Patents

Literature

223results about How to "Excellent fingerprint resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

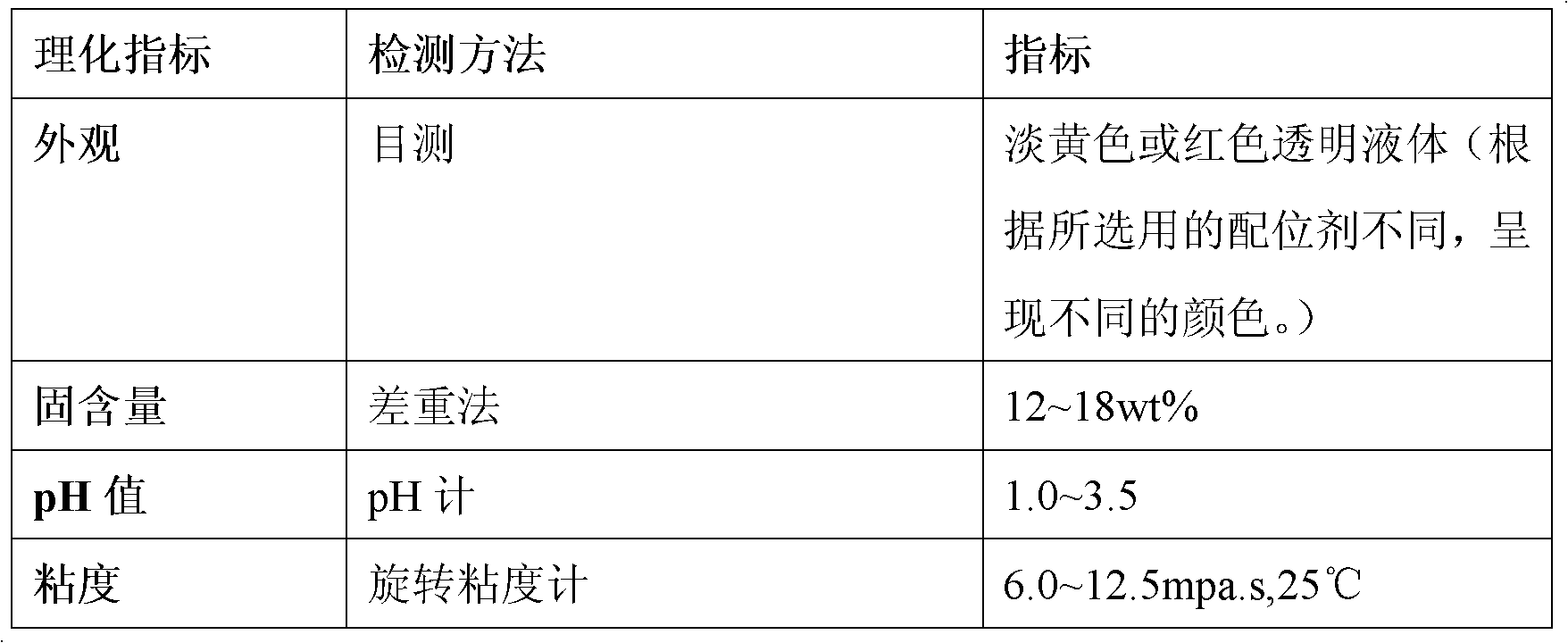

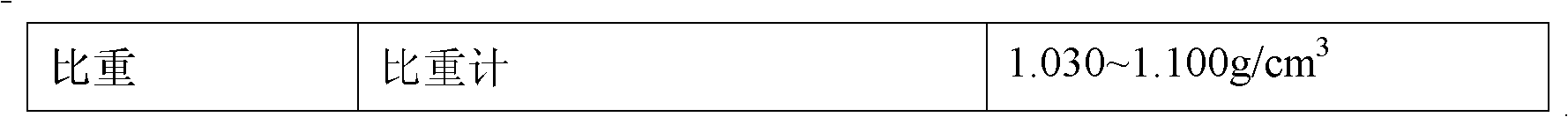

Chromium-free passivation liquid applied to surface of zinc-coated layer

ActiveCN102337532ASimple passivation processStable and reliable passivation processMetallic material coating processesHexavalent chromiumLanthanum

The invention discloses a chromium-free passivation liquid applied to the surface of a zinc-coated layer, belonging to the technical field of new materials for passivating the surfaces of zinc-coated materials (including zinc-coated steel plates and other zinc-coated parts0. The chromium-free passivation liquid does not contain metal element zirconium and is a chromium-free environmental-friendlypassivation liquid which can substitute for hexavalent chromium or trivalent chromium. Each liter of chromium-free passivation liquid comprises 20-100 g of metal element salt, 5-10 g of aqueous silane, 2-10 g of complexing agent, 10-120 g of nano filling material, 1-5 g of oxidizing agent, 5-50 g of film forming aid and the balance of water. In the chromium-free passivation liquid provided by theinvention, organic silicon modified acrylate is used as the film forming aid, cerium salt or lanthanum salt and molybdate are used as inorganic components, and the nano filling material and other aids are used as auxiliaries to form the organic and inorganic compound passivation liquid. The passivation effect of the passivation liquid even exceeds that of the hexavalent chromium or trivalent chromium passivation liquid and can totally substitute for the hexavalent chromium or trivalent chromium passivation liquid.

Owner:武汉迪赛新材料有限公司

Composition and method for surface treatment of metal materials

ActiveCN1614089AExcellent fingerprint resistanceExcellent blackening resistanceMetallic material coating processesEpoxyAcrylic resin

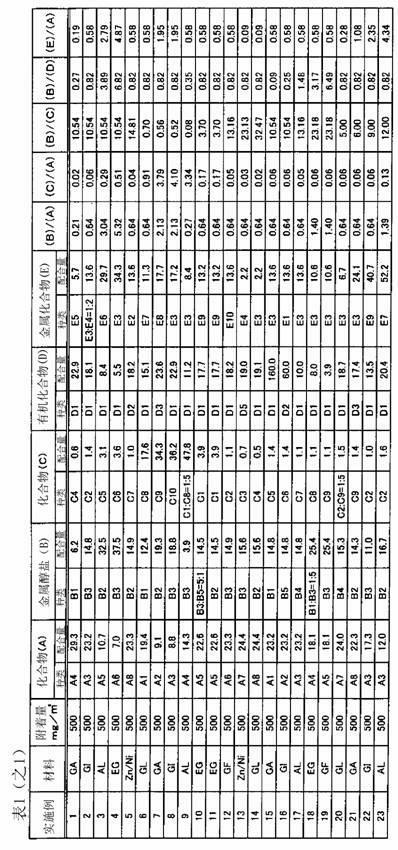

The present invention provides a surface treatment composition and a surface treatment method capable of forming a film having excellent corrosion resistance, fingerprint resistance, blackening resistance, paint adhesion, etc. on the surface of a metal material. It contains an aqueous medium and the following components: (A) metal ions selected from Mn ions, Co ions, Zn ions, Mg ions, Ni ions, Ti ions, V ions and Zr ions, (B) having at least 4 fluorine atoms and elements selected from Ti, Zr, Si, Hf, Al and B, (C) has active hydrogen-containing amino, epoxy, vinyl, mercapto and methacryloxy Silane coupling agent with selected reactive functional groups, and (D) aqueous emulsification using resin selected from cationic or nonionic polyurethane resin, acrylic resin, epoxy resin, polyester resin and polyamide resin as the resin component Resin composition for surface treatment of metal materials and method for surface treatment of metal materials using the same.

Owner:NIHON PARKERIZING

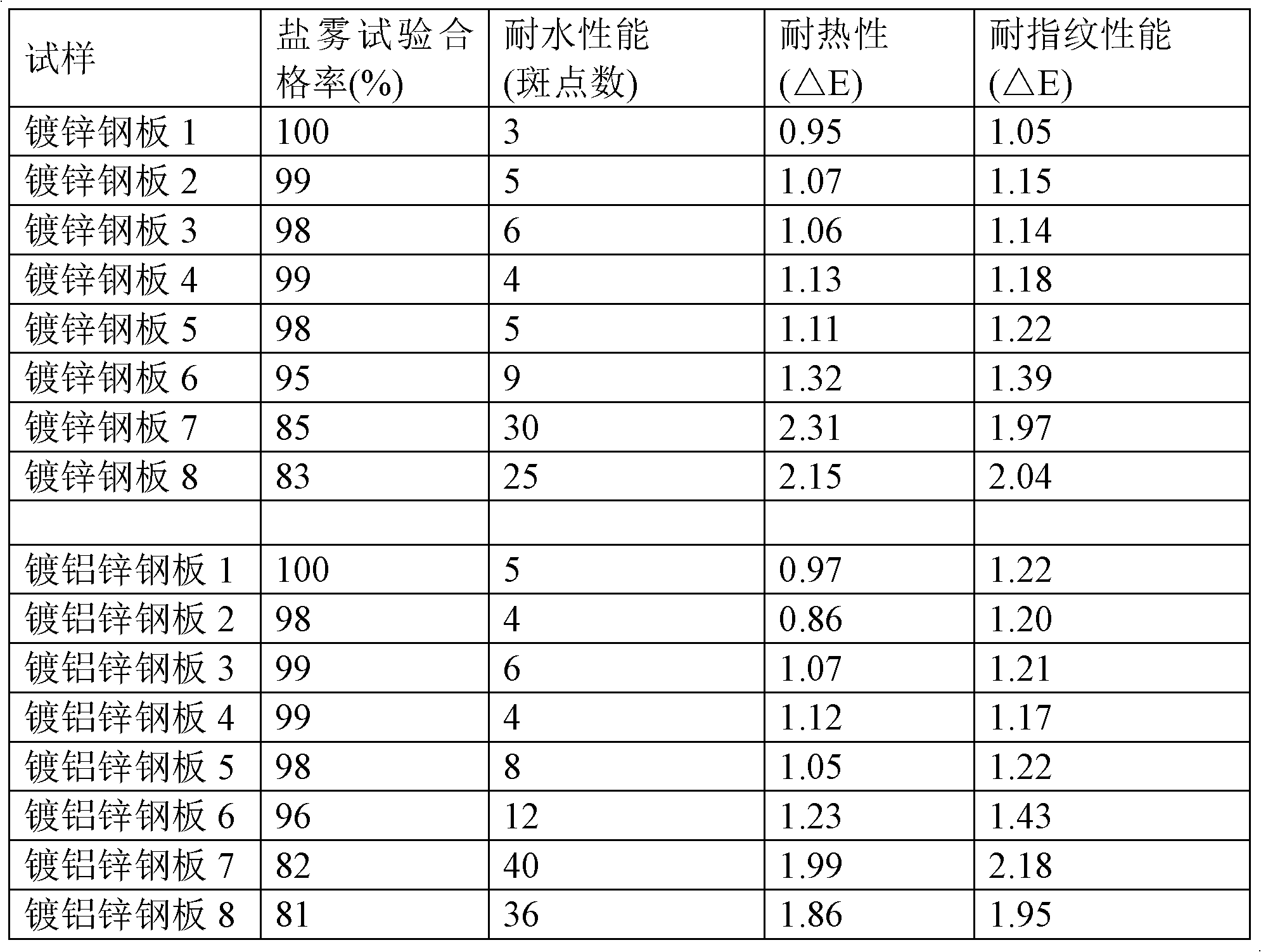

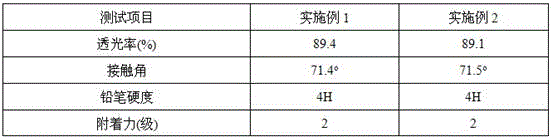

Metal protective coating and hot galvanizing metal material and hot dip aluminum-zinc metal material

ActiveCN103031043AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesThiourea

The invention provides metal protective coating, which is obtained by uniformly mixing a raw material mixture. The raw material mixture contains water soluble silicate, an accelerant, a silane coupling agent, a silicon oxide filler, a water soluble film-forming resin and water; the accelerant is thiourea and / or urea; and the silane coupling agent contains a first silane derivative represented by the formula (1), wherein R1, R2 and R3 are respectively either a methoxy group or an ethyoxyl group, and n is an integer from 1 to 4. The invention further provides a hot galvanizing metal material and a hot dip aluminum-zinc metal material. The protective film prepared by the metal protective coating provided by the invention is excellent in corrosion resistance, water resistance, heat resistance and fingerprint resistance. Formula (1).

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing environment-friendly type anti-corrosive and anti-fingerprint metal surface coating

InactiveCN101392142AImprove anti-corrosion performanceGood fingerprint resistancePretreated surfacesAnti-corrosive paintsEpoxyMicrocrystalline wax

The invention relates to a composition for protecting metal surfaces, in particular to a preparation method of an environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. The composition contains an A component and a B component, the A component takes waterborne epoxy resin as a matrix resin and nano-silica, a silane coupling agent, microcrystalline wax disperse liquid, zirconium complex, deionized water, defoamer and a levelling agent are added, thus obtaining the A component; the B component contains a waterborne epoxy modified amine curing agent and a certain quantity of epoxy curing promoter. The two components are mixed and stirred evenly at a ratio of 4:1 to 3:1 to form the environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. After coating, metal can be heated by going through a baking channel at a certain temperature, the film forming time can be controlled by adjusting the heating period and finally a transparent coating layer which has quite good anticorrosive protection function over metal and fingerprint resistant function is formed.

Owner:TONGJI UNIV

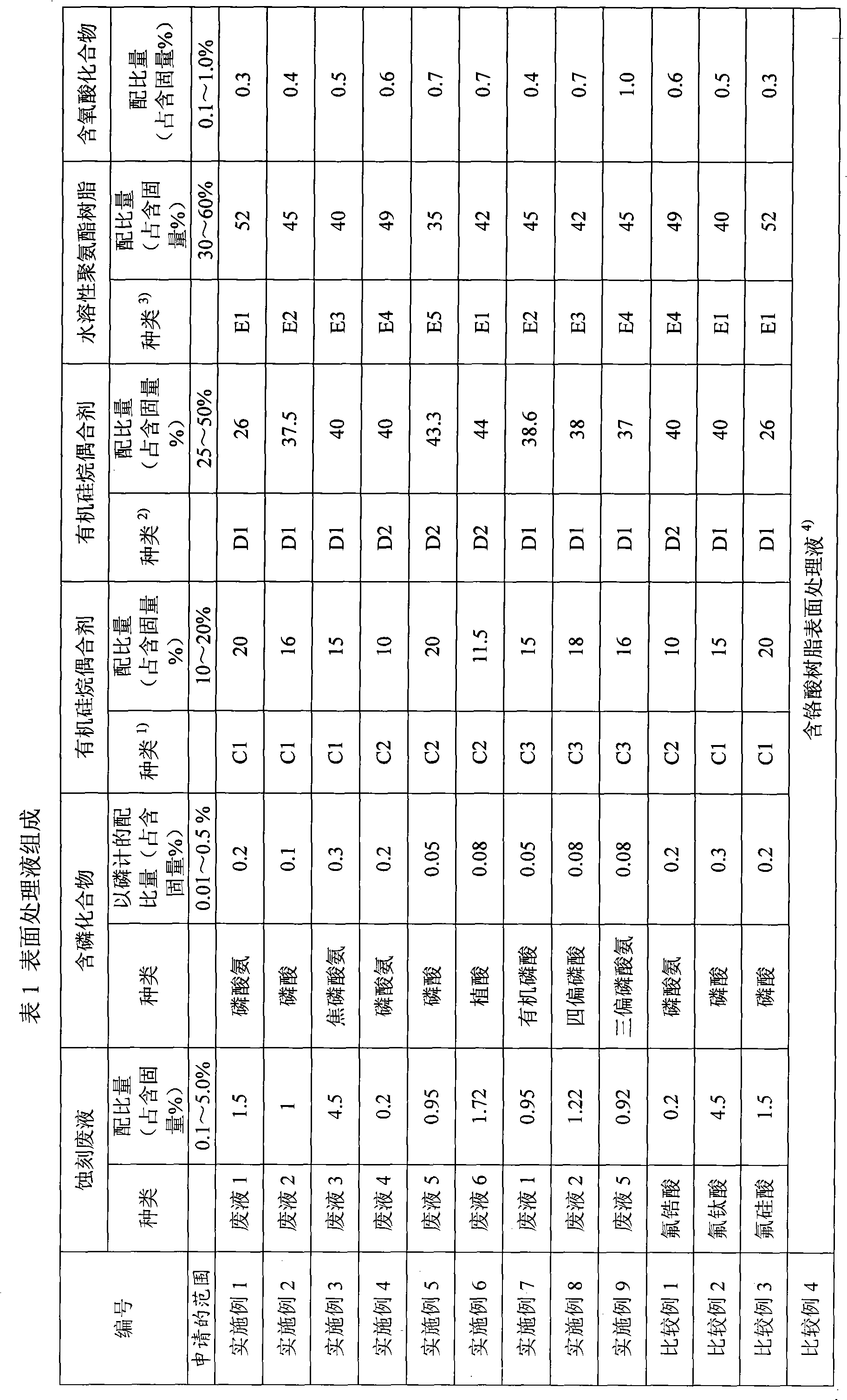

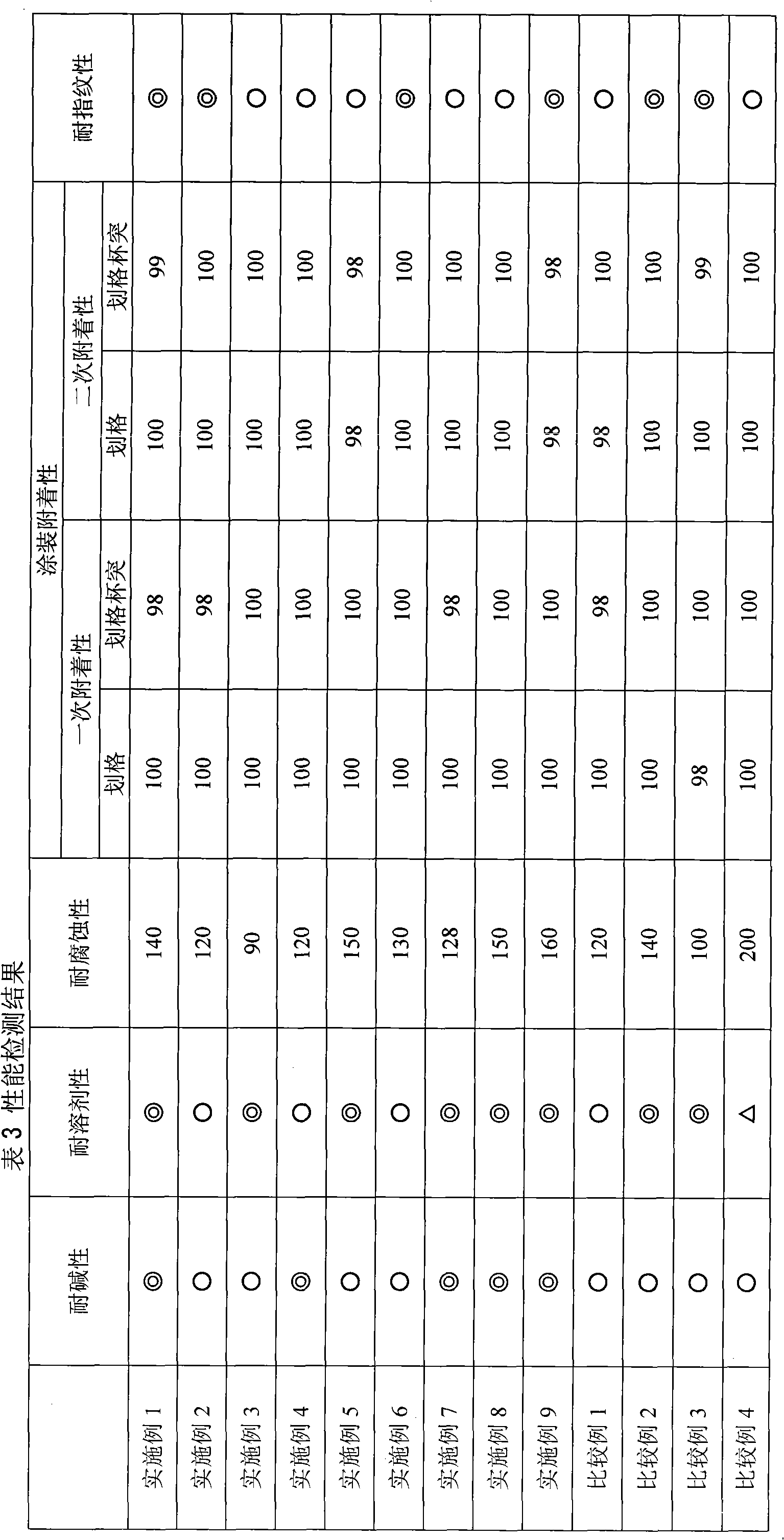

Surface treating agent with excellent alkali resistance and solvent resistance and for zinc coated steel plate

ActiveCN1887449AEasy to handleGood alkali resistancePretreated surfacesAnti-corrosive paintsTectorial membraneSolvent

The present invention relates to surface treating agent for zinc coated steel plate, and is especially one kind of surface treating agent with excellent alkali resistance and solvent resistance for zinc coated steel plate. The surface treating agent is water solution, which consists of fluoric acid with 4 or more fluorine atoms and at least one of Ti, Zr and Si atome in 0.1-5.0 wt%; phsosphorus containing compounding 0.01-0.5 wt%; one or more organic silicon coupling agent with amino group containing at least one active hydrogen atom 10-20 wt%, one or more organic silane coupling agent with at least one epoxy group 25-50 wt%; at least one kind of cationic or non-ionic water soluble polyurethane resin 30-60 wt% and vanadium compound 0.1-1.0 wt%. It is used in forming protecting film with excellent performance on the surface of zinc coated steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Modified polyurethane acrylic ester and ultraviolet light curing coating

ActiveCN101967158AGood weather resistanceImprove corrosion resistanceGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsUltraviolet lightsSolvent

The invention provides a compound with the structure shown in the formula (I), wherein R1 is an acrylic ester group; R2 is an isophorone group, hexyl, methyl cyclohexyl, dicyclohexyl methyl, or tolyl; R3 is a tertiary amine group; m and n are the degrees of polymerization; m is not less than 2 and not larger than 20; and n is not less than 1 and not larger than 12. The invention also provides an ultraviolet light curing coating comprising the following components of 60 to 80 parts by weight of modified polyurethane acrylic ester with the structure of the formula (I): 10 to 18 parts by weight of water, 0.3 to 0.9 part by weight of aqueous flatting agent, 5 to 9 parts by weight of aqueous cosolvent, 2 to 6 parts by weight of aqueous wax auxiliary, 1.3 to 3 parts by weight of aqueous wettingagent, 0.5 to 0.7 part by weight of aqueous antifoaming agent and 3 to 5 parts by weight of photo initiator. The ultraviolet light curing coating of the invention has the advantages of excellent fingerprint resistance property, corrosion resistance property and weatherability, and rapid curing.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

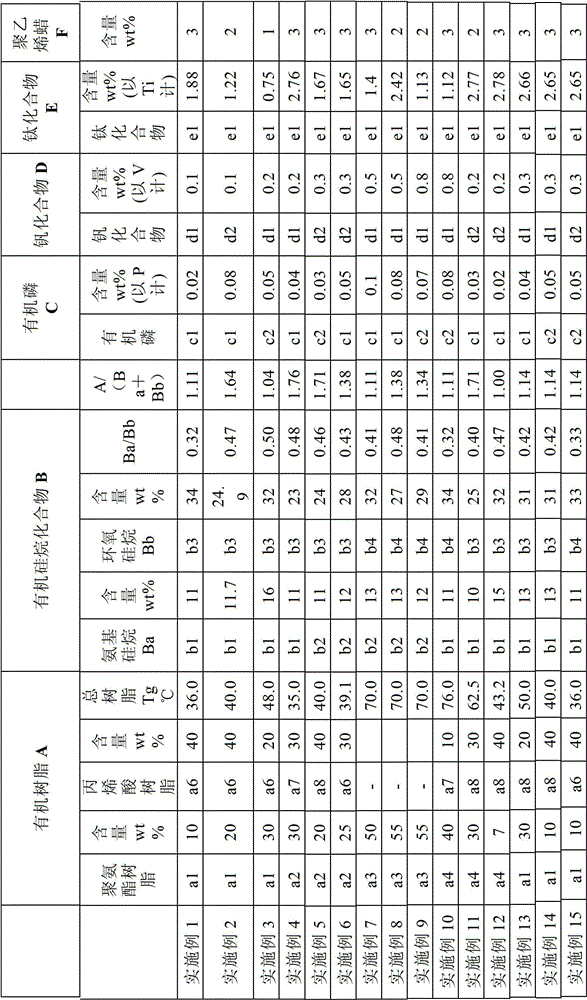

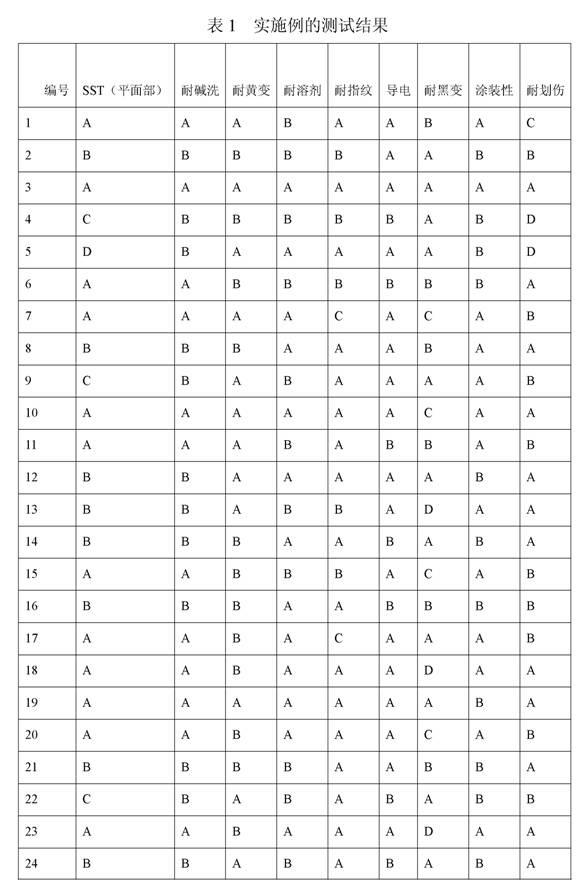

Galvanizing steel strip with good conductivity, high corrosion resistance and fingerprint resistance, surface treatment agent and treatment method

ActiveCN102746778AImprove conductivityImprove corrosion resistancePretreated surfacesAnti-corrosive paintsFunction groupCorrosion

Provided is a galvanizing steel strip with good conductivity, high corrosion resistance and fingerprint resistance, a surface treatment agent and a treatment method. The galvanizing steel strip is covered with a fingerprint-resistant film, wherein the film composition comprises: polyurethane and / or acrylic organic resin (A), with the weight percentage thereof being 40% to 60%; an organic silane coupling agent (Ba) containing one or more amino function groups which has at least one active hydrogen, and an organic silane coupling agent (Bb) containing at least one epoxy function group the number of which is more than one, with the weight ratio of Ba to Bb being from 0.3 to 0.5 and the weight percentage of the organic silane coupling agent being 38% to 53%; organo phosphorous compounds (C), with the weight percentage of phosphorus element being 0.01% to 0.1%; vanadium compounds (D), with the weight percentage of vanadium element being 0. 1% to 1.0%; titanium compounds or fluorine-containing titanium compounds (E), with the weight percentage of titanium element being 0. 1% to 3.0%; and polyethylene wax, with the weight percentage thereof being 1% to 3% of the film.

Owner:BAOSHAN IRON & STEEL CO LTD

Chrome-free fingerprint resistant water-based paint

InactiveCN102134713AImprove corrosion resistanceExcellent fingerprint resistanceMetallic material coating processesWater basedWax

The invention relates to a chrome-free fingerprint resistant water-based paint which is used for coating galvanized plates and belongs to the technical field of paints. The chrome-free fingerprint resistant water-based paint is prepared by intensively and evenly mixing 5-80 parts of nano-oxide concentrated slurry, 30-75 parts of water-based polyurethane emulsion, 0.5-5 parts of metal ion, 0.05-5 parts of phosphorus and 1-5 parts of wax and then adjusting the pH. The invention provides an environment-friendly paint system which can satisfy various comprehensive properties of the galvanized plates and can ensure that the galvanized plates have excellent comprehensive properties such as corrosion resistance, fingerprint resistance, conductivity, coating property, scratch resistance, black patina resistance and the like.

Owner:JIANGSU DAZHONG NEW MATERIAL TECH CO LTD

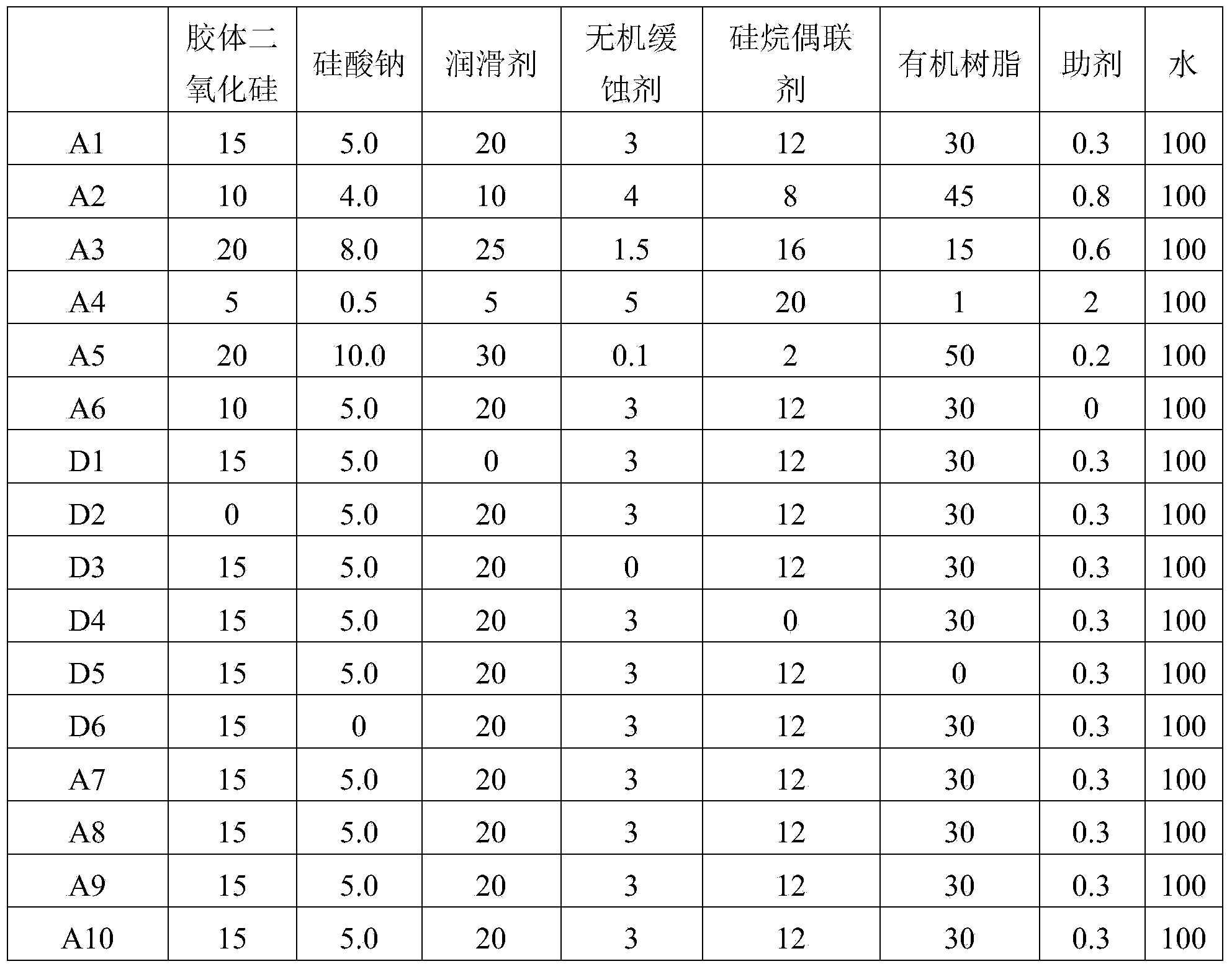

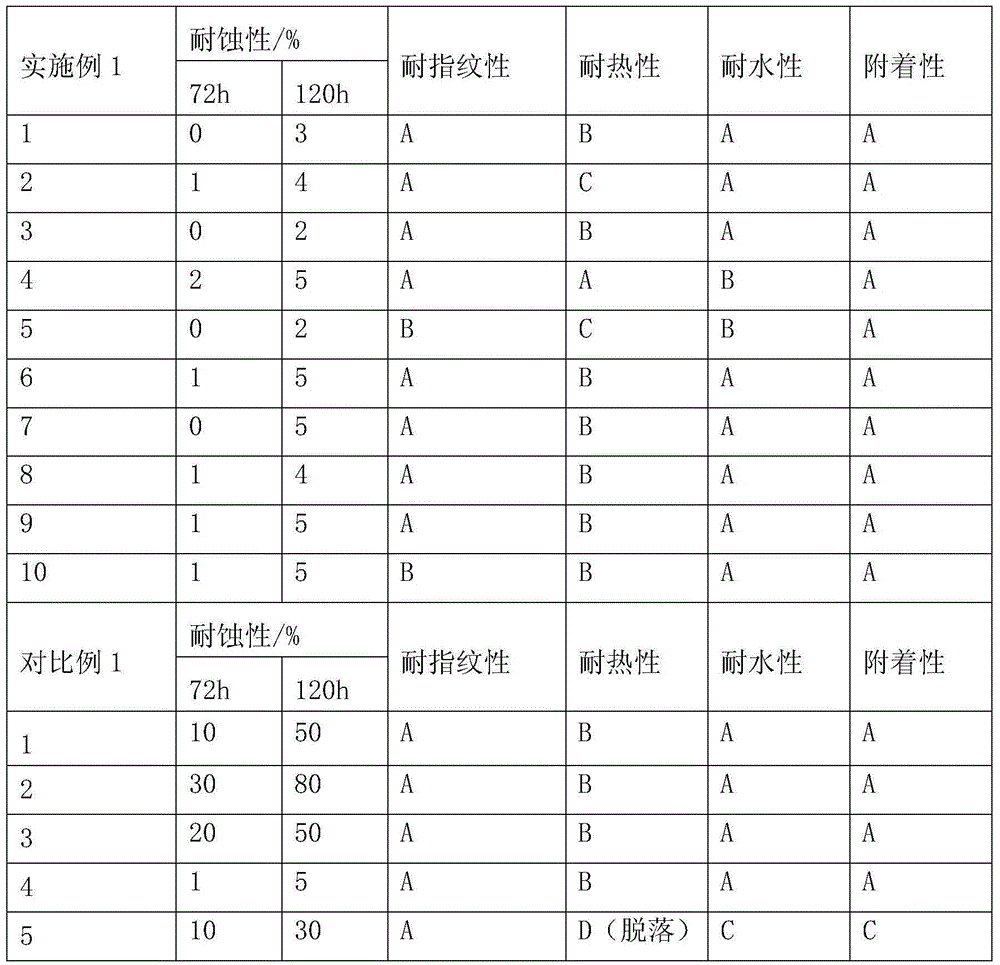

Self-lubricating treating agent composition, hot aluminum/zinc-plated sheet and preparation method thereof

ActiveCN103911063AGood self-lubricating performanceEnvironmentally safePolyurea/polyurethane coatingsMetal layered productsHeat resistanceZinc

The invention discloses a self-lubricating treating agent composition which contains water, colloidal silicon dioxide, sodium silicate, lubricant, inorganic inhibitor, silane coupling agent and organic resin. The invention also discloses a hot aluminum / zinc-plated sheet which comprises a hot aluminum / zinc-plated sheet substrate and a coating attached to the surface of the substrate, wherein the coating is formed by the self-lubricating treating agent composition. The invention the invention also discloses a preparation method of the hot aluminum / zinc-plated sheet, which comprises the following steps: preparing the self-lubricating treating agent composition into a coating solution, coating the coating solution on the hot aluminum / zinc-plated sheet substrate, and curing. The coating formed by curing the self-lubricating treating agent composition has favorable corrosion resistance, heat resistance, water resistance and adsorptivity, and has especially excellent fingerprint resistance and self-lubricating property.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

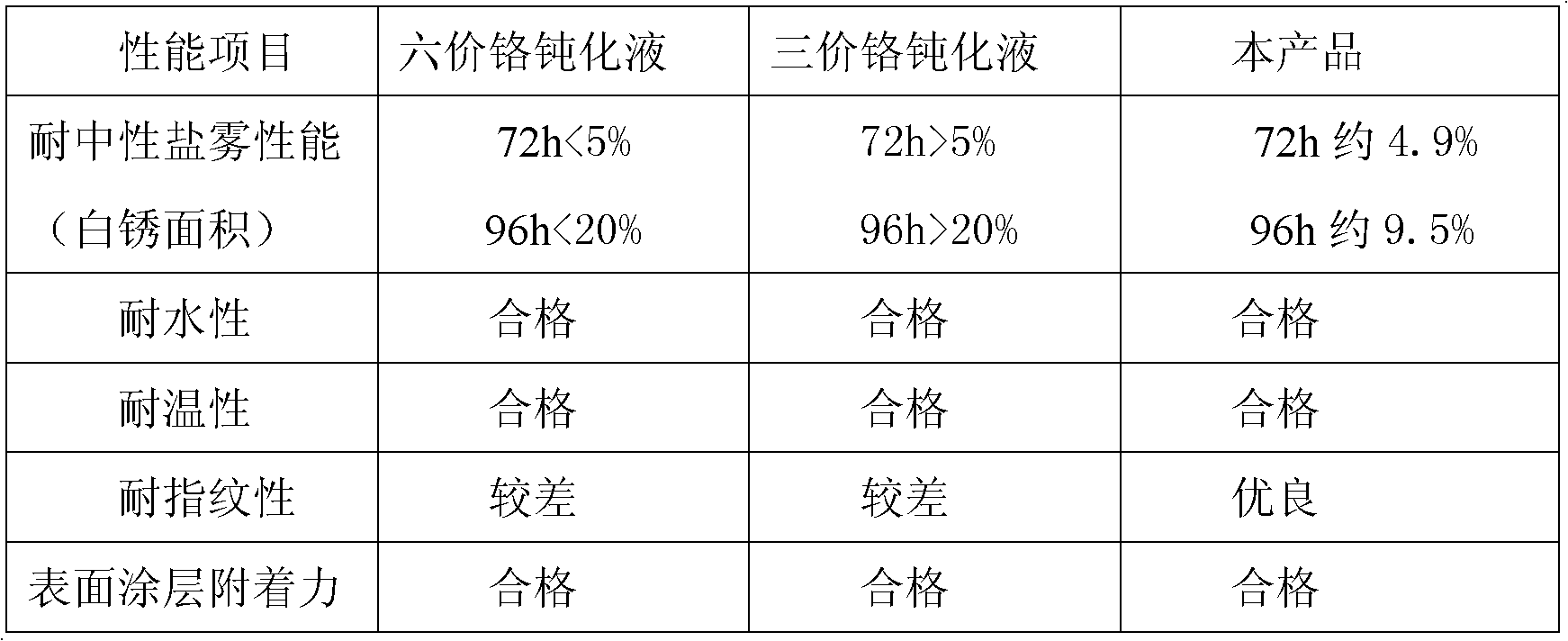

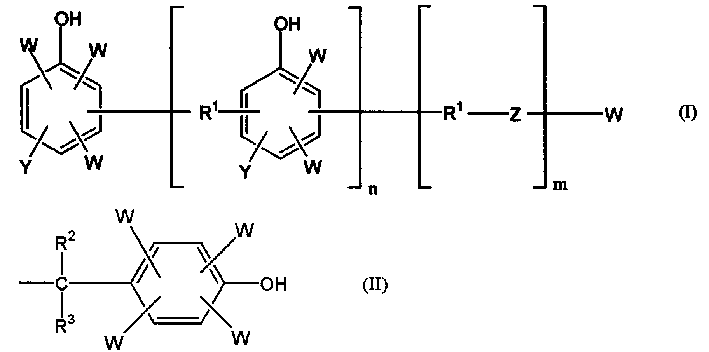

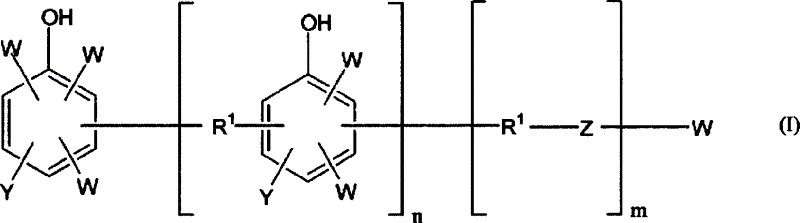

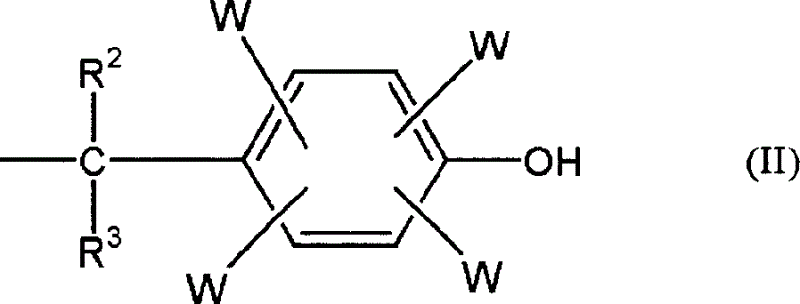

Surface treatment agent for metal, process for surface treatment of metallic substances and surface-treated metallic substances

InactiveCN1520468AImprove use valueCorrosion resistanceLiquid surface applicatorsAnti-corrosive paintsEpoxyHydrogen

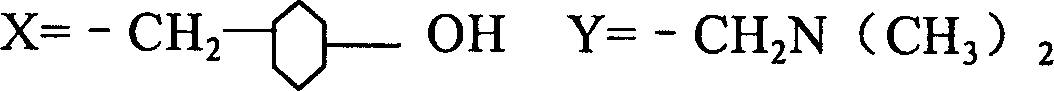

A surface treatment for metal, prepared by adding a cationic or nonionic, urethane, acrylic, epoxy, polyester, or polyamide resin, a resin compound represented by the general formula (I), and a compound of Zr, Ti, V, Mo, W, Mn, or Ce to water; a process for surface treatment of metallic substances; and surface-treated metallic substances: (I) [wherein R1 is -CH2-, -CH2-NH-C H2- , or -CH=N-CH2-; Y is H or a group represented by the general formula (II): (II) Z is a residue of an aromatic compound or the like; W is H or a group ( P) selected from among -CH2X, -CH2NHCH2X, and -CH=NCH2X (wherein X is OH, OR4, halogeno, -N(R5)(R6), or -N+(R7)(R8)(R9)A-) , with the proviso that the degr ee of substitution with the group (P) satisfies the relationship: (number of Ps ) / (total number of benzene rings and Zs) = 0.2 to 4.0; n is 0 to 29; and m is 0 to 10]. The surface treatment is free from chromium and can impart excellent corrosion resistance, alkali resistance and fingerprinting resistance to metallic substances.

Owner:NIHON PARKERIZING

Method for preparing trivalent chromium compound

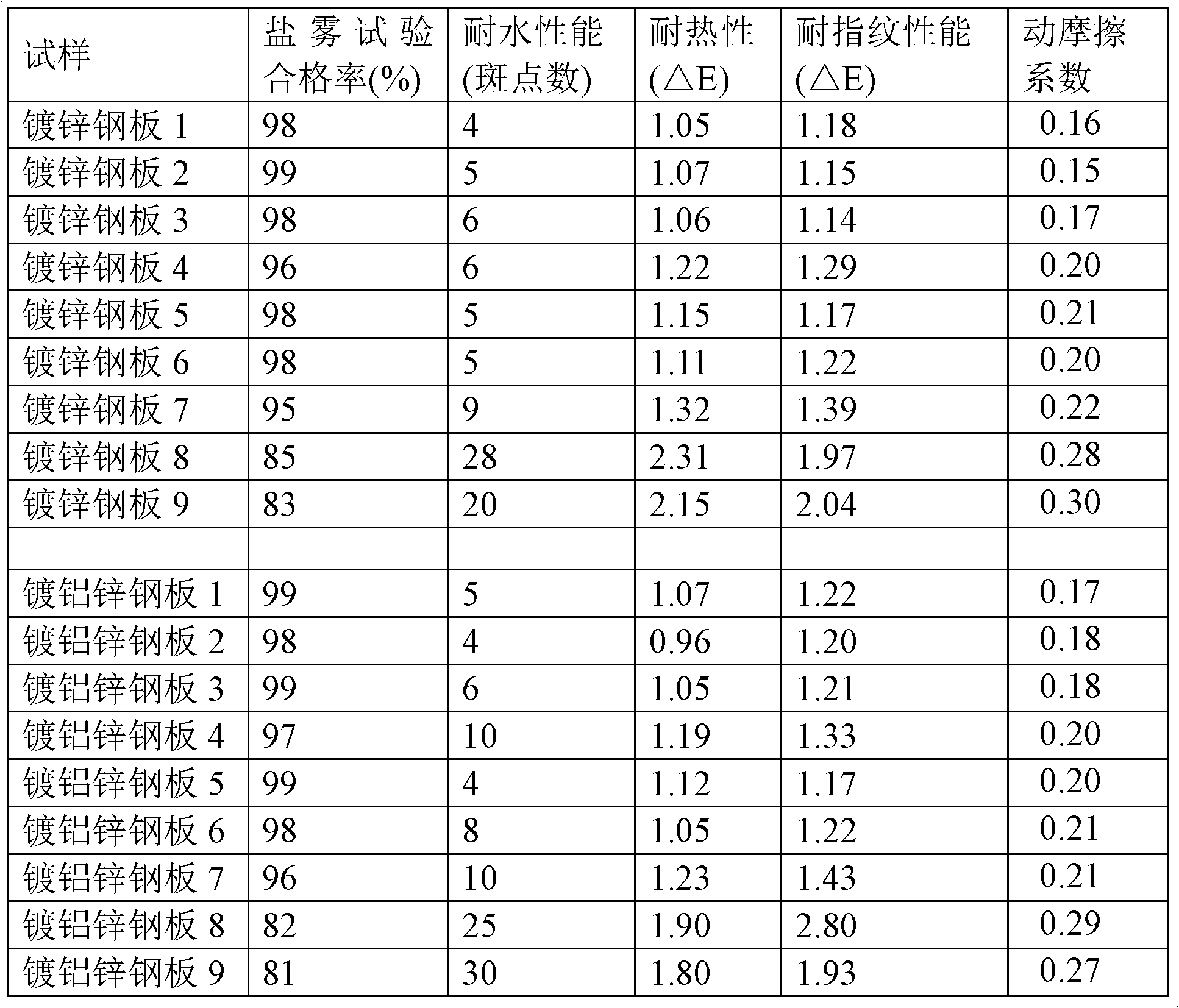

InactiveCN101607738AExcellent fingerprint resistanceLower coefficient of dynamic frictionMetallic material coating processesChromium compoundsSteel platesHexavalent chromium

The invention provides a method for preparing a trivalent chromium compound. The method comprises the following steps that a hexavalent chromium compound contacts with a reducing agent and a complexing agent under the existence of water, wherein the reducing agent is a substance capable of reducing hexavalent chromium into trivalent chromium; and the complexing agent is a substance capable of having complexation with trivalent chromium ions. When the trivalent chromium compound prepared by the method is adopted as a film forming agent of a galvanized self-lubricating steel plate, an obtained self-lubricating coating has obviously improved fingerprint resistance, corrosion resistance and adhesive force as well as obviously reduced coefficient of dynamic friction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Chromium-free fingerprint-resistant coating solution and preparation method of hot-dip aluminizing zinc plate

ActiveCN105038437AImprove stabilityImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedChromium free

The invention belongs to the field of metal surface treatment materials, and particularly relates to a chromium-free fingerprint-resistant coating solution and a preparation method of a hot-dip aluminizing zinc plate. The coating solution is composed of the following components in parts by weight: 0.3-3 parts of phosphate, 0.6-6 parts of molybdate, 0.9-9 parts of nitrite, 0.1-5 parts of pH regulator, 5-25 parts of colloidal silicon dioxide and 10-40 parts of water-based organic resin emulsion. The weight ratio of the phosphate, molybdate and nitrite is 1:(1.5-2):(2.5-3). After being used for the hot-dip aluminizing zinc plate, the chromium-free fingerprint-resistant coating solution has the advantages of favorable corrosion resistance, favorable fingerprint resistance and environment friendliness, and can satisfy the requirements for home appliances, IT (information technology) and other industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-temperature anti-fingerprint surface treating agent for galvanized steel sheet and environment-friendly surface treated galvanized steel sheet

ActiveCN104073100AHighlight corrosion resistanceHighlight drug resistancePolyurea/polyurethane coatingsWater basedSolvent

The invention relates to a low-temperature anti-fingerprint surface treating agent for a galvanized steel sheet and an environment-friendly surface treated galvanized steel sheet of which the surface is treated by use of the surface treating agent. The surface of the galvanized steel sheet does not contain chromium and does not need to be dried at a high temperature, and a surface treatment film can be formed on the surface under a low-temperature drying condition; the manufacturing process is environment-friendly and low in energy consumption; a composition (namely the surface treating agent) containing specific water-based resin and phosphide, specific organic silicon compound, titanium compound, vanadium compound and oxidic polyethylene particles is applied to the surface of the galvanized steel sheet and then dried at a low temperature ranging from 50 to 75 DEG C, and consequently, the obtained surface treated galvanized steel sheet has excellent properties such as excellent alkali resistance, solvent resistance, corrosion resistance, fingerprint resistance, coating adherence and the like.

Owner:BAOSHAN IRON & STEEL CO LTD +2

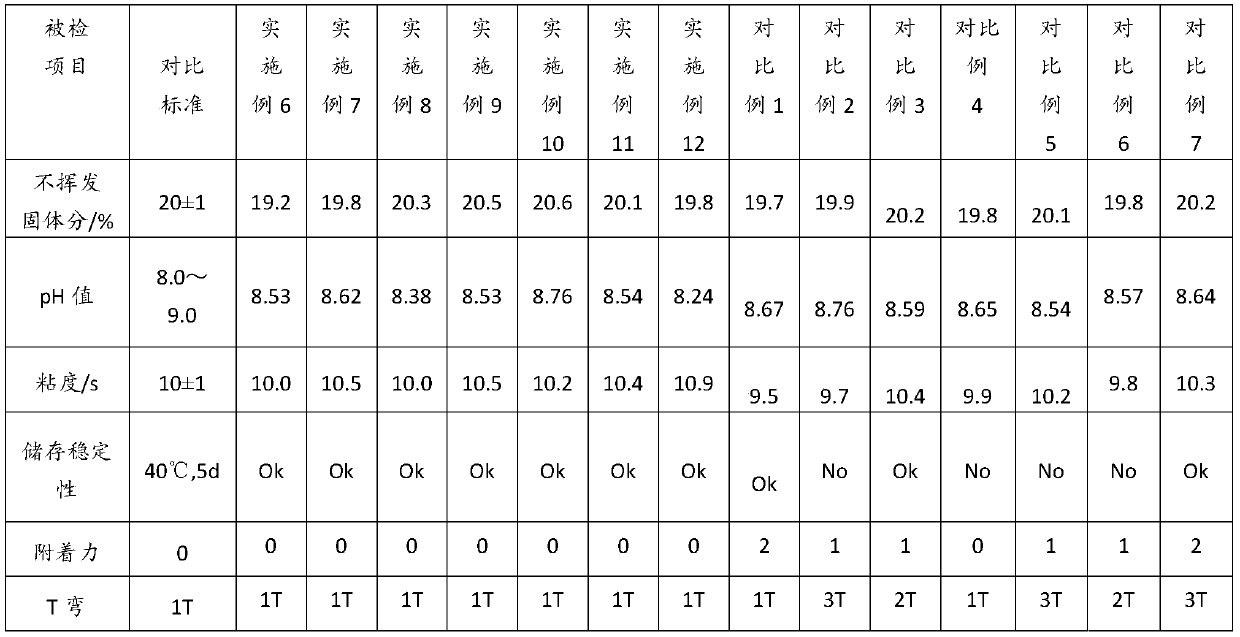

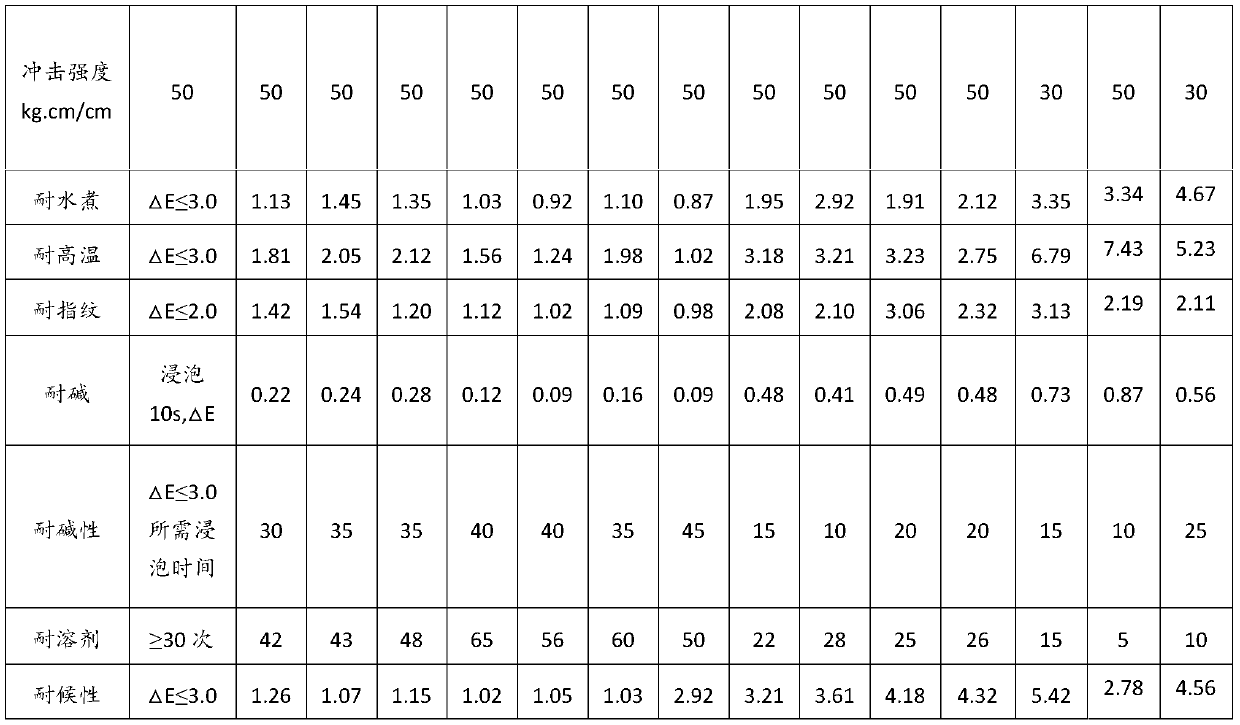

Non-chrome alkali-resistant and solvent-resistant galvanized steel sheet surface treatment liquid and preparation method thereof

InactiveCN101792903AGood alkali resistanceGood solvent resistanceHot-dipping/immersion processesLiquid wasteWater dispersible

The invention discloses a non-chrome alkali-resistant and solvent-resistant galvanized steel sheet surface treatment liquid and a preparation method thereof. The water solution of the galvanized steel sheet surface treatment liquid comprises the following components: glass etching waste liquid and / or silane combustion tower filer washing waste liquid treated by decontaminating and purifying, phosphorous compound, one or more organosilane coupling agent(s) containing at least one amino functional group with active hydrogen, one or more organosilane coupling agent(s) containing at least one epoxy group functional group, at least one cation-type or ionic type water soluble polyurethane resin or water-dispersion polyurethane resin, and at least one accelerating agent which is oxygen acid or oxysalt. The galvanized steel sheet surface treatment liquid has good corrosion resistance, fingerprint resistance and coating adhesiveness, and not only meets the requirements of high quality and environmental protection of home appliances users on and the like, but also solves the problem of recycling of the glass etching waste liquid and the silane combustion tower filer washing waste liquid.

Owner:MAANSHAN WEIDELI LUBRICATION MATERIAL TECH +1

Water-based acrylic acid-epoxy-polyurethane dispersoid and alcohol-rubbing-resistant and alkali-resistant coating

The invention provides a water-based acrylic acid-epoxy-polyurethane dispersoid and an alcohol-rubbing-resistant and alkali-resistant coating; the coating is non-toxic and pollution-free, and the properties of high temperature resistance, alcohol rubbing resistance, fingerprint resistance, flexibility, coating property and the like are good. A preparation method of the dispersoid comprises the following steps: 1) carrying out a reaction on an epoxy compound with a micromolecular alkyd compound to prepare epoxy polyol; 2) carrying out a reaction on epoxy polyol, hydrophilic polyurethane and a chain extension cross-linking agent to prepare water-based epoxy resin modified polyurethane, and neutralizing, shearing and dispersing to obtain an ester mixed emulsion; 3) mixing and dissolving the mixed emulsion and an acrylate monomer, and shearing and dispersing to obtain a ternary system mixed emulsion; 4) after the mixed emulsion is subjected to a chain extension reaction, adding an initiator and a polymerizable monomer containing keto-carbonyl, carrying out a reaction, then adding a reactive monomer containing hydrazide groups, mixing and dissolving, and 5) removing the solvent to obtain the water-based acrylic acid-epoxy-polyurethane dispersoid.

Owner:WANHUA CHEM GRP CO LTD +2

ALuminium plate with envelope and electronic equipment parts using the same

InactiveCN1454046ACrack suppressionExcellent fingerprint resistanceCasings/cabinets/drawers detailsSpecial surfacesCorrosion resistantAluminium

Owner:KOBE STEEL LTD

Surface treating agent for metallic materials, method for surface treating metallic materials using the surface treating agent, and surface treated metallic materials

ActiveCN102257179AImprove heat resistanceImprove conductivityAnti-corrosive paintsMetallic material coating processesMetallic materialsPhosphoric acid

Disclosed is a surface treating agent for metallic materials that can form, on the surface of metallic materials, a novel film, which can simultaneously realize, for example, heat resistance, weldability, continuous processability, electrical conductivity, fingerprint resistance, and coatability, and has excellent liquid stability. The surface treating agent for metallic materials contains a compound (A), which contains in one molecule two or more functional groups (a) represented by -SiR1R2R3 and a hydrophilic functional group (b), in which the molecular weight per functional group (b) (average molecular weight / number of functional groups) is in the range of 300 to 5000, at least one metal alkoxide (B) containing one element selected from the group consisting of Si, Ti, and Zr, at least one compound (C) selected from the group consisting of fluorine-containing compounds and phosphoric acid compounds, organic compounds (D) containing at least one hydrophilic functional group selected from the group consisting of a carboxylic acid group, a phosphonic acid group, and a sulfonic acid group, and water.

Owner:NIHON PARKERIZING

Surface-treated metal material and aqueous metal surface treatment agent

ActiveCN103635607AImprove corrosion resistanceImprove heat resistanceLiquid surface applicatorsLayered productsComposite filmZirconium compounds

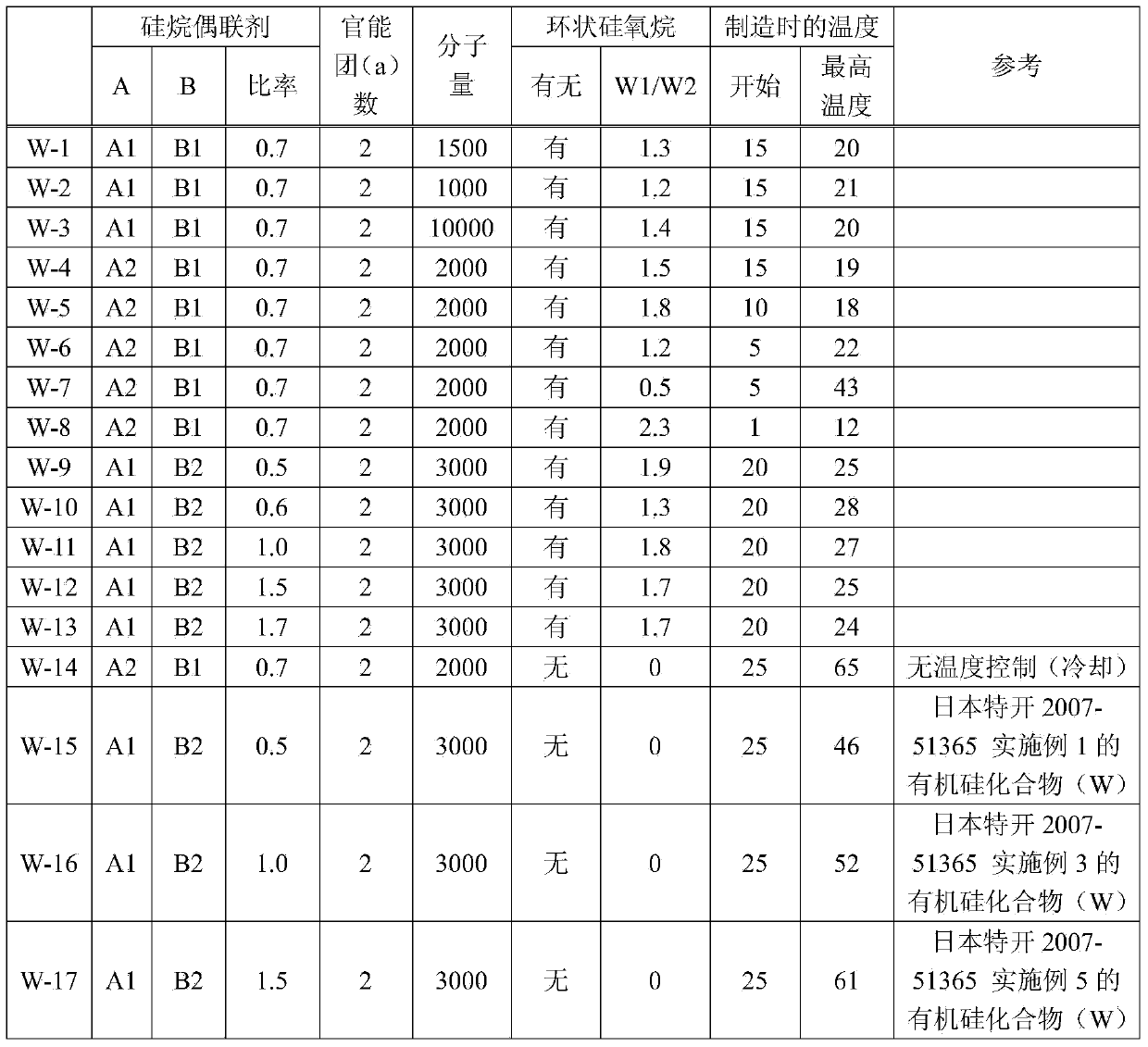

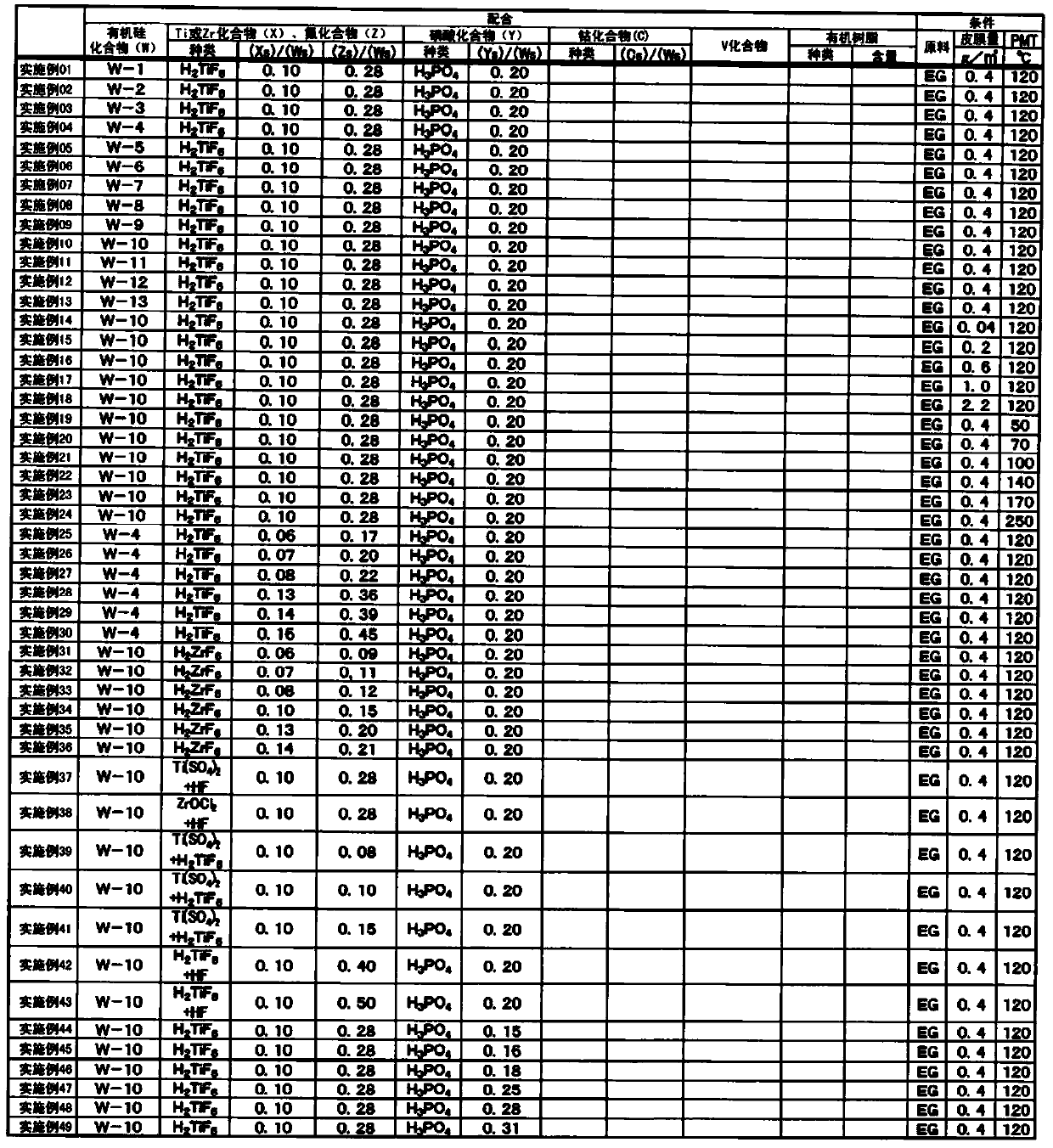

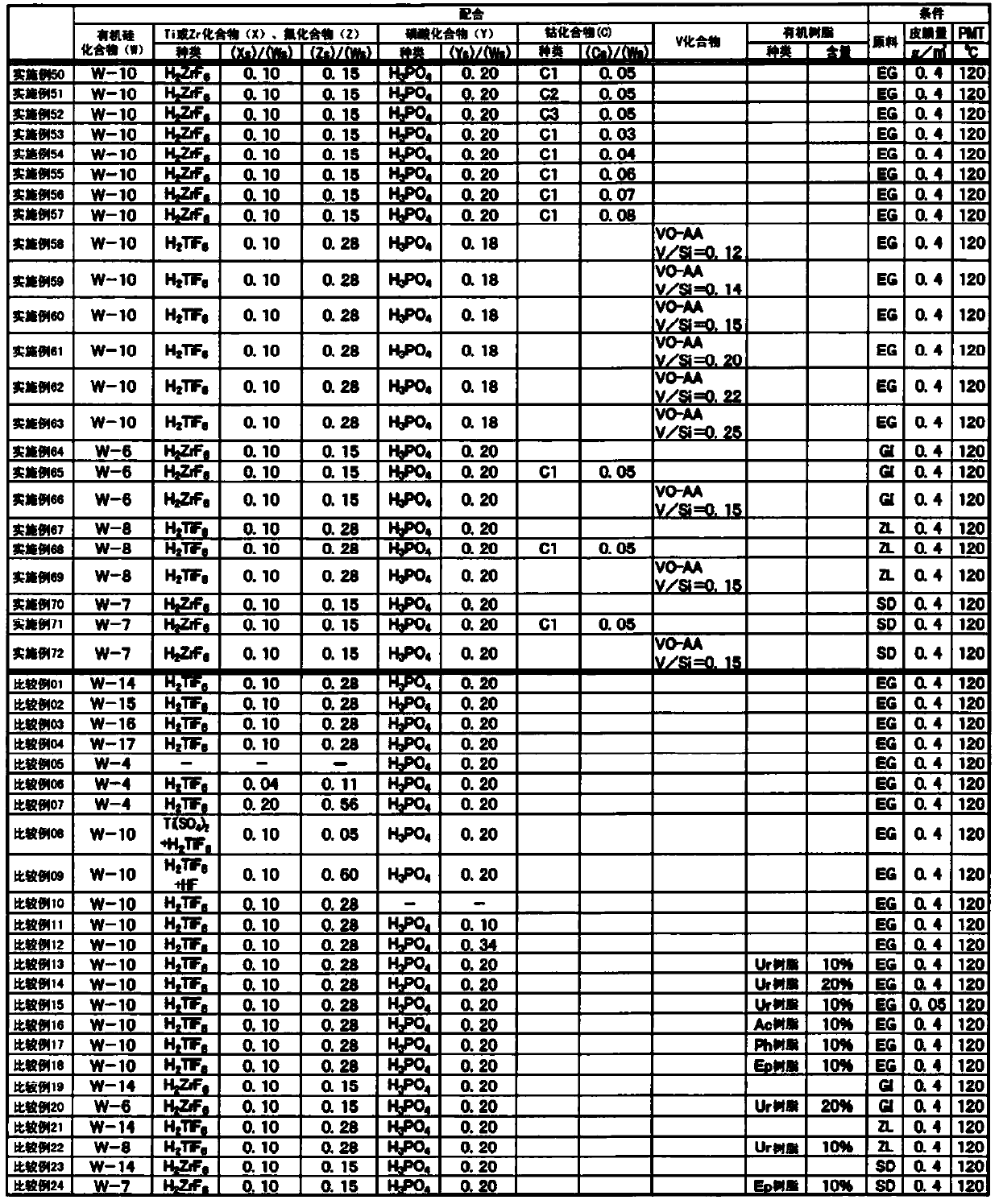

A surface-treated metal material according to the present invention is a metal material the surface of which is coated with a composite film comprising an organic silicon compound (W) having cyclic siloxane bonds, at least one type of metal compound (X) selected from the group consisting of titanium compounds and zirconium compounds, a phosphoric acid compound (Y), and a fluorine compound (Z). In each component of the composite film, the ratio (XS / WS) of the solid content weight (WS) of Si derived from the organic silicon compound (W) and the solid content weight (XS) of the at least one metal component selected from the group consisting of Ti and Zr contained in the metal compound (X) is between 0.06 and 0.16, the ratio (YS / WS) of the solid content weight (WS) and the solid content weight (YS) of P derived from the fluorine compound (Z) is between 0.15 and 0.31, and the ratio (ZS / WS) of the solid content weight (WS) and the solid content weight (ZS) of F derived from the fluorine compound (Z) is between 0.08 and 0.50.

Owner:NIPPON STEEL CORP +1

Method for producing back plate of liquid crystal television

InactiveCN103203310AGood lookingHigh quality appearancePretreated surfacesCoatingsProduction lineStrip steel

The invention relates to the field of color-coated steel sheet production, and particularly to a method for producing a back plate of a liquid crystal television. The method is characterized in that the raw steel material is required to be deep-draw steel at DX53D+Z or above; the surface is required to reach the quality standard of FB level or above; and started with the process control adjustment of pre-treatment, coating and packaging, curing, cooling procedures and coiling technology in the production process, the method for producing the back plate of the liquid crystal television comprises the specific control steps of: 1) carrying out the pre-treatment process, including, pre-degreasing, pre-cleaning, pre-rinsing, and controlling a speed of a production line within 50-70 m / min; 2) passivating, and coating primer and finish paint on the front side of the product and back paint of a product; 3) drying and curing at 18-226 DEC G; 4) cooling strip steel; and 5) using a paper sleeve when coiling the strip steel on line. Compared with the prior art, the method for producing the back plate of the liquid crystal television has the beneficial effects of realizing the quality characteristic requirements of the back plate of the liquid crystal television, and realizing production of a back plate of a liquid crystal television with a good appearance and excellent performances through a color coating technology.

Owner:ANGANG STEEL CO LTD

Non-chrome water-based organic fingerprint-resistant coating and preparation method thereof

ActiveCN101914344ASimple preparation processImprove corrosion resistancePolyurea/polyurethane coatingsWater basedRoom temperature

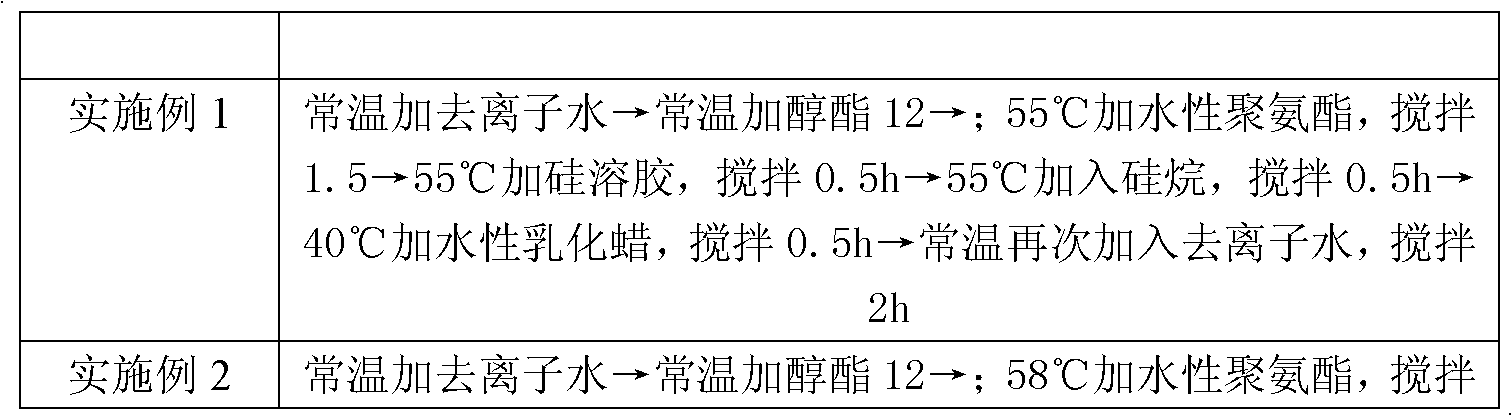

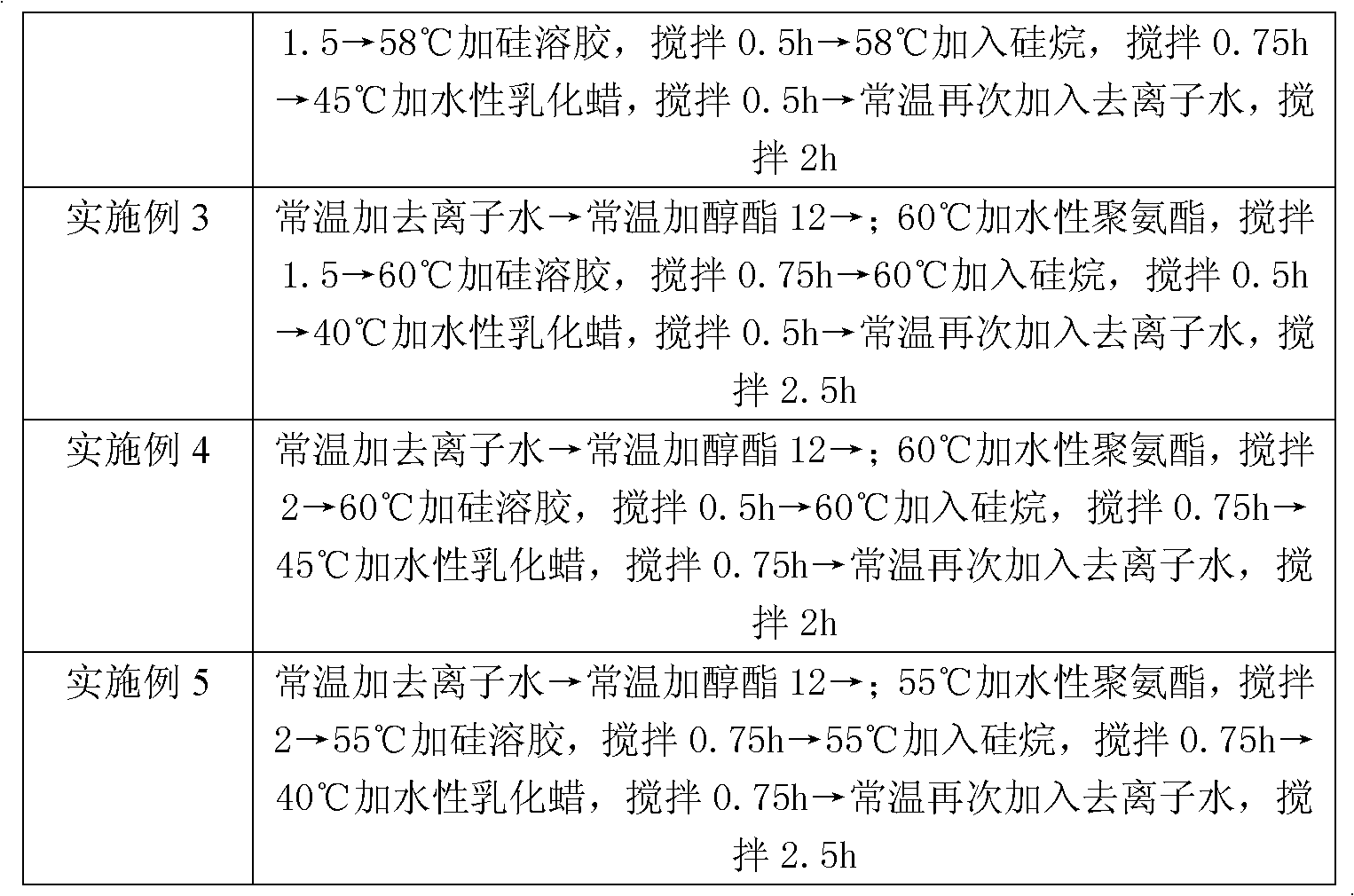

The invention discloses non-chrome water-based organic fingerprint-resistant coating, which comprises the following components in part by mass: 15 to 25 parts of water-based resin, 25 to 65 parts of deionized water, 1 to 2 parts of film-forming aid, 5 to 10 parts of lubricating aid, 5 to 15 parts of silane coupling agent, and 10 to 20 parts of silica sol. Correspondingly, the invention also discloses a method for preparing the non-chrome water-based organic fingerprint-resistant coating, which comprises the following steps of: adding deionized water into a reaction kettle at normal temperature; adding a film-forming aid into the reaction kettle; heating the mixture to the temperature of between 55 and 60 DEG C, adding the water-based resin, and stirring for 1.5 to 2 hours; keeping the temperature, adding the silica sol, and stirring for 0.5 to 0.75 hour; keeping the temperature, adding the silane coupling agent, and stirring for 0.5 to 0.75 hour; cooling to the temperature of between 40 and 45 DEG C, adding the lubricating aid, and stirring for 0.5 to 0.75 hour; and cooling to normal temperature, adding the ionized water once again, and stirring for 2 to 2.5 hours.

Owner:上海丰野表面处理剂有限公司

Novel fluorine-containing siloxane fire retardant, and preparation method and application thereof

The invention relates to the technical field of plastic assistants, and concretely relates to a novel fluorine-containing siloxane fire retardant, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, uniformly mixing organosiloxane monomers, adding the obtained monomer mixture into a catalyst and emulsifier dissolved aqueous solution, and carrying out a reaction to obtain an organopolysiloxane emulsion; 2, adjusting the pH value of the organopolysiloxane emulsion by using an alkali liquid, adding a fluorine-containing styrene monomer and a copolymerization, adding an initiator, a crosslinking agent and a chain transfer agent, and carrying out a reaction to obtain an organosiloxane grafted fluorine-containing styrene polymer emulsion; and 3, diluting the polymer emulsion, adding a de-emulsifier to carry out demulsification, centrifuging the de-emulsified emulsion, and carrying out drying and crushing to prepare the novel fluorine-containing siloxane fire retardant. The novel fluorine-containing siloxane fire retardant prepared in the invention has excellent anti-dripping effect and fire-retardant property without affecting the mechanical properties of a high-molecular material polymer, and also can improve the mechanical properties and the heat resistance of matrix resin.

Owner:铨盛聚碳科技股份有限公司

Production method of surface passivator and coating used for zinc-aluminum-magnesium plating product

PendingCN112176329AExcellent anti-blackening performanceImprove performanceHot-dipping/immersion processesNano siliconSilicon oxide

The invention discloses a production method of a surface passivator and coating used for a zinc-aluminum-magnesium plating product. The production method comprises the procedures of passivator preparation, finishing, coating and drying, and the passivator is composed of high-crosslinking resin, silane, nano silicon oxide, a corrosion inhibitor, an antioxidant and water. By controlling the roughness of a finishing roller, the finishing process, the coating process, the drying temperature and the like, a zinc-aluminum-magnesium product passivated steel plate which is excellent in blackening resistance and integrates multiple excellent functions such as environmental protection, fingerprint resistance, corrosion resistance, heat yellowing resistance, solvent resistance, flame retardance and coating performance is obtained, the requirements of European Union Rohs environmental protection instructions are met, and the thickness of a passivation film layer of the obtained zinc-aluminum-magnesium plating layer passivation steel plate is 1.0-1.5 g / m < 2 >.

Owner:TANGSHAN IRON & STEEL GROUP +1

Optical Disc and an Ultraviolet-Curable Resin Composition Therefor

InactiveUS20090148651A1Reduce warpingHigh transparencyLayered productsRecord information storageEpoxyMeth-

The present invention relates to an optical disc having a cured product layer of an ultraviolet-curable resin composition containing (A) dicyclopentenyloxyethyl acrylate, (B) urethane (meth)acrylate and / or (C) epoxy (meth)acrylate, and (D) photopolymerization initiator, and a resin composition for the cured product layer thereof and a cured product therewith; and the optical disc of the present invention has less warping after curing and is excellent in transparency and durability and therefore suitable for next generation high density optical discs where recording and / or reproducing are performed using a blue laser; the resin composition for said cured product layer has less deterioration with age and less viscosity change in recycle and is suitable for a coating agent of optical discs and for efficient production of optical discs.

Owner:NIPPON KAYAKU CO LTD

Metal protecting coating and hot-dipped metal material

InactiveCN103122157AImprove corrosion resistanceImprove water resistanceHot-dipping/immersion processesAlkali metal silicate coatingsWater basedSilicon oxide

The invention provides a metal protecting coating. The metal protecting coating is obtained after mixing a raw material mixture uniformly, wherein the raw material mixture contains water soluble silicate, an accelerant, a silane coupling agent, a silicon oxide filler, water soluble film-forming resin and water; the accelerant is water-based emulsion of polyethylene wax and / or water-based emulsion of oxidized polyethylene wax; the silane coupling agent contains first silane derivatives shown in a formula (1) in the specification; and in the formula (1), R1, R2 and R3 are respectively methoxy or ethoxy, and n is an integer from 1 to 4. The invention also provides a hot-dipped metal material. The hot-dipped metal material comprises a hot-dipped metal substrate and a coating attached to the hot-dipped metal substrate, wherein the coating is a cured product of the metal protecting coating. Protective films formed by the metal protecting coating provided by the invention have excellent corrosion resistance, water resistance, heat resistance, fingerprint resistance and lubricating property.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

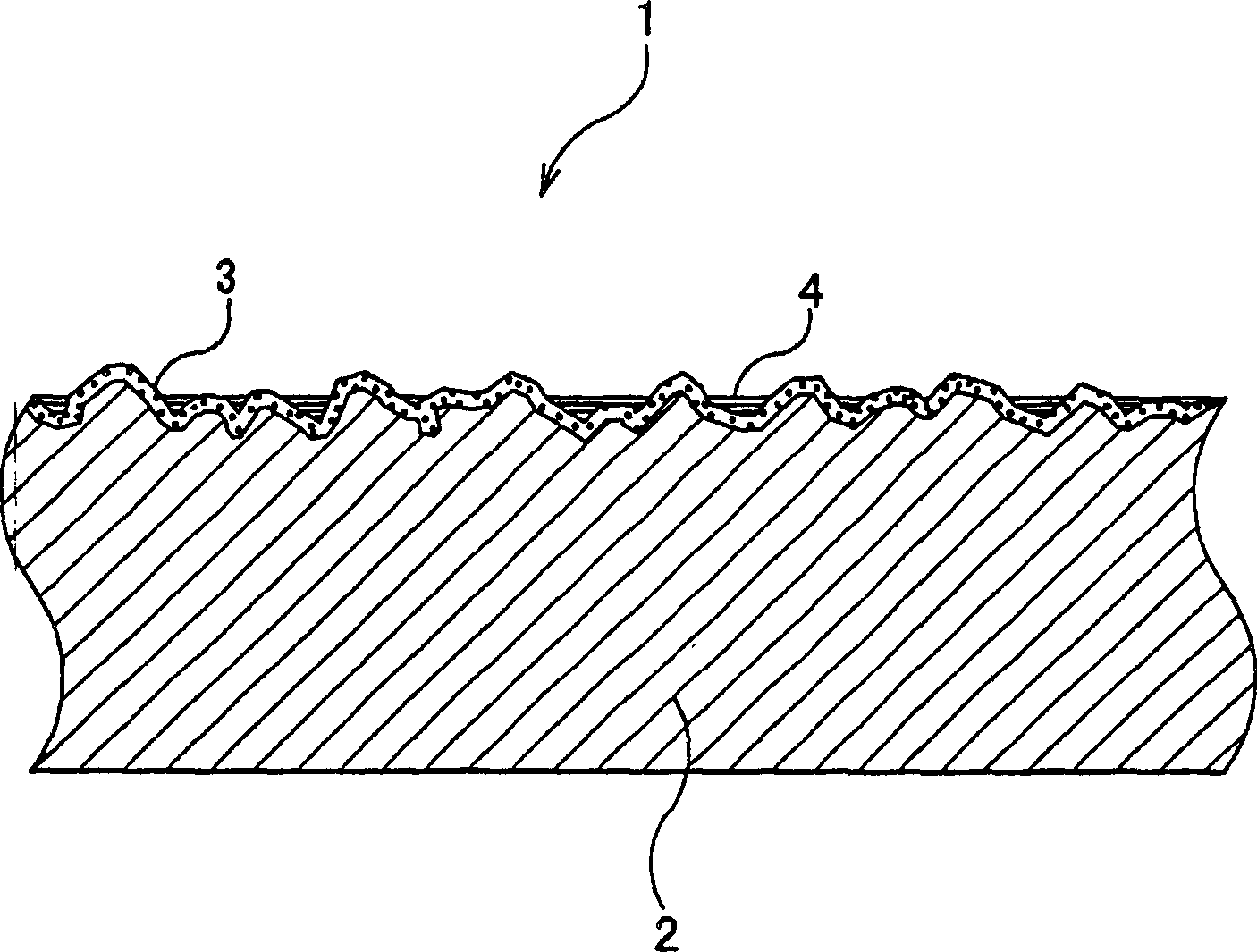

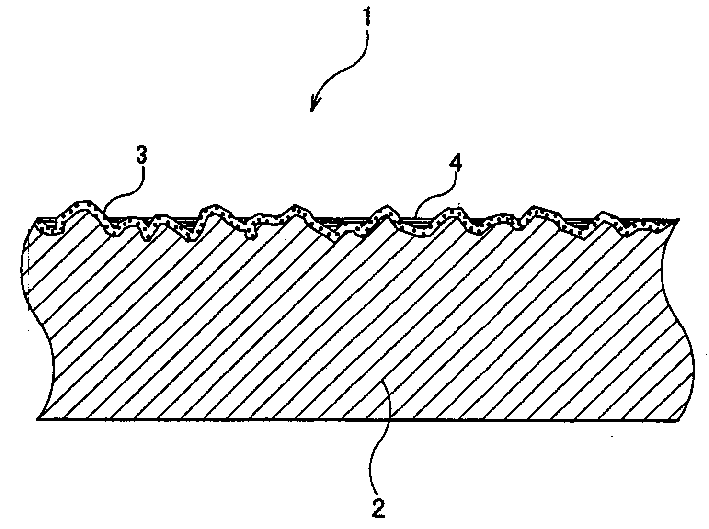

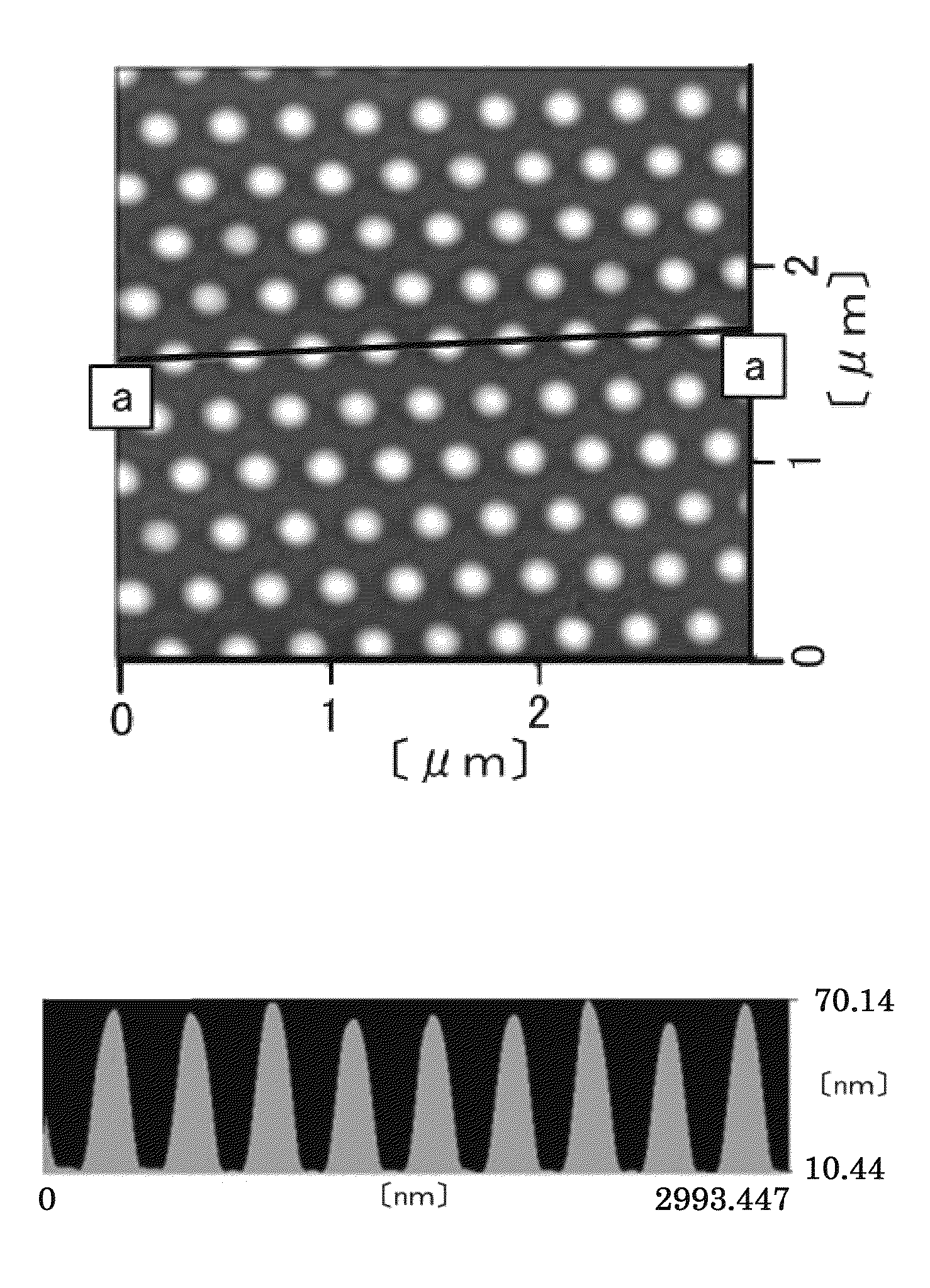

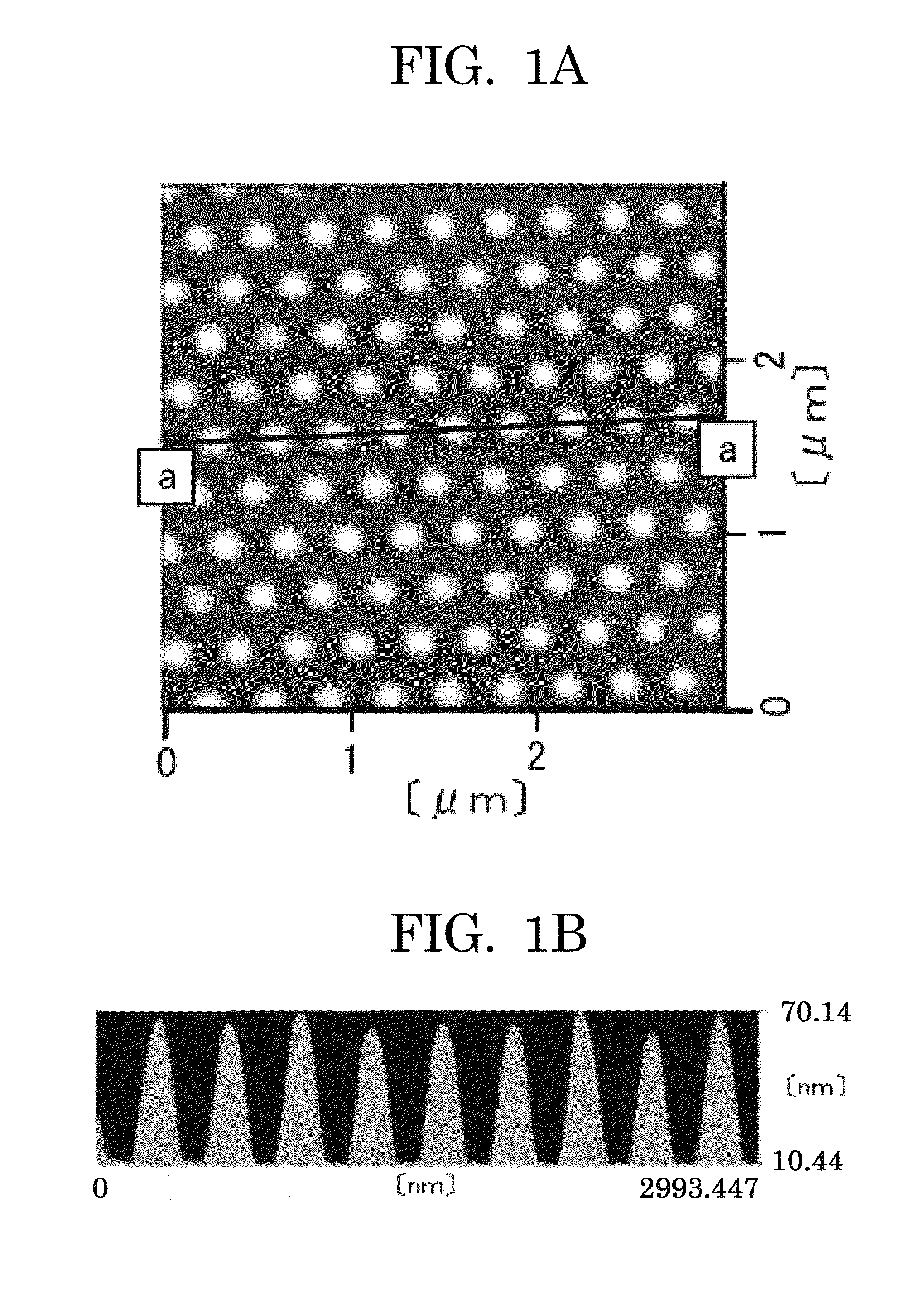

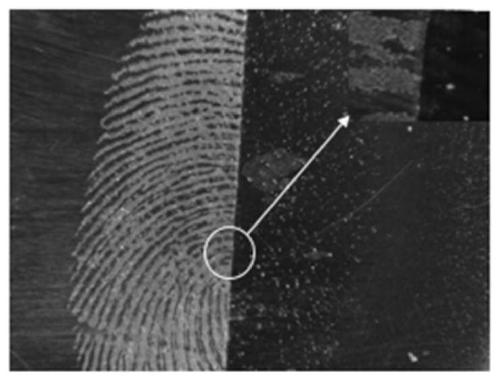

Lipophilic laminate, method for manufacturing the same, product, and method for manufacturing the same

InactiveUS20140295145A1Excellent fingerprint resistanceAvoid large contactAntifouling/underwater paintsSynthetic resin layered productsChemistryOleic Acid Triglyceride

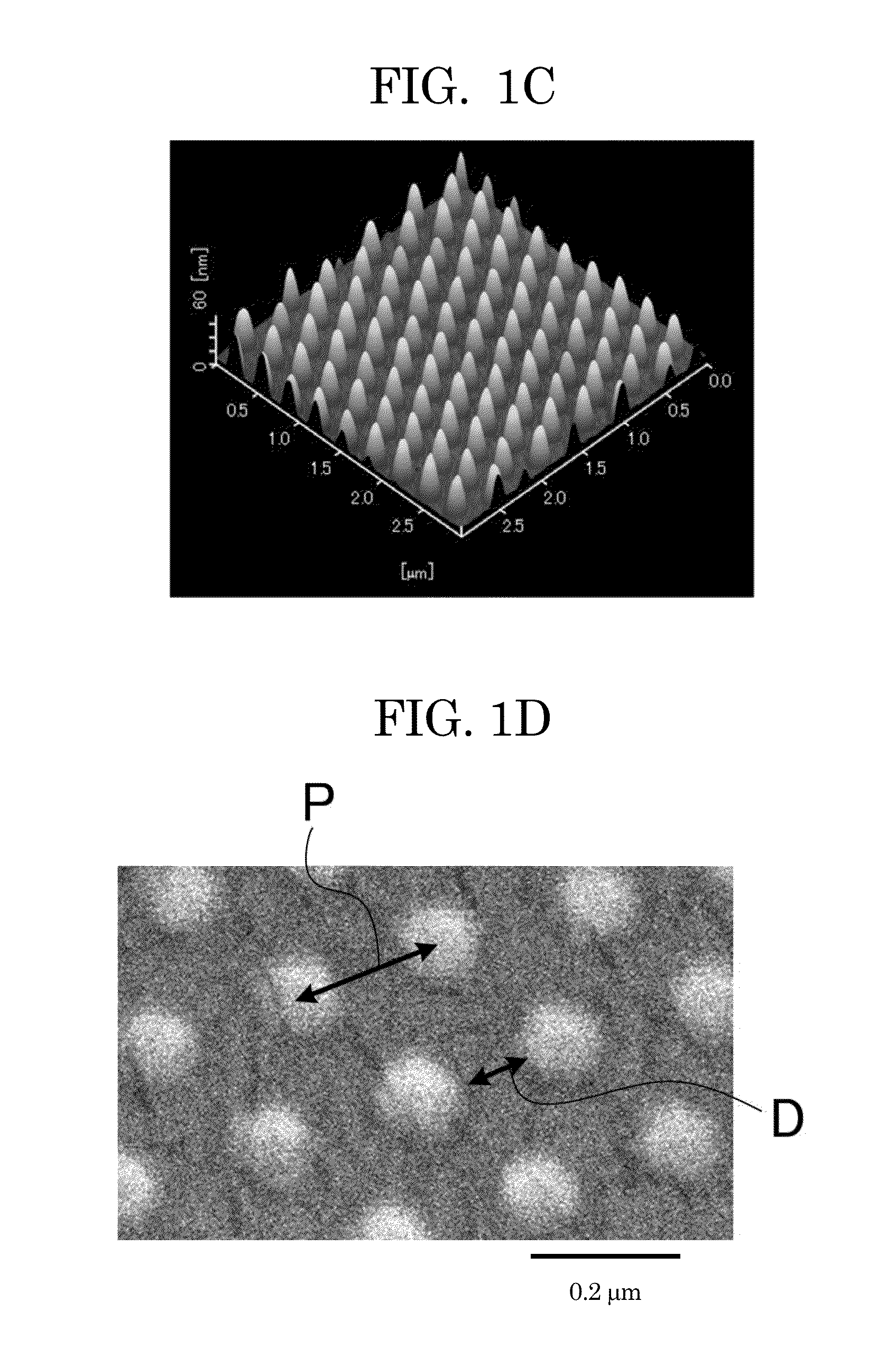

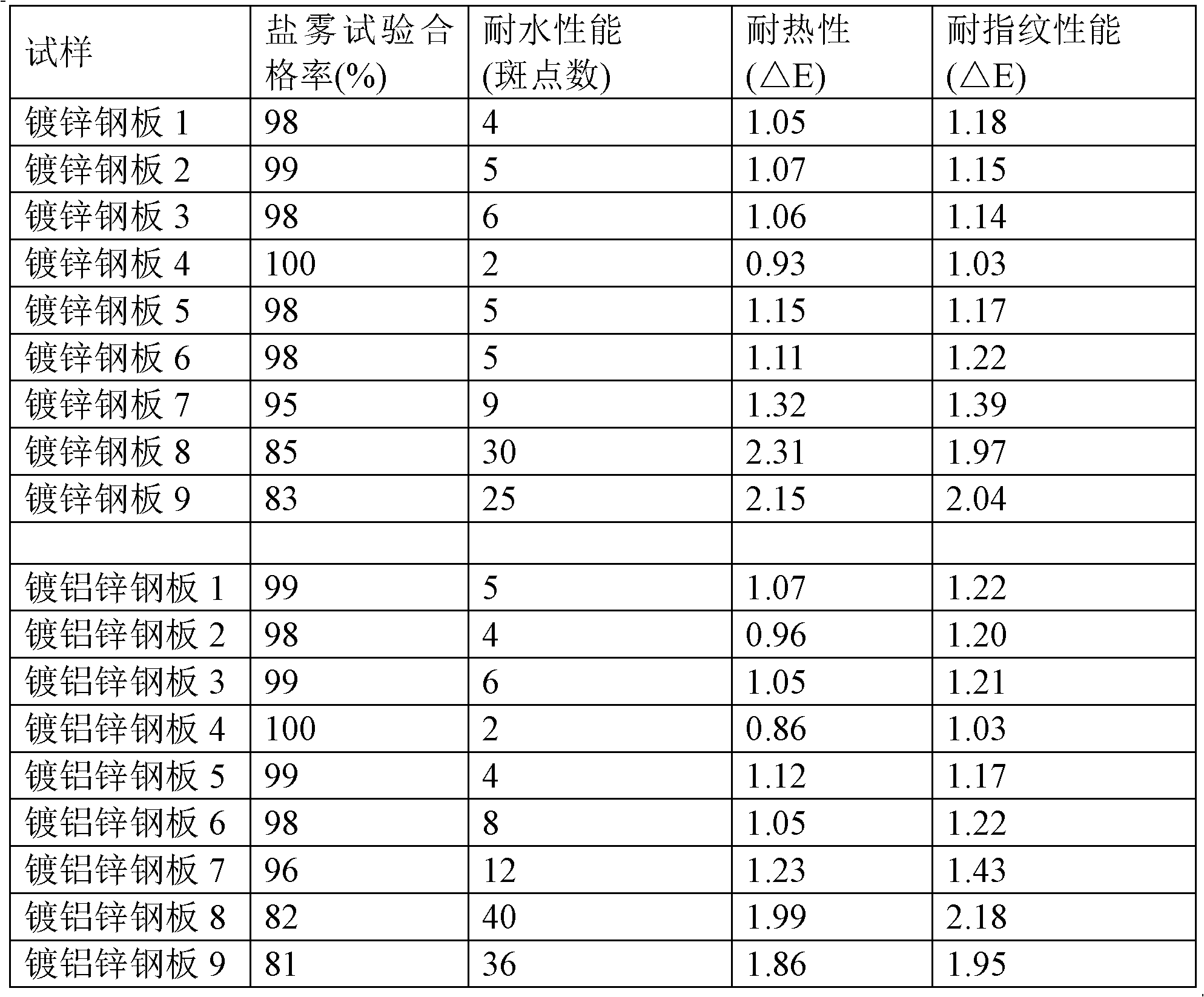

A lipophilic laminate, including: a substrate made of a resin; and a lipophilic resin layer on the substrate made of a resin, wherein the lipophilic resin layer includes micro convex portions or micro concave portions in a surface thereof, and wherein an oleic acid contact angle of the surface of the lipophilic resin layer is 10° or less.

Owner:DEXERIALS CORP

Metal protective coating and hot galvanizing metal material and hot dip aluminum-zinc metal material

ActiveCN103031061AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsSilanesZinc metal

The invention provides metal protective coating which is obtained by uniformly mixing a raw material mixture. The raw material mixture contains water soluble silicate, an accelerant, a silane coupling agent, a silicon oxide filler, a water soluble film-forming resin and water; the accelerant is at least two of a first accelerant, a second accelerant and a third accelerant; and the silane coupling agent contains a first silane derivative represented by the formula (1). The invention further provides a hot galvanizing metal material and a hot dip aluminum-zinc metal material. The protective film prepared by the metal protective coating provided by the invention is excellent in corrosion resistance, water resistance, heat resistance and fingerprint resistance. Formula (1).

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Surface treatment of aquo-metal containing no sexavalence chromium and its treated metal plate for surface treatment

InactiveCN1340635AImprove conductivityExcellent fingerprint resistanceMetallic material coating processesWater dispersibleHexavalent chromium

Provided is an aqueous agent for metal surface treatment without including hexa-valent chromium which form a superior film in corrosion resistance, electroconductivity and fingerprint resistance on a surface of a metal material and to provide a metal plate treated with the treatment agent. The aqueous agent for metal surface treatment without including hexa-valent chromium comprises (A) a trivalent chromium compound, (B) a metal nitrate (C) water-dispersible silica and water, and besides, comprises that the weight ratio of a metal in the component (A) to a metal in the component (B) is in the range of 5 / 95-95 / 5. The aqueous agent preferably includes aqueous resins such as an acryl resin, a urthane resin and an epoxy resin, phosphate compounds, and lubricants as additional components. Water class resin such as acryl resin, urethane resin and epoxy resin, phosphate compounds and a lubricant are preferably included as additional components. A film of 0.1-5 g / m2 by dry coating weight is formed by means of applying the above aqueous agent for metal surface treatment on at least one side of the surface of the metal and drying it.

Owner:NIHON PARKERIZING

Preparation method for curing fingerprint-resistant urethane acrylate with electron beam

InactiveCN105778042AExcellent anti-fingerprint performanceExcellent fingerprint resistanceAntifouling/underwater paintsPaints with biocidesPrepolymerFingerprint

The invention relates to a preparation method for curing fingerprint-resistant urethane acrylate with an electron beam. The preparation method includes: (1) preparing fluorine-containing micromolecular chain extender by esterification reaction and nucleophilic addition reaction; (2) by reaction between the fluorine-containing micromolecular chain extender and isocyanate, preparing polyurethane prepolymer, the end group of which is-NCO; (3) using pentaerythritol triacrylate to block the polyurethane prepolymer, so that the fingerprint-resistant urethane acrylate product is obtained. The fingerprint-resistant urethane acrylate prepared by the invention can be cured by the electron beam, and a cured film which is formed after curing has excellent fingerprint resistance, and can be applied to anti-fingerprint treatment of display panels of touch screens.

Owner:浙江海嘉新材料有限公司

Fingerprint-resistant transparent coating layer and preparation method thereof

InactiveCN111303737AStrong visual transparencyExcellent fingerprint resistanceShellac coatingsLiquid surface applicatorsWoven fabricPerfluoropolyether

The invention provides a fingerprint-resistant transparent coating layer and a preparation method thereof. The preparation method comprises the following steps: under the condition of a room temperature, sequentially adding acrylic resin, a catalyst, a leveling agent, an adhesion promoter, a curing agent, a diluent and perfluoropolyether into a material mixing pot, and carrying out stirring so asto obtain a fingerprint-resistant transparent resin coating material; wiping a to-be-coated substrate with alcohol and acetone through a non-woven fabric so as to remove oil stains in sequence, and spraying or wiping the fingerprint-resistant transparent resin coating material onto the substrate, or dip-coating the substrate in the fingerprint-resistant transparent resin coating material to form afilm, wherein the substrate is glass, polished stainless steel or bright plastic; and putting a coated substrate into a drying oven at 80-120 DEG C, and carrying out curing for 1-2 hours so as to obtain the fingerprint-resistant transparent resin coating layer on the substrate. The hydrophobic and oleophylic fingerprint-resistant transparent coating layer prepared by using the preparation methodprovided by the invention has a deionized water contact angle of 95-100 degrees and a tetradecane contact angle of 10-15 degrees, and belongs to a hydrophobic and oleophylic fingerprint-resistant coating layer.

Owner:SOUTHEAST UNIV

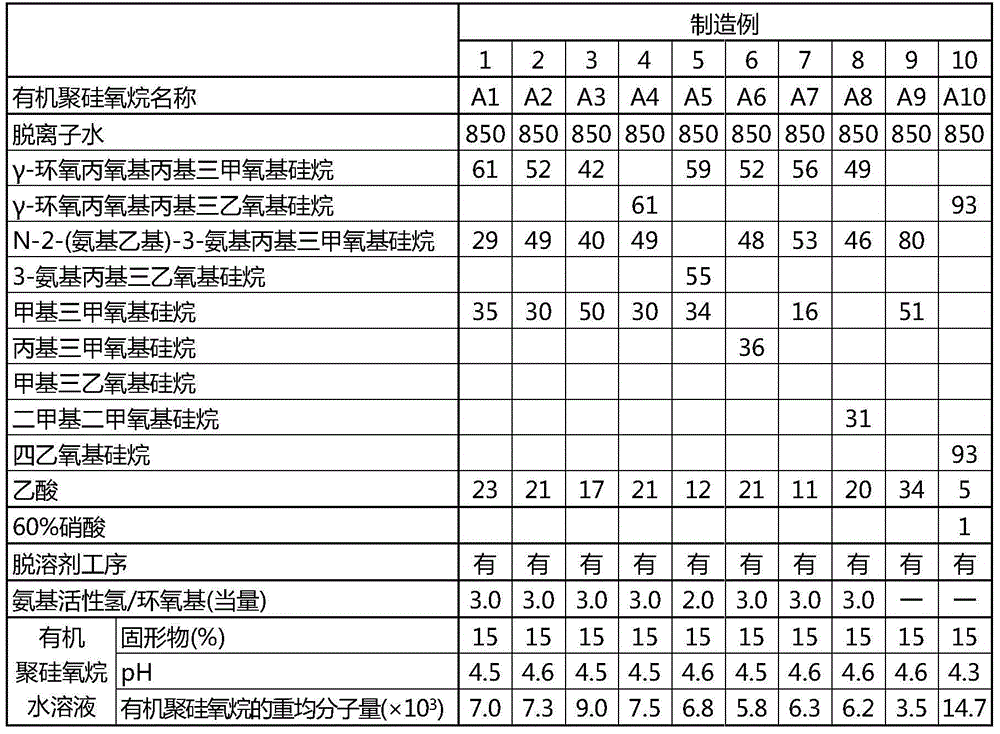

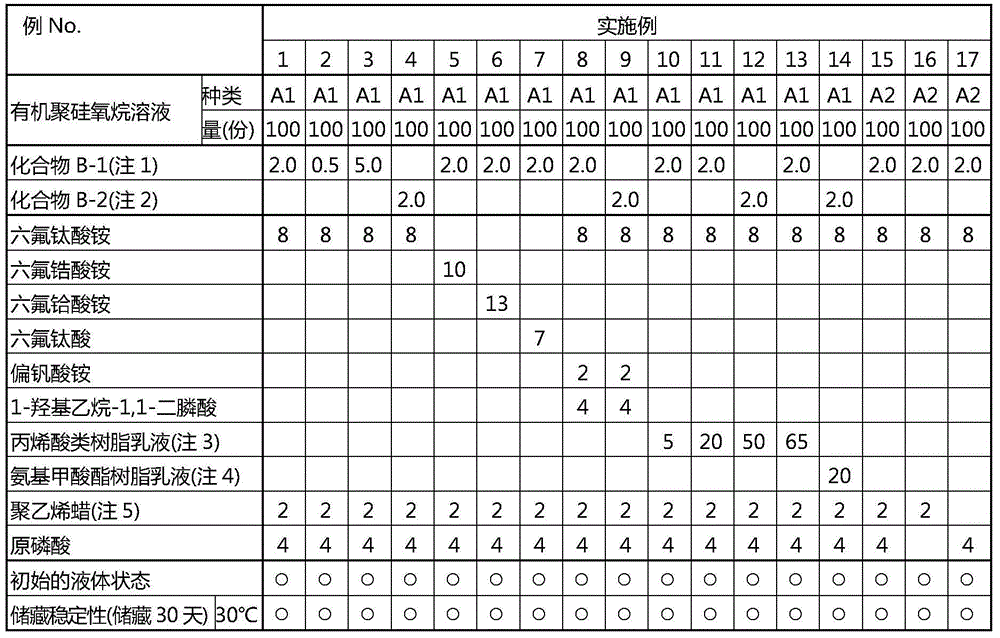

Aquosity metal finishing composition

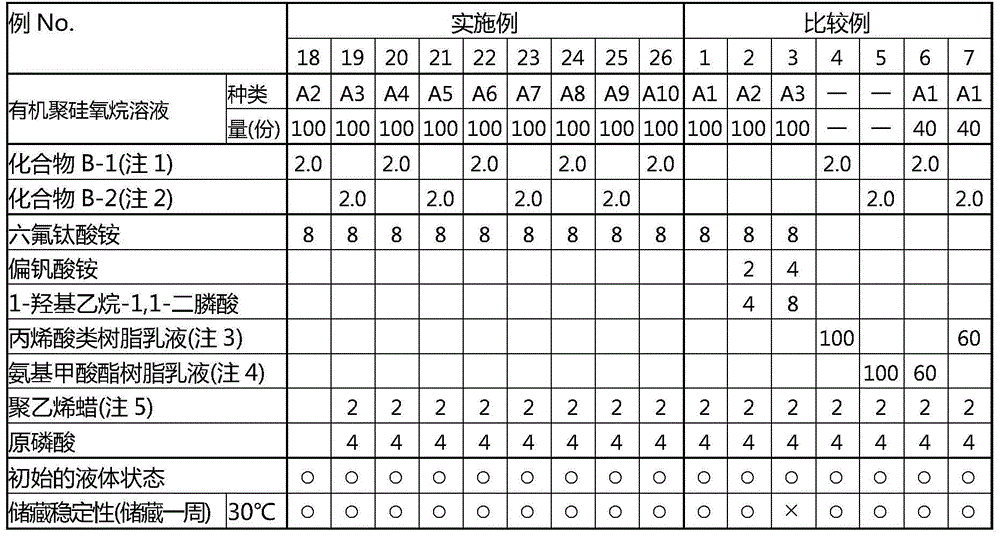

ActiveCN105316668AGood storage stabilityGood corrosion resistanceMetallic material coating processesFingerprintSurface finishing

The present invention provides an aquosity metal finishing composition excellent in paintwork and storage stability, and can form a chromate free surface treatment film excellent in corrosion resistance before and behind degreasing treatment, conductivity, anti-fingerprint property and glazing adhesion. The aquosity metal finishing composition contains organopolysiloxane (A) as a binder main component, and compound (B) having a propargyl group, a hydroxyl group, and mono-oxyethylene or polyoxyalkylene of the molecular weights 100-800, the mono-oxyethylene or polyoxyalkylene in the compound (B) being at least one type chosen from an oxyethylene group, a polyoxyethylene group, an oxypropylene group, a polyoxypropylene group, and a divalent copolymer chain of ethylene oxide and propylene oxide.

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com