Preparation method of gallium-doped polycrystalline silicon film, and application of gallium-doped polycrystalline silicon film in solar cells

A polysilicon thin film and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced carrier lifetime, high diffusion rate, high Auger recombination, etc., and achieves reliable performance, large process window, repeatability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

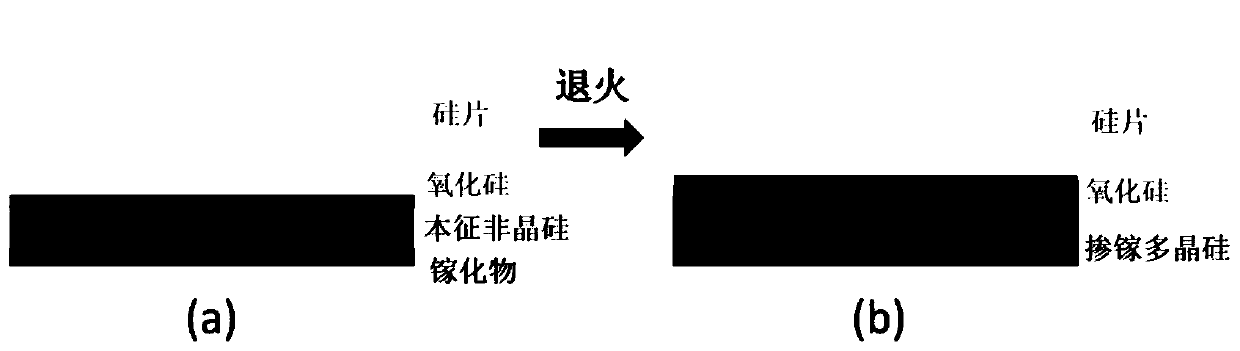

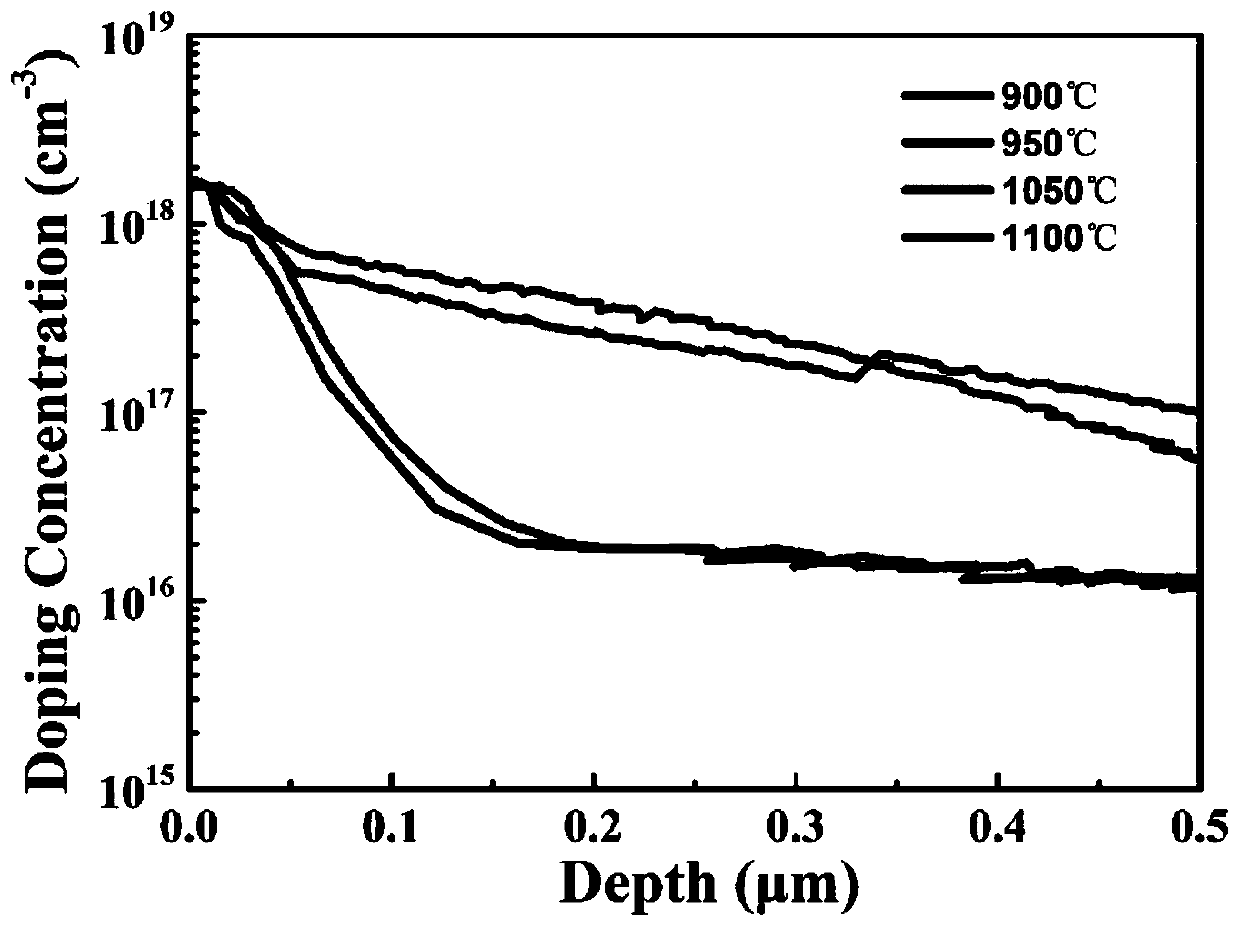

[0029] First, standard RCA cleaning is performed on the silicon wafer to ensure that the surface is sufficiently clean; then a high-quality silicon oxide tunneling layer is prepared on both sides by thermal nitric acid oxidation; an intrinsic amorphous silicon layer with a thickness of 40nm is deposited on both sides by PECVD; A 10nm GaO layer was deposited by electron beam evaporation; the sample was annealed at a high temperature of 1100°C for 60 minutes, the protective atmosphere was a mixture of nitrogen and hydrogen, and then the temperature began to drop; when the temperature dropped below 600°C, water vapor was introduced and kept warm. Using ECV to measure the diffusion curve, it can be seen that gallium atoms can be activated and diffused into the silicon wafer, thereby forming a field passivation effect; at the same time, we can see that gallium atoms do not form accumulations at the silicon oxide interface. Use Sinton WCT-120 to measure passivation quality, typical p...

Embodiment 2

[0031] First, standard RCA cleaning is performed on the silicon wafer to ensure that the surface is sufficiently clean; then a high-quality silicon oxide tunneling layer is prepared on both sides by thermal oxidation; an intrinsic amorphous silicon layer with a thickness of 40nm is deposited on both sides by PECVD; 10nm Ga(NO 3 ) 2 Layer; place the sample at 1050°C for high temperature annealing for 60 minutes, the protective atmosphere is a mixture of nitrogen and hydrogen, and then start to cool down; when the temperature drops below 600°C, pass in water vapor and keep it warm. Using ECV to measure the diffusion curve, it can be seen that the activation concentration of gallium atoms reaches 0-5*10 18 cm -3 , and diffused into the silicon wafer, can form a significant field passivation effect. Use Sinton WCT-120 to measure passivation quality, typical passivation quality iV oc Reach 710 ~ 720mV.

Embodiment 3

[0033] First, standard RCA cleaning is performed on the silicon wafer to ensure that the surface is sufficiently clean; then high-quality silicon oxide tunneling layer is prepared on both sides by plasma-assisted laughing gas oxidation; intrinsic amorphous silicon with a thickness of 40nm is deposited on both sides by PECVD layer; 10nm Ga 2 O layer; place the sample at 950°C for high temperature annealing for 60 minutes, the protective atmosphere is a mixture of nitrogen and hydrogen, and then start to cool down; when the temperature drops below 600°C, inject water vapor and keep it warm. Using ECV to measure the diffusion curve, it can be seen that the activation concentration of gallium atoms reaches 0-5*10 18 cm -3 , and diffused into the silicon wafer, can form a significant field passivation effect. Use Sinton WCT-120 to measure passivation quality, typical passivation quality iV oc Reach 710 ~ 720mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com