Cutting edge passivation device for magneto-rheological diamond cutter

A magnetorheological and cutting tool technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, grinding machine parts, etc., can solve the problems of low passivation efficiency, complex processing, general effect, etc., to achieve no tool wear, dullness, etc. The effect of high chemical precision and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

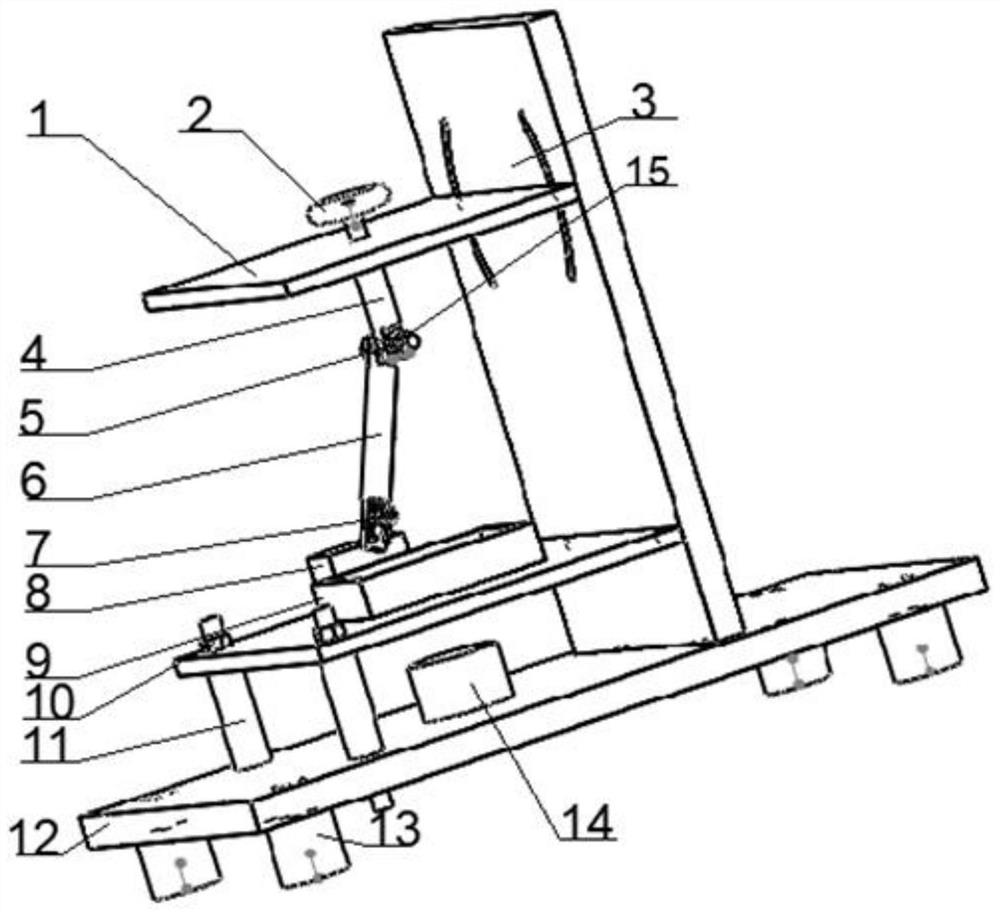

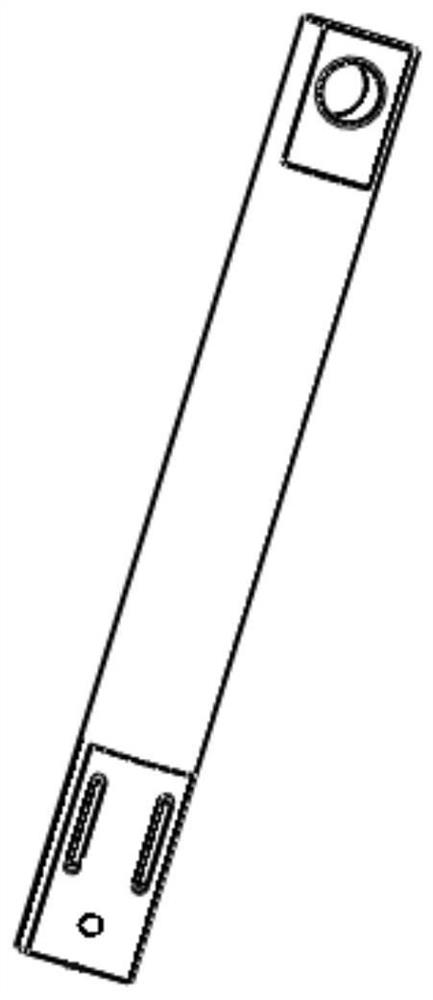

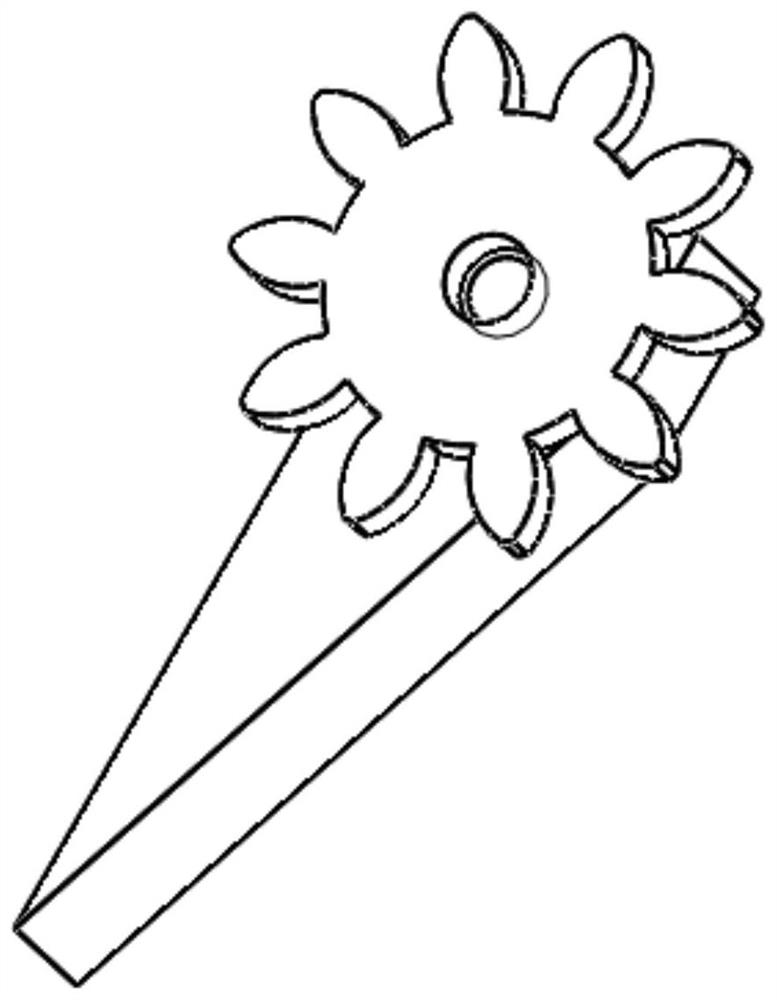

[0024] Such as Figure 1-5 As shown, the present invention is a magneto-rheological rhombic tool edge passivation device, including a positioning clamping device, a magnetic field generating device, a magneto-rheological fluid flow device, and a tool position adjustment device; the tool used in the present invention is: Other shapes than standard tools, such as rhombus, triangle, etc.

[0025] Wherein, the clamping mechanism 7 consists of a left clamping block 704, a right clamping block 708, a left centering gear 703, a right centering gear 707, a left sliding bolt 701, a left sliding nut 702, a right sliding bolt 705, a right The sliding nut 706 is formed; the left clamping block 704, the right clamping block 708, the left centering gear 703, the right centering gear, and the right centering gear 707 are formed by welding, and the threaded holes of the clamping block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com