Self-lubricating treating agent composition, hot aluminum/zinc-plated sheet and preparation method thereof

A technology for hot-dip galvanized sheet and composition, applied in chemical instruments and methods, coatings, layered products, etc. The effect of excellent lubricity and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a hot-dip galvanized sheet, the method comprising: preparing the self-lubricating treatment agent composition described in the present invention into a coating solution, and coating the coating solution on a hot-dip aluminum-zinc plate on a zinc sheet substrate and then cured.

[0032] According to the preparation method of the hot-dip galvanized sheet of the present invention, the amount of the self-lubricating treatment agent is such that the thickness of the coating formed on the hot-dip galvanized sheet substrate is 0.05-0.3 microns.

[0033] According to the preparation method of the hot-dip galvalume sheet of the present invention, the curing temperature and time can be adjusted by those skilled in the art according to the actual situation. Preferably, the curing temperature is 80-110° C. and the curing time is 10 -60s.

[0034]Wherein, the coating method can adopt the conventional coating method used in ...

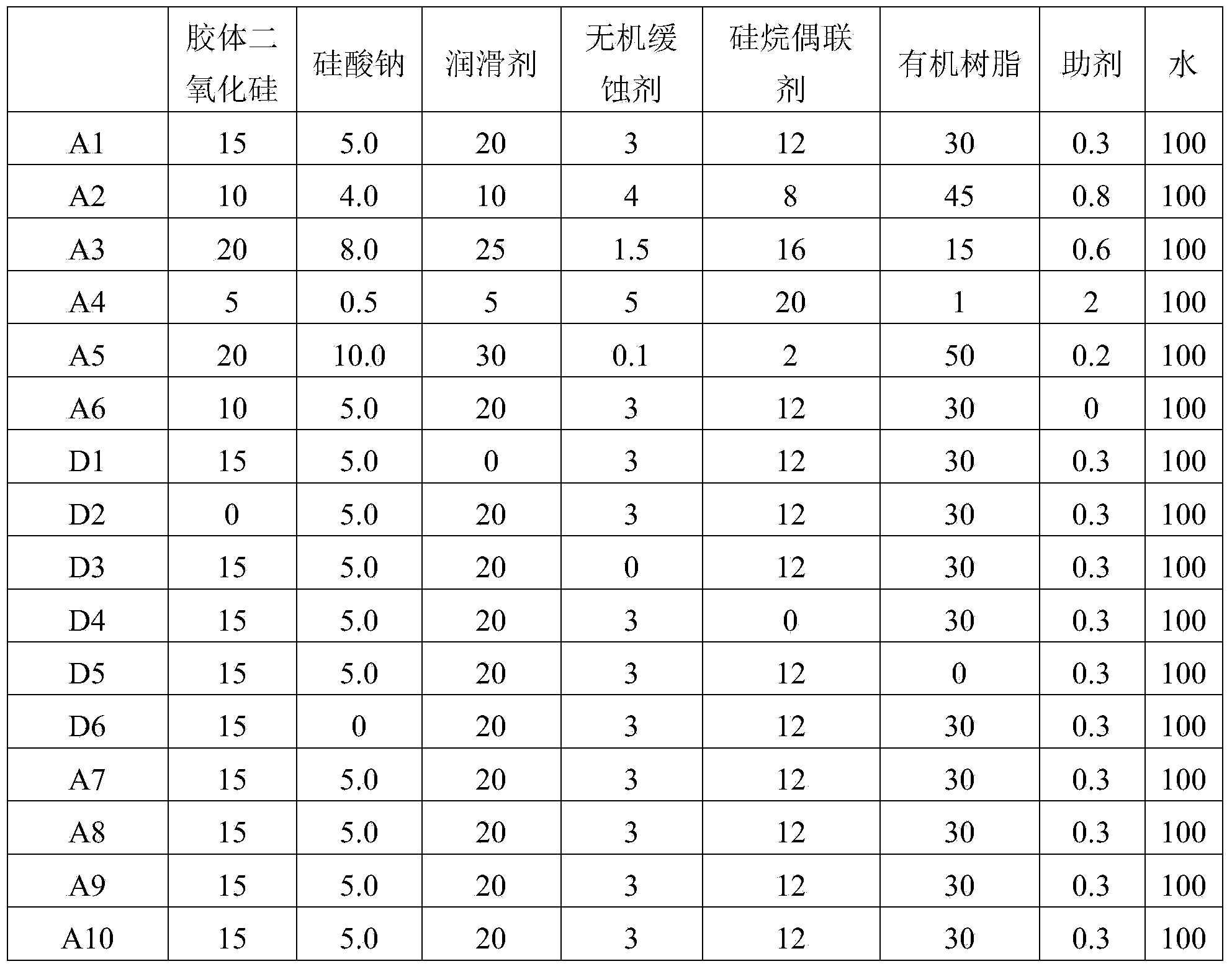

Embodiment 1-10 and comparative example 1-6

[0041] According to the component contents listed in Table 1, the components were uniformly mixed under stirring conditions to obtain self-lubricating agent compositions A1-A10 and D1-D6 respectively.

[0042] Table 1

[0043]

[0044] In self-lubricating agent compositions A1-A10 and D1-D6, the specific selection of each component is as follows:

[0045] The average particle size of colloidal silica is 30nm;

[0046] Sodium silicate is sodium metasilicate, the lubricant is water-based fluorocarbon emulsion (46% solid content) and polyethylene wax emulsion (46% solid content) (the weight ratio of the two is 7:3), inorganic corrosion inhibitor It is sodium nitrite and sodium molybdate (the weight ratio of the two is 3:2), the silane coupling agent is KH560, and the organic resin is water-based polyurethane (solid content is 30%) and water-based styrene-acrylic resin (solid content is 30%) ) (the weight ratio of the two is 4:1), and the additives are leveling agent, surfact...

preparation example 1

[0052] The self-lubricating agent compositions A1-A10 and D1-D6 were coated on the hot-dip galvanized steel strip by roll coating, and cured at a curing temperature of 100°C (the curing temperature was measured by temperature test paper) for 25s to obtain passivation-containing Coated hot-dip galvalume sheets B1-B10 and DB1-DB6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com