Intermittent plasma oxidation method and device and preparation method of solar cell

A plasma and oxidation device technology, applied in circuits, discharge tubes, photovoltaic power generation, etc., can solve the problems of increasing the production cost of TOPCon solar cells, the uniformity of mass production, high efficiency, and low uniformity of silicon oxide layers. Achieve the effects of shortening process time, high passivation quality and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 : the n-type silicon wafer of 166mm is also adopted, through the intermittent plasma oxidation method of the embodiment of the present invention, that is, the excitation signal of the alternately on state and the off state is used to make the plasma ionization of the processing gas to oxidize the surface of the n-type silicon wafer, The PL diagrams of the obtained samples were significantly more Figure 5A The sample in is homogeneous, such as Figure 5B shown.

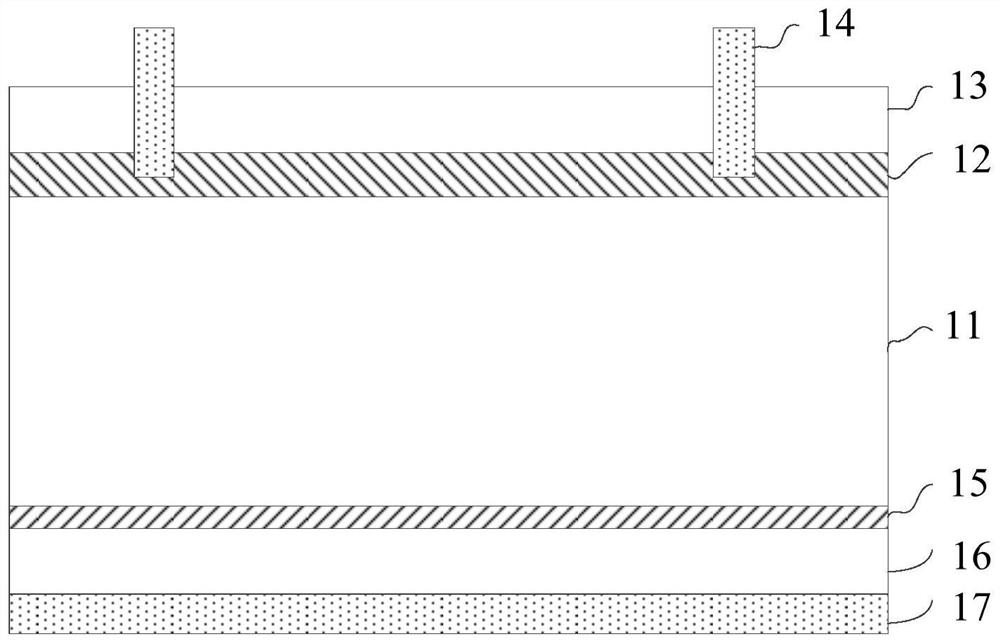

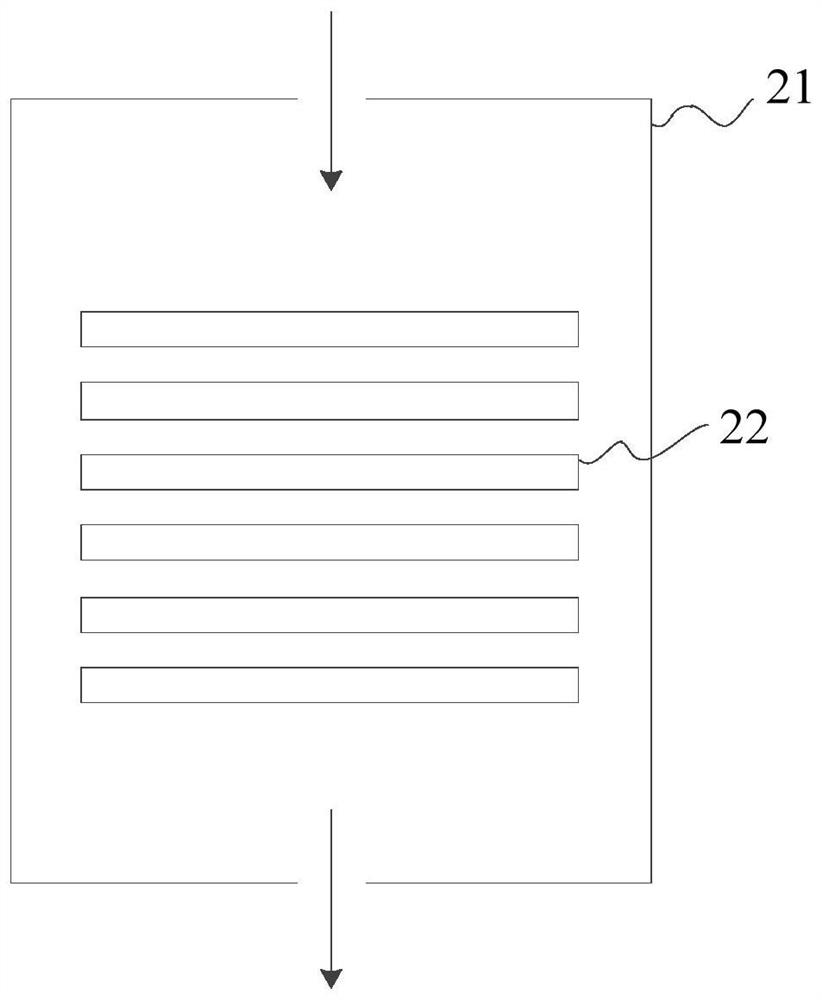

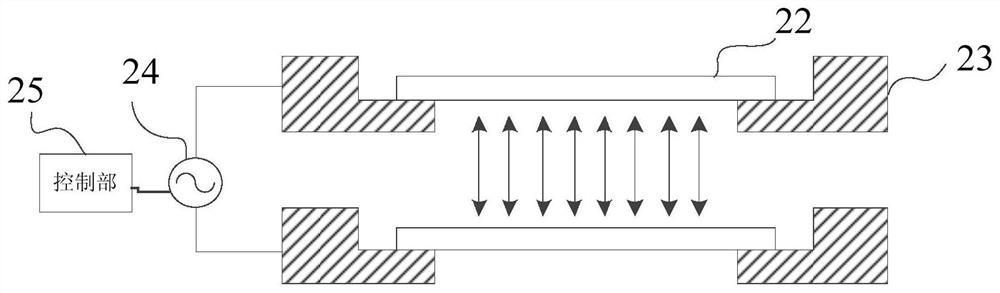

[0039] The inventors of the present invention have found after research that the electric field distribution is relatively uniform in the initial stage of the plasma, and as time goes by, the distribution of charges in the plasma changes and affects the distribution of the electric field, especially the electric field confined in the plasma. The aggregation of negatively charged ions forms large particles, resulting in non-uniform silicon oxide films produced. The excitation signal used in the int...

Embodiment 2

[0042] Example 2 : In TOPCon solar cells, the main factors affecting cell efficiency are passivation quality and contact resistance (ρ c ), while the passivation quality is usually measured by the effective minority carrier lifetime (τ eff ), implied open circuit voltage (iV oc ) and saturation recombination current (J 0,s ) to represent. Table 1 lists when the processing gas is oxygen (O 2 ) and argon (Ar) mixed gas, adopt the intermittent plasma oxidation method of the embodiment of the present invention to oxidize both sides of the n-type silicon substrate to form an oxide layer, and then form a polysilicon layer and an electrode layer on the oxide layer , to test the passivation quality characteristic parameters of the oxide layer. The difference of embodiment 2A, embodiment 2B and embodiment 2C process conditions in table 1 is the oxygen (O 2 ) / Argon (Ar) flow rates are 3000sccm / 1000sccm, 2000sccm / 2000sccm and 1000sccm / 3000sccm respectively, and other process condi...

Embodiment 3

[0046] Example 3 : Table 2 lists when the processing gas is laughing gas (N 2 O) and nitrogen (N 2) mixed gas, adopt the intermittent plasma oxidation method of the embodiment of the present invention to oxidize the passivation quality characteristic parameters of the n-type silicon substrate, the sample structure is the same as that in Example 2, and also oxidize on both sides of the n-type silicon substrate An oxide layer is formed, and then a polysilicon layer and an electrode layer are formed on the oxide layer to test the passivation quality characteristic parameters of the oxide layer. Laughing gas (N 2 O) and nitrogen (N 2 ) flow rate is 2000sccm / 2000sccm, the difference in process conditions is that the plasma start-up time corresponding to embodiment 3A, embodiment 3B and embodiment 3C is respectively 5 seconds, 10 seconds and 20 seconds, and other process conditions are all the same . Comparative Example 3 in Table 2 also shows the characteristic parameters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com