Patents

Literature

38results about How to "Improve passivation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing back fully-passivated contact solar cell by utilizing tubular PECVD and back fully-passivated contact solar cell

InactiveCN111106183AThere will be no plating phenomenonNo burstFinal product manufacturePhotovoltaic energy generationScreen printingEngineering

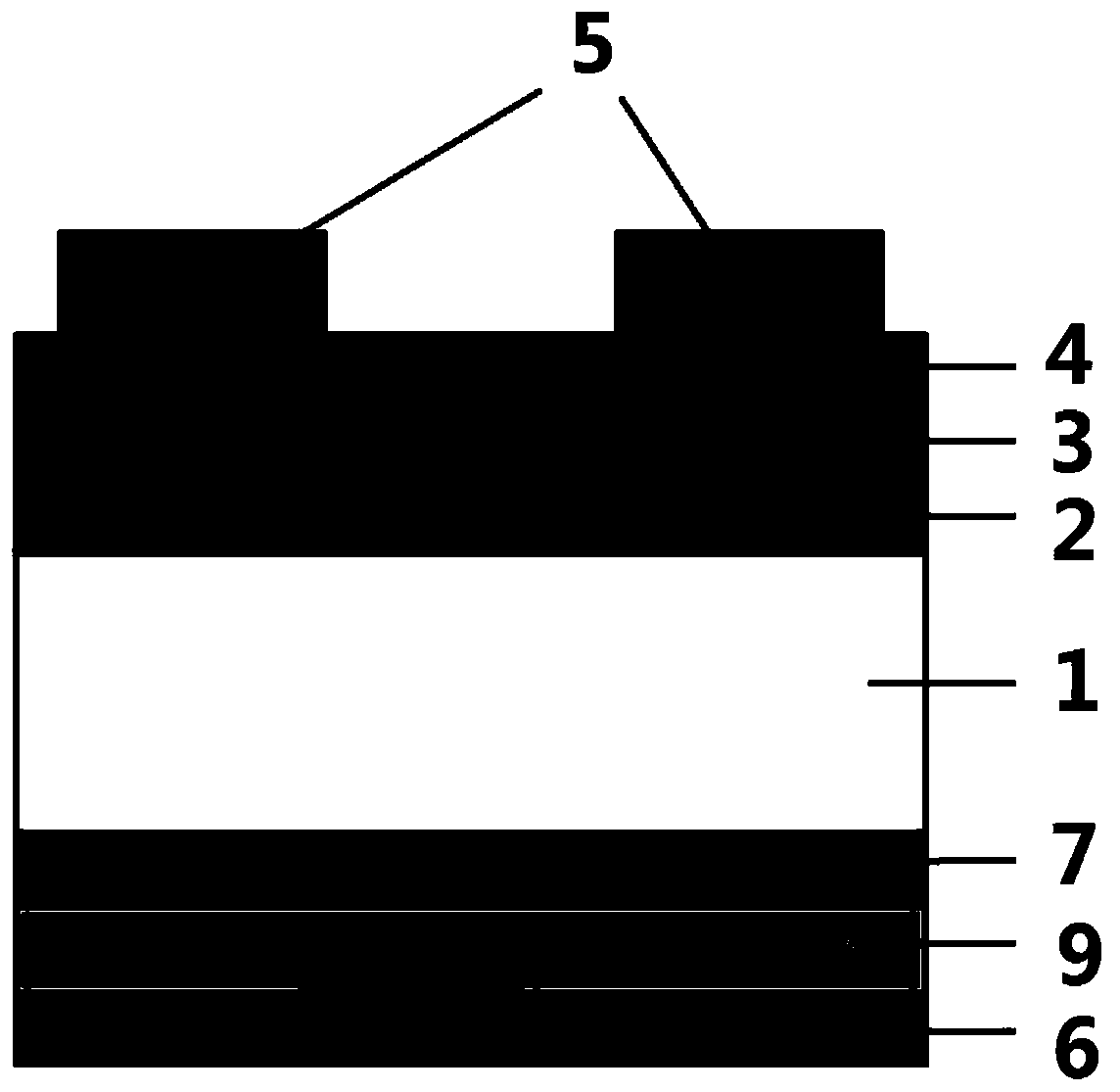

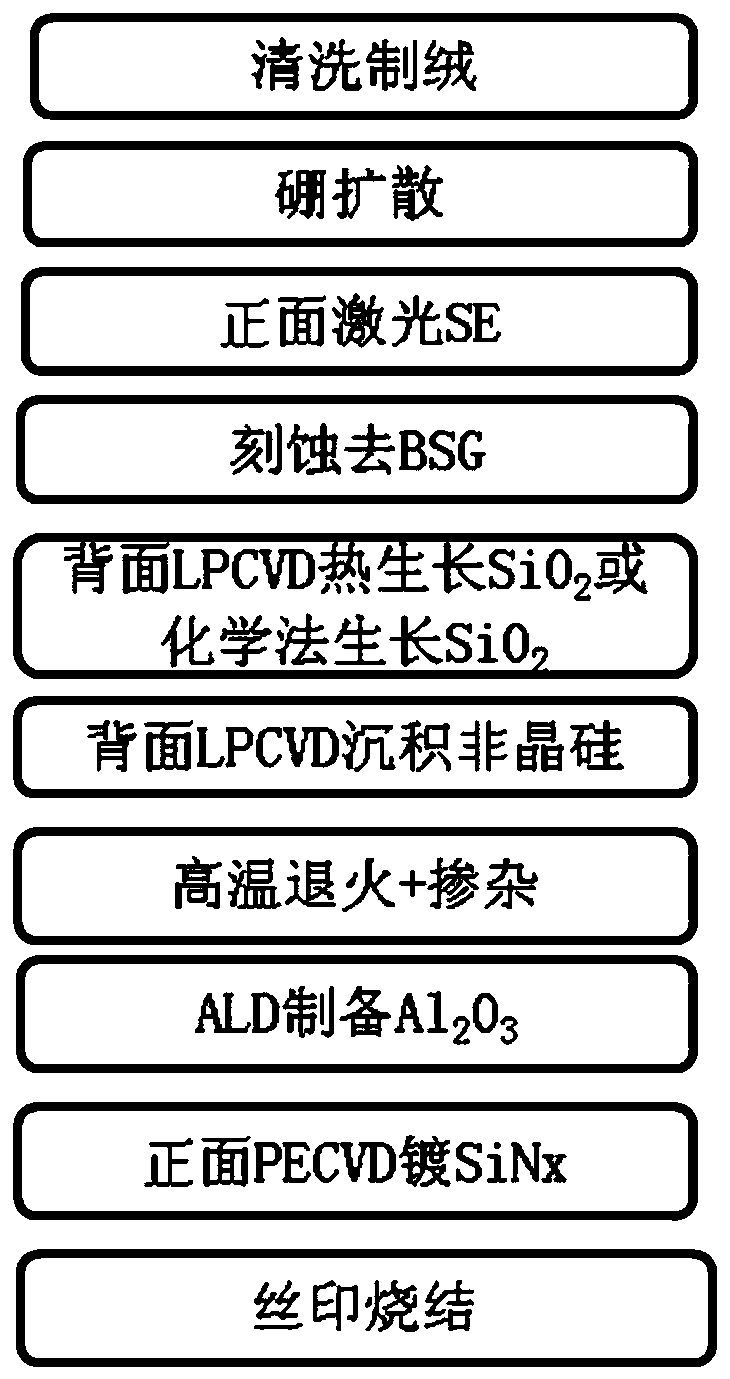

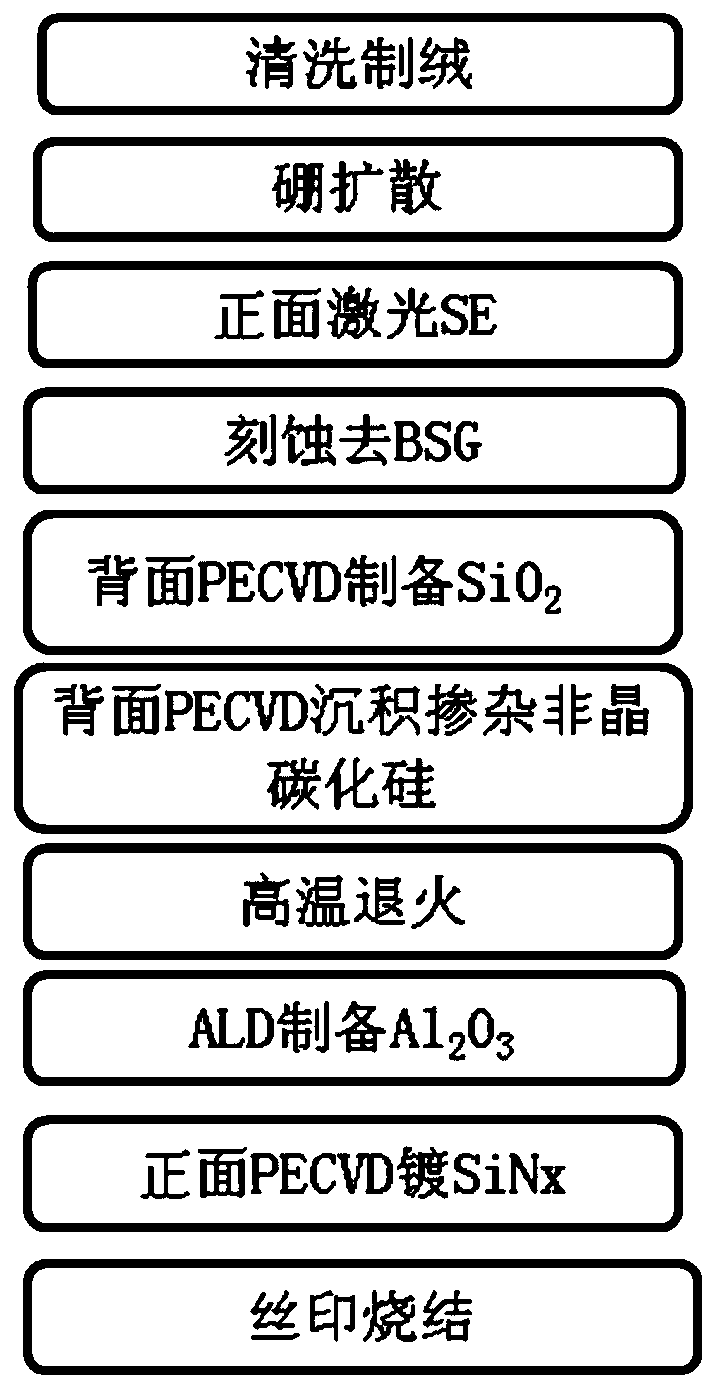

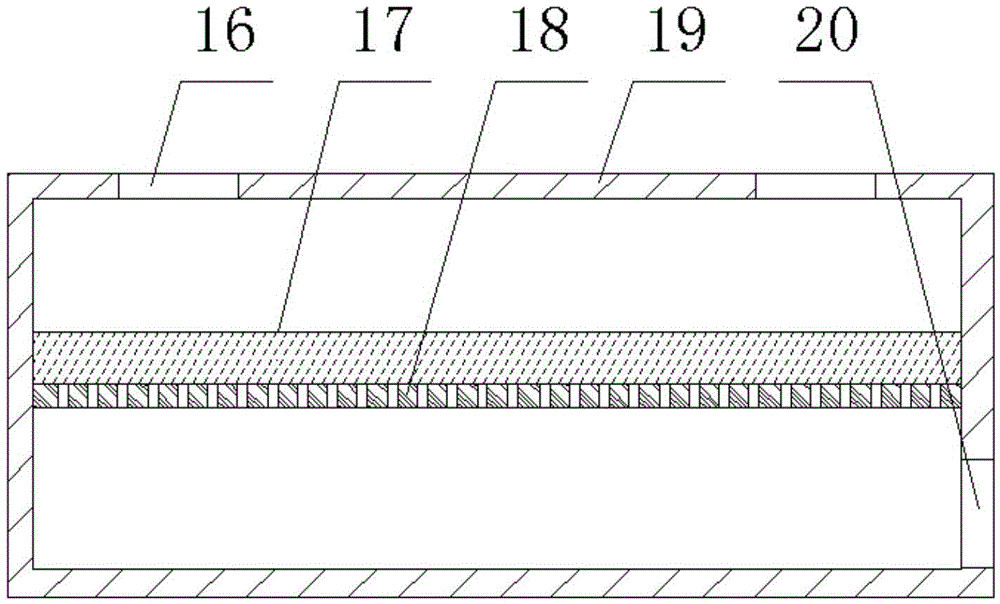

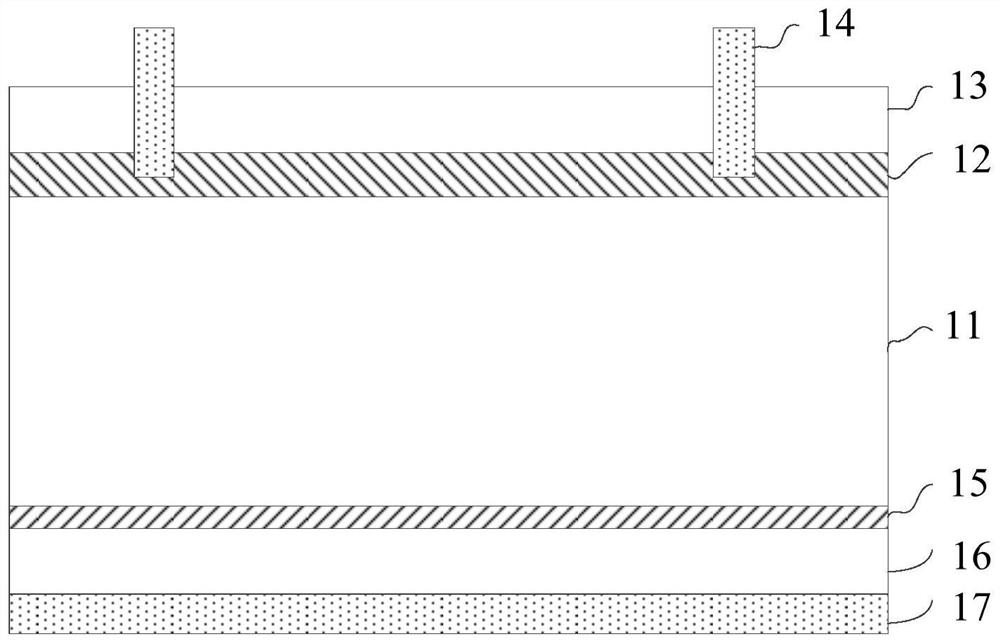

The invention discloses a method for preparing a back fully-passivated contact solar cell by utilizing tubular PECVD and the back fully-passivated contact solar cell. The method comprises the steps of carrying out pre-cleaning, double-sided texturing, front boron diffusion, front laser selective doping, secondary cleaning and back polishing on a silicon wafer; depositing a silicon dioxide thin film layer and a phosphorus-doped amorphous silicon carbide thin film layer on the back surface of the tubular PECVD equipment, and performing annealing treatment to convert amorphous silicon carbide into microcrystalline silicon carbide; depositing an Al2O3 passivation layer and an antireflection layer; and performing silk-screen printing and sintering to obtain the back fully-passivated contact solar cell. The method disclosed by the invention has the advantages of simple process, convenience in operation, low cost, good compatibility with the existing production line, good preparation controllability, high preparation efficiency, good safety and the like, can be used for preparing the high-efficiency back fully-passivated contact solar cell, is suitable for large-scale preparation, is beneficial to industrial application, and has a very high use value and a very good application prospect.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

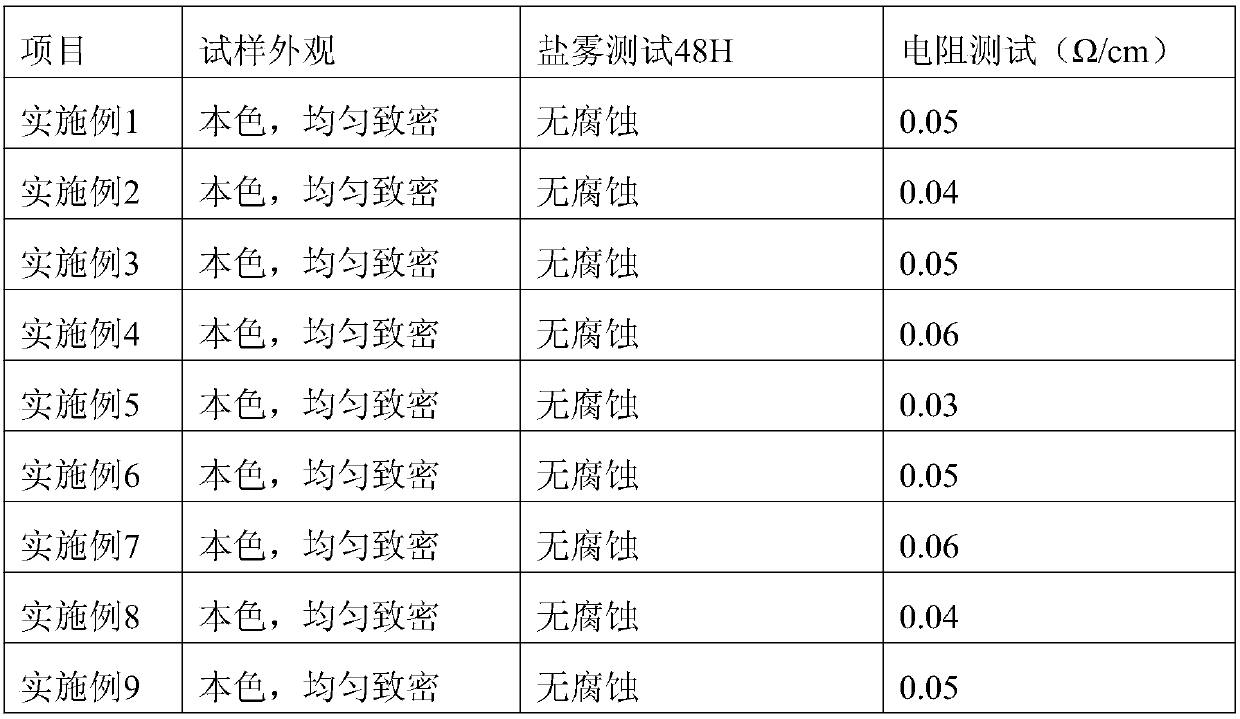

High corrosion resistance passivation solution for zinc alloy die castings and passivation method

InactiveCN104141123AImprove conductivityEasy to useMetallic material coating processesNitrateSalt spray test

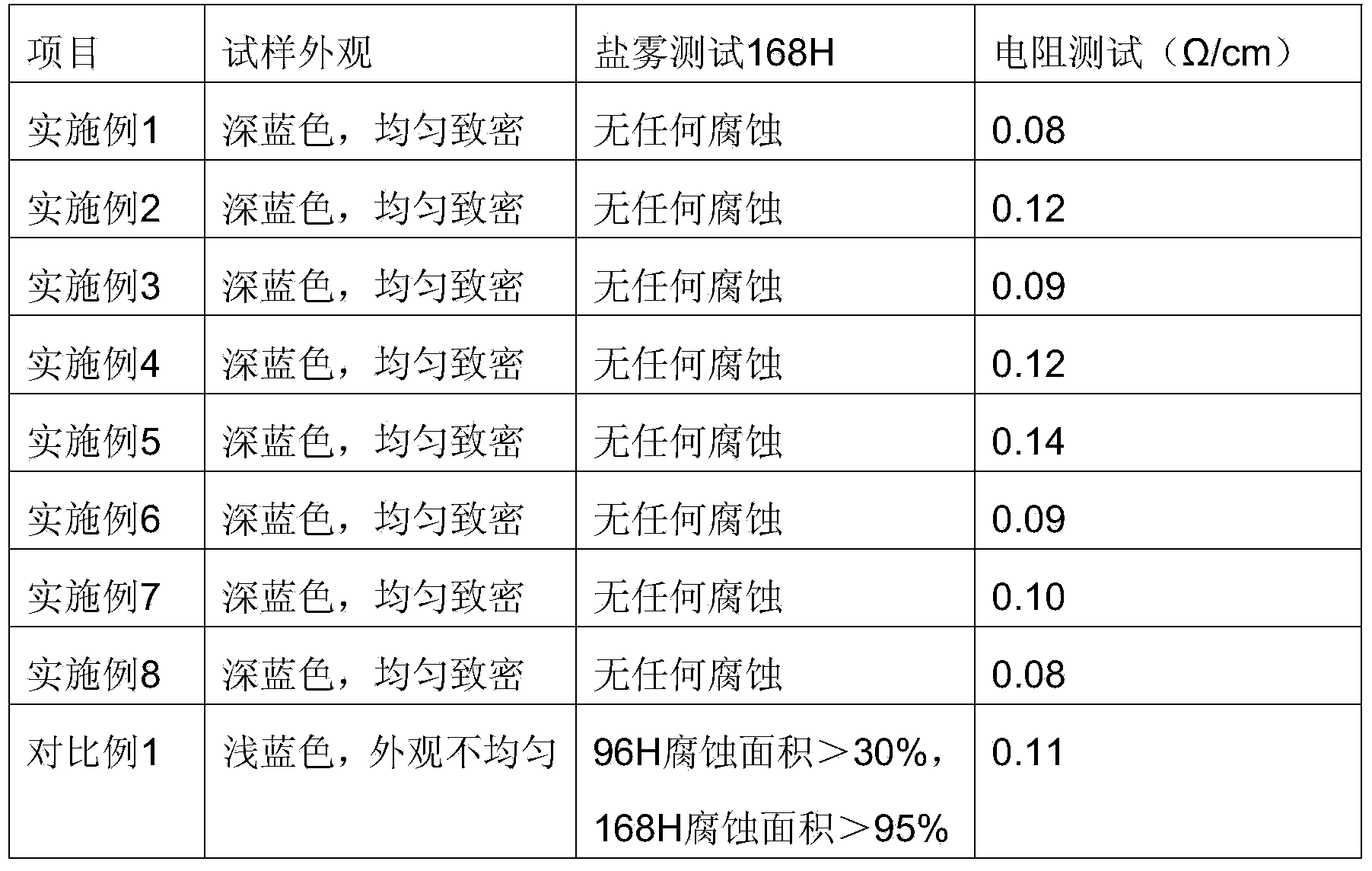

The invention provides a high corrosion resistance passivation solution for zinc alloy die castings and a passivation method. The high corrosion resistance passivation solution comprises 1% to 10% of chromic salts, 1% to 8% of rare earth compounds, 0.1% to 5% of mixed accelerant, 0.01% to 0.05% of surface active agents and the balance water. The mixed accelerant is a mixture of cerous nitrate, ammonium bifluoride and sodium nitrate, wherein the mass ratio of the cerous nitrate to the ammonium bifluoride to the sodium nitrate is (0.5-2):(0.5-2):(3-8). The cleaned zinc alloy die castings are immersed into a working solution prepared by the high corrosion resistance passivation solution to be passivated, cleaned and dried. According to the high corrosion resistance passivation solution, the components are synergized by optimizing the component formula ratio, the passivation time is short, a passivation film layer is dark blue and is uniform, compact and high in corrosion resistance, no corrosion exists in a salt spray test 168H, the electrical conductivity of the film layer is good, the zinc alloy die castings with the oxidized surfaces can be treated, the passivation quality of non-fresh zinc alloy workblanks is greatly improved, and the requirement for industrial production is met.

Owner:SHENZHEN XINMINGDA ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

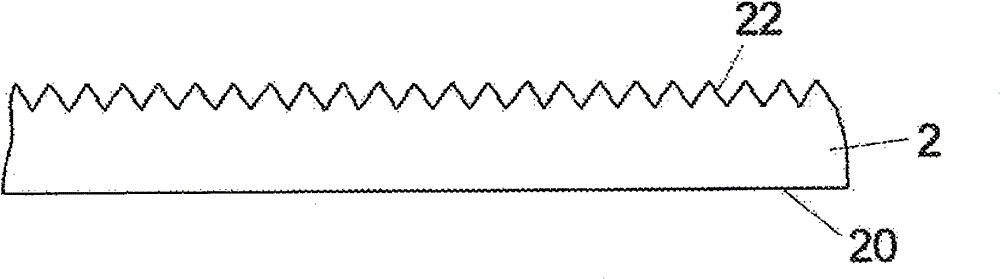

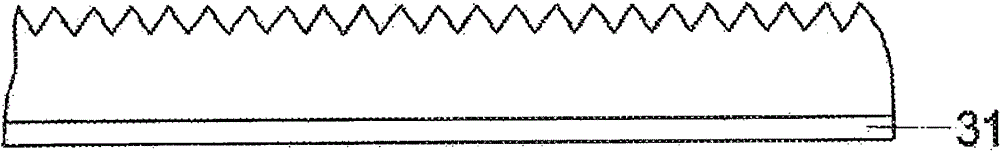

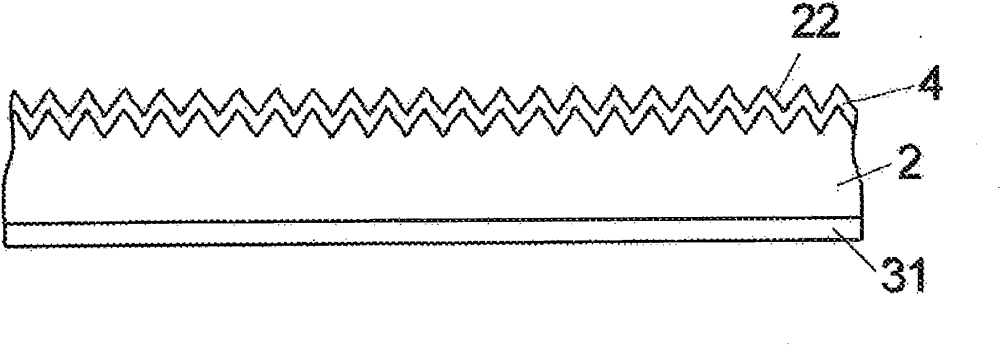

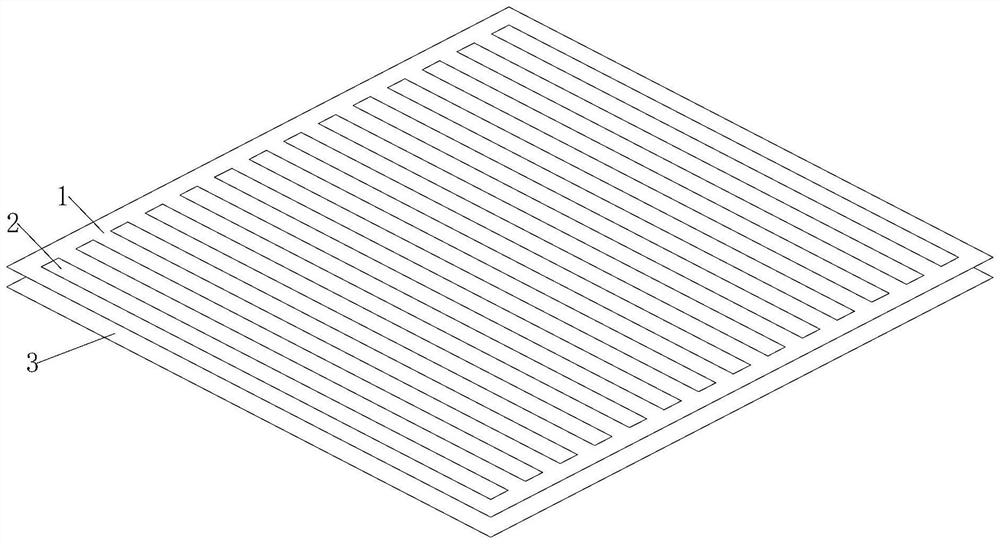

Semiconductor apparatus and method of fabrication for a semiconductor apparatus

ActiveCN102804407AImprove passivation qualityQuality improvementFinal product manufacturePhotovoltaic energy generationSolar cellSemiconductor

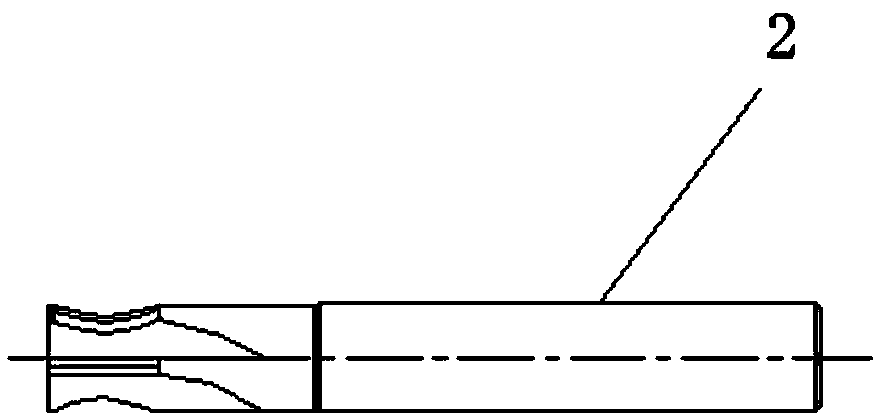

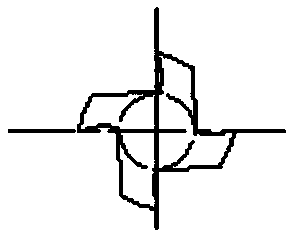

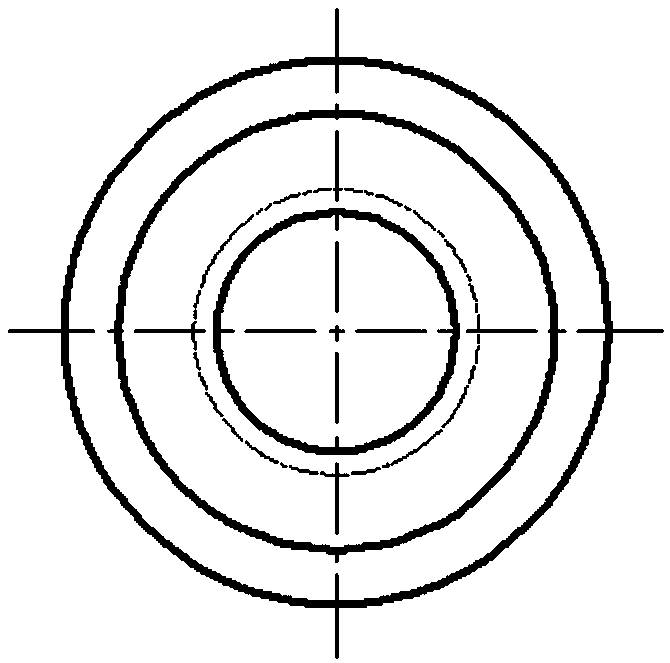

The invention relates to a semiconductor apparatus (1) and a method of fabrication for a semiconductor apparatus (1), wherein the semiconductor apparatus (1) comprises a semiconductor layer (2) and a passivation layer (3), arranged on a surface of the semiconductor layer (2), for passivating the semiconductor layer surface (20), wherein the passivation layer (3) comprises a chemically passivating passivation layer element (31) and a field-effect-passivating passivation layer (33) which are arranged above one another on the semiconductor layer surface (20). The semiconductor apparatus is preferably a solar cell.

Owner:韩华思路信

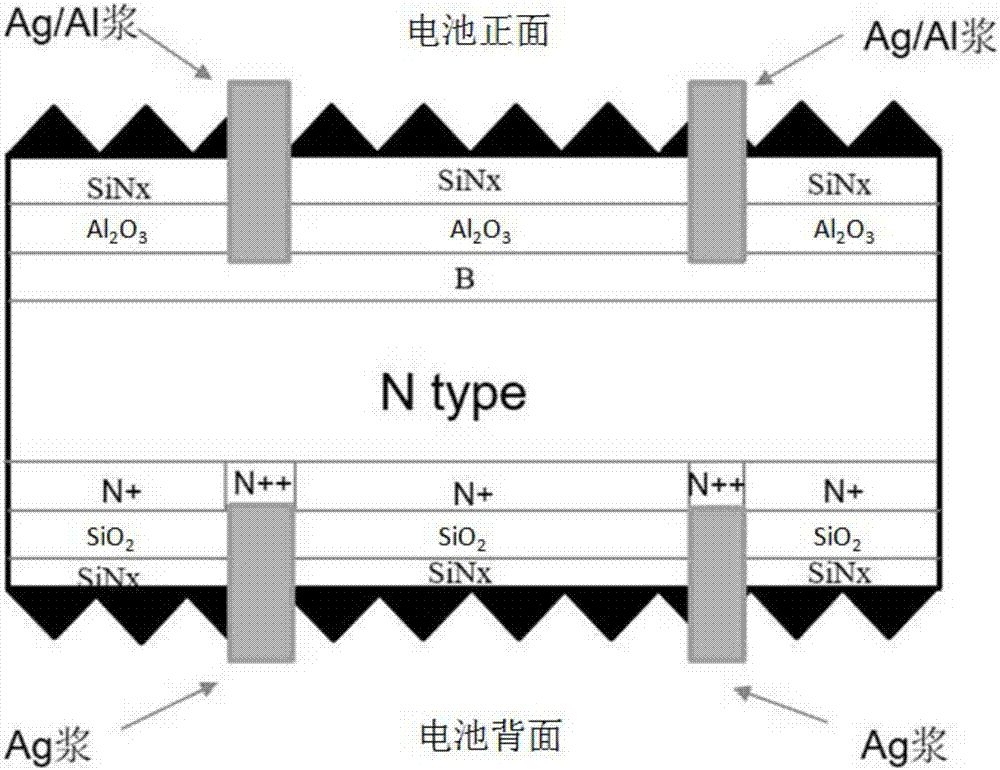

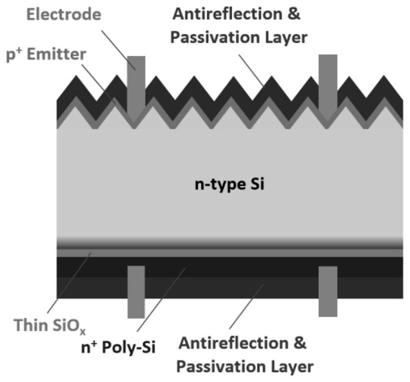

N type double face battery preparation method

ActiveCN107394006AImprove photoelectric conversion efficiencyLong transmission distanceFinal product manufacturePhotovoltaic energy generationScreen printingOptoelectronics

The invention provides an N type double face battery preparation method comprising the following steps: an N type silicon chip is subjected to double face reactive ion etching operation after undergoing damage processing operation, and therefore a nanometer pile face can be made on a surface; a front face of the N type silicon chip is subjected to boron diffusion operation after a back face of the N type silicon chip undergoes SiOx-SiNy mask layer processing operation; the front face is subjected to the SiOx-SiNy mask layer processing operation after the SiOx-SiNy mask layer on the back face is removed via an HF solution, an SiO2 layer is grown on the back face and used as a mask layer, an N++ window is formed after point perforating operation is performed under a main grid, residual damage during perforation can be removed via use of weak alkali liquor, single face phosphorus diffusion is performed on the back face of the N type silicon chip, an N++ layer is formed at a perforated position, N+ layers are formed at other areas, and the N type silicon chip is subjected to HF processing operation after edge isolation is conducted on the N type silicon chip; the SiOx-SiNy mask layer and borosilicate glass on the front face and phosphorosilicate glass on the back face are removed; RCA cleaning operation is performed; the front face and the back face of the N type silicon chip are respectively subjected to A12O3 / SiNx and lamination passivation operation, and sintering operation is conducted after screen printing operation; via the N type double face battery preparation method, Uoc, Isc and FF can be improved; photoelectric conversion efficiency of a front face of a battery can be improved.

Owner:JINKO SOLAR CO LTD +1

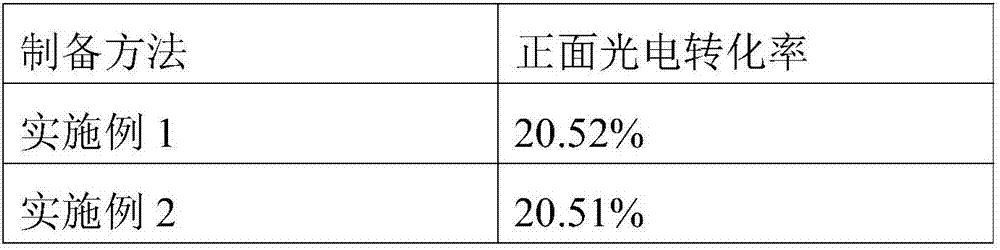

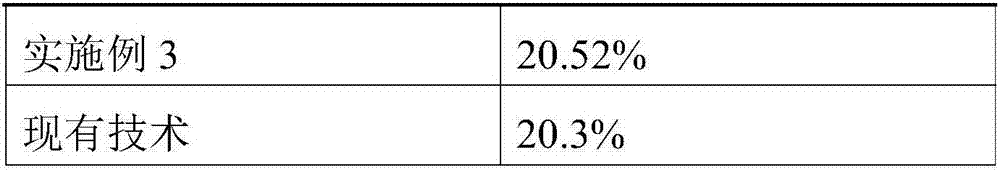

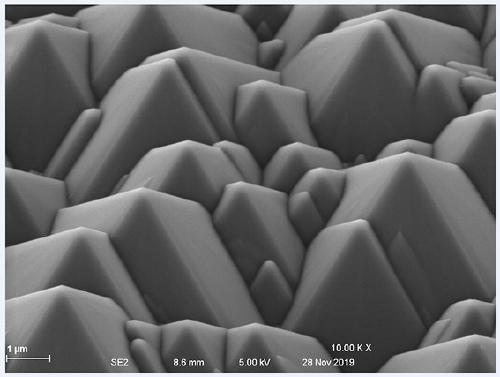

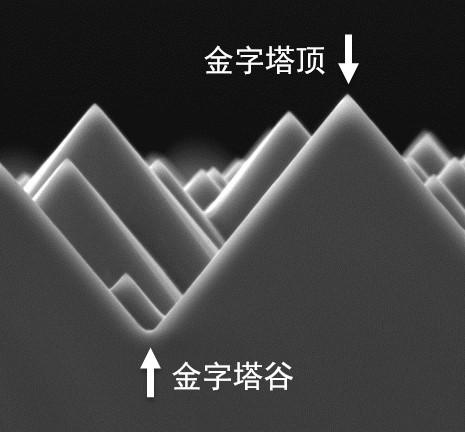

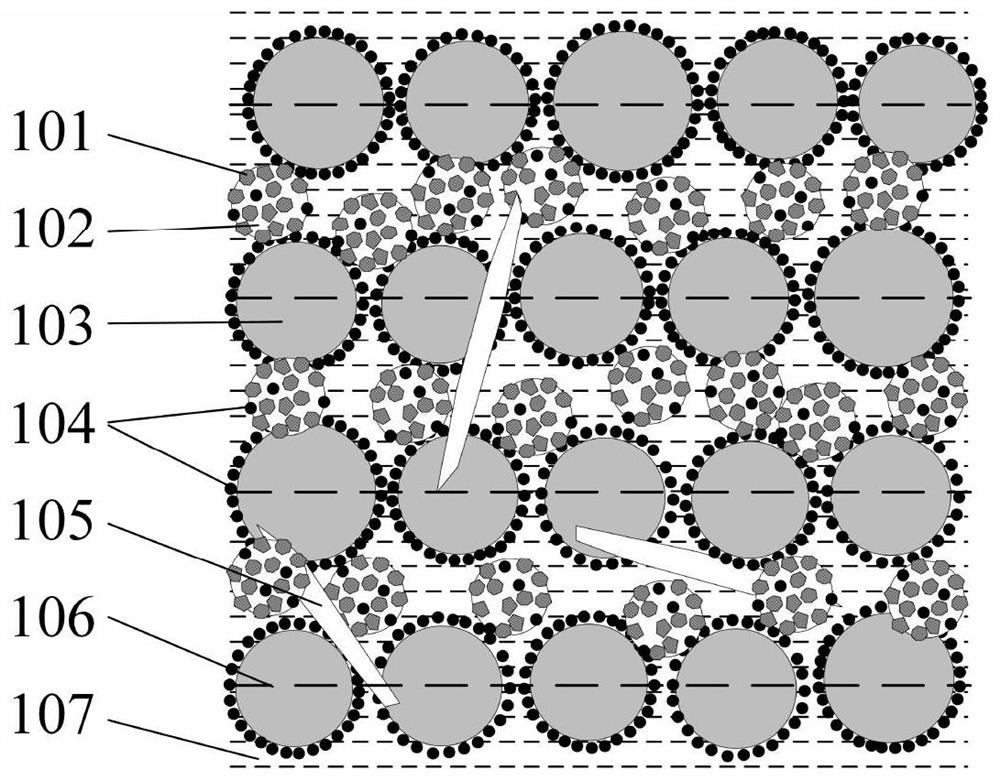

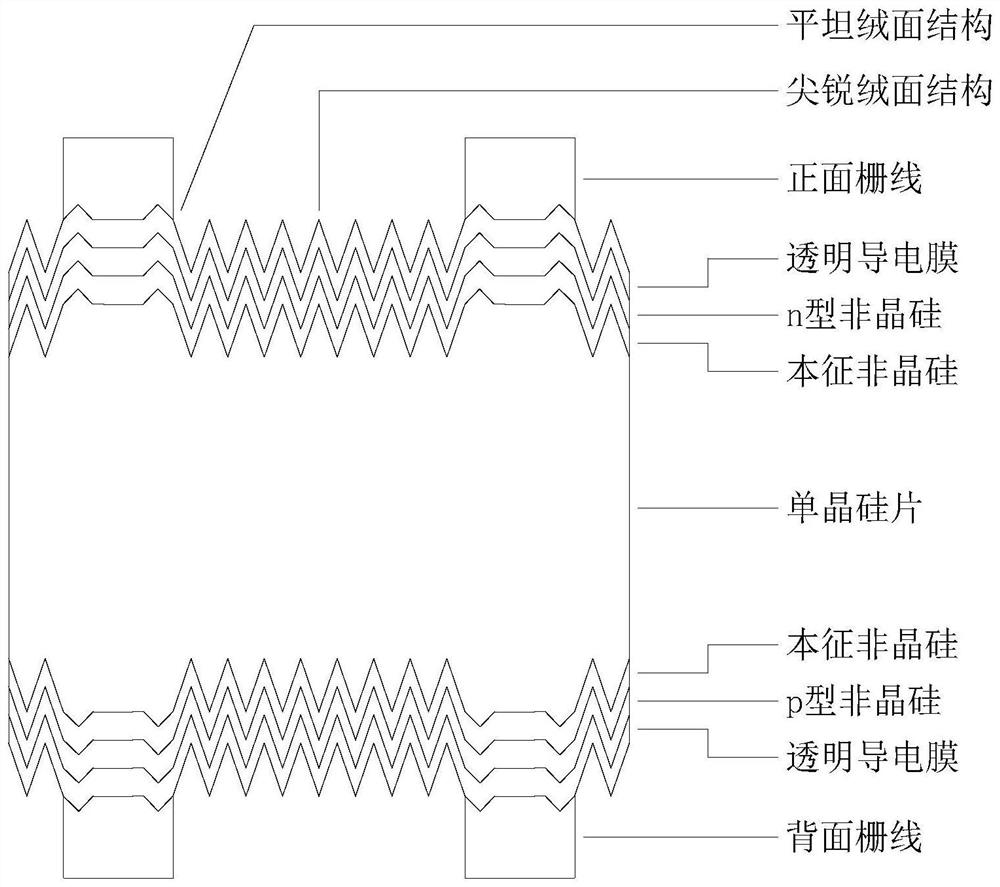

Monocrystalline silicon wafer with rounded pyramid structure and preparation method

InactiveCN111403503AImprove passivation qualityImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationHigh cellHydrofluoric acid

The invention discloses a monocrystalline silicon wafer with a rounded pyramid structure and a preparation method, and mainly relates to the field of monocrystalline texturing. The preparation methodcomprises the steps of pre-cleaning, texturing, rounding treatment, hydrofluoric acid cleaning, slow pulling, drying, and the like. In the rounded treatment process, respective characteristics of nitric acid CP and ozone CP are integrated. Pyramid rounding treatment is performed on a textured silicon wafer by using the scheme, so that the pyramid top and the pyramid valley are enabled to be smooth, the defect state density can be reduced when the amorphous silicon film is deposited, the passivation quality of the silicon wafer can be enhanced, the minority carrier lifetime can be prolonged, and thus higher cell conversion efficiency can be obtained.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

Surface plasma treatment process for tooth roller of flour mill

InactiveCN106086853AGenerate Thickness LiftIncrease the speed of passivationMetallic material coating processesSurface plasmonEconomic benefits

The invention discloses a surface plasma treatment process for a tooth roller of a flour mill. The surface plasma treatment process comprises the following steps of (1) surface polishing, (2) grease removing treatment, (3) washing treatment, (4) passivating treatment, (5) washing and drying and (6) plasma treatment. According to the surface plasma treatment process, the surface of the tooth roller is subjected to passivating treatment first, added modified nano diatomaceous earth and nano silicon dioxide improve the evenness, compactness and stability of a passivation film, and meanwhile a good antibacterial effect is achieved by the passivation film; plasma treatment is conducted after passivating treatment so that fusing of the passivation film and a substrate of the tooth roller can be improved and the hardness and the corrosion resistance of grinding teeth of the tooth roller can also be improved, and the finally the treated tooth roller has excellent strength, corrosion resistance and antibacterial and antirust performance. Compared with an existing tooth roller, the service life is prolonged by 10-12 times, flour yield is improved by about 30%, the power consumption of each ton of flour is reduced by 15-18 KW.h, and the economic benefit is obviously improved.

Owner:WUHE HUANGHUAI GRAIN & OIL MACHINERY CO LTD

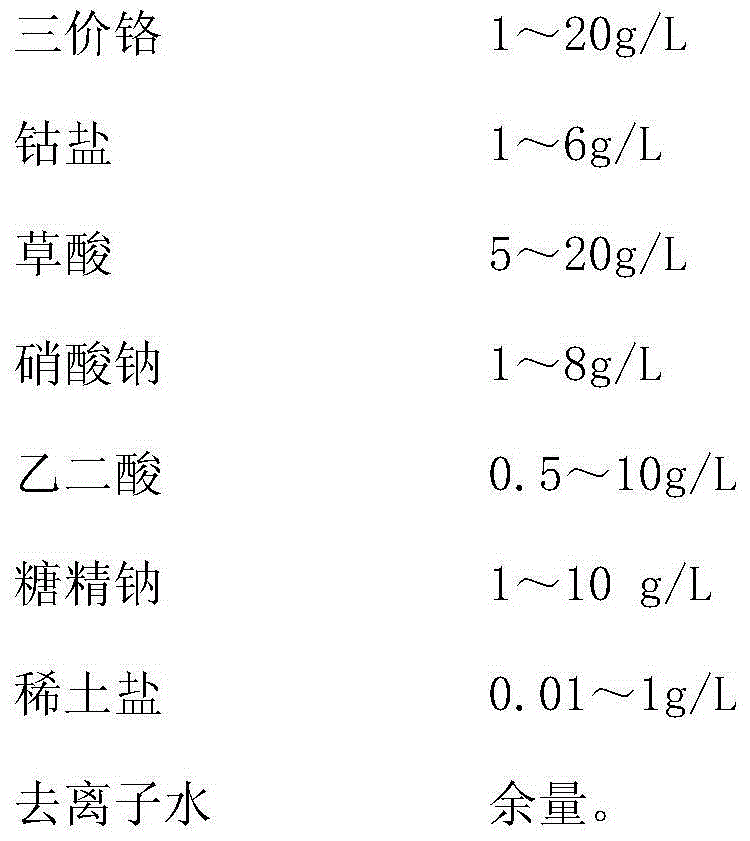

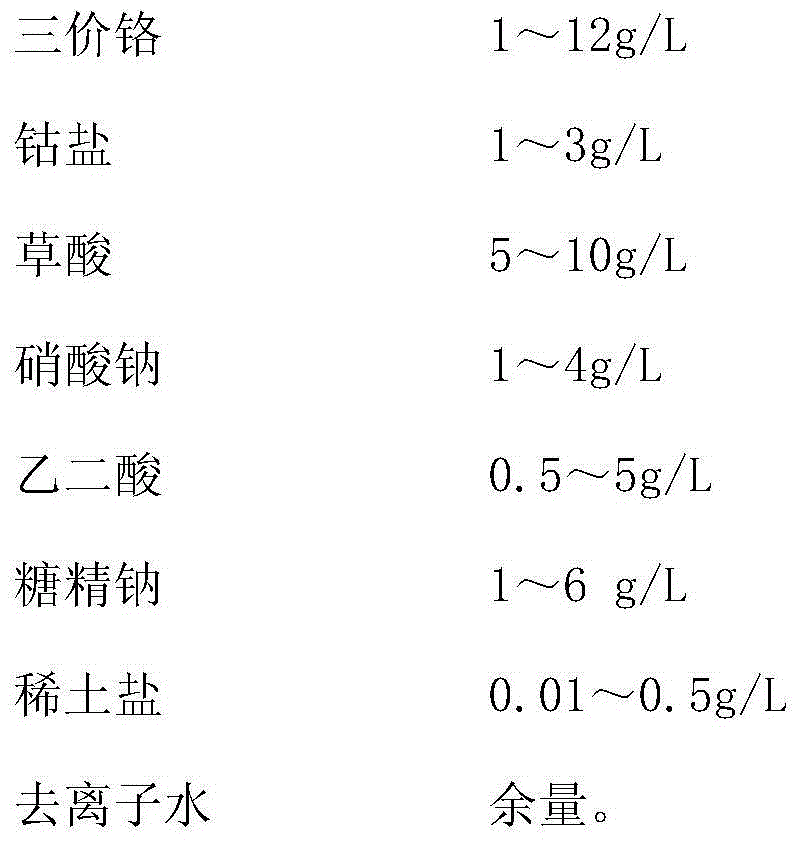

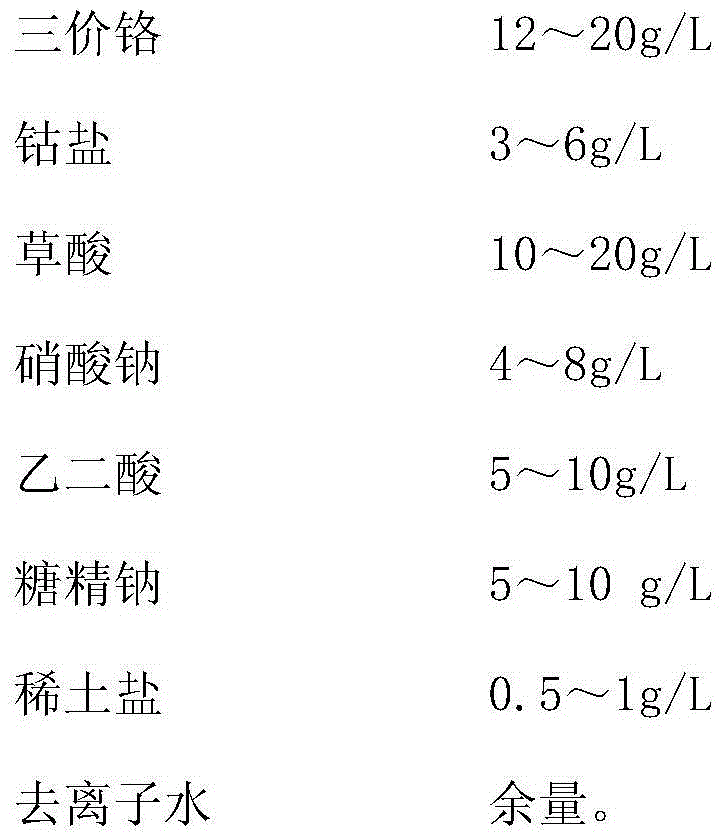

Trivalent-chromium natural-color passivator with high corrosion resistance for zinc-nickel alloy

InactiveCN104451644ALow toxicityPromote environmental protectionMetallic material coating processesNickel alloyZinc

The invention relates to the technical field of metal surface treatment and protection and particularly relates to a trivalent-chromium natural-color passivator with high corrosion resistance for a zinc-nickel alloy. The trivalent-chromium natural-color passivator is prepared from trivalent chromium, cobalt salt, oxalic acid, sodium nitrate, ethane diacid, sodium saccharin, rear-earth salt and deionized water. The appearance and corrosion resistance of a passivation film are regulated by virtue of the rear-earth salt; the passivation film with silver-white appearance obtained after passivation is high in passivation quality, not only stable in performance but also high in corrosion resistance; moreover, trivalent chromium is relatively low in toxicity and high in environment friendliness, thereby completely conforming to the ROHS laws and regulations. A passivation method of the trivalent-chromium natural-color passivator with high corrosion resistance for the zinc-nickel alloy is simple in process and low in cost.

Owner:湖南领湃科技股份有限公司

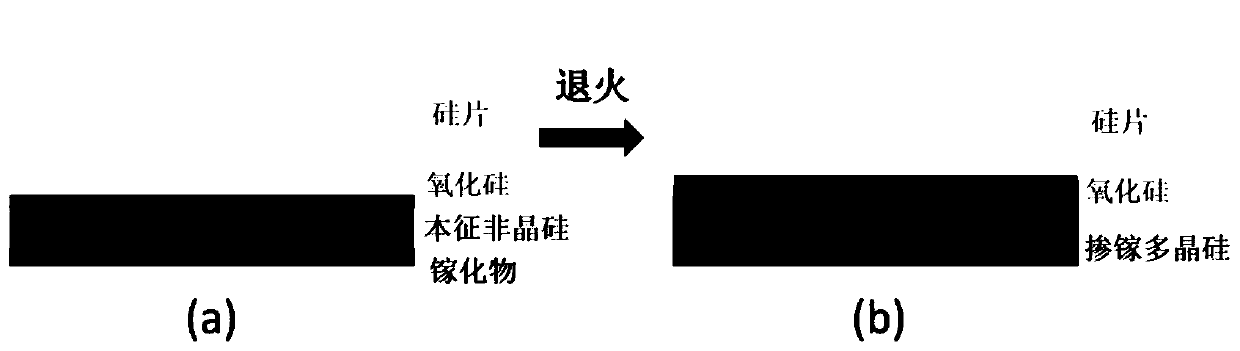

Preparation method of gallium-doped polycrystalline silicon film, and application of gallium-doped polycrystalline silicon film in solar cells

PendingCN111509082AImprove passivation qualityPassivation quality improvementFinal product manufacturePhotovoltaic energy generationSource materialSilicon oxide

The invention discloses a preparation method of a gallium-doped polycrystalline silicon film. The preparation method comprises the following steps: preparing a dielectric layer material on the surfaceof a cleaned silicon wafer; further depositing an intrinsic silicon film layer; then depositing a layer of a gallium-containing compound on the surface of the intrinsic silicon film by using a physical deposition method, wherein the intrinsic silicon layer and the gallium-containing compound can be repeatedly and alternately deposited; and carrying out high-temperature annealing at a temperatureof 800 DEG C or above in a protective atmosphere. According to the invention, the passivation quality of a p type silicon oxide / polycrystalline silicon passivation contact technology is effectively improved, and J0 and s can be reduced to below 10 fA / cm<2>; gallium source materials are rich and wide in source; the required equipment is simple, the treatment method is diversified, the repeatabilityis strong, and the process window is large; the p type silicon oxide / polycrystalline silicon passivation contact is simple in structure, reliable in performance and completely suitable for back passivation of a silicon oxide / polycrystalline silicon passivation contact battery; and the technical cost is relatively low, and the practicability is relatively high.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

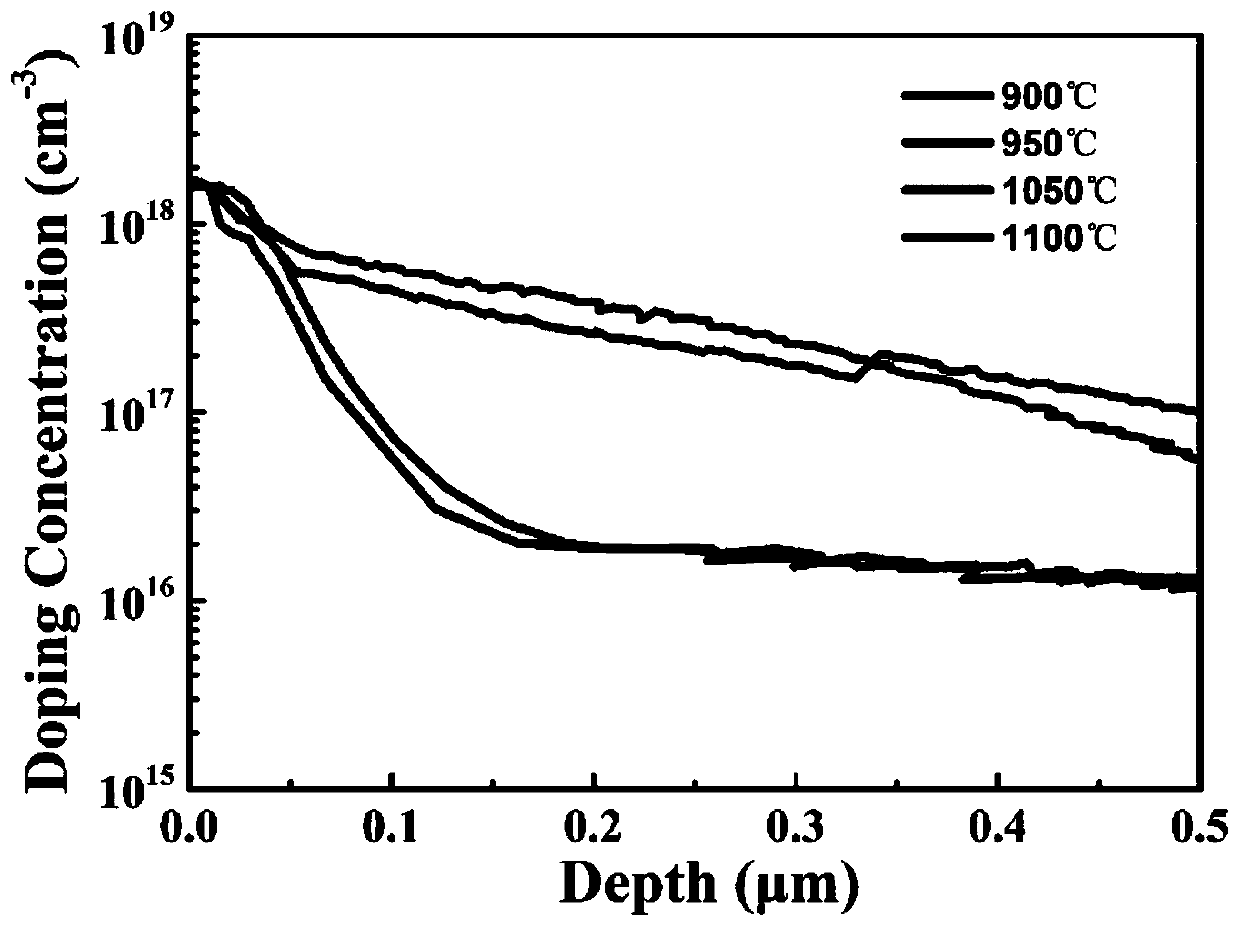

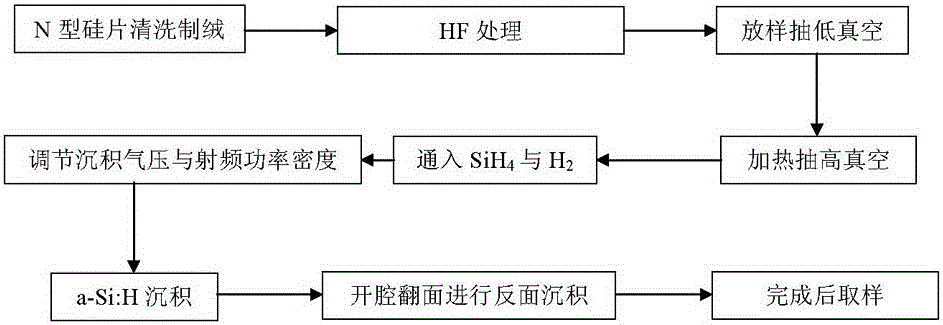

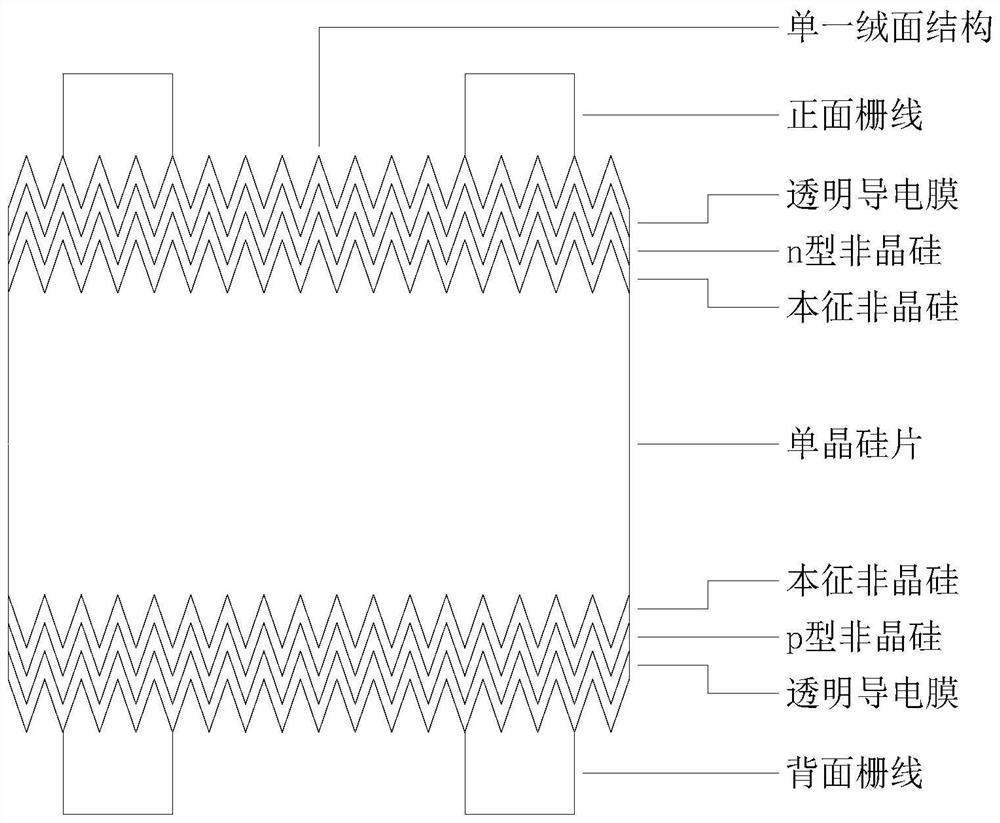

Preparation method of N-type silicon chip a-Si:H film for heterojunction with intrinsic thin layer (HIT) battery

InactiveCN105097997AIncrease the open circuit voltageImprove fill factorFinal product manufacturePhotovoltaic energy generationHeterojunctionThin membrane

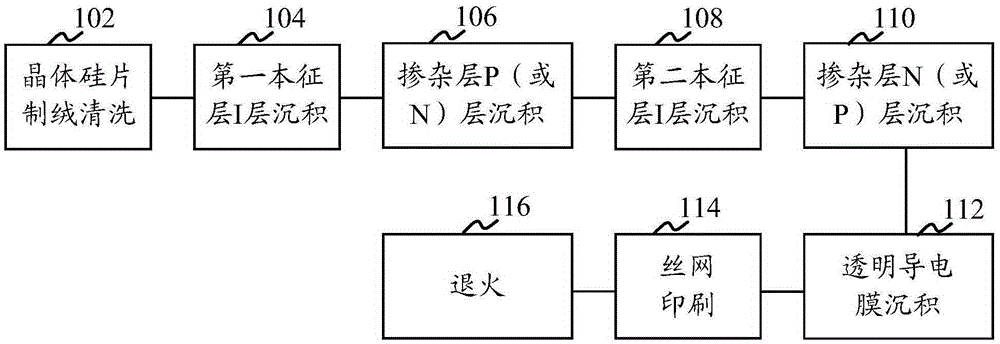

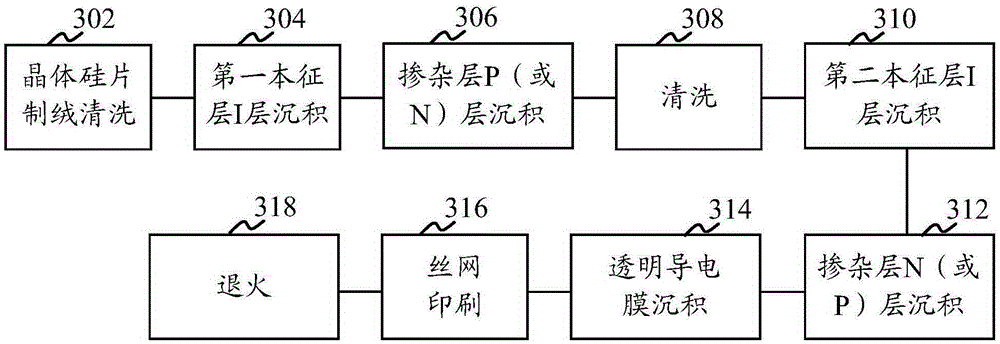

The invention discloses a preparation method of an N-type silicon chip a-Si:H film for a heterojunction with intrinsic thin layer (HIT) battery. The preparation method comprises the following steps: (1) cleaning and texturing an N-type silicon chip; (2) carrying out oxidation layer removal treatment; (3) putting the N-type silicon chip into a plasma enhanced chemical vapor deposition (PECVD) cavity, firstly extracting background vacuum, heating and warming the N-type silicon chip, extracting high vacuum, introducing deposition gases SiH4 and H2, carrying out a-Si:H film deposition on the front surface of the N-type silicon chip, and turning over the silicon chip; and (4) repeating the processes in the step (3), carrying out a-Si:H film deposition on the back surface of the N-type silicon chip, and finishing preparation of the N-type silicon chip a-Si:H film for the HIT battery. According to the preparation method, the a-Si:H film with high passivation quality and low defect density can be obtained; the surface quality of the silicon chip is greatly improved; and the efficiency of the HIT battery is effectively improved.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Aluminum alloy die pressed casting passivation solution, preparation method and passivation treatment method

InactiveCN107641803AImprove conductivityImprove passivation qualityMetallic material coating processesDie castingCobalt salt

The invention provides a corrosion resistant natural color passivation solution for an aluminum alloy die pressed casting. The passivation solution is prepared from the following components in percentage by mass: 1 to 10 percent of trivalent chromium salt, 1 to 8 percent of zirconium salt compound, 0.1 to 5 percent of mixed accelerant, 0.01 to 0.05 percent of surfactant and the balance of water, wherein the mixed accelerant is a mixture of cobalt salt, sodium fluoride and sodium nitrate with a mass ratio of (0.5 to 2) to (0.5 to 2) to (5 to 15). The invention also provides a preparation methodof the passivation solution and a method for performing corrosion resistant natural color passivation treatment on the surface of the aluminum alloy die pressed casting. A film obtained by the methodhas natural color, is uniform and dense, has strong corrosion resistance and good conductivity and does not affect natural color metal texture of die-cast aluminum.

Owner:深圳市鸿美特科技有限公司

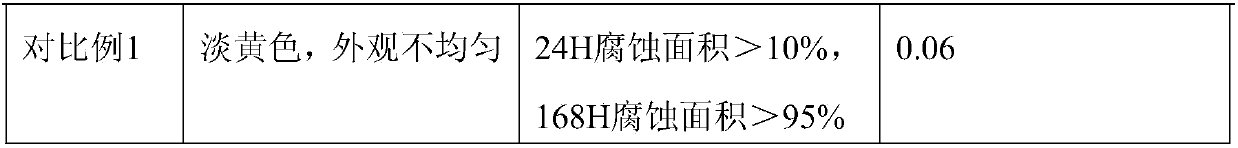

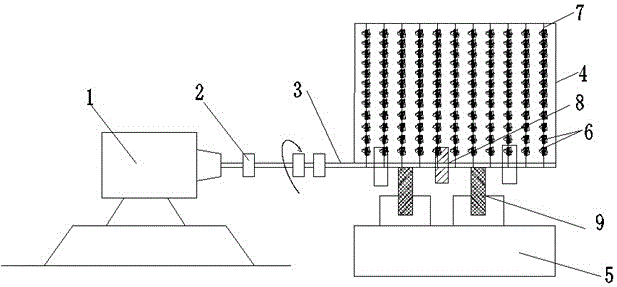

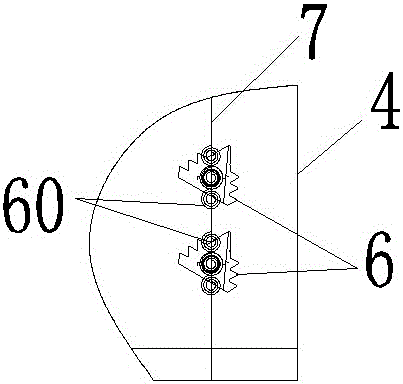

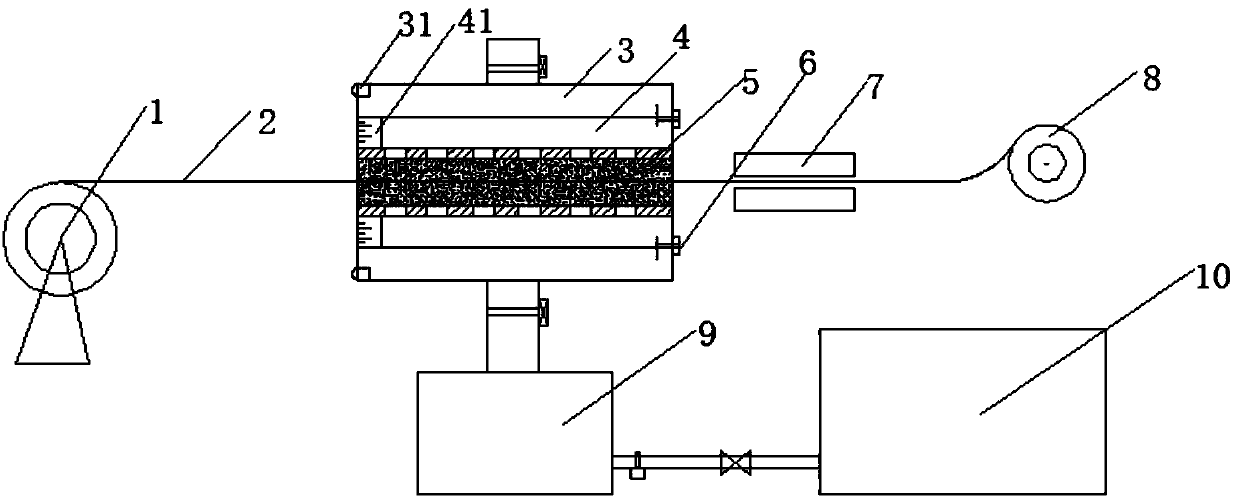

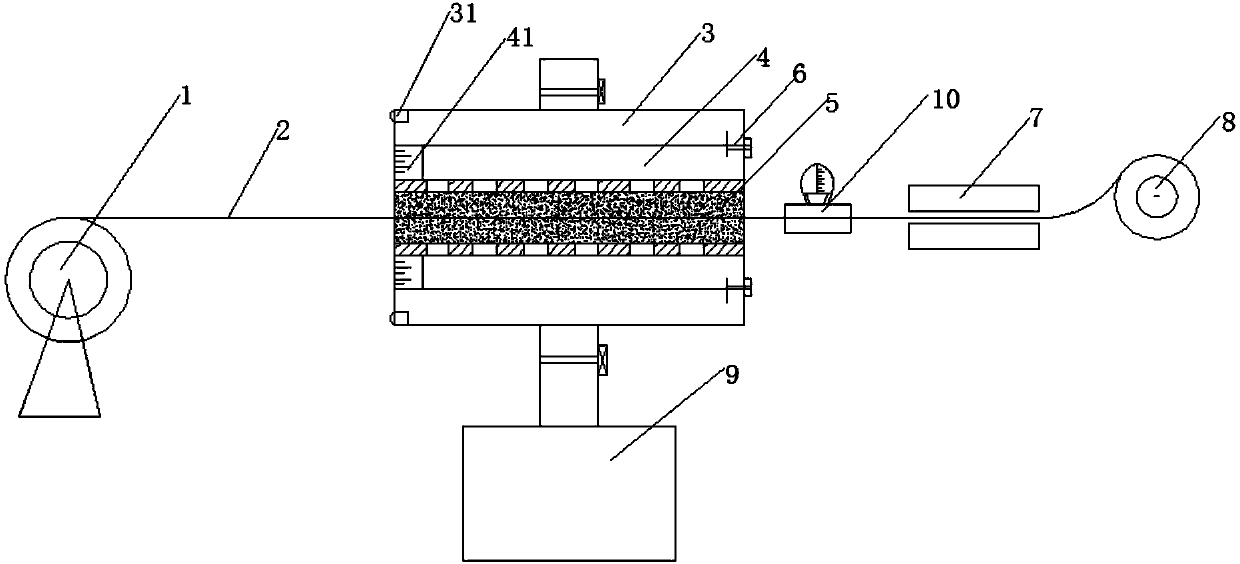

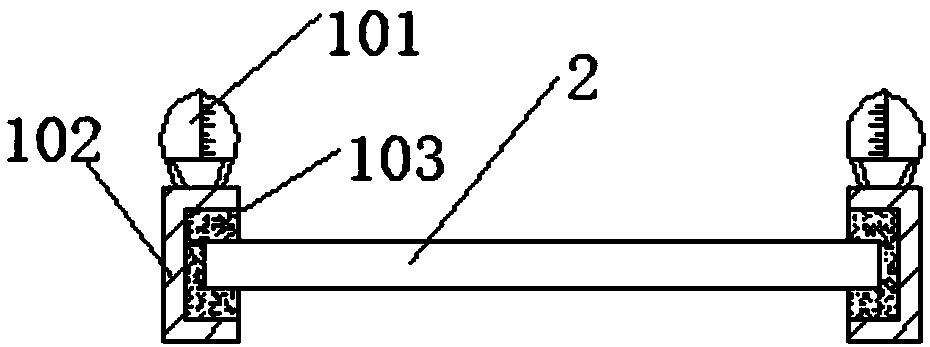

Automatic spraying system of galvanized pipe passivation liquid

ActiveCN105603412AImprove passivation qualityAvoid watermarkMetallic material coating processesSteel tubeEngineering

The invention relates to an automatic spraying system of galvanized pipe passivation liquid. The automatic spraying system is characterized by being composed of a passivation liquid storage box, a filter tank, a spraying base, a spraying cover and atomization spraying mechanisms, a water suction pump is arranged in the passivation liquid storage tank, the upper portion of the spraying base is covered with the spraying cover, openings for a pipeline to pass through are formed in the left end and the right end of the spraying cover, the atomization spraying mechanisms arranged with one above the other are installed on the front cover wall and the rear cover wall of the spraying cover respectively, steam outlets are formed in the two ends of the lower portion of the spraying cover and connected with the inlet of the filter tank through a three-way pipeline, the outlet of the filter tank is connected to the passivation liquid storage box through a pipeline, and a liquid outlet is formed in the bottom of the spraying base and connected to the passivation liquid box through a pipeline connected with a negative pressure machine. The automatic spraying system is scientific and reasonable in structural design, and has the advantages of being uniform in passivation liquid attachment, high in passivation efficiency, capable of ensuring surface attractiveness of steel pipes and reducing passivation cost, convenient to operate and easy to obtain.

Owner:TIANJIN TIANYINGTAI STEEL PIPE CO LTD

Heterojunction solar cell and preparation method thereof

InactiveCN105304746AImprove fill factorImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionFill factor

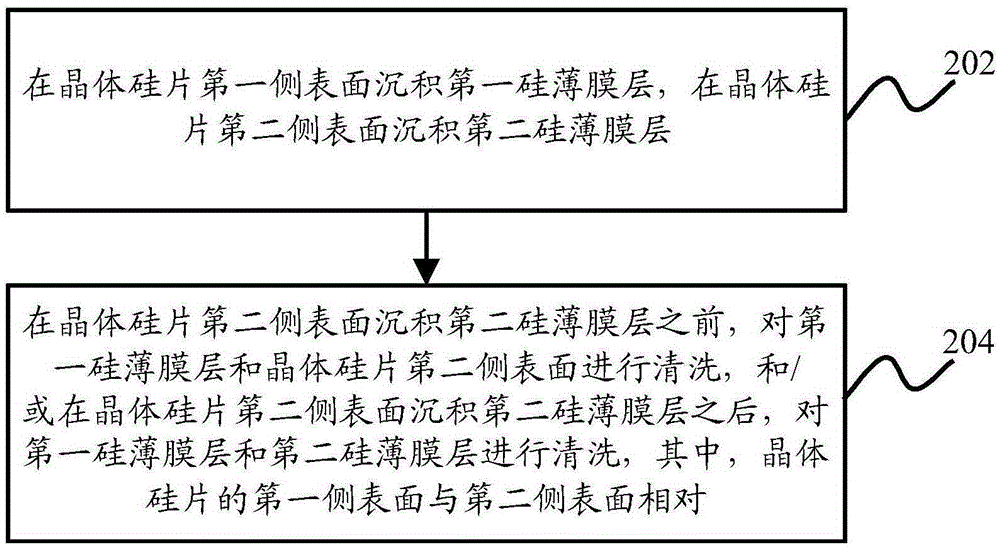

The invention discloses a heterojunction solar cell and a preparation method thereof, and aims at removing contamination and the oxide layer on the surface of a crystalline silicon wafer and silicon thin film layers in the transmission process so that passivation quality of the surface of the crystalline silicon wafer is enhanced and the fill factor and conversion efficiency of the cell are enhanced. The preparation method of the heterojunction solar cell comprises the steps that a first silicon thin film layer is deposited on the surface of the first side of the crystalline silicon wafer, and a second silicon thin film layer is deposited on the surface of the second side of the crystalline silicon wafer; and the first silicon thin film layer and the surface of the second side of the crystalline silicon wafer are cleaned before deposition of the second silicon thin film layer on the surface of the second side of the crystalline silicon wafer, and / or the first silicon thin film layer and the second silicon thin film layer are cleaned after deposition of the second silicon thin film layer on the surface of the second side of the crystalline silicon wafer.

Owner:ENN SOLAR ENERGY

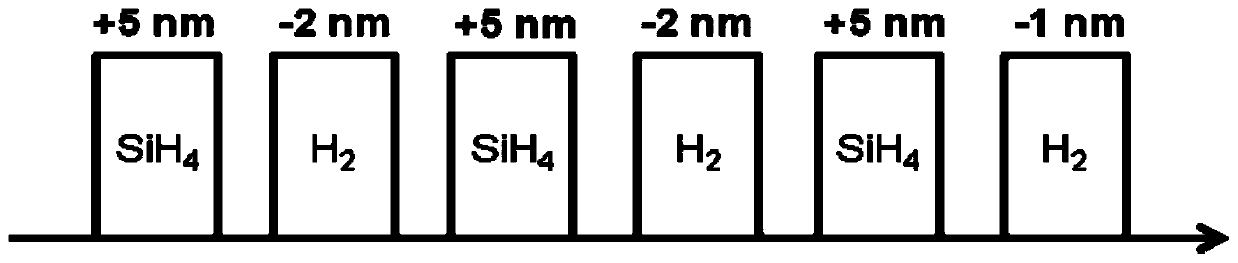

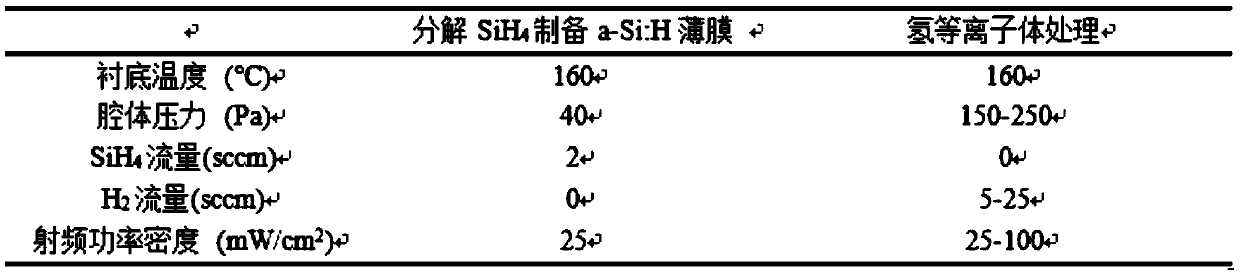

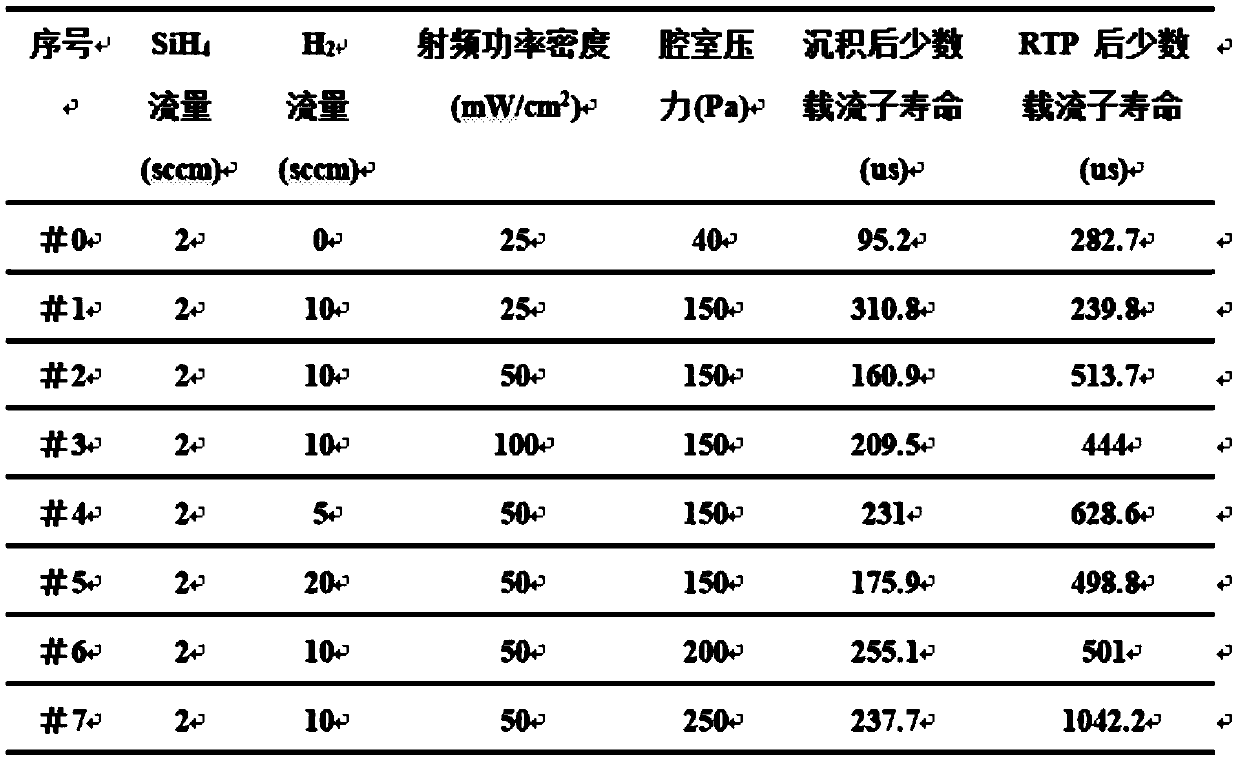

Method for preparing a-Si: H thin film based on hydrogen plasma treatment

InactiveCN109943823AImprove passivation qualityPassivation quality improvementFinal product manufactureChemical vapor deposition coatingChemistryPlasma treatment

The invention relates to the technical field of preparation methods of a-Si: H, in particular to a method for preparing an a-Si: H thin film based on hydrogen plasma treatment. The method includes steps that a, SiH4 is decomposed in a depositing cavity to deposit the a-Si: H thin film; and b, depositing stops, remaining gas in the depositing cavity is discharged, then H2 is introduced into the depositing cavity, and is decomposed to form hydrogen plasma which acts on an amorphous silicon thin film, and the step a and the step b are alternately adopted to finally obtain the a-Si: H thin film ata set thickness. The method has the beneficial effects that compared with the prior art, according to the periodically alternated hydrogen plasma treatment process adopted by the method, by interrupting production of low-order silicon and hydrogen elements or etching the a-Si: H thin film high in content of the low-order silicon and hydrogen elements, the passivating quality is remarkably improved; and more atomic hydrogen is injected into the a-Si: H thin film, in cooperation with the later period high temperature fast heat treatment process, a basis is laid for filling up the electrical defects in the a-Si: H thin film and saturating the dangling bond state of the c-Si surface, and therefore the passivating quality is remarkably improved.

Owner:上海米蜂激光科技有限公司

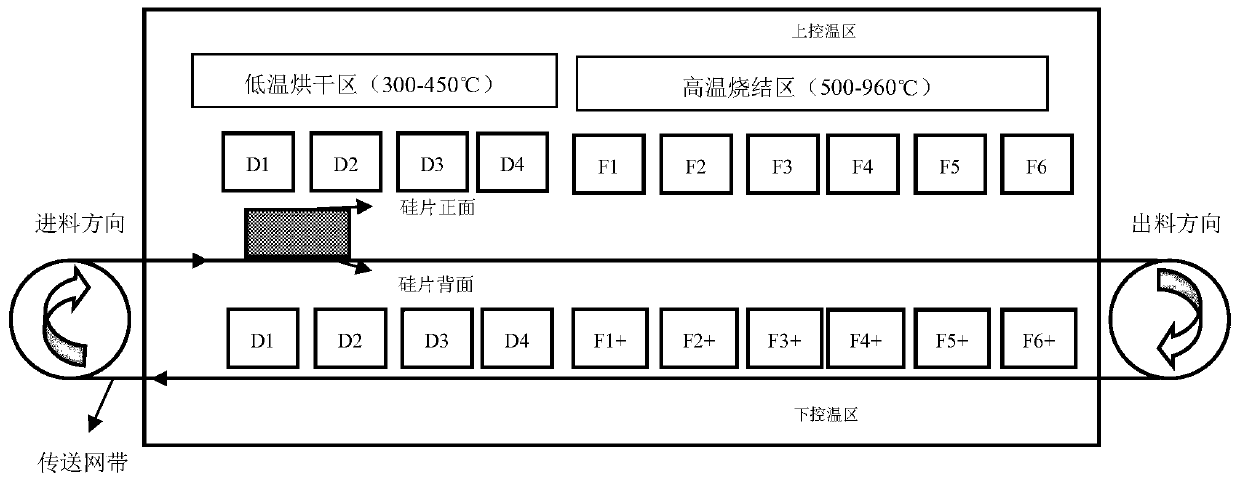

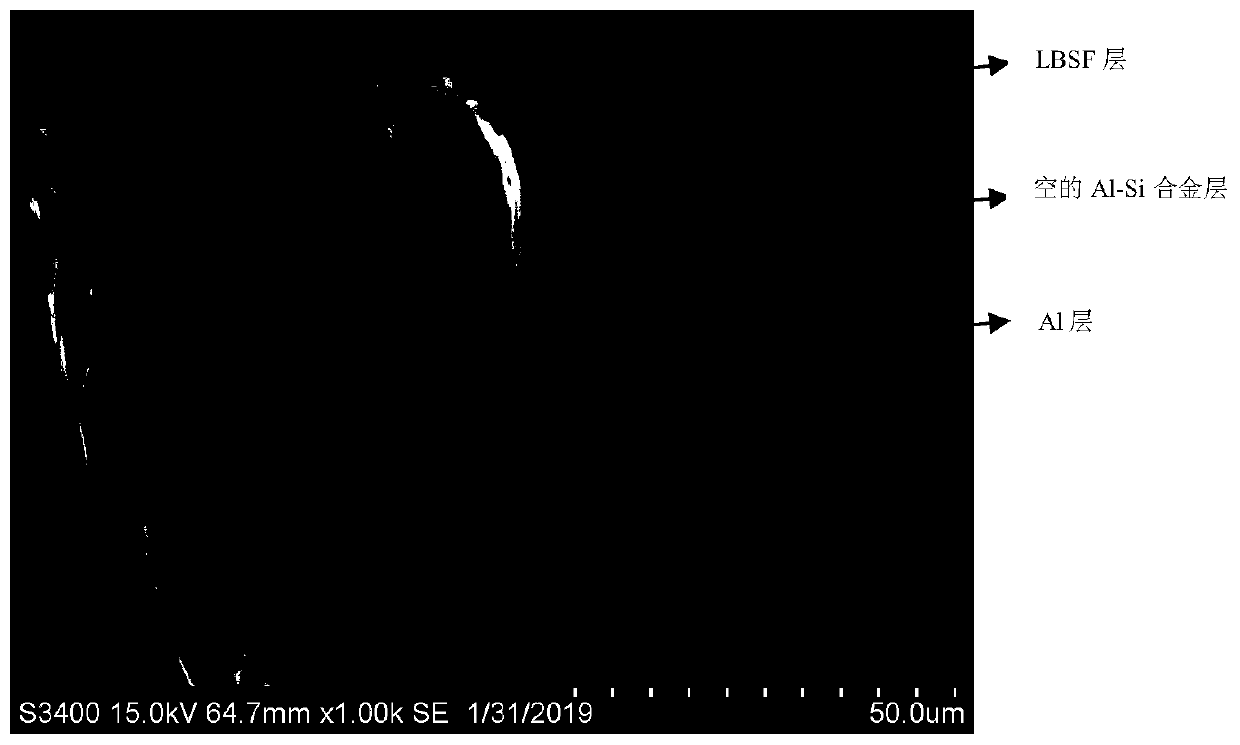

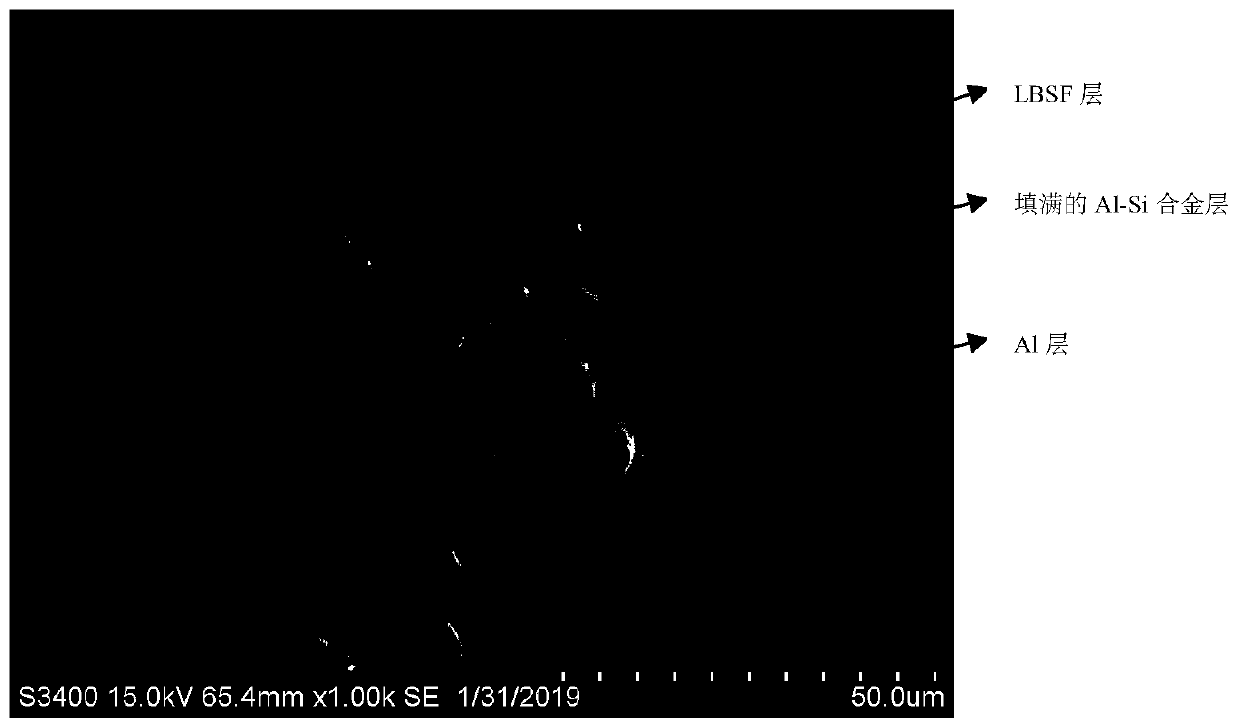

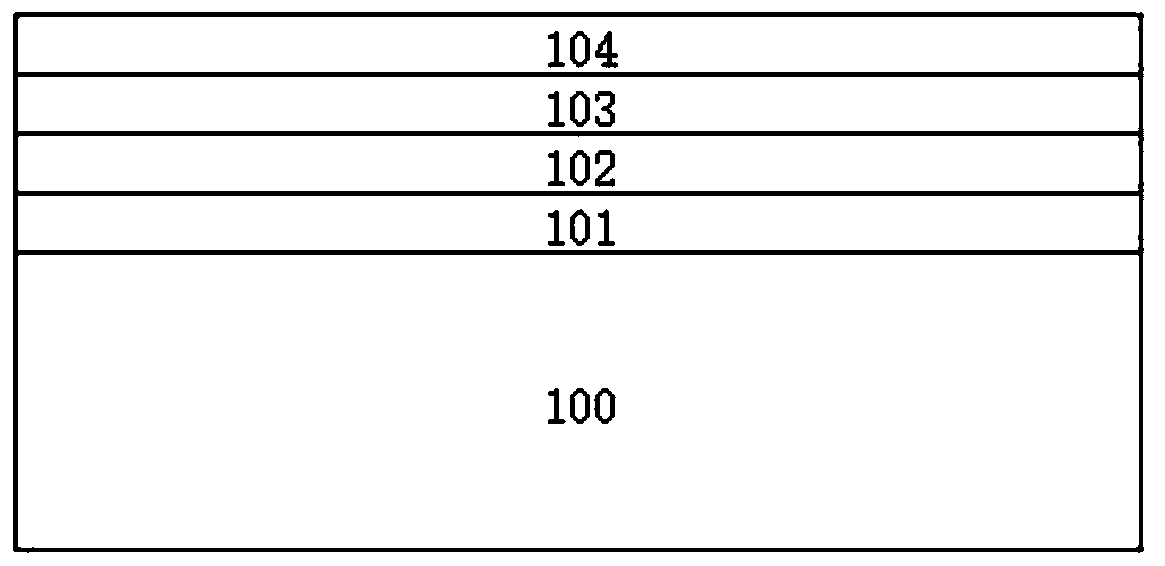

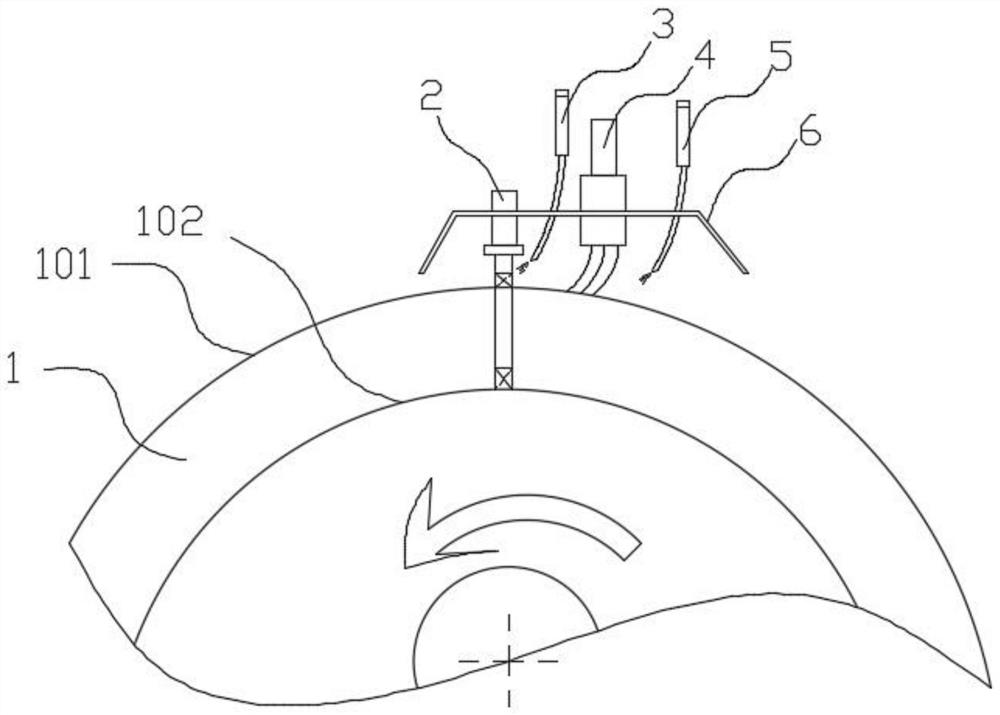

Sintering method for reducing PERC battery aluminum cavities

ActiveCN109888029AImprove passivation effectIncreasing the thicknessFinal product manufacturePhotovoltaic energy generationTemperature controlThermocouple

The invention discloses a sintering method for reducing PERC battery aluminum cavities. The sintering method comprises the steps that a silicon slice with printed paste is despatched into sintering equipment for sintering, and the sintering temperature on the front of the silicon slice is set to be lower than the set sintering temperature on the back of the silicon slice. According to the sintering method for reducing the PERC battery aluminum cavities, non-isothermal sintering of the front and the back of the silicon slice is set through thermocouple temperature control, common PERC aluminumcavities are avoided, aluminum-silicon contact is improved, the thickness of an LBSF is increased, and the passivation effect is improved. Through the preparation method, the problems of aluminum cavities, small LBSF thickness and poor quality brought by traditional PERC sintering are solved and relieved, and the efficiency of a PERC battery without aluminum cavities is further improved.

Owner:HANWHA SOLARONE QIDONG

TOPCON passivation structure and preparation method thereof

InactiveCN111509054ASimple preparation processImprove passivation qualityFinal product manufacturePhotovoltaic energy generationSilicon oxideSolar cell

The invention aims to disclose a TOPCON passivation structure and a preparation method thereof. The TOPCON passivation structure comprises an N type or P type silicon wafer substrate, wherein a tunneling silicon dioxide layer, a doped polycrystalline silicon layer / amorphous silicon layer of a TOPCon structure, a phosphorus-containing silicon oxide layer SiOx:P or a boron-containing silicon oxide layer SiOx:B and a SiNx top cover layer are sequentially arranged on the surface of the silicon wafer substrate from inside to outside. Compared with the prior art, the TOPCON passivation structure ofthe invention has the following characteristics that a phosphorus-containing silicon oxide layer SiOx:P or boron-containing silicon oxide layer SiOx:B growing in an annealing process is used as the surface passivation layer of the TOPCon structure of the solar cell, so that the growth of the surface passivation layer of the doped layer is realized without an additional process, the preparation process flow of the solar cell is simplified, the passivation quality of the TOPCon structure to the doped layer of the silicon wafer substrate is improved, and the purpose of the invention is realized.

Owner:SPIC XIAN SOLAR POWER CO LTD +3

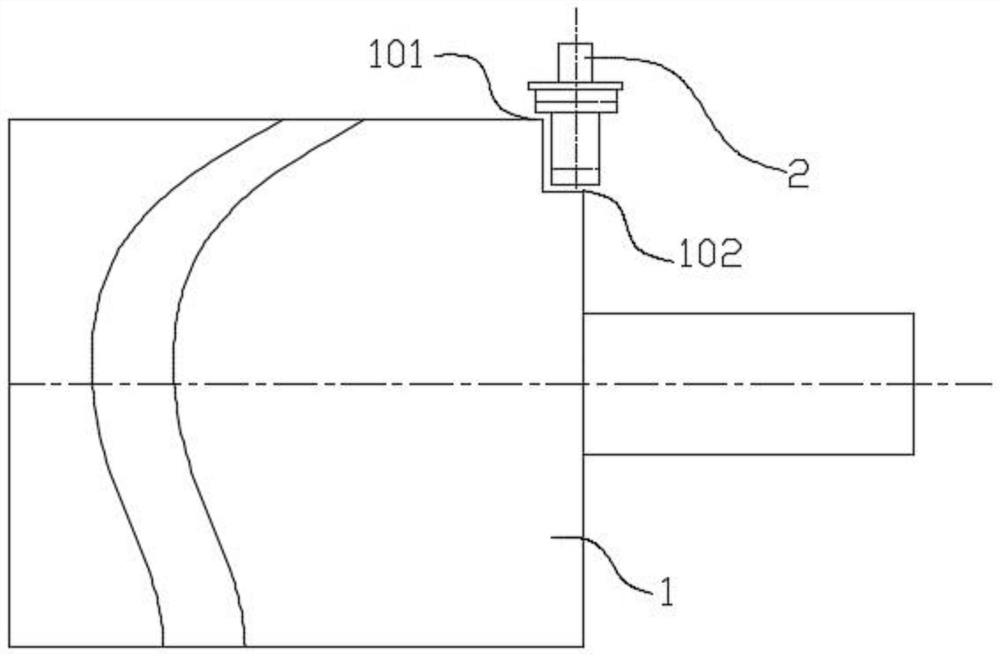

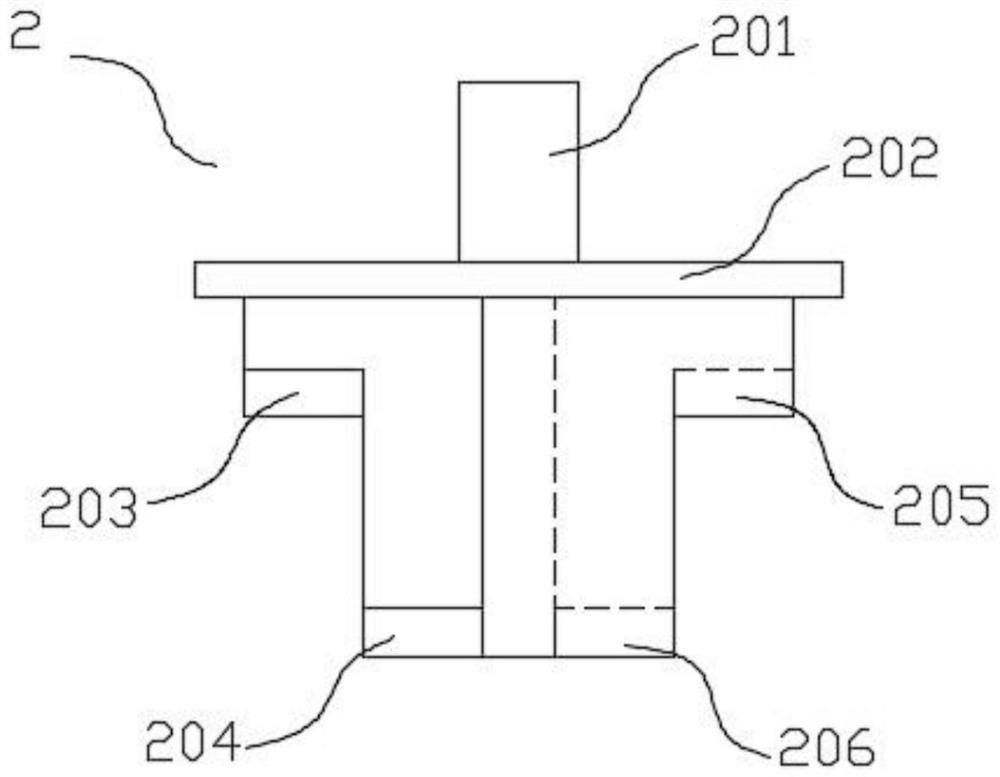

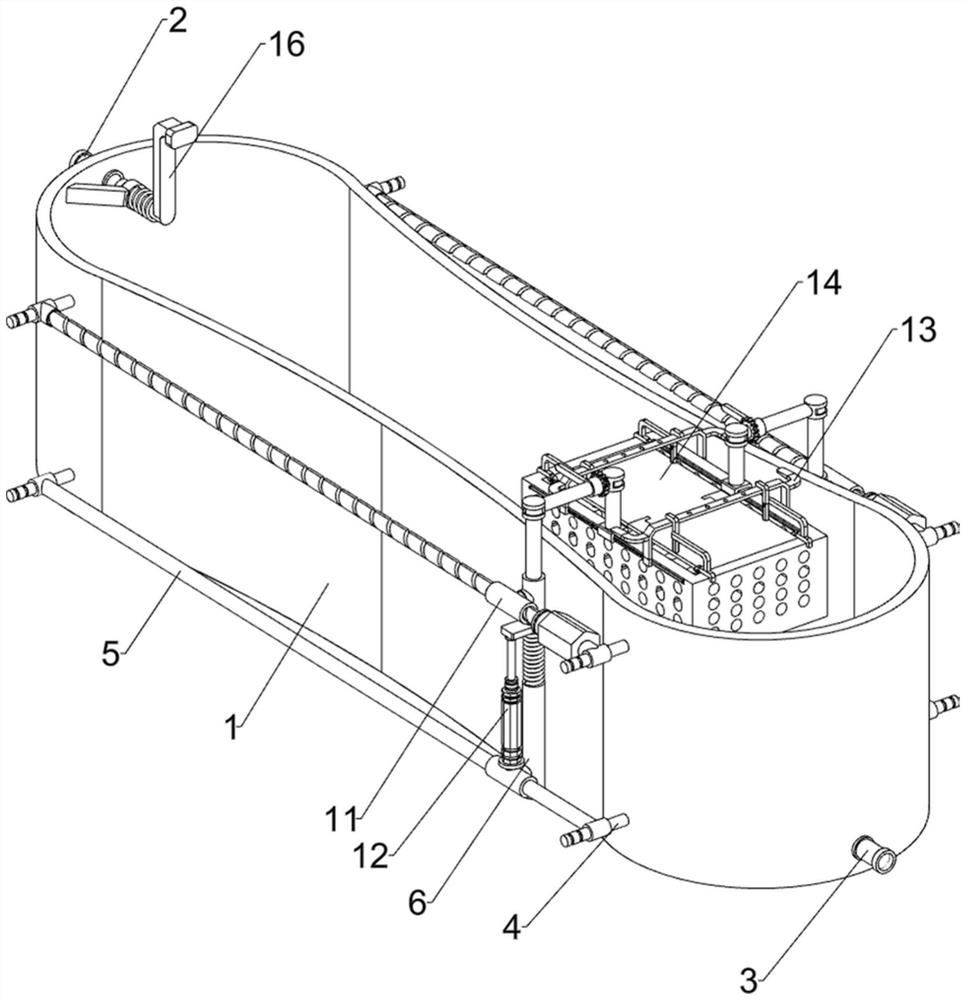

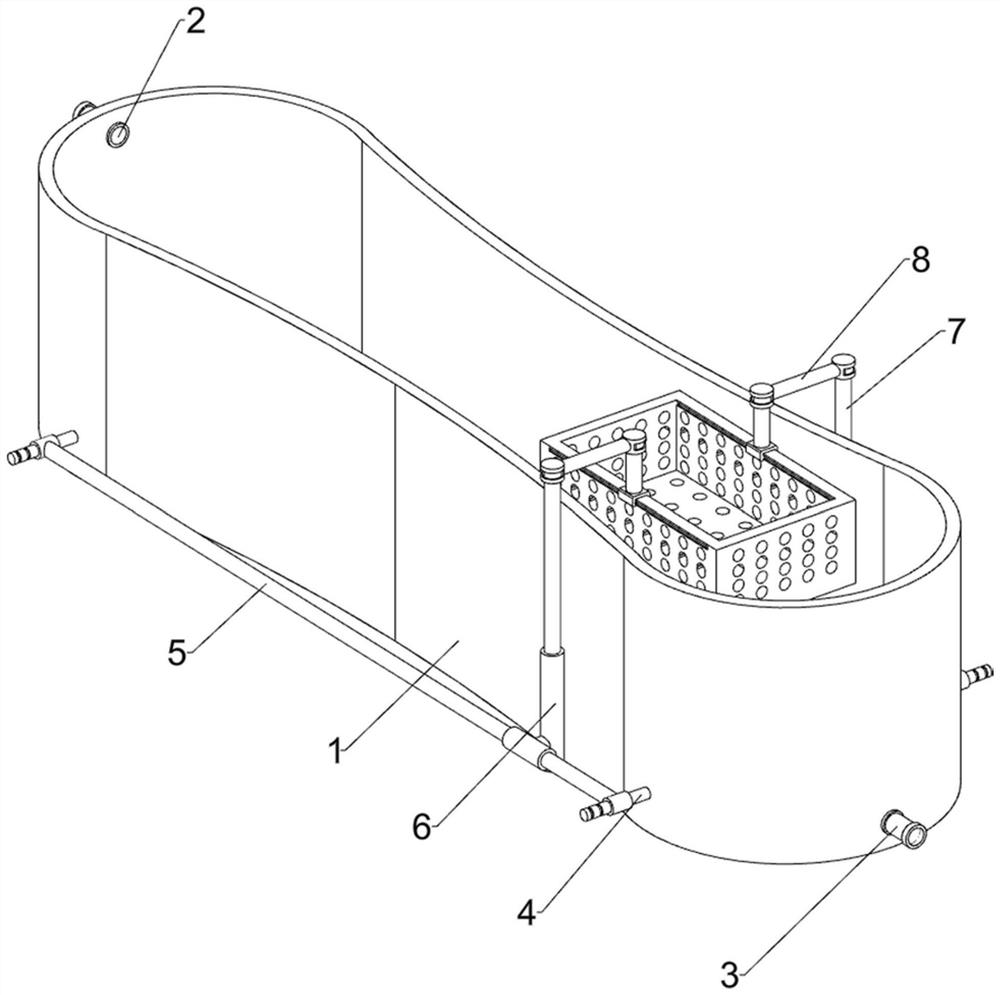

Roller coater liquid throwing prevention device for improving hot galvanizing passivation quality and liquid throwing prevention method

The invention discloses a roller coater passivation roller coating device suitable for a continuous hot galvanizing high-speed unit, relates to the technical field of roller coater liquid throwing prevention devices for improving the passivation quality of continuous hot galvanizing, and in particular to a roller coater liquid throwing prevention device for improving the hot galvanizing passivation quality and a liquid throwing prevention method. Liquid throwing prevention device bodies are symmetrically arranged on a rack on the two sides of a coating roller of a roller coater, the liquid throwing prevention device bodies comprise slag scraping and grinding plates, flushing mechanisms, liquid blocking brushes and flow guide protective covers, and the problems that when an existing rollercoater is used, passivation liquid is prone to being thrown out, the passivation liquid is caused to flow to the edge part of strip steel or splash to the middle of the strip steel, a large amount ofpassivation liquid splashes to pollute the surrounding operation environment, even the passivation liquid is thrown out into eyes of an observer, and eye injuries are caused are solved. The working efficiency is improved, guarantee is provided for smooth production of a production line, and the safety risk of field operators caused by liquid throwing is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Adjusting method for passivation temperature of steel structure

ActiveCN105369242AReduce porosityImproves attachment stabilityMetallic material coating processesPorosityZinc

The invention discloses an adjusting method for the passivation temperature of a steel structure. The adjusting method includes the following steps that firstly, a galvanized steel plate is dried and cooled; secondly, first-level passivation is conducted; thirdly, second-level passivation is conducted; fourthly, third-level passivation is conducted; and fifthly, drying is conducted. According to the adjusting method for the passivation temperature of the steel structure, the segmented passivation temperature adjustment is conducted , porosity of a passivation film is effectively reduced, passivation quality is improved, meanwhile, adhesion stability of the passivation film is improved, and therefore passivation quality is effectively improved, corrosion resistance performance of a zinc coating is improved, and the salt spray resistance property of a passivated product is good.

Owner:CHANGSHU FENGFAN POWER EQUIP

Water-based paint coating process after metallization and silver plating of common material antenna

PendingCN113546822ALow costIncrease headroomPretreated surfacesLiquid/solution decomposition chemical coatingChemical platingPunching

The invention discloses a water-based paint coating process after metallization and silver plating of a common material antenna. The water-based paint coating process comprises the following steps that S1, a 5G frequency band standard is set for a terminal client, the frequency band, the antenna layout and the requirements are met by the terminal client, and an antenna line is designed for a product covered under a mainboard; and S2, according to the line mold design in the step S1, the punching and shutting off requirement is met, burrs generated by mold punching are optimized through laser punching, the glue thickness of a punched hole is controlled to be 0.03 mm, and the product with the thickness being 0.1 mm touches the punching burrs; and injection molding is carried out according to the designed content. According to the water-based paint coating process after metallization and silver plating of the common material antenna, the appearance surface of the common material is subjected to chemical plating to generate the metallized antenna, the bottleneck of the LDS raw material is broken through, the chemical plating antenna metallization process is optimized, metalized chemical plating antenna can be completed by using any shape of the common material as reserved size, so that the internal clearance space of a mobile phone can be effectively improved, and the radio frequency signal of the mobile phone can be improved; and the silver plating mode meets the nickel-containing standard, and the surface flatness of the chemical silver plating layer is high.

Owner:DONGGUAN TOPVIEW PLASTIC MFG

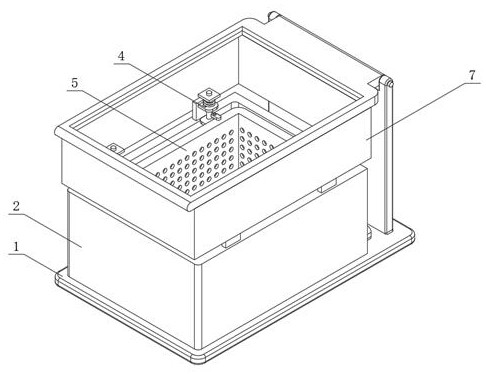

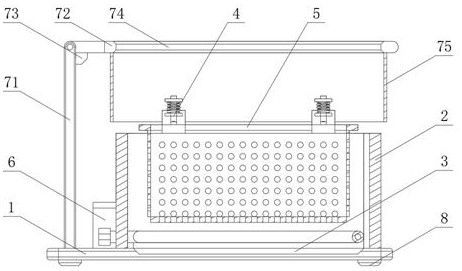

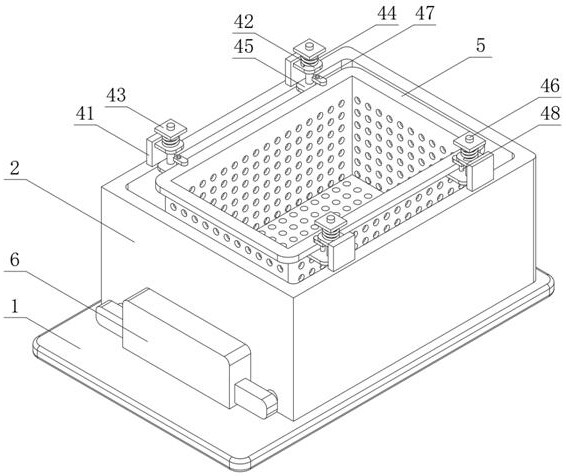

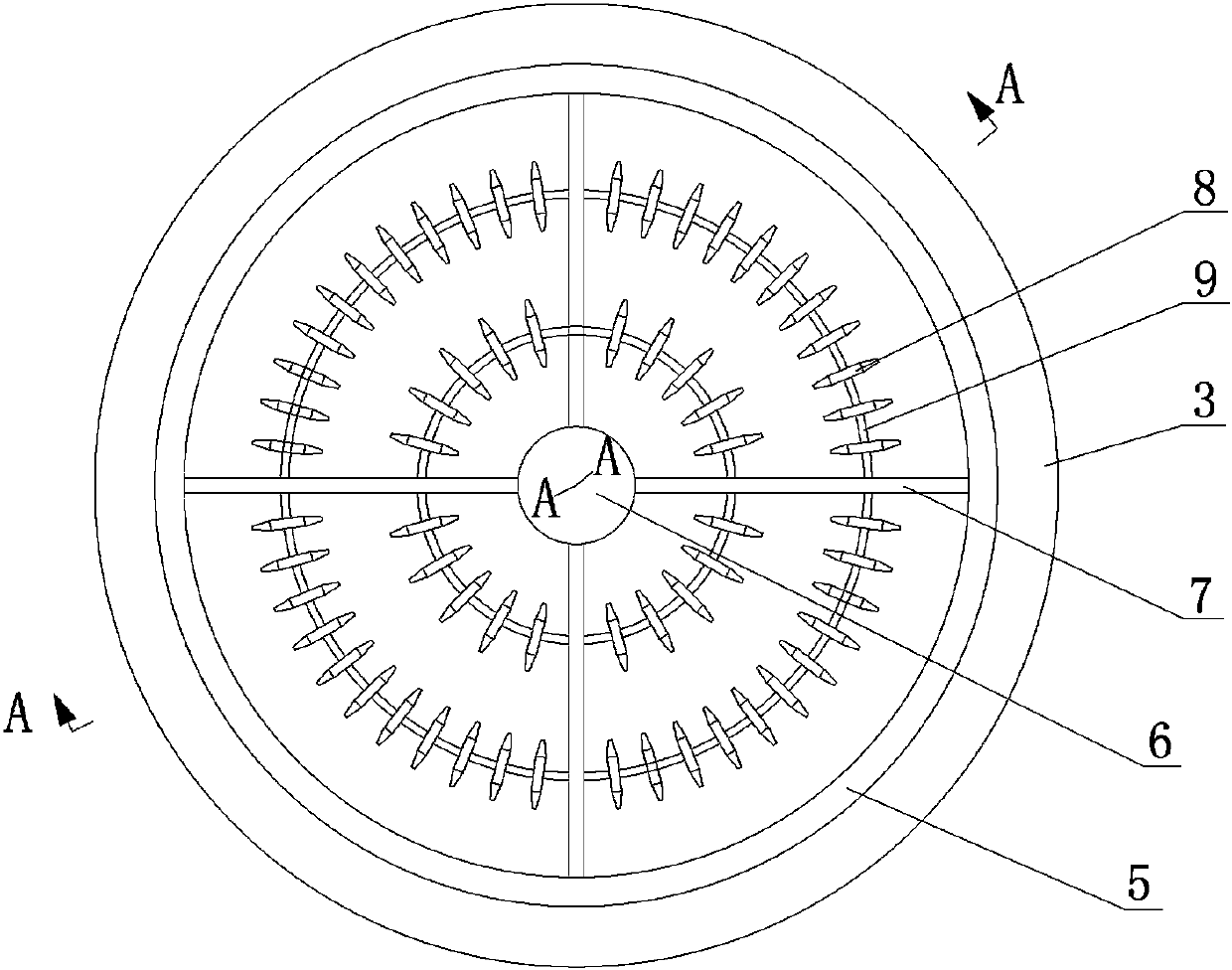

Compartment type passivation device used for threaded carding tool edges

ActiveCN105058217AEnsure consistencyImprove the efficiency of passivation treatmentEdge grinding machinesPolishing machinesCardingEngineering

The invention discloses a compartment type passivation device used for threaded carding tool edges. The compartment type passivation device comprises a motor, stepless speed regulators, a transmission shaft, a passivation container and a base. The motor is connected with the transmission shaft through the stepless speed regulators, multiple installing shafts used for fixing carding tools are arranged inside the passivation container and sleeved with the multiple threaded carding tools, every two threaded carding tools are spaced through a spring, the transmission shaft is sleeved with eccentric wheels placed below the passivation container, and compression springs are arranged above the base and tightly attached to the transmission shaft. In this way, the passivation quality and efficiency can be improved, and the service life of blades can be prolonged.

Owner:KUNSHAN HIECISE PRECISION TOOL

A kind of processing technology of metal surface

ActiveCN112176376BImprove corrosion resistanceImprove the lubrication effectMetallic material coating processesZincElectroplating

The invention discloses a metal surface treatment process, the main steps of which are the following steps: putting a metal workpiece into a pool for removing oxide film for 60 to 80 seconds, then taking it out, putting it into a clear water pool for cleaning, and drying; Conduct electroplating, electroplate a layer of zinc plate on the surface of the metal workpiece; put the electroplated metal workpiece into the passivation solution for passivation, soak for 1-3 minutes at 25-40°C, and put the taken-out metal workpiece in the cleaning pool Wash for 10-15 minutes. In the present invention, by adding self-made passivation solution and limiting the raw material weight ratio and molar ratio of the passivation solution, the treated metal workpiece can obtain excellent corrosion resistance, fingerprint resistance and lubricity.

Owner:伸荣(上海)水处理环保工程有限公司

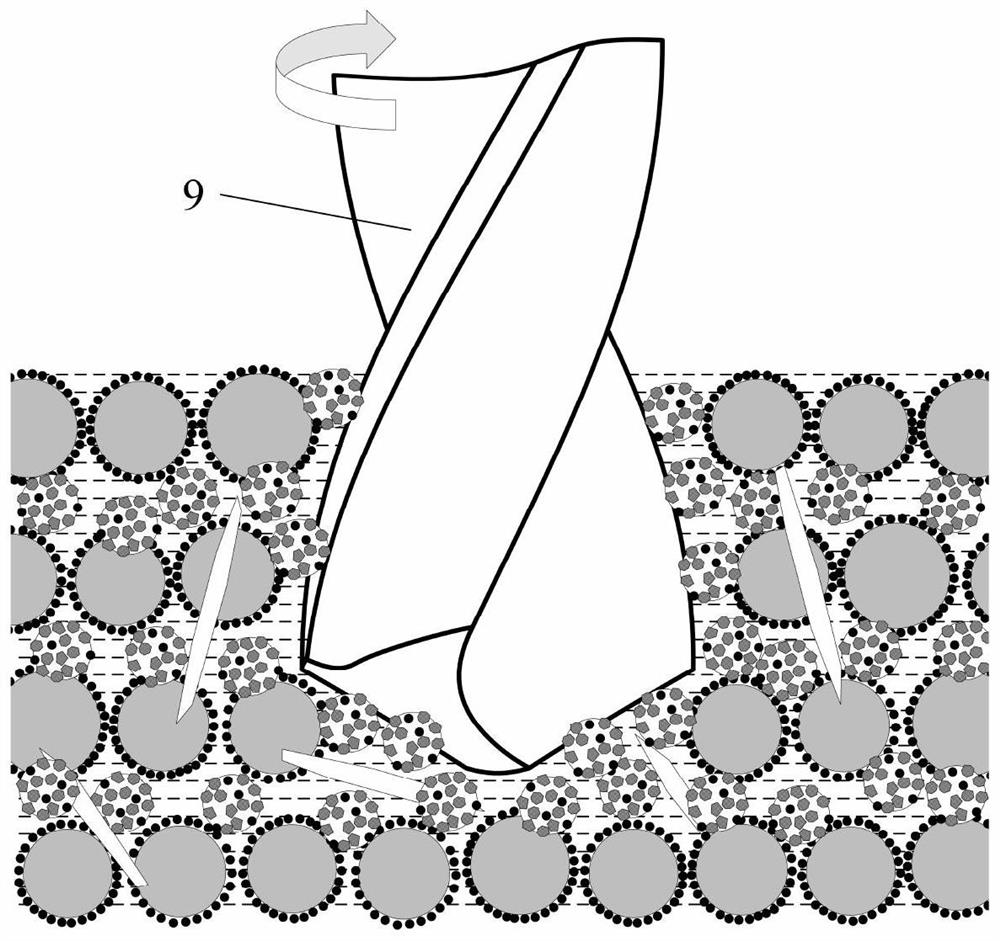

Micro cutter passivation method and device based on flexible abrasive particles and magnetic composite fluid

ActiveCN114131431AHigh passivation precisionImprove consistencyEdge grinding machinesPolishing machinesMetallurgyWear particle

The invention relates to a micro cutter passivation method and device based on flexible abrasive particles and magnetic composite fluid, a cutting edge of a micro cutter is treated by adopting a magnetic composite fluid polishing principle, and a material on the surface of the cutter is slightly removed by utilizing the rheological property of the magnetic composite fluid and the flexible abrasive particles. Cutting edge passivation treatment and surface polishing treatment of the cutter can be achieved at the same time, and the cutter is high in passivation precision and good in consistency; batch passivation of the miniature cutters is achieved through the multi-clamp design, cutter passivation work and disassembly and assembly operation can be carried out at the same time, and the cutter passivation efficiency is improved. According to the micro cutter passivation method and device based on the flexible abrasive particles and the magnetic composite fluid, micro defects of a cutting edge of a micro cutter can be effectively removed, the contour shape of the cutting edge is improved, tiny burrs on the surface of the cutter are eliminated, the surface quality of the cutter is improved, the service life of the cutter is prolonged, and the part machining quality is improved; and high-precision and high-efficiency passivation treatment on the micro cutter is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

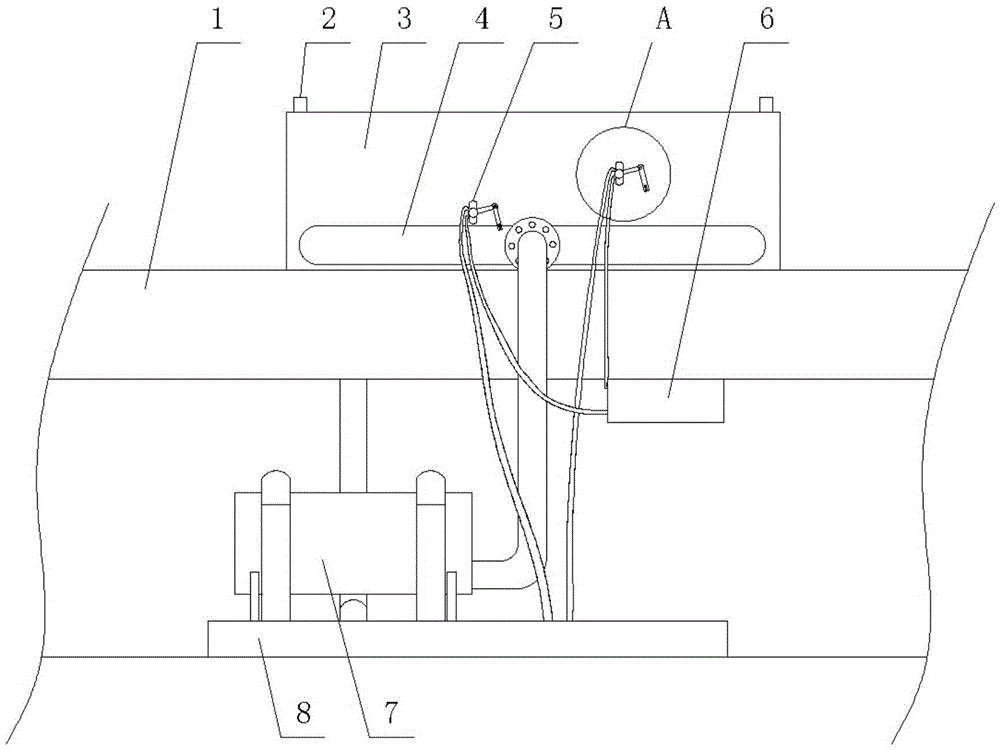

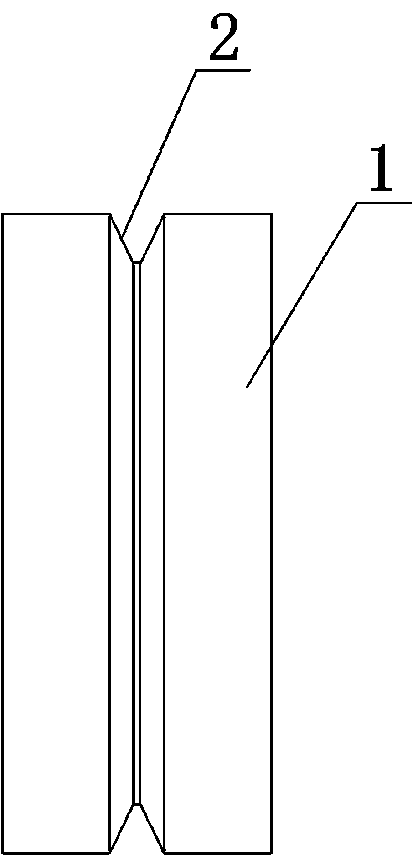

A kind of edge passivation process

ActiveCN105922147BImprove the finishImprove passivation efficiencyEdge grinding machinesPolishing machinesAlloyGrinding wheel

The invention discloses a cutting edge passivation technology which comprises the following steps: S1, manufacturing a foam grinding wheel; S2, forming an annular groove (2) matched with the cutter tooth of a hard alloy groove cutter in the cylindrical surface of the foam grinding wheel (1); S3, carrying out coarse passivation on the cutting edge of the hard alloy groove cutter; S4, manufacturing a finishing polish device; and S5, carrying out finishing polish on the cutting edge of the hard alloy groove cutter, and starting a motor (4) to drive a turntable (3) to rotate at the speed of 56-60 rpm. During the rotation process, carborundum carries out finishing polish on the cutting edge, so that finishing polish on the cutting edge of the hard alloy groove cutter is realized. The cutting edge passivation technology has the following beneficial effects: the passivation quality is improved, the degree of finish of the cutting edge is increased, and the passivation efficiency of the cutting edge is remarkably improved.

Owner:CHENGDU XIN THREAD TOOLS

Method for manufacturing selective texturing heterojunction solar cell

PendingCN114171643AImprove anti-reflection effectImprove passivation qualityPolycrystalline material growthAfter-treatment detailsHeterojunctionAmorphous silicon

The invention discloses a method for manufacturing a selective texturing heterojunction solar cell, which comprises the following steps of: pre-cleaning a monocrystalline silicon wafer, removing damages, manufacturing a delay layer in a selective texturing area on the surface of the monocrystalline silicon wafer by using a delay material, texturing the monocrystalline silicon wafer, dissolving the delay layer in the selective texturing area by using texturing liquid in the texturing process, and then, preparing a texturing solution in the selective texturing area; and enabling the suede of the selective texturing area to be later than the delay-layer-free area, forming at least two suede microstructures in different position areas on the monocrystalline silicon wafer at one time, and depositing and printing grid lines after texturing to obtain the battery. Different textured microstructures can be formed on the same surface of the same monocrystalline silicon wafer, so that the heterojunction solar cell can obtain the optimal antireflection effect, and meanwhile, the amorphous silicon passivation quality can be greatly enhanced; the delay layer can be arranged differently, different suede microstructures can be formed at a time, the delay material of the delay layer can be directly removed in the texturing process, the production process is reduced, and the cost is reduced.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

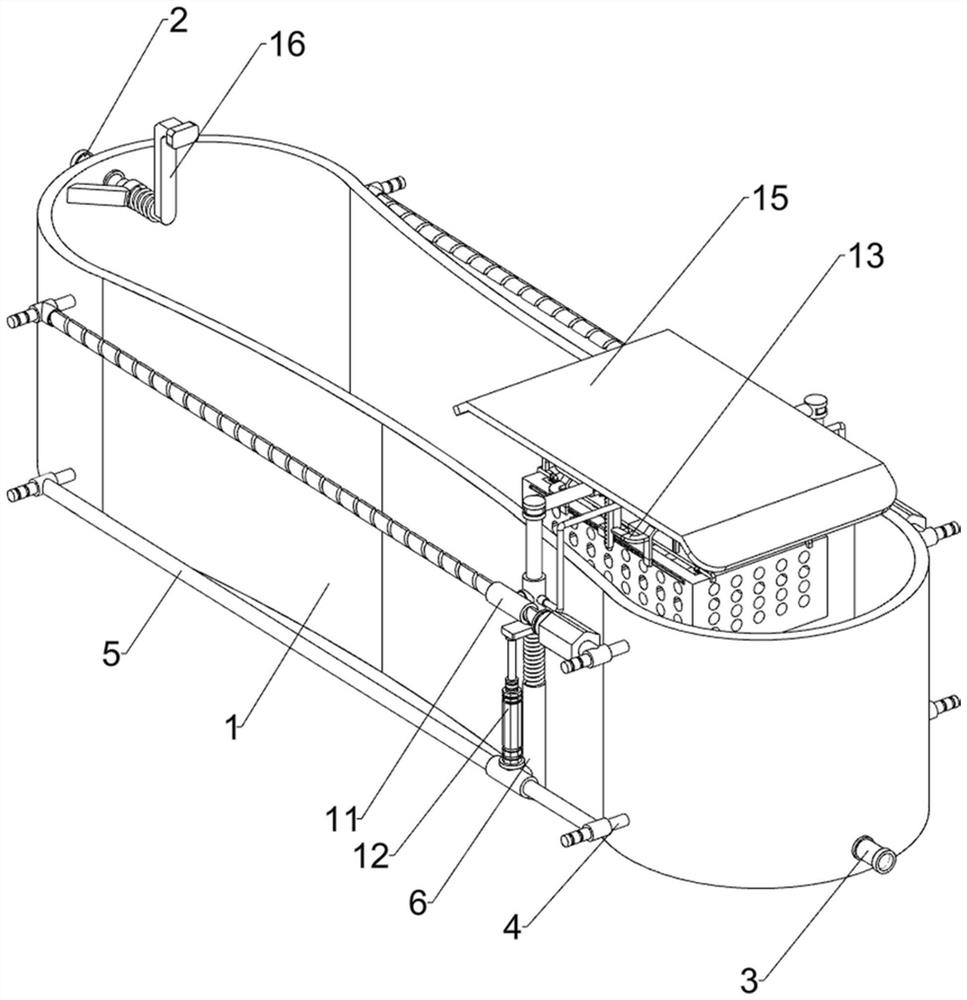

Steel plate passivation apparatus

InactiveCN107858669AUniform coatingImprove passivation qualityMetallic material coating processesSheet steelBuffer tank

The invention provides a steel plate passivation apparatus. The apparatus comprises a steel plate releasing device, a steel plate, a coating passivation device, a drying device and a steel plate rolling device, the coating passivation device comprises a passivation coating assembly, a passivation solution buffer box and a passivation solution preparing box which are sequentially connected by a pipeline, and a flow-controllable valve and a circulation pump are correspondingly arranged on the pipeline; and the passivation coating assembly includes an upper coating assembly and a lower coating assembly which are oppositely arranged and structurally similar, each of the upper and lower coating assemblies includes a passivation solution chamber and coating sponge fixedly arranged at the inner sides of the passivation solution chambers and communicating with the chambers, every passivation solution chamber is divided into an outer chamber and an inner chamber by a separator plate, an openingis arranged at a position, close to the corresponding passivation solution chamber, of the separator plate, and the opening is provided with a sealing door. The steel plate passivation apparatus hasthe advantages of good passivation coating effect, simple structure, low device cost, and simplicity in maintenance.

Owner:天津市顺天盛典运动器材有限公司

Metal plate passivation apparatus with lateral passivation assembly

InactiveCN107841734AUniform coatingImprove passivation qualityMetallic material coating processesEngineeringCirculating pump

The invention provides a metal plate passivation apparatus with a lateral passivation assembly. The metal plate passivation apparatus comprises a steel plate unreeling device, a steel plate, a coatingand passivation device, a drying device and a steel plate reeling device, wherein the coating and passivation device comprises a passivation and coating assemblies and a passivation solution preparing case which are connected with each other via pipelines, and the pipelines are correspondingly provided with valves capable of controlling flow and circulating pumps; supplementary passivation assembles are arranged between the passivation and coating device and the drying device; the passivation and coating assemblies are respectively arranged at an upper part and a lower part for coating of theupper and lower surfaces of the galvanized steel plate; and the supplementary passivation assembles are respectively arranged at a left part and a right part for coating of the left and right sides of the galvanized steel plate. The metal plate passivation apparatus with a lateral passivation assembly is good in passivation and coating effect, simple in structure, low in equipment cost and easy to maintain.

Owner:天津市顺天盛典运动器材有限公司

Electroplated part treatment equipment

PendingCN114686945AUniform passivationImprove passivation qualityMetallic material coating processesProcess efficiency improvementGear wheelRack and pinion

The invention relates to passivation treatment equipment, in particular to electroplated part treatment equipment. The technical problem to be solved is to provide the electroplated part treatment equipment which can tightly and stably press an electroplated part and can prevent a passivation solution from splashing. The electroplated part treatment equipment comprises a circulating box, an injection pipe, a discharge pipe, a first mounting rod and the like, an injection pipe is connected to the rear side of the upper part of the circulating box, a discharge pipe is connected to the front side of the lower part of the circulating box, and first mounting rods are symmetrically connected to the left and right sides of the lower part of the circulating box. According to the passivating device, a driving gear moves up and down, is meshed with a rack, drives a swing rod to rotate alternately in the positive and negative directions and is matched with a wedge-shaped plate, so that a passivating frame is finally pushed to swing back and forth in a reciprocating manner, the effect of uniformly passivating an electroplated part is achieved, and the passivating quality of the electroplated part is improved; the first pressing plate and the second pressing plate are fixed to the passivation frame, so that the electroplated part is pressed and limited, and the effect that the electroplated part is pressed in the passivation frame can be achieved.

Owner:赣州市文祥电镀有限公司

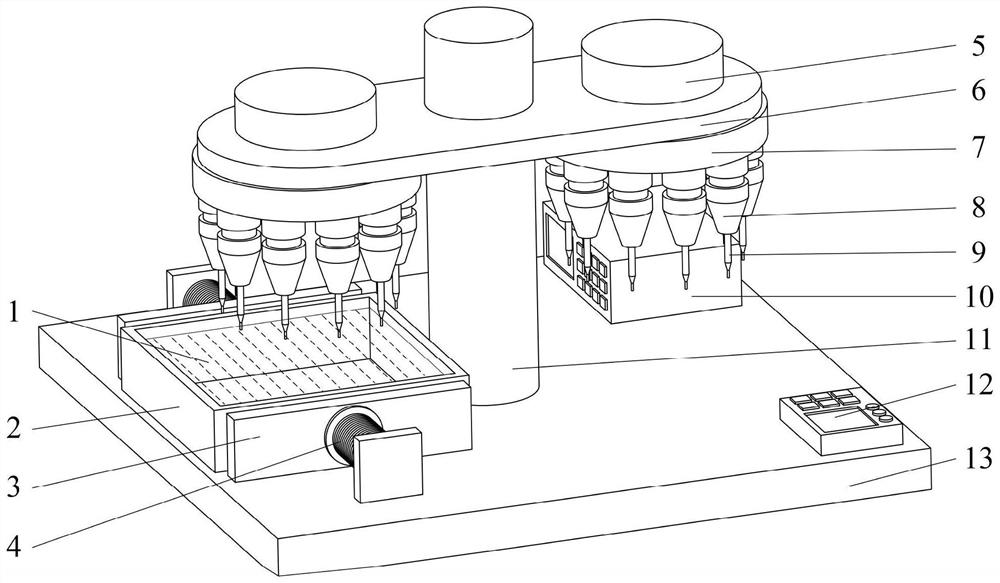

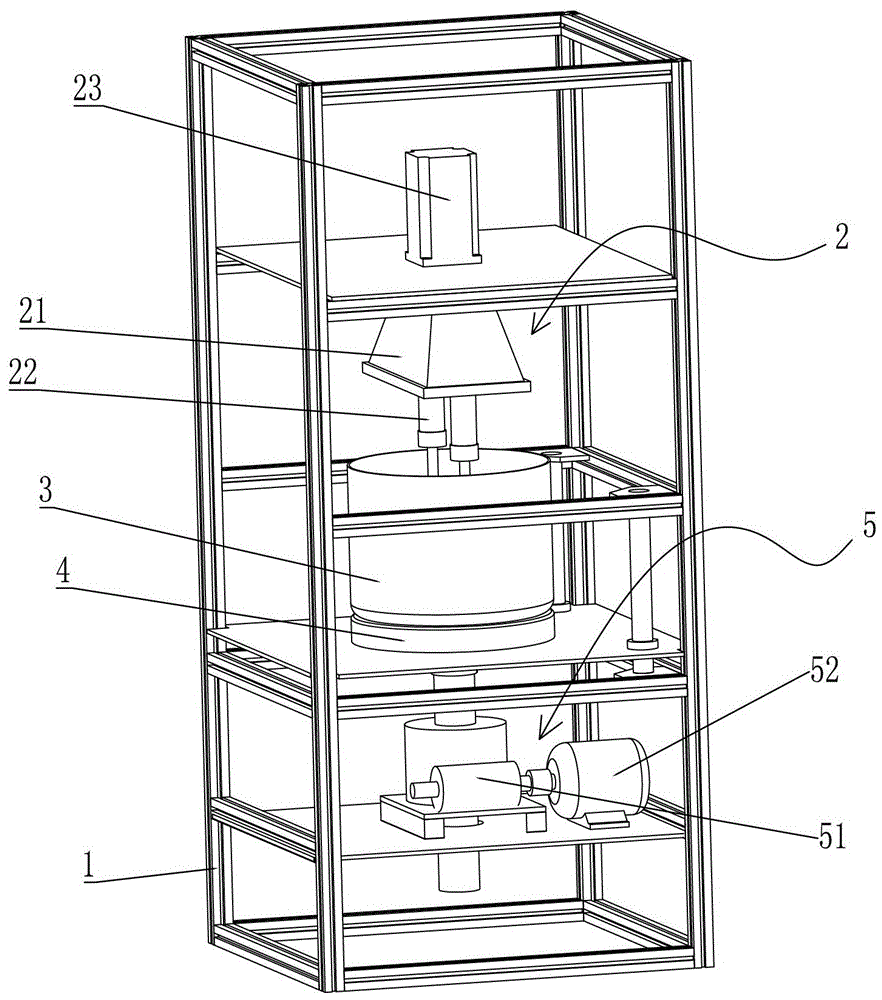

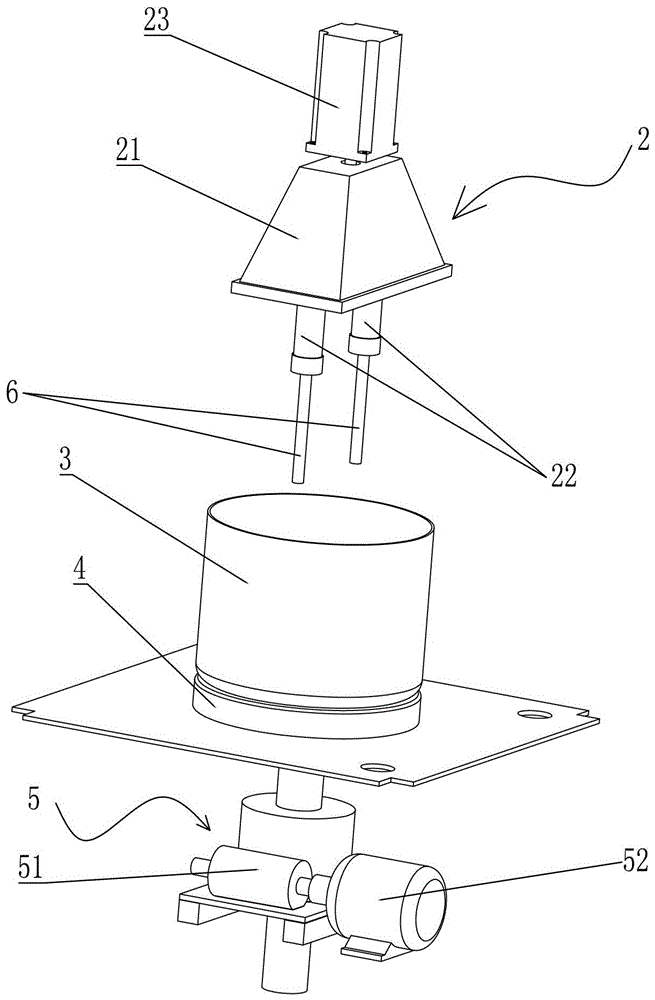

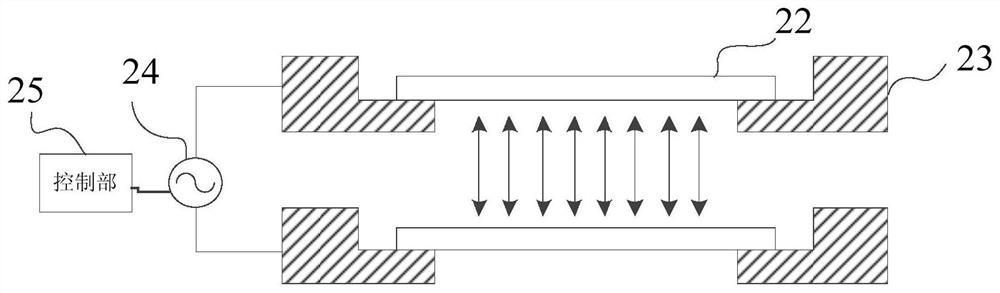

A tool passivation device

InactiveCN103143992BImprove efficiency of passivation polishingFully sharpenedOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to a cutter passivation device. The cutter passivation device is characterized by comprising a framework (1), wherein a cutter holding device (2) is arranged on the framework (1) and comprises a cutter head connector (21), a cutter mounting head (22) arranged below the cutter head connector (21) and a first motor (23) arranged above the cutter head connector (21) and used for driving the cutter mounting head (22) to rotate; a material grinding tube (3) allowing a cutter to extend therein is arranged below the cutter holding device (2); and a driving device (4) used for driving the material grinding tube (3) to rotate is arranged on the framework (1). As the cutter mounting head and the material grinding tube of the cutter passivation device are respectively driven by different motors, the rotation speed of the cutter is improved and the cutter passivating and polishing efficiencies are also improved.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC +2

A method for adjusting passivation temperature of steel structure

ActiveCN105369242BReduce porosityImproves attachment stabilityMetallic material coating processesPorosityZinc

The invention discloses an adjusting method for the passivation temperature of a steel structure. The adjusting method includes the following steps that firstly, a galvanized steel plate is dried and cooled; secondly, first-level passivation is conducted; thirdly, second-level passivation is conducted; fourthly, third-level passivation is conducted; and fifthly, drying is conducted. According to the adjusting method for the passivation temperature of the steel structure, the segmented passivation temperature adjustment is conducted , porosity of a passivation film is effectively reduced, passivation quality is improved, meanwhile, adhesion stability of the passivation film is improved, and therefore passivation quality is effectively improved, corrosion resistance performance of a zinc coating is improved, and the salt spray resistance property of a passivated product is good.

Owner:CHANGSHU FENGFAN POWER EQUIP

Post-treatment process of high-gloss formed cutter

InactiveCN108857607AImprove passivation qualityUniform passivationEdge grinding machinesPolishing machinesPistonReciprocating motion

The invention discloses a post-treatment process of a high-gloss formed cutter. The post-treatment process comprises the following steps that a cutter hole is formed in the center of a clamp, the part, directly participating in polishing, of the clamp is arranged to be in a cutter profile shape according to distribution of cutter edges, it is ensured that the distances between all the positions ofthe cutter and the clamp are equal, and four evenly-distributed pressure relief holes are additionally formed in the clamp; an abrasive material for cutter fluid polishing is made of a macromoleculesemi-solid carrier and abrasive grains in a mixed configuration mode according to the ratio of 3:2; and the fluid polishing process is conducted through the steps that (1) a power switch of a polisheris turned on, the configured abrasive material for cutter fluid polishing is put into a lower cylinder of the polisher, the clamp is fixed to a worktable, and the to-be-passivated cutter is fixed tothe clamp; (2) the polishing time and the abrasive material pressure are set, a machine is started, pistons in an upper cylinder and the lower cylinder make reciprocating movement at a constant speed,thus the abrasive grains flow through the cutter and edge openings uniformly, and polishing passivation is completed; and (3) after being polished, the cutter is taken out, and replaced with a new to-be-polished cutter. Overall force bearing is uniform and constant, the passivation effect is ensured, and the passivation time is saved.

Owner:WUXI GUOHONG MEASURING & CUTTING TOOLS

Intermittent plasma oxidation method and device and preparation method of solar cell

PendingCN113629161AImprove uniformityImprove passivation qualityElectric discharge tubesFinal product manufacturePhysical chemistrySolar cell

The embodiment of the invention provides an intermittent plasma oxidation method, a preparation method of a TOPCon solar cell, an intermittent plasma oxidation device and a computer readable storage medium. The intermittent plasma oxidation method comprises the steps: enabling processing gas plasma in a plasma processing chamber to be ionized through an excitation signal, so that to-be-processed gas in the processing chamber is oxidized to form an oxide layer, wherein the excitation signal comprises an on state and an off state which are alternately carried out, a pulse or sinusoidal signal is output during the on state, and no power is output during the off state; and the duration of the on state and the off state is longer than a pulse or sinusoidal signal period.

Owner:苏州拓升智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com