Preparation method of self-lubricating copper-based powder metallurgy structural part for helicopter

A copper-based powder, self-lubricating technology, applied in the field of powder metallurgy, can solve problems such as the service life does not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

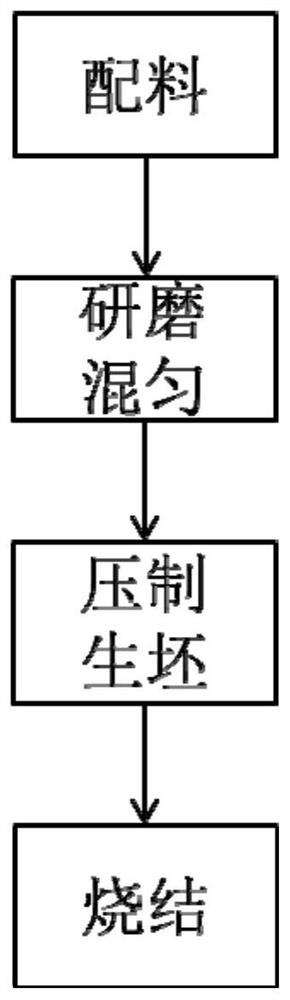

[0024] The preparation method of the self-lubricating copper-based powder metallurgy structural part for helicopters provided by the present invention will be explained below in conjunction with the accompanying drawings.

[0025] The purpose of the present invention is to prepare a graphite-containing tin bronze sintered part with a density of 6.5-7.1g / cm3, a tensile strength σb≥92MPa, and a self-lubricating function by adopting a powder metallurgy process. It is used as an assembly component of the helicopter autoclinometer to ensure the smooth realization of the function of the autoclinometer.

[0026] In the invention, a certain amount of graphite and paraffin are added to copper and tin metal powders, uniformly mixed, pressed and formed, and then sintered in a protective atmosphere to realize a copper-based powder metallurgy structural part whose comprehensive performance meets the requirements of use. The present invention can improve the self-lubricating performance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com