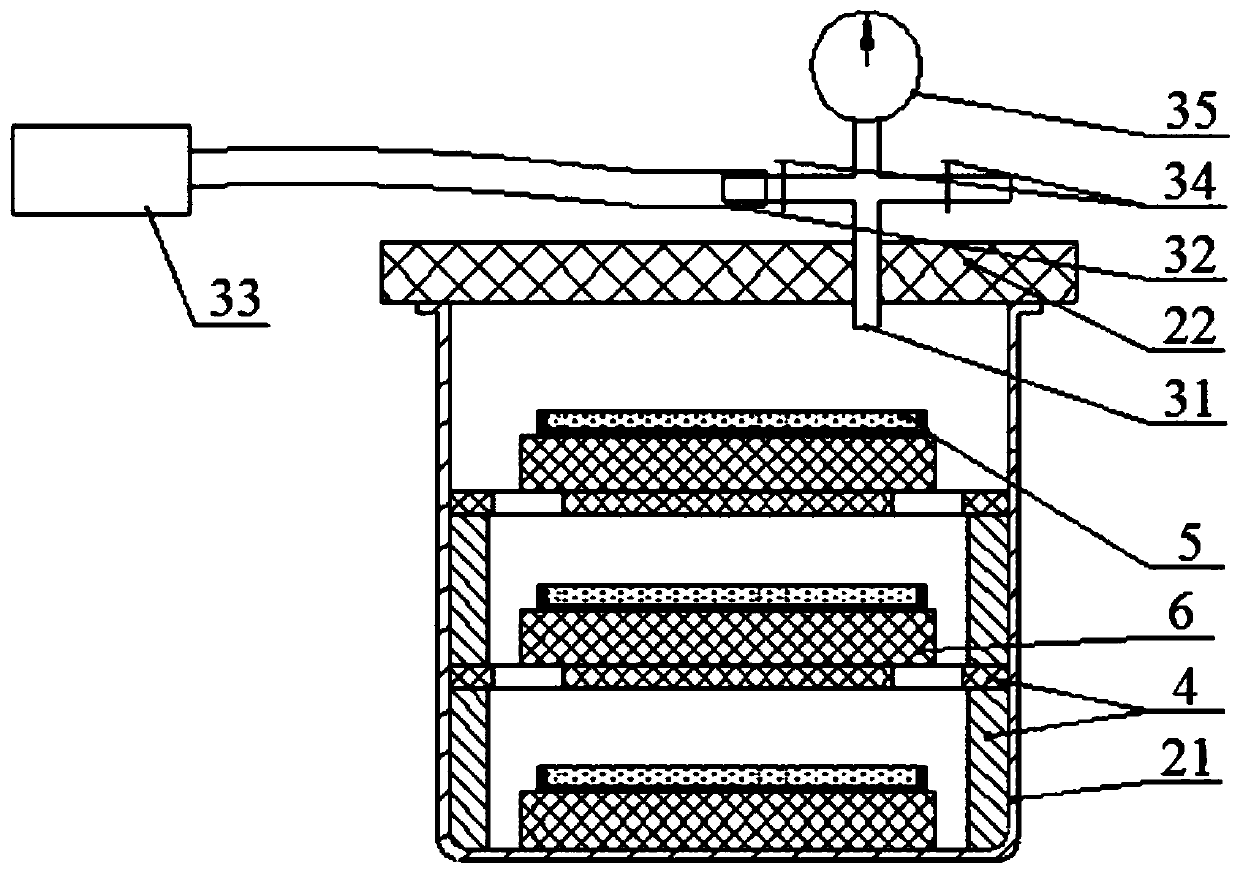

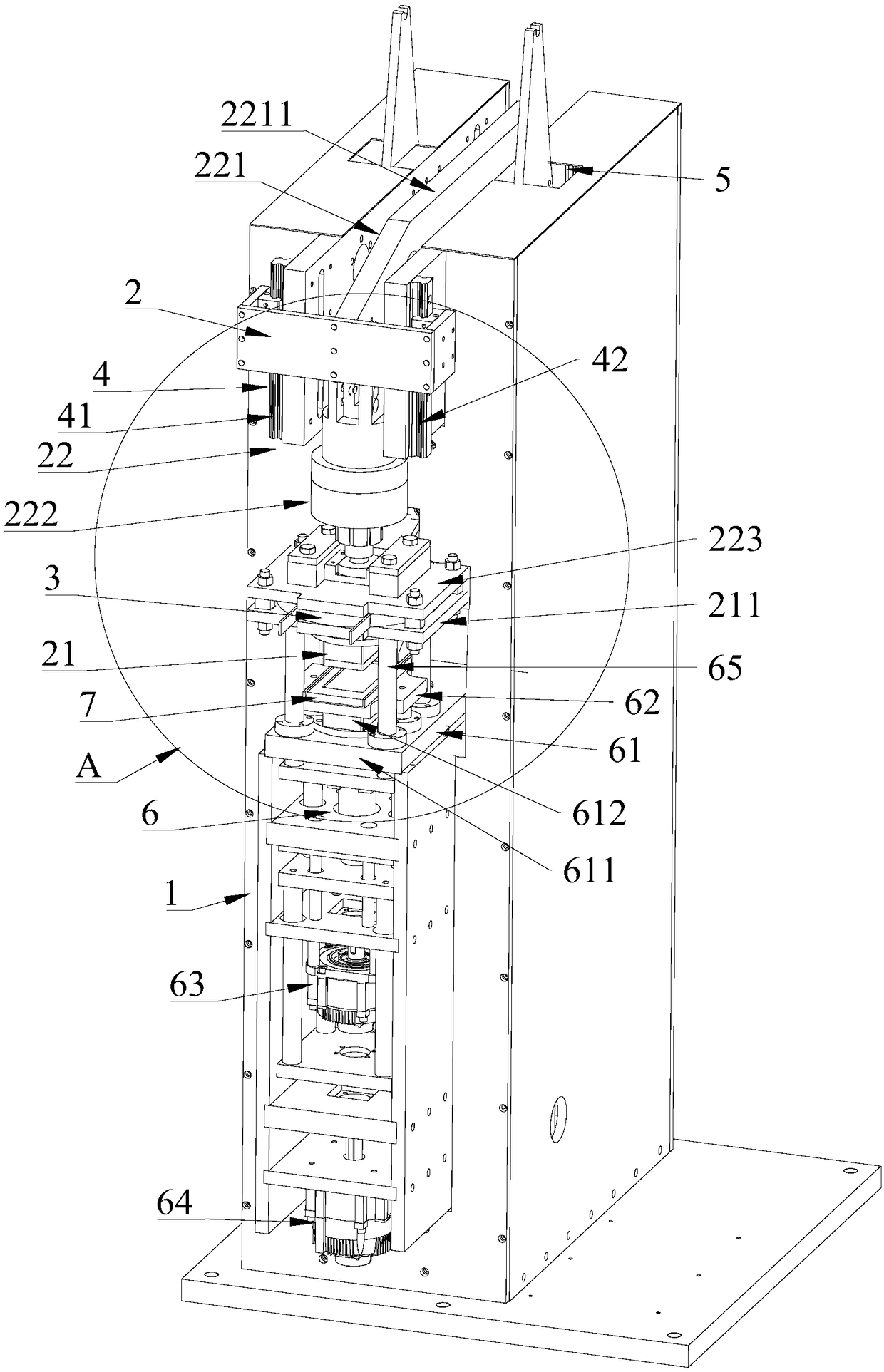

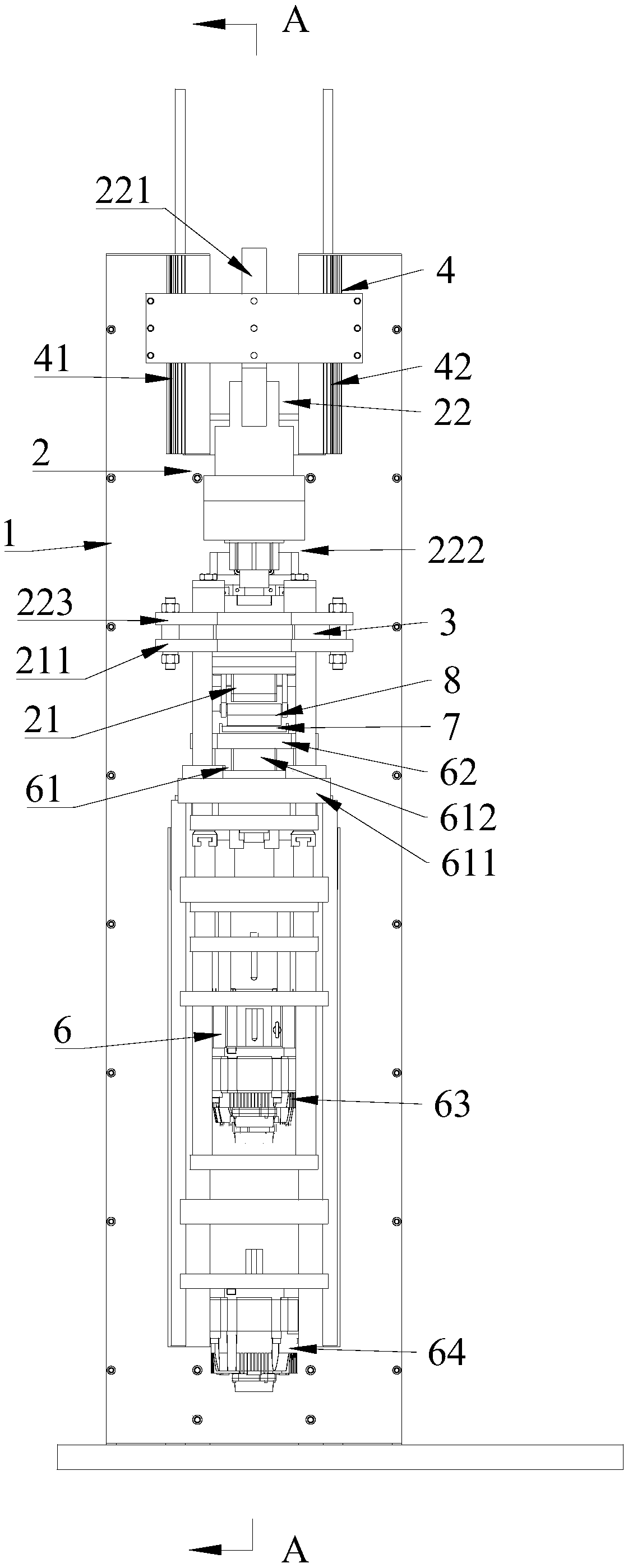

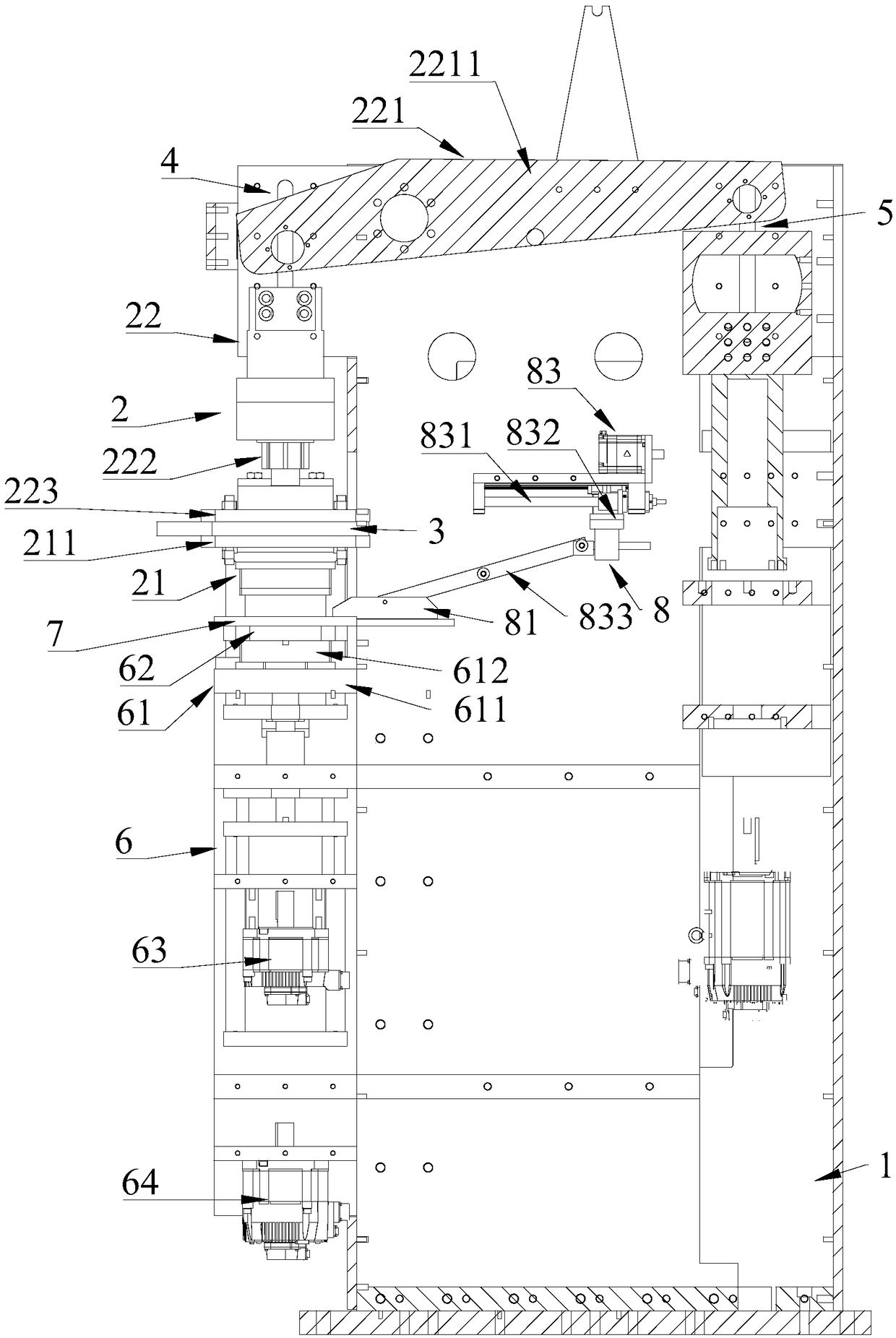

Powder pressing machine

The invention relates to a powder pressing machine. The powder pressing machine comprises a rack, an upper punching device, a lower punching device and a die device, wherein the upper punching deviceand the lower punching device are respectively located on the upper and lower sides of the die device, the lower punching device comprises a lower punch assembly which is installed on the rack, a connecting seat which is connected with the die device and a first driving mechanism which is in driving connection with the connecting seat, the die device can move up and down relative to an upper punchassembly under the action of the first driving mechanism, the upper punching device is provided with the upper punch assembly, a second driving mechanism and a coil assembly, the coil assembly is installed between the upper punch assembly and the second driving mechanism, and an electric box is electrically connected to the coil assembly. Compared with the prior art, the powder pressing machine is combined with a servo punching mode and a pulse punching mode so as to punch a pressing piece for two times, so that the density of finished products is greatly increased.

Owner:东莞市新日宝成形机器设备有限公司

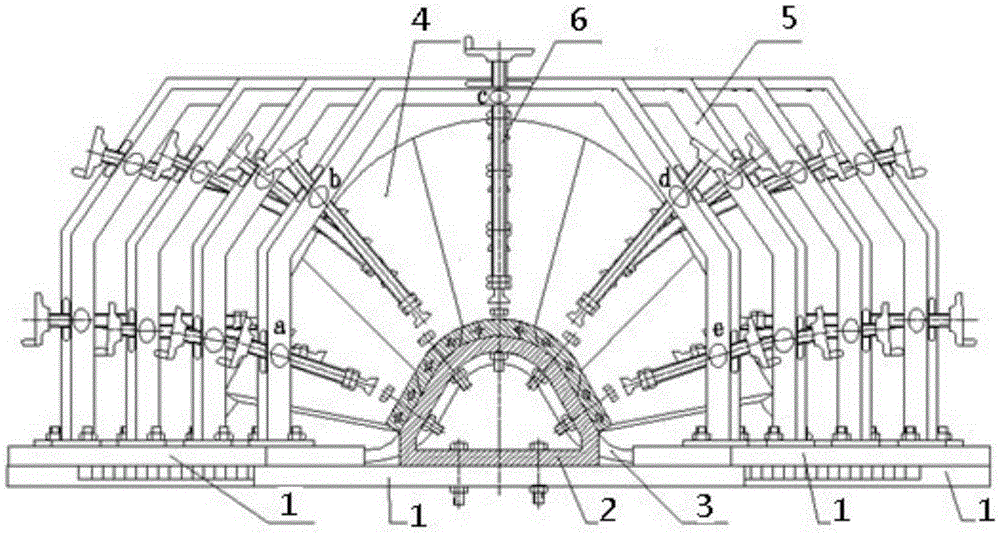

Multi-point pressurizing device for controlling layer density and uniformity of complex surface stitched fabric

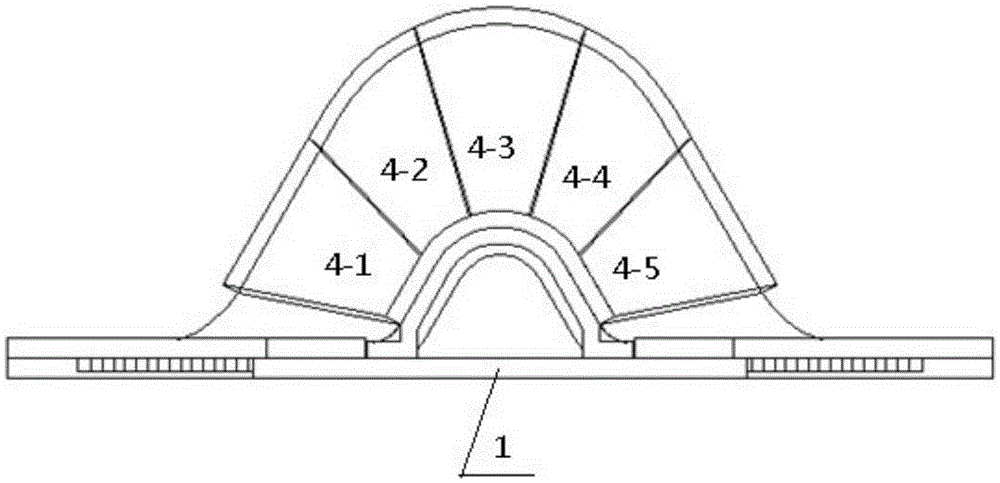

The invention discloses a multi-point pressurizing device for controlling layer density and uniformity of a complex surface stitched fabric. The device comprises a male mold, a female mold and a multi-point pressurizing component, wherein the multi-point pressurizing component comprises an arched bracket and a pressurizing component; the arched bracket is arranged at the outer periphery of the female mold; the pressurizing component comprises a screw rod, a rotating handle and a rubber pad; the screw rod is in threaded connection to the arched bracket; one end of the screw rod penetrates through the arched bracket to extend to the outer surface of the female mold, and the other end is left outside the arched bracket; the rotating handle is connected to one end, left outside the arched bracket, of the screw rod; and the rubber pad is arranged at the end part of one end, extending to the outer surface of the female mold, of the screw rod. The multi-point pressurizing device for controlling the layer density and the uniformity of the complex surface stitched fabric is simple in structure, is easy to be machined and assembled, is convenient for use, and can effectively control the layer density and the uniformity of the complex surface three-dimensional fabric to improve the quality of the complex surface stitched fabric.

Owner:SINOMA SCI & TECH

Corrosion-resistant large-specific gravity titanium alloy sphere and manufacturing method thereof

ActiveCN101482183AStructural Design ImplementationAchieve spheroid preparationOperating means/releasing devices for valvesLift valveVolumetric Mass DensityTitanium alloy

The invention discloses a corrosion-resistance high-specific gravity titanium alloy sphere and a manufacturing method thereof. The sphere is prepared by coating a pure titanium or titanium alloy material on a shot surface layer; the wall thickness of the pure titanium or the titanium alloy outside of the metal shot is more than 2mm. The manufacture method thereof is as follows: the shot is fixedly arranged in the spherical center of a black lead die; drilling is correspondingly carried out on the shot and the black lead wall one by one and pure titanium or titanium alloy wires are used for connection; then the titanium alloy material is molt and cast; finally a sphere cast is processed so as to meet demands. The sphere of the invention has a density approaching to a steeliness sphere which can meet the density demands of the sphere; the sphere has the corrosion resistance and eroding resistance performances equivalent to the pure titanium or titanium alloy, can improve the service life of a sphere in a floating valve used for a boat, and enhance the reliability of a floating device. The application prospect of the invention is good and the economic benefit is obvious.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Preparation method of the high-density iridium alloy billet

The invention discloses a high-density iridium alloy billet and a preparation method of the high-density iridium alloy billet. The high-density iridium alloy billet contains 0.1%-0.5% of tungsten by weight, 40ppm-80ppm of thorium, and the balance of iridium and unavoidable impurities. The preparation method includes the steps as follows: according to the requirement for the components of the final iridium alloy billet, conducting high energy activation on tungsten powder, tungsten-thorium alloy powder and iridium powder by adopting a high-energy ball mill, uniformly mixing the tungsten powder, the tungsten-thorium alloy powder and the iridium powder, then placing the mixed powder into a vacuum oven to dry so as to obtain a high-energy activated mixed powder, later pressing and moulding the high-energy activated mixed powder in a mould pressing or cold isostatic pressing way to botain a powder pressed billet, then placing the powder pressed billet in a high-temperature sintering furnace to sinter, and cooling along with the furnace to obtain the high-density iridium alloy billet. In the invention, high-energy ball milling activation and mixing in batches are adopted, thus achievingthe uniform distribution of trace thorium in the alloy powder and reducing sintering activation energy; and the high-density iridium alloy billet which meets the requirements of an iridium alloy applying piece and follow-up hot working on the density of the billet is prepared, and the relative density achieves above 95%.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

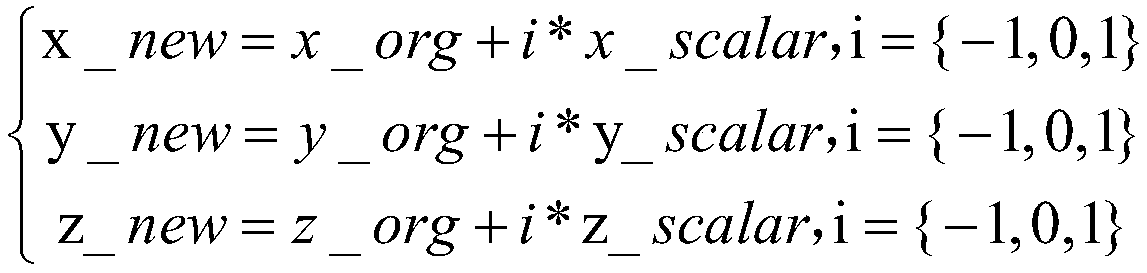

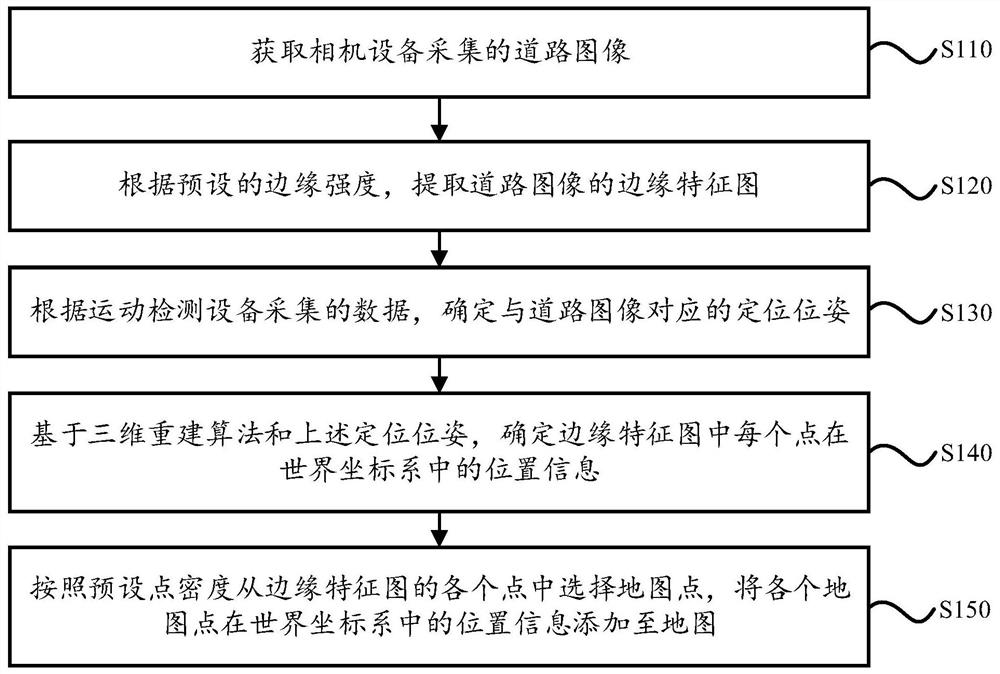

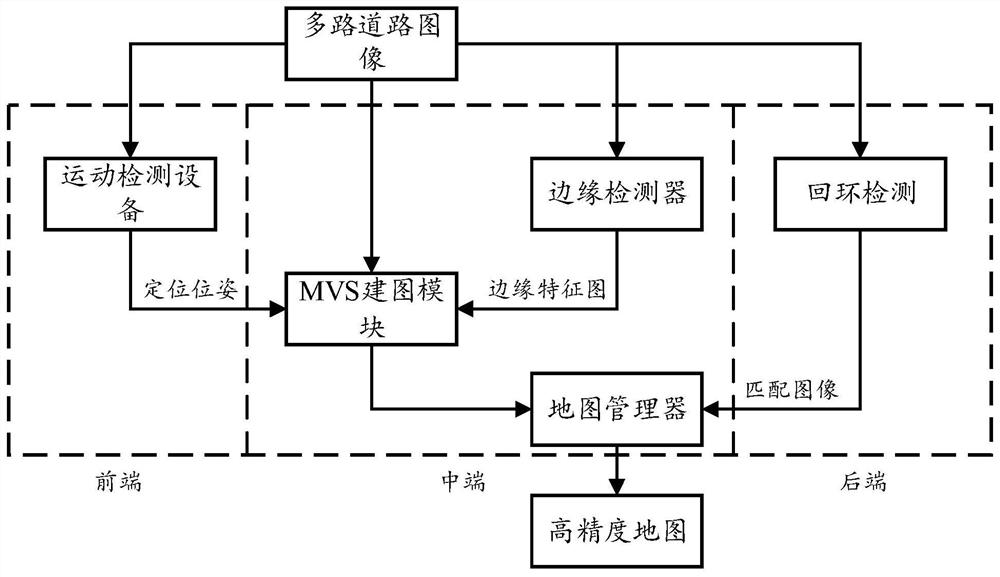

Vision-based mapping method and device and vehicle-mounted terminal

PendingCN112308904AIncrease the amount of effective informationRich edge features and anti-noiseInstruments for road network navigationImage analysisPattern recognitionComputer graphics (images)

The embodiment of the invention discloses a vision-based mapping method and device and a vehicle-mounted terminal. The method comprises the following steps: acquiring a road image acquired by camera equipment; extracting an edge feature map of the road image according to preset edge intensity; determining a positioning pose corresponding to the road image according to the data acquired by the motion detection equipment; determining position information of each point in the edge feature map in a world coordinate system based on a three-dimensional reconstruction algorithm and the positioning pose; and selecting map points from all points of the edge feature map according to preset point density, and adding position information of all the map points in the world coordinate system to a map, wherein the positioning pose is a pose in a world coordinate system where the map is located. By applying the scheme provided by the embodiment of the invention, the effective information amount for visual positioning in the map can be increased.

Owner:BEIJING CHUSUDU TECH CO LTD

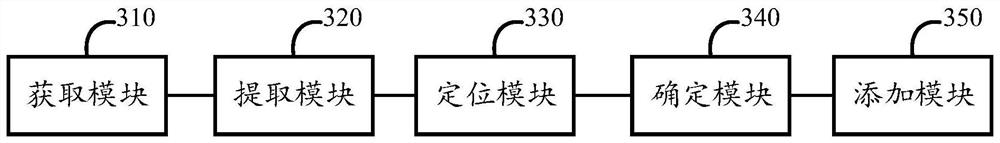

Preparation method of self-lubricating copper-based powder metallurgy structural part for helicopter

PendingCN112536436AGood self-lubricating performanceWell mixedTransportation and packagingMetal-working apparatusParaffin waxPowder metallurgy

The invention provides a preparation method of a self-lubricating copper-based powder metallurgy structural part for a helicopter. The preparation method comprises the steps that 1, copper metal powder, tin metal powder, graphite and paraffin are selected according to the requirements of the structural part; step 2, copper and tin metal powder are fully and uniformly mixed with graphite and paraffin to obtain uniformly mixed powder; and step 3, the uniformly mixed powder is pressed into a green body by adopting isostatic cool pressing, and the green body is sintered in an H2 protective atmosphere. By adding the graphite, the self-lubricating property of the structural part can be improved; and paraffin is added, it can be guaranteed that graphite with the large density difference is uniformly mixed with copper and tin metal powder, the influence of component segregation caused by the density difference can be eliminated, and the density requirement is met.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

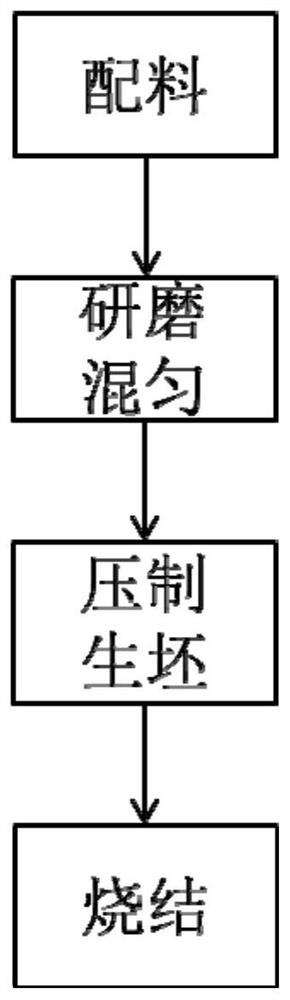

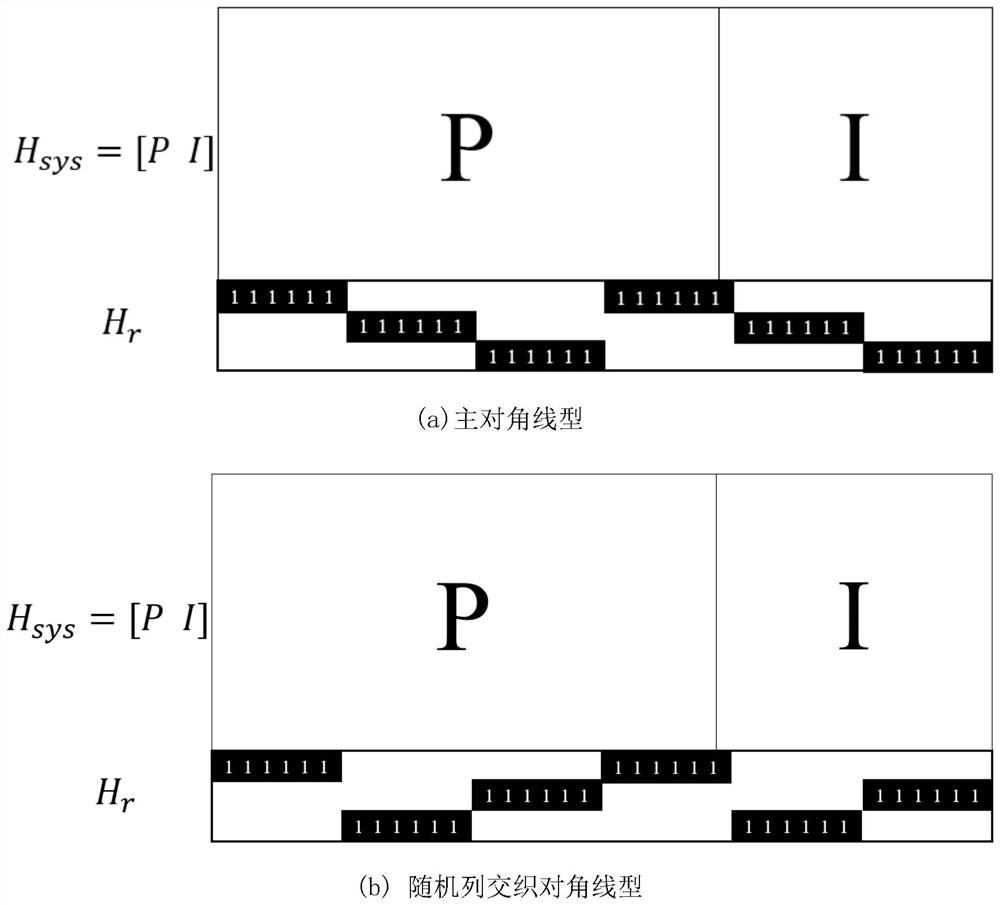

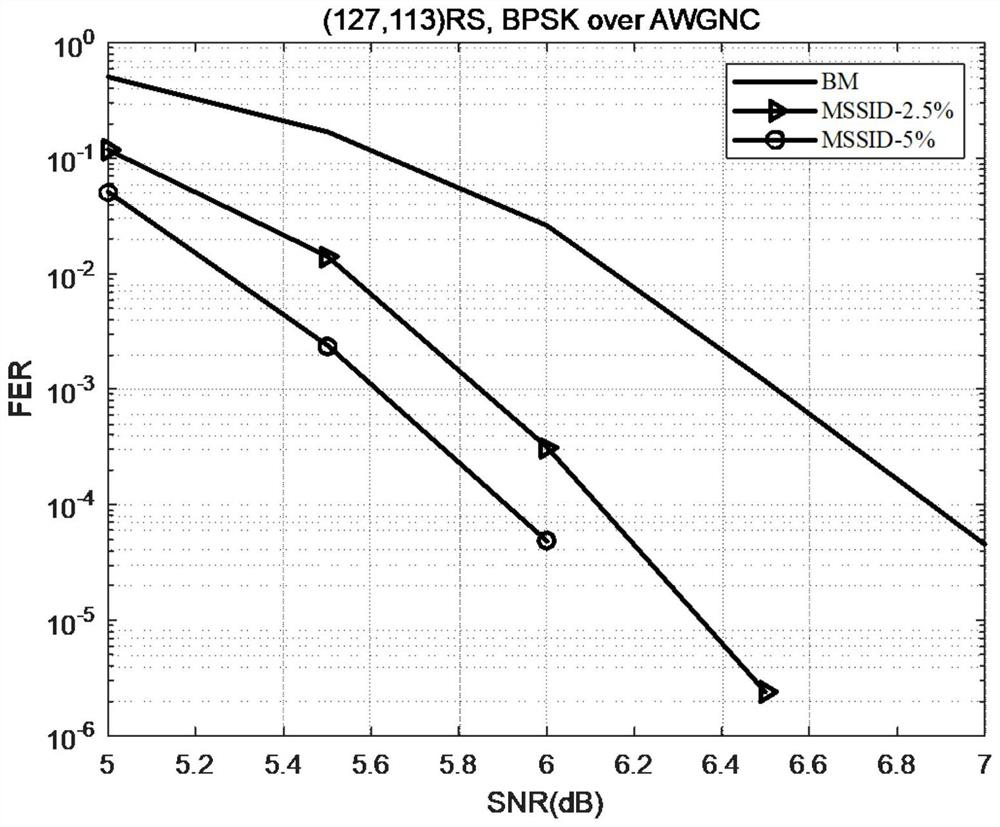

RS code coding method based on parity check precoding

PendingCN114050835AImprove error correction performanceMeet density requirementsError correction/detection using multiple parity bitsCode conversionAlgorithmEngineering

The invention discloses an RS code coding method based on parity check precoding. The method comprises the following steps of: 1, constructing an RS code check matrix Hr based on parity check precoding; 2, performing elimination processing on the matrix Hr constructed in the step 1 to obtain an Hpre matrix; 3, independently carrying out Gaussian elimination on the Hpre matrix obtained in the step 2 to obtain a parity check precoding generation matrix Gpre-sys; 4, performing parity check pre-coding by using the generated matrix Gpre-sys obtained in the step 3, namely outer code coding to obtain a parity check pre-coding codeword row vector v; and 5, coding to obtain an RS code coding codeword row vector w based on parity check precoding. According to the method, the soft-decision decoding algorithm of the RS code is more suitable for engineering implementation, and the error correction performance of the RS code under the BP type decoding algorithm is obviously improved under the condition that the coding complexity is not obviously improved.

Owner:SOUTHEAST UNIV

Machining process of wind power bearing sealing rubber strip

The invention discloses a machining process of a wind power bearing sealing rubber strip, which is made of oil and weathering ageing resistant rubber. The machining process comprises the following steps of: filtering mixing rubber materials by using a filter screen and ensuring that the rubber materials are free of impurities; matching mouthpieces by using an extruder so as to pre-form the rubbermaterials and ensuring the sizes of the rubber materials so as to satisfy the weight requirement; preheating the pre-formed mixing rubber materials so as to increase the fluidity; dragging the pre-formed rubber materials to each die cavity by using a fixture and putting neatly; carrying out die assembly and vulcanization molding; and trimming the vulcanization molded products and removing the rough edges so as to obtain the wind power bearing sealing rubber strip which satisfies the assembling requirement. Through the invention, the quality of the sealing rubber strip can be improved and the quality stability can be ensured.

Owner:常州市中昊轨道交通科技发展有限公司

Low-temperature quick-setting grouting material for offshore oil wells and preparation method thereof

ActiveCN105199692BEffective Support Strength RequirementsShort coagulation timeDrilling compositionAnti freezingMass ratio

The invention relates to a low temperature rapid hardening grouting material for an offshore oil well. The low temperature rapid hardening grouting material for the offshore oil well comprises the following raw materials in parts by weight: 2,000 parts of gel materials, 950-965 parts of inorganic mineral active materials, 25-35 parts of retarders, 5-10 parts of anti-freezing ingredients, 3-5 parts of high efficiency slushing agents, and 0.1-0.3 part of defoaming agents, wherein the gel materials are quick-hardening sulphate aluminium cement and oil well cement; the mass ratio of the quick-hardening sulphate aluminium cement and oil well cement is 5:5-8:2. The invention also provides a preparation method thereof. The grouting material is suitable for construction under a well cementation low-temperature environment, slurry can maintain better mobility and is high in early strength, the slurry is full without shrinkage, the long-term strength is high, and the well cementation construction time and the underground grouting environment parameter requirement are effectively ensured.

Owner:河北铁园科技发展有限公司

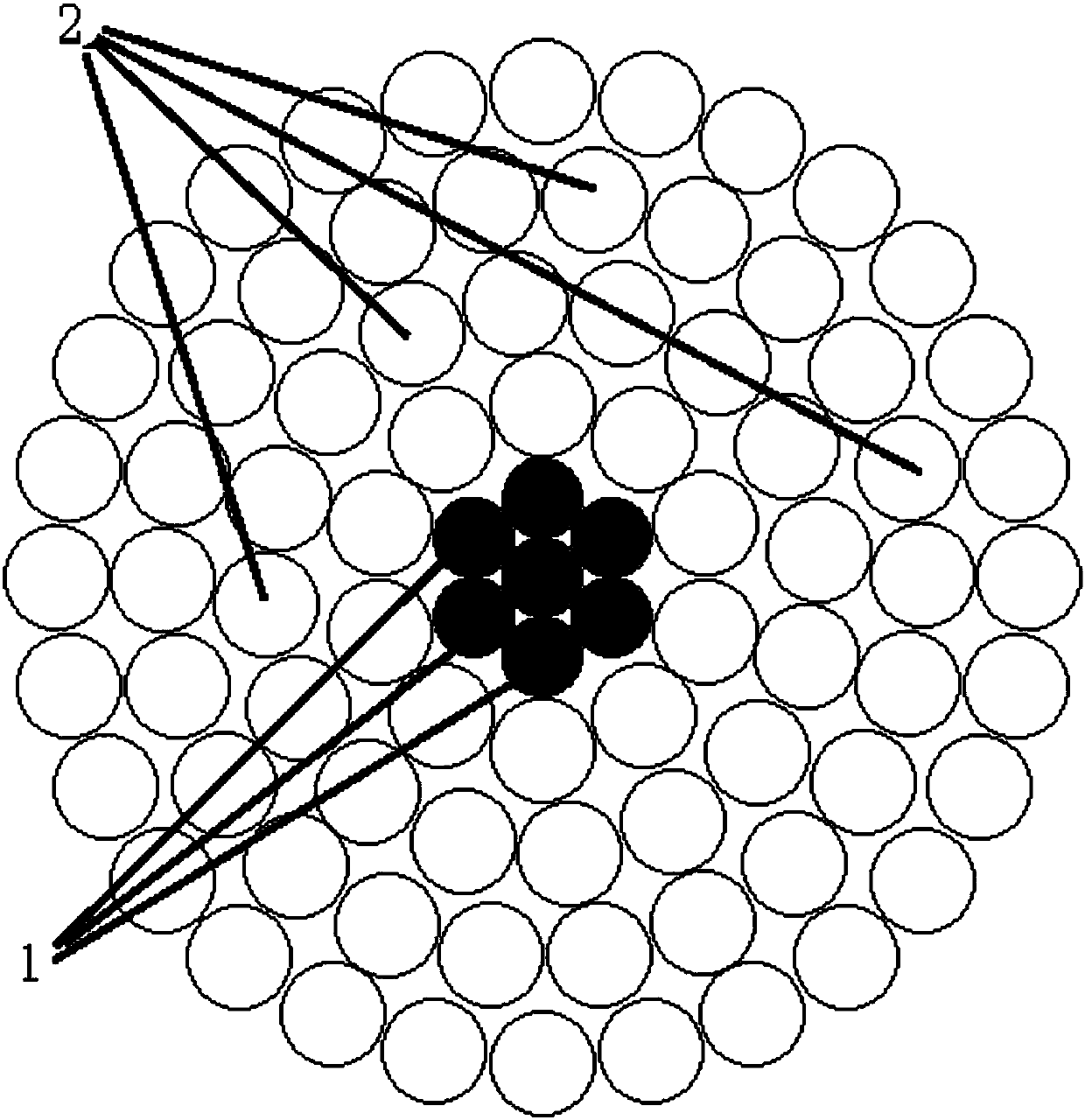

Large-section stranded conductor

InactiveCN110164618AHigh strengthCorrosion resistantNon-insulated conductorsInsulated cablesSocial benefitsElectrical conductor

The invention relates to a large-section stranded conductor. The large-section stranded conductor comprises a coaxially arranged strengthening core and a conductor formed by a semi-hard aluminum stranded wire layer, the strengthening core is formed by twisting a plurality of strands of wires which are made of a carbon fiber composite material; and the semi-hard aluminum stranded wire layer is a multi-layer structure formed by stranding semi-hard aluminum single wires, and the sections of the semi-hard aluminum single wires are circular. The large-section stranded conductor provided by the invention is high in strength, corrosion resistant, large in current-carrying capacity, small in linear expansion coefficient, small in sag and light in weight, can meet the higher requirements of energyconservation and environmental protection in the field of overhead power transmission; and moreover, the semi-hard aluminum stranded wire layer adopts semi-hard aluminum, so that the conductivity is greatly improved compared with that of a common hard aluminum wire, the resistivity is improved by about 3% compared with that of a hard aluminum monofilament, and the power transmission loss is effectively reduced, so that the large-section stranded conductor has important economic benefits and social benefits for constructing an intelligent power grid, achieving 'clean substitution' and promotingenergy conservation and environmental protection.

Owner:CHINA ELECTRIC POWER RES INST

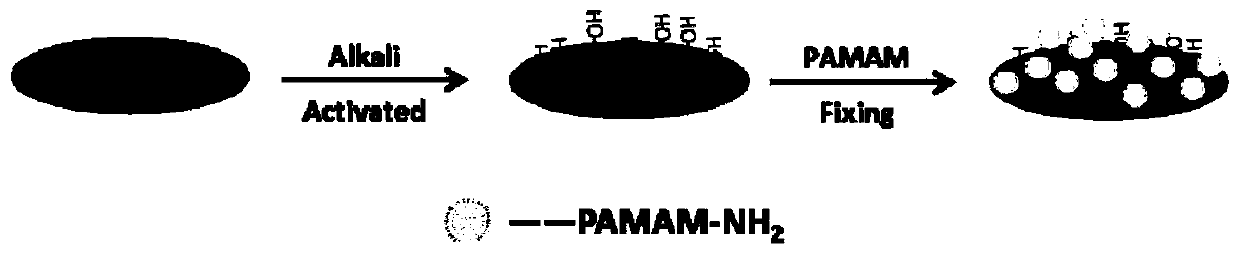

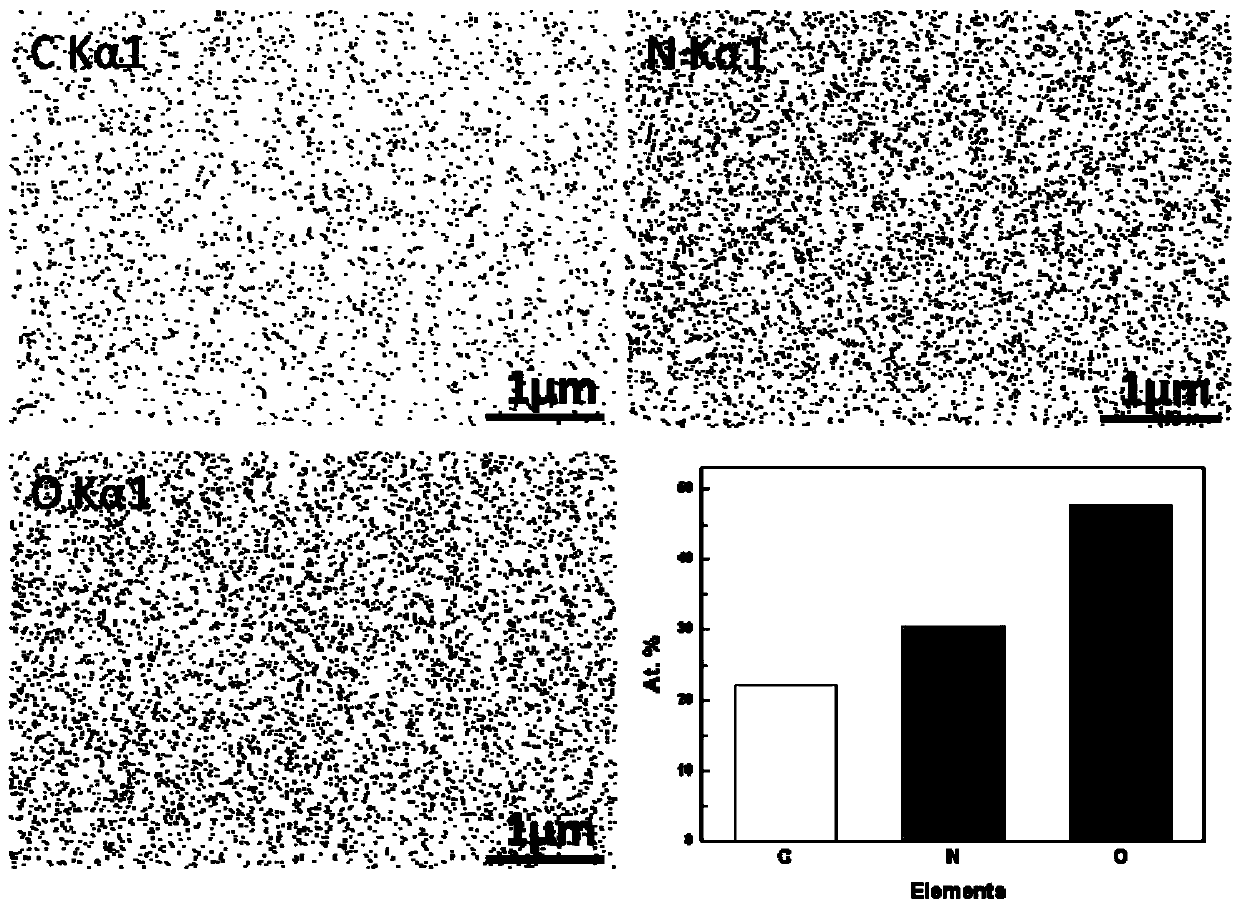

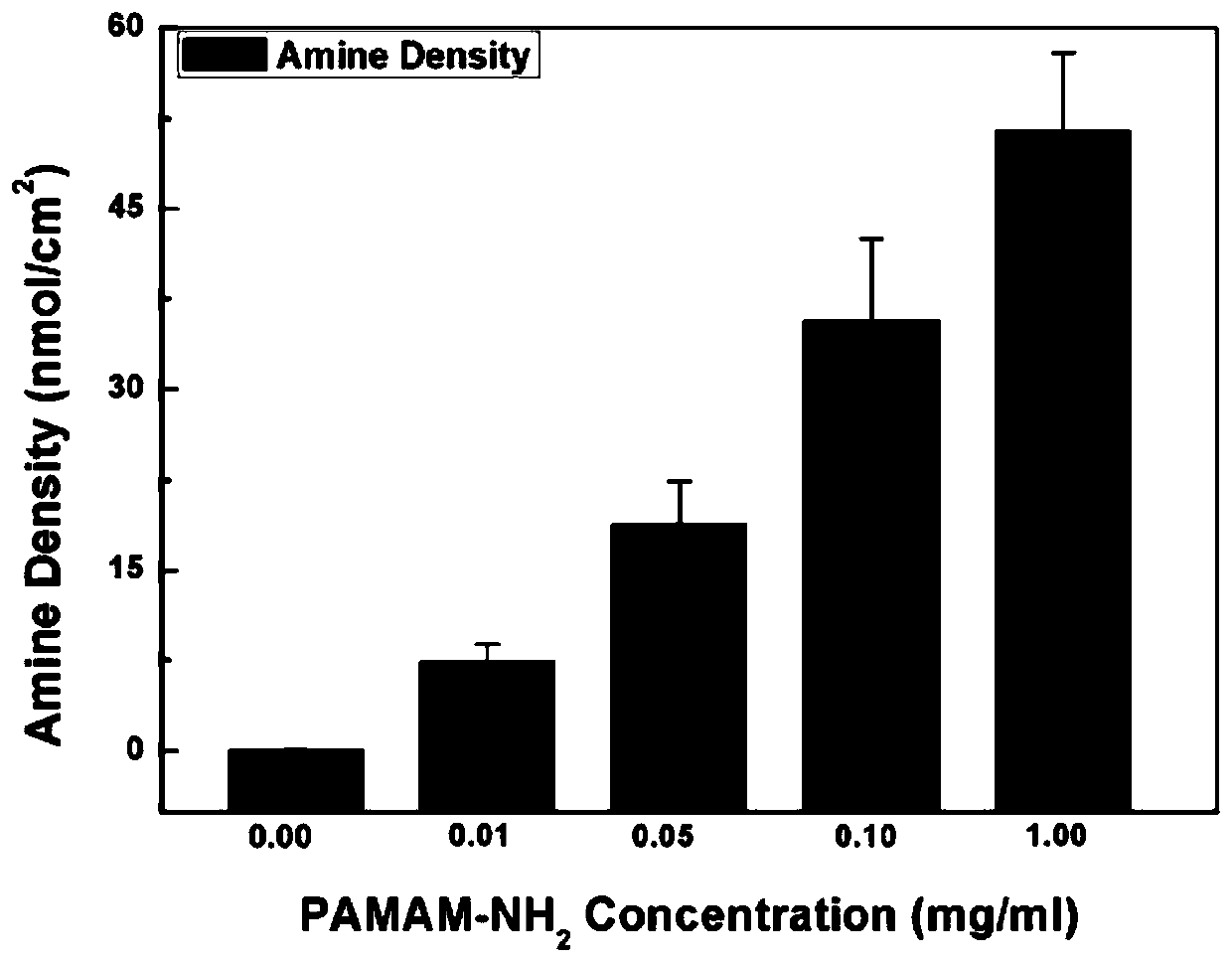

Method for rapidly forming amine group on surface of material, medical material with surface loaded with high-density amine group and application of medical material

Owner:SOUTHWEST JIAOTONG UNIV

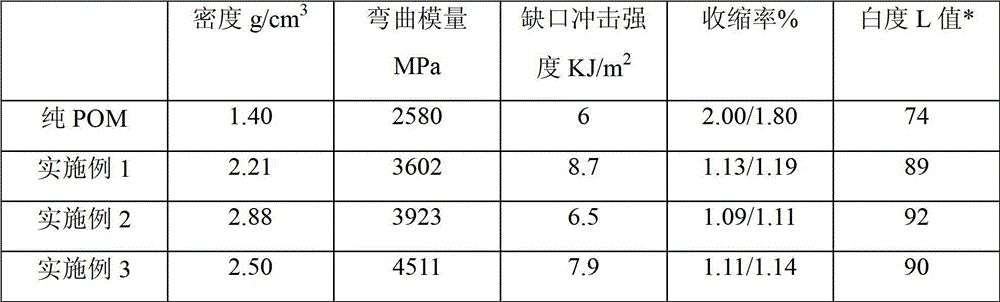

Polyformaldehyde material for automobile inertia disc, preparation method and application thereof

ActiveCN103819868AUniform mass distributionMeet the requirements of mass distribution uniformityAntioxidantZinc

The invention belongs to the technical field of high polymer materials, and relates to a polyformaldehyde material, a preparation method and application of the material. The polyformaldehyde material is prepared from the following ingredients in parts by weight: 100 parts of polyformaldehyde, 100-230 parts of zinc oxide, 0.1-0.2 part of white oil, 0.5-1 part of calcium stearate, 0.3-0.6 part of a primary antioxidant, 0.3-0.6 part of an auxiliary antioxidant, 0.5-0.8 part of a formaldehyde absorbent, 0.1-0.3 part of a nucleating agent, and 5-15 parts of hollow glass. Compared with the prior art, the prepared material is high in density, low in percentage of contraction, uniform in mass distribution, good in surface quality, high in whiteness, good in rigidity, and excellent in tenacity.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com