Patents

Literature

62results about How to "Short passivation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

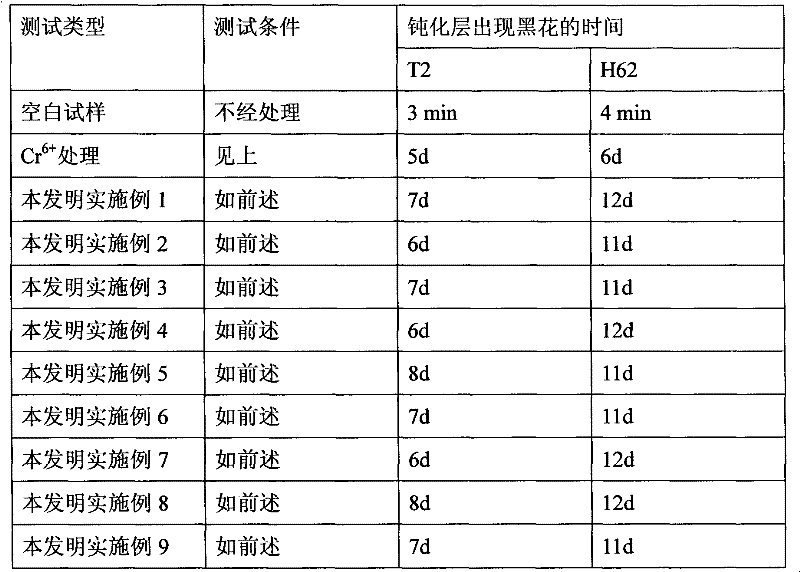

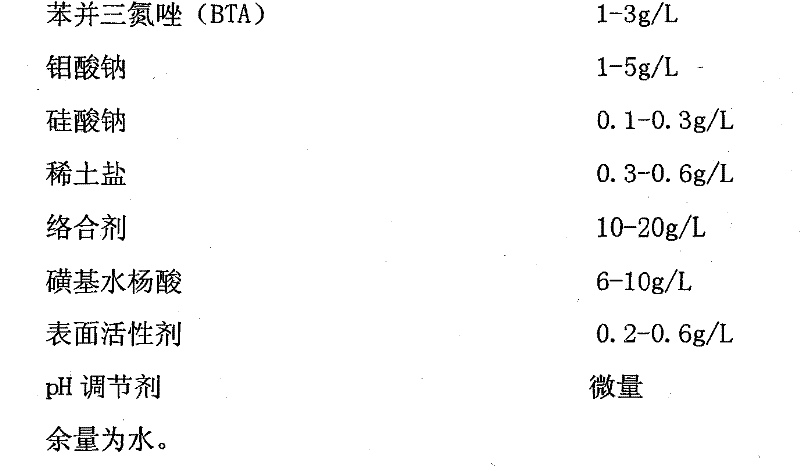

Rare earth modified surface treating agent for copper and copper alloys and preparation method thereof

ActiveCN102071415AImprove corrosion resistanceShort passivation timeMetallic material coating processesRare earthSulfosalicylic acid

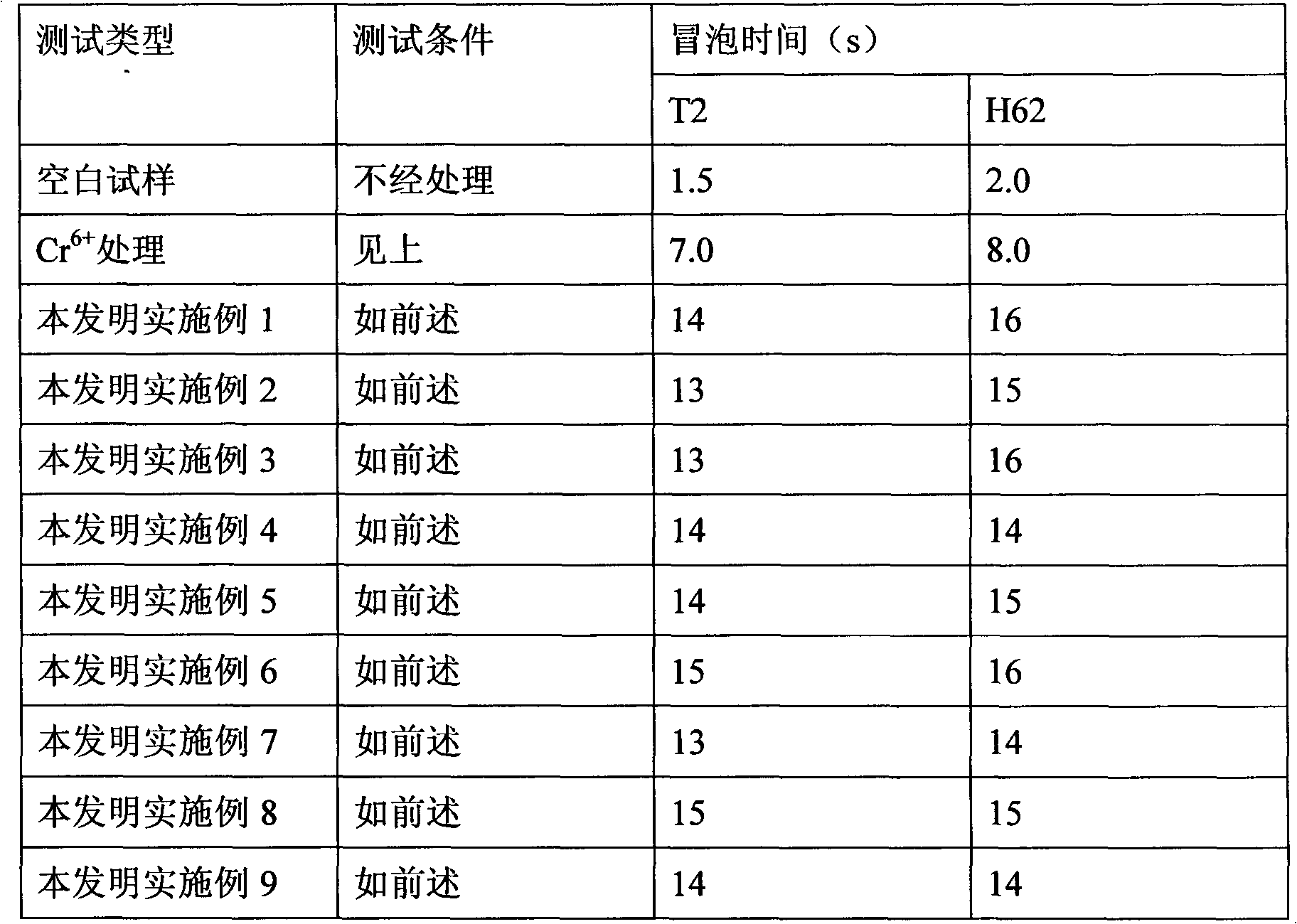

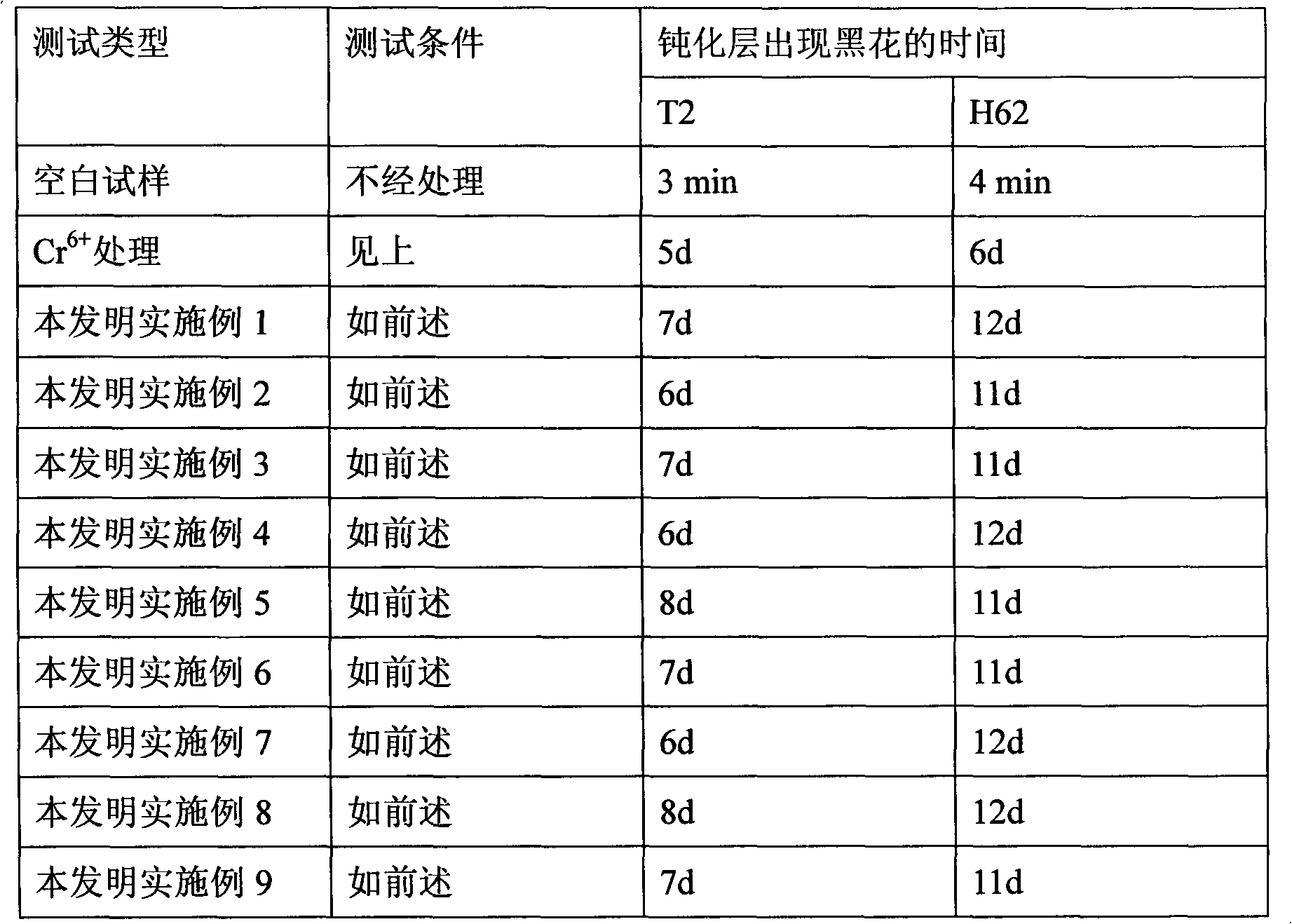

The invention discloses a rare earth modified surface treating agent for copper and copper alloys and a preparation method thereof. The surface treating agent per liter comprises the following raw materials by weight: 1-3g of benzotriazole, 1-5g of sodium molybdate, 0.1-0.3g of sodium silicate, 0.3-0.6g of rare earth salt, 10-20g of complexing agent, 6-10g of sulfosalicylic acid, 0.2-0.6g of surfactant, a small amount of pH regulator and the balance water. The surface treating agent of the invention can be used for passivation at the room temperature, have short passivation time and be green and environmentally friendly; the passivated copper or copper alloy surface has good corrosion resistance; and the treating agent has simple treatment technology and is convenient for actual production.

Owner:斯特凯新材料(上海)有限公司

Non-chromium inactivating technique of aluminum pipe for refrigerator, ice chest evaporator and deactivation liquid

ActiveCN101158037AImprove corrosion resistanceSimple processMetallic material coating processesAlkylphosphateSilanes

The invention relates to a non-chromium passivation technique and passivation solution of an aluminum pipe. The aluminum pipe is used for evaporators of ice refrigerators and ice chests. The invention belongs to the aluminum material surface treatment technical field. The invention aims at promoting the corrosion resistance of the aluminum pipe for evaporators of ice refrigerator and ice chest, etc. The continuous extrusion shape aluminum pipe is cooled off and quickly passivated in the passivation solution under the temperature from 20 DEG C to 90 DEG C. A tier of passivated film is formed on the surface of the aluminum pipe through airing and solidifying. The passivation solution contains passivant alkyl phosphate ester. The mass concentration of the passivant alkyl phosphate ester is from 1 percent to 15 percent. The mass concentration of the silane coupler is from 0.1 percent to 0.5 percent. The mass concentration of the sodium silicate is from 0.01 percent to 0.15 percent. The rest of the passivation solution is water. The passivated aluminum pipe is dried through wind under 20 DEG C to 60 DEG C and packed through the turn plate. The technique of the invention has the advantages of simple process, low cost and high speed, and the corrosion resistance of the passivated aluminum pipe is greatly promoted, and pharmaceuticals and passivation process has the performance of safety and environmental protection.

Owner:CENT SOUTH UNIV

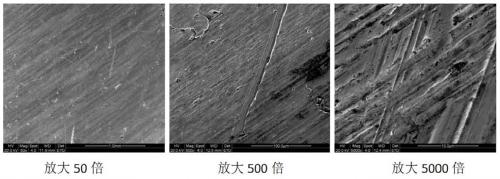

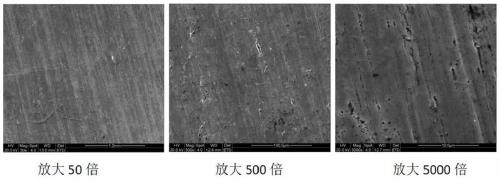

Continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel

ActiveCN103243339AAvoid intergranular corrosionSpeed up the formation of passivation filmHydrofluoric acidConcentration ratio

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Chromium-free passivating agent for galvanized plate with organosilane as main component and preparation process thereof

ActiveCN102732869AImprove corrosion resistanceImprove coating adhesionMetallic material coating processesSodium molybdateSalicylic acid

Owner:合肥华清高科表面技术股份有限公司

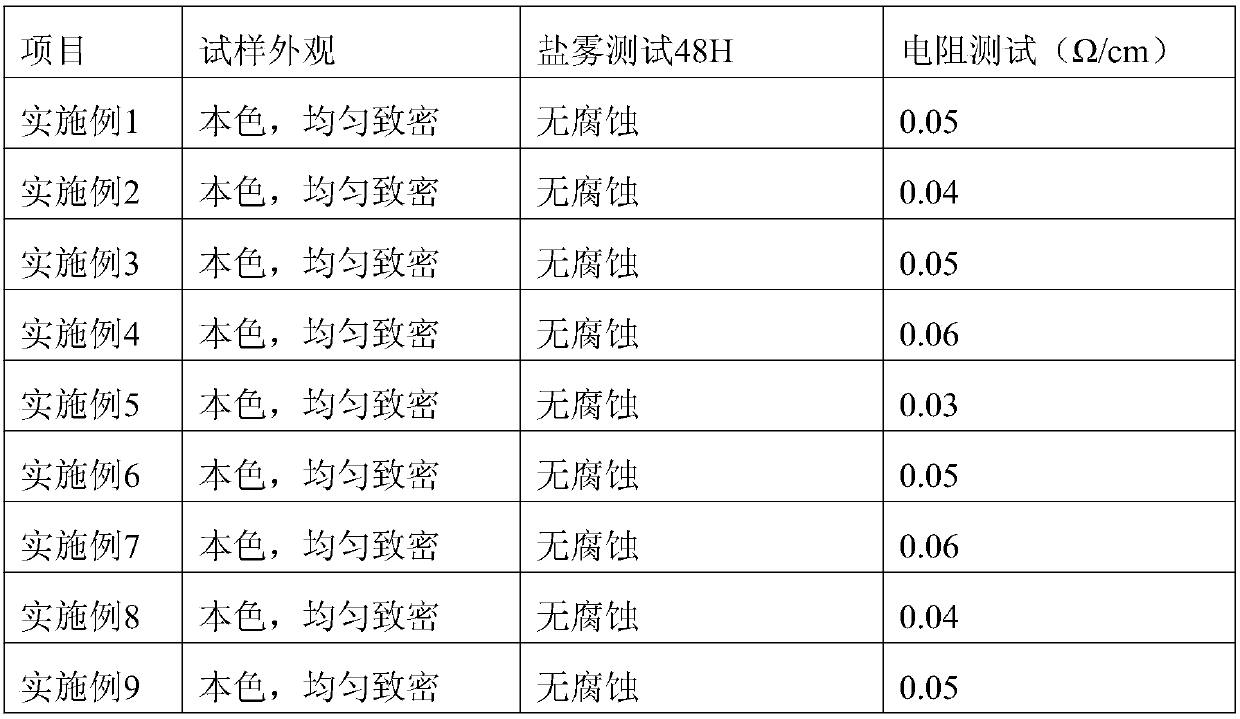

High corrosion resistance passivation solution for zinc alloy die castings and passivation method

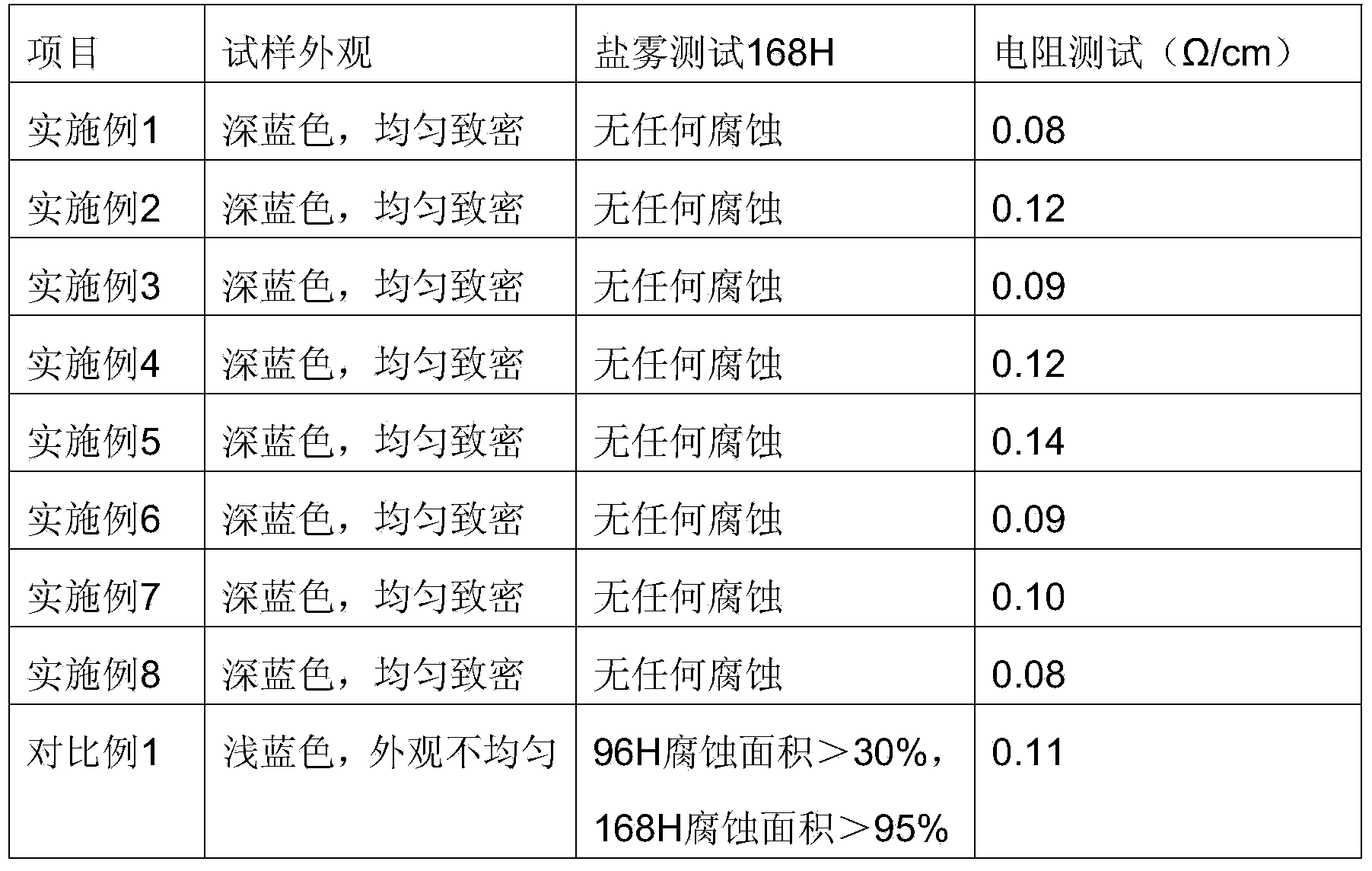

InactiveCN104141123AImprove conductivityEasy to useMetallic material coating processesNitrateSalt spray test

The invention provides a high corrosion resistance passivation solution for zinc alloy die castings and a passivation method. The high corrosion resistance passivation solution comprises 1% to 10% of chromic salts, 1% to 8% of rare earth compounds, 0.1% to 5% of mixed accelerant, 0.01% to 0.05% of surface active agents and the balance water. The mixed accelerant is a mixture of cerous nitrate, ammonium bifluoride and sodium nitrate, wherein the mass ratio of the cerous nitrate to the ammonium bifluoride to the sodium nitrate is (0.5-2):(0.5-2):(3-8). The cleaned zinc alloy die castings are immersed into a working solution prepared by the high corrosion resistance passivation solution to be passivated, cleaned and dried. According to the high corrosion resistance passivation solution, the components are synergized by optimizing the component formula ratio, the passivation time is short, a passivation film layer is dark blue and is uniform, compact and high in corrosion resistance, no corrosion exists in a salt spray test 168H, the electrical conductivity of the film layer is good, the zinc alloy die castings with the oxidized surfaces can be treated, the passivation quality of non-fresh zinc alloy workblanks is greatly improved, and the requirement for industrial production is met.

Owner:SHENZHEN XINMINGDA ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

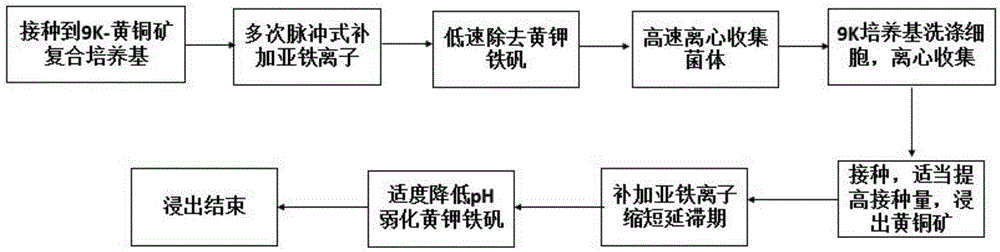

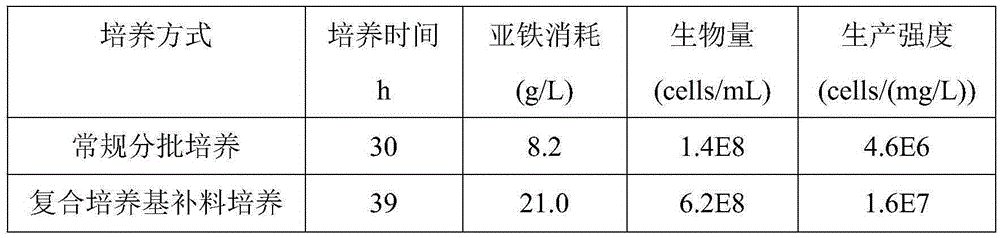

Method for leaching chalcopyrite through reinforced iron oxidized culture

ActiveCN105256133AIncrease cell concentrationImprove leaching efficiencyProcess efficiency improvementChalcopyriteHigh density

The invention discloses a method for leaching chalcopyrite through a reinforced iron oxidized culture and belongs to the technical field of bioleaching. The method includes the steps that on the basis of a 9K-chalcopyrite complex medium, a ferrous energy substrate is added through an impulse type supplementary material in the middle and later periods of cultivation, and ferric oxide thiobacillus is cultured at high density; centrifugal operation and suspended elution cells of the 9K medium are adopted for removing jarosite, the cells not containing jarosite are adopted for inoculation, the inoculation size is increased properly, and meanwhile ferrous ions are supplemented and included to shorten a lag phase; and the pH of lixivium is lowered level by level in the later leaching period, accumulation of the jarosite is reduced, and the leaching effect of the chalcopyrite is improved in the whole process. By the adoption of the method, the iron oxidized culture can be more efficiently cultured, the lag phase can be shortened, the passivation effect caused by accumulation of the jarosite can be weakened, the leaching process of the chalcopyrite is improved while iron metabolism is reinforced, operation is easy and feasible, and the method is suitable for being applied and popularized on a large scale.

Owner:JIANGNAN UNIV

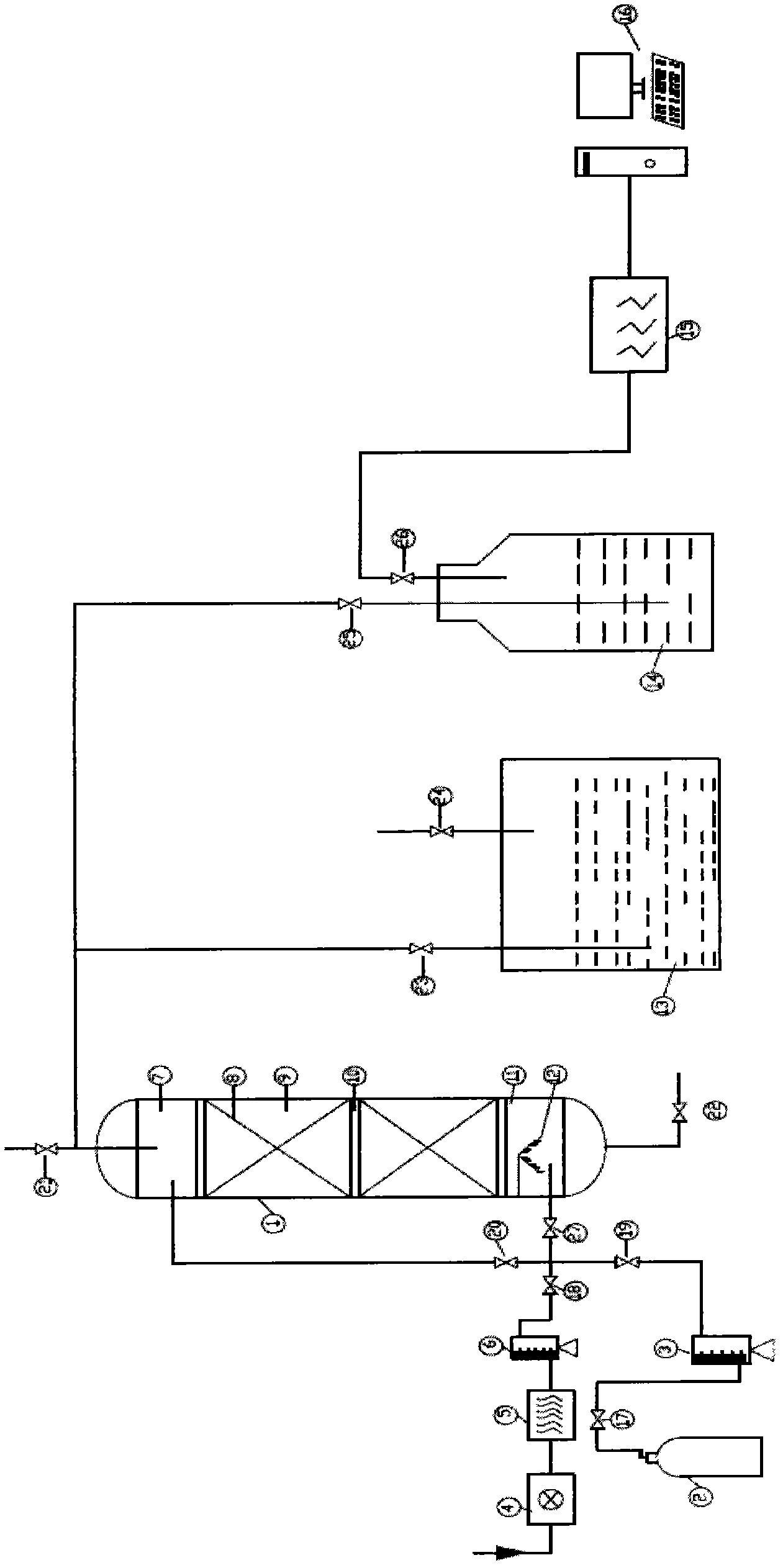

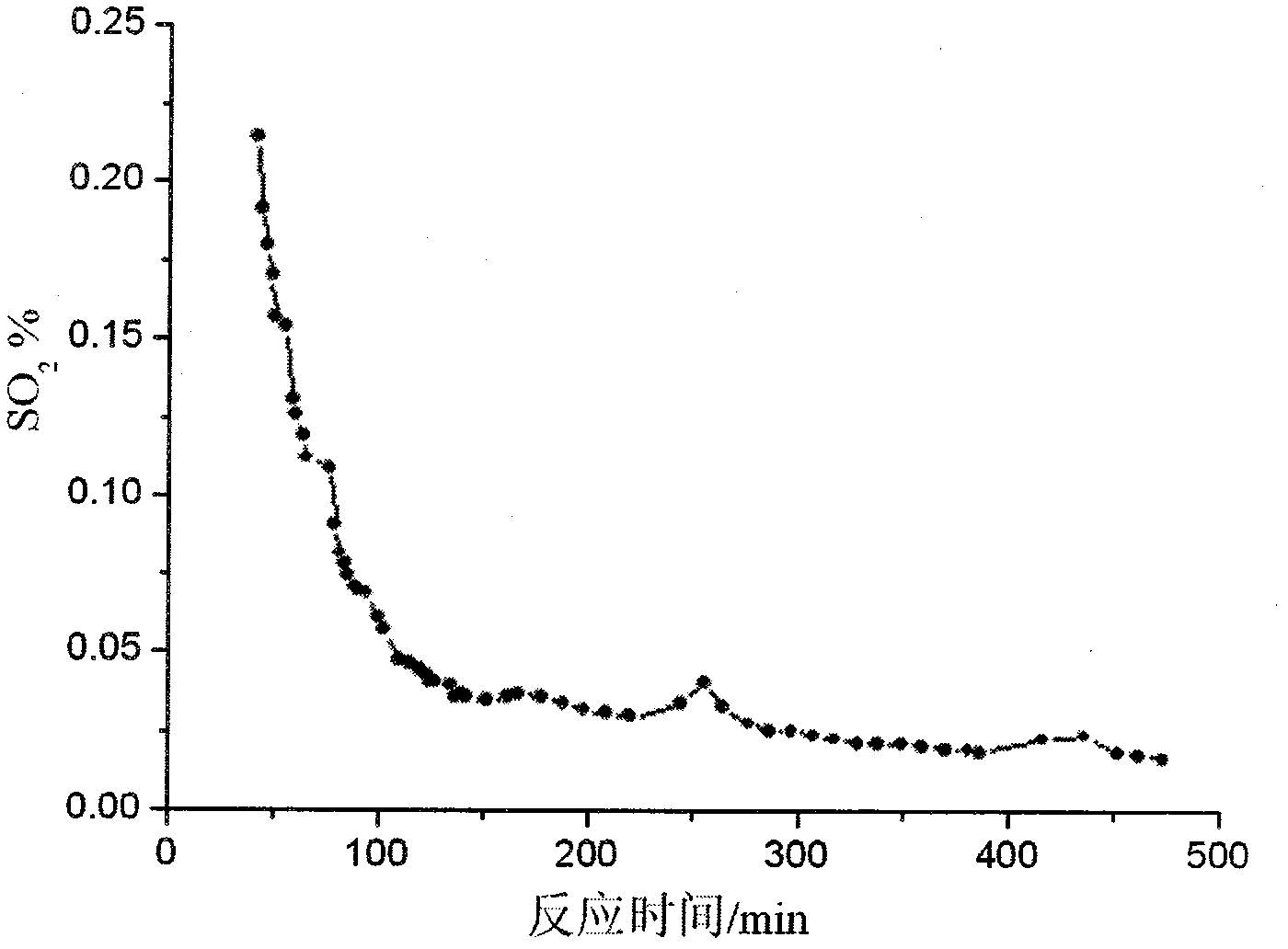

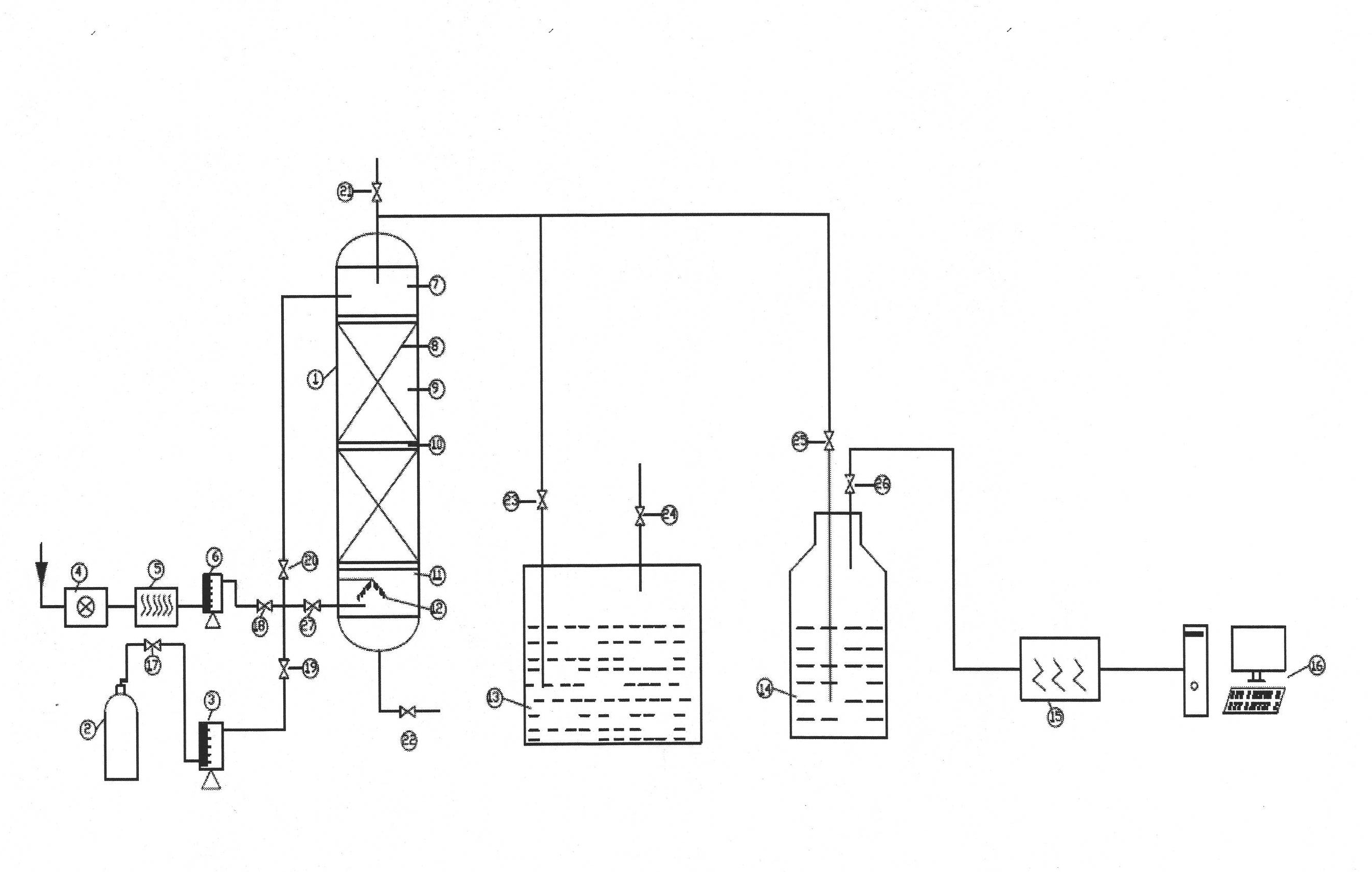

Ferrous sulfide gas phase passivation device

The invention discloses a ferrous sulfide gas phase passivation device. The gas phase passivation device contains a steam supply part, an oxygen supply part and a sealing part. The gas phase passivation device is connected with a tail gas treatment device and a data analysis device respectively to perform gas phase passivation to a petrochemical device. The steam supply part contains a water softener, a steam generator, a steam flowmeter and an oxygen valve. The oxygen supply part contains a compressed oxygenized air bottle, a gas flowmeter, an oxygen inlet valve and an oxygen valve. The sealing part contains a packed tower, a tail gas valve and a gathering tank valve. Compared with the liquid phase passivation method in the prior art, the phase passivation method of the invention mainly uses oxygenized air, is convenient to use and has lower cost. Waste gas is easy to treat. The waste gas which is easily treated through gas phase passivation can meet the emission standard. The treatment time is short; and passivation can be performed evenly and the channeling phenomenon does not exist.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly composite colorful passivating solution and preparation method thereof

ActiveCN107740085AColorfulUniform film formationMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite colorful passivating solution and a preparation method thereof and belongs to the technical field of surface treatment of metal materials. Thepassivating solution comprises the components of 17-22 g / L of sodium silicate, 4-8 g / L of sodium molybdate, 6-10 g / L of sodium nitrate, 3-7 mL / L of hydrogen peroxide, 1-3 g / L of potassium fluoride, 2-6 mL / L of nitrilotrimethylene triphosphonic acid, 2-4 g / L of sodium gluconate, 2-4 mL / L of tartaric acid and the balance water, wherein the pH value of the passivating solution is 2.0-2.5. The preparation method of the passivating solution comprises the steps that the sodium silicate, the sodium molybdate, the sodium nitrate, the potassium fluoride, the nitrilotrimethylene triphosphonic acid, thesodium gluconate, the tartaric acid and the hydrogen peroxide are sequentially added into deionized water to be evenly mixed; the water with the constant volume is added to the needed volume; and sulfuric acid is used for adjusting the pH value to be 2.0-2.5, and thus environment-friendly composite colorful passivating solution is obtained. A galvanized layer passivated film treated by the passivating solution is colorful, bright in color, even in film forming and excellent in corrosion resistant performance; the passivating solution does not contain trivalent chromium, hexavalent chromium and other harmful substances and is environmentally friendly, free of pollution, simple in passivating process and high in passivating efficiency, and the corrosion resistance of a film layer is good.

Owner:KUNMING UNIV OF SCI & TECH

Ferrous sulfide gas-phase passivation method

The invention discloses a ferrous sulfide gas-phase passivation method, comprising the steps of monitoring, feeding air, passivating, sealing and discharging, wherein the passivating is implemented as follows: vapor carrying oxygen enriched air enter a container for carrying out gas phase passivation on ferrous sulfide. The vapor is water vapor, the pressure of the water vapor is 0.1-0.9 MPa, and the oxygen enriched air contains 21-50 percent of oxygen by volume. Compared with the ferrous sulfide liquid-phase passivation method, the ferrous sulfide gas-phase passivation method has low cost, is easy to implement, mainly adopts oxygen enriched air which is convenient to use and has low cost for gas phase passivation, ensures uniform ferrous sulfide passivation, is free from channeling phenomenon and dead corners due to gas-phase action and boasts of easy treatment of waste gas which is produced in ferrous sulfide gas-phase passivation and can reach the emission standard after being treated simply, and has short treatment time.

Owner:CHINA PETROLEUM & CHEM CORP +1

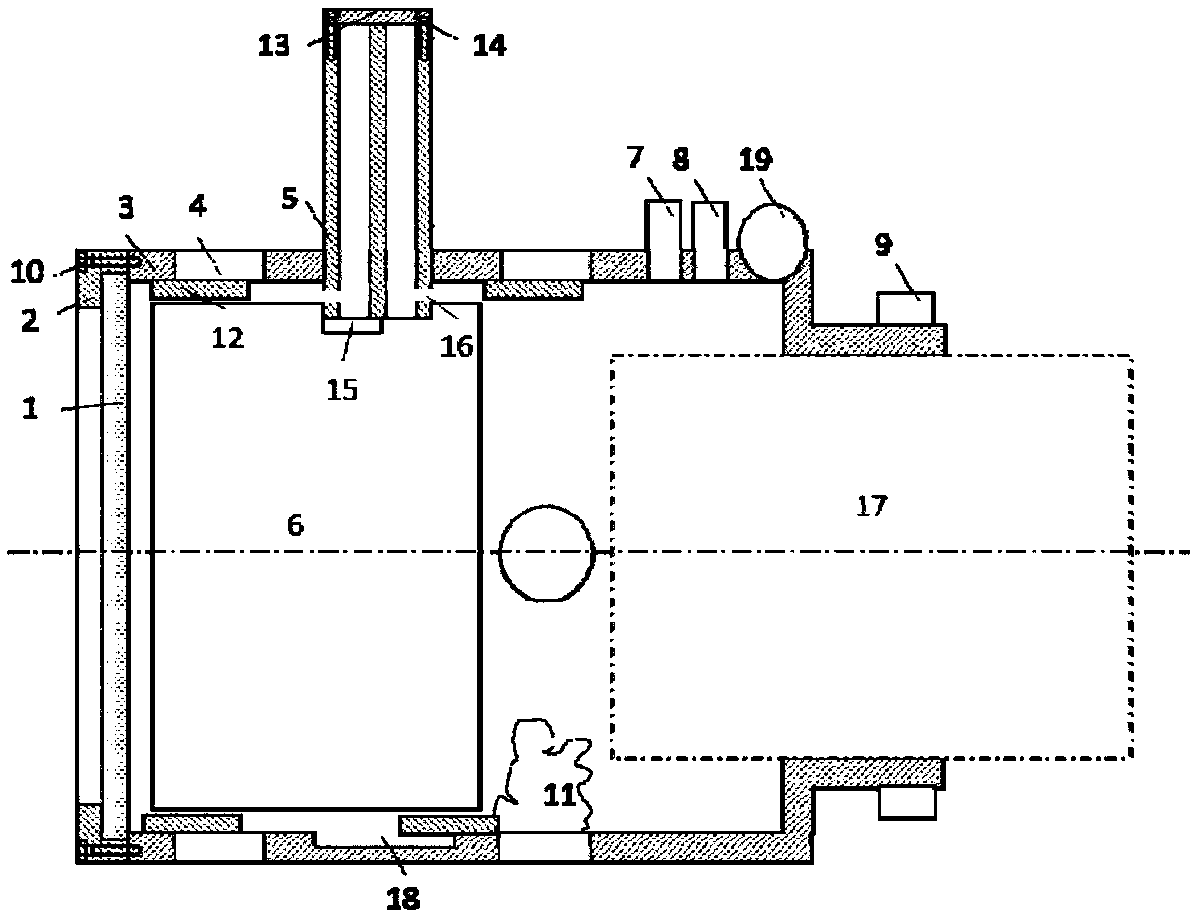

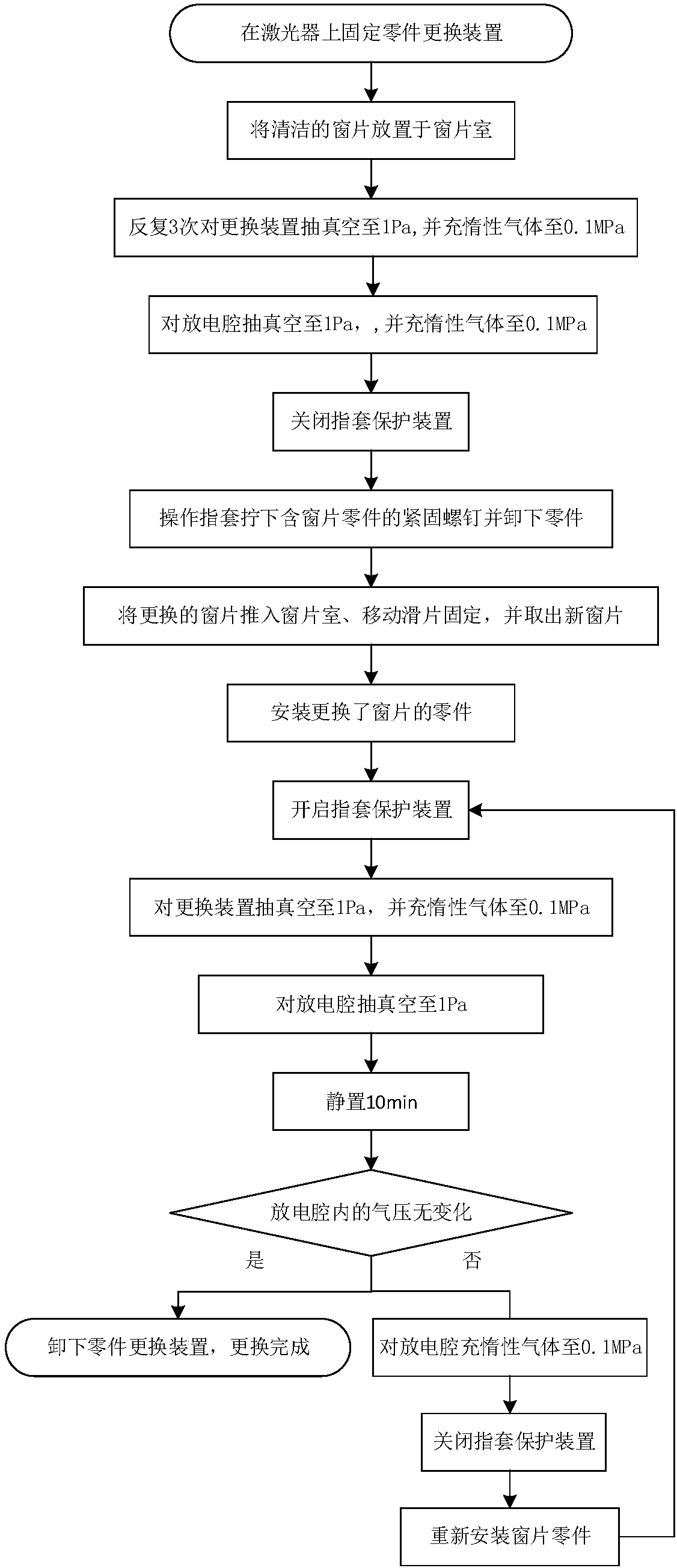

Replacement device and replacement method of excimer laser window

InactiveCN108183382APrevent proliferationHarm reductionGas laser constructional detailsEngineeringAtmospheric pressure

The invention relates to a replacement device and replacement method of an excimer laser window. The device comprises a replacement main cavity with an opening at one end. A cavity wall of the replacement main cavity is provided with multiple observation windows for observing the internal part of the replacement main cavity, a barometer for detecting the internal air pressure in the replacement main cavity, a vacuuming passage, an inflation passage, a plurality of finger sleeve holes and a window chamber. Both the vacuuming passage and the inflation passage communicate with the internal part of the replacement main cavity, and the finger sleeve holes are equipped with operation finger sleeves which facilitate the window replacement in the replacement main cavity. According to the replacement device and the replacement method, a diffusion phenomenon of a halogen medium in the process of replacing an excimer laser window can be significantly reduced, the contamination of parts in atmospheric exposure can be effectively avoided, the number of times of cleaning a discharge chamber and the harm to an operator can be effectively reduced, the passivation process is avoided or the passivation time is significantly reduced, and the use efficiency of a laser and the utilization rate of energy sources are improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Surface plasma treatment process for tooth roller of flour mill

InactiveCN106086853AGenerate Thickness LiftIncrease the speed of passivationMetallic material coating processesSurface plasmonEconomic benefits

The invention discloses a surface plasma treatment process for a tooth roller of a flour mill. The surface plasma treatment process comprises the following steps of (1) surface polishing, (2) grease removing treatment, (3) washing treatment, (4) passivating treatment, (5) washing and drying and (6) plasma treatment. According to the surface plasma treatment process, the surface of the tooth roller is subjected to passivating treatment first, added modified nano diatomaceous earth and nano silicon dioxide improve the evenness, compactness and stability of a passivation film, and meanwhile a good antibacterial effect is achieved by the passivation film; plasma treatment is conducted after passivating treatment so that fusing of the passivation film and a substrate of the tooth roller can be improved and the hardness and the corrosion resistance of grinding teeth of the tooth roller can also be improved, and the finally the treated tooth roller has excellent strength, corrosion resistance and antibacterial and antirust performance. Compared with an existing tooth roller, the service life is prolonged by 10-12 times, flour yield is improved by about 30%, the power consumption of each ton of flour is reduced by 15-18 KW.h, and the economic benefit is obviously improved.

Owner:WUHE HUANGHUAI GRAIN & OIL MACHINERY CO LTD

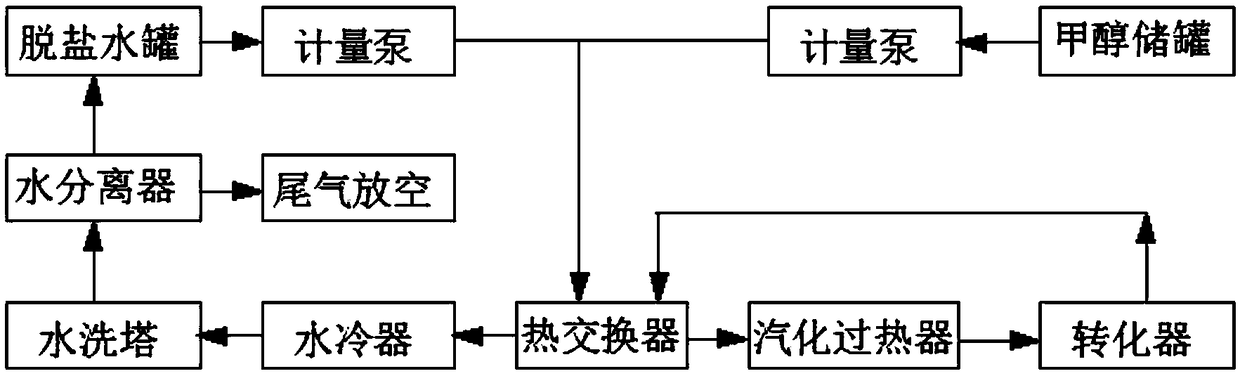

Reduction and passivation method of copper-based catalyst for hydrogen production from methanol reforming

ActiveCN108993615AEasy temperature controlShort passivation timeHydrogenCatalyst activation/preparationMethanol waterHeat carrier

The invention discloses a reduction method of a copper-based catalyst for hydrogen production from methanol reforming. The reduction method comprises the following steps: firstly, taking heat-conduction oil as a heating source, taking air with a heating space velocity of 100-500 h<-1> as a heat carrier, heating a catalyst bed layer in a converter to 160 DEG C, then heating the catalyst bed layer in the converter to 230 DEG C by using water vapor, and reducing the catalyst by using a methanol water mixed solution with a methanol mass concentration of 2-3%. The reduction method is used to solvethe technical problem that a conventional method is complex in process, large in investment cost, and long in heating time. The invention further discloses a passivation method of the copper-based catalyst for hydrogen production from methanol reforming. The passivation method comprises the following steps: the temperature in the converter is kept at 150-160 DEG C by using saturated water vapor under a normal pressure condition; a proper amount of an air passivation catalyst is added into gas in the convertor under a condition that the temperature in the converter is maintained to be not higher than 160 DEG C; and after the gas is completely converted to air, the temperature is reduced to room temperature, so that the passivation of the catalyst is realized. The passivation method is usedto solve a technical problem that a conventional N2-air passivation method is difficult to control and time consumption is large.

Owner:四川蜀泰化工科技有限公司

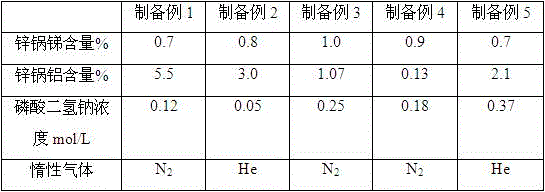

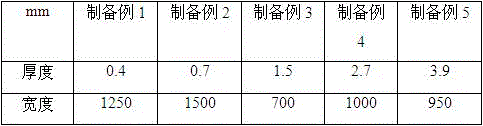

Preparation technology of galvanized steel sheet with continuous hot-dip spangles

ActiveCN106702101AGuaranteed mechanical propertiesImprove anti-corrosion performanceHot-dipping/immersion processesFurnace typesAir knifeMechanical property

The invention relates to the technical field of galvanizing of steel sheets, and discloses a preparation technology of a galvanized steel sheet with continuous hot-dip spangles. The preparation technology comprises the following steps of uncoiling, and cleaning; annealing: sending a steel sheet into an annealing furnace to reduce and calcine, wherein the annealing atmosphere is a H2 (hydrogen) and N2 (nitrogen) mixed gas, and the annealing temperature is 720 to 800 DEG C; hot-dip: cooling the steel sheet by air, cooling to 470 to 520 DEG C at the average temperature, sending into a zinc pot, and performing hot-dip, wherein the temperature of the zinc pot is 455 to 470 DEG C, and the content of antimony in the zinc pot is 0.7 to 1.0% (in percentage by mass); spraying: enabling an air knife to scrape the excessive hot-dip liquid on the steel sheet, spraying and cooling, wherein the temperature of spraying liquid is 55 to 60 DEG C, and the spraying liquid is a monosodium phosphate water solution; flattening, and passivating; coiling. The preparation technology has the advantages that the production cycle is short, the spangles are small and uniform, and the mechanical property and anticorrosive property of the prepared steel sheet are excellent.

Owner:重庆万达薄板有限公司

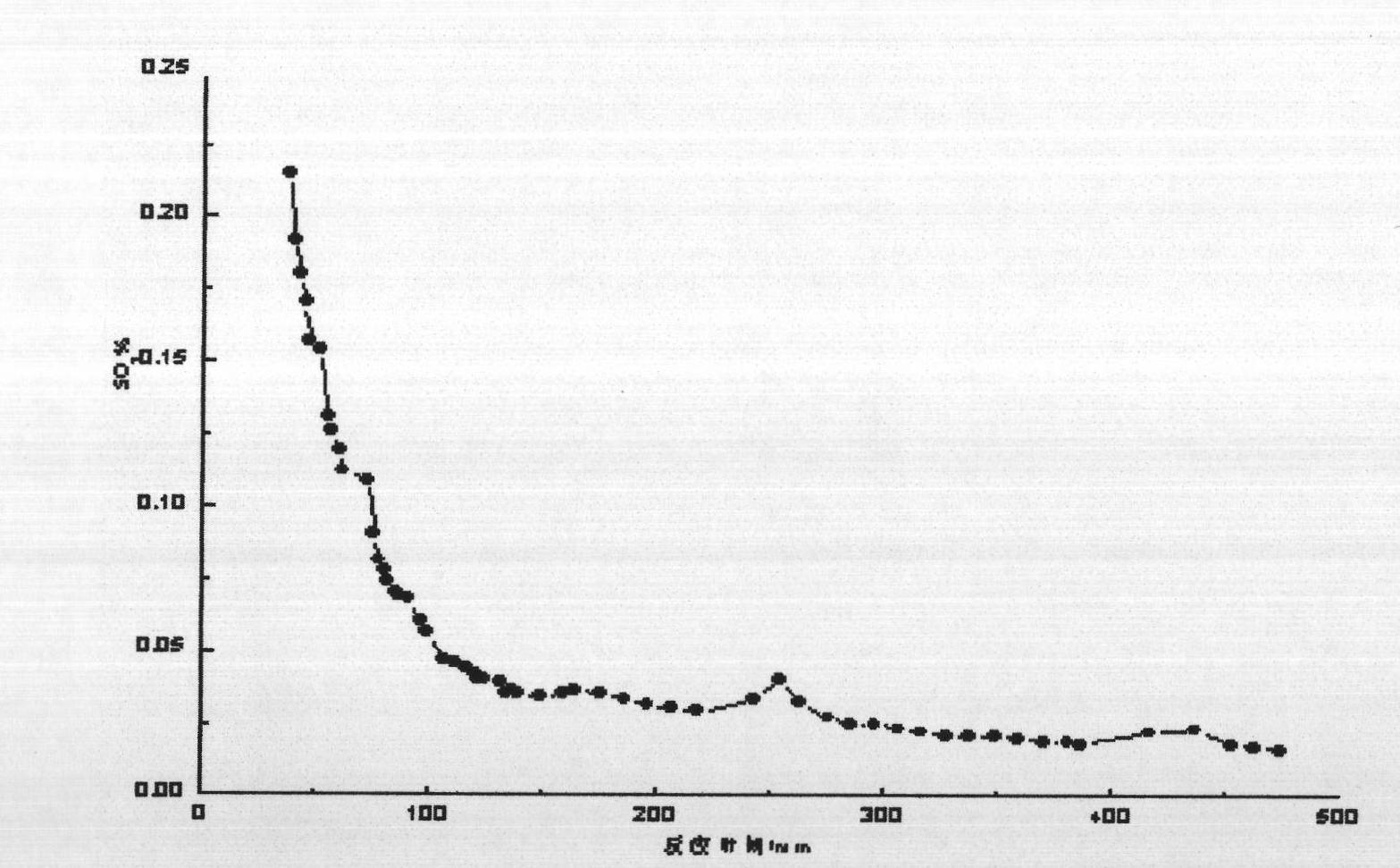

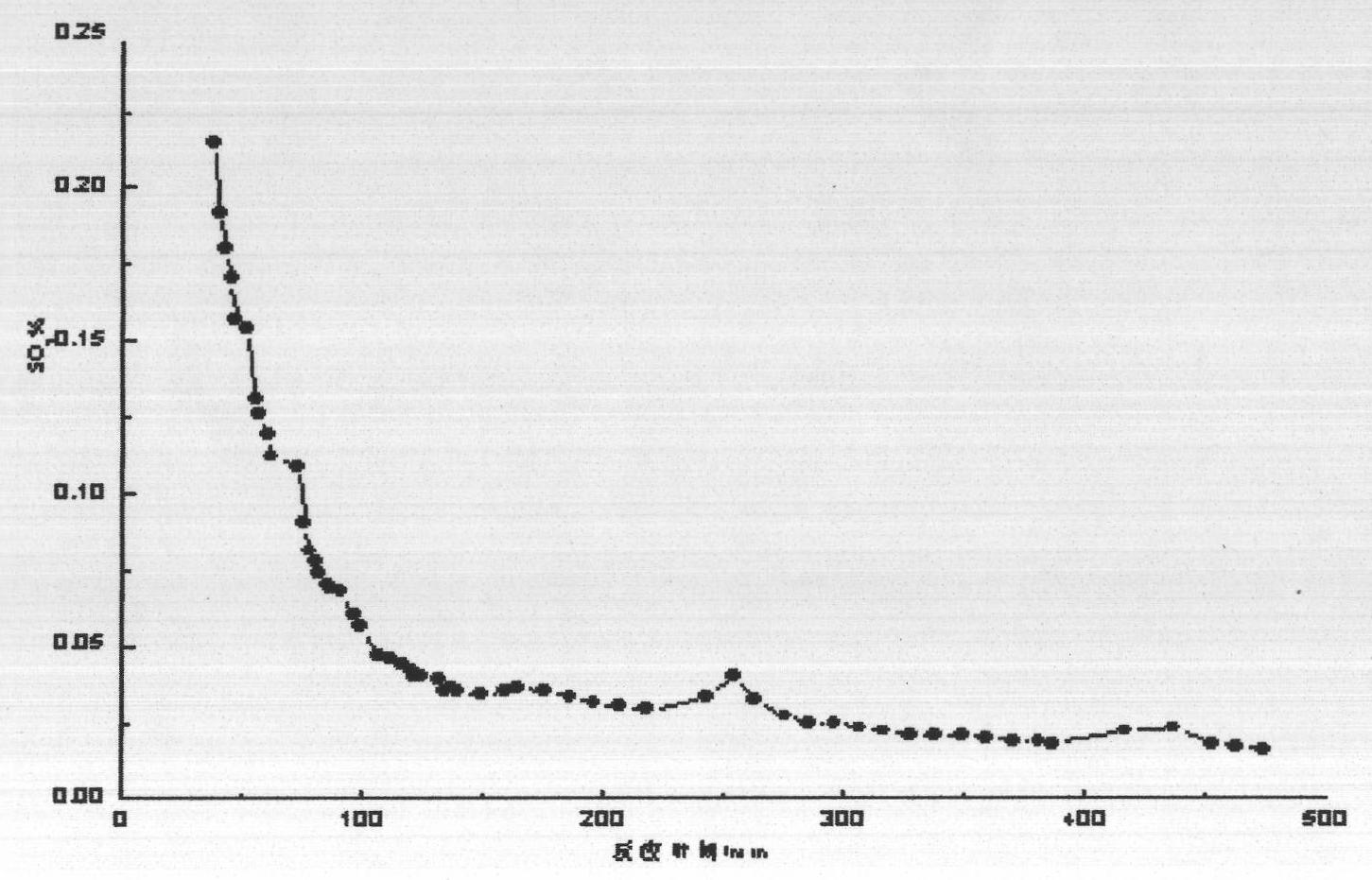

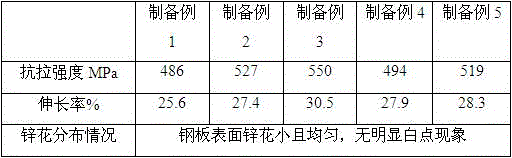

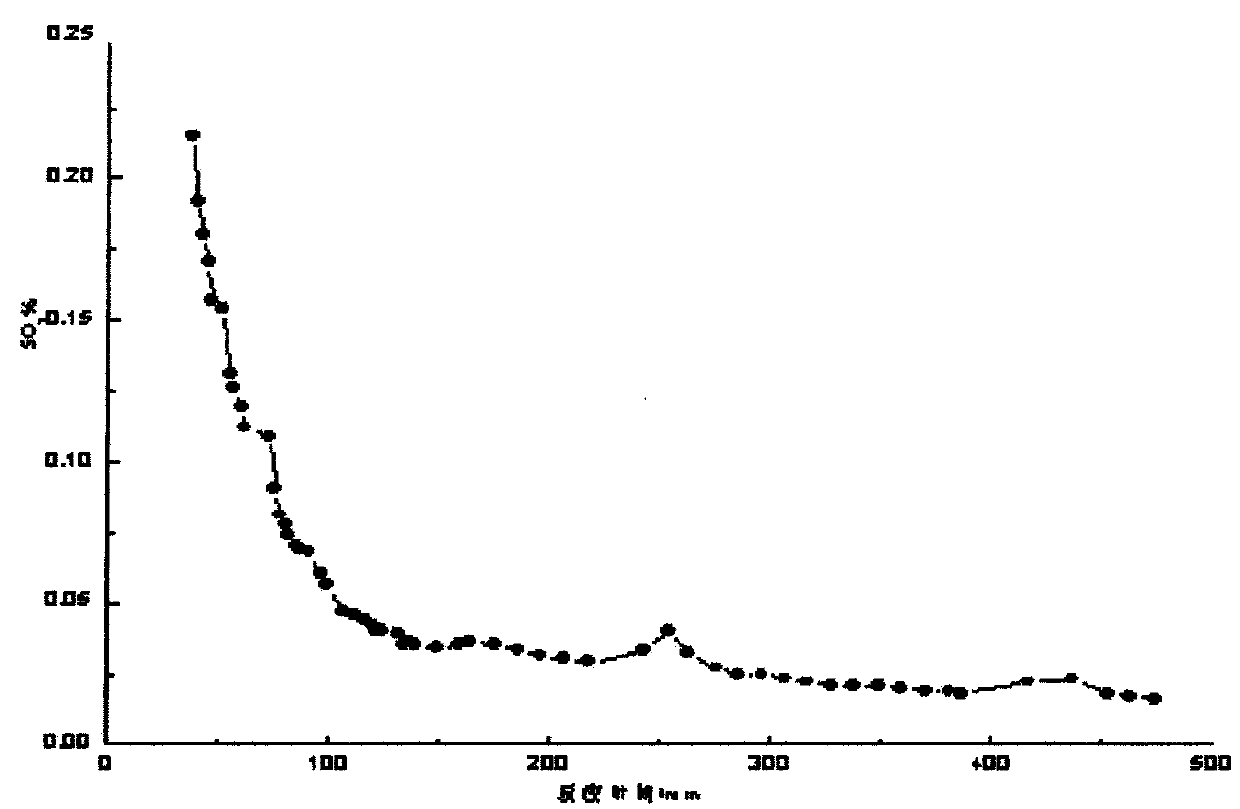

Gas phase deactivation method for petrochemical device

ActiveCN102154612AEasy to handleLow costFuel testingSolid state diffusion coatingExhaust valveGas phase

The invention discloses a gas phase deactivation method for a petrochemical device. The method comprises the following steps of: sequentially opening a tail gas valve, an exhaust valve, a monitoring air inlet valve and a monitoring air outlet valve, and then starting an online gas chromatograph to monitor the concentration of SO2, wherein the SO2 content of the tail gas is high when the gas phasedeactivation process starts, and the volume concentration of the SO2 is reduced to 0.001-0.09 percent after 7 to 19 hours; and finishing the tower reaction when the volume concentration of the SO2 isnot changed in 30 to 60 minutes, finishing the gas phase deactivation, and resetting the valves. Compared with the deactivation method in the prior art, the method has the advantages that: the treatment of waste gas is easy; the gas phase deactivated waste gas can reach discharge standards by simple treatment; the treatment time is short; the cost is low, and the implementation is simple; oxygen rich air is mainly used in the gas phase deactivation, is convenient to use and has low cost; and because of gas phase action, channeling and dead angles are not caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wet method for passivating surface of germanium monocrystal

InactiveCN102220643AEasy to operateImprove passivation effectPolycrystalline material growthAfter-treatment detailsSolubilityProcess manufacturing

The invention discloses a wet method for passivating the surface of a germanium monocrystal, which comprises the following steps of: mixing hydrofluoric acid and hydrogen peroxide solution in a volume ratio of (1-4):(4-1); heating the mixed solution to the temperature of between 30 and 80 DEG C; and putting the germanium monocrystal into the mixed solution, and reacting for 30 to 300 seconds, so that a GeOx passivation layer is formed on the surface of the germanium monocrystal. The oxidizability of hydrogen peroxide and the selective dissolubility of the hydrofluoric acid on germanium oxidesare combined organically, so that a good passivation effect is achieved on the surface of the germanium monocrystal. The method is easy to operate and high in efficiency, and the complex operation process of removing the oxides on the surfaces of germanium monocrystal sheets is avoided simultaneously. The method can be used for the passivation of germanium chips for solar cells, complementary metal oxide semiconductor (CMOS) devices and the like in the field of process manufacturing of semiconductor devices.

Owner:ZHEJIANG SCI-TECH UNIV

Chemical oxidation liquid for magnesium alloy

ActiveCN104611689AStrong adhesionImprove corrosion resistanceMetallic material coating processesSalt spray testRare earth

The invention discloses a chemical oxidation liquid for magnesium alloy. In parts by weight, each 100 parts of the chemical oxidation liquid contains 0.012-0.039 part of mixed rare earth, 0.349-0.98 part of potassium dichromate, 0.012-0.039 part of ammonium fluoride, 0.058-0.196 part of citric acid, 0.012-0.039 part of boric acid, 0.093-0.235 part of aluminium potassium sulfate, 0.058-0.157 part of acetic acid and the balance of water, and the pH value is 2.0-2.5. A magnesium alloy test sample passivated by the chemical oxidation liquid can bear a neutral salt spray test for more than 48 hours, has good corrosion resistance, and has good coating adhesion; the chemical oxidation liquid is low in chromate concentration, short in passivating time and high in film forming speed, can be widely applied to surface treatment of a magnesium alloy profile, a magnesium alloy cast and other products.

Owner:SHANXI UNIV OF CHINESE MEDICINE

Silicate blue-white passivation solution and preparation method thereof

InactiveCN107574430AColorfulUniform film formationMetallic material coating processesHazardous substanceMetallic materials

The invention discloses a silicate blue-white passivation solution and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The silicate blue-white passivation solution consists of 26-34g / L of sodium silicate, 2-4g / L malic acid, 8-12g / L sodium fluoride, 9-14mL / L hydrogen peroxide, 8-13mL / L amino trimethylene phosphonic acid and the balance water, and the pH of the silicate blue-white passivation solution is 3.0-3.5. The preparation method of the silicate blue-white passivation solution comprises the steps that sodium silicate, malic acid, sodiumfluoride, amino trimethylene phosphonic acid and hydrogen peroxide are sequentially added to deionized water and are mixed uniformly, water is added for constant volume treatment till the required volume is reached, and the pH is adjusted to 3.0-3.5 by adopting sulfuric acid, thus the silicate blue-white passivation solution is obtained. A zinc coating passivation film after the treatment by thesilicate blue-white passivation solution is blue-white, and is bright in color, the film forming is uniform, and the corrosion resistance is excellent; the silicate blue-white passivation solution isfree of trivalent chromium, sexavalent chrome and other hazardous materials, so that the silicate blue-white passivation solution is environment-friendly and pollution-free; a passivation technology is simple; the passivation efficiency is high; and the film layer corrosion resistance is good.

Owner:KUNMING UNIV OF SCI & TECH

Aluminum alloy die pressed casting passivation solution, preparation method and passivation treatment method

InactiveCN107641803AImprove conductivityImprove passivation qualityMetallic material coating processesDie castingCobalt salt

The invention provides a corrosion resistant natural color passivation solution for an aluminum alloy die pressed casting. The passivation solution is prepared from the following components in percentage by mass: 1 to 10 percent of trivalent chromium salt, 1 to 8 percent of zirconium salt compound, 0.1 to 5 percent of mixed accelerant, 0.01 to 0.05 percent of surfactant and the balance of water, wherein the mixed accelerant is a mixture of cobalt salt, sodium fluoride and sodium nitrate with a mass ratio of (0.5 to 2) to (0.5 to 2) to (5 to 15). The invention also provides a preparation methodof the passivation solution and a method for performing corrosion resistant natural color passivation treatment on the surface of the aluminum alloy die pressed casting. A film obtained by the methodhas natural color, is uniform and dense, has strong corrosion resistance and good conductivity and does not affect natural color metal texture of die-cast aluminum.

Owner:深圳市鸿美特科技有限公司

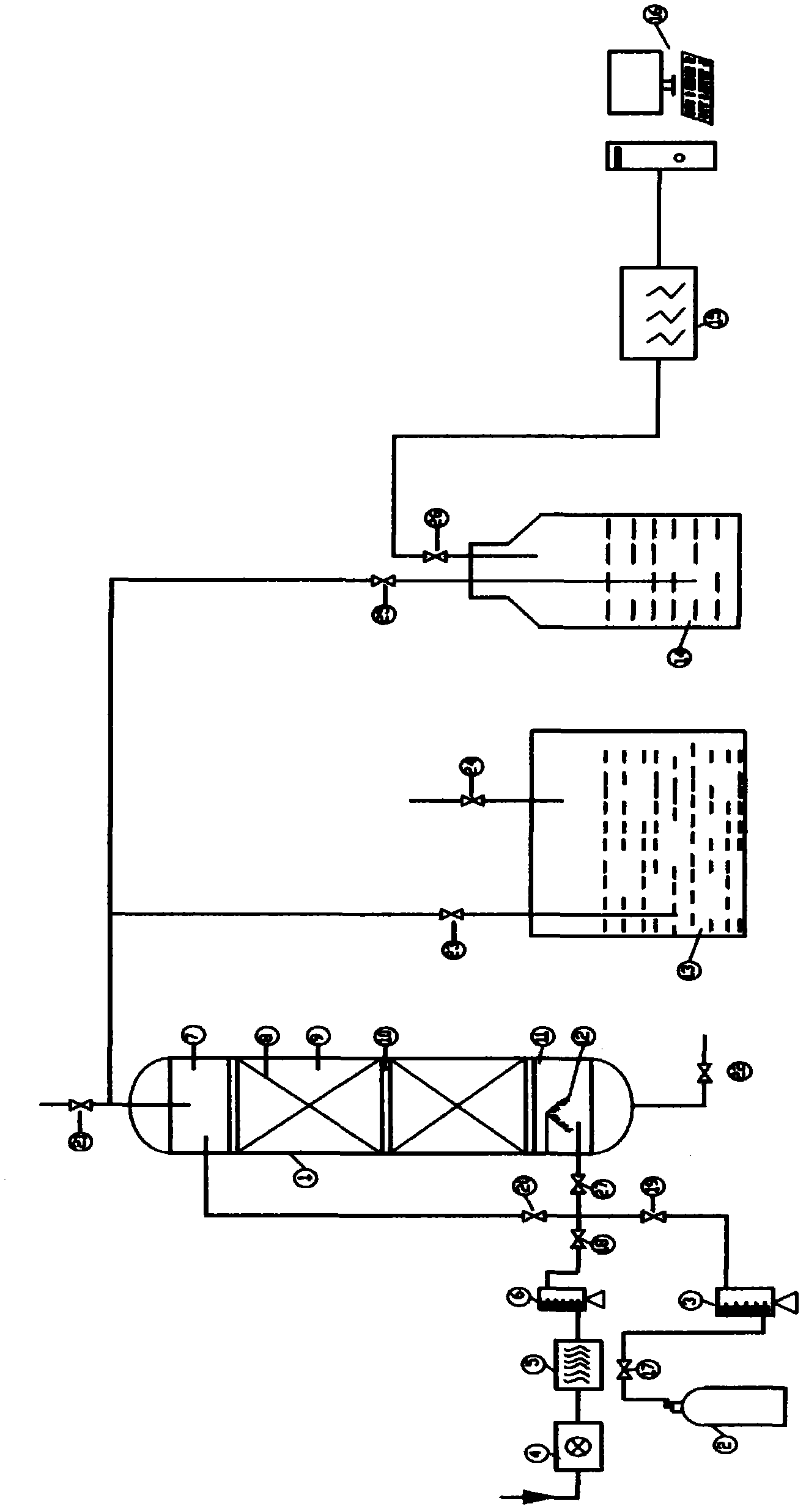

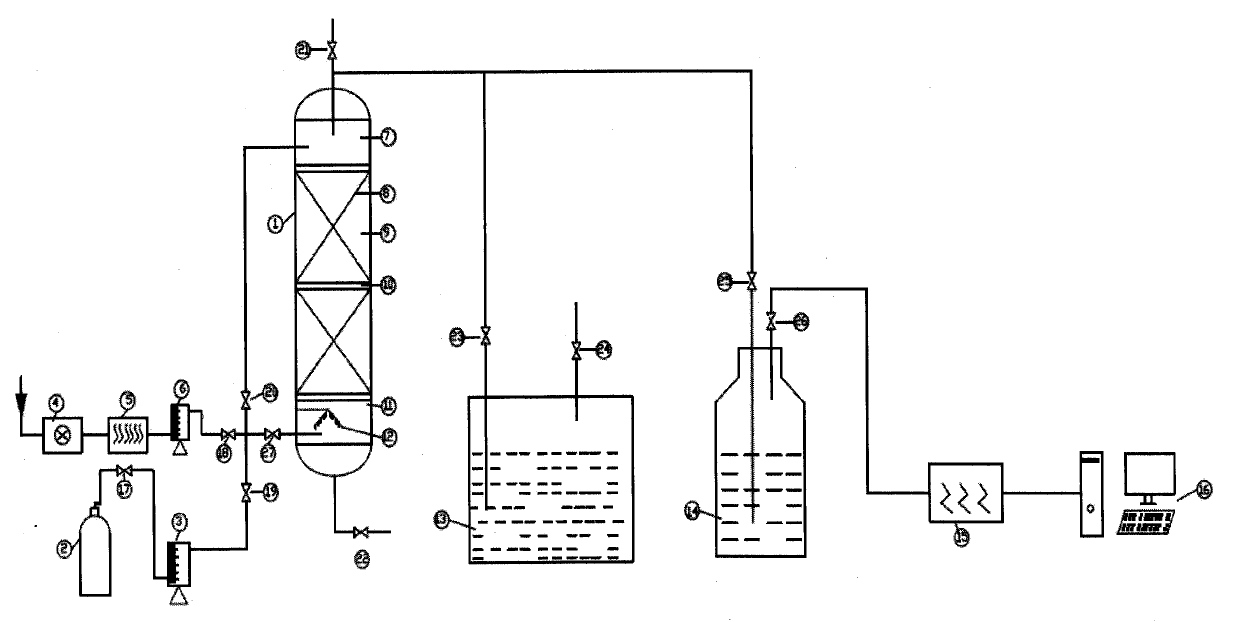

Gas-phase passivation system for petrochemical device

The invention discloses a gas-phase passivation system for a petrochemical device. The gas-phase passivation system comprises a gas-phase passivation device, a tail gas treatment device and a data analysis device, wherein the tail gas treatment device is connected with the gas-phase passivation device and is used for treating harmful gases generated in a passivation process; the tail gas treatment device further comprises a lye tank in which 10 percent sodium hydroxide solution is accommodated, a tail gas valve and an exhausting valve; the data analysis device is connected with the gas-phase passivation device and is used for detecting data of combustible gases before gas-phase passivation and linearly detecting the concentration of sulfur dioxide (SO2) generated by passivation in a gas-phase passivation process; and the data analysis device further comprises a gas drying apparatus, a gas chromatograph, a metering machine, an air inlet monitoring valve and an air outlet monitoring valve. By the passivation system, waste gases are easy to treat, and the waste gases generated by gas-phase passivation can meet the discharge standard after being treated simply.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stainless steel passivation process

InactiveCN103451646BPromote passivation reactionGuaranteed cleanlinessMetallic material coating processesAcetic acidElectrolysis

The invention relates to a stainless steel passivation process. The stainless steel passivation process comprises the following steps: mechanically polishing stainless steel; placing the stainless steel into a deoiling solution for soaking for 10-15min at normal temperature so as to remove oil stain on the surface of the stainless steel; further placing the stainless steel into an acid washing solution for soaking for 6-8min so as to remove oxide scales and corrosion products on the surface of the stainless steel; then placing the stainless steel into an electrolyte prepared by H3PO4, polyethylene glycol, H2SO4 and glucose, performing electrolysis for 6-7min at the temperature of 40-80 DEG C by adopting voltage of 6-8V, and washing the surface with deionized water to enable the surface to be smooth after the end of electrolysis; placing the stainless steel into a 5%-10% NaHCO3 solution for soaking for 3-6min at normal temperature to neutralize the residual electrolyte on the surface; placing the stainless steel into a passivation solution prepared by citric acid and acetic acid for soaking for 30-60min at room temperature; placing the stainless steel into a 5%-7% NaHCO3 solution for neutralizing for 3-5min at room temperature, and then completely washing with the deionized water; and drying.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Non-chromium inactivating technique of aluminum pipe for refrigerator, ice chest evaporator and deactivation liquid

ActiveCN100513639CImprove corrosion resistanceSimple passivation processMetallic material coating processesChromium freeSilanes

The invention relates to a chromium-free passivation process and a passivation solution for aluminum tubes used in evaporators of refrigerators and freezers. The invention belongs to the technical field of surface treatment of aluminum materials and aims to improve the corrosion resistance of aluminum tubes used in evaporators of refrigerators and freezers. The continuously extruded aluminum tube is cooled, quickly passivated in a passivation solution at 20°C to 90°C, and then air-dried and solidified to form a passivation film on the surface of the aluminum tube. The passivation solution contains a passivation agent The mass concentration of alkyl phosphate is 1-15%, the mass concentration of silane coupling agent is 0.1-0.5%, the mass concentration of sodium silicate is 0.01-0.15%, and the rest is water. The passivated aluminum tube is dried with wind at 20-60°C and then packaged on a turntable. The process flow is simple, the cost is low, the speed is fast, the corrosion resistance of the passivated aluminum tube is greatly improved, and the agent and the passivation process are safe and environment-friendly.

Owner:CENT SOUTH UNIV

Chromium-free passivation method of aluminum pipe for evaporator of refrigerator or freezer and passivation solution thereof

ActiveCN101775596BImprove corrosion resistanceSimple passivation processMetallic material coating processesChromium freePhosphate

Owner:CENT SOUTH UNIV +1

Environment-friendly composite color passivation solution and preparation method thereof

InactiveCN108531900ABright colorUniform thicknessMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite color passivation solution and a preparation method thereof, and belongs to the technical field of surface treatment of metal materials. The passivation solution comprises the components of 5-8g / L of tannic acid, 4-8mL / L of titanium trichloride, 4-7mL / L of nitric acid, 15-20mL / L hydrogen peroxide, 2-5mL / L concentrated sulfuric acid, 8-12mL / L of phosphoric acid, 2-7g / L of sodium silicate, 6-10g / L of potassium fluoride, 2-5mL / L of ascorbic acid, 4-7mL / L of aminotrimethylene fork phosphonic acid, and the balance water, and the pH value is1.5-2.0. A zinc plating coating passivation film treated by the passivation solution is bright in color, uniform in color and film thickness and excellent in corrosion resistance; and the passivationsolution has no trivalent chromium, hexavalent chromium and other harmful substances, environmental protection and no pollution are achieved, the passivation process is simple, the passivation efficiency is high, and corrosion resistance of the film is good.

Owner:KUNMING UNIV OF SCI & TECH

Recipe design for enabling aluminum alloy spraying oil removal groove and chromate-free passivation groove chemical to be compatible

InactiveCN109706460AReduce manufacturing costRun smoothlyMetallic material coating processesIonCorrosion inhibitor

The invention discloses recipe design for enabling an aluminum alloy spraying oil removal groove and chromate-free passivation groove chemical to be compatible. The recipe design thoroughly solves theproblems that a 1# oil removal groove and a 4# chromate-free passivation groove are not stable, fluorine-containing sludge is generated on the groove bottom easily, and toxic and dangerous waste needs to be cleared manually. Stable ingredients of groove liquid in a traditional oil removal groove and a chromate-free passivation groove are insufficient and are decomposed and deposited easily; and ingredients of oil removing liquid is brought into the 4# chromate-free passivation groove through a 3# water washing groove, and incompatibility is caused. By means of the design for enabling the ingredients of the 1# oil removing groove and the ingredients of the 4# chromate-free passivation groove to be compatible, the oil removing liquid does not consume chromate-free passivation groove chemical and can supplement ingredients, and the production cost is reduced. By means of addition of a corrosion inhibitor, a chelating agent and bonderite, and chelation with positive ions, generation of fluoride and hydroxide is eradicated, it is ensured that the groove liquid is not turbid or deposited, and aluminum alloy powder spraying chromate-free passivation pre-treatment stable production is achieved.

Owner:熊映明

Rare earth modified surface treating agent for copper and copper alloys and preparation method thereof

ActiveCN102071415BImprove corrosion resistanceShort passivation timeMetallic material coating processesRare earthSulfosalicylic acid

The invention discloses a rare earth modified surface treating agent for copper and copper alloys and a preparation method thereof. The surface treating agent per liter comprises the following raw materials by weight: 1-3g of benzotriazole, 1-5g of sodium molybdate, 0.1-0.3g of sodium silicate, 0.3-0.6g of rare earth salt, 10-20g of complexing agent, 6-10g of sulfosalicylic acid, 0.2-0.6g of surfactant, a small amount of pH regulator and the balance water. The surface treating agent of the invention can be used for passivation at the room temperature, have short passivation time and be green and environmentally friendly; the passivated copper or copper alloy surface has good corrosion resistance; and the treating agent has simple treatment technology and is convenient for actual production.

Owner:合肥华清斯特凯新材料有限公司

Reverse tandem water-saving device for aluminium alloy spraying pre-treatment chromium-free passivating line cleaning water

ActiveCN109504959ASolve pollutionImprove stabilityMetallic material coating processesChromium freeWater saving

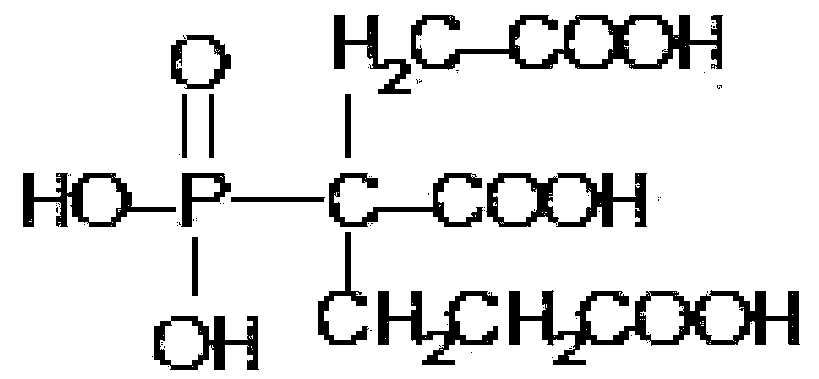

The invention discloses a reverse tandem water-saving device for aluminium alloy spraying pre-treatment chromium-free passivating line cleaning water. A 6# slot, a 5# slot, a 3# slot and a 2# slot arein reverse tandem connection; cleaning water is in reverse tandem flow through the 6# slot, the 5# slot, the 3# slot and the 2# slot; an oil remover is contained in a 1# oil removal slot; the oil remover is prepared from the following chemical components: fluotitanic acid, fluozirconic acid and phosphonobutane tricarboxylic acid; and a chromium-free passivating agent is contained in a 4# chromium-free passivating slot, and the chromium-free passivating agent is prepared from the following chemical components: fluotitanic acid, fluozirconic acid and phosphonobutane tricarboxylic acid. All metal cations are chelated by utilizing the unique design which is compatible with a medicament in the 4# chromium-free passivating slot, and chemical properties with ultra-strong chelating ability on PBTCA, so that the 1# slot to 6# slot are kept to be not muddy and free of precipitates; and two sets of cleaning water are in reverse tandem connection, so that one half of cleaning water is reduced, treatment amount of fluorine-containing wastewater is greatly reduced, conventional pure water cleaning is abandoned, and production and environment-friendly cost is greatly reduced.

Owner:熊映明

Gas-phase passivation system for petrochemical device

ActiveCN101988179BEasy to handleLow costSolid state diffusion coatingGas phaseVapor phase chromatography

The invention discloses a gas-phase passivation system for a petrochemical device. The gas-phase passivation system comprises a gas-phase passivation device, a tail gas treatment device and a data analysis device, wherein the tail gas treatment device is connected with the gas-phase passivation device and is used for treating harmful gases generated in a passivation process; the tail gas treatment device further comprises a lye tank in which 10 percent sodium hydroxide solution is accommodated, a tail gas valve and an exhausting valve; the data analysis device is connected with the gas-phase passivation device and is used for detecting data of combustible gases before gas-phase passivation and linearly detecting the concentration of sulfur dioxide (SO2) generated by passivation in a gas-phase passivation process; and the data analysis device further comprises a gas drying apparatus, a gas chromatograph, a metering machine, an air inlet monitoring valve and an air outlet monitoring valve. By the passivation system, waste gases are easy to treat, and the waste gases generated by gas-phase passivation can meet the discharge standard after being treated simply.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stainless steel electrolytic passivator, preparation method and application thereof

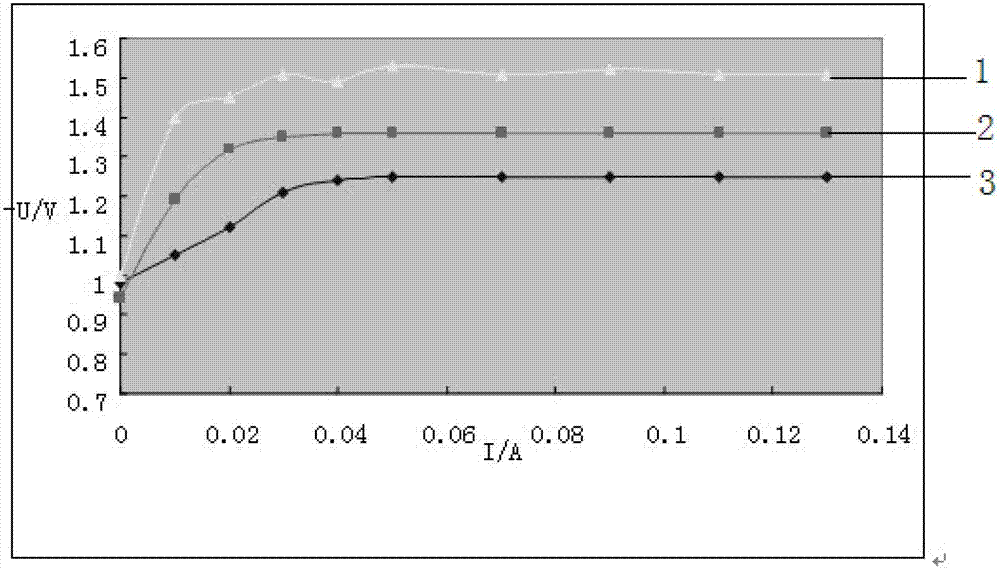

ActiveCN109957826AEnvironmentally friendly ingredientsReduce consumptionAnodisationSurface finishingSulfuric acid

The invention relates to the technical field of stainless steel surface treatment, in particular to a stainless steel electrolytic passivator, a preparation method and application thereof. The stainless steel electrolytic passivator is prepared from the following raw materials: sulfuric acid, manganese sulfate, a corrosion inhibitor, a wetting agent and water. Compared with an existing passivator,the stainless steel electrolytic passivator is more environment-friendly in components, faster in electrolytic passivation efficiency under the action of a specific current and thicker in passivationfilms on the surface of stainless steel after passivation, higher corrosion resistance requirements are met, and the service life of stainless steel products is prolonged.

Owner:Dongguan Kaimeng Chemical Co Ltd

Environment-friendly blue-white passivation liquid and preparation method thereof

InactiveCN108754475AImprove corrosion resistanceUniform film formationMetallic material coating processesEnvironmental resistanceThiourea

The invention discloses environment-friendly blue-white passivation liquid and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The passivation liquid comprises the components of 4-8 g / L of sodium silicate, 23-27 g / L of sodium nitrate, 1-5 g / L of nickel sulfate, 3-7 mL / L of titanium trichloride, 8-12 mL / L of hydrogen peroxide, 3-7 g / L of succinic acid, 0.35-0.45 g / L of benzylidene acetone, 1-3 g / L of thiourea and the balance deionized water, and the pH value is 0.5-1.5. The preparation method of the passivation liquid comprises the steps that the sodium silicate is dissolved in the deionized water; then the sodium nitrate, the nickel sulfate, the titanium trichloride, the hydrogen peroxide, the succinic acid, the benzylidene acetone andthe thiourea are sequentially added and evenly mixed; the deionized water is added to conduct constant volume to the required volume; and sulfuric acid is adopted to adjust the pH value to be 0.5-1.5,and then the silicate blue-white passivation liquid is obtained. A zinc coating passivation film treated through the passivation liquid is blue white, the color is bright, film forming is uniform, corrosion resistance is excellent, the passivation liquid does not contain trivalent chromium, hexavalent chromium and other harmful substances, environmental protection is achieved, pollution is avoided, the passivation process is simple, the passivation efficiency is high, and the film layer corrosion resistance is good.

Owner:KUNMING UNIV OF SCI & TECH

High-crack-resistance passivating agent

InactiveCN108441849AExcellent anti-rustImprove wear resistanceMetallic material coating processesCrack resistanceDiethylenetriamine

The invention discloses a high-crack-resistance passivating agent. The high-crack-resistance passivating agent comprises, by weight, 3-9 parts of sec-alkyl sodium sulfate, 10-20 parts of high magnesium powder, 4-8 parts of urotropine, 2-8 parts of organic phosphonic acid, 1-10 parts of barium metaborate, 1-5 parts of polyoxyethylene monolaurate, 1-5 parts of N-phenyl-naphthylamine, 5-15 parts of anti-crack agents, and 1-5 parts of diethylenetriamine. The high-crack-resistance passivating agent has excellent rust resistance, abrasion resistance, corrosion resistance and crack resistance and ishigh in passivating efficiency and short in passivating time, a passivation film can be rapidly formed on the surface of metal, and the film is uniform and compact and has good surface smoothness.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Popular searches

To achieve the goal of green environmental protection Easy to produce Meet environmental protection requirements High speed No process changes required Meet corrosion resistance requirements Improve surface corrosion resistance Improve surface condition Simple preparation process Strong corrosion resistance

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com