Device for grinding hard alloy cutter through laser

A cemented carbide and laser technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost and long time, and achieve the effect of less energy consumption, great flexibility, and no tool loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

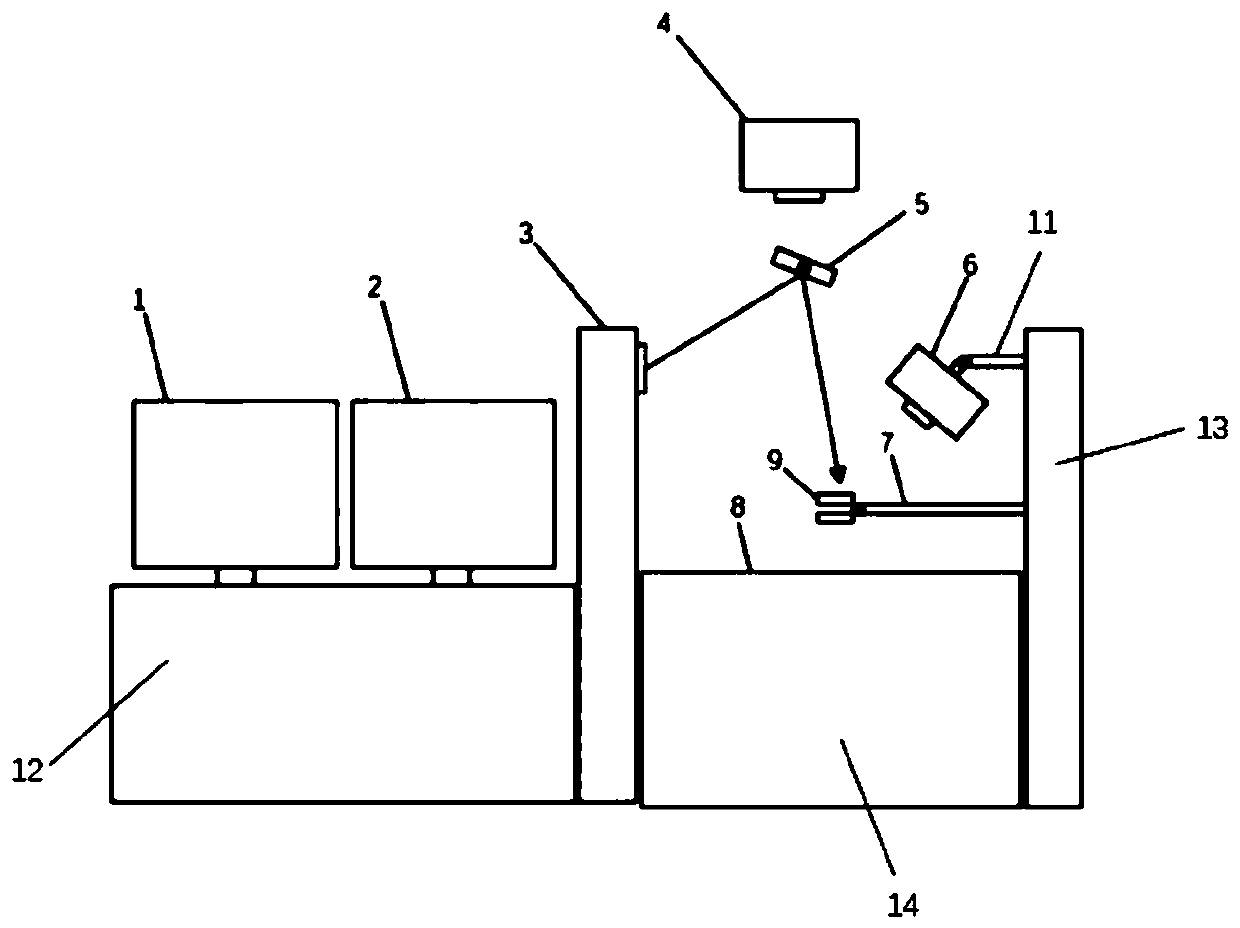

[0024] refer to figure 1 , figure 1 Disclosed is an installation schematic diagram of a device for grinding cemented carbide tools with lasers according to an embodiment of the present invention. In this embodiment, a device for grinding cemented carbide cutting tools by laser includes a manipulator 1, an observer 2, a laser 3, a first camera 4, a scanning device 5, a second camera 6, a robot arm 7, a working Table 12, transfer table 8 and first fixture 9; wherein, manipulator 1 and observer 2 are arranged on workbench 12, and laser device 3 is arranged on the top of one side of transfer table 8, and is installed above the other side of transfer table 8 The second camera 6 is provided with a scanning device 5 above the laser 3 and the second camera 6, the first camera 4 is located above the scanning device 5, and the robot arm 7 is located at the bottom of the second camera 6 and the transfer table 8 Above, a first gripper 9 is provided on the robot arm 7, and the first grip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com