A kind of passivated magnesium powder, passivated aluminum-magnesium alloy powder and its wet production process

An aluminum-magnesium alloy powder and production process technology, which is applied in metal material coating process, metal processing equipment, transportation and packaging, etc., can solve the problems of high sealing requirements of equipment, unsatisfactory nitrogen protection effect, large specific surface area, etc. The effect of excellent anti-oxidation performance, excellent site environment and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

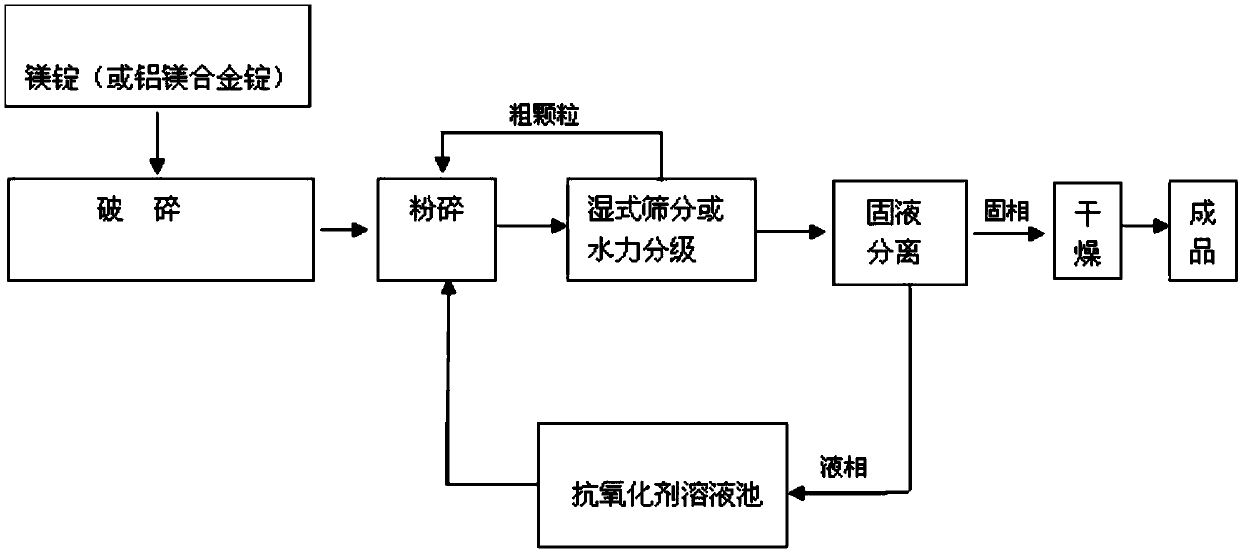

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the wet process production technique of passivated aluminum-magnesium alloy powder, comprises the steps:

[0023] Step 1, preparation of an antioxidant aqueous solution, by weight, phytic acid, boric acid, and potassium dichromate are prepared into an aqueous solution with a total concentration of antioxidants of 5%. The aqueous solution contains 1% of phytic acid, 2% of boric acid, 2% of potassium dichromate and the rest is water.

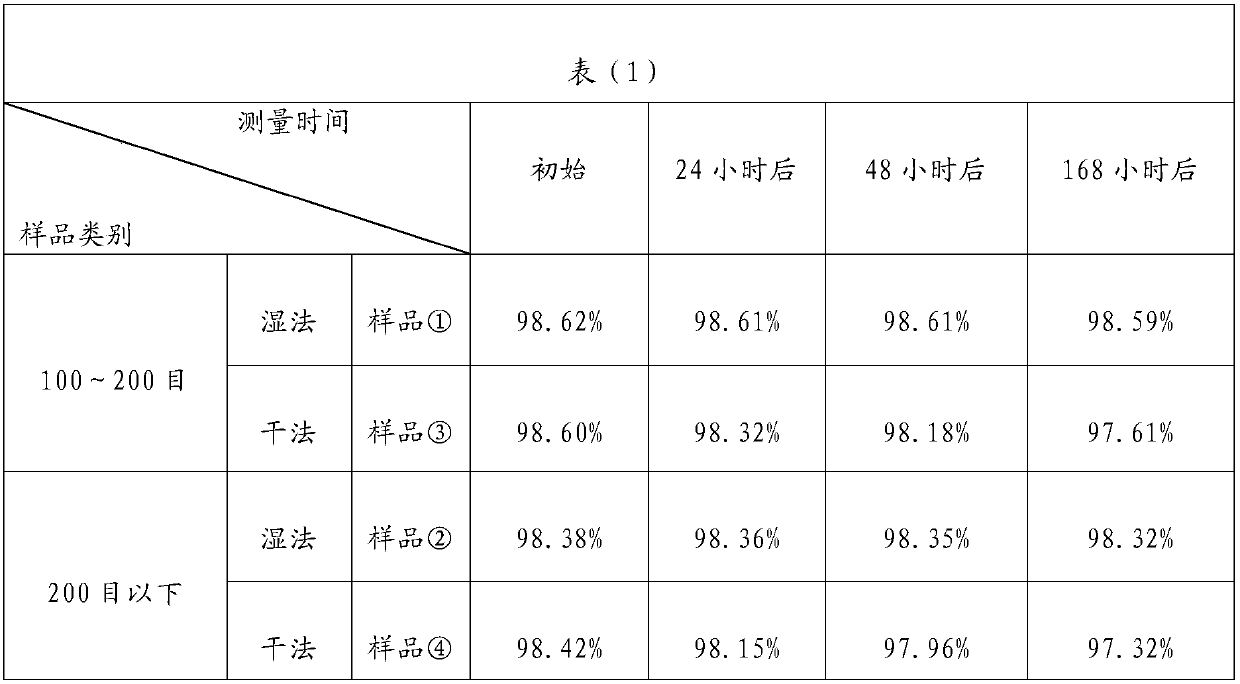

[0024] Step 2, through crushing, the aluminum-magnesium alloy particles with a total activity of 99.5% are arbitrarily divided into two parts, one part is processed according to the wet process of the present invention as the experimental group; the other part is processed according to the traditional dry process as the control group;

[0025] Experimental group: Al-Mg alloy grains were added to the antioxidant aqueous solution with a total concentration of 5% prepared in step 1, and wet crushed to obtain a solid-liquid mixtur...

Embodiment 2

[0032] Embodiment 2: the wet process production technique of passivated magnesium powder, comprises the steps:

[0033] Step 1, preparation of antioxidant aqueous solution, boric acid and potassium dichromate are prepared by weight into an aqueous solution with a total concentration of antioxidant of 10%. The aqueous solution contains 3% of boric acid, 7% of potassium dichromate, and the rest is water.

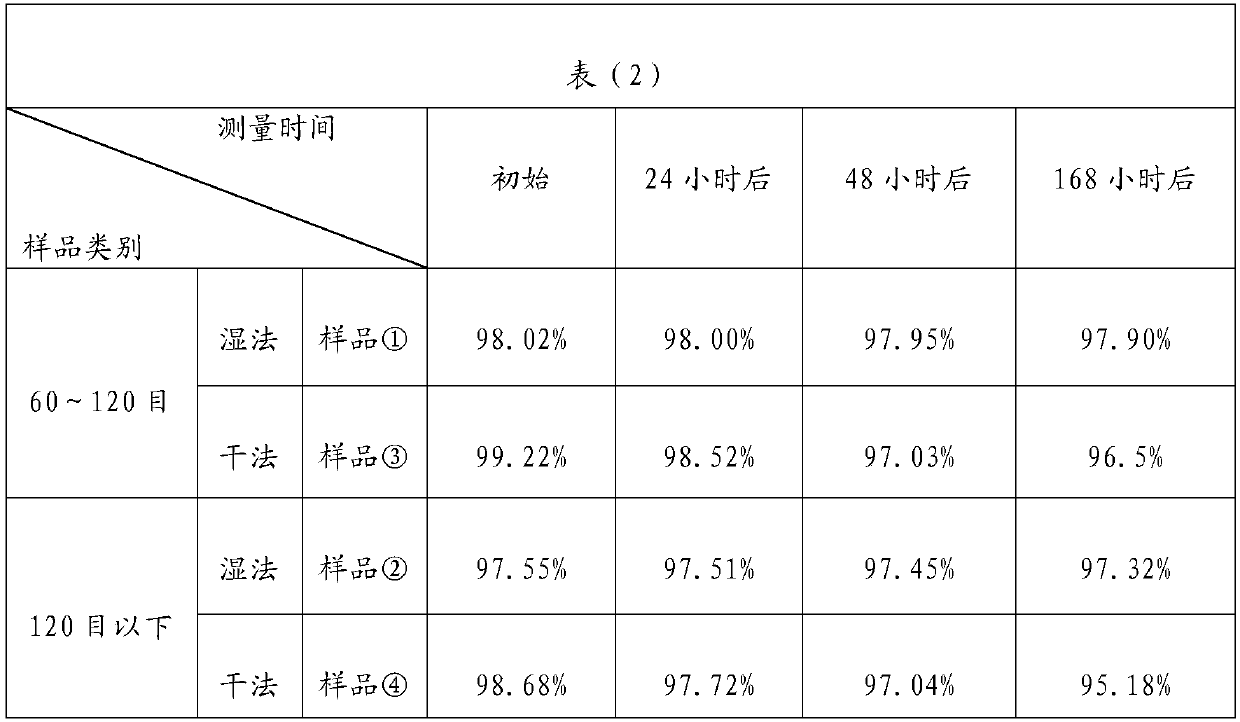

[0034] Step 2, broken through milling short-cut method, active total amount is 99.7% flaky metallic magnesium particle and is arbitrarily divided into two parts, one part is processed by wet process of the present invention as experimental group; another part is processed by traditional method as control group dry processing;

[0035] Experimental group: the flaky metal magnesium particles are added to the antioxidant aqueous solution with a total concentration of 10% prepared in step 1, and wet crushed until the 60-mesh sieve passes through to obtain a solid-liquid mixture; ...

Embodiment 3~8

[0046] Embodiments 3-8 are different from Embodiment 1 or 2 in that in the preparation of the antioxidant aqueous solution in step 1, the type, quantity, proportioning of the selected antioxidant and the total antioxidant content in the antioxidant aqueous solution are different, See table (4) below for details.

[0047]

[0048]In each formula of above table, all the other are water. It should be noted that the formulation of the antioxidant aqueous solution of the present invention is not limited to the content listed in each example. According to specific needs (such as different requirements for passivation degree, speed and activity content), different types and proportions of antioxidant aqueous solutions can be used, combined with different passivation temperatures and passivation times, to produce passivated magnesium powder and passivated magnesium powder for different purposes. Aluminum-magnesium alloy powder, and each antioxidant used alone or in any combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com