Chromium-free passivation liquid applied to surface of zinc-coated layer

A chromium-free passivation and galvanized layer technology, which is applied in the coating process of metal materials, etc., can solve the problems of biological toxicity and achieve the effect of simple passivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The mixture of 20g cerium nitrate and ammonium phosphomolybdate (weight ratio is 1: 1.7), 2g phytic acid, 2g ammonium persulfate, 50g aminopropyltriethoxysilane modified nano-silica, 10g vinyltrimethoxy Silane, 10g epoxypropyltriethoxysilane, 50g silicone modified acrylate emulsion, add water to prepare 1 liter of passivation solution, adjust pH to 1 with 6M nitric acid, to obtain light red passivation solution.

[0032] When in use, it is diluted with deionized water according to the ratio (volume ratio passivation solution: water=1:5-10) to obtain the passivation solution working solution.

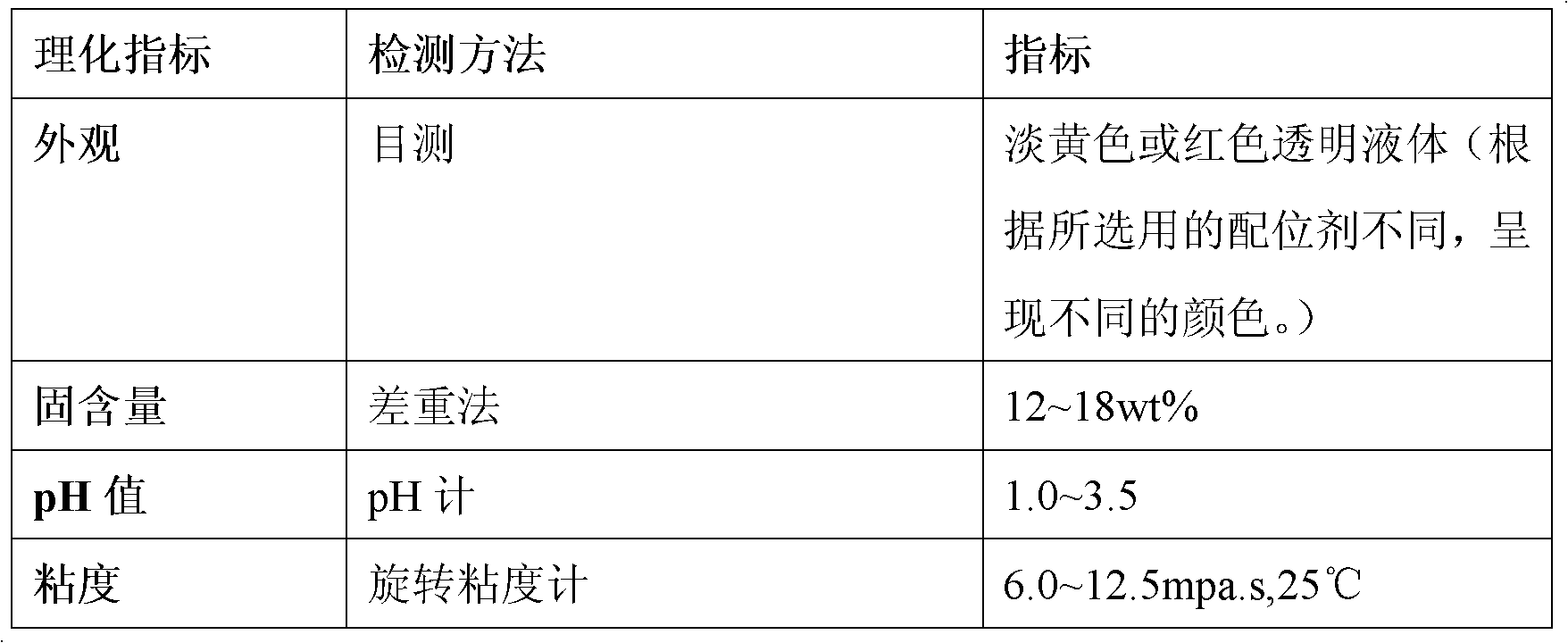

[0033] Take the galvanized parts out of the electroplating tank, rinse them in 3wt% dilute nitric acid, rinse twice in deionized water, and then put them into the prepared passivation working solution. The passivation time is 20-60s , after leaving the tank, dry it at 100°C for 5-15 minutes. The properties of the passivated galvanized layer are as follows:

[0034]

[0035] U...

Embodiment 2

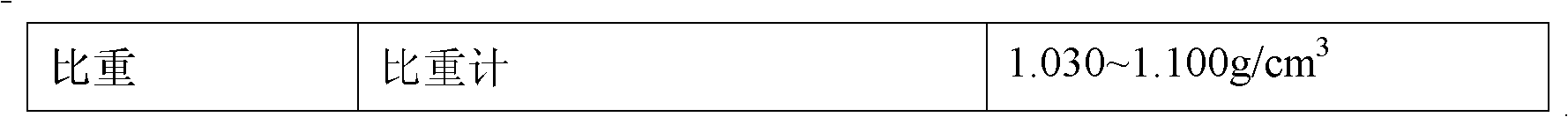

[0037] 35g mixture of cerium nitrate and ammonium phosphomolybdate (weight ratio is 1:1.9), 4g tartaric acid, 3.5g ammonium persulfate, 40g aminopropyltriethoxysilane modified nano-zirconia, 20g aminopropyltriethoxy Base silane, 5g epoxypropyltriethoxysilane, 40g silicone-modified acrylic emulsion, add water to prepare 1 liter of passivation solution, adjust the pH to 1 with 6M nitric acid, and obtain a light red passivation solution. The using method of passivation solution is the same as embodiment 1. The properties of the passivated galvanized layer are as follows:

[0038] performance item

[0039] Use hexavalent chromium passivation solution and trivalent chromium passivation solution to directly passivate the same object as a control.

Embodiment 3

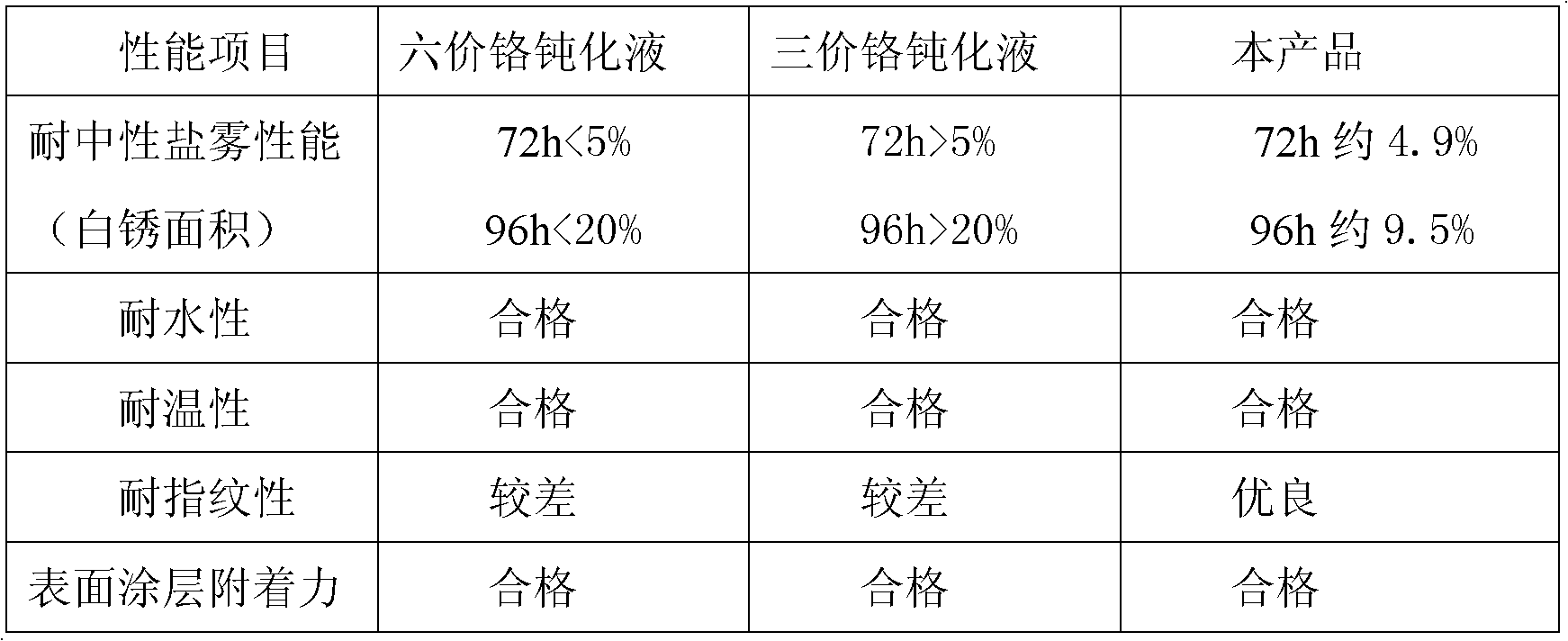

[0041] The mixture of 50g lanthanum nitrate and ammonium phosphomolybdate (weight ratio 1: 2), 5g phytic acid, 4g ammonium persulfate, 30g ureidopropyltrimethoxysilane modified nano-silica and epoxypropyltriethyl The mixture of oxysilane-modified nano-zirconia (weight ratio is 2:1), 25g epoxypropyltriethoxysilane, 30g organic silicon-modified acrylate emulsion, add water to prepare 1 liter, and use 6M nitric acid Adjust the pH to 1 to obtain a light yellow passivation solution. The using method of passivation solution is the same as embodiment 1. The properties of the passivated galvanized layer are as follows:

[0042]

[0043] Use hexavalent chromium passivation solution and trivalent chromium passivation solution to directly passivate the same object as a control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com