Aluminum alloy die pressed casting passivation solution, preparation method and passivation treatment method

A technology for die castings and aluminum alloys, which is used in the field of preparation and corrosion resistance of aluminum alloy die castings, and can solve the problems of poor corrosion resistance and inability to meet industrialization requirements, achieve strong corrosion resistance and improve passivation quality. , the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

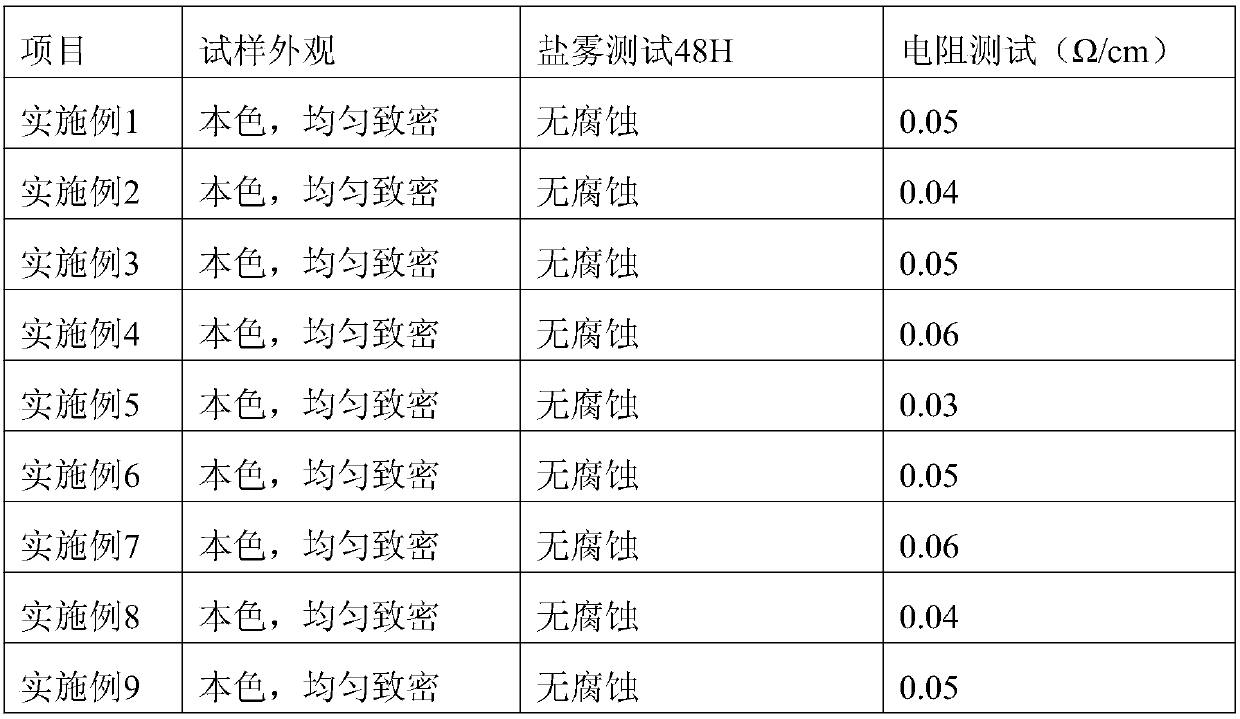

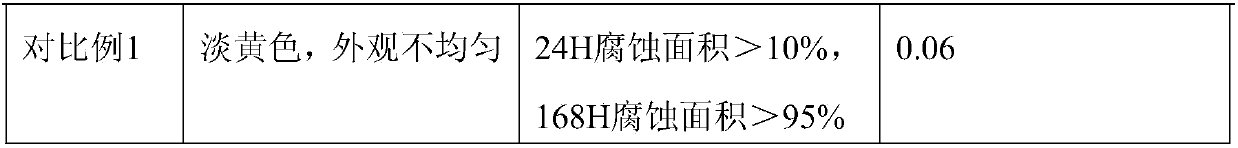

Examples

Embodiment 1

[0037] The corrosion-resistant natural color passivation solution for aluminum alloy die-casting provided in this embodiment includes the following components in terms of mass percentage, trivalent chromium salt, which can be anhydrous chromium sulfate, hexahydrate chromium sulfate, dodeca One or more of hydrated chromium sulfate, octadecahydrate chromium sulfate, anhydrous chromium chloride, hexahydrate chromium chloride, anhydrous chromium acetate, dihydrate chromium acetate, such as Cr 2 (SO 4 ) 3 ·6H 2 O is 5%, a zirconium salt compound, which can be one or more of potassium fluorozirconate, sodium fluorozirconate, ammonium fluorozirconate, anhydrous zirconium oxychloride, and zirconium oxychloride octahydrate, such as K 2 ZrF 6is 3%, the mixing accelerator is 0.5%, the polyethylene glycol is 0.01%, and the balance is water, wherein the mixing accelerator is cobalt nitrate hexahydrate, sodium fluoride and sodium nitrate in a mass ratio of 1:1:10 mixture.

[0038] The ...

Embodiment 2

[0050] The corrosion-resistant natural color passivation solution for aluminum alloy die-casting provided by this embodiment includes the following components (by mass percentage): trivalent chromium salt, which can be anhydrous chromium sulfate, hexahydrate chromium sulfate, dodeca One or more of hydrated chromium sulfate, octadecahydrate chromium sulfate, anhydrous chromium chloride, hexahydrate chromium chloride, anhydrous chromium acetate, dihydrate chromium acetate, such as Cr 2 (SO 4 ) 3 ·6H 2 O is 7%, a zirconium salt compound, which can be one or more of potassium fluorozirconate, sodium fluorozirconate, ammonium fluorozirconate, anhydrous zirconium oxychloride, and zirconium oxychloride octahydrate, such as K 2 ZrF 6 It is 5%, the mixed additive is 1.5%, the polyethylene glycol is 0.03%, and the balance is water. Wherein, the mixing accelerator is a mixture of cobalt nitrate hexahydrate, sodium fluoride and sodium nitrate in a mass ratio of 1:1:10.

[0051] The p...

Embodiment 3

[0055] A corrosion-resistant natural color passivation solution for aluminum alloy die-casting provided in this embodiment includes the following components (by mass percentage): Cr 2 (SO 4 ) 3 ·6H 2 O is 5%, K 2 ZrF 6 It is 3%, the mixed additive is 1.0%, the polyethylene glycol is 0.02%, and the balance is water. Wherein, the mixing accelerator is a mixture of cobalt nitrate hexahydrate, sodium fluoride and sodium nitrate in a mass ratio of 1:1:10.

[0056] The preparation process method of the corrosion-resistant natural color passivation solution for aluminum alloy die-casting provided in this embodiment, under normal temperature and pressure, Cr 2 (SO 4 ) 3 ·6H 2 Dissolve O in an appropriate amount of water, add K while stirring 2 ZrF 6 and mixed accelerator, continue to stir to make it completely dissolved; then add polyethylene glycol, stir evenly; finally add the remaining water, that is.

[0057] The above prepared solution is prepared into a 10% working so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com