Micro cutter passivation method and device based on flexible abrasive particles and magnetic composite fluid

A technology of micro-tools and knives, which is applied to machine tools suitable for grinding workpiece edges, polishing compositions containing abrasives, grinding machines, etc., can solve the problems of small geometric structure size of micro-tools, tool breakage due to mechanical force, tool strength, Low rigidity and other problems, to achieve the effect of batch passivation, slow down settlement, and high precision of tool passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

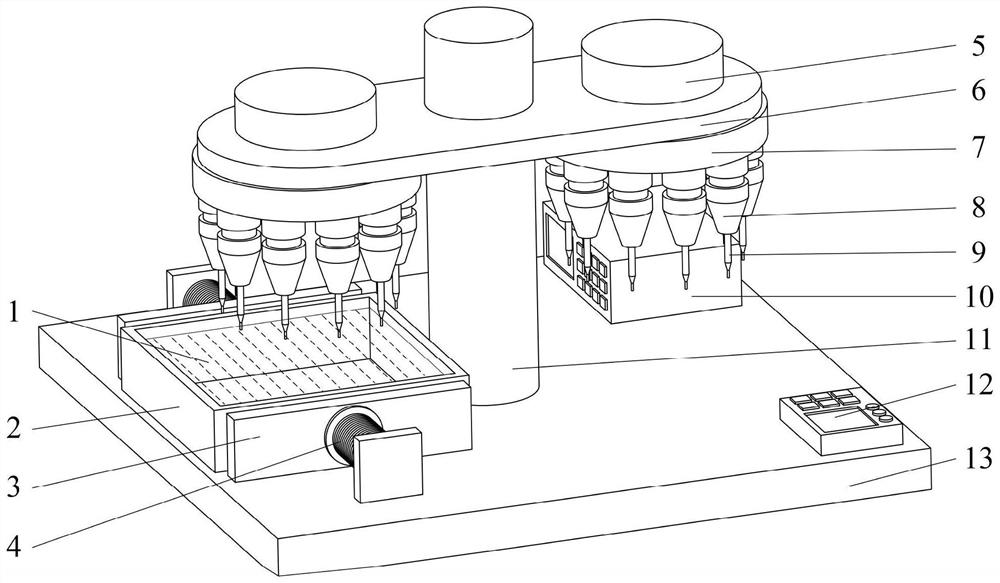

[0028] The present invention will be described in detail in conjunction with the accompanying drawings.

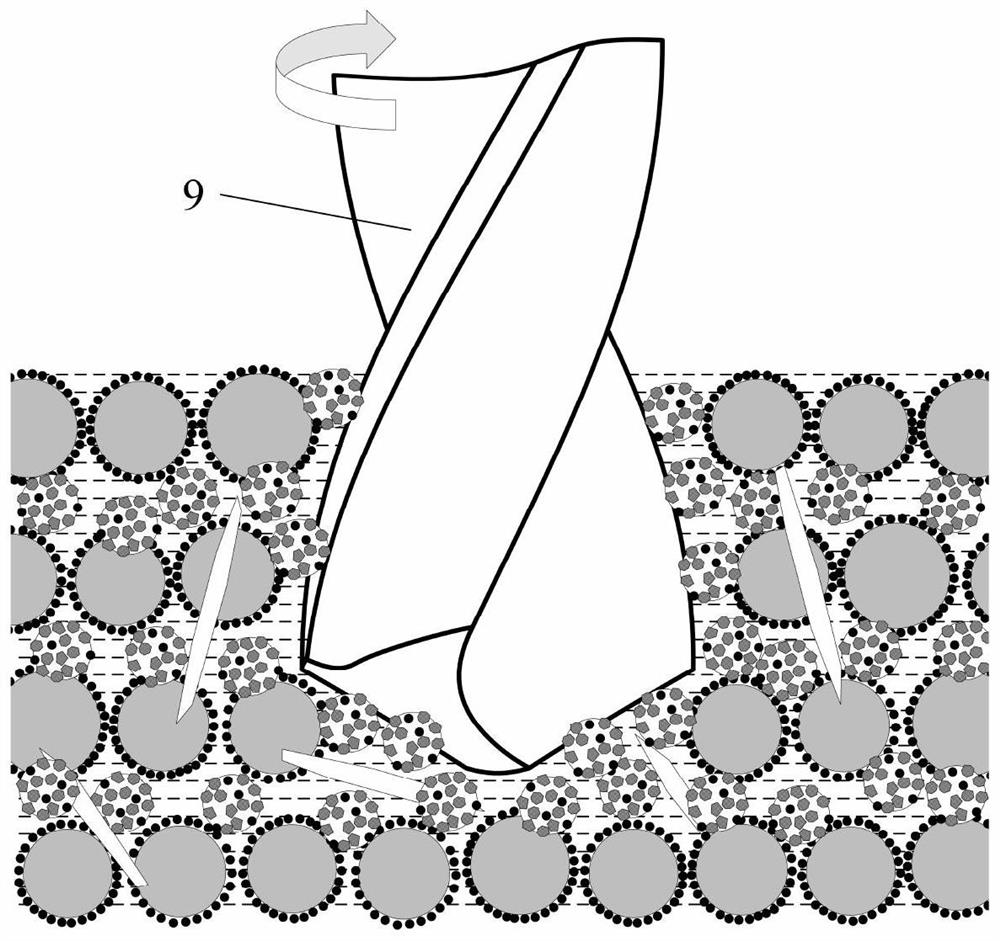

[0029] Such as figure 1 and figure 2 , The flexible abrasive particles and magnetic composite micro tool fluid inactivation method based on the magnetic composite flexible abrasive grain mixed fluid, the tool is configured to a passivation solution;

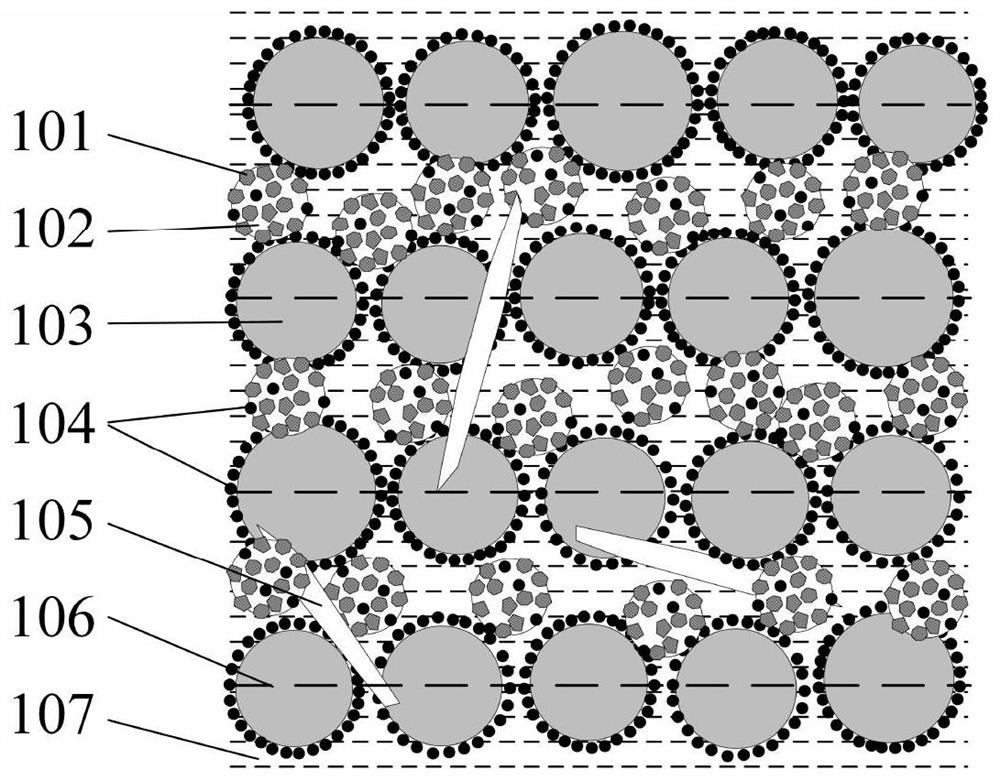

[0030] The flexible abrasive grain is diamond abrasive grains 101 nanoscale iron oxide and tetrakis magnetic particles 104 embedded in the organic elastomeric polymer matrix 102 is formed of a flexible composite particles; the magnetic fluid is a composite of a micron hydroxy iron 103, nanoscale Fe3O4 104, α- 105 cellulose, deionized water, glycerol uniformly mixed. Under an applied magnetic field, the ferromagnetic phase tool passivating solution 1 (103 micron iron and hydroxyl free nanoscale iron tetroxide 104) are arranged in the direction of magnetic field 106, aggregate, form a chain structure, and sandwiched holding the fle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com