Post-treatment process of high-gloss formed cutter

A technology for forming tools and post-processing, applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., can solve the problems of inability to polish and polish the tools, inability to guarantee the passivation effect, uneven tool passivation, etc., to save dullness passivation time, guaranteed passivation effect, and improved surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

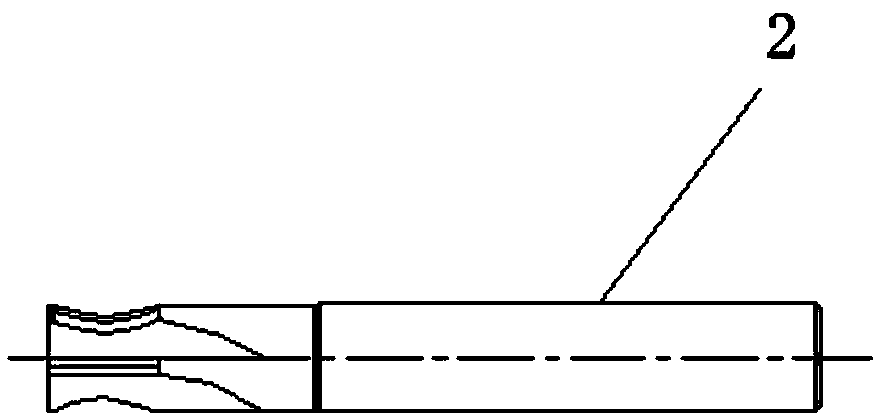

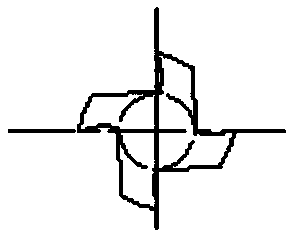

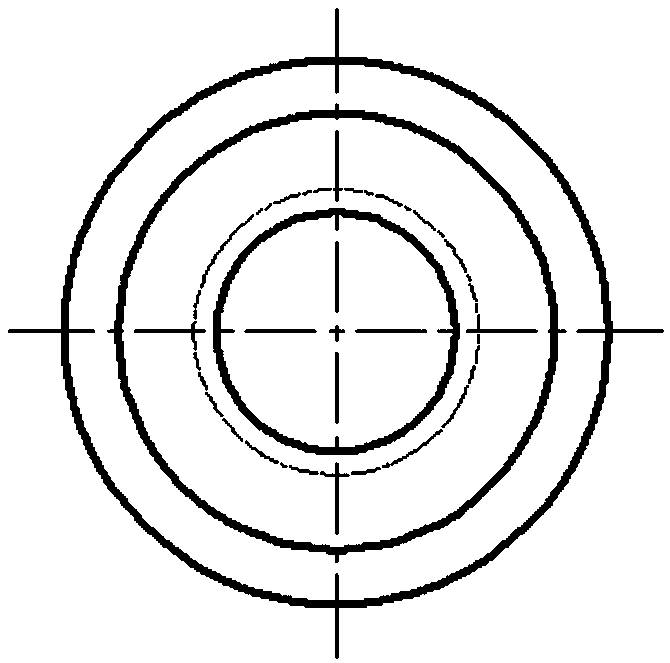

[0022] Such as Figure 1-6 As shown, a post-processing process for high-gloss forming tools includes the following steps: 1) Design a fixture 1, a tool hole is arranged in the center of the fixture, and the part directly involved in polishing on the fixture is set into a tool contour shape according to the distribution of the knife edge, and the tool is guaranteed The distance between each position and the fixture is equal, and four evenly distributed decompression holes are added on the fixture;

[0023] 2) Abrasives for polishing are configured. The abrasives for tool fluid polishing are made of a polymer semi-solid carrier with viscoelasticity, softness and cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com