Patents

Literature

33results about How to "Uniform passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

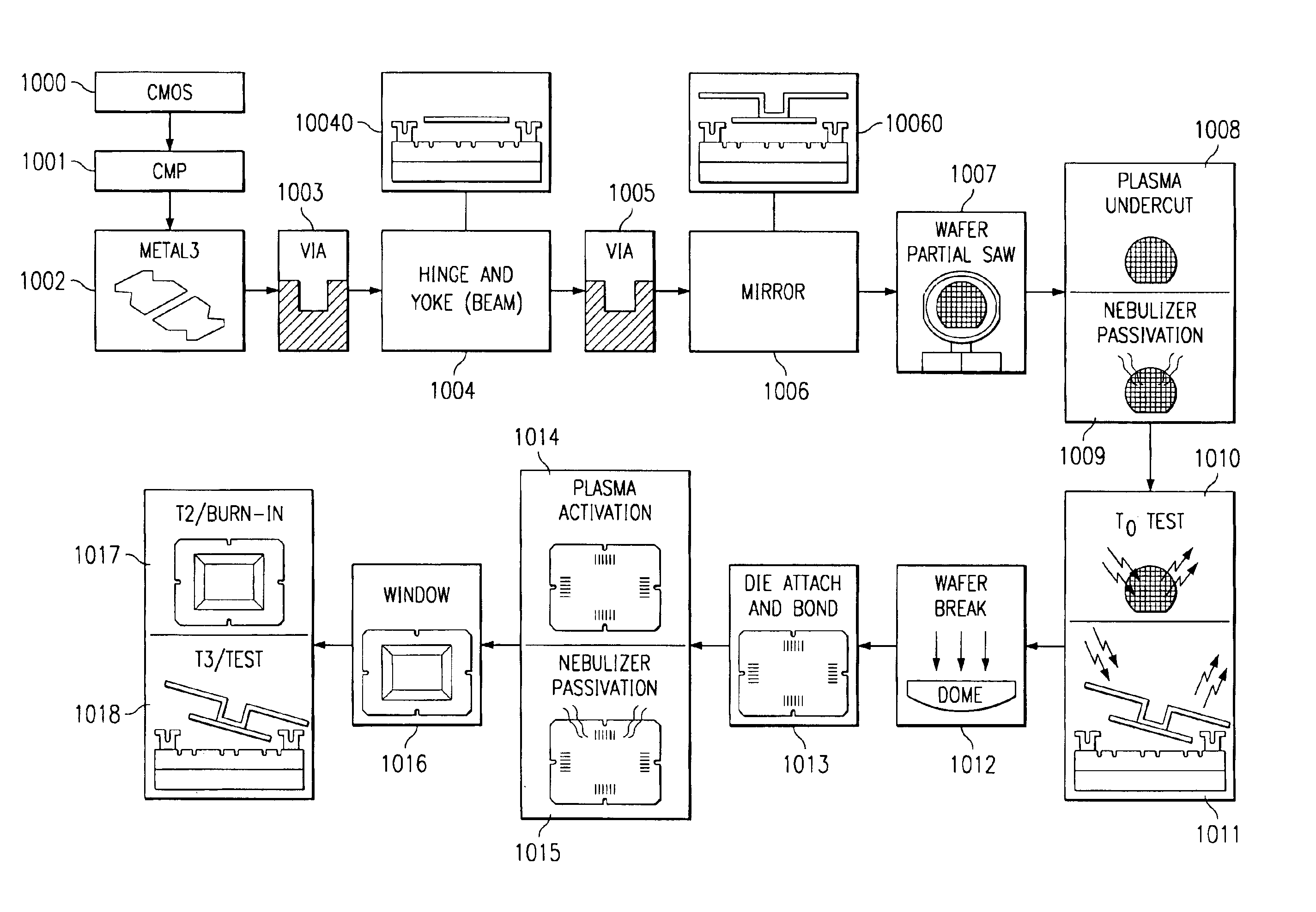

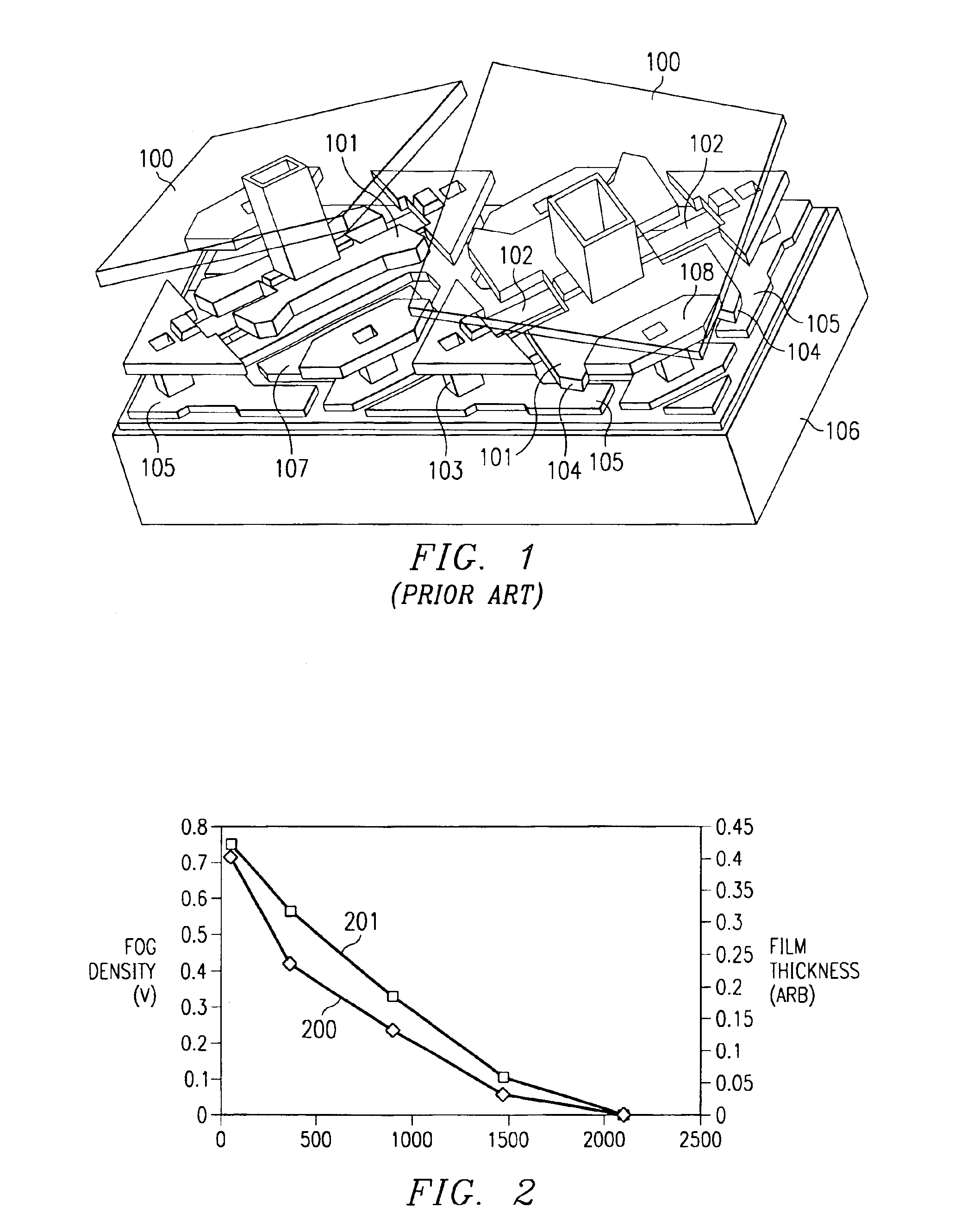

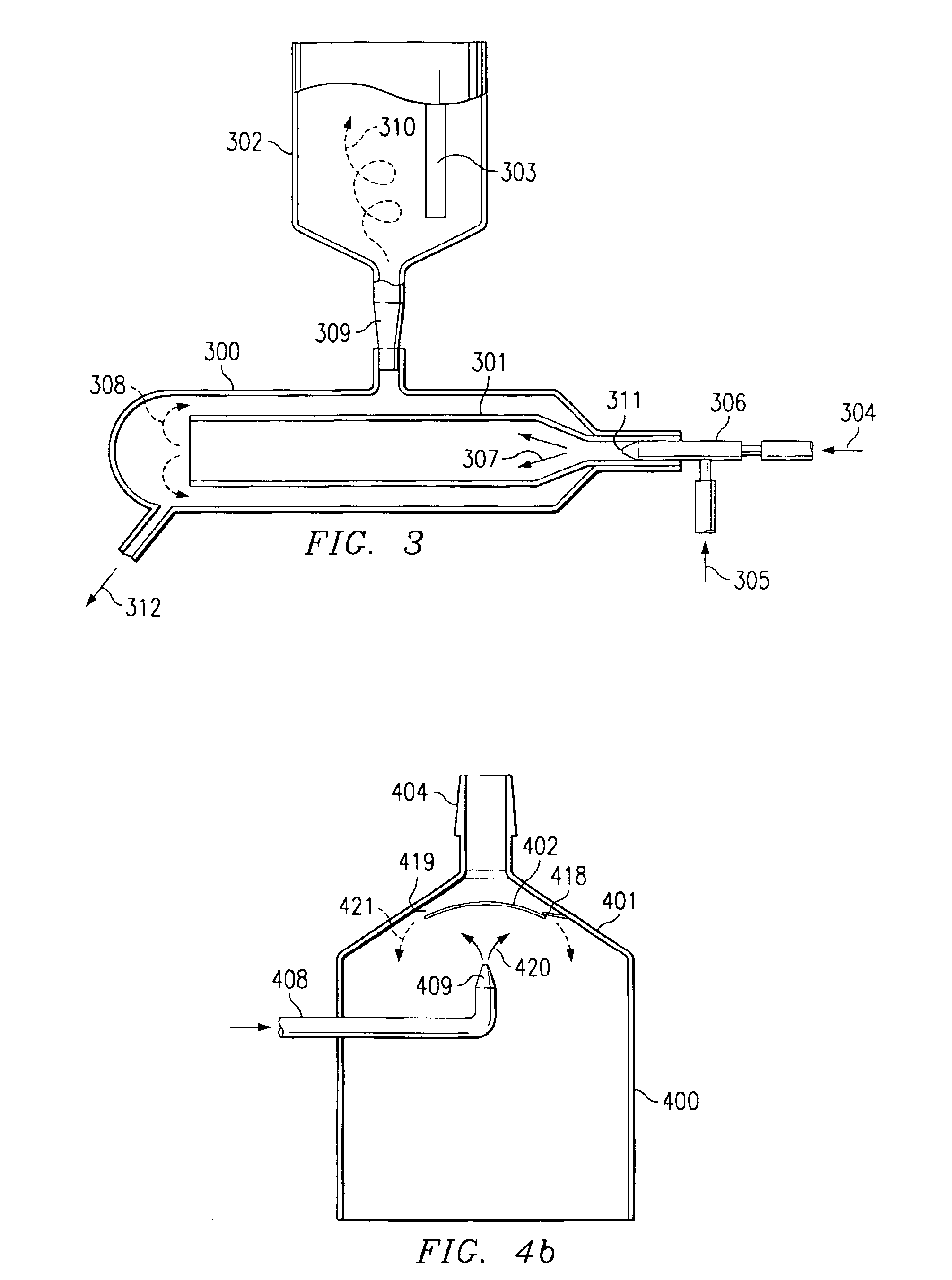

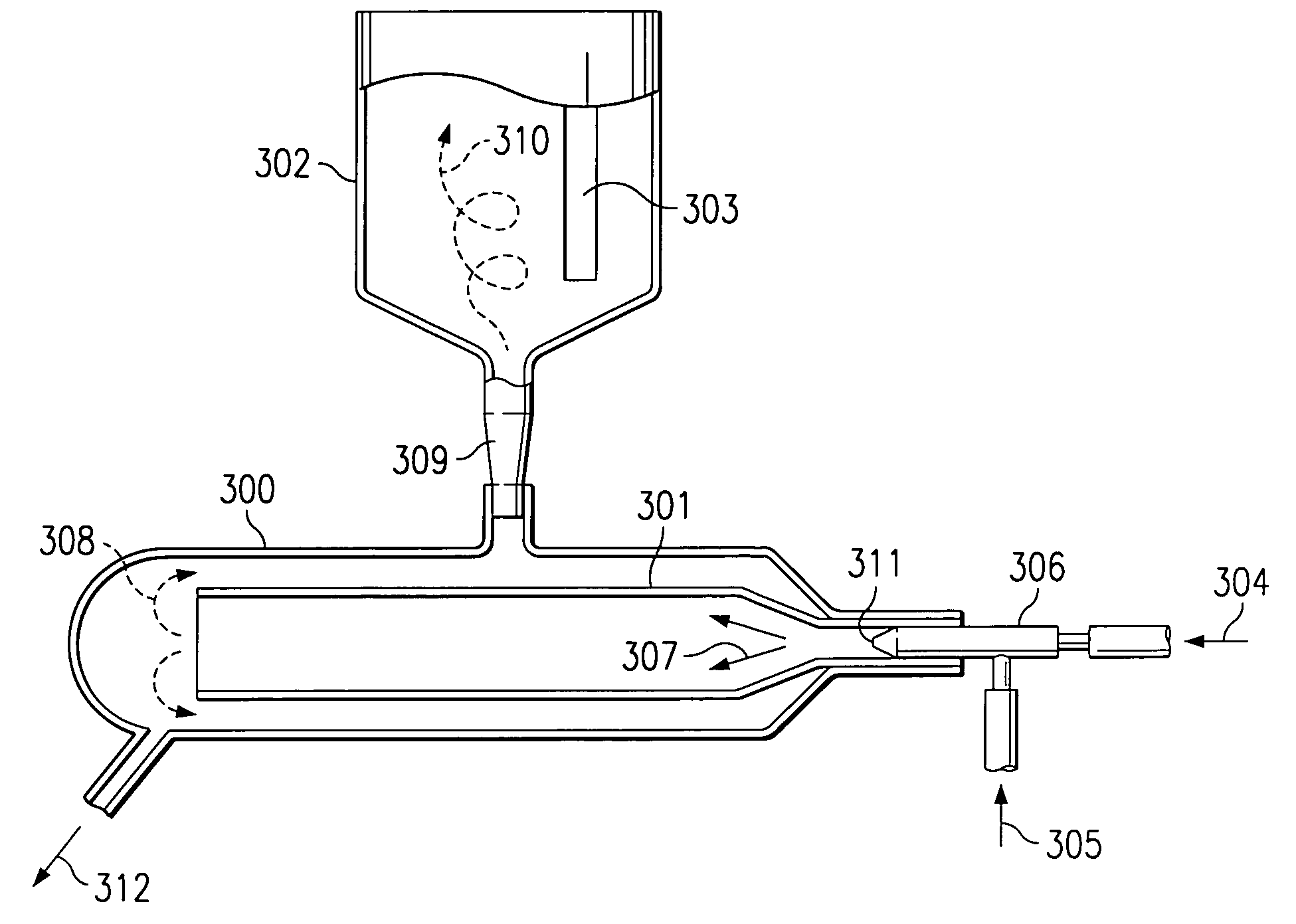

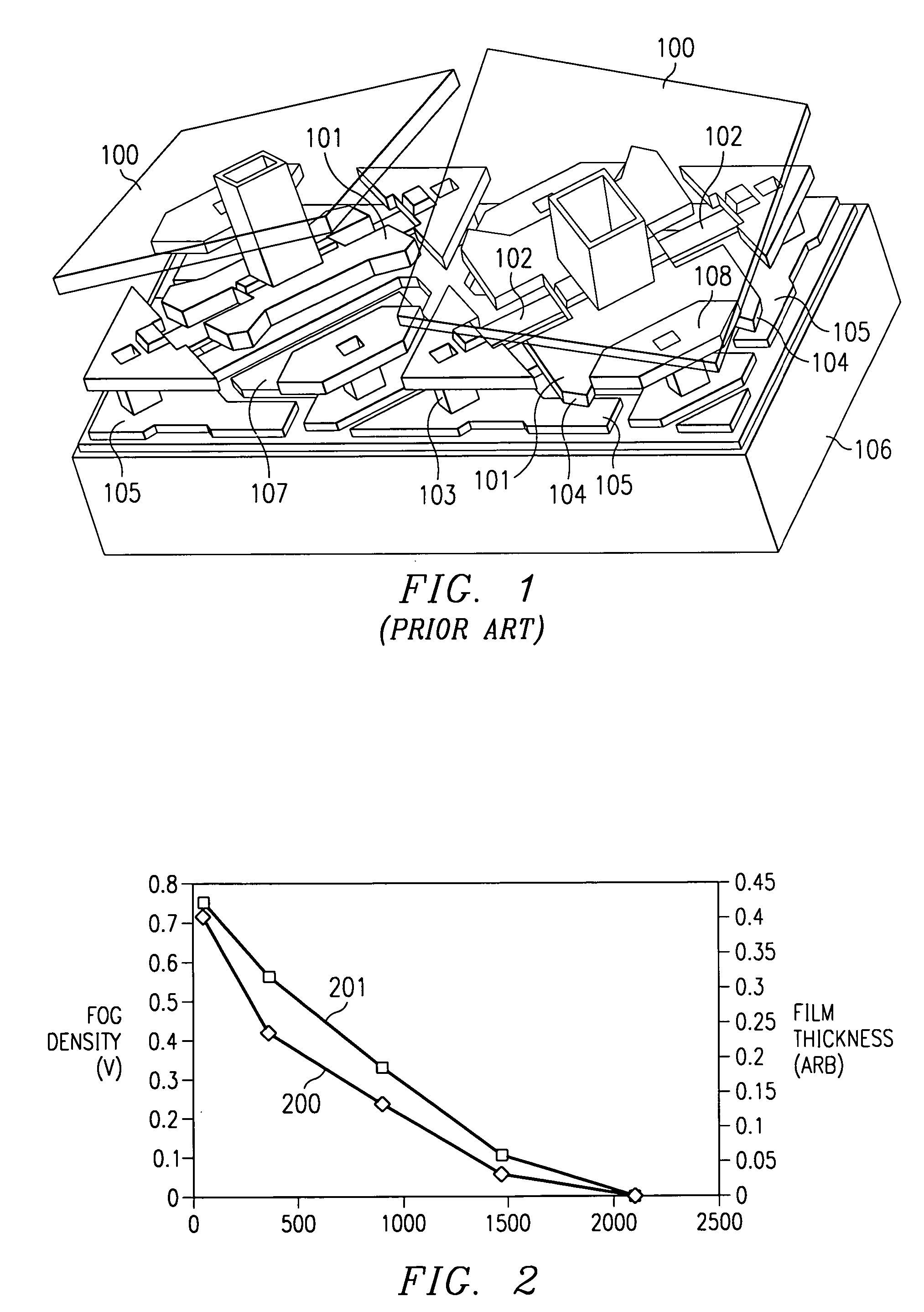

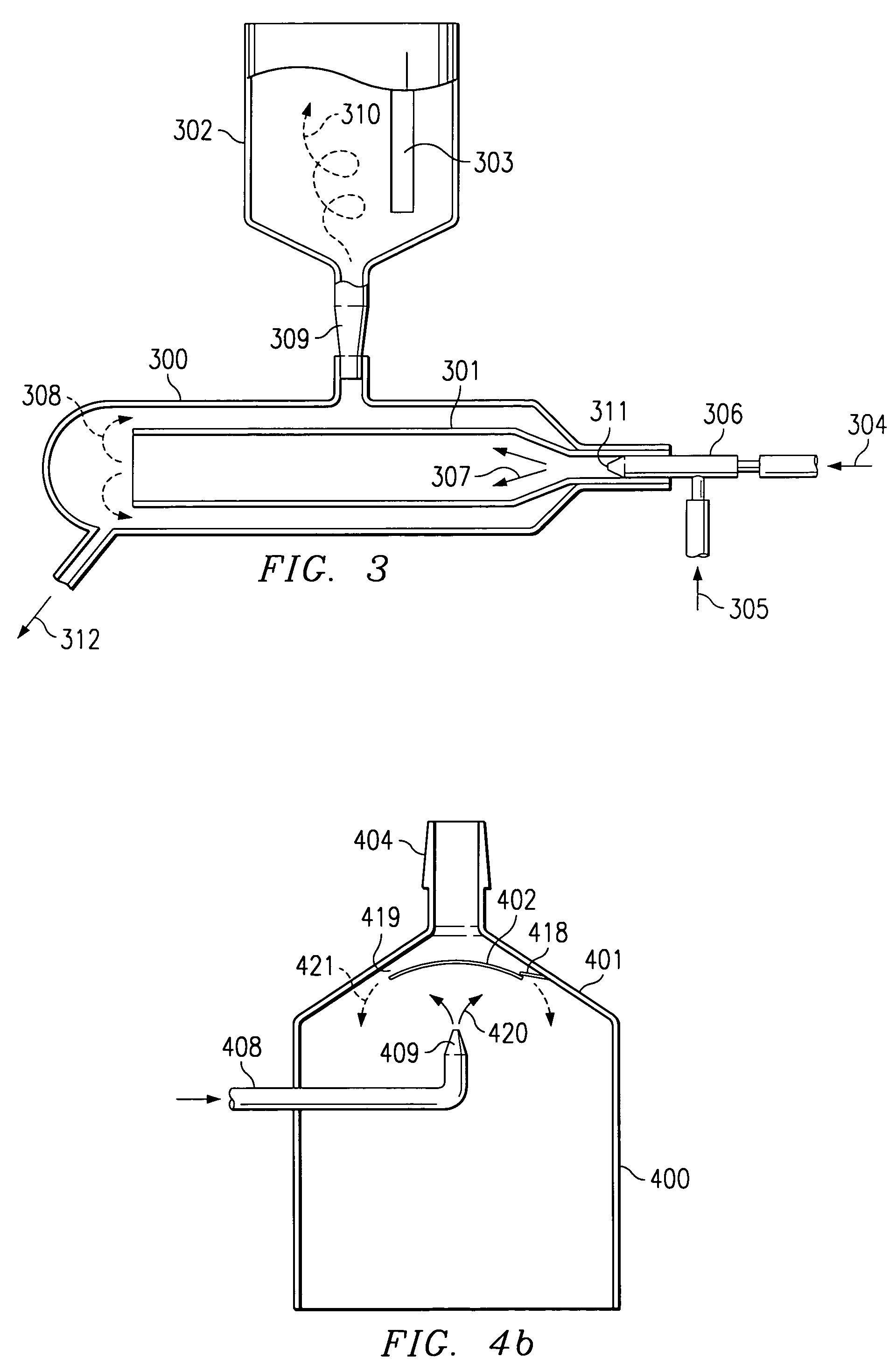

Method and apparatus for MEMS device nebulizer lubrication system

InactiveUS6921680B2Uniform surfaceReasonable costSemi-permeable membranesSemiconductor/solid-state device manufacturingLubricationEngineering

A nebulization system, which creates a uniform fog of tiny suspended liquid droplets, to lubricate the surfaces of MEMS devices. These droplets fall over the edge of a baffle and are then mixed with an umbrella-like sheet of N2 turbulation gas to generate a uniform cloud of droplets that fill a passivation chamber. The MEMS device is then positioned in this uniform cloud of lubricant droplets for a specified amount of time, thereby uniformly lubricating all the surfaces of the device. The system uses a laser monitoring approach to control the uniformity of the lubricant cloud by providing feedback to the system to control the flow of gases. The system also equalizes the pressure around the sample device seal to prevent gases from entering or exiting the chamber and thereby influencing the environment inside the chamber.

Owner:TEXAS INSTR INC

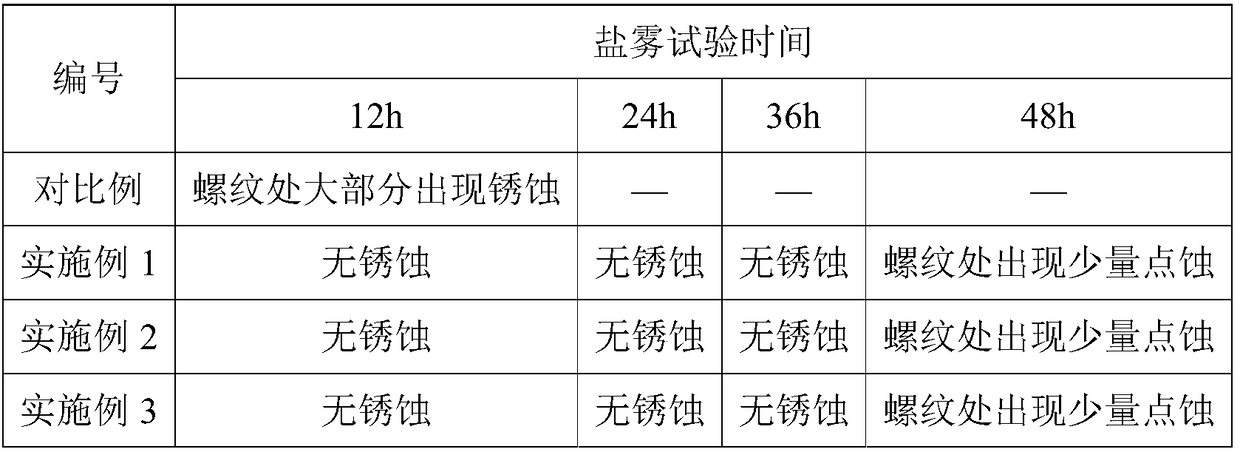

Method for improving corrosion resistance of 1Cr17Ni2 martensitic stainless steel fastener

InactiveCN109487326AHigh surface finishImprove uniform densityMetallic material coating processesMartensitic stainless steelFastener

The invention relates to a method for improving corrosion resistance of a 1Cr17Ni2 martensitic stainless steel fastener. The method comprises the following steps that 1) electric polishing is conducted, the 1Cr17Ni2 martensitic stainless steel fastener is immersed in an electric polishing solution for electric polishing treatment, and cleaning is conducted for later use after the treatment; 2) passivation is conducted, the fastener after the electric polishing treatment is immersed into a passivation solution for passivation treatment, and cleaning and drying are conducted for later use afterthe treatment; and 3) sealing is conducted, the fastener after the passivation treatment is immersed in a sealed liquid for sealing treatment. According to the method, the 1Cr17Ni2 martensitic stainless steel fastener is subjected to the electric polishing treatment, the passivation treatment and the sealing treatment, so that the surface smoothness of the fastener is effectively improved, the uniformity and compactness of a passivation film layer are improved, the defects of a traditional process are eliminated, the salt mist resistance test time of the fastener reaches 48 hours or above, andthe corrosion resistance of the corresponding fastener is remarkably improved.

Owner:河南航天精工制造有限公司

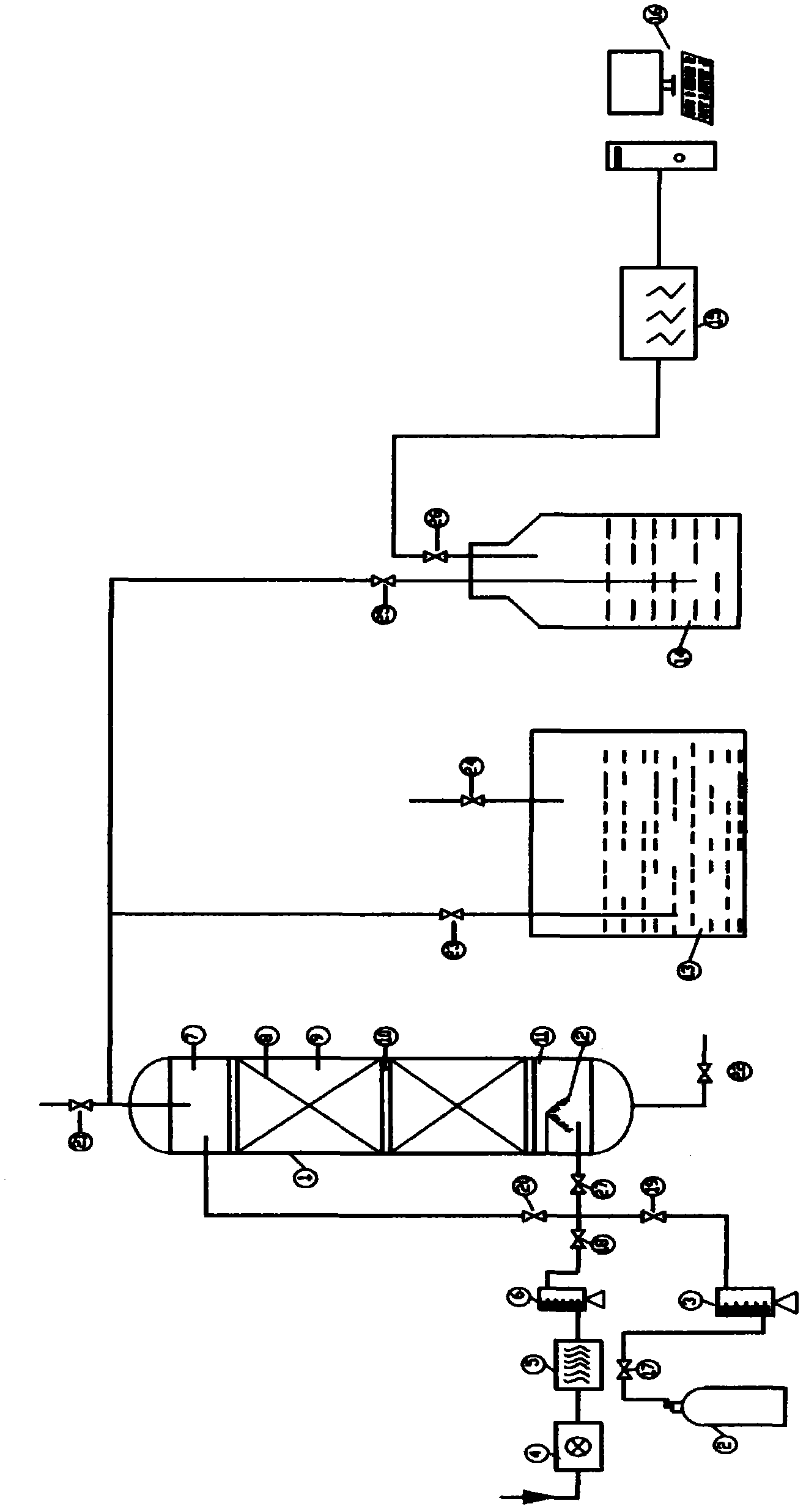

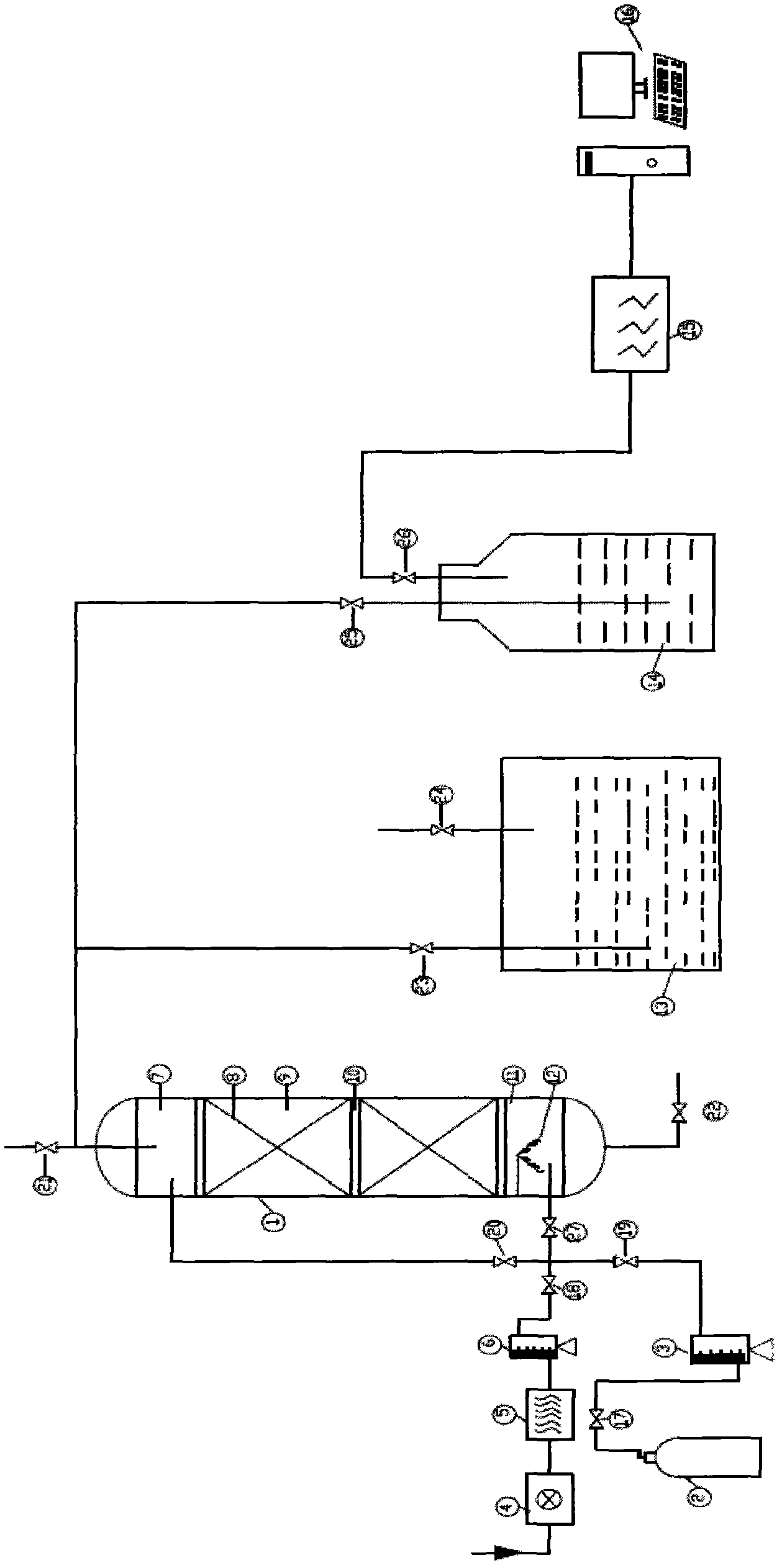

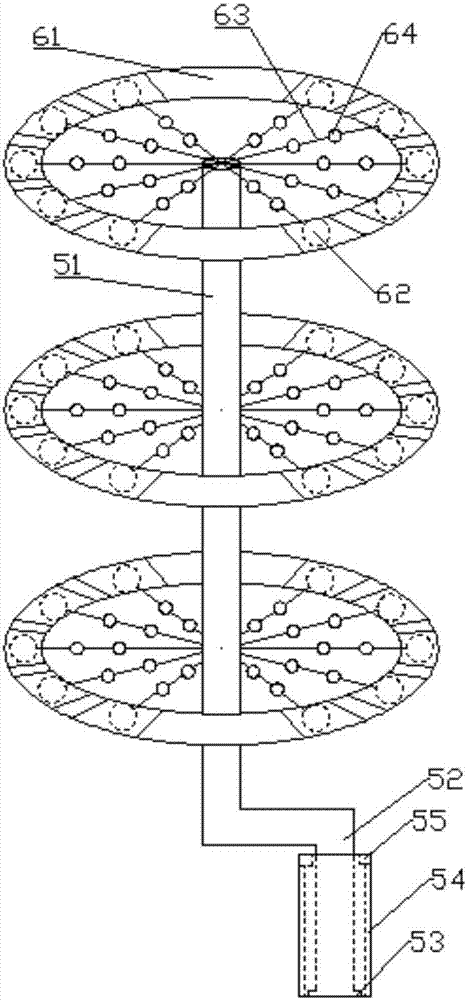

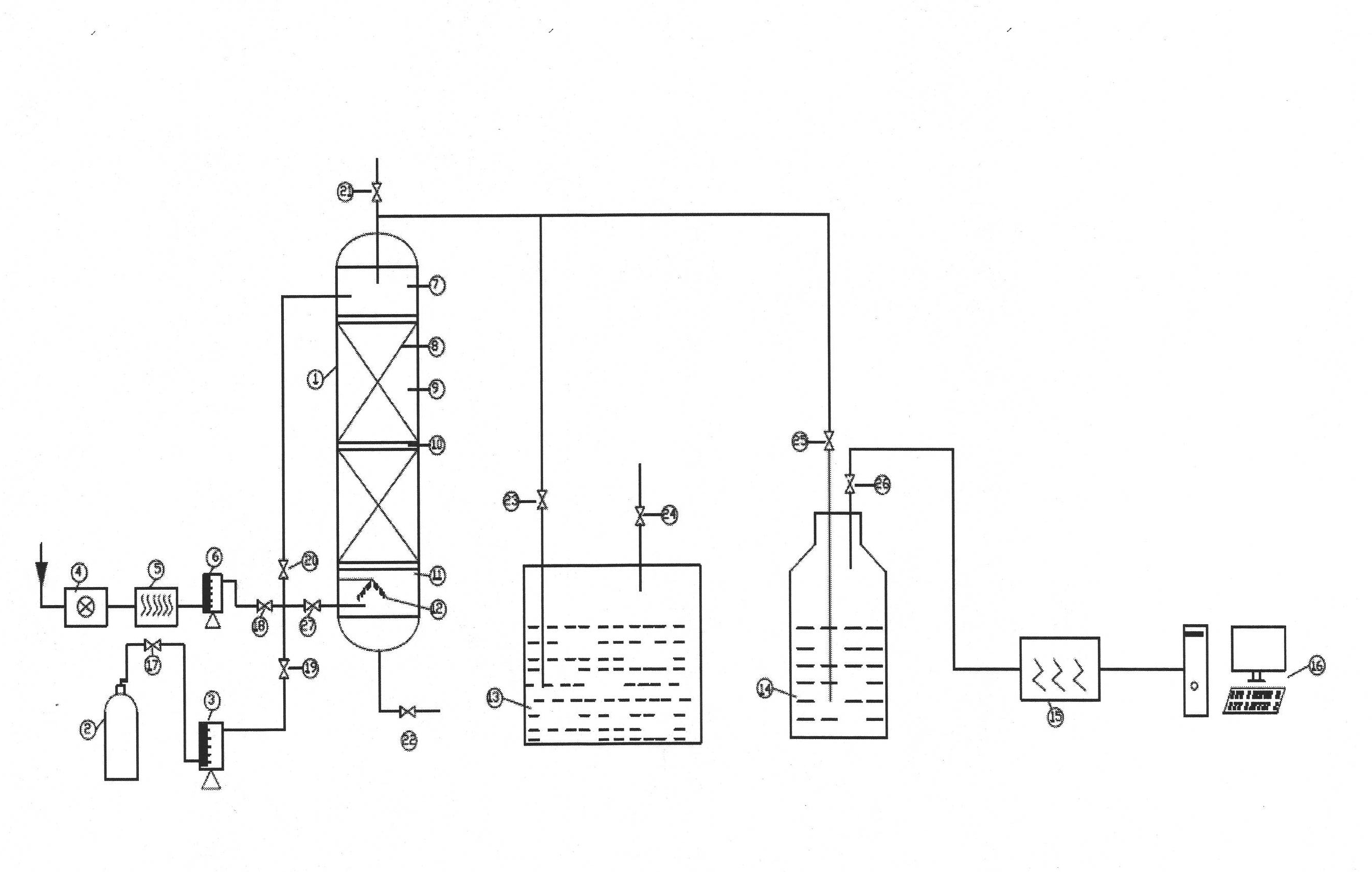

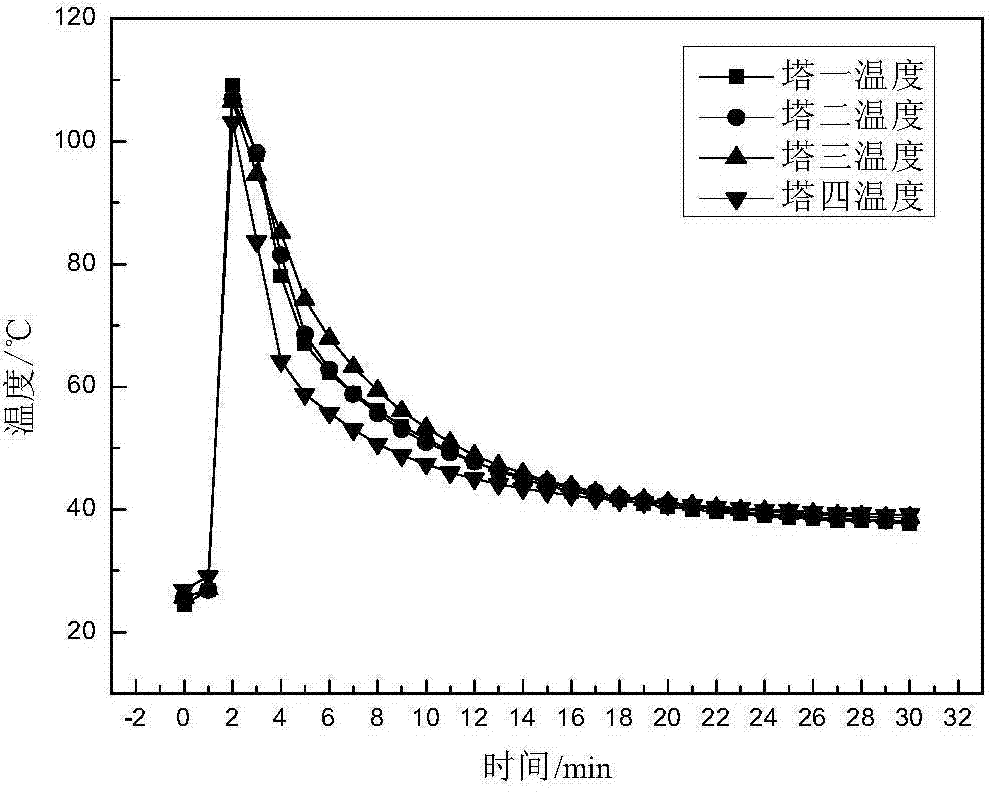

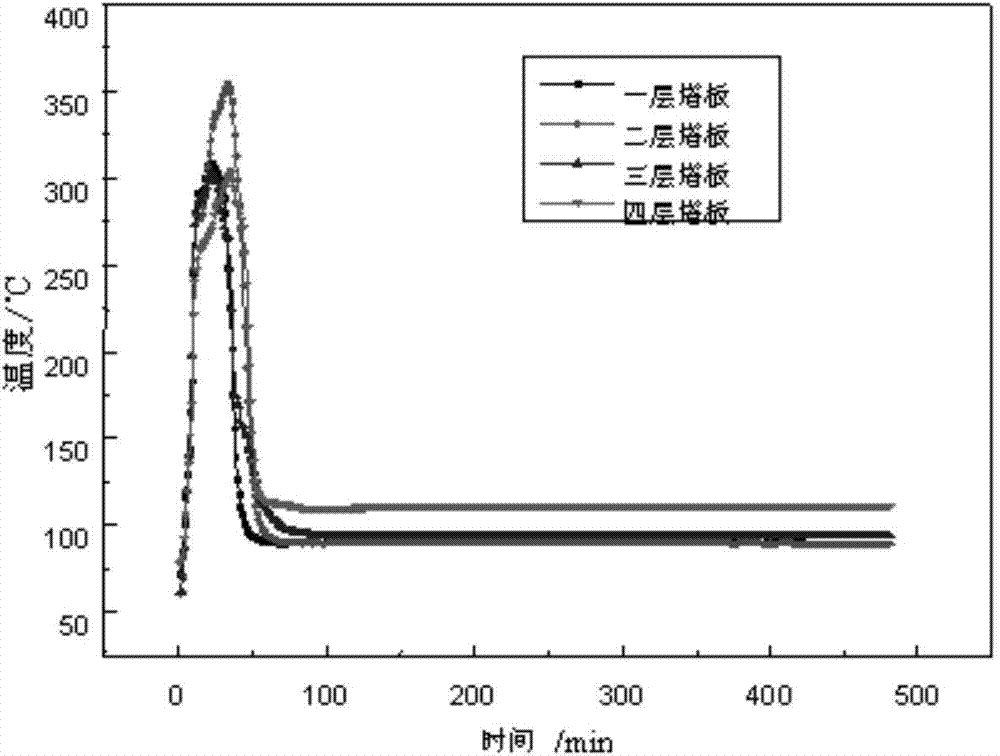

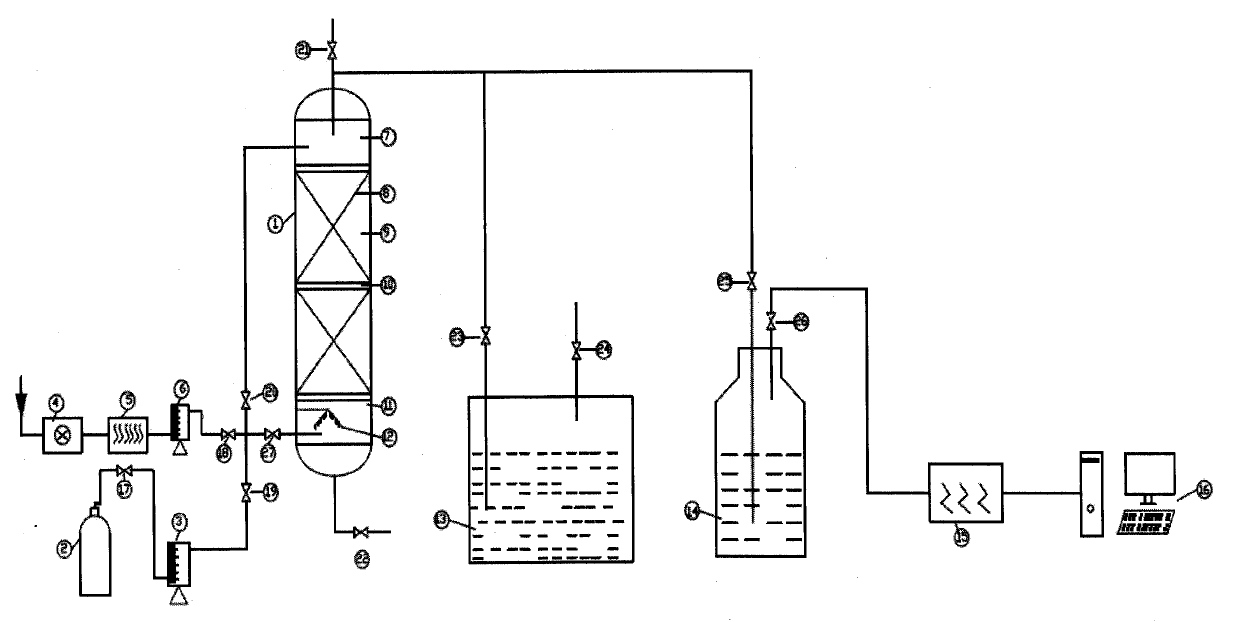

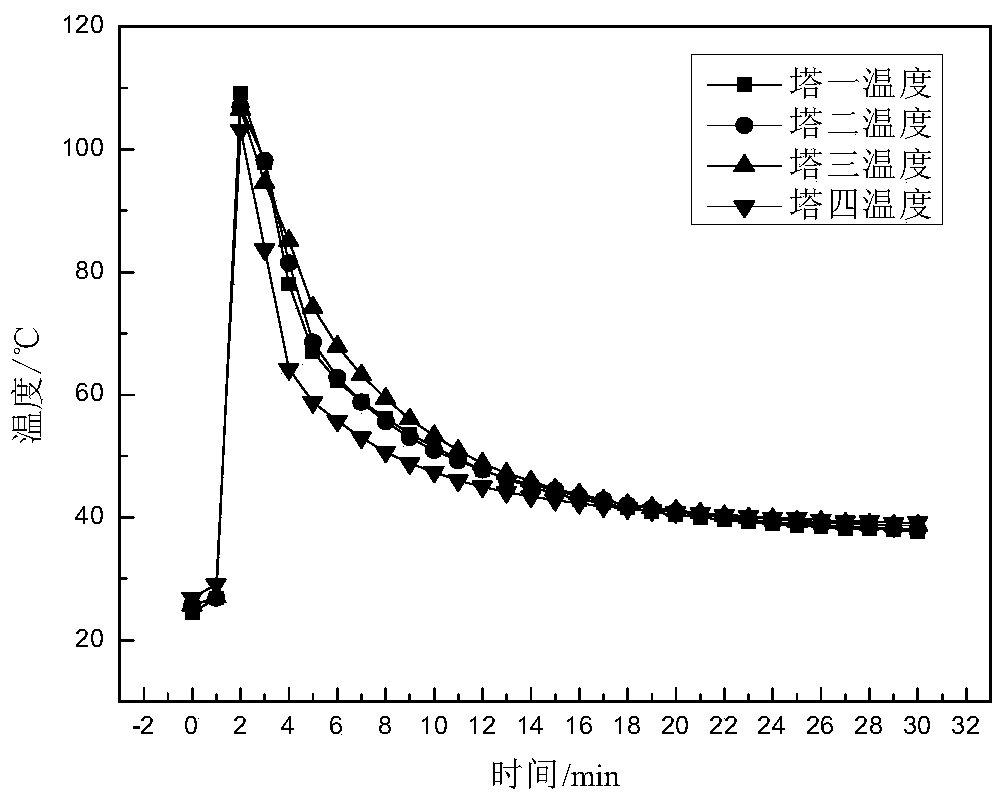

Ferrous sulfide gas phase passivation device

The invention discloses a ferrous sulfide gas phase passivation device. The gas phase passivation device contains a steam supply part, an oxygen supply part and a sealing part. The gas phase passivation device is connected with a tail gas treatment device and a data analysis device respectively to perform gas phase passivation to a petrochemical device. The steam supply part contains a water softener, a steam generator, a steam flowmeter and an oxygen valve. The oxygen supply part contains a compressed oxygenized air bottle, a gas flowmeter, an oxygen inlet valve and an oxygen valve. The sealing part contains a packed tower, a tail gas valve and a gathering tank valve. Compared with the liquid phase passivation method in the prior art, the phase passivation method of the invention mainly uses oxygenized air, is convenient to use and has lower cost. Waste gas is easy to treat. The waste gas which is easily treated through gas phase passivation can meet the emission standard. The treatment time is short; and passivation can be performed evenly and the channeling phenomenon does not exist.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ferrous sulfide gas-phase passivation method

The invention discloses a ferrous sulfide gas-phase passivation method, comprising the steps of monitoring, feeding air, passivating, sealing and discharging, wherein the passivating is implemented as follows: vapor carrying oxygen enriched air enter a container for carrying out gas phase passivation on ferrous sulfide. The vapor is water vapor, the pressure of the water vapor is 0.1-0.9 MPa, and the oxygen enriched air contains 21-50 percent of oxygen by volume. Compared with the ferrous sulfide liquid-phase passivation method, the ferrous sulfide gas-phase passivation method has low cost, is easy to implement, mainly adopts oxygen enriched air which is convenient to use and has low cost for gas phase passivation, ensures uniform ferrous sulfide passivation, is free from channeling phenomenon and dead corners due to gas-phase action and boasts of easy treatment of waste gas which is produced in ferrous sulfide gas-phase passivation and can reach the emission standard after being treated simply, and has short treatment time.

Owner:CHINA PETROLEUM & CHEM CORP +1

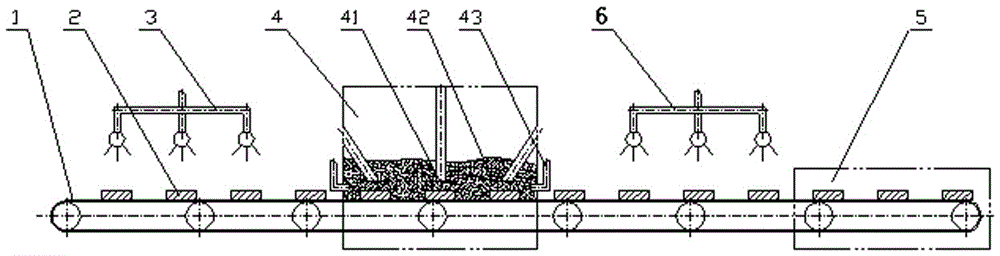

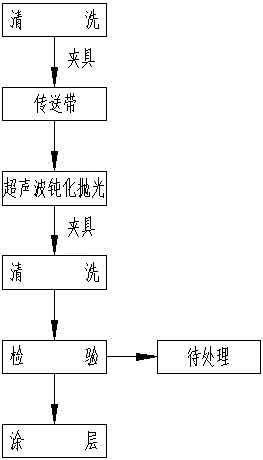

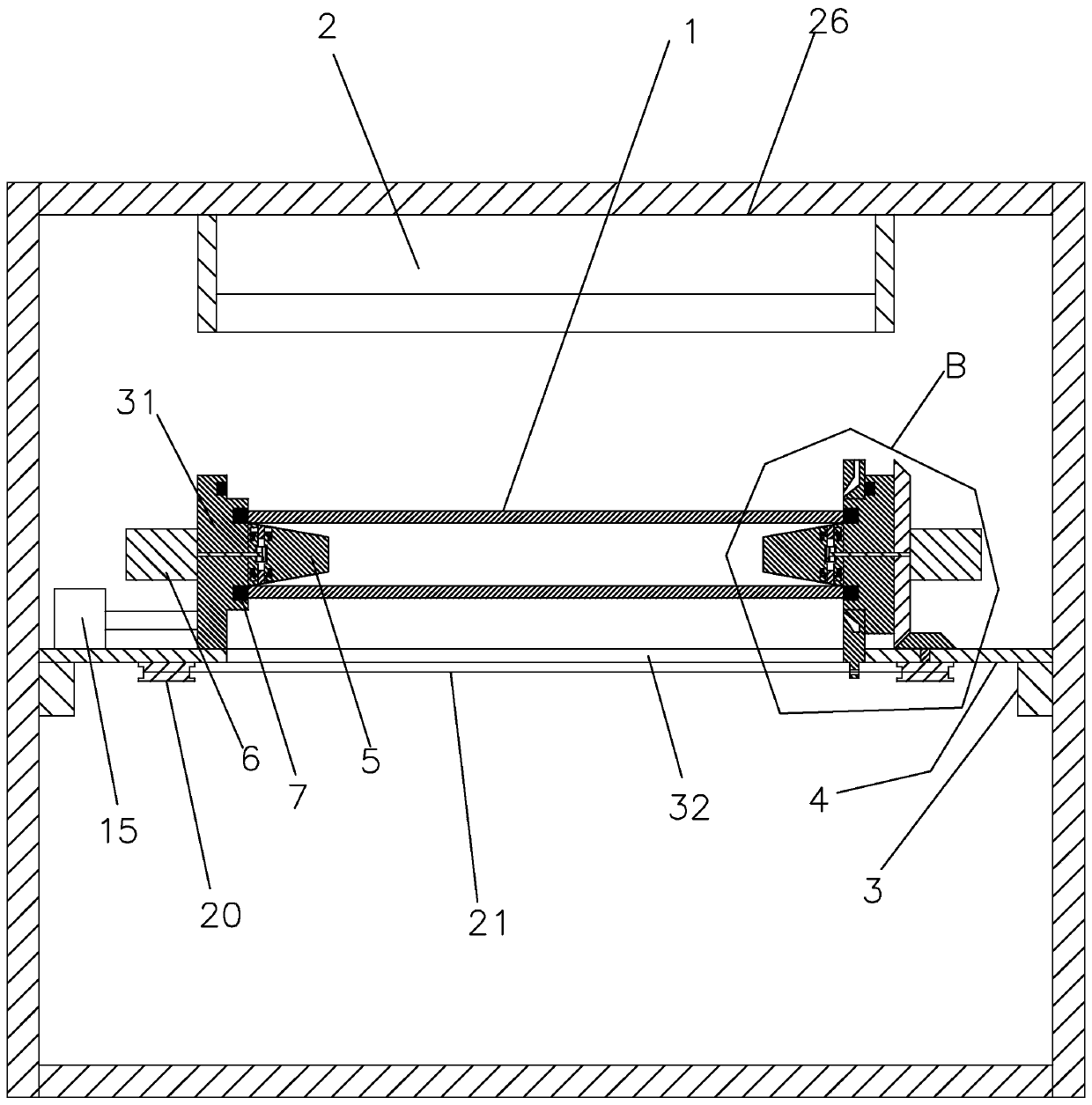

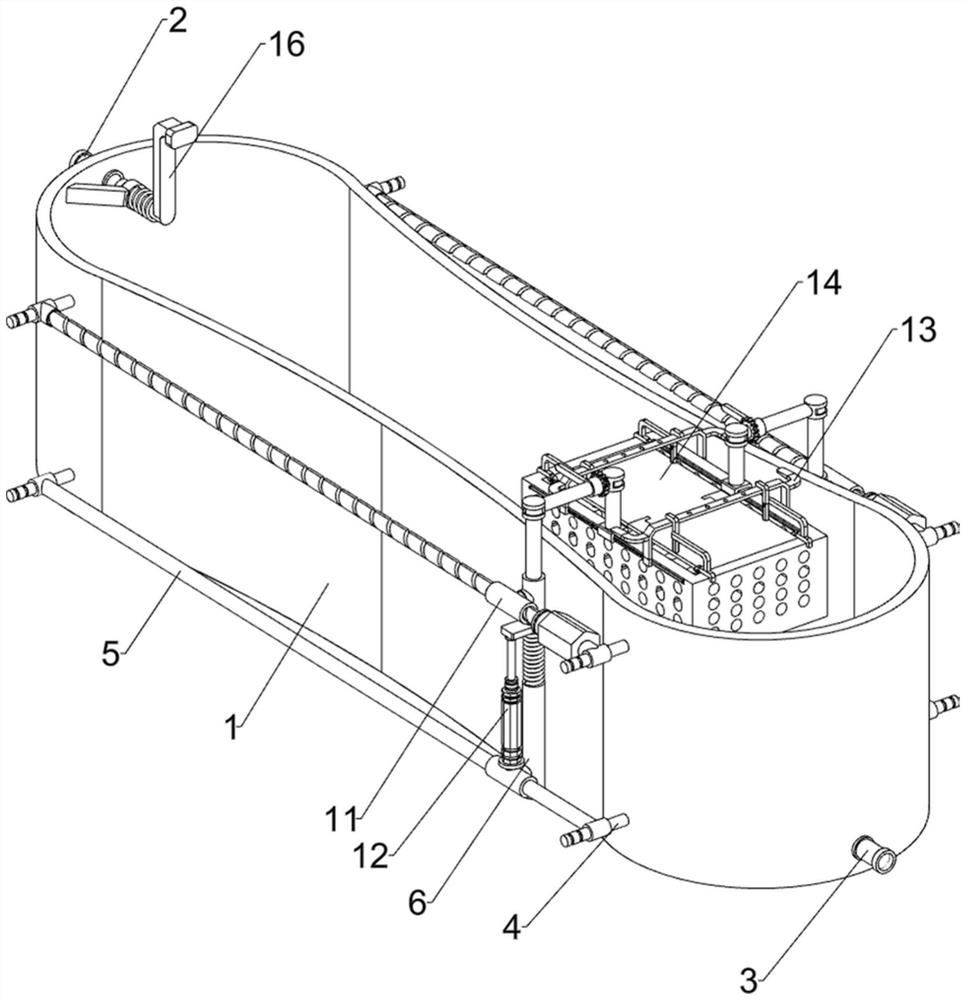

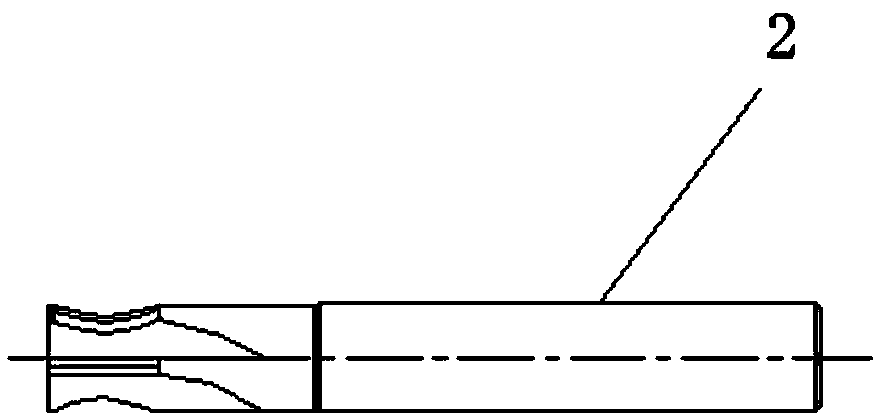

Ultrasonic passivating device and method for carbide blade

InactiveCN105710735AExtended service lifeThe size is easy to controlGrinding feedersCavitationCarbide

The invention provides an ultrasonic passivating device and method for a carbide blade. The ultrasonic passivating device for the carbide blade comprises a conveying belt, an ultrasonic machine, a quality testing device, a first cleaning mechanism and a second cleaning mechanism. The conveying belt penetrates the ultrasonic machine. An ultrasonic generator and a passivating solution are arranged in the ultrasonic machine. The part, located in the ultrasonic machine, of the conveying belt is immersed in the passivating solution. An inflation gas pipe is arranged on the ultrasonic machine. The first cleaning mechanism and the second cleaning mechanism are located above the conveying belt and arranged at the two sides of the ultrasonic machine. The quality testing device is arranged at the tail end of the conveying belt. According to the ultrasonic passivating device and method, ultrasonic microcosmic explosions are utilized for promoting the cutting effect of adhesive particles of the passivating solution on a workpiece to act on a cutting edge of the carbide blade, so that the cutting edge is passivated, and passivating is even; and the material of the cutting edge of the carbide blade is hardened through the cavitation effect of ultrasonic waves while the cutting edge is passivated, and the service life of the carbide blade is prolonged.

Owner:曾凡之

Method and apparatus for MEMS device nebulizer lubrication system

ActiveUS20050178848A1Solution to short lifeUniform densityLiquid surface applicatorsWatering devicesNebulizerEngineering

A nebulization system, which creates a uniform fog of tiny suspended liquid droplets, to lubricate the surfaces of MEMS devices. These droplets fall over the edge of a baffle and are then mixed with an umbrella-like sheet of N2 turbulation gas to generate a uniform cloud of droplets that fill a passivation chamber. The MEMS device is then positioned in this uniform cloud of lubricant droplets for a specified amount of time, thereby uniformly lubricating all the surfaces of the device. The system uses a laser monitoring approach to control the uniformity of the lubricant cloud by providing feedback to the system to control the flow of gases. The system also equalizes the pressure around the sample device seal to prevent gases from entering or exiting the chamber and thereby influencing the environment inside the chamber.

Owner:TEXAS INSTR INC

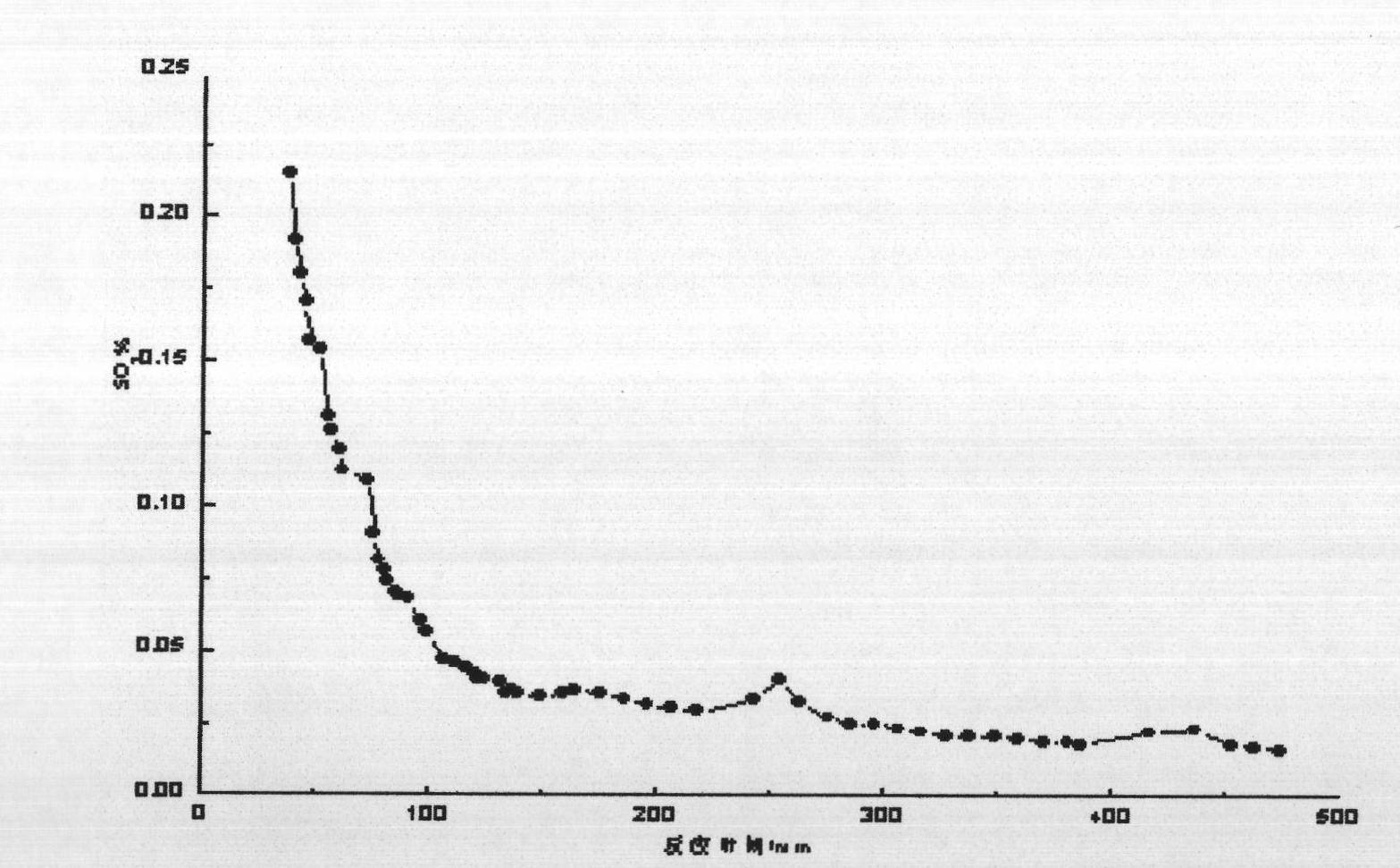

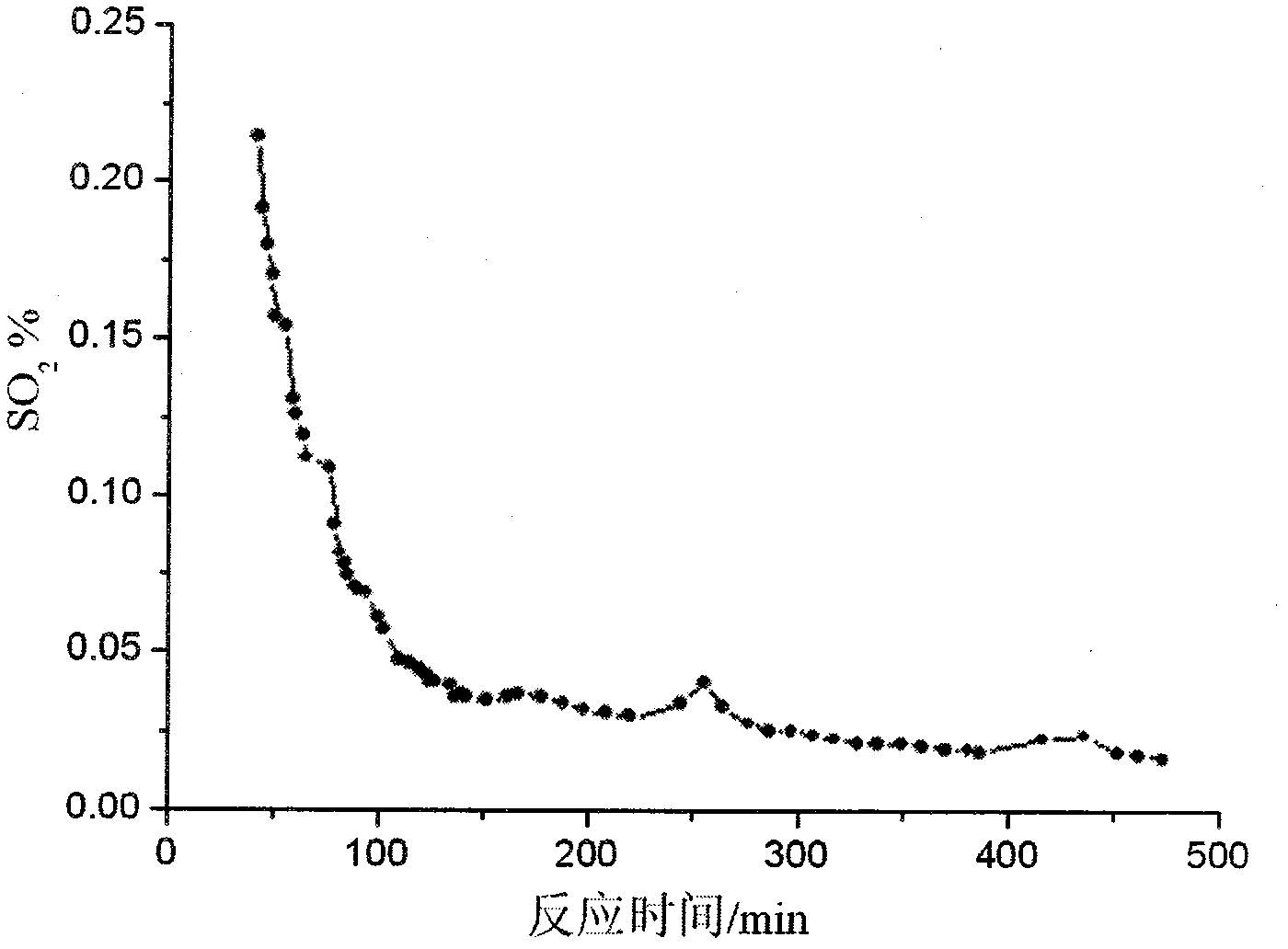

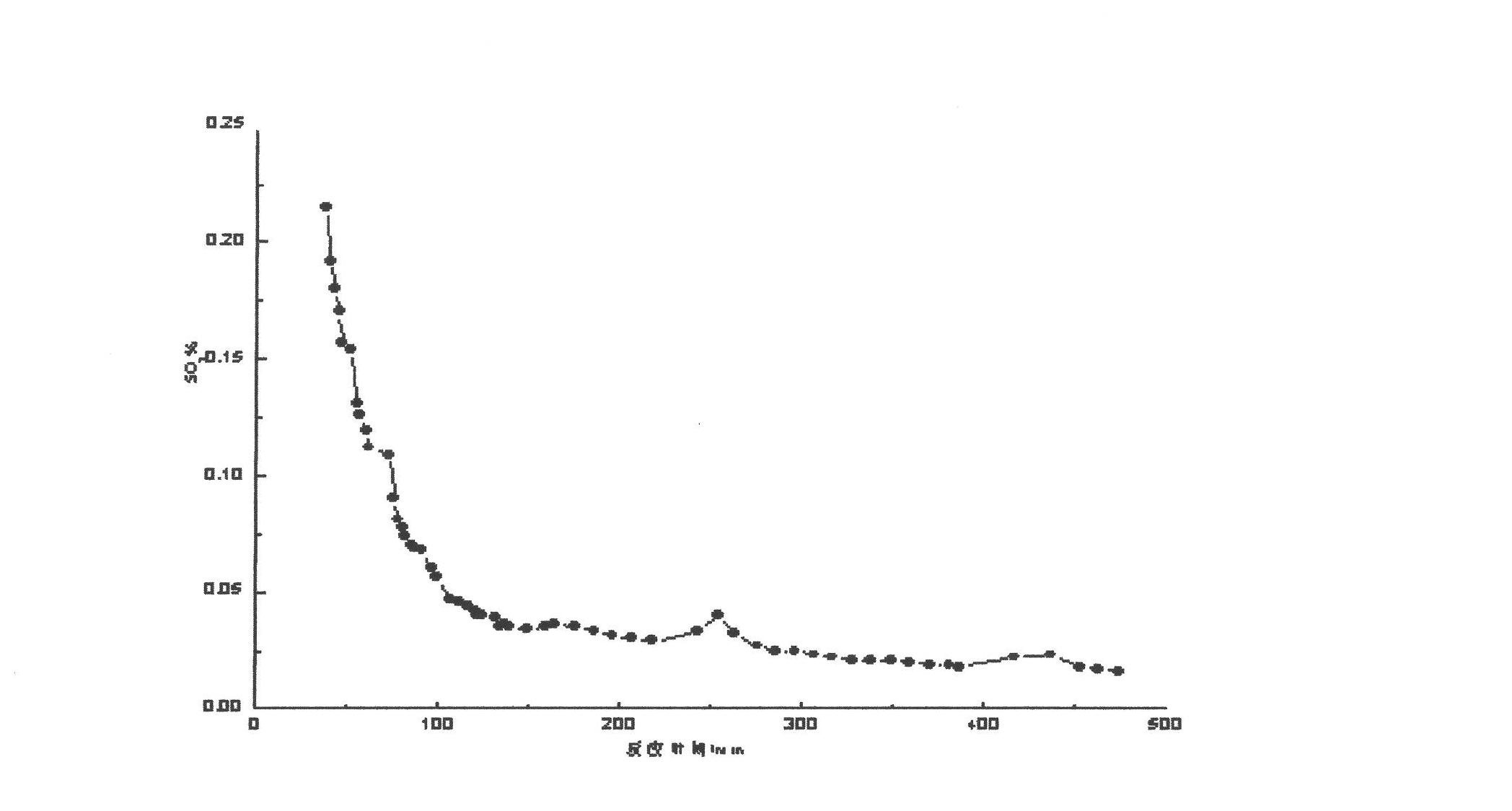

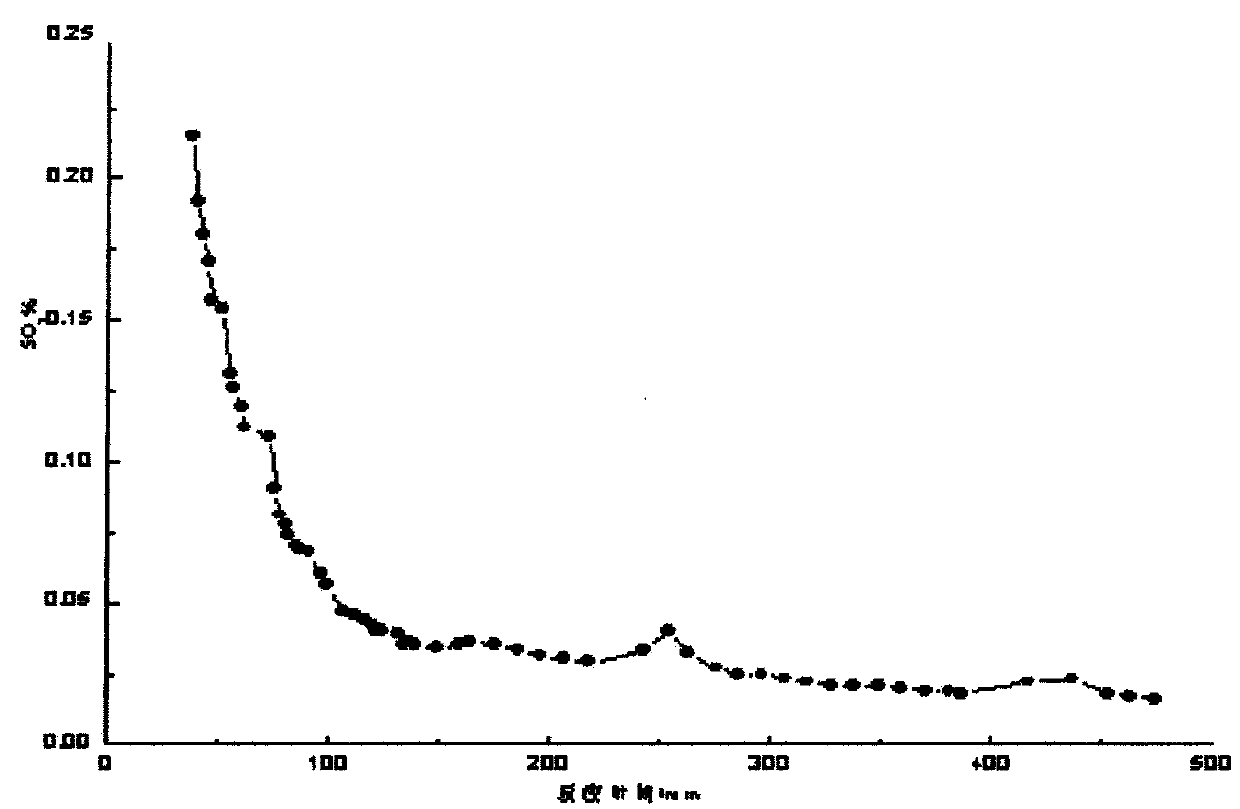

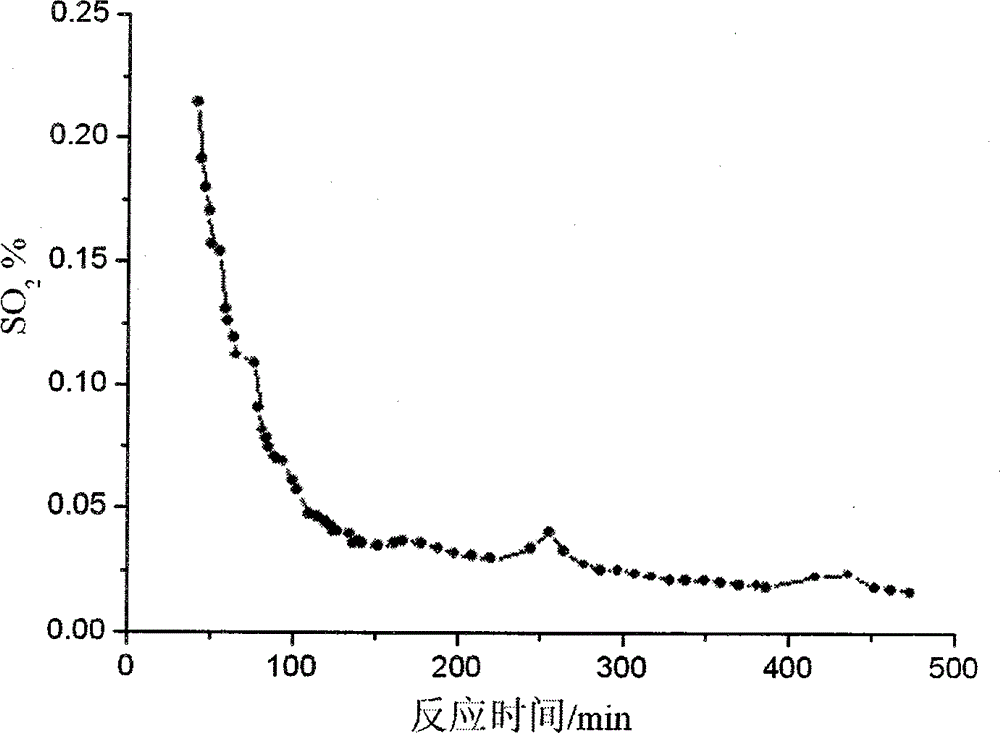

Gas phase deactivation method for petrochemical device

ActiveCN102154612AEasy to handleLow costFuel testingSolid state diffusion coatingExhaust valveGas phase

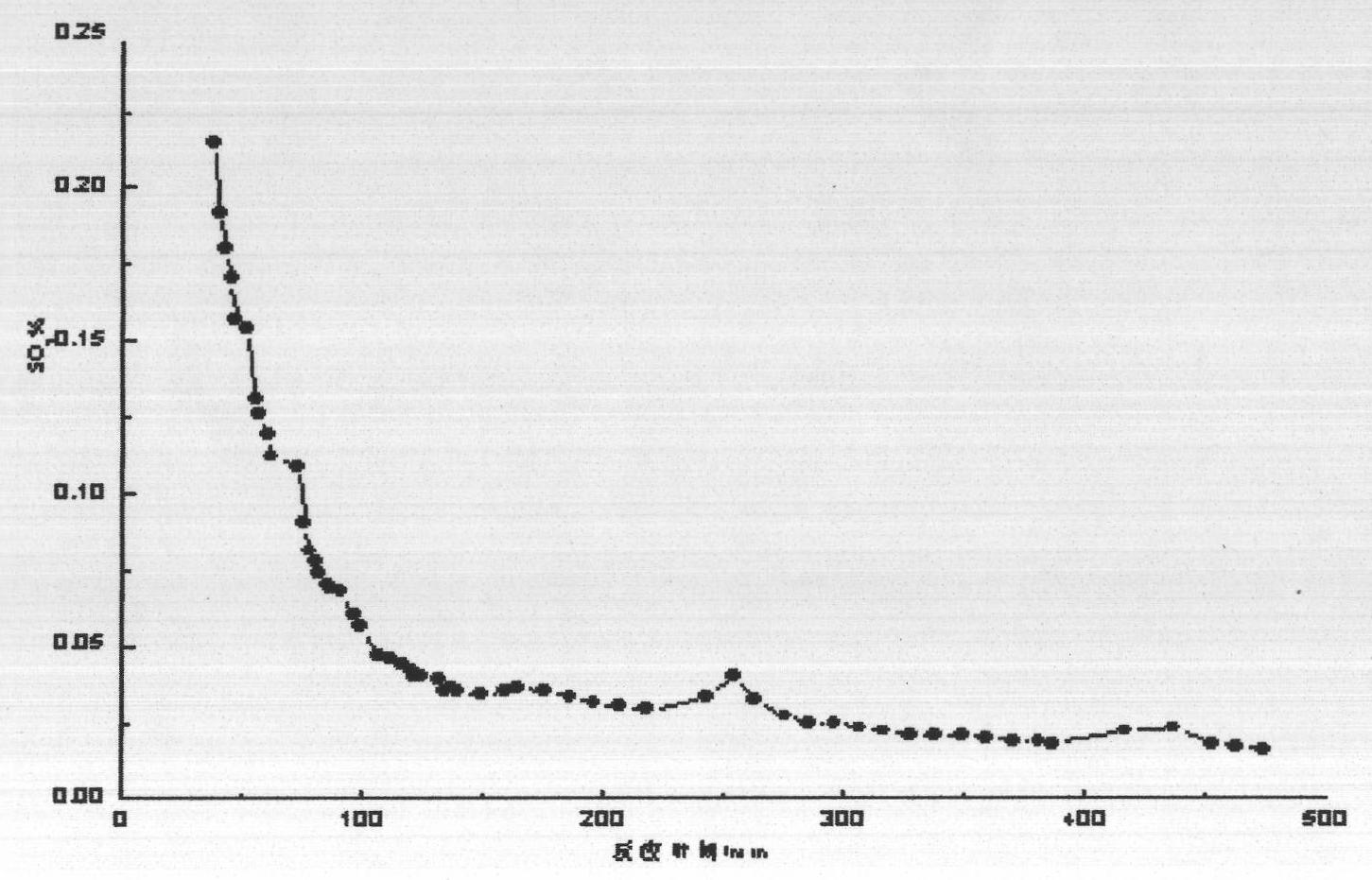

The invention discloses a gas phase deactivation method for a petrochemical device. The method comprises the following steps of: sequentially opening a tail gas valve, an exhaust valve, a monitoring air inlet valve and a monitoring air outlet valve, and then starting an online gas chromatograph to monitor the concentration of SO2, wherein the SO2 content of the tail gas is high when the gas phasedeactivation process starts, and the volume concentration of the SO2 is reduced to 0.001-0.09 percent after 7 to 19 hours; and finishing the tower reaction when the volume concentration of the SO2 isnot changed in 30 to 60 minutes, finishing the gas phase deactivation, and resetting the valves. Compared with the deactivation method in the prior art, the method has the advantages that: the treatment of waste gas is easy; the gas phase deactivated waste gas can reach discharge standards by simple treatment; the treatment time is short; the cost is low, and the implementation is simple; oxygen rich air is mainly used in the gas phase deactivation, is convenient to use and has low cost; and because of gas phase action, channeling and dead angles are not caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tin plate passivation solution and passivation process

ActiveCN110373661AEnvironmentally friendlyUniform passivationMetallic material coating processesHydrofluoric acidPhosphate

The invention discloses a tin plate passivation solution and a passivation process. The passivation solution comprises the following composition according to mass concentration: 30-40g / L of fluorotitanate ion, 30-40g / L of fluorozirconate ion, 10-20g / L of permanganate ion, 2-3ml / L of hydrofluoric acid, 5-15g / L of phosphate, 5-8g / L of organosilane, and the rest of water.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Passivation technology of cast steel for chemical pump

InactiveCN105506599AGood antifoulingImproved anti-fingerprint press capabilityMetallic material coating processesPre treatmentCorrosion

The invention relates to a passivation technology of cast steel for a chemical pump. The passivation technology comprises the following steps that (1) cast steel is cast into the required shape, then the surface of a cast piece is ground, and the cast piece is subjected to soaking treatment with a sodium carbonate solution of which the mass fraction is 1.5% for 2h, during which the surface of the cast piece is brushed by using a banister brush; (2) pickling is carried out; and (3) passivation treatment is carried out. The passivation technology of cast steel is simple; through carrying out cleaning, pretreatment and pickling treatment before passivation, the passivation effect is improved, the passivation is more uniform, and the density of a passivation layer is high; and the corrosion resistance of the cast piece can be improved greatly.

Owner:ANHUI WOLONG PUMP & VALVE CO LTD

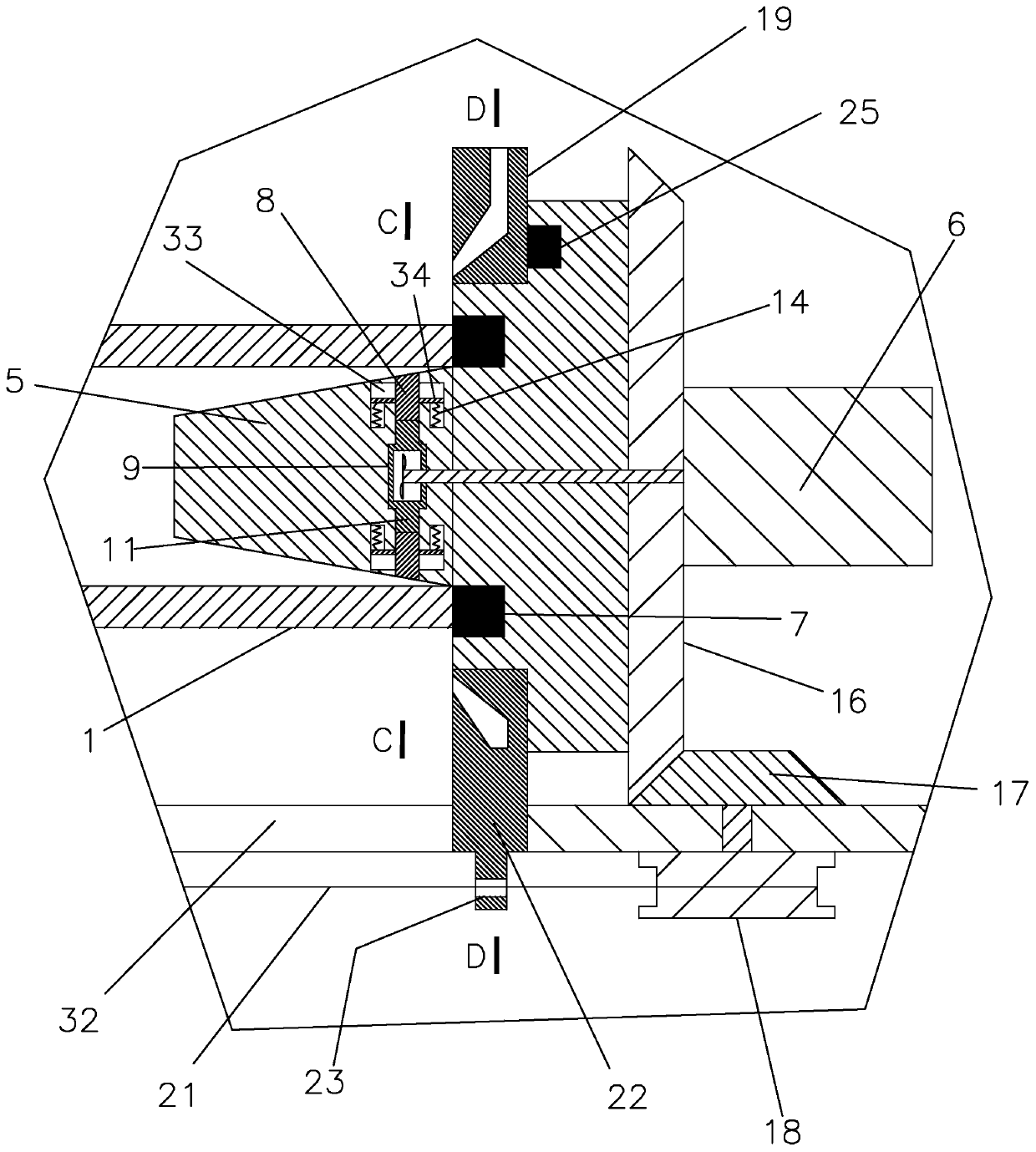

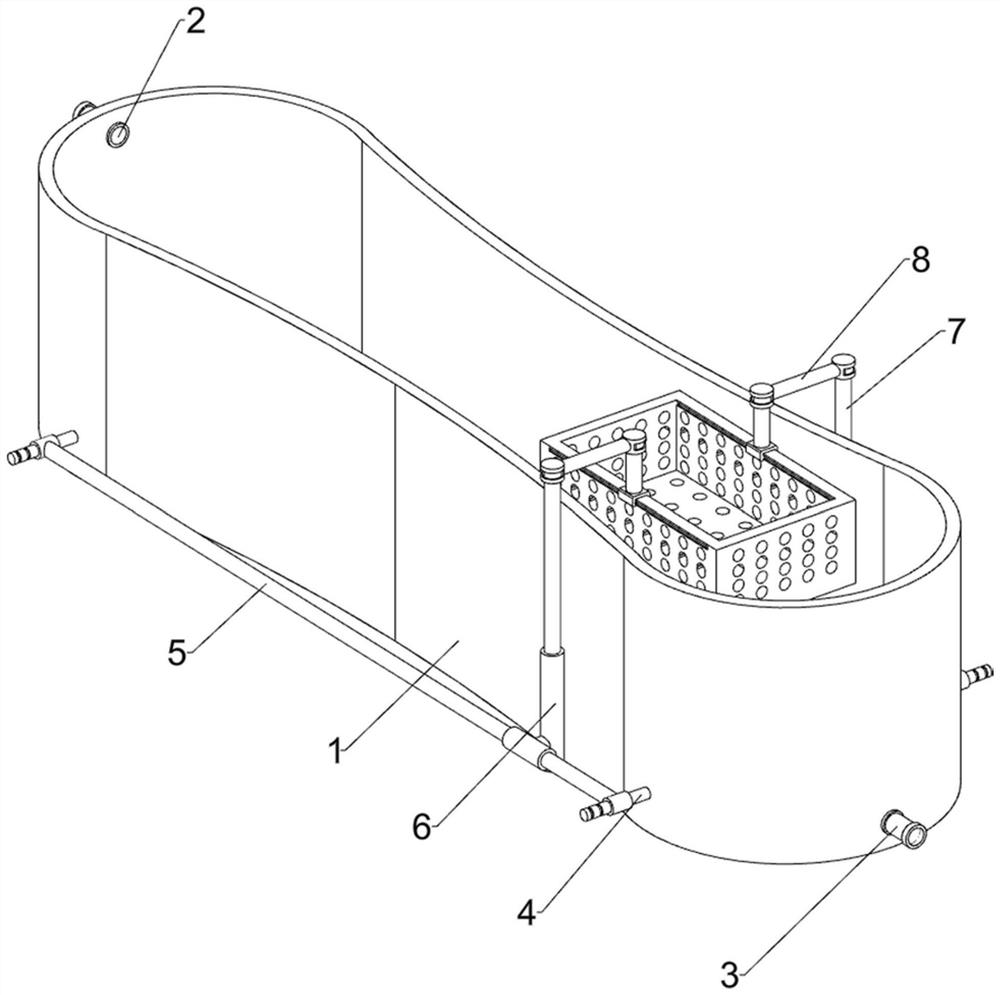

Galvanized part passivation device

PendingCN111501037APassivation solution entersWon't enterHot-dipping/immersion processesElectric machineryStructural engineering

The invention discloses a galvanized part passivation device and relates to the technical field of galvanizing devices. The galvanized part passivation device comprises a spray head used for sprayingpassivation liquid to the surface of a round tube, a clamping mechanism used for clamping the two ends of the round tube and guide rails slidably connected with the clamping mechanism. The clamping mechanism comprises a base plate slidably connected to the guide rails, clamping blocks located at the two ends of the round tube and used for clamping the round tube, locating blocks rotatably connected to the clamping blocks and inserted into the round tubes, fixed connecting mechanisms located on the locating blocks and used for realizing fixed connection between the locating blocks and the roundtube, motors used for driving the locating blocks to rotate and bearings located between the round tube and the locating blocks and used for reducing the rotating resistance of the round tube. Through the galvanized part passivation device provided by the invention, passivation liquid cannot go into the ends of the round tube, passivation is uniform, and the stability is good.

Owner:浙江航峰铁塔有限公司

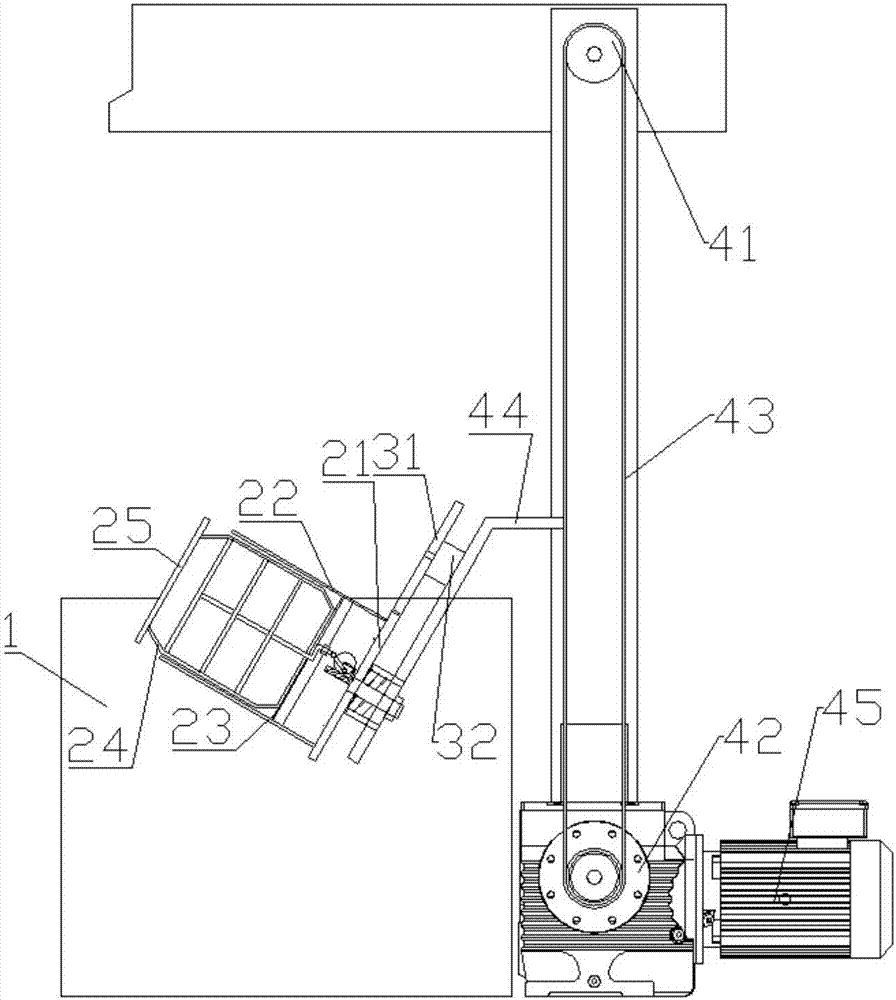

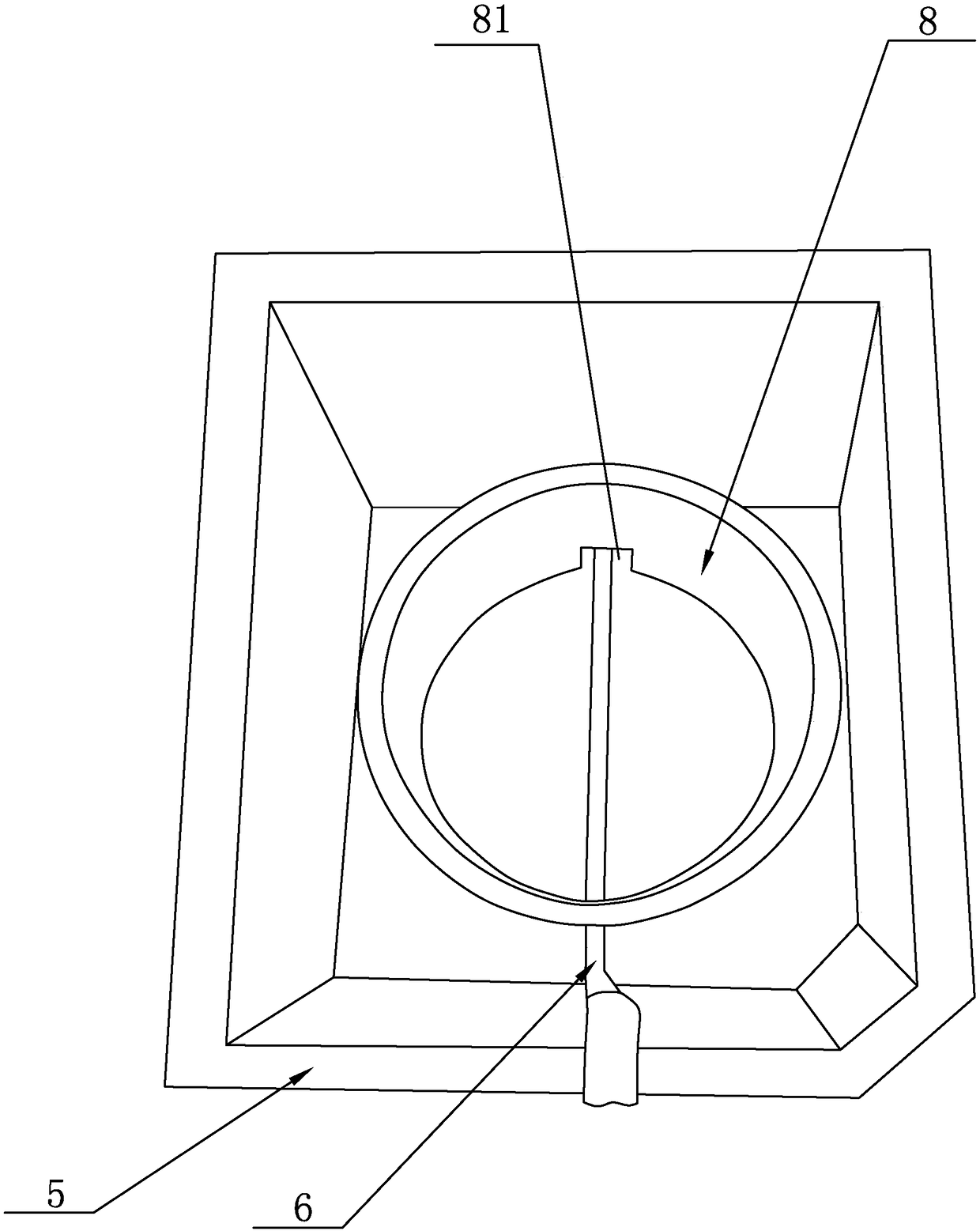

Galvanizing passivation facility

ActiveCN107268051AAvoid sticking to each otherPromotes relative motionMetallic material coating processesGear wheelChain link

Disclosed is a galvanizing passivation facility. The galvanizing passivation facility comprises a passivating tank, a rotating barrel, a power mechanism, a lifting mechanism and a dispersion mechanism. The rotating barrel comprises a rotating frame and a pierced roller. The lifting mechanism comprises an upper gear, a lower gear, a chain and a quasi-L-shaped plate, wherein the chain is meshed with the upper gear and the lower gear. The quasi-L-shaped plate is set in the mode that when the quasi-L-shaped plate upwards moves to the destination, the lower side of the rotating frame is higher than the liquid level of a passivating solution, and when the quasi-L-shaped plate downwards moves to the destination, the lower side of the rotating frame is lower than the liquid level of the passivating solution, and the upper side of the rotating frame is higher than the liquid level of the passivating solution. The dispersion mechanism comprises a connecting rod, a transmission unit and a plurality of dispersion units. The galvanizing passivation facility has the advantages that the passivating solution makes contact with the surfaces of parts to be passivated in an accelerated mode, the parts to be passivated are passivated in a batch mode, the phenomenon that the passivated parts are attached with each other in the batch passivation process, and the part surface passivation can be more uniform and more efficient.

Owner:廊坊京磁精密材料有限公司

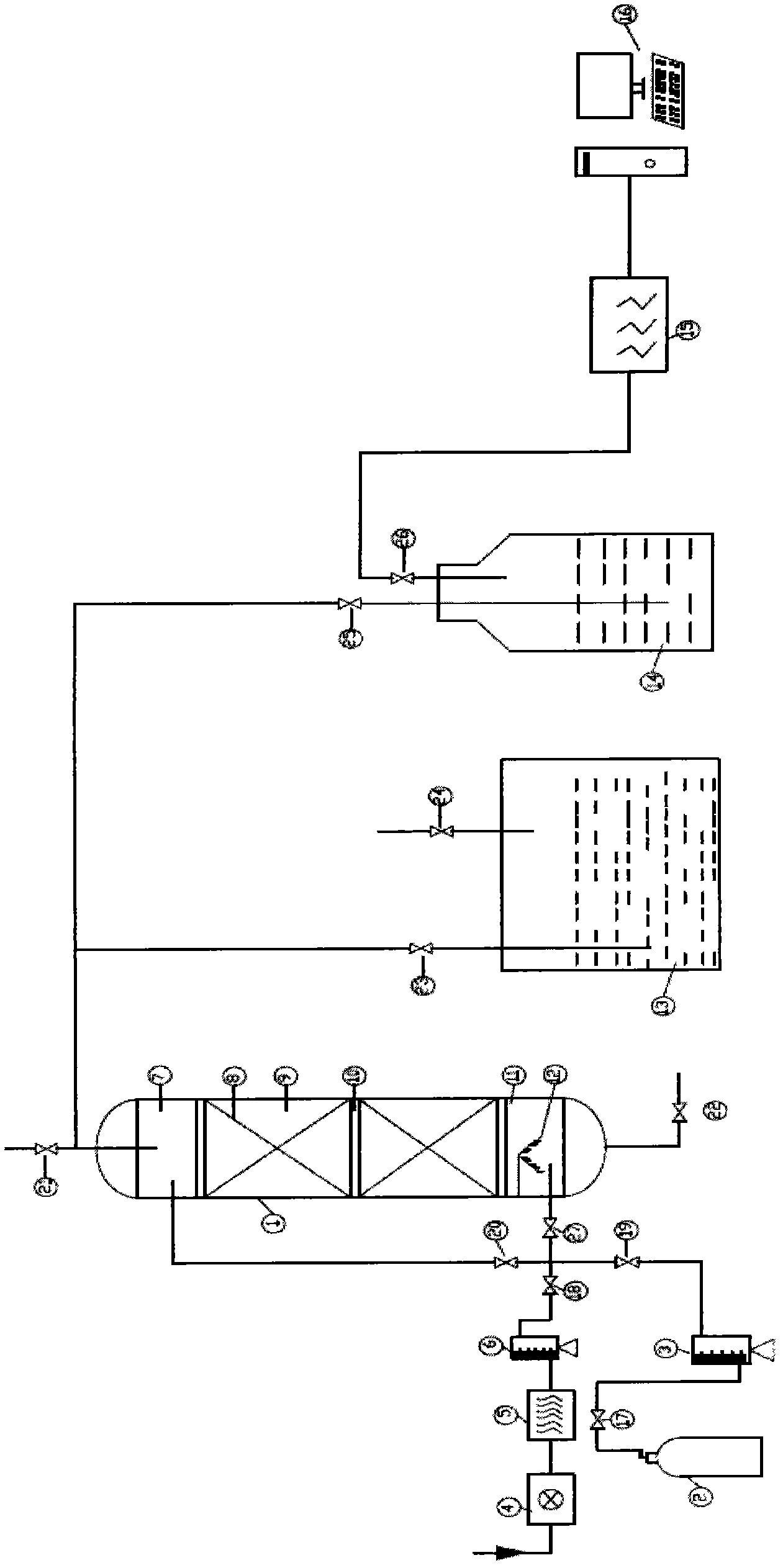

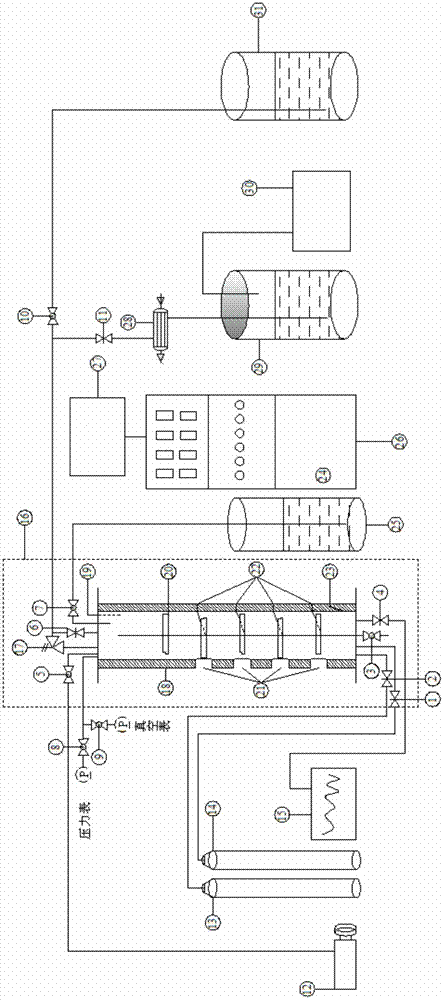

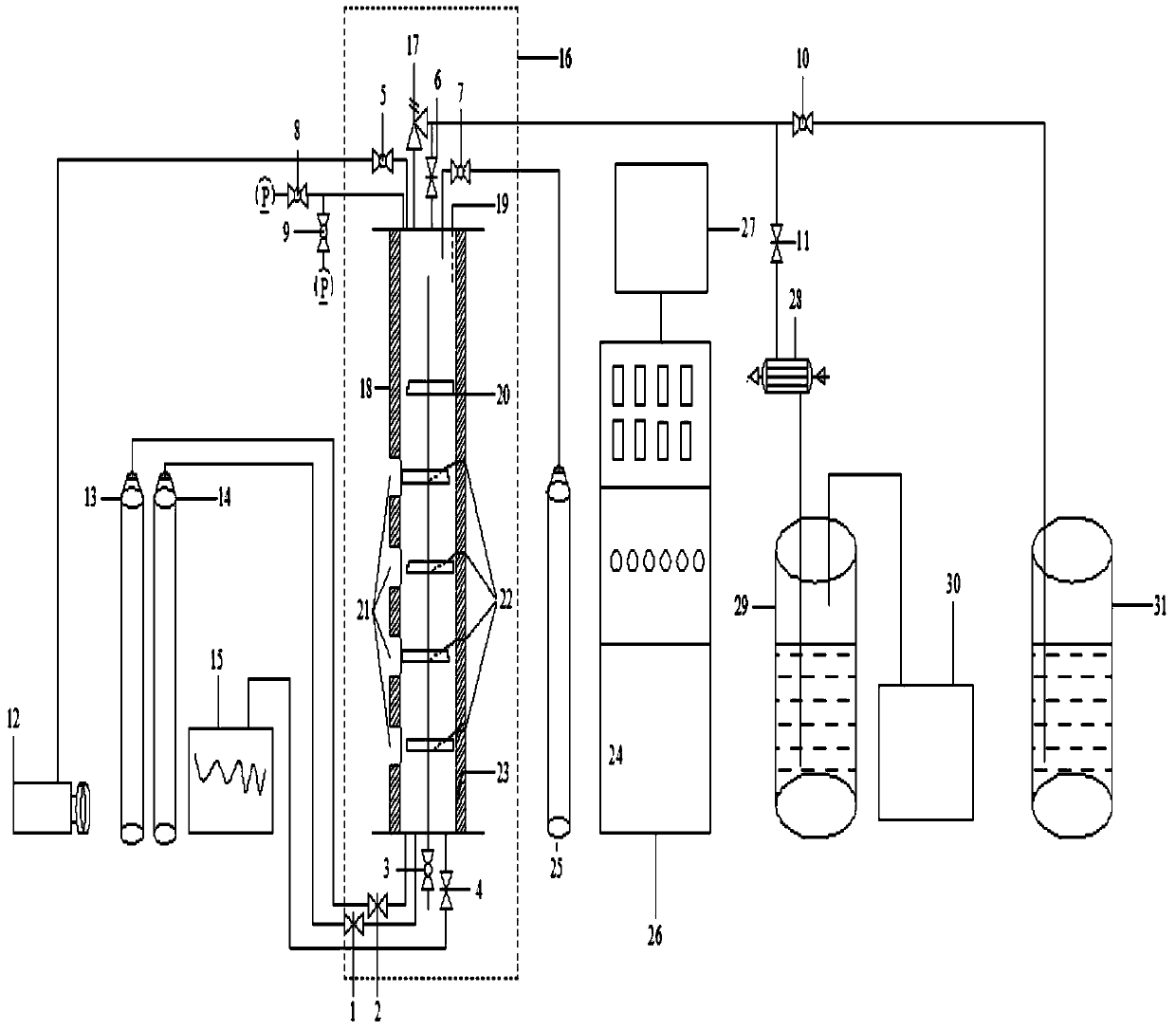

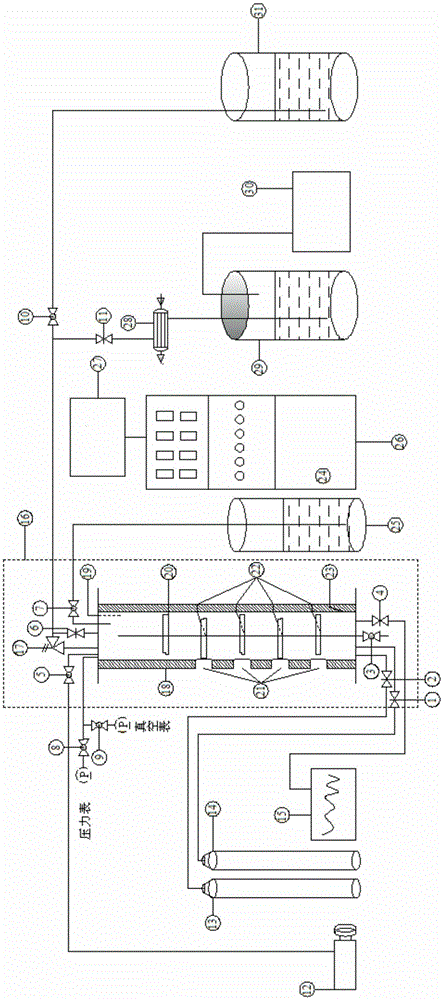

Gas-phase passivation system for petrochemical device

The invention discloses a gas-phase passivation system for a petrochemical device. The gas-phase passivation system comprises a gas-phase passivation device, a tail gas treatment device and a data analysis device, wherein the tail gas treatment device is connected with the gas-phase passivation device and is used for treating harmful gases generated in a passivation process; the tail gas treatment device further comprises a lye tank in which 10 percent sodium hydroxide solution is accommodated, a tail gas valve and an exhausting valve; the data analysis device is connected with the gas-phase passivation device and is used for detecting data of combustible gases before gas-phase passivation and linearly detecting the concentration of sulfur dioxide (SO2) generated by passivation in a gas-phase passivation process; and the data analysis device further comprises a gas drying apparatus, a gas chromatograph, a metering machine, an air inlet monitoring valve and an air outlet monitoring valve. By the passivation system, waste gases are easy to treat, and the waste gases generated by gas-phase passivation can meet the discharge standard after being treated simply.

Owner:CHINA PETROLEUM & CHEM CORP +1

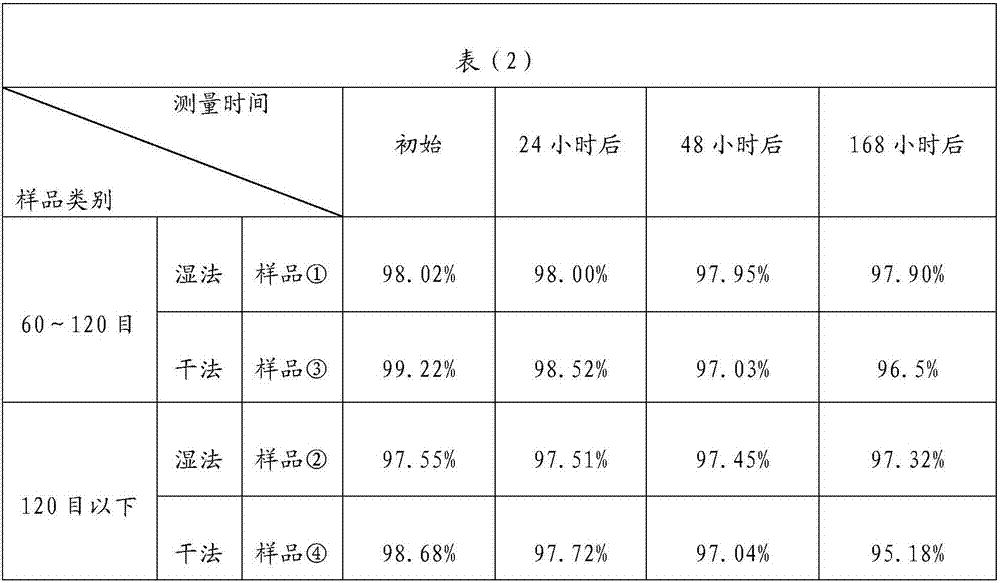

Preparation method of modified anti-felting wool fiber

InactiveCN109137513AImprove enzymatic hydrolysis efficiencyUniform passivationBiochemical treatment with enzymes/microorganismsGrip property fibresIonProtease

The invention discloses a preparation method of modified anti-felting wool fiber. The method particularly comprises the following steps that 1, an oxidative antibacterial solution is prepared; 2, theoxidative antibacterial solution is added into a stirring tank, water bath heating is conducted to reach 40-45 DEG C, and the wool fiber is poured into the stirring tank; 3, compound enzymatic hydrolysate is prepared; 4, the wool fiber processed in step 2 is soaked in the compound enzymatic hydrolysate, and a normal temperature enzymatic hydrolysis reaction is conducted; 5, a chitosan solution isprepared and added into the stirring tank, the wool fiber prepared in step 4 is added, stirring is conducted for 5 h and then fished out, and then air-drying is conducted at normal temperature. Accordingly, the wool fiber is oxidized, protein of the wool fiber is exposed, the exposed protein is subjected to enzymolysis through protease, by means of enzymolysis, negative ions on the surface of thewool fiber are increased, chitosan is adsorbed to the surface of the wool fiber conveniently, and the texture is soft while the wool fiber anti-felting property is improved.

Owner:合肥五凡工程设计有限公司

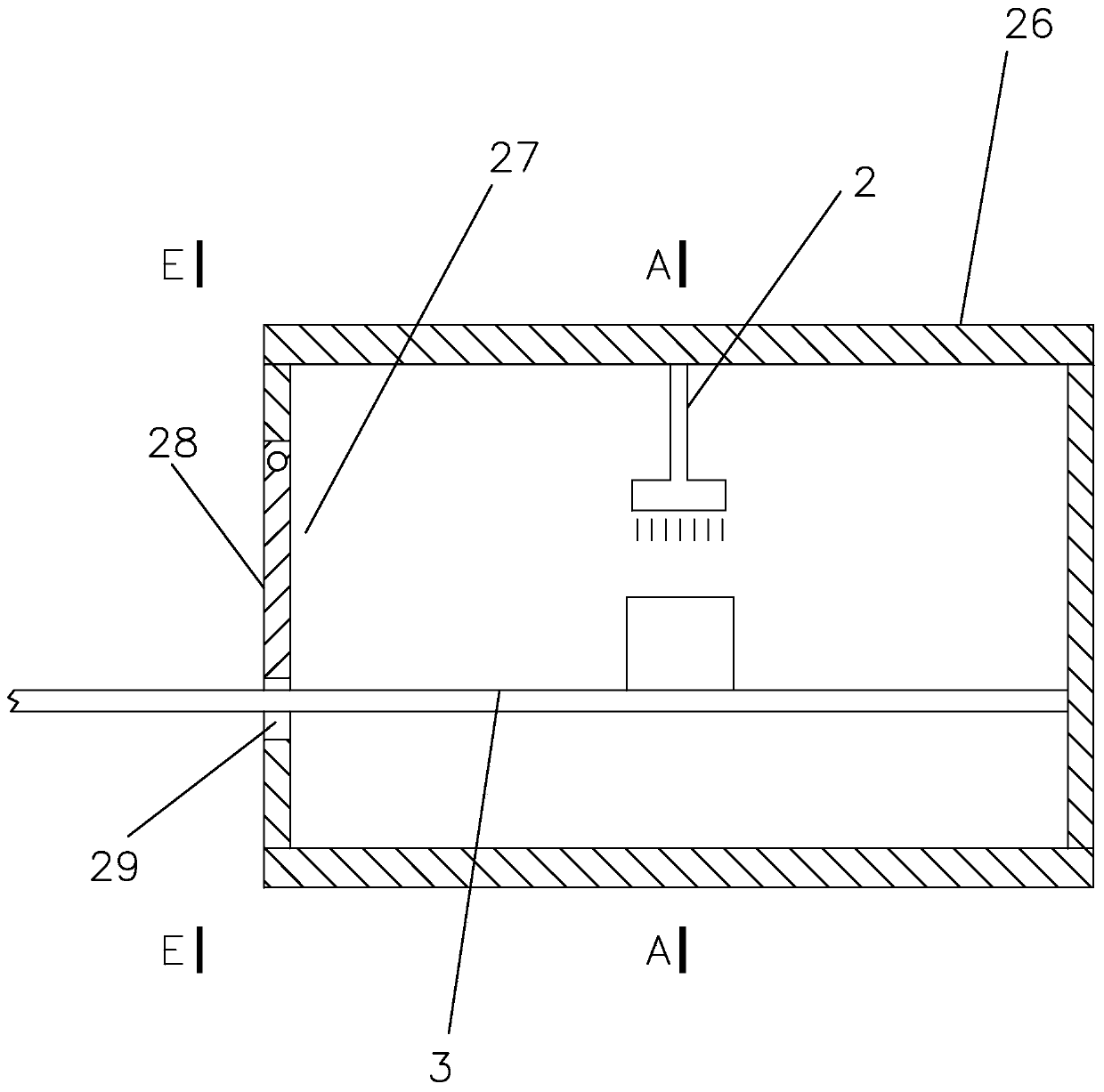

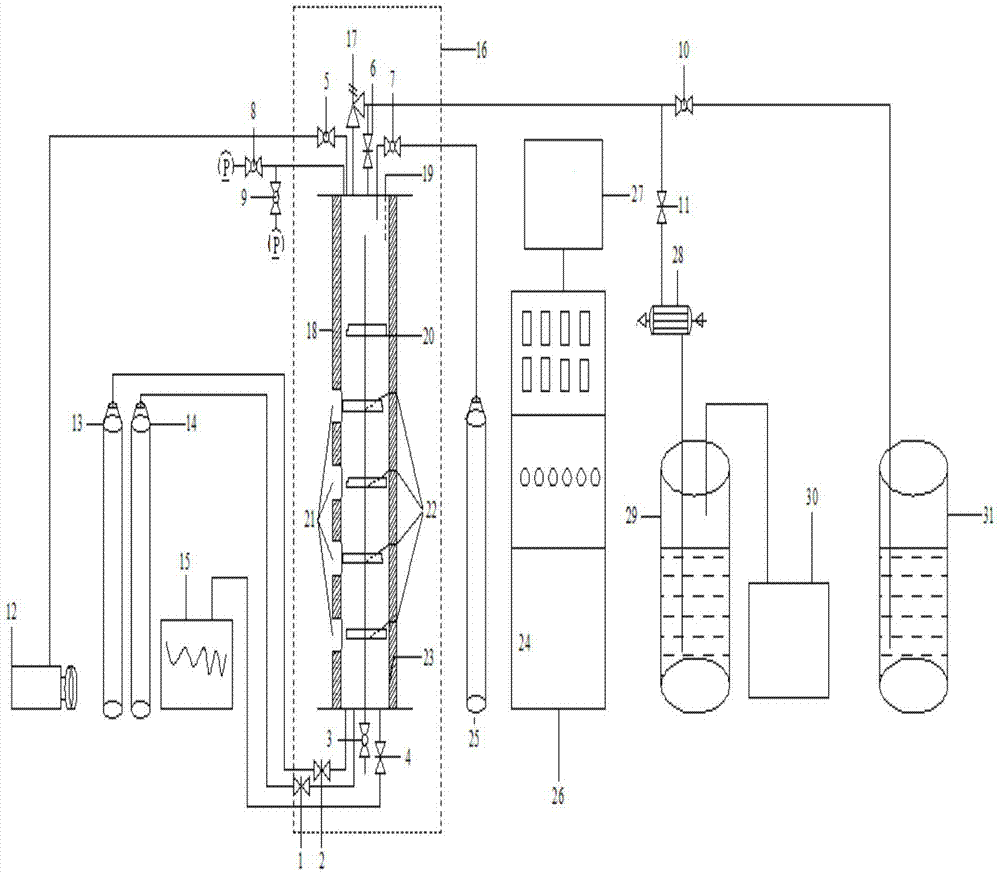

Method for assessing passivation effect of iron sulfides

ActiveCN104762588AHigh activityPromote absorptionSolid state diffusion coatingMaterial analysis using radiation diffractionCondition activityGas cylinder

The invention provides a method for assessing the passivation effect of iron sulfides. A gas supply apparatus comprises an inert gas bottle, an oxygen-rich air bottle, a steam generator and a hydrogen sulfide bottle, the gas supply apparatus is connected with a passivation apparatus through respective pipelines, and supplies a gas to the passivation apparatus, a sample is disposed on the tray of the passivation apparatus, direct sulfuration of the sample can be realized when a hydrogen sulfide gas is introduced into the passivation apparatus, and the iron sulfides are prepared through a reaction of hydrogen sulfide and iron oxide, have high activity, and are close to the condition activity. Safe operation boundary parameters capable of realizing good passivation effect, obvious economic benefit and safe and reliable operation can be found through changing of the concentaration and amount of oxygen introduced in the passivation process and through comparison of a large amount of experiments in order to find the rapid passivation reaction conditions of the iron sulfides in water steam and oxygen, so safety guarantee is provided for maintenance of a tower, a tank and a kettle in an industrial apparatus.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

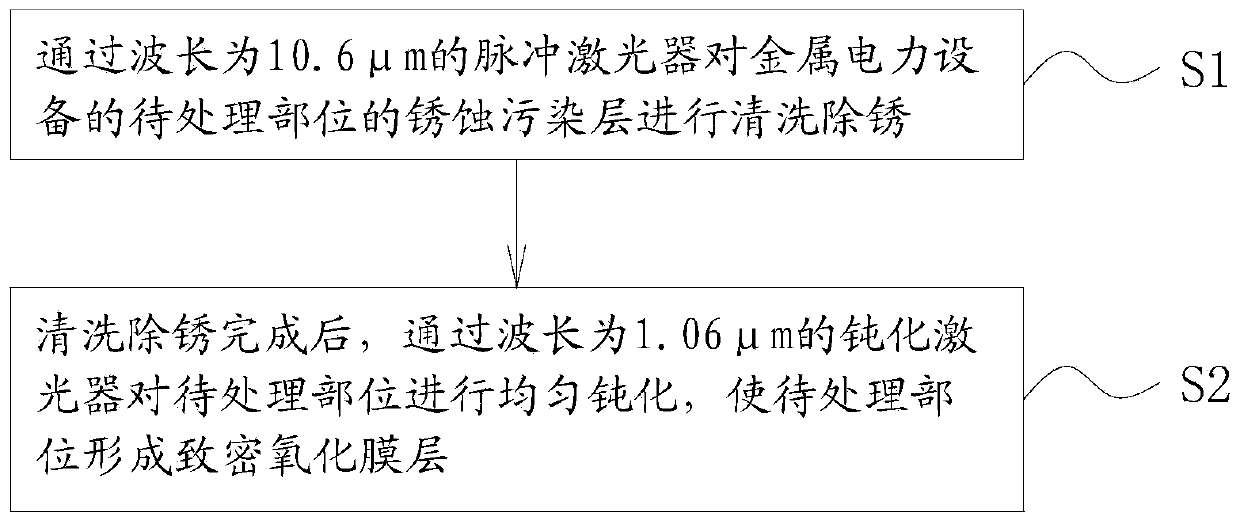

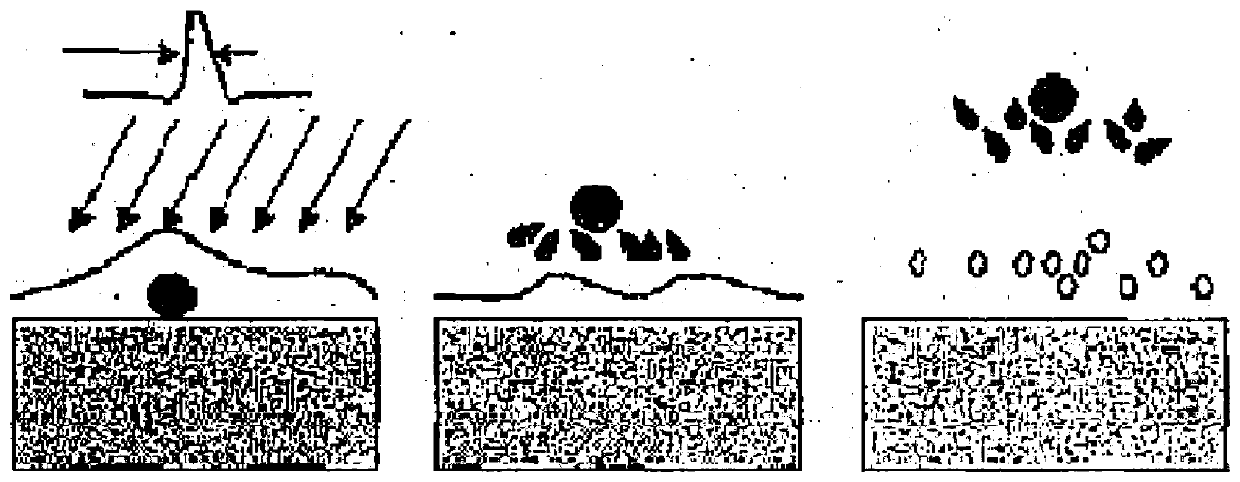

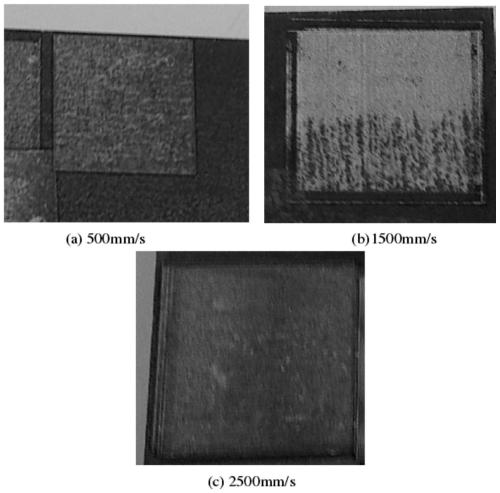

Double-laser derusting method

InactiveCN111495881ASolve the problem of decontaminationSolve corrosiveCleaning processes and apparatusElectric power equipmentErbium lasers

The invention relates to a double-laser derusting method. The double-laser derusting method comprises the following steps that cleaning derusting is conducted on a rusted contamination layer of a to-be-processed portion of metal electrical equipment through a pulse laser device with the wave length being 10.6 [mu]m; after cleaning derusting is completed, the to-be-processed portion is subjected touniform passivation through a passivation laser device with the wave length being 1.06 [mu]m, and a compact oxidation film layer is formed on the to-be-processed portion. The double-laser derusting method can conduct short-time efficient derusting on the corroded rusted electrical equipment and conduct uniform passivation on the surface of the equipment to delay metal corrosion.

Owner:KAILI POWER SUPPLY BUREAU

Gas-phase passivation system for petrochemical device

ActiveCN101988179BEasy to handleLow costSolid state diffusion coatingGas phaseVapor phase chromatography

The invention discloses a gas-phase passivation system for a petrochemical device. The gas-phase passivation system comprises a gas-phase passivation device, a tail gas treatment device and a data analysis device, wherein the tail gas treatment device is connected with the gas-phase passivation device and is used for treating harmful gases generated in a passivation process; the tail gas treatment device further comprises a lye tank in which 10 percent sodium hydroxide solution is accommodated, a tail gas valve and an exhausting valve; the data analysis device is connected with the gas-phase passivation device and is used for detecting data of combustible gases before gas-phase passivation and linearly detecting the concentration of sulfur dioxide (SO2) generated by passivation in a gas-phase passivation process; and the data analysis device further comprises a gas drying apparatus, a gas chromatograph, a metering machine, an air inlet monitoring valve and an air outlet monitoring valve. By the passivation system, waste gases are easy to treat, and the waste gases generated by gas-phase passivation can meet the discharge standard after being treated simply.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of tin plate passivation solution and passivation process

ActiveCN110373661BEnvironmentally friendlyUniform passivationMetallic material coating processesPhosphateTin plating

The present invention provides a tinplate passivation solution and a passivation process. The passivation solution provided by the present invention has the following components in terms of mass concentration: 30-40g / L of fluorotitanate ions, 30-40g / L of fluorozirconate ions L, permanganate ion 10‑20g / L, hydrofluoric acid 2‑3ml / L, phosphate 5‑15g / L, organosilane 5‑8g / L, and the rest is water.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

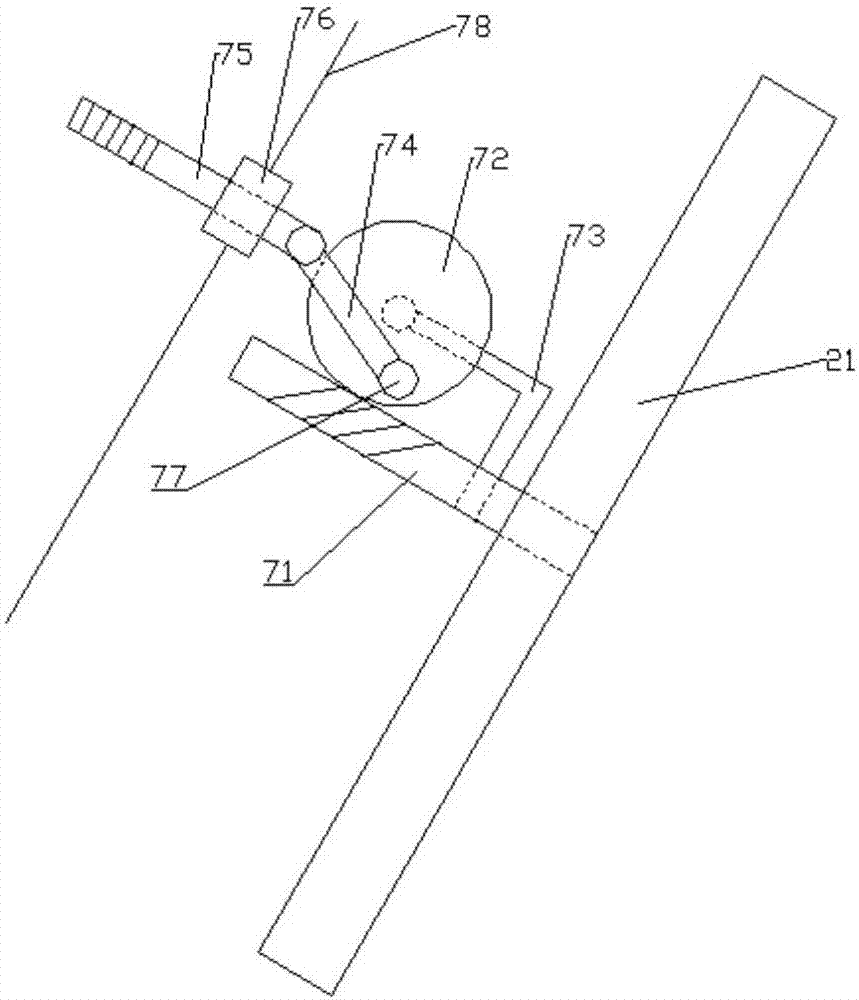

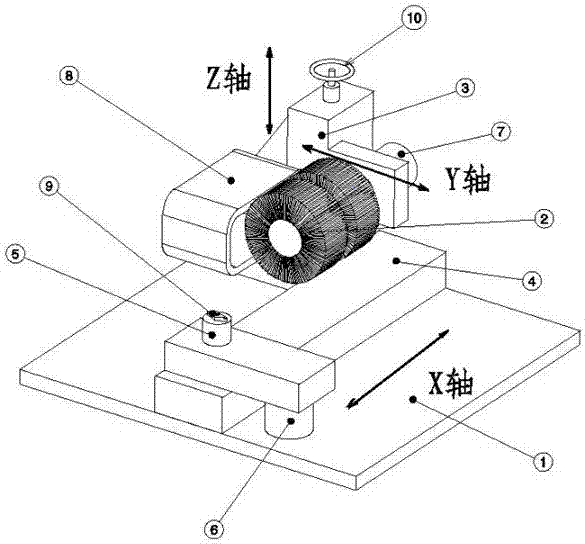

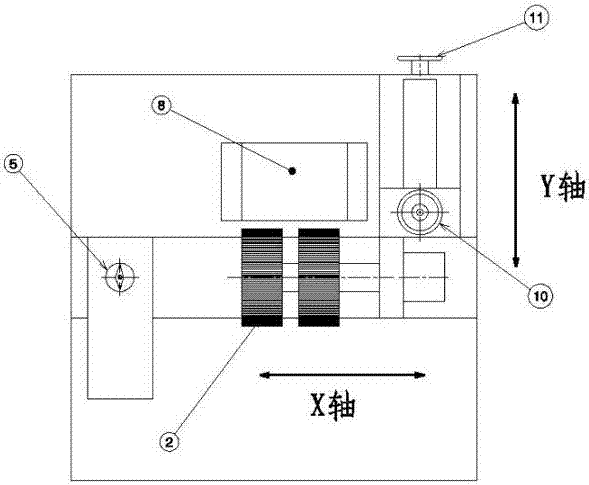

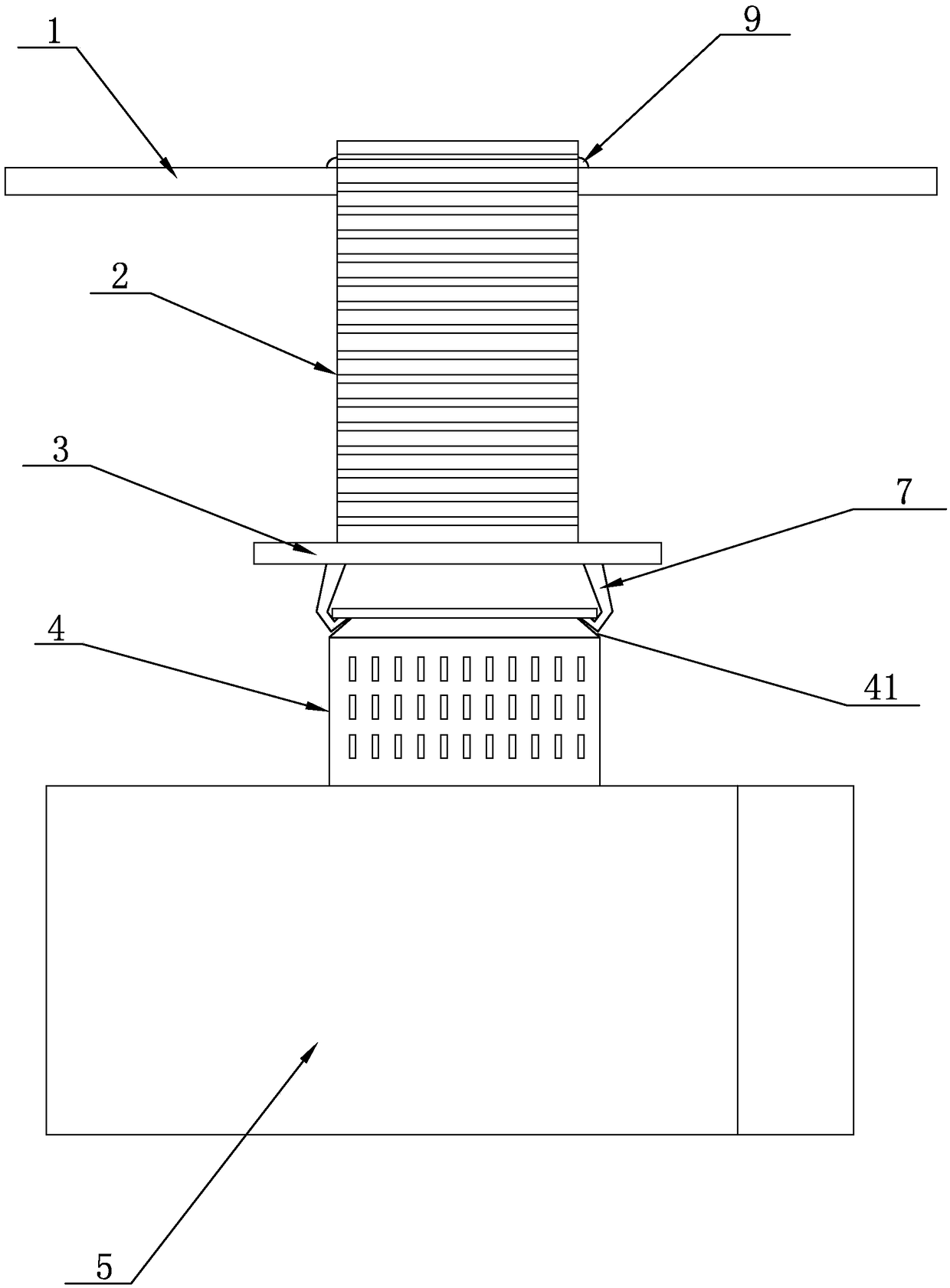

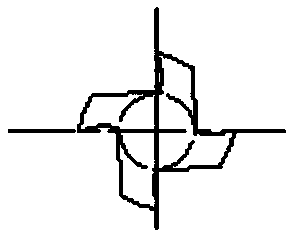

Numerically-controlled machine tool used for passivation of indexable numerically-controlled blade cutting edge

InactiveCN107479495AGuaranteed stabilityUniform passivationNumerical controlNumerical controlLinear motor

The invention relates to a numerically controlled machine tool for edge passivation of an indexable numerically controlled blade, comprising a machine tool frame, the machine tool frame is provided with a brush bracket, and a passivation brush is carried on the brush bracket, and the brush bracket A handle in the Z direction and a handle in the Y direction are provided on the top; a brush servo motor is also provided on the brush bracket, and the brush servo motor is connected with a passivation brush transmission; a linear motor is provided on the machine tool frame, and a linear motor is provided on the linear motor. There are indexable NC blade clamping system, indexable NC blade clamping driving stepping motor, the indexable NC blade clamping system is equipped with indexable NC blade, linear motor and indexable NC blade clamping The system transmission connection, the indexable CNC blade clamping drive stepper motor is connected with the transmission connection of the indexable CNC blade clamping system. The invention is mainly applicable to the field of edge passivation of an indexable numerical control blade, and realizes the passivation of the edge of the blade by utilizing the motion track of the indexable numerical control blade.

Owner:郭亮

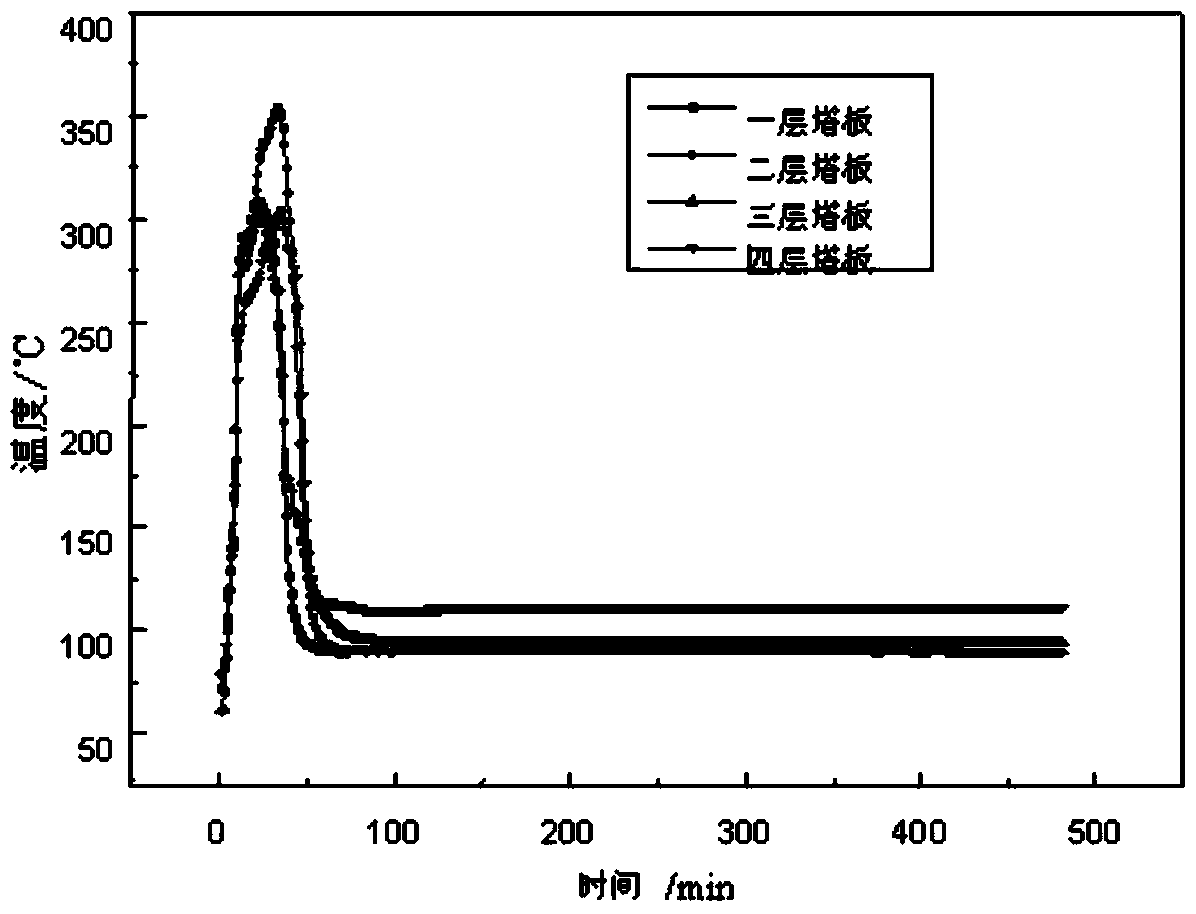

Ferrous sulfide gas phase passivation method

The invention relates to a ferrous sulfide gas phase passivation method, which mainly solves the problems of high passivation cost, uneven passivation, long passivation time, and complicated operation in the prior art. The ferrous sulfide gas phase passivation method involved in the invention comprises the steps of: (1) conveying a ferrous sulfide suspension into a passivation tower, discharging the fluid from the passivation tower, and removing water from ferrous sulfide; (2) in a water vapor environment, introducing oxygen-enriched air into the passivation tower and passivating ferrous sulfide; (3) dividing the gas discharged from the passivation tower into at least two ways, making one way of the discharged gas enter sulfur dioxide and hydrogen sulfide content detection equipment after condensation and drying, and making the other way of the discharged gas enter an alkali liquor absorption pot; and (4) analyzing the ferrous sulfide content before and after passivation, the concentration of sulfate ions in the passivated condensate, and the content of sulfur dioxide and hydrogen sulfide in tail gas. The technical scheme well solves the problems and can be used in ferrous sulfide gas phase passivation.

Owner:CHINA PETROLEUM & CHEM CORP +1

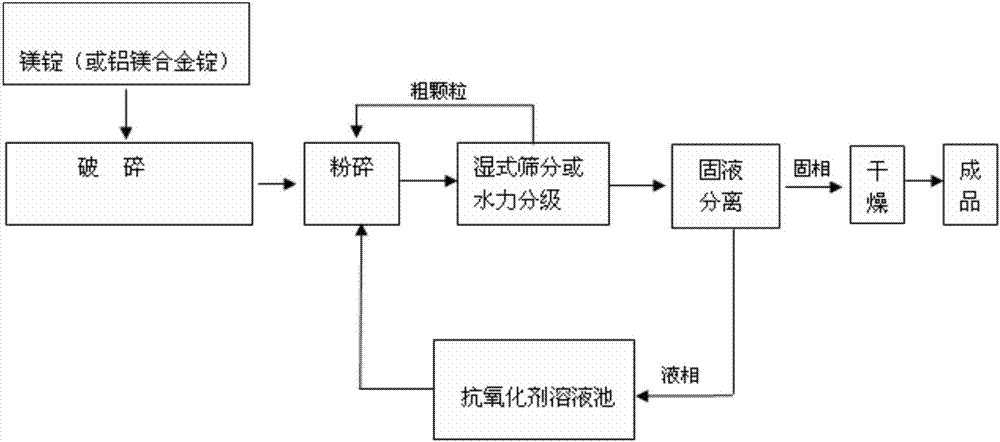

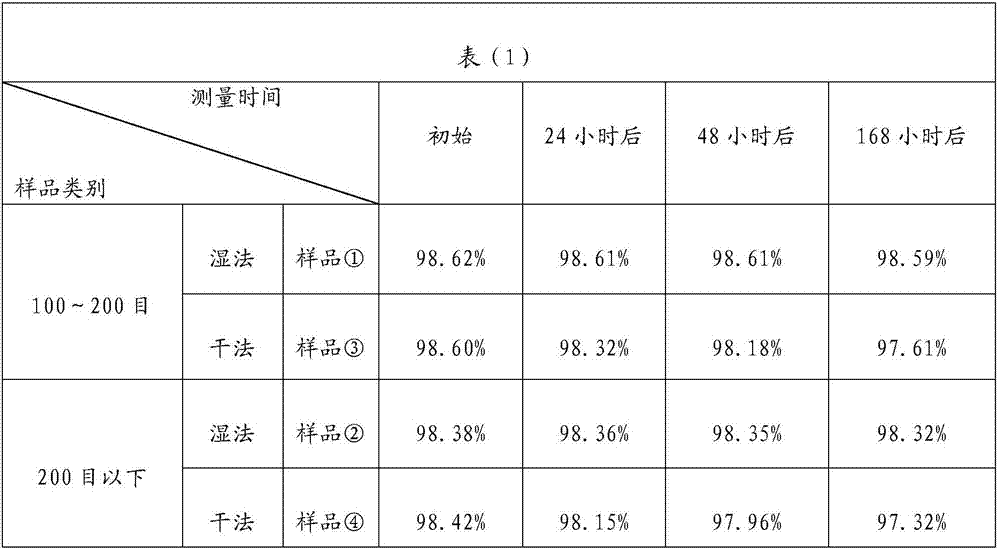

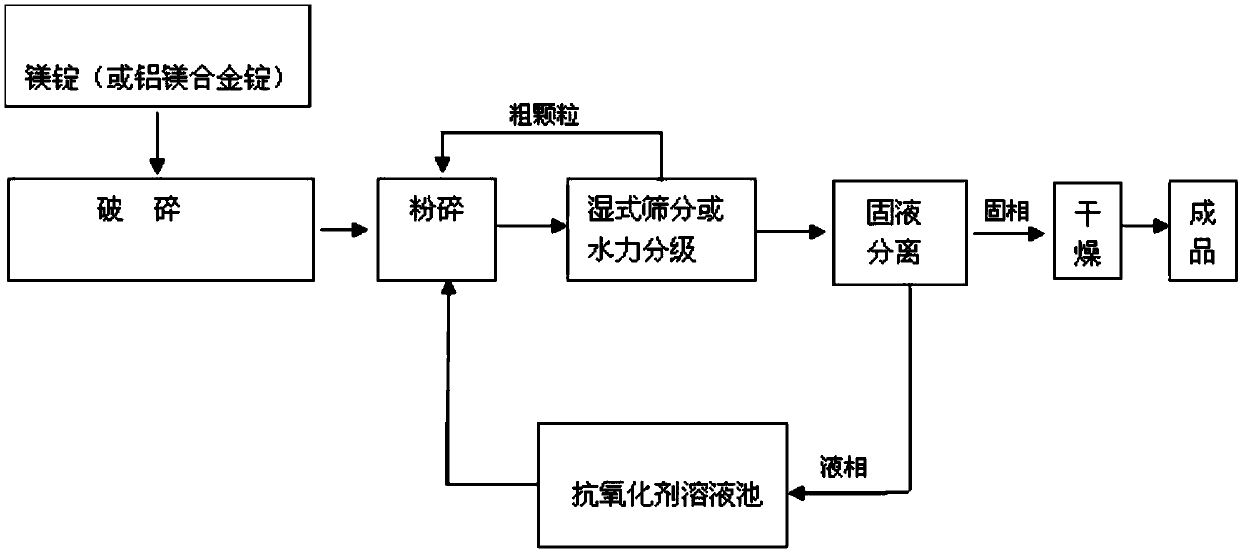

Passivation magnesium powder, passivation aluminum magnesium alloy powder and wet process production process of passivation magnesium powder and passivation aluminum magnesium alloy powder

ActiveCN107088655AImprove securityImprove the environmentTransportation and packagingMetal-working apparatusWastewaterWet grinding

The invention discloses passivation magnesium powder, passivation aluminum magnesium alloy powder and a wet process production process of the passivation magnesium powder and the passivation aluminum magnesium alloy powder. Magnesium particles, aluminum magnesium alloy particles and an antioxidant aqueous solution are added into wet grinding equipment to be subject to wet grinding; then a solid-liquid mixture is subjected to wet type screening or waterpower classification to complete solid-liquid separation; and the passivation magnesium powder or the passivation aluminum magnesium alloy powder is obtained after drying is carried out. Surfaces of particles of the finished magnesium powder and the aluminum magnesium alloy powder are wrapped with passivation protection films. The powder production process is fully carried out under the antioxidant aqueous solution protection, and is a production method high in safety factor, simple in equipment and excellent in site environment. Passivation, grinding and size grading are completed through one step. Finished products are even in passivation, compact, stable and excellent in anti-oxidation performance. The antioxidant aqueous solution can be used for a long time in a circulated manner, waste water emission is avoided, and the process method is environment-friendly.

Owner:浏阳市科力烟花材料有限公司

New ancient-method preparation process of jujube-bud black tea

PendingCN113693150AAccelerate moisture evaporationGuaranteed to kill evenlyTea substituesBiotechnologyEngineering

The invention discloses a new ancient-method preparation process of jujube-bud black tea. The process comprises the following steps: sorting and tedding, sunning, withering, rocking, automatic weighing, rolling, fermenting, composite primary drying, forming and deblocking, secondary drying, primary preparation and aroma enhancing, static aged storage, and alcoholization refining aroma enhancing. According to the new ancient-method preparation process of the jujube-bud black tea, quick-heating withering process equipment is specially designed according to different water contents of coarse and old leaves and different properties of green leaves, so that the requirements of quality control and large-scale production can be met; the water content of the tea leaves is more uniform by utilizing atomized water adding, and polyphenol substances in the tea leaves generate oxidative polymerization under the enzymatic action through aerobic fermentation; the microwave frequency is high, the temperature of a material is rapidly increased by heat so as to achieve the effect of rapidly heating to remove green and astringent taste, the jujube-bud black tea is newly prepared by using an ancient method, the unique taste and the quality of jujube leaf tea are improved; and furthermore, alcoholization aroma enhancing has a sterilization function and has the significant effect of removing the bitter and astringent taste of the tea. A powerful process technology guarantee is provided for high-end tea enterprises.

Owner:山西茗玥茶叶有限公司

Gas phase deactivation method for petrochemical device

ActiveCN102154612BEasy to handleLow costFuel testingSolid state diffusion coatingExhaust valveGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

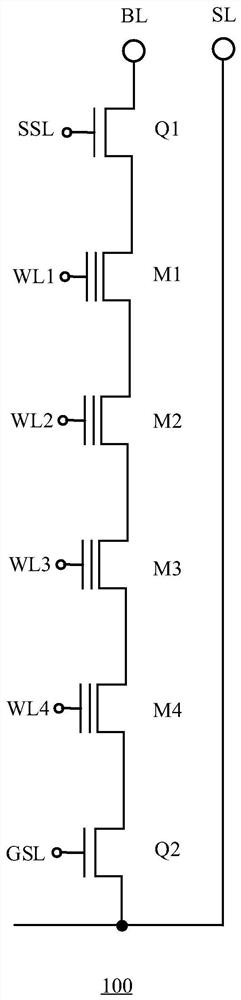

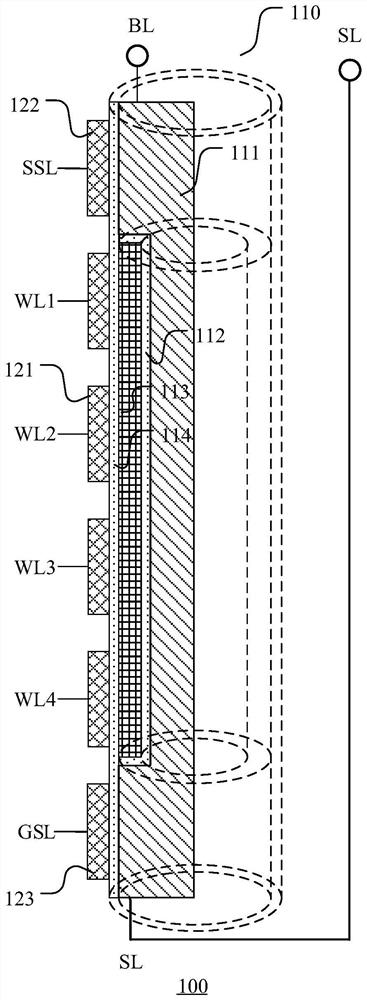

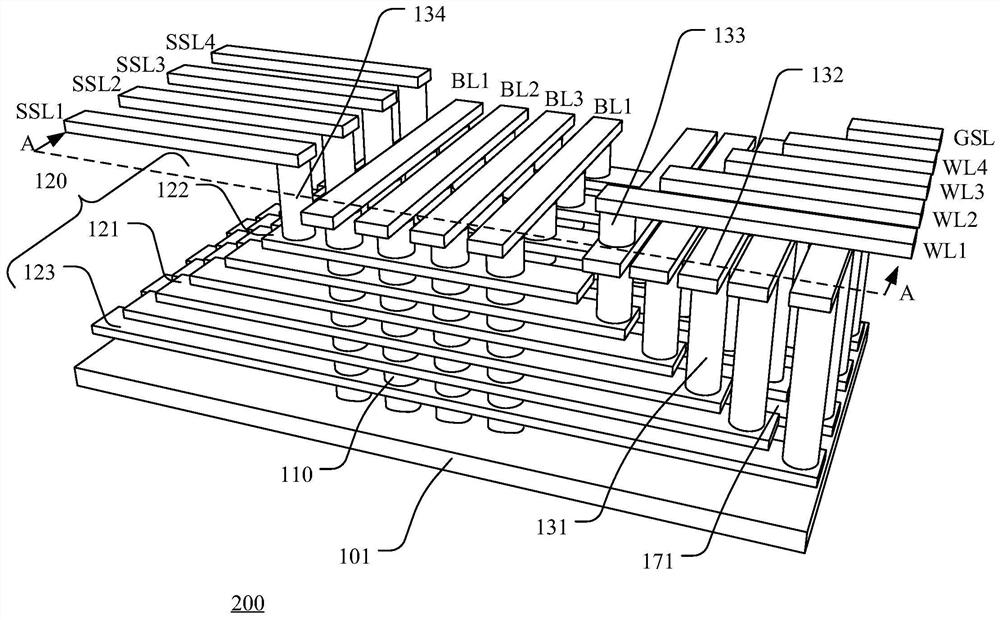

3D memory device and manufacturing method thereof

ActiveCN109671715BImprove yieldImprove reliabilitySolid-state devicesSemiconductor devicesEngineeringGate stack

Owner:YANGTZE MEMORY TECH CO LTD

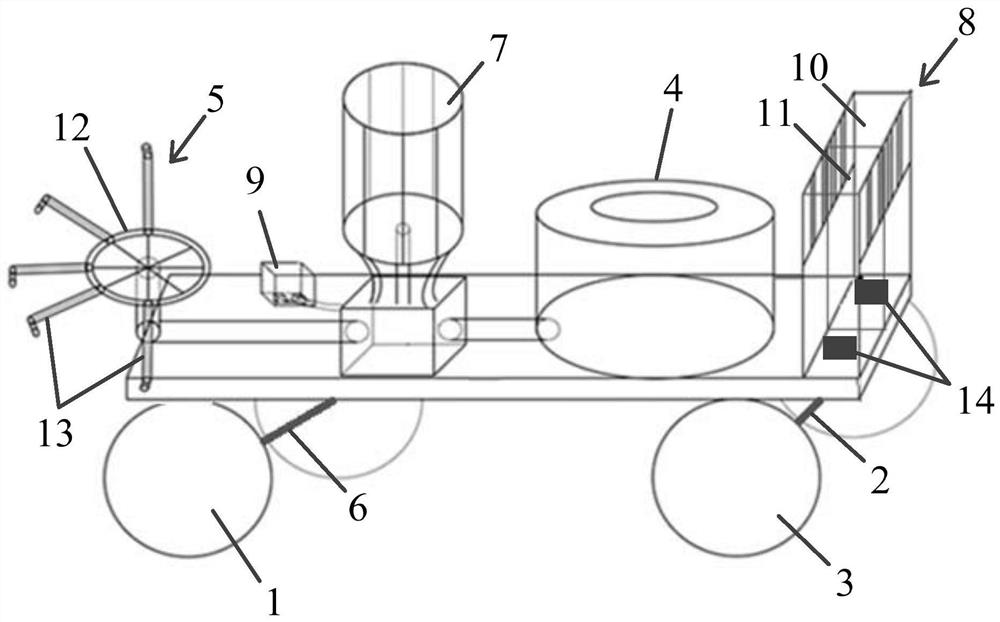

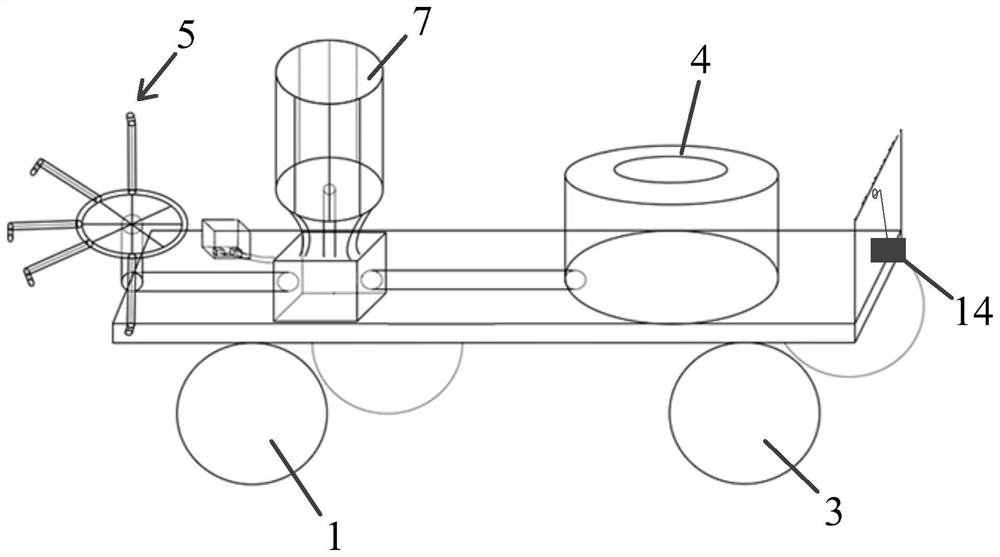

Method for passivating heavy metal contaminated soil

InactiveCN111630969AImprove pHIncrease productionCalcareous fertilisersContaminated soil reclamationSoil scienceEnvironmental engineering

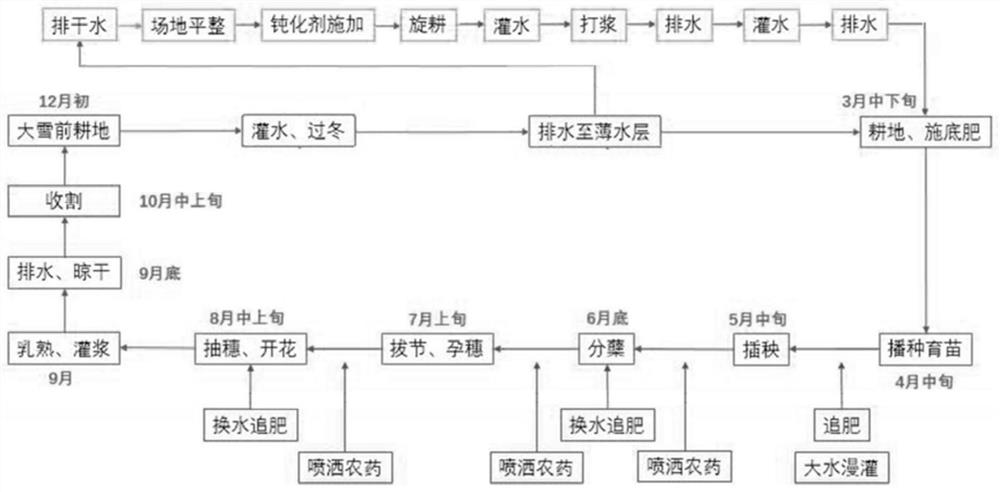

The invention provides a method for passivating heavy metal contaminated soil. The method comprises the following steps of performing passivation construction: sequentially performing passivator spreading, rotary tillage, pulping, first standing and first draining on the heavy metal contaminated soil; and performing redundant passivator removal: performing flood irrigation until the water surfaceis higher than the earth surface of the passivated soil, and performing second standing and second draining. Rotary tillage mixing in an oxidation environment and pulping mixing in a reduction environment are cooperatively performed, so that the construction efficiency is improved, and the reaction of a passivator and heavy metal is promoted; meanwhile, redistribution of the passivator and balanced passivation of the contaminated soil are promoted; after the passivation construction, namely the sufficient reaction of the passivator, the flood irrigation is carried out until the water surface is higher than the earth surface of the passivated soil, and standing is carried out, so that redistribution work of the passivator and the balanced passivation of the contaminated soil can be effectively promoted; and finally the redundant passivator is removed from an area with the relatively low contamination degree (few passivators are needed) through drainage, so that the soil is effectively repaired, and the passivation effect and the crop yield are improved.

Owner:中节能大地环境修复有限公司

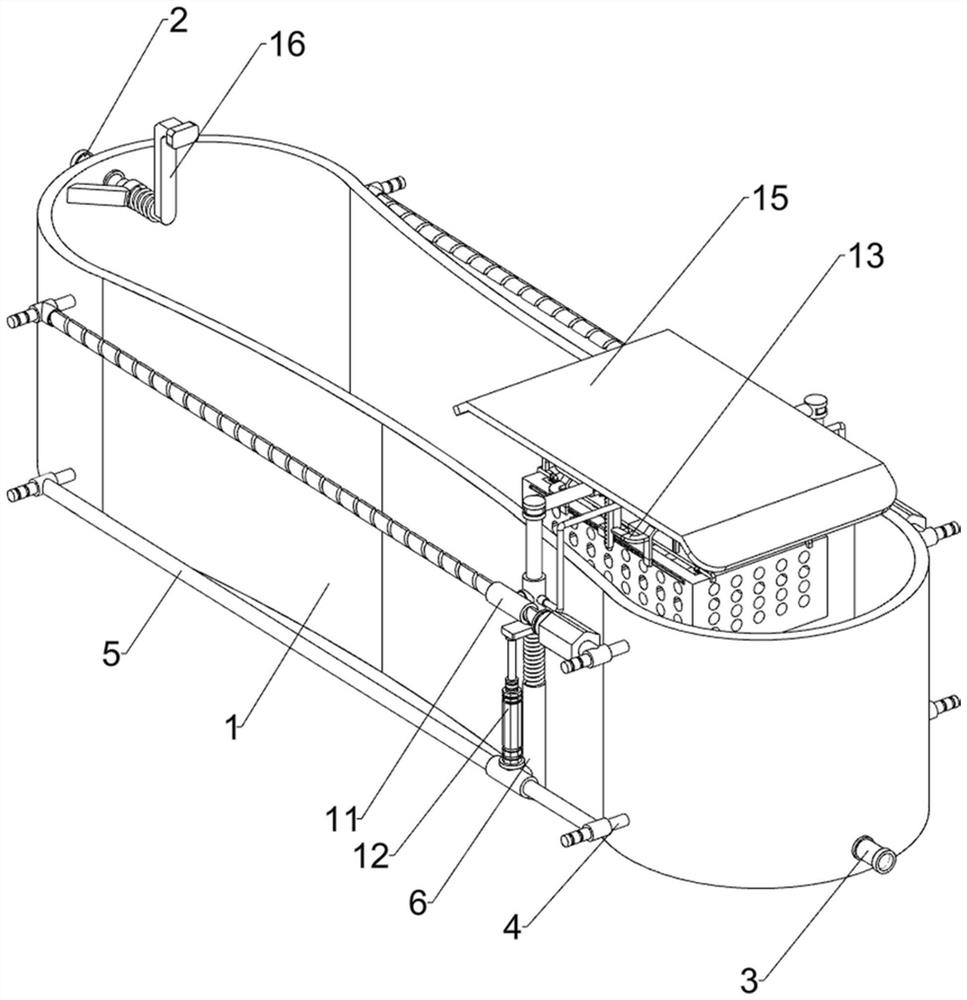

Electroplated part treatment equipment

PendingCN114686945AUniform passivationImprove passivation qualityMetallic material coating processesProcess efficiency improvementGear wheelRack and pinion

The invention relates to passivation treatment equipment, in particular to electroplated part treatment equipment. The technical problem to be solved is to provide the electroplated part treatment equipment which can tightly and stably press an electroplated part and can prevent a passivation solution from splashing. The electroplated part treatment equipment comprises a circulating box, an injection pipe, a discharge pipe, a first mounting rod and the like, an injection pipe is connected to the rear side of the upper part of the circulating box, a discharge pipe is connected to the front side of the lower part of the circulating box, and first mounting rods are symmetrically connected to the left and right sides of the lower part of the circulating box. According to the passivating device, a driving gear moves up and down, is meshed with a rack, drives a swing rod to rotate alternately in the positive and negative directions and is matched with a wedge-shaped plate, so that a passivating frame is finally pushed to swing back and forth in a reciprocating manner, the effect of uniformly passivating an electroplated part is achieved, and the passivating quality of the electroplated part is improved; the first pressing plate and the second pressing plate are fixed to the passivation frame, so that the electroplated part is pressed and limited, and the effect that the electroplated part is pressed in the passivation frame can be achieved.

Owner:赣州市文祥电镀有限公司

An electroplating passivation device

ActiveCN106498376BReasonable settingEasy to useMetallic material coating processesEngineeringMechanical engineering

The invention discloses an electroplating passivating device. The electroplating passivating device comprises a guide rail, a driving device, a connecting device, a passivated product placing barrel and a passivating pool, wherein the passivating pool is internally provided with a passivating liquid conveying pipe; the guide rail is transversely arranged; clamping jaws are arranged on the connecting device; a clamping jaw positioning groove is formed in the outer wall surface of the upper end of the passivated product placing barrel; the passivated product placing barrel is positioned over the passivating pool; the passivated product placing barrel is driven by the driving device to decline and sink into the passivating pool; a passivating liquid limiting guiding device for enabling passivating liquid to flow upwards is arranged on the bottom surface of the passivating pool at the position of the middle part; the passivating liquid limiting guiding device comprises a guiding cylinder, the guiding cylinder is vertically arranged, the height of the upper end face of the guiding cylinder is arranged to be lower than the upper end face of the passivating pool, and the lower end of the guiding cylinder is fixedly or detachably connected with the bottom surface of the passivating pool. Through the technical scheme, the electroplating passivating device is reasonable in structure set, simple in structure, convenient in operation, uniform in passivation for each surface of the product and high in processing efficiency.

Owner:浙江明泰控股发展股份有限公司

Post-treatment process of high-gloss formed cutter

InactiveCN108857607AImprove passivation qualityUniform passivationEdge grinding machinesPolishing machinesPistonReciprocating motion

The invention discloses a post-treatment process of a high-gloss formed cutter. The post-treatment process comprises the following steps that a cutter hole is formed in the center of a clamp, the part, directly participating in polishing, of the clamp is arranged to be in a cutter profile shape according to distribution of cutter edges, it is ensured that the distances between all the positions ofthe cutter and the clamp are equal, and four evenly-distributed pressure relief holes are additionally formed in the clamp; an abrasive material for cutter fluid polishing is made of a macromoleculesemi-solid carrier and abrasive grains in a mixed configuration mode according to the ratio of 3:2; and the fluid polishing process is conducted through the steps that (1) a power switch of a polisheris turned on, the configured abrasive material for cutter fluid polishing is put into a lower cylinder of the polisher, the clamp is fixed to a worktable, and the to-be-passivated cutter is fixed tothe clamp; (2) the polishing time and the abrasive material pressure are set, a machine is started, pistons in an upper cylinder and the lower cylinder make reciprocating movement at a constant speed,thus the abrasive grains flow through the cutter and edge openings uniformly, and polishing passivation is completed; and (3) after being polished, the cutter is taken out, and replaced with a new to-be-polished cutter. Overall force bearing is uniform and constant, the passivation effect is ensured, and the passivation time is saved.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

A method for evaluating the passivation effect of sulfur-iron compounds

ActiveCN104762588BHigh activityPromote absorptionMaterial analysis using wave/particle radiationSolid state diffusion coatingCondition activityGas cylinder

The invention provides a method for assessing the passivation effect of iron sulfides. A gas supply apparatus comprises an inert gas bottle, an oxygen-rich air bottle, a steam generator and a hydrogen sulfide bottle, the gas supply apparatus is connected with a passivation apparatus through respective pipelines, and supplies a gas to the passivation apparatus, a sample is disposed on the tray of the passivation apparatus, direct sulfuration of the sample can be realized when a hydrogen sulfide gas is introduced into the passivation apparatus, and the iron sulfides are prepared through a reaction of hydrogen sulfide and iron oxide, have high activity, and are close to the condition activity. Safe operation boundary parameters capable of realizing good passivation effect, obvious economic benefit and safe and reliable operation can be found through changing of the concentaration and amount of oxygen introduced in the passivation process and through comparison of a large amount of experiments in order to find the rapid passivation reaction conditions of the iron sulfides in water steam and oxygen, so safety guarantee is provided for maintenance of a tower, a tank and a kettle in an industrial apparatus.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Ferrous sulfide vapor phase passivation device

The invention relates to a ferrous sulfide gas-phase passivation device mainly used for solving problems of existing technology that passivation cost is relatively high; passivation is nonuniform, passivation time is relatively long, and operation is complex. According to the ferrous sulfide gas-phase passivation device, a inert gas container, a oxygen-enriched air container, and a steam generator are connected with the bottom of a passivation tower body respectively; a ferrous sulfide suspension liquid container is connected with the top of the passivation tower body; side walls of the passivation tower body are provided with hand holes and a temperature sensor installation interface; trays are arranged in the passivation tower body; passivation tower body outlet pipelines are divided into at least two parts, one part is connected with a sulfur dioxide and hydrogen sulfide content detecting device through a condenser and a drier, and the other part is connected with an alkaline liquor absorbing tank. The ferrous sulfide gas-phase passivation device is capable of solving the above problems preferably, and can be used for ferrous sulfide gas-phase passivation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of passivated magnesium powder, passivated aluminum-magnesium alloy powder and its wet production process

ActiveCN107088655BImprove securityImprove the environmentTransportation and packagingMetal-working apparatusAntioxidantWater soluble

The invention discloses a passivated magnesium powder, a passivated aluminum-magnesium alloy powder and a wet-process production process thereof. Magnesium grains, aluminum-magnesium alloy grains and an antioxidant aqueous solution are added to wet-type pulverization equipment for wet-process pulverization, and then the solid-liquid The mixture is subjected to wet sieving or hydraulic classification to complete solid-liquid separation, and after drying, passivated magnesium powder or passivated aluminum-magnesium alloy powder is obtained. The particle surface of the obtained finished magnesium powder and aluminum-magnesium alloy powder is coated with a passivation protective film. The powder production process of the present invention is all carried out under the water-soluble protection of the antioxidant, and is a production method with high safety factor, simple equipment and excellent site environment. Passivation, crushing and particle size classification can be completed in one step. The passivation of the finished product is uniform, dense, stable, and has excellent oxidation resistance. The antioxidant solution can be recycled for a long time without waste water discharge, and is an environmentally friendly process method.

Owner:浏阳市科力烟花材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com