Ultrasonic passivating device and method for carbide blade

A cemented carbide blade, ultrasonic technology, applied in the direction of metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of unstable passivation quality, uneven force on the edge of the tool, etc., to achieve improved Micro-grinding efficiency, promotion of blasting and generation, uniform effect of passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

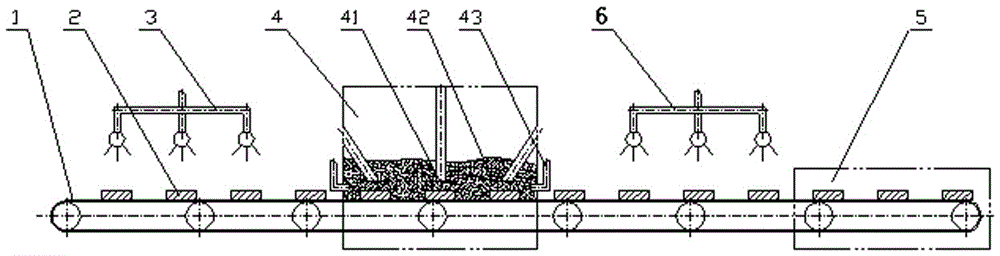

[0024] Such as figure 1 As shown, the present invention includes a conveyor belt 1 , an ultrasonic machine 4 , a quality inspection device 5 , a first cleaning mechanism 3 and a second cleaning mechanism 6 . The transmission belt 1 passes through the ultrasonic machine 4; the ultrasonic machine 4 is provided with an ultrasonic generator 41 and a passivation solution 42, and the part of the conveyor belt 1 located in the ultrasonic machine 4 is immersed in the passivation solution 42. The passivation solution 42 is made by mixing abrasive grains and water. The abrasive grains are SiC grains with a diameter of 1 μm-3 μm, and the mass concentration is 15-20%. Ultrasonic microscopic explosion is used to promote the cutting effect of the abrasive particles of the passivation solution 42 on the workpiece to act on the cutting edge of the cemented carbide blade 2 to passivate it,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com