Trivalent-chromium natural-color passivator with high corrosion resistance for zinc-nickel alloy

A zinc-nickel alloy and trivalent chromium technology, which is applied in the coating process of metal materials, can solve the problems of passivation difficulties and the absence of zinc-nickel alloys, and achieve high passivation quality, high corrosion resistance, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

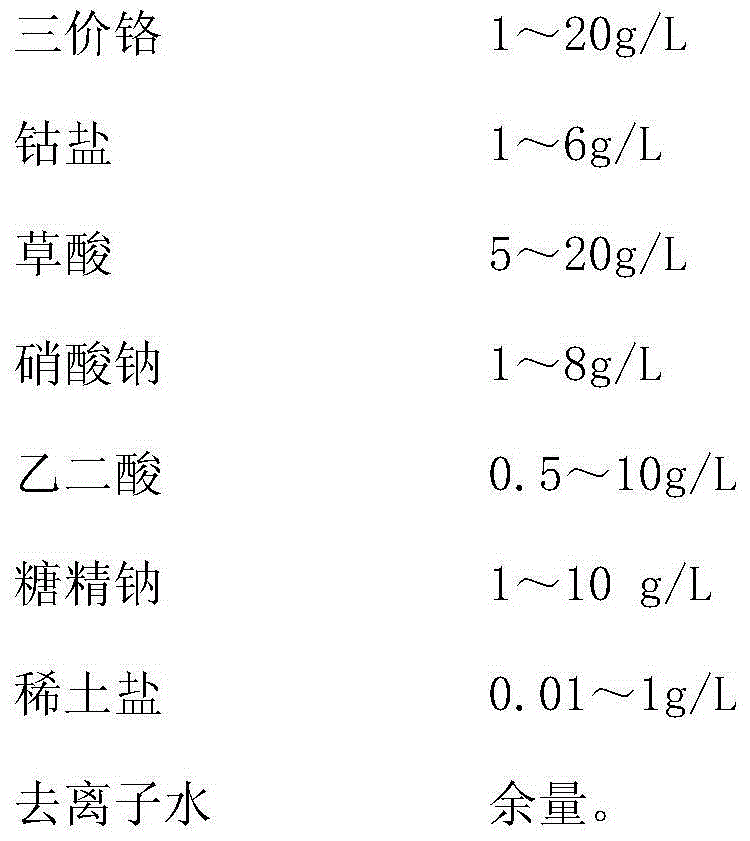

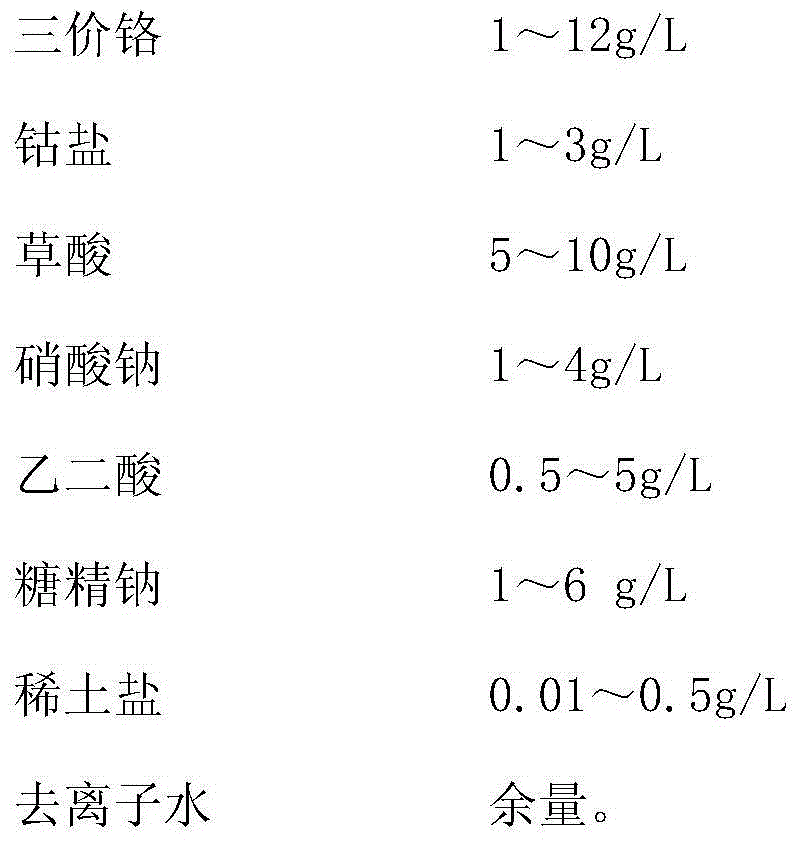

[0019] The trivalent chromium high corrosion resistance natural color passivation agent 1L for zinc-nickel alloy in this embodiment includes 1 g of chromium sulfate, 1 g of cobalt nitrate, 5 g of oxalic acid, 1 g of sodium nitrate, 0.5 g of oxalic acid, 1 g of sodium saccharin, and lanthanum oxide 0.01g, made with deionized water.

[0020] Apply the trivalent chromium passivator of this embodiment to carry out the passivation of zinc-nickel alloy, the nickel content of the zinc-nickel alloy is 9%, the pH of the trivalent chromium passivator is 3.5, and the passivation temperature is 25°C. The passivation time was 18s, and the surface of the obtained coating was silvery white.

Embodiment 2

[0022] The trivalent chromium high-corrosion-resistant natural color passivator 1L for zinc-nickel alloys of this embodiment includes 6 g of chromium nitrate, 2 g of cobalt sulfate, 8 g of oxalic acid, 3 g of sodium nitrate, 1 g of oxalic acid, 3 g of sodium saccharin, and 0.1 g of cerium oxide. g, made of deionized water.

[0023] Apply the trivalent chromium natural color passivator of the present embodiment to carry out zinc-nickel alloy passivation, the nickel content of zinc-nickel alloy is 8%, the pH of described trivalent chromium natural color passivator is 3.6, and passivation temperature is 27 ℃, The passivation time was 15s, and the surface of the obtained coating was silvery white.

Embodiment 3

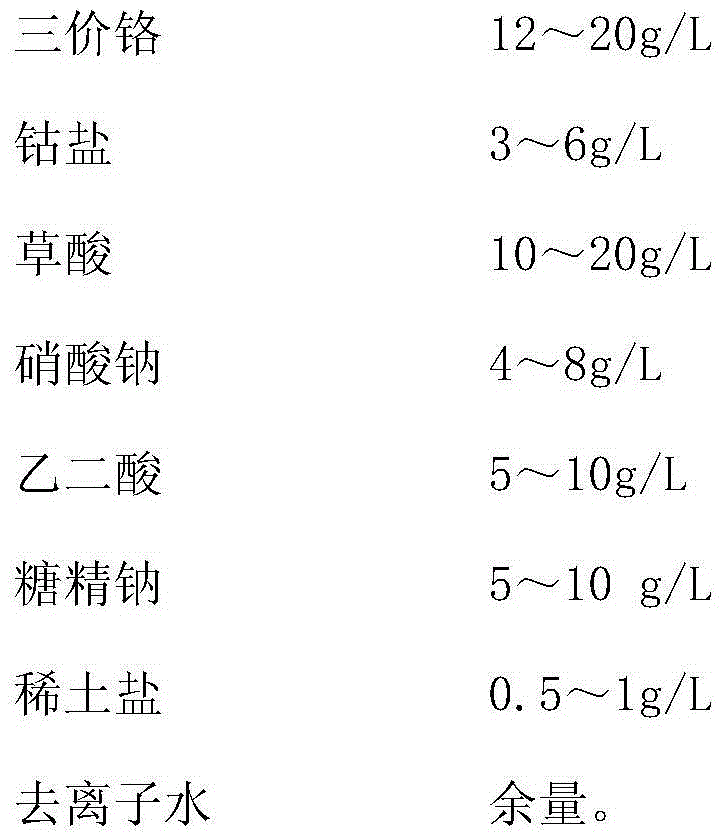

[0025] The trivalent chromium high corrosion resistance natural color passivation agent 1L for zinc-nickel alloy of this embodiment includes 8 g of chromium sulfate, 3 g of cobalt sulfate, 10 g of oxalic acid, 4 g of sodium nitrate, 3 g of oxalic acid, 5 g of sodium saccharin, and 0.3 g of lanthanum oxide. g, made of deionized water.

[0026] Apply the trivalent chromium passivator of the present embodiment to carry out the passivation of zinc-nickel alloy, the nickel content of the zinc-nickel alloy is 11%, the pH of the trivalent chromium passivator is 3.7, and the passivation temperature is 26°C. The passivation time is 20s, and the surface of the obtained coating is silvery white.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com