Patents

Literature

98results about How to "Improve passivation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Passivator for treating Cd/Pb-polluted soil and polluted soil in-situ restoration method by using passivator

ActiveCN105950154ASimple componentsLow costAgriculture tools and machinesContaminated soil reclamationIn situ remediationPhosphate

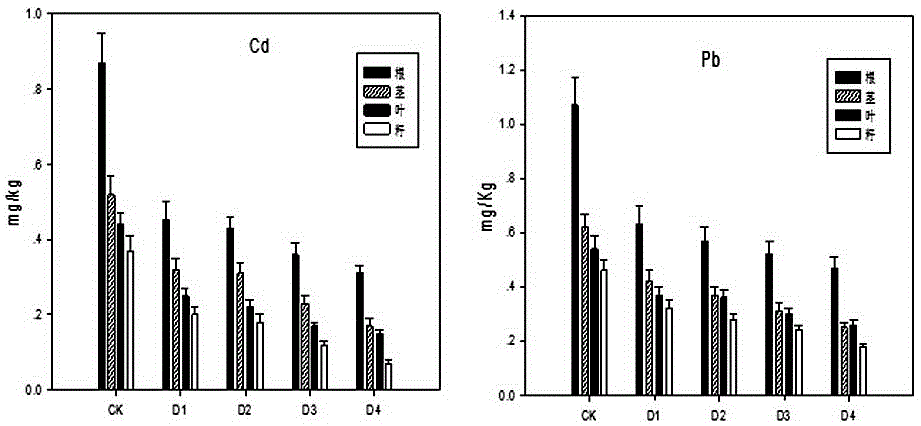

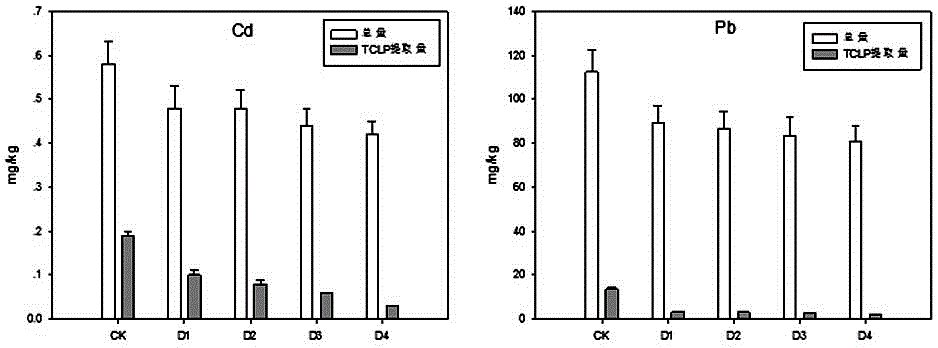

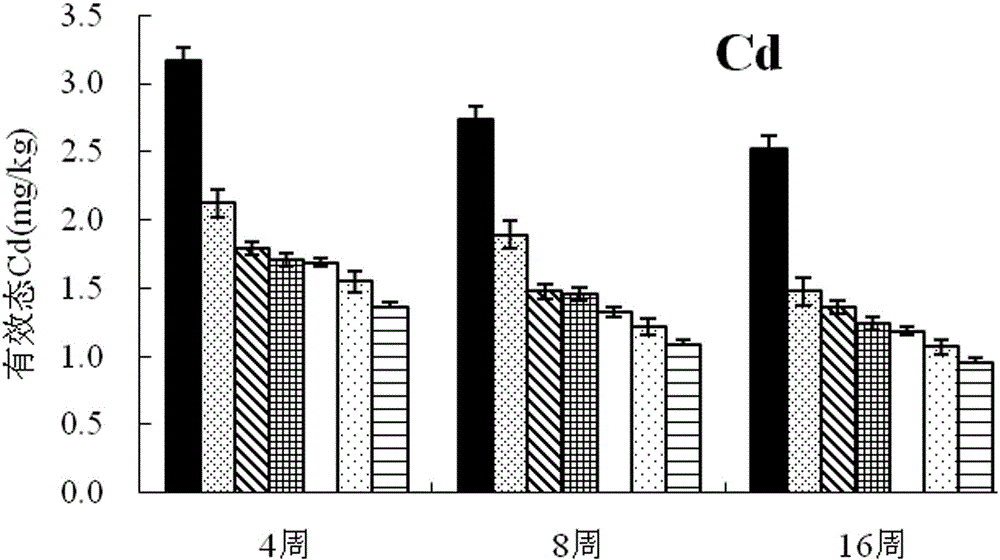

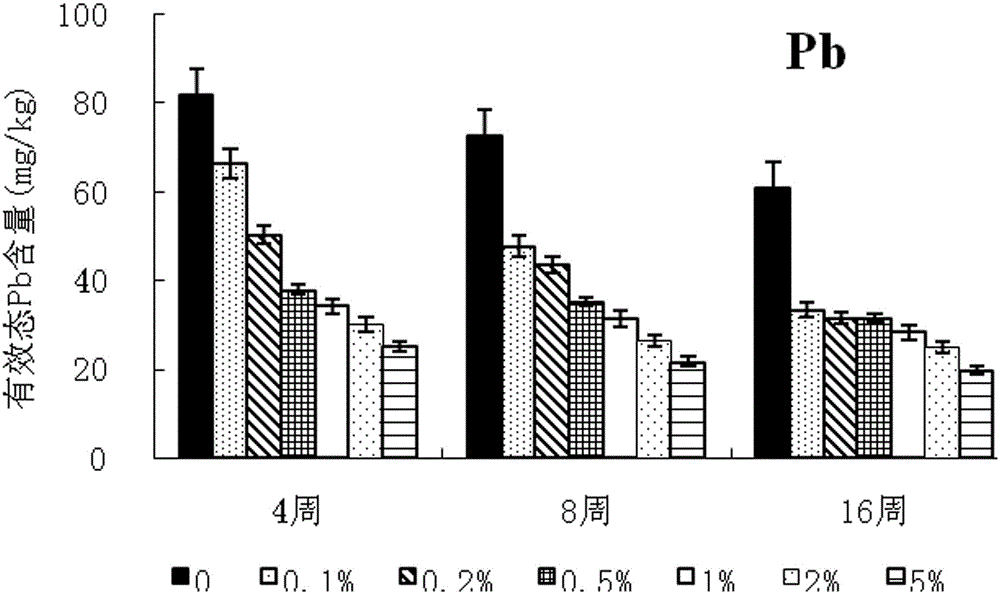

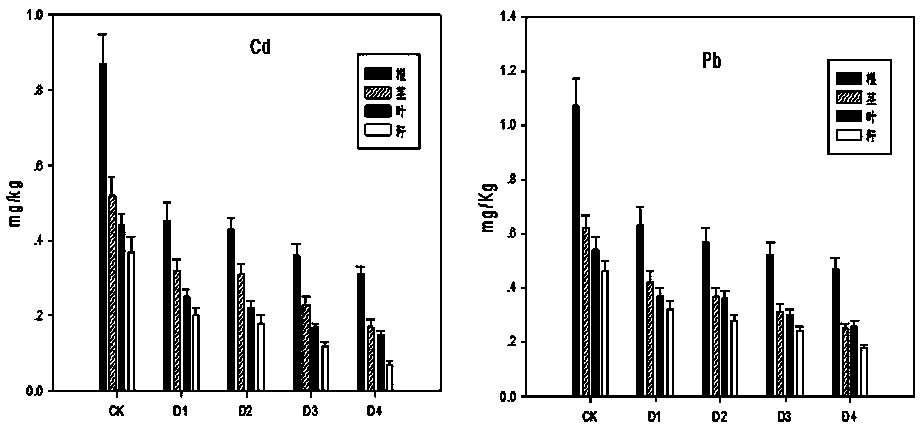

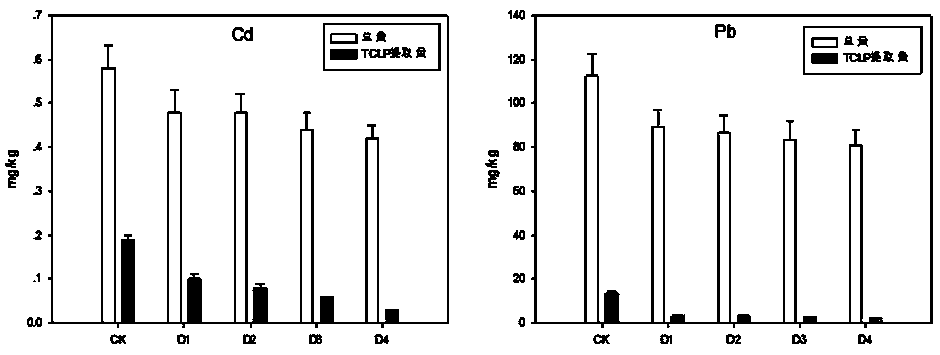

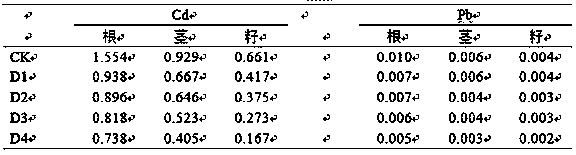

The invention discloses a passivator for treating Cd / Pb-polluted soil. The passivator is proportionally composed of biochar, red mud and monoammonium phosphate. When the passivator is in use, a TCLP (toxicity characteristic leaching procedure) process is utilized to evaluate the heavy metal pollution conditions in soil, the weight of the passivator is determined according to the mass ratio of the soil, and the passivator is applied into the soil many times at appropriate time intervals, thereby effectively improving the soil microenvironment. In the slightly alkaline high-reducibility soil, the mobility of Cd and Pb is greatly lowered, and the biochar can absorb abundant Cd and Pb in the soil. The nano red mud has fine particles, contains rich iron aluminum oxides, and can effectively combine Cd-Pd; the applied monoammonium phosphate and red mud further enhance the Cd / Pb adsorptivity, thereby obviously lowering the bioavailable-state Cd / Pb content in the soil, and greatly lowering the Cd / Pb content in crops. Meanwhile, the passivator has high soil environment friendliness, can not generate secondary pollution, and thus, has popularization and application values.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

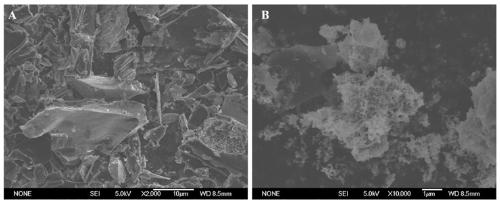

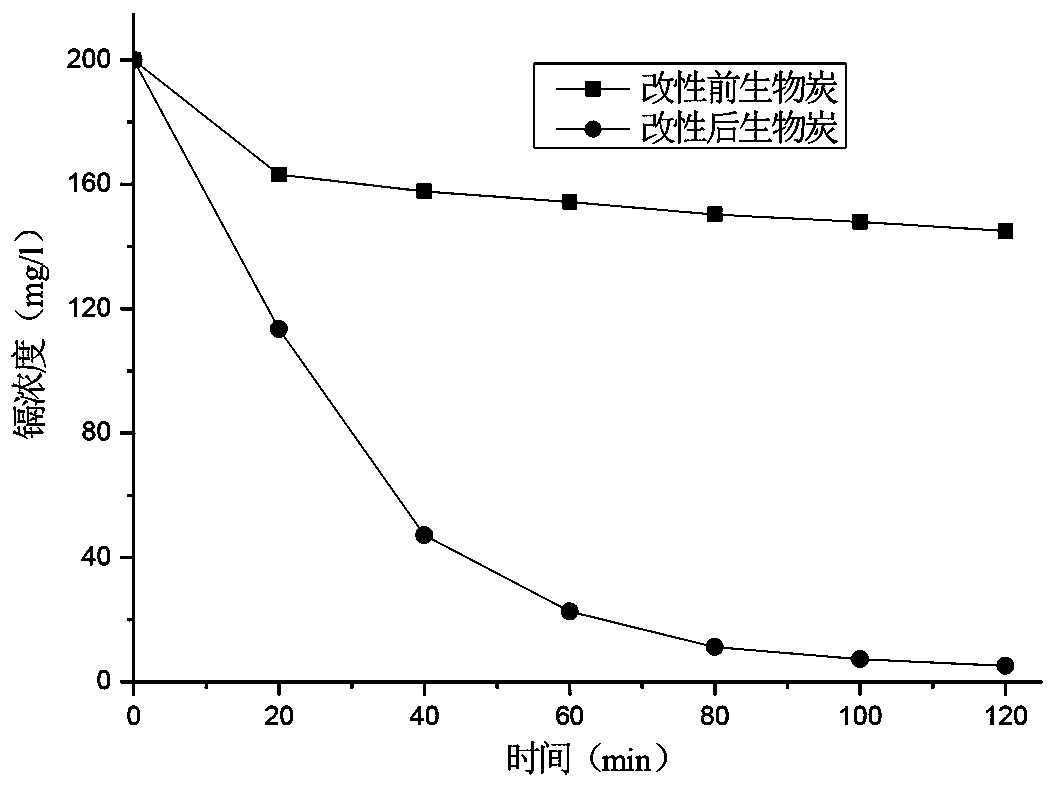

High magnetic modified biochar, preparation method of high magnetic modified biochar, and application to treatment of heavy metal pollution to soil

InactiveCN109913228ALarge specific surface areaLow priceContaminated soil reclamationOrganic fertilisersSoil heavy metalsAqueous solution

The invention belongs to the technical field of restoration and treatment of heavy metals in soil, and discloses a high magnetic modified biochar, a preparation method of the high magnetic modified biochar, and an application to treatment of the heavy metal pollution to the soil. The preparation method comprises the following steps: grinding and sieving the biochar, adding the biochar into a NaOHsolution, stirring, filtering, and washing with water; adding a filter residue into an HCl solution, continuing to stir, filtering, washing with water to obtain a basic charcoal material, and drying for later use; adding the basic charcoal material into an FeCl2-7H2O aqueous solution, regulating the pH value, adding a sodium borohydride solution until no bubble is generated, then adding a saturated sodium dimethyl dithio carbamate aqueous solution, continuing to stir, collecting a residue in the solution through a magnetic field, and washing and drying to obtain the high magnetic modified biochar. The specific surface area of the modified biochar is increased, the passivating efficiency of the heavy metals in the soil is improved, the magnetic property of the high magnetic modified biocharis strong, the high magnetic modified biochar is removed from the soil through a magnet, and the total content of the heavy metals in the soil is reduced.

Owner:HENAN UNIVERSITY

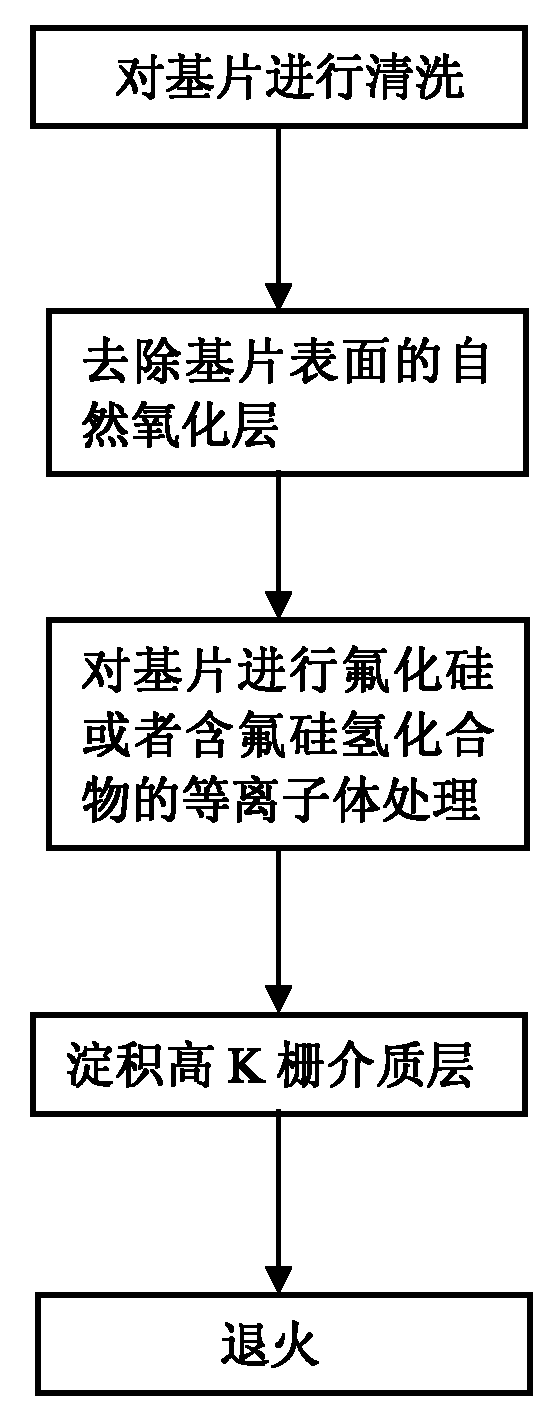

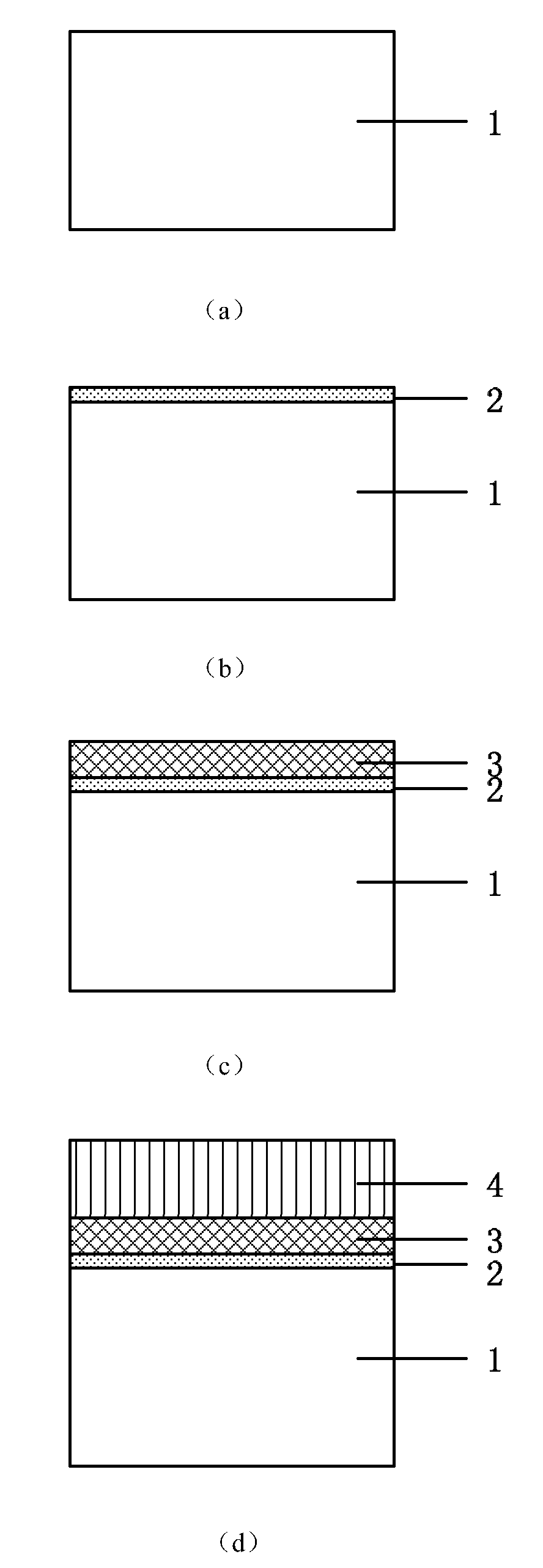

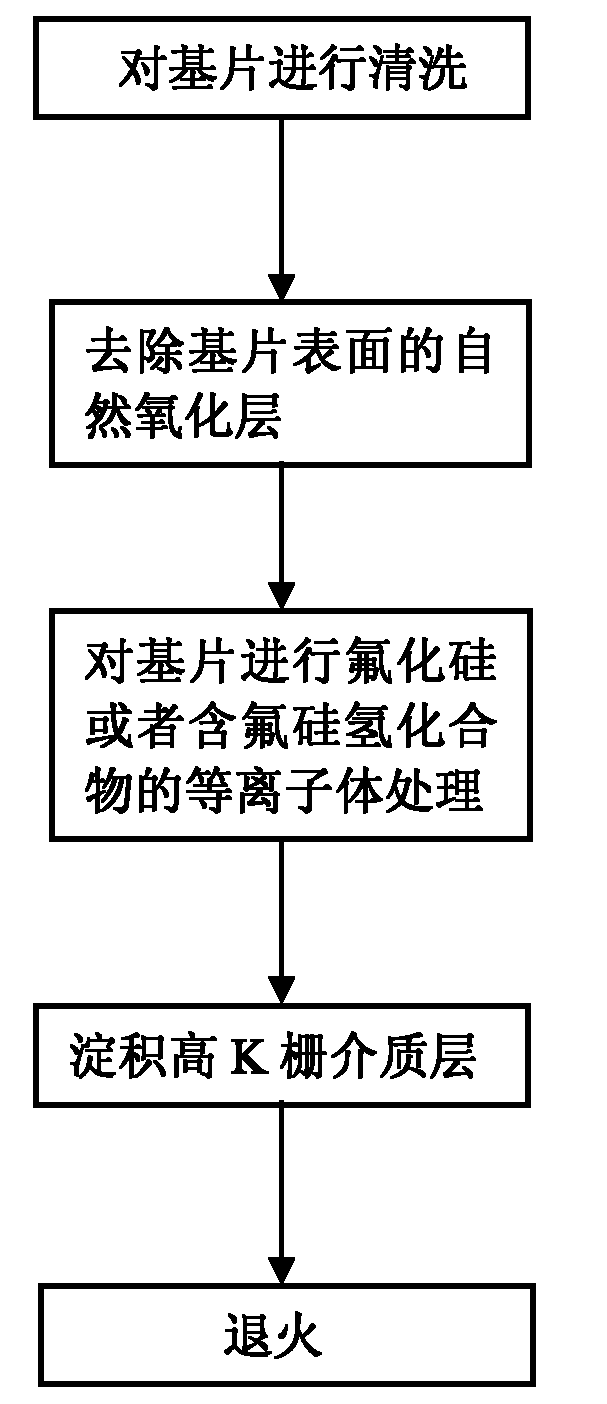

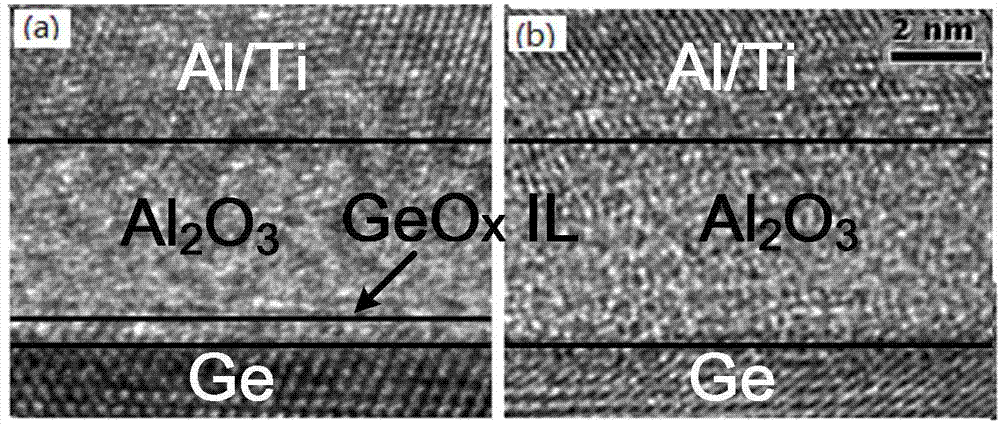

Surface passivation method for germanium-based MOS (Metal Oxide Semiconductor) device substrate

ActiveCN102206799AImprove passivation effectReduce interface state densitySemiconductor/solid-state device manufacturingSolid state diffusion coatingSemiconductor materialsGate dielectric

The invention discloses a surface passivation method for a germanium-based MOS device substrate, which belongs to the field of semiconductor material devices. The method comprises the steps of: firstly, washing a semiconductor germanium substrate which is used as a substrate for removing organic, inorganic and metallic granular contaminations on a surface and removing an autoxidation layer on thesurface of the substrate; performing plasma treatment on the substrate through use of silicon fluoride or silicone and fluorin containing hydrogen compound for depositing a silicon passivation layer on the substrate; and finally, after depositing a layer of high-k gate dielectric material, and annealing. The surface passivation method disclosed by the invention has the advantages of greatly reducing the density of an interface state between interfaces of the germanium substrate and the gate dielectric material, effectively restraining the diffusion of the germanium in the substrate into the gate dielectric material, and obviously enhancing the passivation efficiency.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

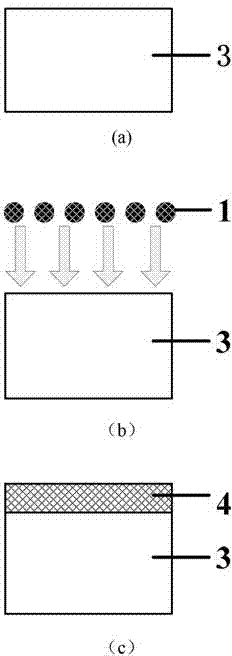

Dual-layer silicon nitride film for crystalline silicon solar cell and preparation method thereof

InactiveCN102130185AImprove anti-reflection effectImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingSilanesRefractive index

The invention discloses a dual-layer silicon nitride film for a crystalline silicon solar cell and a preparation method thereof and relates to the technical field of crystalline silicon solar cell production. The dual-layer silicon nitride film consists of two silicon nitride sublayer films with different refractive indexes; and the two silicon nitride sublayer films are obtained in a one-time PECVD (Plasma Enhanced Chemical Vapor Deposition) process. In two sublayers, the first sub layer (an inner layer) in contact with a silicon chip has higher refractive index (that is to say, n1 is more than n2) compared with that of the second sublayer film (an outer layer). The one-time deposition process is carried out by two stages; and in the two stages, two different flow ratios of silane to ammonia gas, two different growth temperatures, two different high-frequency output powers of a power supply, two different deposition times and two different work air pressures are applied. When the dual-layer silicon nitride film is used for the crystalline silicon solar cell, compared with a single-layer silicon nitride film, the dual-layer silicon nitride film has better antireflection effect and better surface passivation efficiency and the photoelectric conversion efficiency of the solar cell can be improved, therefore, the dual-layer silicon nitride film has higher practical value.

Owner:EOPLLY NEW ENERGY TECH

Heavy metal passivator and preparation method thereof, and method for restoring cadmium/lead polluted soil

InactiveCN105038804AReduced bioavailabilityReduce absorptionAgriculture tools and machinesContaminated soil reclamationSoil scienceIn situ remediation

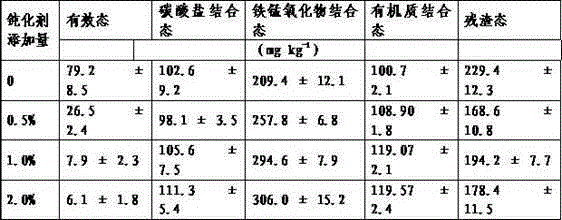

The invention provides a heavy metal passivator and a preparation method thereof. The metal passivator is hydroxy alum sludge, and can be used for in-situ restoration of polluted soil of which the total Cd content is at most 5.0 mg kg<-1> and the total Pb content is at most 800 mg kg<-1>. The method for restoring cadmium / lead polluted soil comprises the following steps: before crops are planted in the soil to be restored, applying 50-200kg of the heavy metal passivator to every mou of soil, plowing and mixing uniformly, watering, keeping the soil moist for 4-16 weeks until the effect Cd content in the soil is at most 0.5 mg kg<-1> and the effective Pb content is at most 300 mg kg<-1>, and planting and managing the crops by the conventional process. The heavy metal passivator provided by the invention has the advantages of low raw material cost, simple production technique, high passivation efficiency and stable effect, and can directly, quickly and effectively solve the problems of large Cd and Pb polluted area, low pollution degree and difficulty in soil restoration in the farmland soil in China.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Passivating anticorrosion treatment method for surface of stainless steel sieving plate

InactiveCN107815678AInhibit corrosion reactionImprove corrosion resistanceMetallic material coating processesMetallurgyCorrosion resistant

The invention discloses a passivation and anticorrosion treatment method for the surface of stainless steel sieve plate, which relates to the technical field of stainless steel sieve plate, including: (1) cleaning; (2) vacuum impregnation; (3) surface irradiation treatment; (4) passivation: The surface passivation anticorrosion treatment method of the stainless steel sieve plate of the present invention can not only form a corrosion-resistant passivation film on the surface of the stainless steel sieve plate, but also make the surface of the passivation film smoother, and effectively improve the contact angle of the surface of the passivation film , thereby significantly improving the fouling resistance of the passivation film surface.

Owner:安徽屹翔滤材有限公司

Environment-friendly composite colorful passivating solution and preparation method thereof

ActiveCN107740085AColorfulUniform film formationMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite colorful passivating solution and a preparation method thereof and belongs to the technical field of surface treatment of metal materials. Thepassivating solution comprises the components of 17-22 g / L of sodium silicate, 4-8 g / L of sodium molybdate, 6-10 g / L of sodium nitrate, 3-7 mL / L of hydrogen peroxide, 1-3 g / L of potassium fluoride, 2-6 mL / L of nitrilotrimethylene triphosphonic acid, 2-4 g / L of sodium gluconate, 2-4 mL / L of tartaric acid and the balance water, wherein the pH value of the passivating solution is 2.0-2.5. The preparation method of the passivating solution comprises the steps that the sodium silicate, the sodium molybdate, the sodium nitrate, the potassium fluoride, the nitrilotrimethylene triphosphonic acid, thesodium gluconate, the tartaric acid and the hydrogen peroxide are sequentially added into deionized water to be evenly mixed; the water with the constant volume is added to the needed volume; and sulfuric acid is used for adjusting the pH value to be 2.0-2.5, and thus environment-friendly composite colorful passivating solution is obtained. A galvanized layer passivated film treated by the passivating solution is colorful, bright in color, even in film forming and excellent in corrosion resistant performance; the passivating solution does not contain trivalent chromium, hexavalent chromium and other harmful substances and is environmentally friendly, free of pollution, simple in passivating process and high in passivating efficiency, and the corrosion resistance of a film layer is good.

Owner:KUNMING UNIV OF SCI & TECH

Chromium-free passivation solution

ActiveCN103114281AImprove stabilityImprove corrosion resistanceMetallic material coating processesChromium freePhosphoric acid

The invention discloses a chromium-free passivation solution. The chromium-free passivation solution comprises the following raw materials in percentage by weight: 20-70% of trisodium phosphate, 1-4% of cobalt sulfate, 1-3% of phosphoric acid, 0.5-0.7% of boracic acid, 1-3% of hydrogen peroxide and 80-200% of water. The passivation solution does not contain chromium and is environment-friendly, and a tin plate passivated by the passivation solution has higher corrosion resistance and oxidization resistance.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

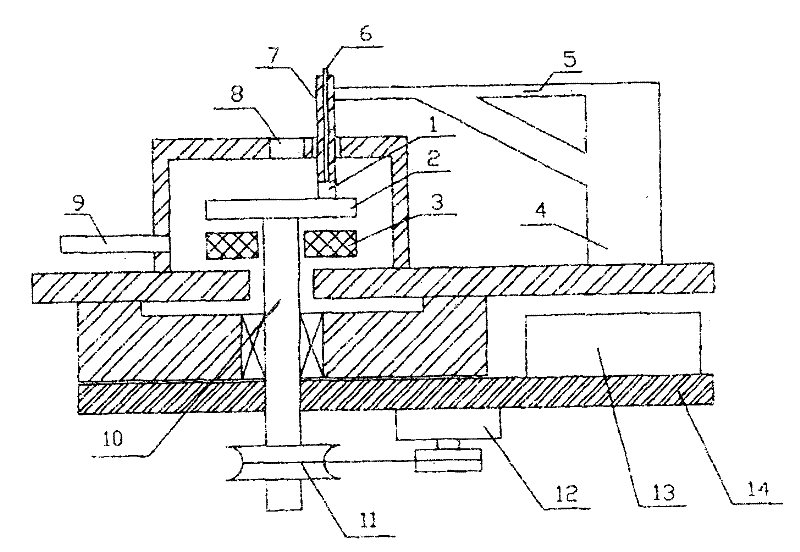

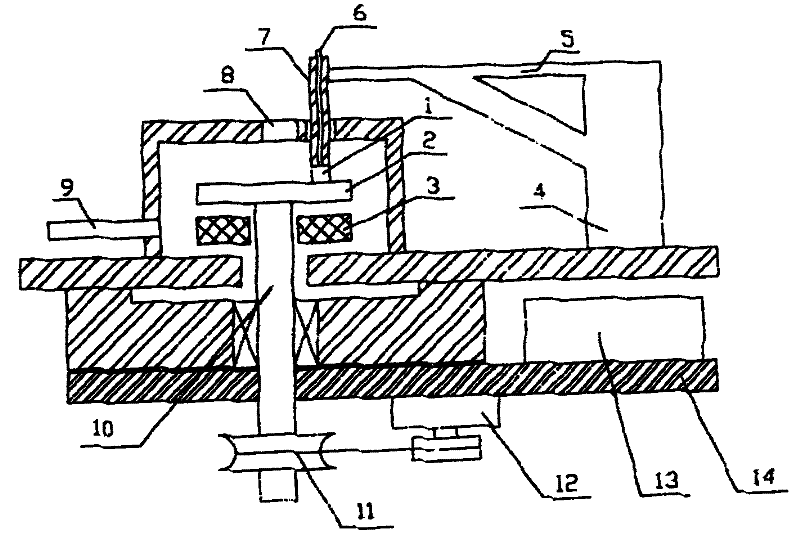

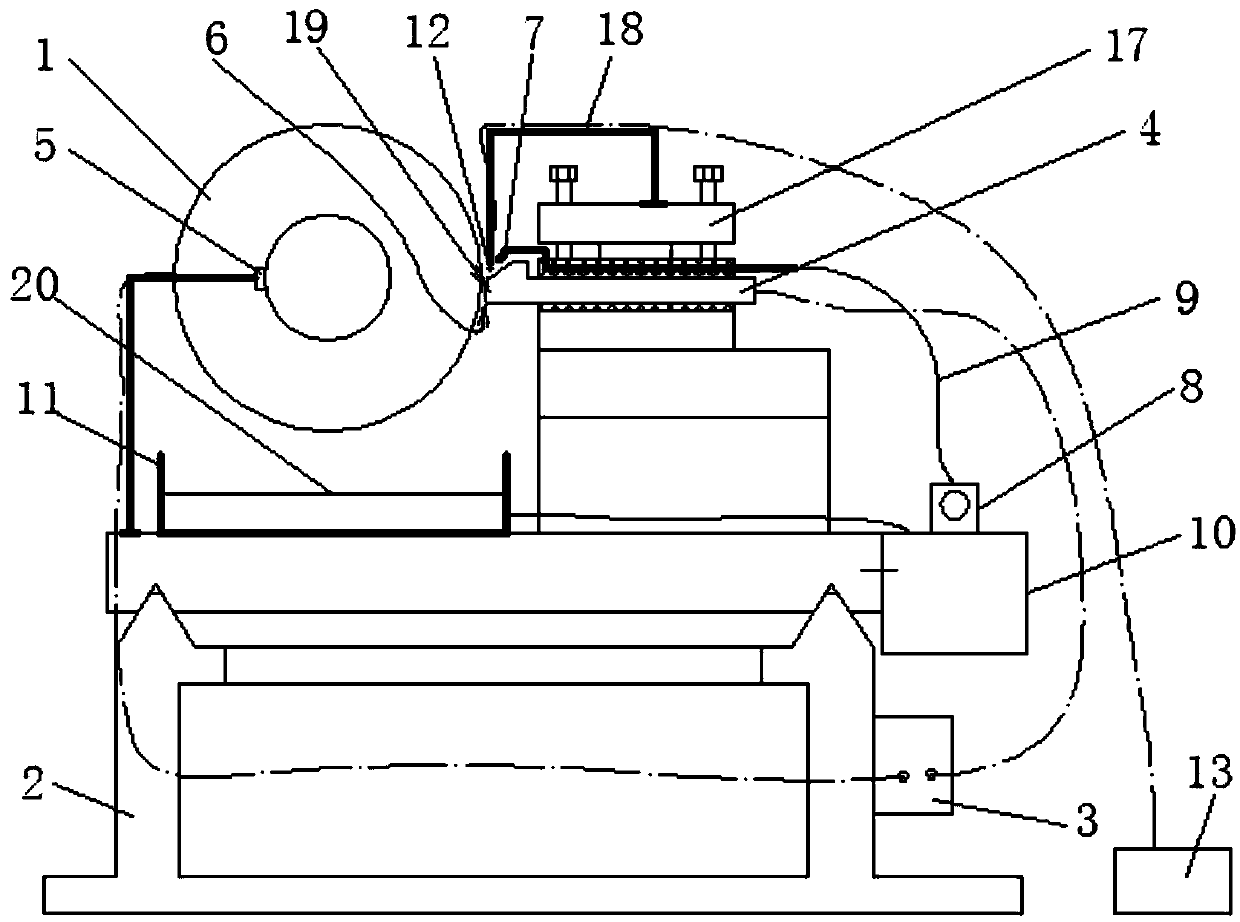

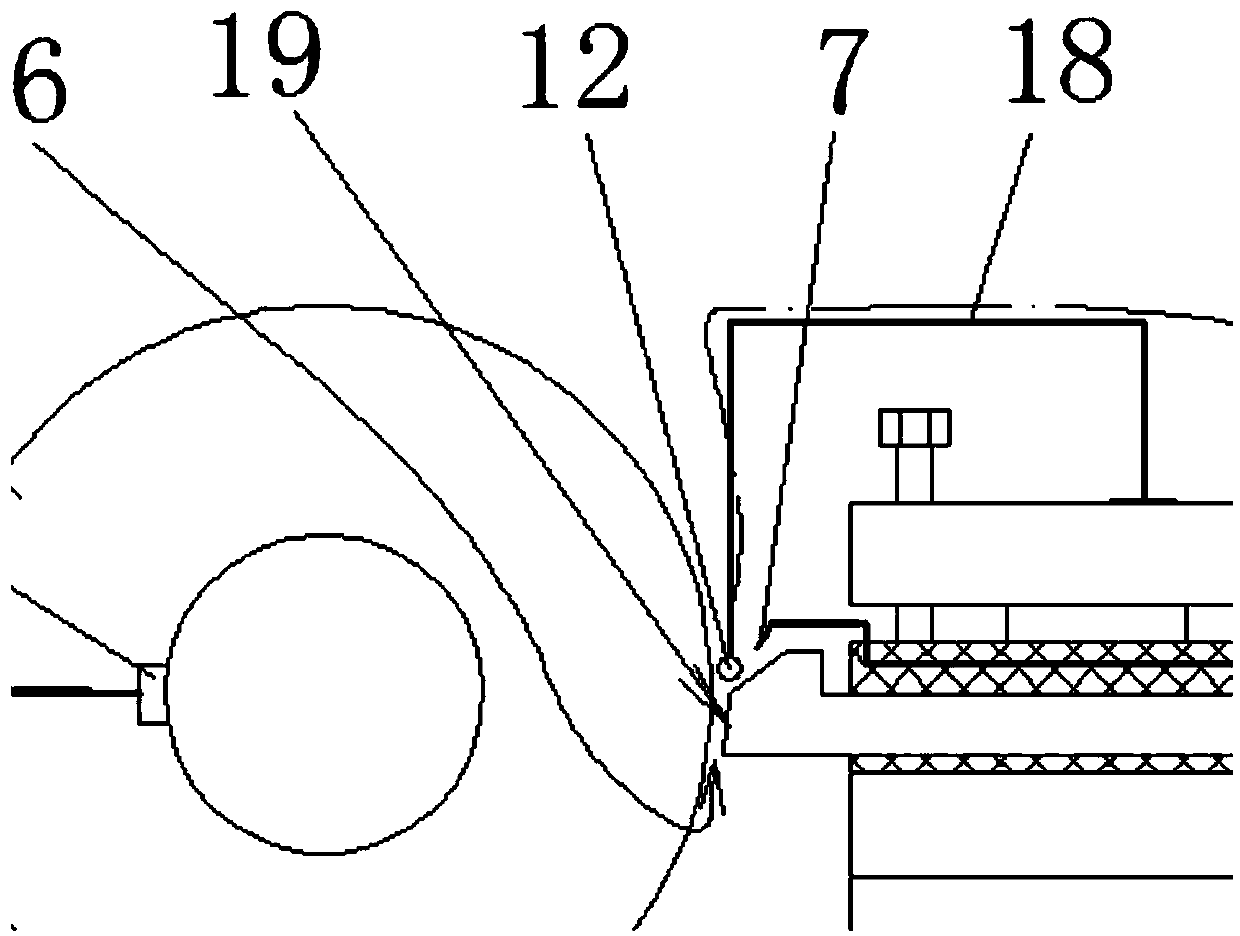

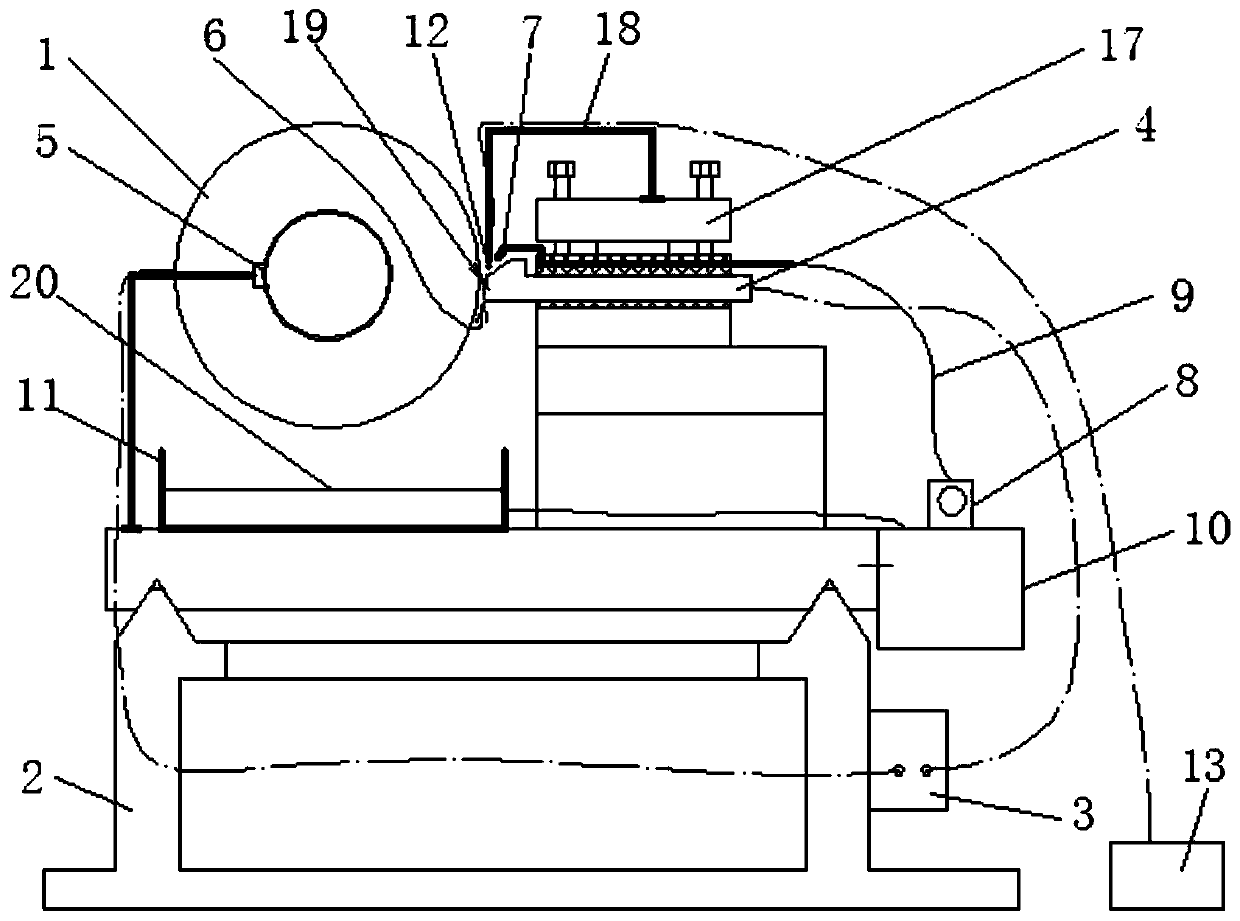

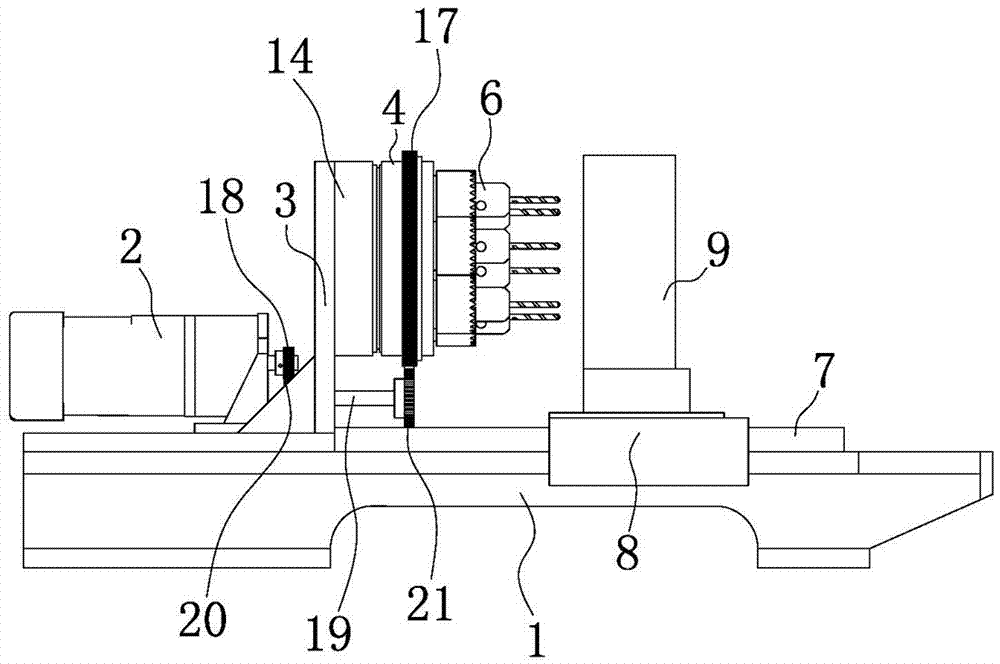

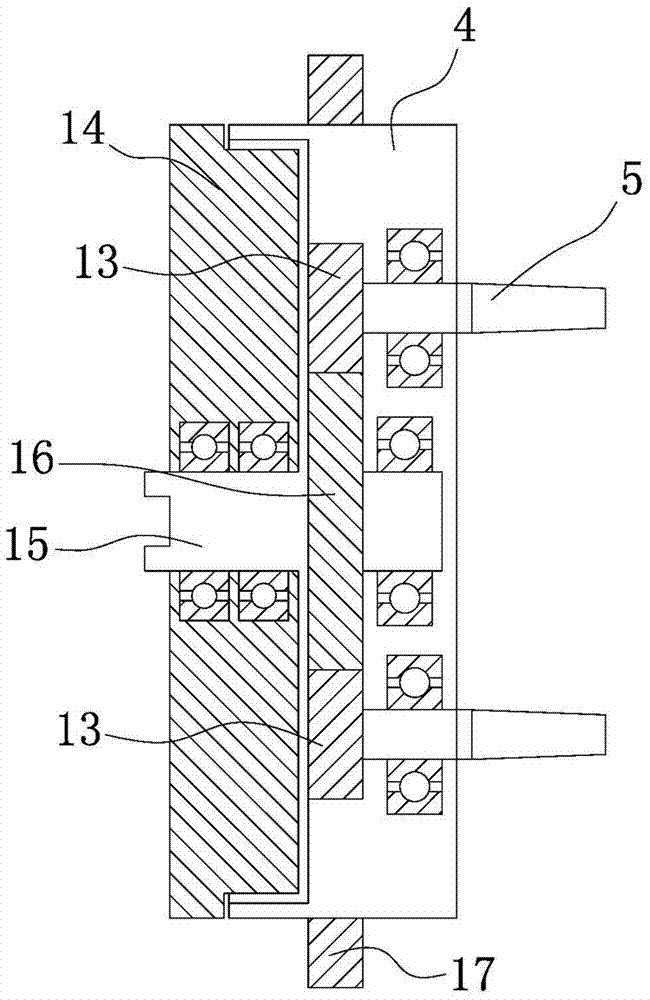

Passivation mechanism and method of diamond cutter

InactiveCN102343530APrevent oxidationExtended service lifeOther manufacturing equipments/toolsHydrogenDrive shaft

The invention discloses a passivation mechanism and method of a diamond cutter. The passivation mechanism comprises a frame, a bracket, a grinding disc, a driving device, a transmission device and a control device, wherein the driving device consists of a motor and a belt pulley; the transmission device consists of a belt pulley and a transmission shaft; a grinding cavity is arranged on the frame (14); an air inlet pipe (9) is arranged on the grinding cavity; the shaft end of the transmission shaft (10), which is fixedly connected with the grinding disc (2), is arranged in the grinding cavity in an extending way; a heater (3) is arranged below the grinding disc; the upper end of the grinding disc can be in contact with the diamond cutter (1) at the bottom end of a clamp (7); the upper end of the clamp extends out of the grinding cavity and is connected with a dynamometric strain gauge (5) arranged on the bracket (4); and optical fiber (6) which is connected with the control device (13) is arranged in the clamp. When the diamond cutter is passivated, the temperature of the grinding disc is 700-900 DEG C; under the atmosphere condition of hydrogen, the rotation speed of the motor is 20-200r / min and the grinding time is 3-20s, and a 3-50mum blade arc can be obtained; and the passivation mechanism and method disclosed by the invention have the advantages of high passivation efficiency, good effect and low cost.

Owner:常州卓铸精艺精密工具有限公司

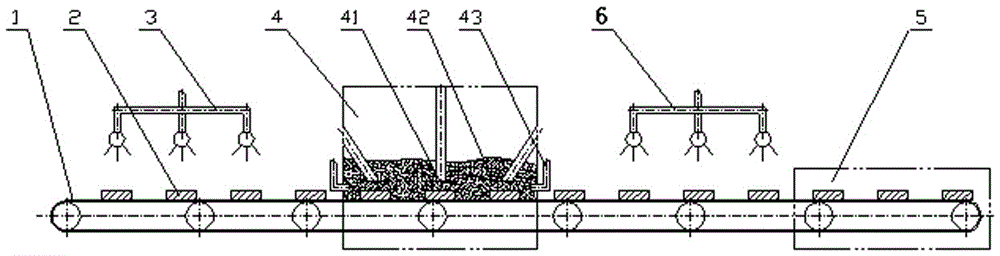

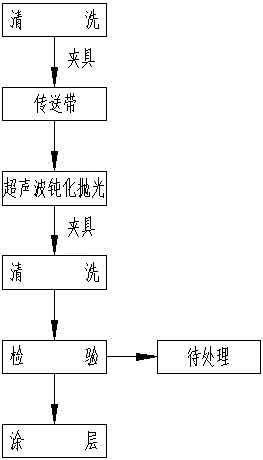

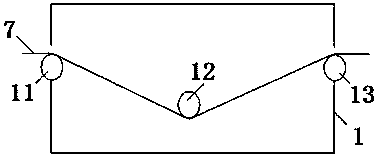

Ultrasonic passivating device and method for carbide blade

InactiveCN105710735AExtended service lifeThe size is easy to controlGrinding feedersCavitationCarbide

The invention provides an ultrasonic passivating device and method for a carbide blade. The ultrasonic passivating device for the carbide blade comprises a conveying belt, an ultrasonic machine, a quality testing device, a first cleaning mechanism and a second cleaning mechanism. The conveying belt penetrates the ultrasonic machine. An ultrasonic generator and a passivating solution are arranged in the ultrasonic machine. The part, located in the ultrasonic machine, of the conveying belt is immersed in the passivating solution. An inflation gas pipe is arranged on the ultrasonic machine. The first cleaning mechanism and the second cleaning mechanism are located above the conveying belt and arranged at the two sides of the ultrasonic machine. The quality testing device is arranged at the tail end of the conveying belt. According to the ultrasonic passivating device and method, ultrasonic microcosmic explosions are utilized for promoting the cutting effect of adhesive particles of the passivating solution on a workpiece to act on a cutting edge of the carbide blade, so that the cutting edge is passivated, and passivating is even; and the material of the cutting edge of the carbide blade is hardened through the cavitation effect of ultrasonic waves while the cutting edge is passivated, and the service life of the carbide blade is prolonged.

Owner:曾凡之

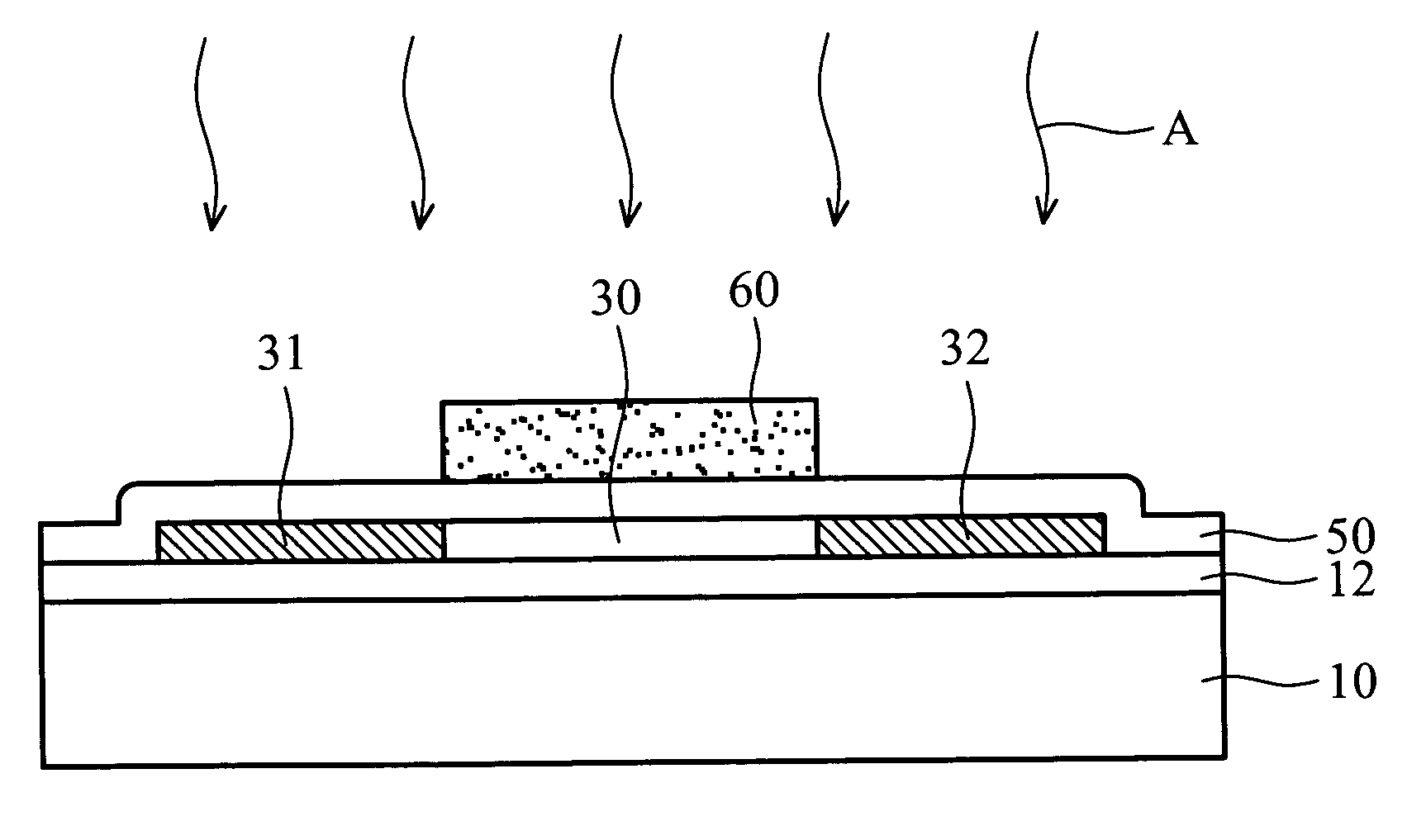

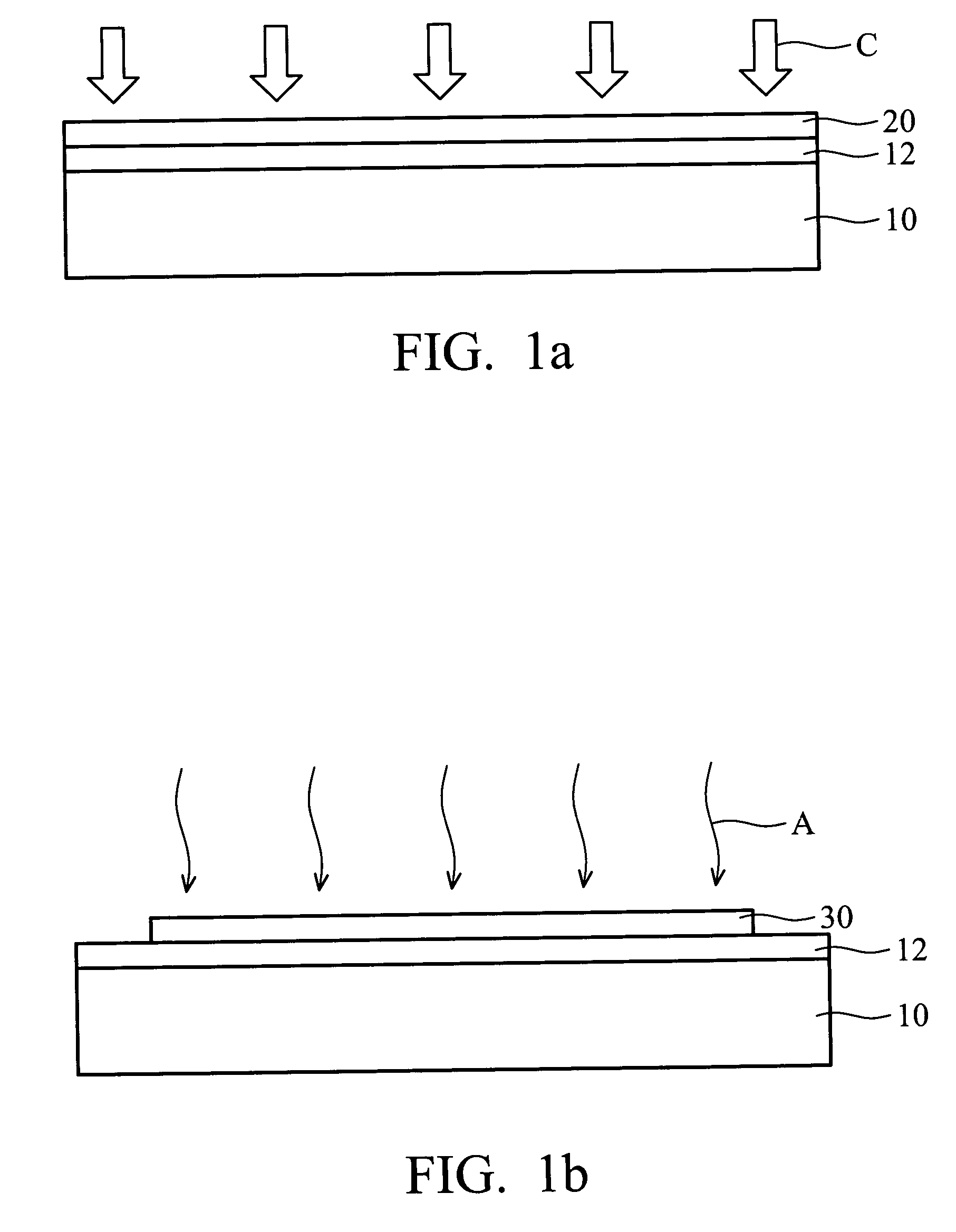

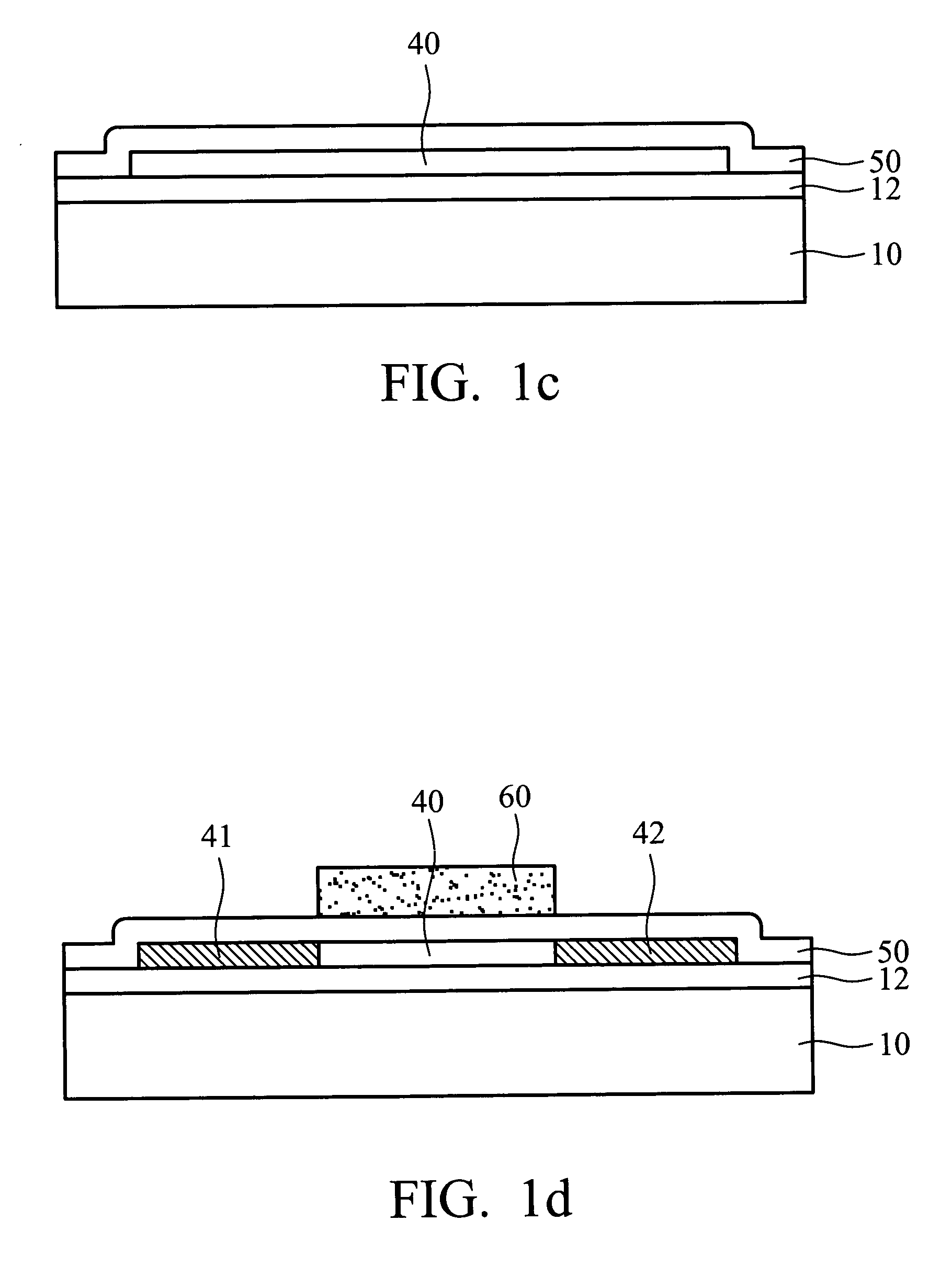

Process for passivating polysilicon and process for fabricating polysilicon thin film transistor

ActiveUS7199063B2Improve passivation efficiencyShortens passivation timeTransistorSemiconductor/solid-state device manufacturingNitrogenHigh pressure

A process for passivating polysilicon and a process for fabricating a polysilicon thin film transistor. A polysilicon layer is formed. Next, high-pressure annealing is performed using a fluorine-containing gas, a chlorine-containing gas, an oxygen-containing gas, a nitrogen-containing gas, or mixtures thereof to passivate the polysilicon layer.

Owner:INNOLUX CORP

Stainless steel passivation treatment method

ActiveCN109972186AAvoid corrosionUniform colorAnodisationMetallic material coating processesChromium freeElectrolysis

The invention relates to the technical field of stainless steel surface treatment, and particularly relates to a stainless steel passivation treatment method. The stainless steel passivation treatmentmethod comprises the following steps that (A1), a stainless steel product is soaked in an electrolyzing pickling solution for electrolyzing pickling treatment for 3-5 minutes, and then the stainlesssteel product is washed with water; (A2), the stainless steel product treated in the step (A1) is soaked in an electrolysis passivation agent for electrolysis passivation for 3-8 minutes, wherein thecurrent density is 0.05-0.3 A / dm<2> and the temperature is 20-40 DEG C, and then the stainless steel product is washed with water; and (A3), the stainless steel product treated in the step (A2) is soaked in a chromium-free passivation solution for chemical passivation for 3-5 minutes, and then the stainless steel product is washed with water. According to the stainless steel passivation treatmentmethod, the three steps of the electrolyzing pickling, the electrolysis passivation and the chemical passivation are adopted to complete the stainless steel passivation treatment, so that the passivation efficiency is improved, the corrosion risk is greatly reduced, the passivated stainless steel surface is uniform in color and luster, and is brightened.

Owner:Dongguan Kaimeng Chemical Co Ltd

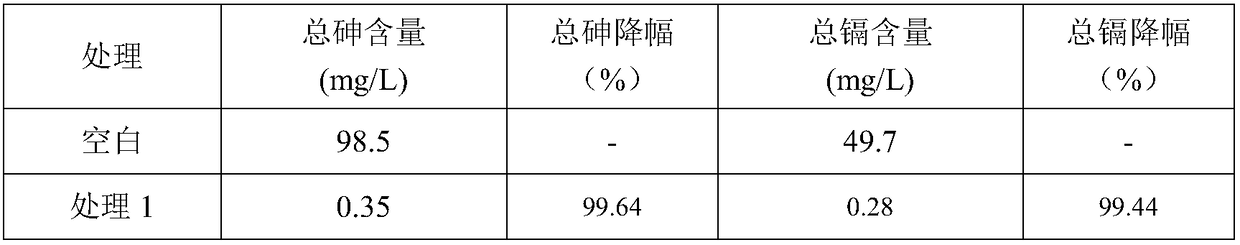

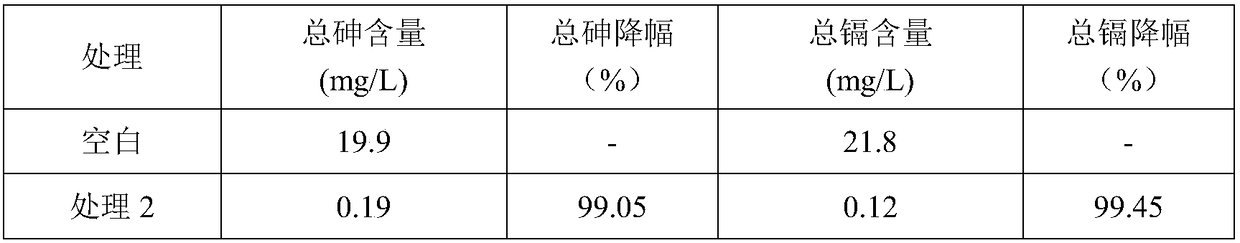

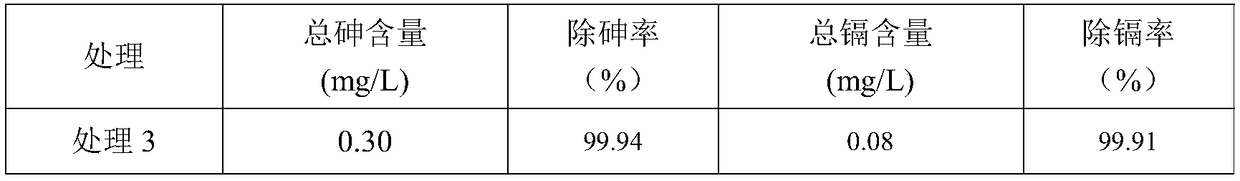

Method for preparing arsenic-cadmium passivator, arsenic-cadmium passivator prepared through method and application

ActiveCN109174958ARealize the packageThe effect is long-lasting and stableCalcareous fertilisersMagnesium fertilisersManganeseCadmium Cation

The invention provides a method for preparing an arsenic-cadmium passivator, the arsenic-cadmium passivator prepared through the method and an application. The preparation method comprises the following steps that an aluminosilicate material is mixed with an activating agent and a fluxing agent, and then undergoes high-temperature roasting treatment; the roasted material, ferric salt and manganesesalt are added into water, and the system pH value is adjusted for reaction; and solid-liquid separation is performed, the obtained solid is dried to obtain the passivator. The passivator is a novelpassivator which is efficient, environment-friendly, low in cost and capable of being used for treating soil (such as a farmland and a field), waste residues or water bodies with arsenic and cadmium contents exceeding the standard, the technological difficulty that arsenic (trivalent arsenic / pentavalent arsenic) and cadmium cannot be efficiently passivated at the same time is solved, and the passivator and the method have very good popularization and application values.

Owner:通化海汇龙洲化工有限公司 +1

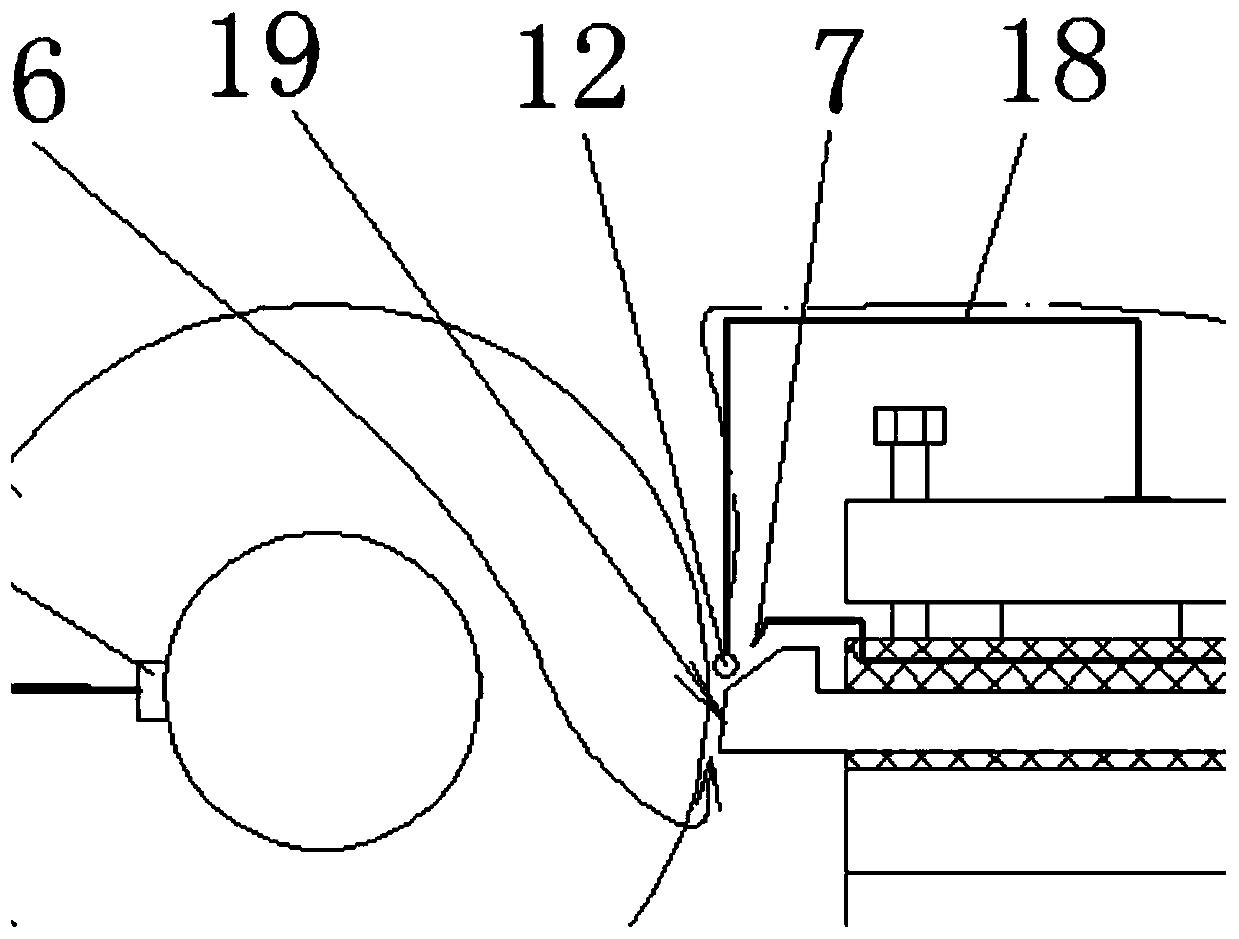

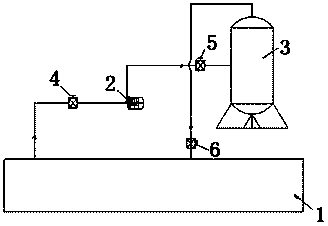

Surface passivation system for prolonging service life of EDT roughened cold rollers

ActiveCN109514012AExtended service lifeAchieve passivation effectMachining electrodesMachining working media supply/regenerationElectrolysisManufacturing technology

The invention relates to the technical field of cold roller manufacturing, and discloses a surface passivation system for prolonging service life of EDT roughened cold rollers. The system comprises rotary driving equipment and a pulse electrochemical burr removing device; the pulse electrochemical burr removing device comprises a pulse power supply, a tool electrode and an electric brush; the electric brush is contacted with outer circle surfaces of cold rollers; the head part of the tool electrode is near roughened outer circle surfaces of the cold rollers; a gap for enabling electrolyte to pass through is formed between the head part of the tool electrode and the roughened outer circle surfaces of the cold rollers; an electrolyte nozzle with a spout aligned to the gap is arranged above the gap; the electrolyte nozzle is connected to an electrolyte box through a pump and a pipeline; an electrolyte collecting tank for collecting electrolyte is arranged under the roughened outer circlesof the cold rollers; and the electrolyte collecting tank is connected with the electrolyte box. The system prolongs the service life of the EDT roughened cold rollers, improves the quality of rolledparts, and reduces the roller change efficiency.

Owner:JIANGYIN RUNYUAN MACHINERY

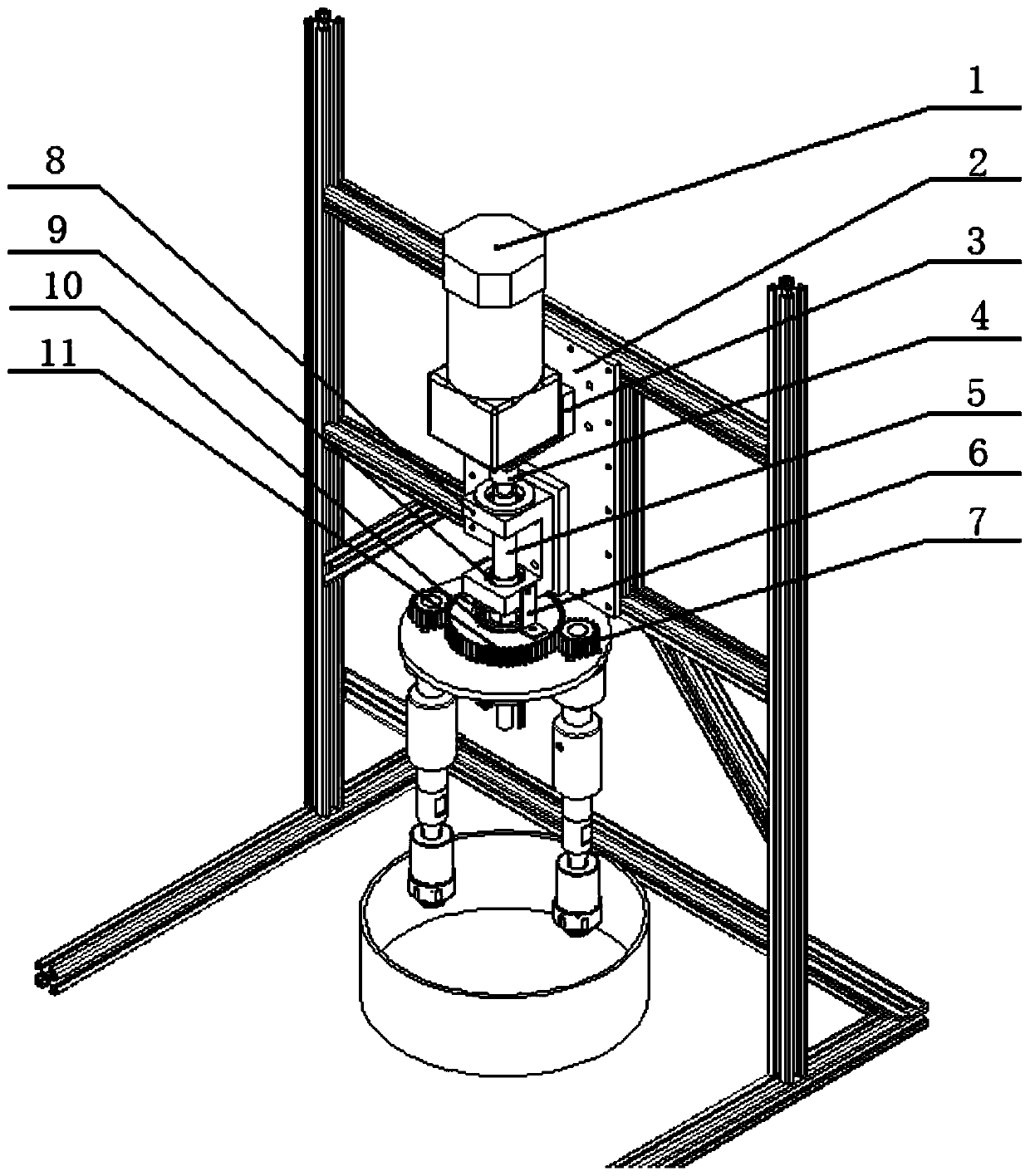

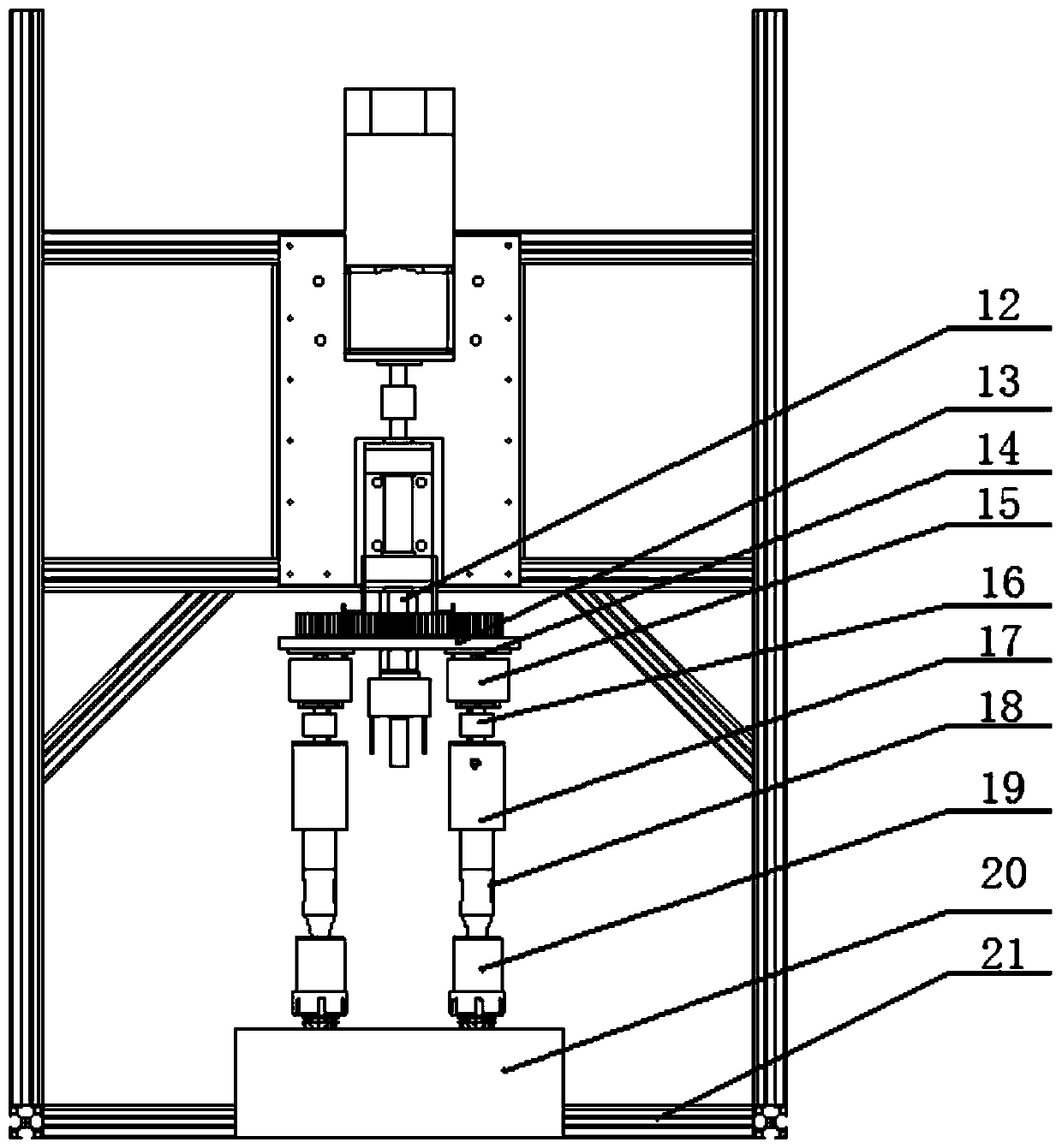

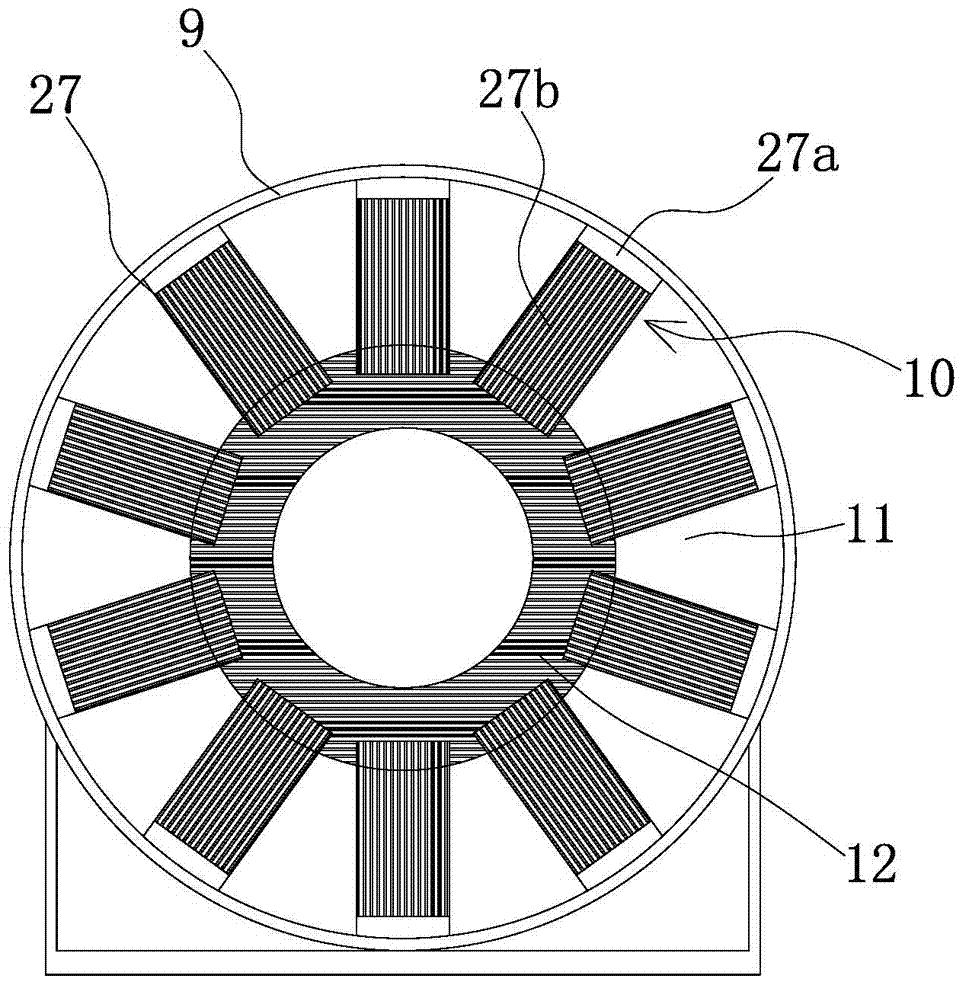

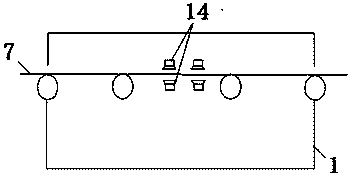

Novel cutter passivation machine

PendingCN109773595AAchieve rotationSolve the entanglementEdge grinding machinesPolishing machinesUltrasonic sensorBall bearing

The invention provides a novel cutter passivation machine which comprises a motor, a motor fixing plate, a large rotating shaft, a bearing, a bearing fixing seat, a rotating disk, a gearwheel, pinions, a coupling, a small rotating shaft, an ultrasonic transducer, an ultrasonic amplitude-change pole, a spring chuck, a grinding barrel and a whole frame, wherein the motor is mounted on the motor fixing plate; the motor fixing plate is mounted on the whole frame; an output shaft of the motor is connected with the large rotating shaft by means of the coupling; the large rotating shaft is fixed on the motor fixing plate by means of the bearing and the bearing fixing seat; the rotating disk is in threaded connection with the large rotating shaft; the pinions are connected with the small rotatingshaft; the gearwheel is engaged with at least two pinions; the gearwheel is mounted on the rotating disk by means of a thrust ball bearing; the gearwheel is in a forbidding manner; the small rotatingshaft is connected with the ultrasonic transducer and the ultrasonic amplitude-change pole by virtue of the coupling; the spring chuck is connected with the ultrasonic amplitude-change pole; the grinding barrel is positioned below the rotating disk; and the grinding barrel and the rotating disk are concentrically arranged. The novel cutter passivation machine is good in passivation effect, and high in passivation efficiency.

Owner:ZHEJIANG UNIV OF TECH

Passivating agent for hot-dip galvanized steel plate and preparation method

InactiveCN108690979AImprove stabilityImprove dispersion uniformityMetallic material coating processesChromium CompoundsCarboxylic acid

The invention discloses a passivating agent for a hot-dip galvanized steel plate. The passivating agent for the hot-dip galvanized steel plate comprises, by weight, 25-48 parts of trivalent chromium compounds, 12-24 parts of sodium hypophosphite, 8-18 parts of sodium sulfate, 6-10 parts of sodium fluorosilicate, 18-25 parts of cobalt chloride, 10-15 parts of boric acid, 20-30 parts of organic carboxylic acid, 1-3 parts of sodium dodecyl benzene sulfonate, 10-20 parts of glycerin and 40-60 parts of deionized water. The passivating agent for the hot-dip galvanized steel plate has good stabilityand good dispersion uniformity, and is used for achieving passivation of the hot-dip galvanized steel plate. A utilization method is high in passivating efficiency, an obtained passive film is high inbinding force, smooth in surface and good in compactness, the thickness of the passive film can range from 5mg / m2 to 12mg / m2, and the passive film is high in rigidity and wear resistance. A preparation method of the passivating agent is simple, green and environmentally friendly, accords with the ideas of safety and environmental protection in China, is free of the investment of large equipment,is low in preparation cost and suitable for industrial production, and is worth popularizing.

Owner:天津市迪斯科通科技有限公司

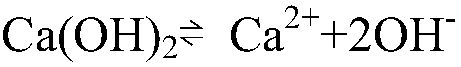

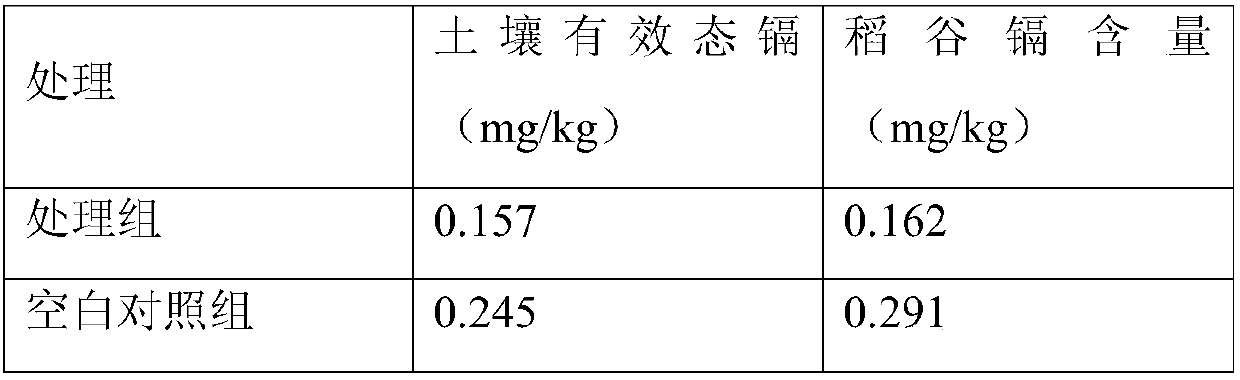

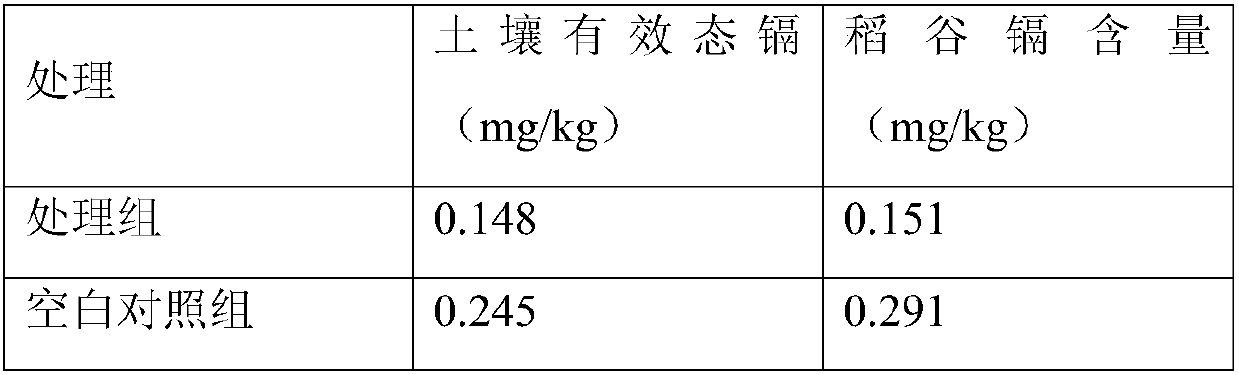

Paddy rice soil heavy metal cadmium sustained-release passivating agent and use method thereof

InactiveCN107629802AImprove passivation effectThe passivation effect is long-lasting and stableOrganic fertilisersSoil-working methodsSodium BentoniteSoil heavy metals

The invention discloses a paddy rice soil heavy metal cadmium sustained-release passivating agent and a use method thereof, and belongs to the field of soil heavy metal pollution control. The paddy rice soil heavy metal cadmium sustained-release passivating agent comprises the following components in parts by mass: 10-15 parts of quick lime, 8-20 parts of an organic fertilizer, 80-125 parts of humic acid, 0.25-0.5 part of potassium thiosulfate, and 40-60 parts of bentonite. The use method comprises the steps: applying calcium oxide and the organic fertilizer to acid contaminated soil, adjusting the pH of the soil to 7.0-8.0, acting for 7-10 days, then adding humic acid, potassium thiosulfate and bentonite to the soil, and acting for 1-2 days, wherein crops can be planted on the obtained soil. The heavy metal cadmium sustained-release passivating agent has high passivation efficiency, has durable and stable sustained-release and passivation effects, and has the function of improving andenhancing soil fertilizer efficiency, and cannot cause secondary pollution; the used materials are low in cost, safe and reliable, and the paddy rice soil heavy metal cadmium sustained-release passivating agent has good social and environmental benefits.

Owner:四川长虹格润环保科技股份有限公司

Manufacturing process for cold-rolling roll

ActiveCN109807554AAchieve passivation effectExtended service lifeIncreasing energy efficiencyFurnace typesCold treatmentManufacturing technology

The invention relates to the technical field of rolling roll manufacturing, and discloses a manufacturing process for a cold-rolling roll. The manufacturing process for the cold-rolling roll sequentially comprises the procedures of ingot casting, forging, heat treatment after forging, rough turning machining, quenching and tempering treatment, finish turning machining, surface quenching, cold treatment, low-temperature tempering, accurate grinding machining, surface texturing, and electrochemical passivation, wherein in the procedure of surface quenching, double-frequency quenching treatment is carried out on the working surface of the cold-rolling roll through a double-frequency quenching machine tool; in the procedure of surface texturing, texturing treatment is carried out on the working surface of the cold-rolling roll through an EDT electric spark texturing machine tool; and in the procedure of electrochemical passivation, deburring passivation treatment is carried out on microcosmic tip parts on the working surface of the cold-rolling roll through pulse electrochemical deburring equipment. According to the manufacturing process for the cold-rolling roll, the service life of the EDT textured cold-rolling roll is prolonged, the quality of a rolled part is improved, and the roll changing frequency is reduced.

Owner:JIANGYIN RUNYUAN MACHINERY

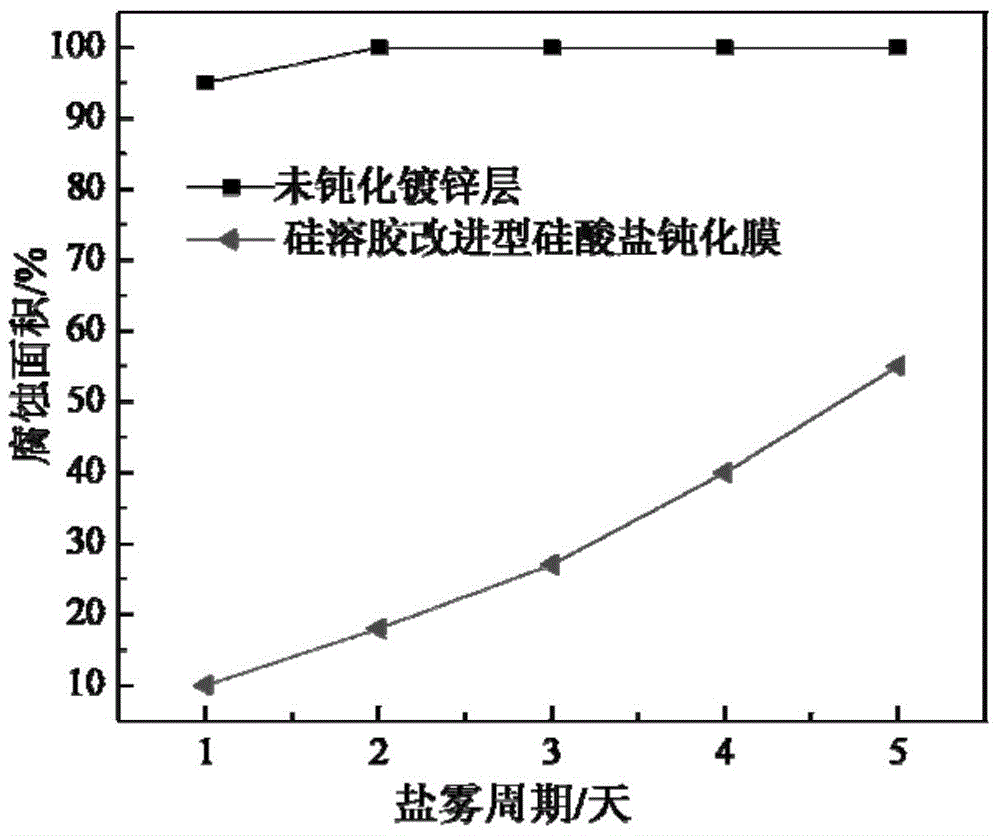

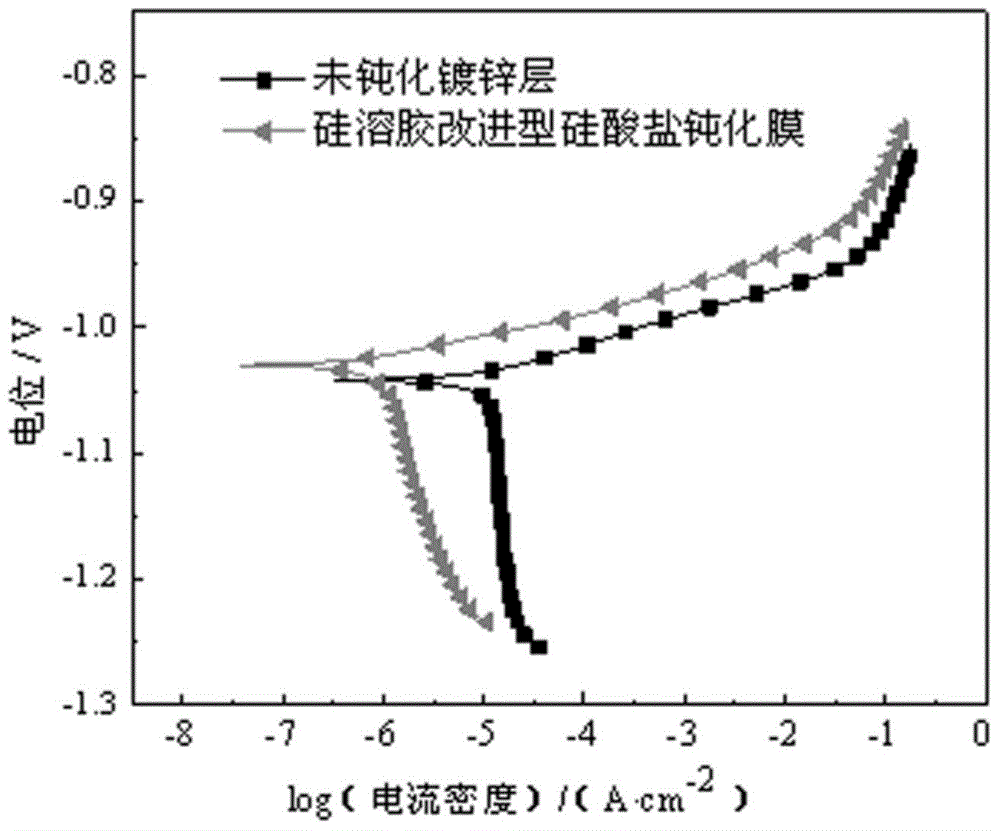

Silicate blue-white passivation solution and preparation method thereof

InactiveCN107574430AColorfulUniform film formationMetallic material coating processesHazardous substanceMetallic materials

The invention discloses a silicate blue-white passivation solution and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The silicate blue-white passivation solution consists of 26-34g / L of sodium silicate, 2-4g / L malic acid, 8-12g / L sodium fluoride, 9-14mL / L hydrogen peroxide, 8-13mL / L amino trimethylene phosphonic acid and the balance water, and the pH of the silicate blue-white passivation solution is 3.0-3.5. The preparation method of the silicate blue-white passivation solution comprises the steps that sodium silicate, malic acid, sodiumfluoride, amino trimethylene phosphonic acid and hydrogen peroxide are sequentially added to deionized water and are mixed uniformly, water is added for constant volume treatment till the required volume is reached, and the pH is adjusted to 3.0-3.5 by adopting sulfuric acid, thus the silicate blue-white passivation solution is obtained. A zinc coating passivation film after the treatment by thesilicate blue-white passivation solution is blue-white, and is bright in color, the film forming is uniform, and the corrosion resistance is excellent; the silicate blue-white passivation solution isfree of trivalent chromium, sexavalent chrome and other hazardous materials, so that the silicate blue-white passivation solution is environment-friendly and pollution-free; a passivation technology is simple; the passivation efficiency is high; and the film layer corrosion resistance is good.

Owner:KUNMING UNIV OF SCI & TECH

Arsenic passivator and application thereof

InactiveCN108085016APromote passivationPassivation does not affectContaminated soil reclamationOrganic fertilisersPyrolusiteSodium Bentonite

The invention provides an arsenic passivator and an application thereof. The arsenic passivator comprises an agent A and an agent B, wherein the agent A is prepared from raw materials in parts by weight as follows: 40-60 parts of polyferric sulfate, 45-65 parts of ferrous sulfate and 0-15 parts of sodium humate; the agent B is prepared from raw materials in parts by weight as follows: 20-35 partsof pyrolusite powder, 25-45 parts of calcium bentonite and 30-50 parts of slaked lime, and the agent A and the agent B of the arsenic passivator are used in a mass ratio being 1:1. Compared with the prior art, the arsenic passivator is applied to passivation treatment of arsenic in soil and solid waste, does not affect pH of a system basically, has the advantages of being low in reagent dosage, good in treatment effect, high in treatment stability and environmentally friendly, taking effect quickly, realizing simple and convenient engineering operation and the like, and is low in comprehensivecost and wide in applicable range.

Owner:芜湖格丰环保科技研究院有限公司 +1

Rigid superhard material precision cutting tool passivating machine

ActiveCN107009201ASimple structureReduce manufacturing costOther manufacturing equipments/toolsSuperhard materialBristle

The invention provides a rigid superhard material precision cutting tool passivating machine, and belongs to the technical field of cutting tool manufacturing. The problem that existing passivating machines are poor in passivating effect is solved. The rigid superhard material precision cutting tool passivating machine comprises a machine base and a servo motor. A machine frame is arranged on the machine base. A columnar rotary plate of which the axis is horizontally arranged is arranged on the machine frame. A plurality of rotary shafts around the axis of the rotary plate are arranged on the rotary plate in a penetrating mode. A clamping is connected to the rotary shaft. The servo motor drives all the rotary shafts to rotate through a driving mechanism. A horizontal guide rail is arranged on the machine base. A supporting plate is arranged on the guide rail. A tubular passivating barrel arranged coaxially with the rotary plate is arranged on the supporting plate. A circle of radial bristle brushes protruding radially is arranged on the inner wall of the passivating barrel. A mounting plate is connected to the end, away from the rotary plate, of the passivating barrel. An annular axial bristle brush protruding axially is arranged on the inner end face, facing the rotary plate, of the mounting plate. The rigid superhard material precision cutting tool passivating machine has the advantages of being low in manufacturing cost, high in rigid superhard material precision cutting tool passivating efficiency and good in passivating effect.

Owner:玉环卡布里尔刀具科技有限公司 +1

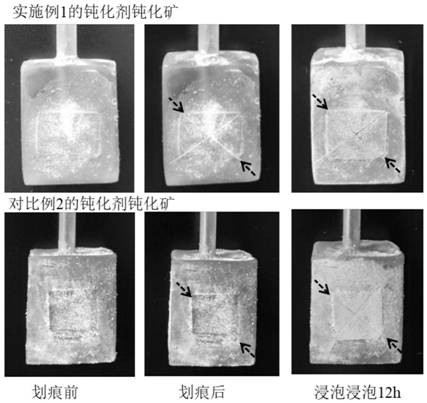

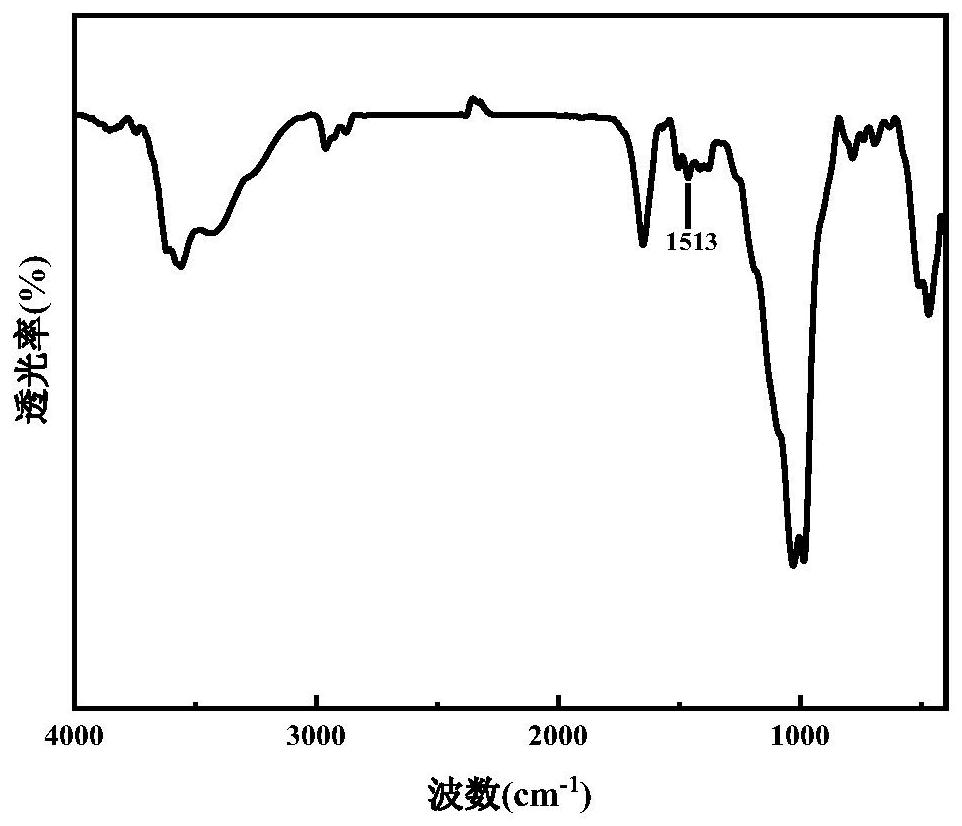

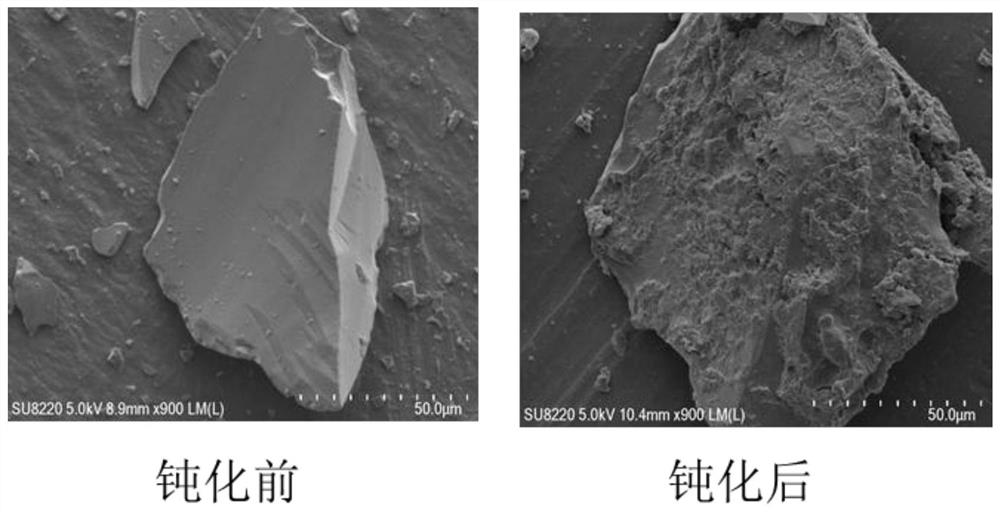

Passivator with self-repairing function as well as preparation method and application thereof

ActiveCN112375492AImprove passivation efficiencyLong passivation timeTransportation and packagingSolid waste disposalComposite materialCrazing

The invention discloses a passivator with a self-repairing function as well as a preparation method and application thereof. According to the method, mixed organosilane is used as a main body passivator, a modified nano container loaded with a repairing agent is used as a nano filler, and sodium alginate is used as an assistant cross-linking agent, so that the surface coating passivation of the pyrite is realized. According to the method, the physical performance and stability of the passivation film can be greatly improved, the passivation film is endowed with a self-repairing function, micropores or microcracks appearing in the passivation film can be self-repaired, and the oxidation rate of pyrite is effectively decreased. Meanwhile, the use amount of organosilane and the use frequencyof the passivator are also reduced, and the tailing pollution treatment cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

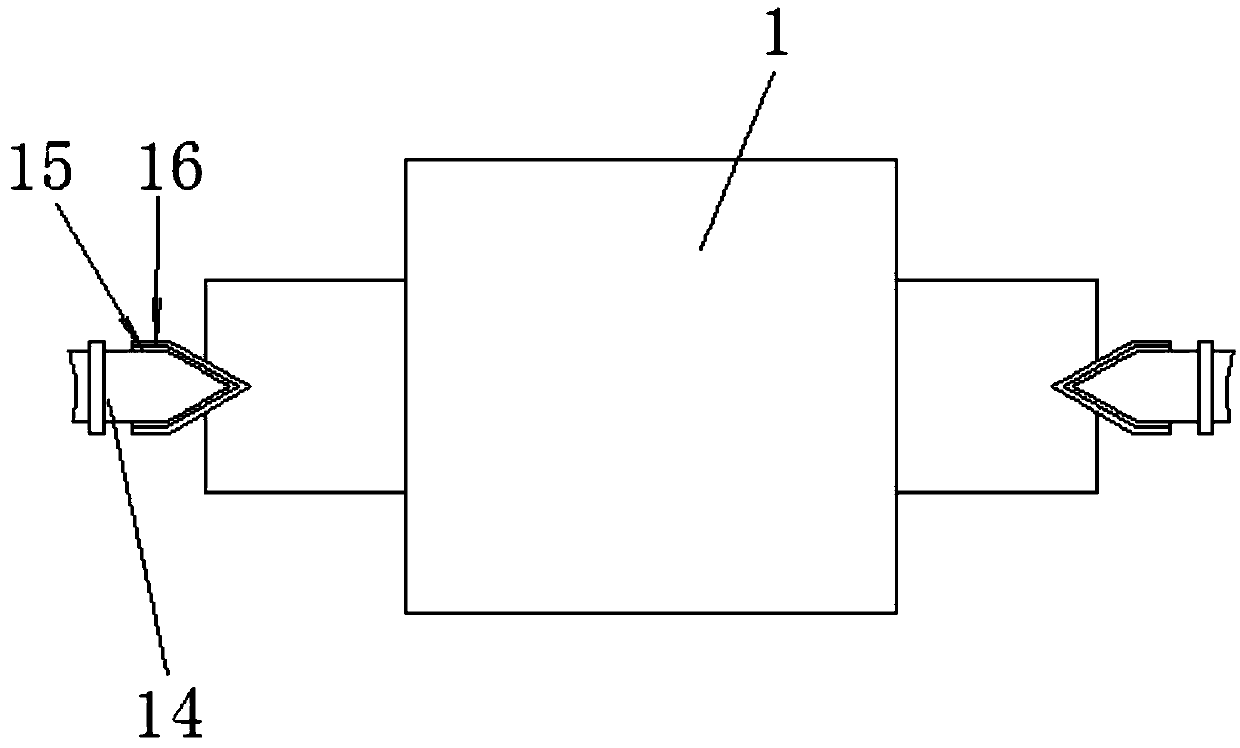

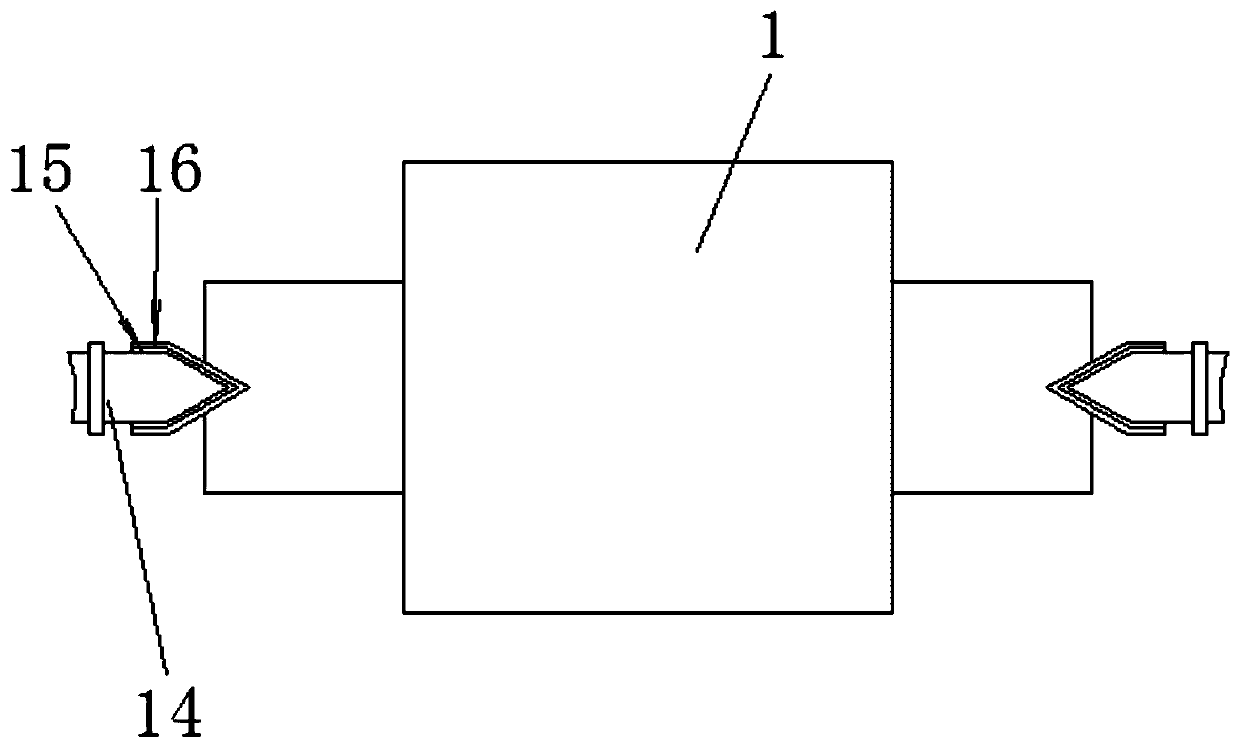

Copper strip surface passivation device

InactiveCN104005017ARealize online passivation treatmentImprove passivation efficiencyMetallic material coating processesProduction lineCopper tape

The invention discloses a copper strip surface passivation device comprising a passivation tank and a passivation solution arranged in the passivation tank, wherein one side of the passivation tank is provided with an inlet for feeding a copper strip, and the other side of the passivation tank is provided with an outlet for discharging a passivated copper strip; and a structure for enabling the copper strip to be in contact with the passivation solution is arranged between the inlet and the outlet in the passivation tank. The device can be used for realizing online passivation treatment, and passivation operation can be continuously carried out if only the copper strip on a production line passes through the passivation tank, so that the passivation efficiency is high; the passivation solution in the passivation tank is circularly filtered through a filter to remove copper powder and other particles entering from the surface of the copper strip to the passivation solution in a passivation process, so that the purity of the passivation solution is ensured, and furthermore, the passivation quality is ensured; and in addition, the passivation solution does not need to be replaced frequently, so that the passivation efficiency is increased, and the cost is reduced.

Owner:ANHUI YONGJIE COPPER

Germanium-base substrate surface passivation method

ActiveCN102903625ALower interface stateReduce the chance of spreadingSemiconductor/solid-state device manufacturingInterface layerDangling bond

The invention discloses a germanium-base substrate surface passivation method, which comprises the following steps of: cleaning a surface of a germanium-base substrate; putting the cleaned germanium-base substrate into a plasma cavity; utilizing reaction gas corresponding to multiply-bound atoms to generate a plasma; carrying out plasma bath processing on the surface of the germanium-base substrate; and applying a guiding electric field in a plasma bath processing process to guide the plasma to drift to the surface of the germanium-base substrate. Due to the processing, covalently joint of activated the multiply-bound atoms and germanium surface atoms is formed, but an interface layer containing germanium compounds is not generated, so that a surface dangling bond is passivated, the probability that the germanium surface atoms are separated from the surface of the germanium-base substrate to be dispersed is reduced, and simultaneously, the phenomenon that the thinning of the EOT is unfavorable as the interface layer is introduced is avoided. In addition, the guiding electric filed is applied, so that the formation of germanium oxides can be effectively suppressed, the passivation efficiency is improved, and the density of interfacial states is reduced.

Owner:PEKING UNIV

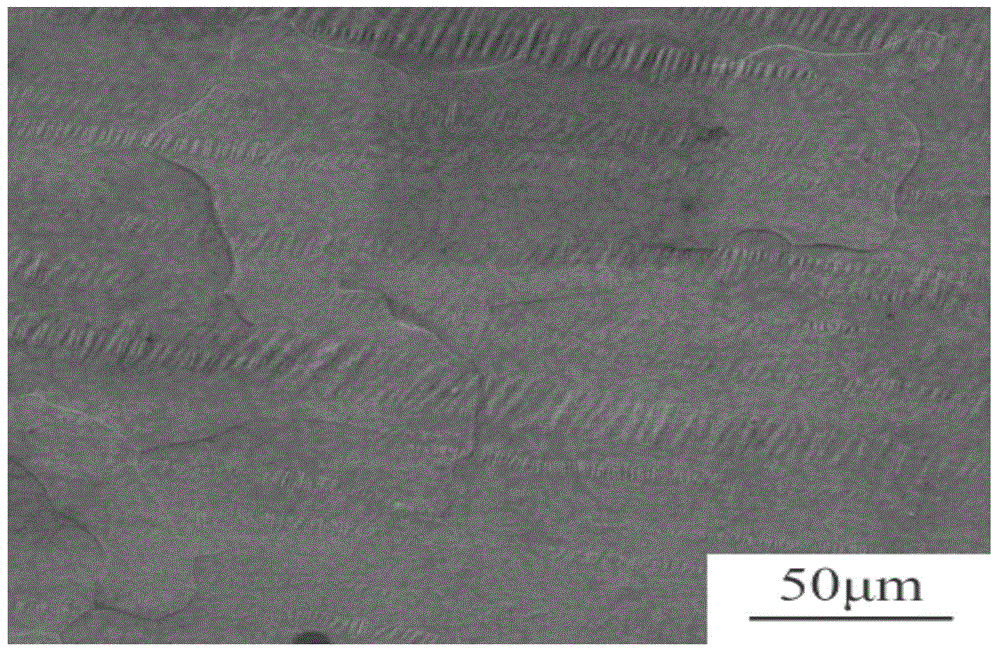

Environment-friendly silicate passivation solution for galvanization, and preparation method and application thereof

ActiveCN103911609AImprove bindingGood anti-white rust performanceMetallic material coating processesSilicon dioxideSodium hydroxide

The invention discloses an environment-friendly silicate passivation solution for galvanization, and a preparation method and an application thereof. Raw materials of the silicate passivation solution comprise 1-20 g / L of sodium hydroxide, 5-50 g / L of silicon dioxide, 20-160 mL / L of silica sol, and the balance being water. A pH value of the passivation solution is 7.0-12.0. When the passivation solution is in use, after a steel workpiece is galvanized, the workpiece is put in the environment-friendly silicate passivation solution for galvanization by adopting a constant temperature impregnation; the workpiece is taken out after 0.5-5 min; and the workpiece is processed at a temperature of 20-80 DEG C to form a silicate protective film for a high-corrosion galvanized layer. The obtained film by passivated by the passivation solution has good adhesion with the galvanized layer, is dense, colorless and transparent, and has good white rust-prevention performance. The passivation solution takes silicate to replace chromium salt as a main raw material, and overcomes the disadvantages of high toxicity and carcinogenesis of a conventional chromium salt passivation process.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

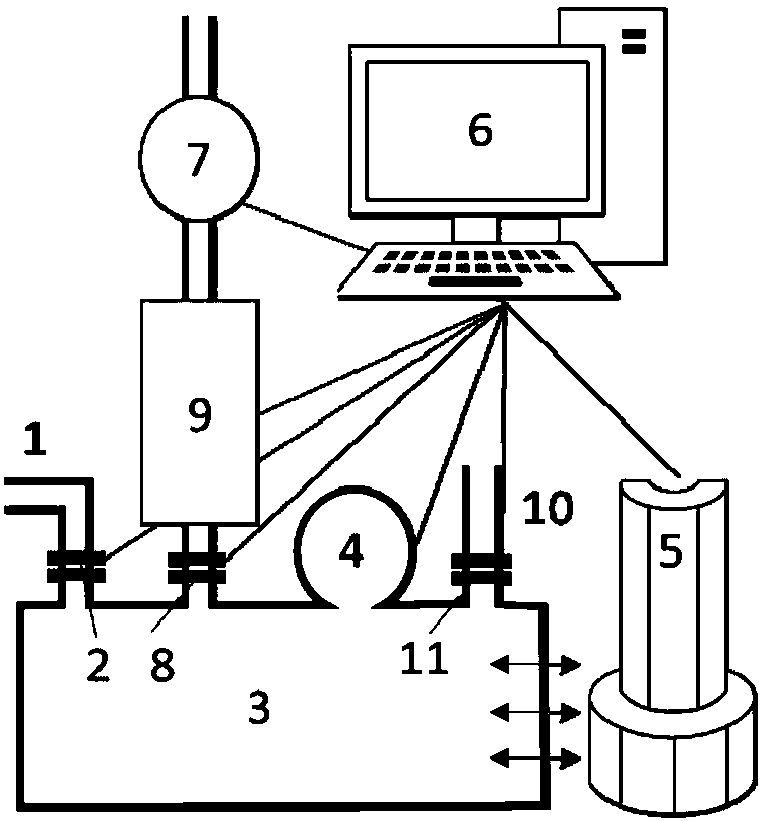

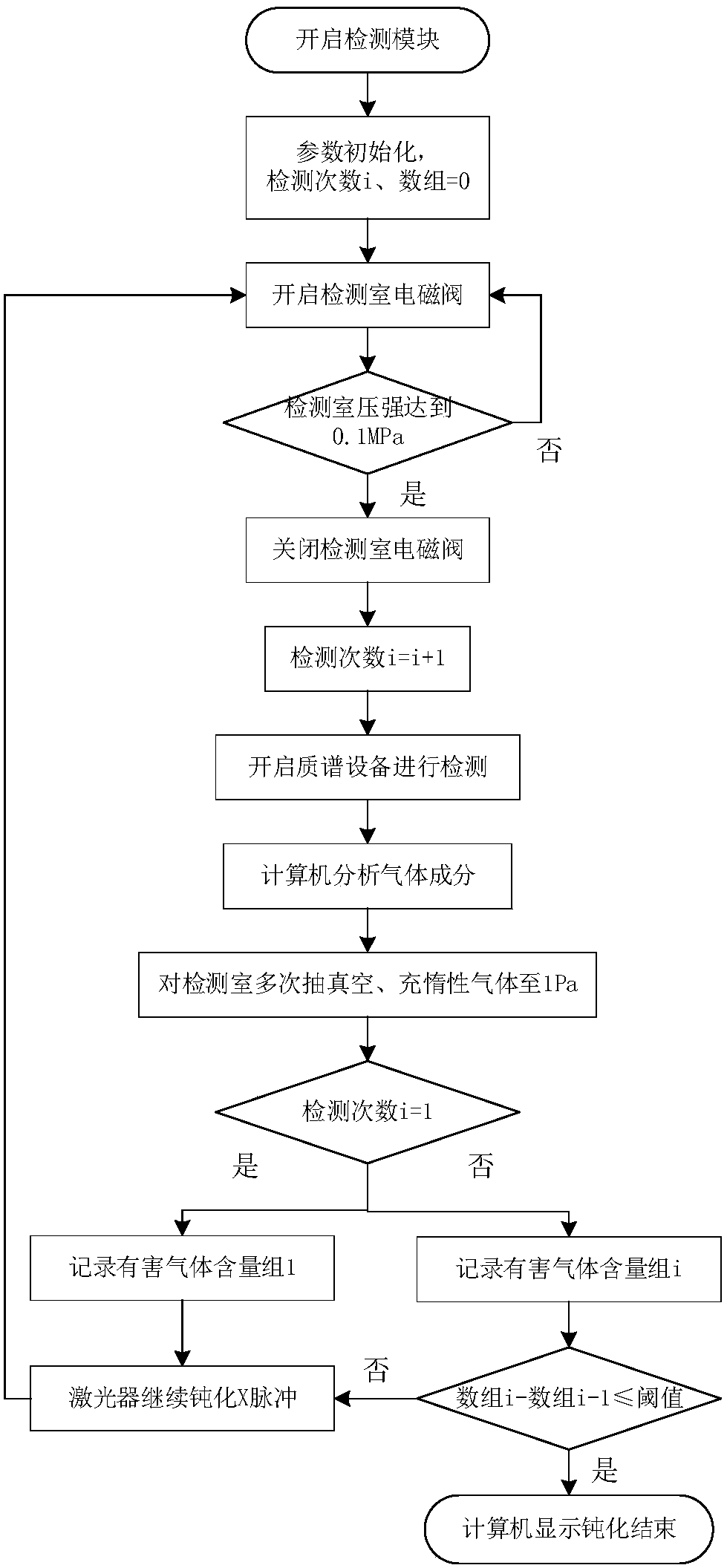

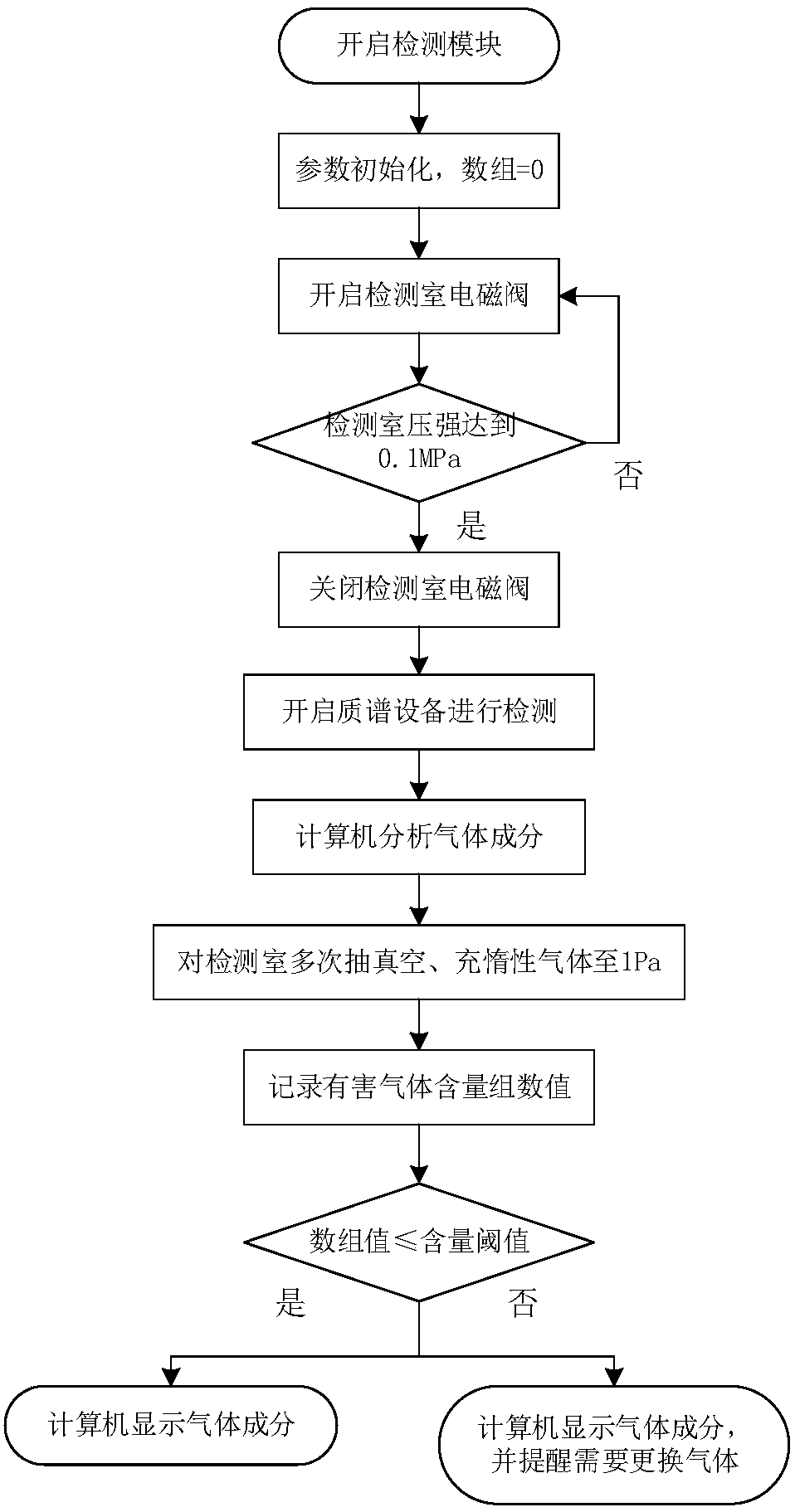

Method and module for detecting gas in excimer laser discharge chamber

PendingCN108414612AReduce time and energy wasteImprove efficiency and operational effectivenessMaterial analysis by electric/magnetic meansHalogenGas processor

The invention relates to a method and module for detecting a gas in an excimer laser discharge chamber. The detection module comprises a gas inlet tube, a gas inlet solenoid valve, a gas chamber, a pressure detector, a mass spectrometer, a computer, a vacuum pump, a vacuum pipeline solenoid valve, a halogen gas processor, an inert gas pipeline and an inert gas solenoid valve. The detection of thegas in the excimer laser discharge chamber in the passivation process or the passivation / operation process is realized by the detection module. T The detection method and the module reduce unnecessarytime and energy wastes in the passivation / operation process, and improve the passivation efficiency and the operation effect.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

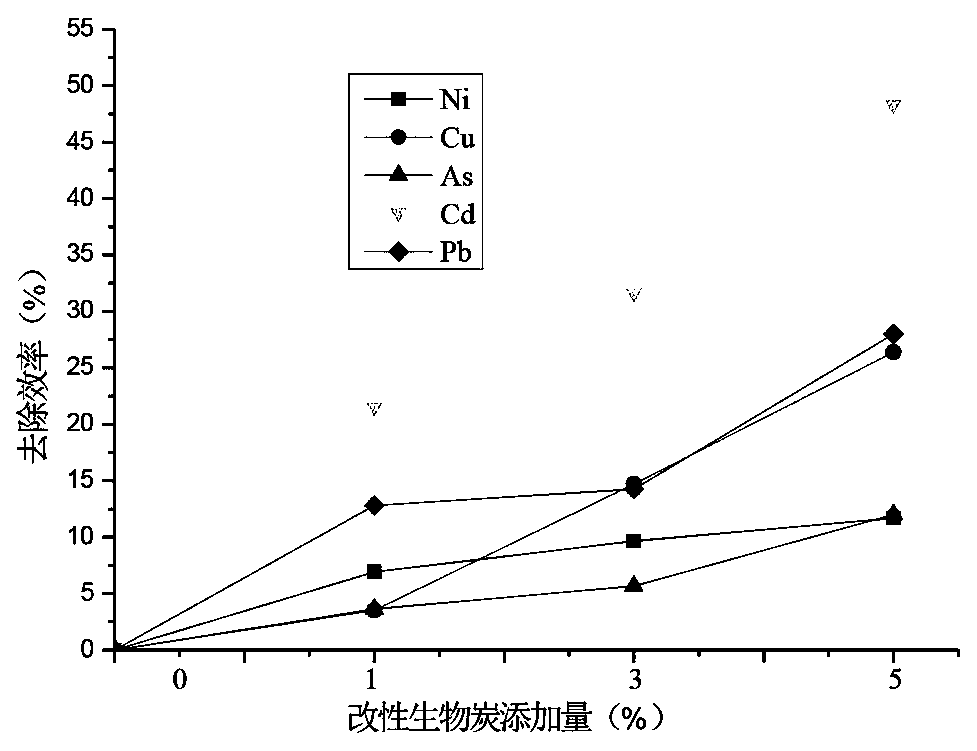

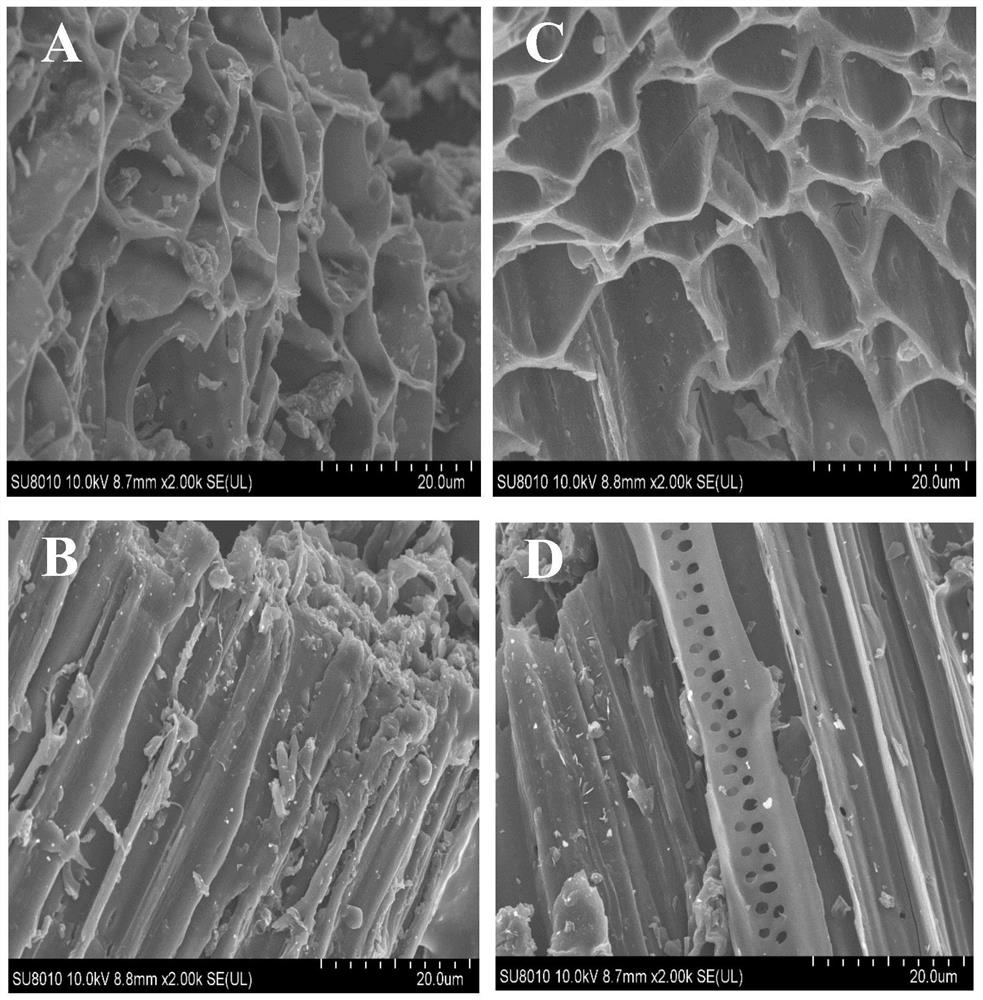

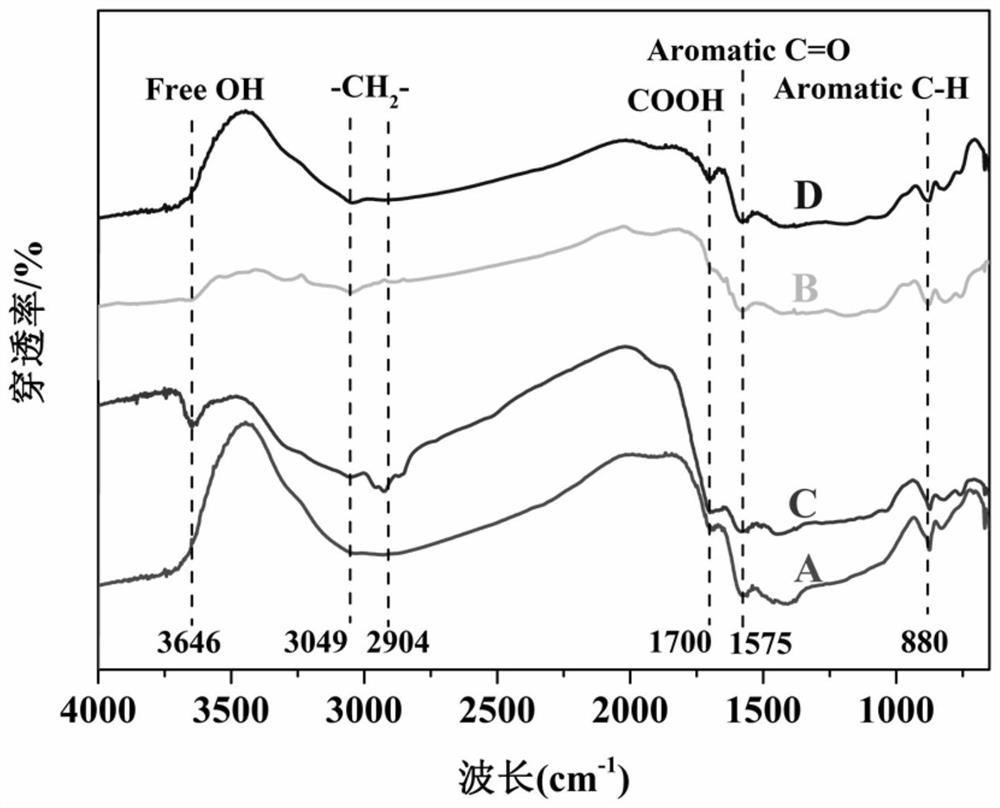

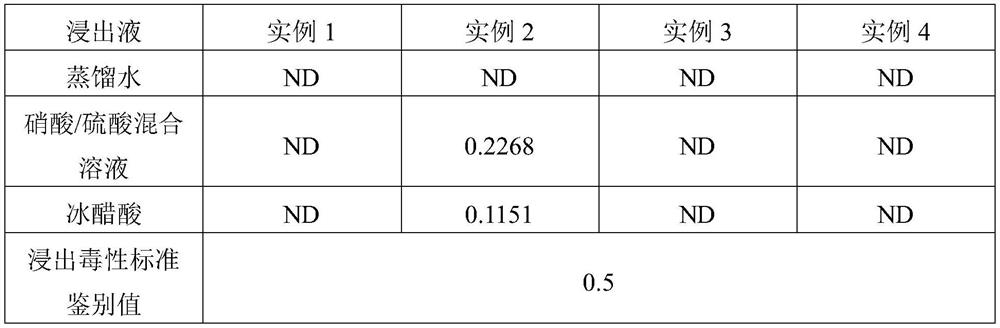

Preparation method of modified remediation plant biochar for remediation of cadmium-contaminated soil

InactiveCN111821946ALow toxicity leachingAcceptableOther chemical processesContaminated soil reclamationContaminated soilsBiomass

The invention discloses a preparation method of modified remediation plant biochar for cadmium-contaminated soil remediation. The preparation method comprises the following steps: (1) harvesting remediation plants containing a certain concentration of heavy metals, washing, drying, crushing and screening to obtain biomass raw materials; (2) putting the biomass into a tubular furnace in a nitrogenatmosphere for high-temperature carbonization, keeping the pyrolysis temperature at 400-700 DEG C and the retention time at 1-2 hours, cooling to room temperature, and grinding to obtain remediation plant biochar with different pyrolysis temperatures; (3) taking a certain mass of repair plant biochar, flatly laying the repair plant biochar in a glass ware of about 2 mm, and irradiating the repairplant biochar under a 250 W ultraviolet lamp for 8-24 h; and (4) taking out the culture dish after the irradiation is finished to obtain the modified repair plant biochar. The remediation plant biochar prepared by the method is low in toxic leaching amount, has environmental acceptability, and is simple in preparation method, the modified biochar effectively inhibits the effectiveness and mobilityof heavy metals in soil, and dual values of safe disposal and resource reutilization of hazardous wastes are realized.

Owner:江苏省地质工程勘察院 +1

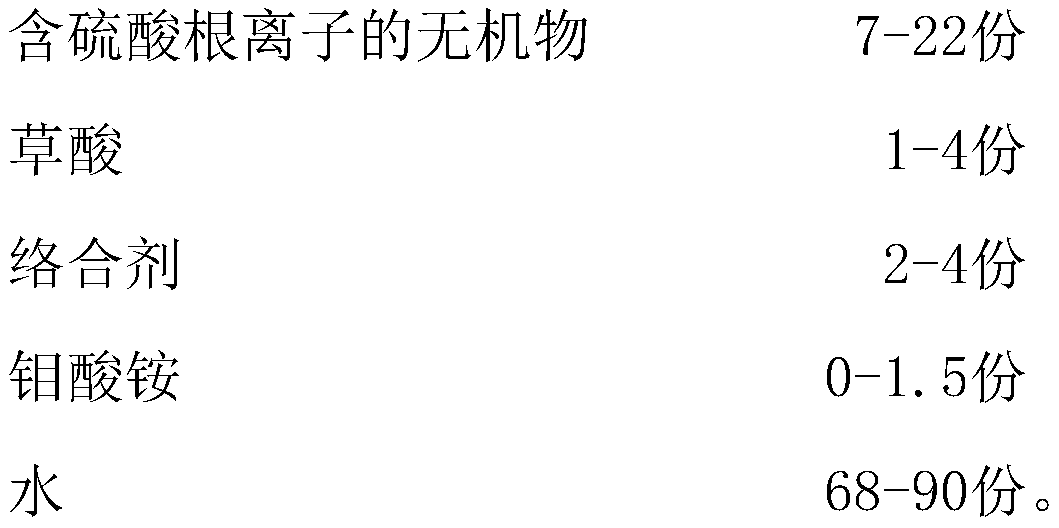

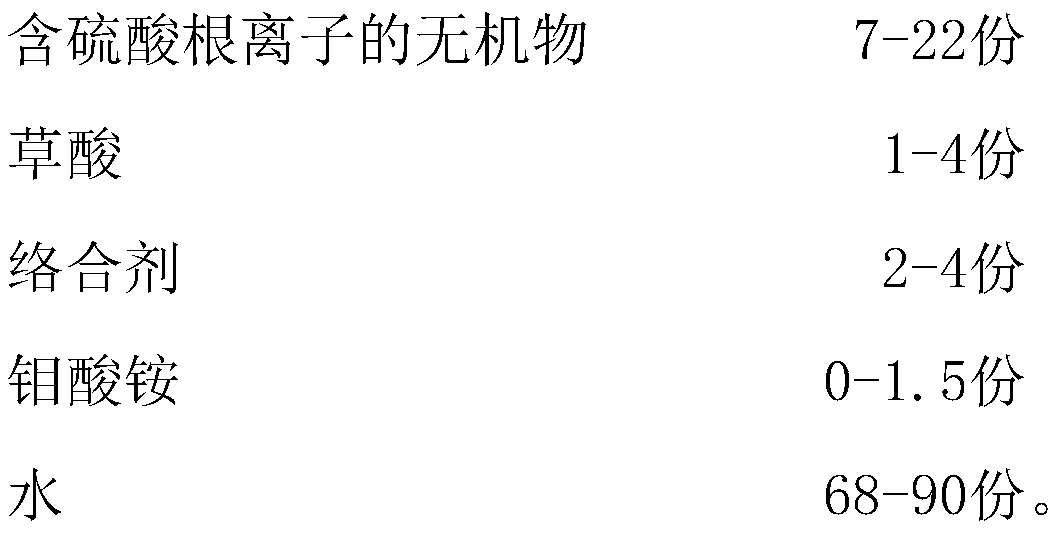

Passivation agent for treating heavy metal pollution of farmland soil and preparation method thereof

InactiveCN109627118AReduce the effective contentImprove qualityCalcareous fertilisersAgriculture tools and machinesPhosphateSoil remediation

The invention relates to the technical field of soil heavy metal pollution remediation, in particular to a passivation agent for treating heavy metal pollution of farmland soil and a preparation method thereof. The passivation agent is prepared from, by weight, 1-2 parts of composite bio-organic fertilizer, 0.1-0.2 part of phosphate rock powder and 0.1-0.2 part of attapulgite. The preparation method of the passivation agent comprises the following step that the composite bio-organic fertilizer and the phosphate rock powder are uniformly mixed according to a proportion to obtain the passivationagent for treating the heavy metal pollution of the farmland soil. The passivation agent can effectively reduce the effective-state content of heavy metal in the farmland soil and improve the soil remediation degree and the soil fertility, the passivation effect is long-acting and stable, the preparation method of the passivation agent is simple and efficient, the operation control is convenient,the product quality is stable, and the industrial production is facilitated.

Owner:GUANGDONG KAIYUAN ENVIRONMENT TECH

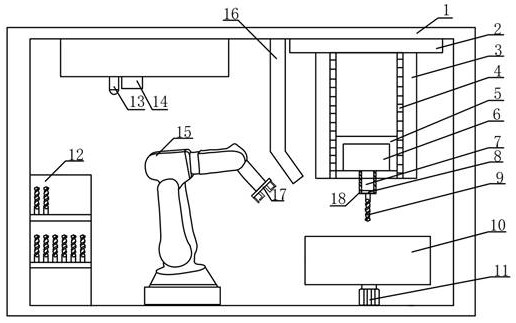

Automatic cutter passivation device

PendingCN112917253ARealize real-time detectionReal-time detectionEdge grinding machinesPolishing machinesPhysicsElectric machinery

The invention relates to an automatic cutter passivation device, and belongs to the technical field of cutter surface machining. The automatic cutter passivation device is divided into a passivation area, a detection area and a feeding and discharging area. The passivation area comprises a rotating disc, a linkage table, a guide rail, a lifting table, a first motor, a second motor, a transmission shaft, a cutter clamping device, a transmission shaft protection sleeve, a grinding material barrel, a first blast pipe and the like. The detection area comprises a photoelectric sensor, a scanning electron microscope lens and the like. The feeding and discharging area comprises a mechanical arm, a mechanical gripper, a cutter frame and the like. When the automatic cutter passivation device works, a cutter is moved to the three areas through the mechanical arm, the cutter clamping device clamps the cutter in the passivation area and inserts the cutter into the grinding material barrel to passivate the cutter, the requirement for machining different cutter cutting edges is met, the shape of the cutter cutting edges is detected in the detection area, and the cutter is assembled and disassembled in the feeding and discharging area. The automatic cutter passivation device is easy to operate, high in passivation efficiency and high in automation degree, and the passivation precision meets the machining and production requirements.

Owner:HARBIN UNIV OF SCI & TECH

The method of remediating cd and pb polluted soil in situ with passivating agent

ActiveCN105950154BSimple componentsLow costAgriculture tools and machinesContaminated soil reclamationPb contaminated soilToxicity characteristic leaching procedure

The invention discloses a passivator for treating Cd / Pb-polluted soil. The passivator is proportionally composed of biochar, red mud and monoammonium phosphate. When the passivator is in use, a TCLP (toxicity characteristic leaching procedure) process is utilized to evaluate the heavy metal pollution conditions in soil, the weight of the passivator is determined according to the mass ratio of the soil, and the passivator is applied into the soil many times at appropriate time intervals, thereby effectively improving the soil microenvironment. In the slightly alkaline high-reducibility soil, the mobility of Cd and Pb is greatly lowered, and the biochar can absorb abundant Cd and Pb in the soil. The nano red mud has fine particles, contains rich iron aluminum oxides, and can effectively combine Cd-Pd; the applied monoammonium phosphate and red mud further enhance the Cd / Pb adsorptivity, thereby obviously lowering the bioavailable-state Cd / Pb content in the soil, and greatly lowering the Cd / Pb content in crops. Meanwhile, the passivator has high soil environment friendliness, can not generate secondary pollution, and thus, has popularization and application values.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com