Wind driven generation set main shaft self-aligning slide bearing

A technology for wind turbines and sliding bearings, which is applied to wind turbine components, wind turbines, sliding contact bearings, etc., can solve the problems that the bearings cannot be oiled and maintained, the installation and disassembly of rolling bearings are troublesome, and the bearing seat requirements are high. Long-term and reliable oil lubrication, low manufacturing cost, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

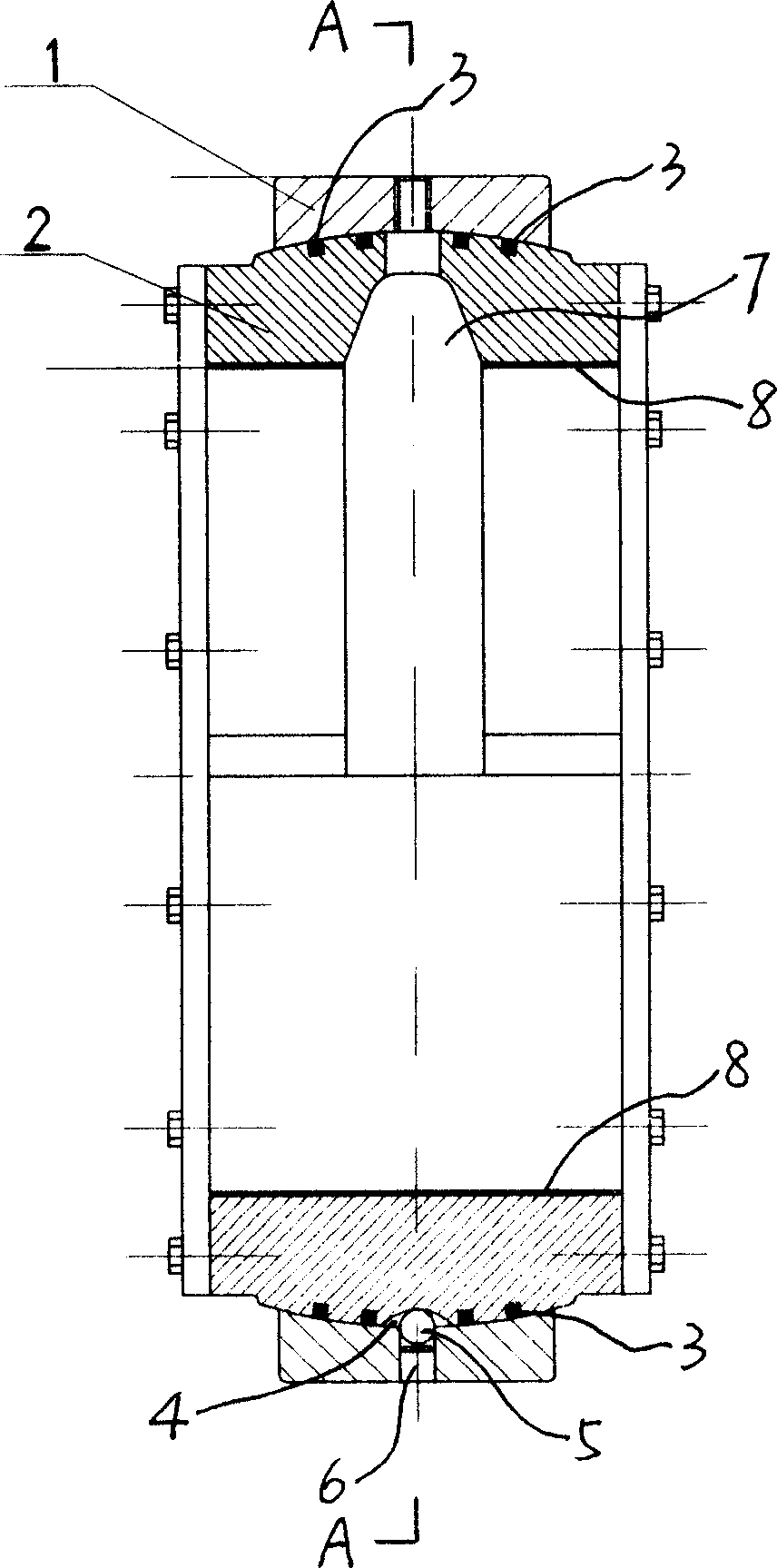

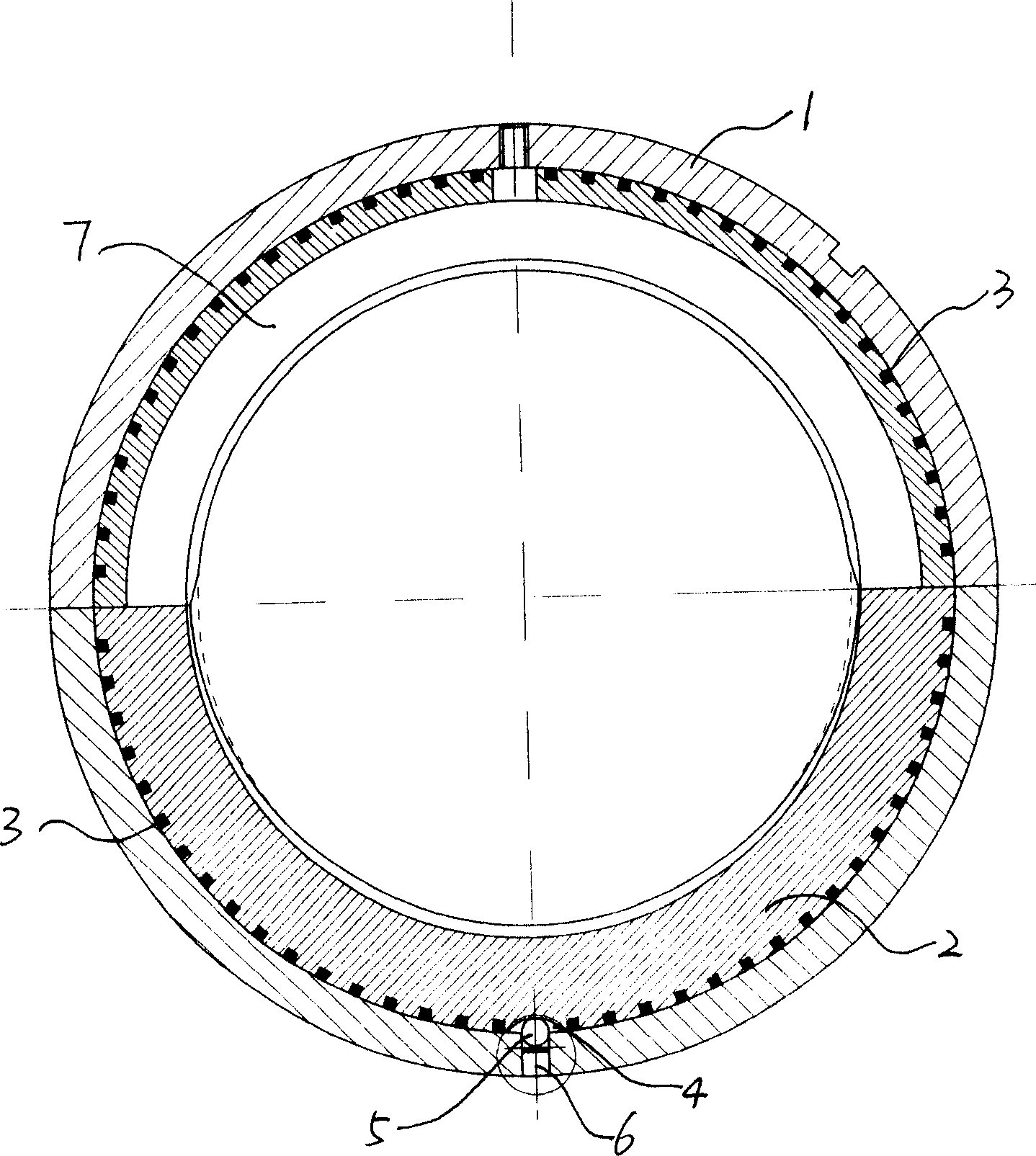

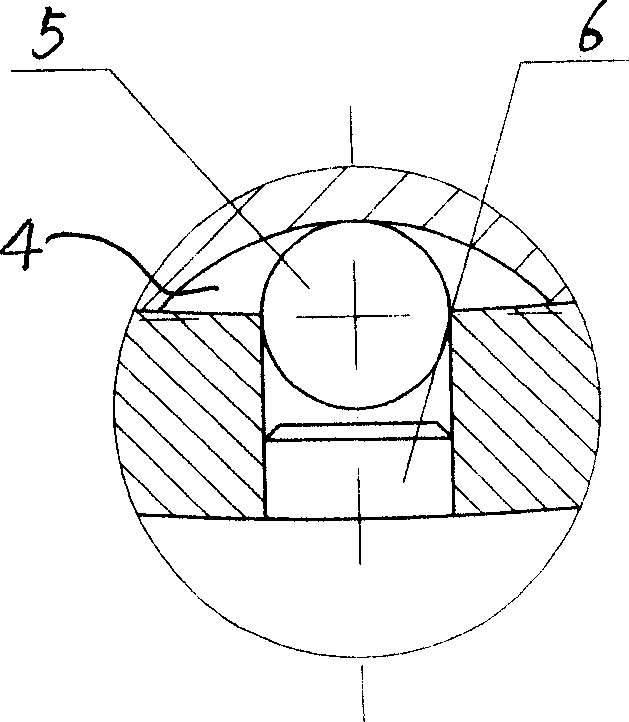

[0018] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. like figure 1 , 2 , 3, a wind turbine main shaft self-aligning sliding bearing, the overall structure of the bearing can be an upper and lower split structure or an integral structure, depending on the bearing assembly form. There are an outer ring 1 and an inner ring 2, the inner diameter of the outer ring 1 is an inner spherical surface, and the outer diameter of the inner ring 2 is an outer spherical surface, forming a pair of sliding spherical surfaces, which has a centering function. Blind holes are evenly arranged on the outer diameter of the inner ring 2 , and solid lubricants 3 are embedded in the blind holes. The solid lubricant 3 accounts for 18-25% of the outer spherical surface area of the outer diameter of the inner ring 2 . A circular groove 4 is arranged on the outer diameter of the inner ring 2, and a rolling body 5 and a floating limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com