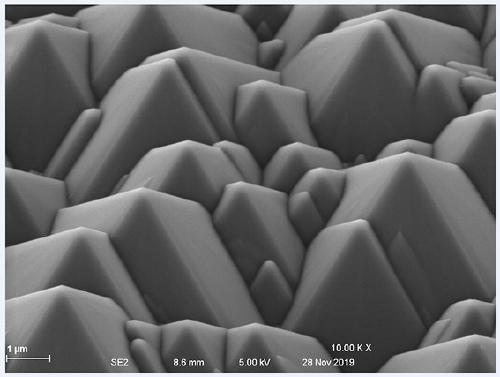

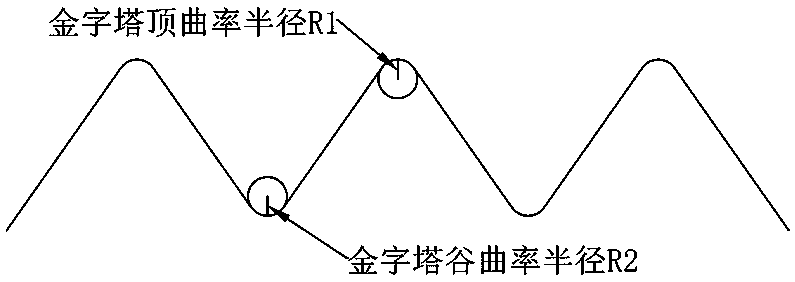

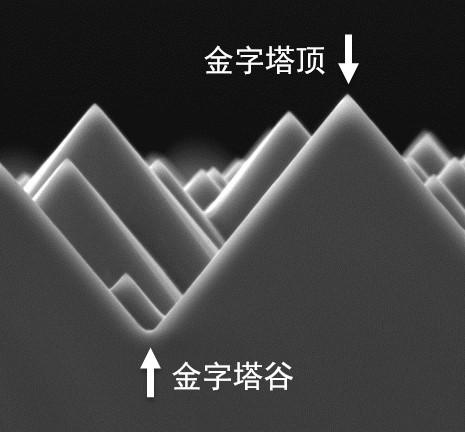

Monocrystalline silicon wafer with rounded pyramid structure and preparation method

A technology of pyramid structure, single crystal silicon wafer, applied in the direction of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problem that the pyramid top and tower valley are smooth, affect the passivation effect, and the sharp position is difficult to cover the non-contact surface. Crystal silicon passivation layer and other problems, to achieve the effect of reducing the density of defect states, improving passivation quality and minority carrier lifetime, and high cell conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 is to carry out nitric acid CP first, then carry out ozone CP, and concrete steps are as follows:

[0044] Step 1: Pre-cleaning, cleaning the silicon wafer in a mixed solution of hydrogen peroxide and KOH, the mass fraction of KOH is 1%, the mass fraction of hydrogen peroxide is 3%, the temperature is 65°C, and the time is 5min. After pre-cleaning, in pure water Rinse silicon wafer for 3 minutes;

[0045] Step 2: Texturing, the mass fraction of KOH in the texturing solution is 7%, and the texturing additive is an additive from Hayashi Pure HPC Company in Japan, and the ratio of the additive to pure water is TT72C13:TK81:DIW=1:7.5:18.4. Put the silicon wafer treated in step 1 into the texturing solution for texturing at a temperature of 85° C. for 15 minutes, and rinse the silicon wafer in pure water for 3 minutes after texturing;

[0046] Step 3: SC1 cleaning, cleaning the silicon wafer in a mixed solution of hydrogen peroxide and KOH, the mass fraction of...

Embodiment 2

[0053] Embodiment 2 is to carry out ozone CP first, then carry out nitric acid CP, and concrete steps are as follows:

[0054] Step 1: Pre-cleaning, cleaning the silicon wafer in a mixed solution of hydrogen peroxide and KOH, the mass fraction of KOH is 1%, the mass fraction of hydrogen peroxide is 3%, the temperature is 65°C, and the time is 5min. After pre-cleaning, in pure water Rinse silicon wafer for 3 minutes;

[0055] Step 2: Texturing, the mass fraction of KOH in the texturing solution is 7%, and the texturing additive is an additive from Hayashi Pure HPC Company in Japan, and the ratio of the additive to pure water is TT72C13:TK81:DIW=1:7.5:18.4. Put the silicon wafer treated in step 1 into the texturing solution for texturing at a temperature of 85° C. for 15 minutes, and rinse the silicon wafer in pure water for 3 minutes after texturing;

[0056] Step 3: SC1 cleaning, cleaning the silicon wafer in a mixed solution of hydrogen peroxide and KOH, the mass fraction of...

Embodiment 3

[0063] Embodiment 3 is to carry out ozone CP and nitric acid CP simultaneously, and concrete steps are as follows:

[0064] Step 1: Pre-cleaning, cleaning the silicon wafer in a mixed solution of hydrogen peroxide and KOH, the mass fraction of KOH is 1%, the mass fraction of hydrogen peroxide is 3%, the temperature is 65°C, and the time is 5min. After pre-cleaning, in pure water Rinse silicon wafer for 3 minutes;

[0065] Step 2: Texturing, the mass fraction of KOH in the texturing solution is 7%, and the texturing additive is an additive from Hayashi Pure HPC Company in Japan, and the ratio of the additive to pure water is TT72C13:TK81:DIW=1:7.5:18.4. Put the silicon wafer treated in step 1 into the texturing solution for texturing at a temperature of 85° C. for 15 minutes, and rinse the silicon wafer in pure water for 3 minutes after texturing;

[0066] Step 3: SC1 cleaning, cleaning the silicon wafer in a mixed solution of hydrogen peroxide and KOH, the mass fraction of KO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com